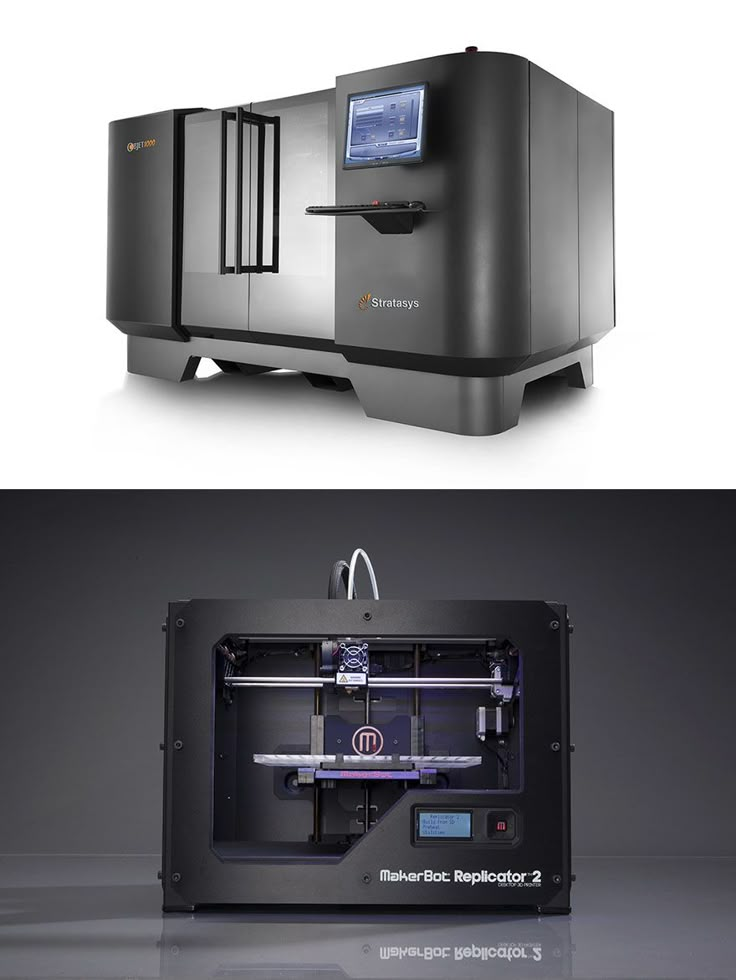

Stratasys dimension sst 1200 3d printer

Dimension 1200 Review 2022 - Why This 3D Printer Is AWESOME [Updated]

Should you buy the Stratasys Dimension 1200 printer? Check out our review here to find out whether it's worth the money or not.

By Justin Evans

4.4

See Price

If you work in the medical or aerospace department, you might benefit from the faster prototyping and flexibility that a 3D printer offers. However, not just any will do: for these industries, you’ll need a highly specialized printer. Bad news first: these are usually very pricey. Good news? We’ve found one that might be suitable.

We’re talking, of course, about the Stratasys Dimension 1200. This is a heavy-duty printer in every sense of the phrase, but is its performance as high as its price tag? Today, we’ll take a closer look to try and find out. Keep reading to see what we thought.

| Size | 33 x 29 x 45” |

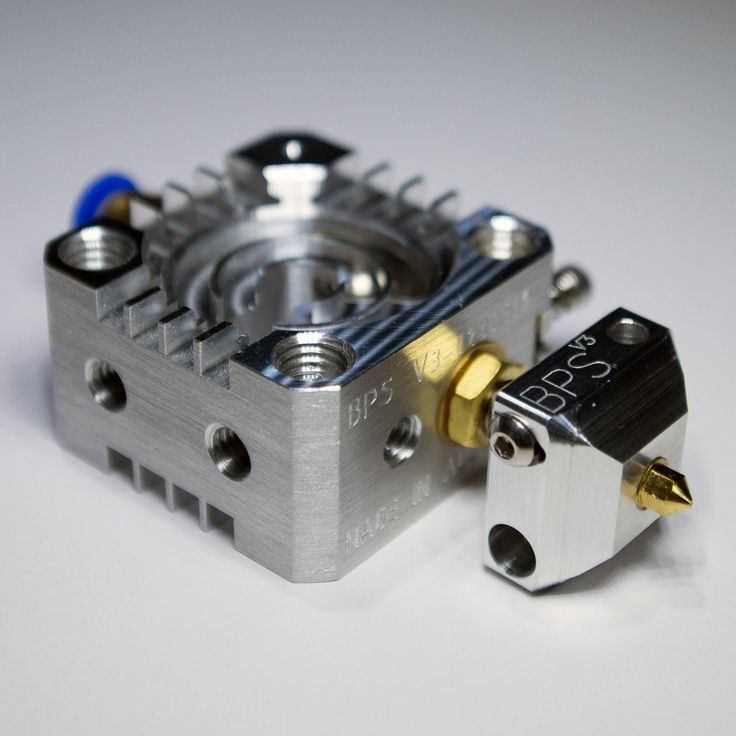

| Extruders | 1 |

| Supported Materials | Proprietary ABSplus filament |

| Connectivity | Ethernet |

| Layer Thickness | 0. |

| Build Volume | 10 x 10 x 12” |

Table of ContentsShow

Design

Let’s address the elephant in the room: standing 45” tall without the base, this printer is absolutely colossal. Setup is a two-person job since the Dimension 1200 weighs over 300lbs. Additionally, there’s just one extruder – something of a rarity in high-end 3D printers. However, with an enclosed (and exceptionally large) build area, maintaining a consistent temperature is easy.

We were pretty surprised by the lack of connectivity and limited OS support, too. There’s not even a USB port – everything has to be controlled via the Ethernet connection, and only Windows devices are supported. This is hardly ideal, particularly in the design sector, where Macs are more common.

There’s a small, neat control panel on the right-hand side. This allows you to select CAD files and make minor tweaks before printing. It’s a nice touch, but with even mid-range printers offering mobile app support, we have to wonder what the designers were thinking. After all, it’s not like this is a specially cheap model.

It’s a nice touch, but with even mid-range printers offering mobile app support, we have to wonder what the designers were thinking. After all, it’s not like this is a specially cheap model.

Printing

Say what you like about the aesthetics of this machine, it does an extraordinary job of recreating virtual models. Complex shapes are no problem, and the layers are all but imperceptible. If you value speed more than quality, you can slightly increase the layer size, but even this produces models to a higher standard than many other printers on the market.

Unfortunately, the Dimension 1200 supports only a handful of materials, all proprietary. There’s a more durable, ABS-based filament named ABSplus, as well as both water-soluble and snap-off support material. It seems as though Stratasys wanted to do one thing very well, rather than including half-baked support for as many materials as possible.

It’s hard not to be impressed here: there’s very little filament wasted, and finished models usually require very little post-processing. Evidently, this depends on what exactly you’re printing, but for prototyping, there are very few 3D printers that can match this one.

Evidently, this depends on what exactly you’re printing, but for prototyping, there are very few 3D printers that can match this one.

Features

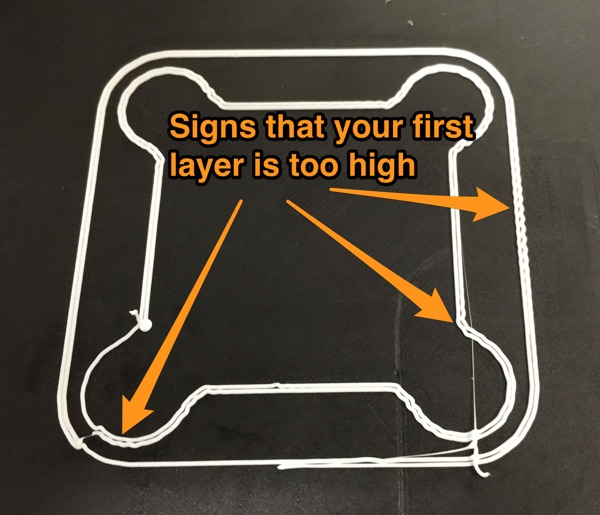

One of the things that takes the most time when printing is bed-leveling and calibration. Thankfully, both of these things are done automatically with the 1200, so you can spend more time actually getting work done. That said, there’s very little advanced functionality included, considering the price.

The Dimension 1200 uses RFID chips on the filament cartridge to help keep track of how much material is left. As long as you keep an eye on the reading, you’ll never run out mid-print again. On the other hand, this does mean that there’s no way to use third-party materials.

There are a few additions that really would have made this printer shine: we’re talking of course about greater connectivity options and increased OS support. There’s really no excuse for not including a USB port, or SD card slot, at the very least. It’s disappointing, especially when you consider how little they’d cost to add.

Cost

This is not a cheap machine. It retails for around $35,000, meaning it’s priced well out of the reach of the vast majority of people. Stratasys has instead focused on marketing to the top-level businesses in the world. It’s a good thing too because this isn’t the only cost you’ll have to deal with.

How much do you think a 56” spool of ABSplus costs? If we said almost $180, you’d think we were crazy, right? Well, it’s the truth. Let’s be clear: this is not a printer you’d use without a specific item in mind. To put it another way, for the price of two spools, you can buy a fairly decent, mid-range 3D printer.

Still, if you work in one of the industries that this model is designed for, the cost is likely not a huge issue. After all, ABSplus claims to be 40% more resilient than standard ABS and can be used to create everything from engines to tank parts.

Support

To its credit, Stratasys offers a good selection of customer support materials. There are user guides, quick start manuals, and FAQs for all of the company’s 3D printers. You can also download the latest firmware patches here, but for some reason, the Dimension 1200 isn’t included. It may not be the newest model around, but legacy customers have the right to be supported too.

There are user guides, quick start manuals, and FAQs for all of the company’s 3D printers. You can also download the latest firmware patches here, but for some reason, the Dimension 1200 isn’t included. It may not be the newest model around, but legacy customers have the right to be supported too.

There are a couple of additional services that this company offers. Users can attend 3D printing seminars explaining how to use their products, and there’s even a recycling service for old cartridges.

A one-year warranty is included with all of Stratasys’ 3D printers, which is fine if a little underwhelming. For $35,000 you’d really expect to see a five-year guarantee at least. Customer support can be reached by email, phone, or live chat, although there are no details on whether it is 24/7 or not.

MakerBot Replicator Z18 Review

Stratasys Dimension 1200es 3D Printer

| Brand | Stratasys |

| Machine type | 3D Printer |

| Technology | FDM (Fused Deposition Modeling) |

| Materials | ABS, HIPS, PC-ABS, ASA |

| Website | http://www. stratasys.com/3d-printers/design-series/dimension-1200es stratasys.com/3d-printers/design-series/dimension-1200es |

| Average Price | Contact manufacturer |

About Dimension 1200es

Durability Meets Affordability

You don’t need to kick your ideas out of the nest to make them fly. In-source your prototyping and functional testing.

The Dimension 1200es is your gateway into the best-selling family of professional 3D printers. Make your models where you hatch your ideas. The money you save will make you feel even smarter.

Print models in production-grade thermoplastic. Dimension 1200es 3D Printers use ABSplus™ modeling material, a production-grade thermoplastic that is durable enough to perform virtually the same as production parts. Models printed with Dimension 3D Printers have customer-proven toughness – from commercial sprayers tested at pressures up to 60 psi, to final parts on M1 tanks normally machined in aircraft-grade aluminum

Models printed with Dimension 3D Printers have customer-proven toughness – from commercial sprayers tested at pressures up to 60 psi, to final parts on M1 tanks normally machined in aircraft-grade aluminum

At the core of every model: FDM® Technology. Stratasys FDM (Fused Deposition Modeling) technology is the foundation for all Dimension 3D Printers. Models are printed from the bottom up with precisely deposited layers of modeling and support material. There’s no waiting for models to “cure” — they’re ready for support removal right from the printer. The SST 1200es uses Soluble Support Technology which dissolves the supports in a water-based solution. The BST 1200es uses Breakaway Support Technology in which the supports are simply snapped off to reveal the final model. Then, models can be drilled, tapped, sanded and painted.

A tool for today’s fast-track product development. You’ll dramatically improve your product development process with Dimension 1200es 3D Printers. They print models that help you check form, fit and function, and correct errors, before your product goes into production. And they’re versatile enough to produce functional models, molds, patterns, customized tools and fixtures. To shorten product development cycles and accelerate time-to-market, start with Dimension 1200es 3D Printers — and bring your ideas to life.

They print models that help you check form, fit and function, and correct errors, before your product goes into production. And they’re versatile enough to produce functional models, molds, patterns, customized tools and fixtures. To shorten product development cycles and accelerate time-to-market, start with Dimension 1200es 3D Printers — and bring your ideas to life.

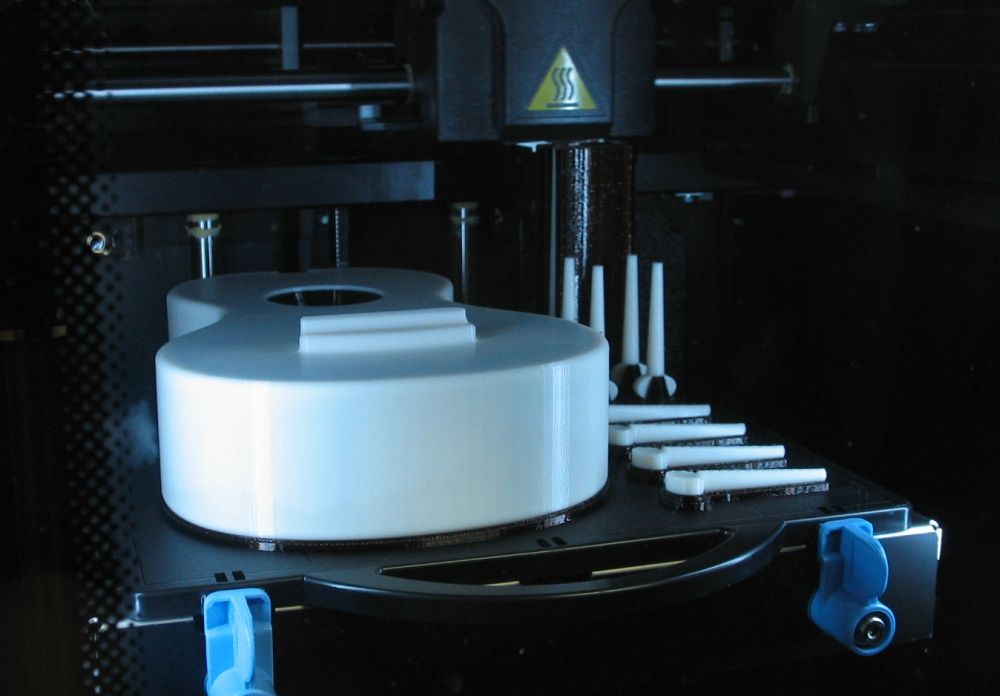

3D printed products made using the Dimension 1200es

Stratasys Dimension 1200 es SST 3D Printer

Print large functional 3D models right in your office

Dimension 1200es large build chamber allows you to print large and robust functional models (254 x 254 x 305 mm) for evaluation and testing in real conditions.

The printers are easy to operate: just press "Print" to prepare the CAD file, print the model and remove the support material to see your model design in three dimensions. nine0005

Robust thermoplastic ABSplus

The model material of the Dimension 1200es printer is an industrial grade thermoplastic that is strong enough to replace the actual part in test trials. Models are printed from bottom to top by layer-by-layer deposition of model material and support material. There is no need to wait for anything - the parts can be released from the support material immediately after the completion of the building process.

Models are printed from bottom to top by layer-by-layer deposition of model material and support material. There is no need to wait for anything - the parts can be released from the support material immediately after the completion of the building process.

Models can be drilled, carved, sanded and painted, making the 1200es ideal for functional prototyping, moulding, template making or even custom tooling and fixtures. nine0005

Cost effective

Dimension's functional 3D models and parts allow you to make the right decisions. The result is fewer product design changes, lower manufacturing costs and faster time to market.

Specifications

| Dimension SST 1200es | |

| Dimensions, mm | 838x737x1143 |

| Working area, mm | 254x254x305 |

| Weight, kg | 146 |

| Material | ABS+, colored |

| Layer thickness | 0. 254/0.330 254/0.330 |

| Remove support | Solution bath |

| Power supply | 220-240V, 60Hz, 7A |

| Specification | CE/ELT/RoHS/WEEE |

| Local network | TCP/IP 100/10baseT |

| Operating system | nine0029 Windows 2000/XP |

Materials

Model Materials

The Dimension SST1200 es 3D printer can produce prototypes and end products from the following industrial grade thermoplastics:

- ABS Plus is a high strength thermoplastic. Available in 9 colors.

Support material

- Soluble

Software

CatalystEX software

CatalystEX software converts stl files produced by CAD applications into printhead paths for 3D model production, including the structure of the required support material.

CatalystEX provides:

- 3D view of the model or models to be printed

- Ability to scale models to the required size nine0115 Model location control in build chamber

- Automatic or custom layout of models on a tray in one build cycle

- Queue print jobs with the ability to estimate print time and media usage.

3D printer Dimension 1200es from manufacturer Stratasys Ltd0147 Brief characteristics:

Printing technology: Fused deposition modeling (FDM/FFF)

Construction area, mm: 254x254x305

Printing material: ABS Plus,

All features

Description of Dimension 1200es 3D printer

You no longer need to try the impossible to make your ideas come true. Prototype and perform functional tests yourself. The Dimension 1200es opens up a popular family of professional 3D printers. Create your models in the same place where your ideas are born. And you will benefit even more from saving money. The Dimension 1200es printer series has the largest print chamber of any Stratasys Design 3D printer. Using FDM (Fused Deposition Modeling) technology, he prints ABSplus thermoplastic in nine colors. This 3D printer allows you to choose high resolution or faster printing with a layer thickness of 0.254mm or 0.33mm. nine0002 About Dimension 1200es To realize your ideas, you no longer need to try to do the impossible. Prototype and perform functional tests yourself. The Dimension 1200es opens up a popular family of professional 3D printers. Create your models in the same place where your ideas are born. And you will benefit even more from saving money. The Dimension 1200es printer series has the largest print chamber of any Stratasys Design 3D printer. Using FDM (Fused Deposition Modeling) technology, he prints ABSplus thermoplastic in nine colors.

Create your models in the same place where your ideas are born. And you will benefit even more from saving money. The Dimension 1200es printer series has the largest print chamber of any Stratasys Design 3D printer. Using FDM (Fused Deposition Modeling) technology, he prints ABSplus thermoplastic in nine colors. This 3D printer allows you to choose high resolution or faster printing with a layer thickness of 0.254mm or 0.33mm. nine0002 About Dimension 1200es To realize your ideas, you no longer need to try to do the impossible. Prototype and perform functional tests yourself. The Dimension 1200es opens up a popular family of professional 3D printers. Create your models in the same place where your ideas are born. And you will benefit even more from saving money. The Dimension 1200es printer series has the largest print chamber of any Stratasys Design 3D printer. Using FDM (Fused Deposition Modeling) technology, he prints ABSplus thermoplastic in nine colors. This 3D printer allows you to choose high resolution or faster printing with a layer thickness of 0.254mm or 0.33mm. The 3D printing kit is everything you need to start 3D modeling. It includes the following: 3D printer SST 1200es SCA-1200 Auxiliary Material Cleaning System Initial batch of materials Materials and bases Dimension 3D printers use ABSplus thermoplastic to create models. Modeling materials and soluble auxiliaries are supplied in convenient sealed cartridges that are easy to load. Inside the 3D printer, the plastic fiber travels through a tube to the print head, where it is heated to a semi-liquid state and extruded in thin, precise layers. The modeling framework provides a stable platform on which to model prototypes. Once the print is complete, you simply remove the reusable flexible plastic base from the 3D printer and separate the model. nine0005

This 3D printer allows you to choose high resolution or faster printing with a layer thickness of 0.254mm or 0.33mm. The 3D printing kit is everything you need to start 3D modeling. It includes the following: 3D printer SST 1200es SCA-1200 Auxiliary Material Cleaning System Initial batch of materials Materials and bases Dimension 3D printers use ABSplus thermoplastic to create models. Modeling materials and soluble auxiliaries are supplied in convenient sealed cartridges that are easy to load. Inside the 3D printer, the plastic fiber travels through a tube to the print head, where it is heated to a semi-liquid state and extruded in thin, precise layers. The modeling framework provides a stable platform on which to model prototypes. Once the print is complete, you simply remove the reusable flexible plastic base from the 3D printer and separate the model. nine0005

Dimension 1200es Owners Articles

More

Featured 3D Printers

Anet A8

1464 articles 1719 owners

Anet A8 3D printer is a budget 3D printer from China.