3D digital laser scanner

Laser Scanners | Leica Geosystems

- Home

- Products

- Laser Scanners

The BLK Series Goes Autonomous

BLK2FLY and BLK ARC provide fully autonomous mobile reality capture

Learn More

Laser Scanning Webinar Hub

Access all our webinars on-demand and register for upcoming webinars in our webinar hub.

Watch Now

Leica RTC360

3D reality capture solution combining a high-performance laser scanner and mobile-device app to capture and pre-register scans in real time.

Read More

Leica Cyclone FIELD 360

In-field data visualisation and pre-registration for all Leica Geosystems 3D laser scanners.

Learn More

Introducing the new Leica BLK360

Faster, smaller, and easier to use than ever before, the new BLK360 is a supercharged next-generation imaging laser scanner.

Previous Next

Software

Leica Geosystems 3D laser scanning software suite sets the industry standard to capture, visualise, extract, analyse, share and represent point cloud data.

Leica Geosystems 3D laser scanning software suite sets the industry standard to capture, visualise, extract, analyse, share and represent point cloud data.

Learn More

Scanners

Delivering outstanding range, speed and highest quality 3D data, Leica Geosystems laser scanners are the perfect partner for any tasks in 3D laser scanning.

Delivering outstanding range, speed and highest quality 3D data, Leica Geosystems laser scanners are the perfect partner for any tasks in 3D laser scanning.

Learn More

Accessories

Whatever accessory that you require for a job, you can select from a wide range of original accessories from Leica Geosystems.

Whatever accessory that you require for a job, you can select from a wide range of original accessories from Leica Geosystems.

Learn More

What is 3D Scanning? | Laser Design

First of all, let’s be clear that 3D laser scanning is not magical. True, the technologies that make it possible are very advanced and quite amazing. But behind the mirrors—found in the laser probe (without any smoke)—there is a lot of know-how and experience that makes the laser scanning experience seem so easy to Laser Design customers.

Read on or watch our video on What is 3D Scanning?

What is 3D Scanning?

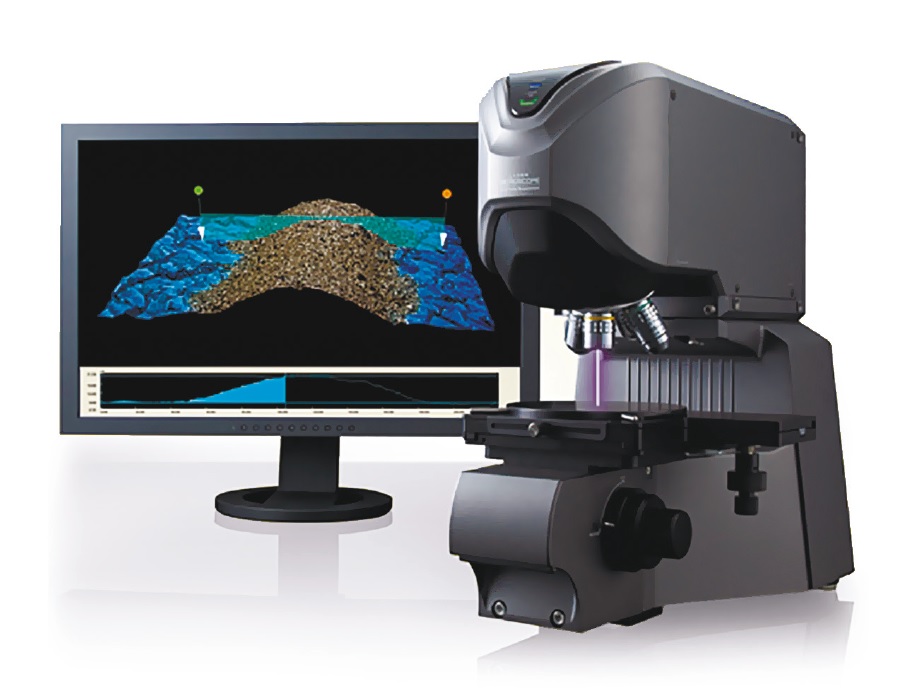

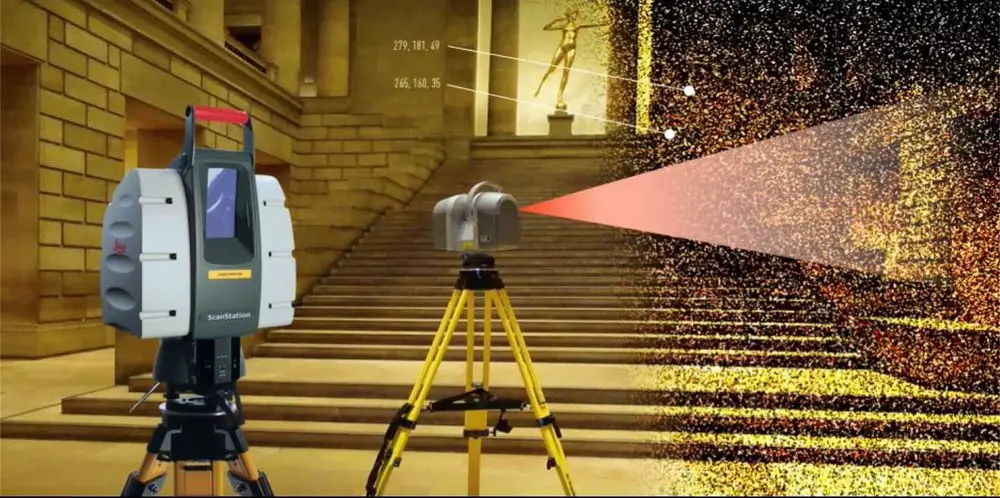

3D Laser Scanning is a non-contact, non-destructive technology that digitally captures the shape of physical objects using a line of laser light. 3D laser scanners create “point clouds” of data from the surface of an object. In other words, 3D laser scanning is a way to capture a physical object’s exact size and shape into the computer world as a digital 3-dimensional representation.

3D laser scanners measure fine details and capture free-form shapes to quickly generate highly accurate point clouds. 3D laser scanning is ideally suited to the measurement and inspection of contoured surfaces and complex geometries which require massive amounts of data for their accurate description and where doing this is impractical with the use of traditional measurement methods or a touch probe.

The 3D Scanning Process:

Data Acquisition via 3D Laser Scanning

3D Laser Scanning Process An object that is to be laser scanned is placed on the bed of the digitizer. Specialized software drives the laser probe above the surface of the object. The laser probe projects a line of laser light onto the surface while 2 sensor cameras continuously record the changing distance and shape of the laser line in three dimensions (XYZ) as it sweeps along the object.

Resulting Data

The shape of the object appears as millions of points called a “point cloud” on the computer monitor as the laser moves around capturing the entire surface shape of the object. The process is very fast, gathering up to 750,000 points per second and very precise (to ±.0005″).

The process is very fast, gathering up to 750,000 points per second and very precise (to ±.0005″).

Modeling Choice Depends on Application

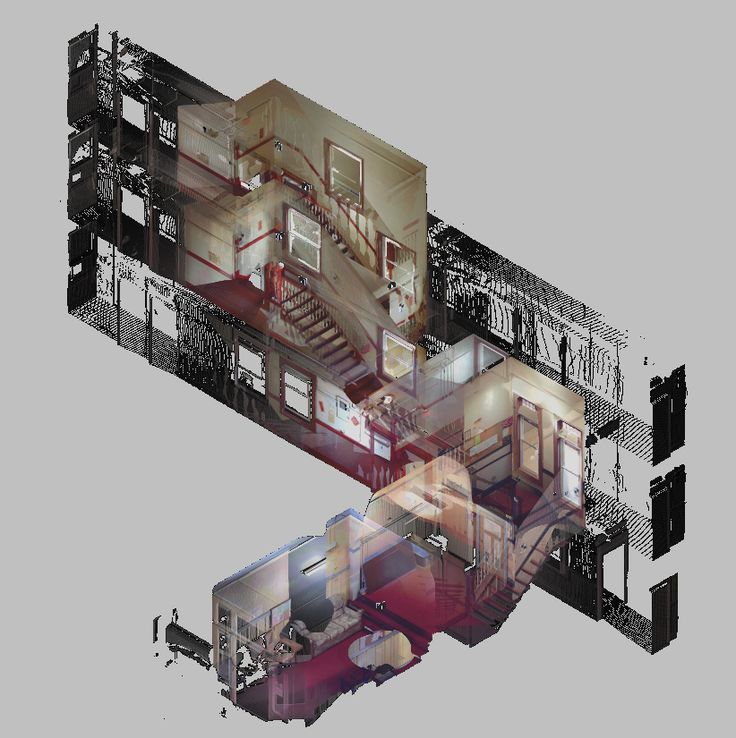

After the huge point cloud data files are created, they are registered and merged into one three-dimensional representation of the object and post-processed with various software packages suitable for a specific application.

Point Cloud Data for Inspection

If the data is to be used for inspection, the scanned object can be compared to the designer’s CAD nominal data. The result of this comparison process is delivered in the form of a “color map deviation report,” in PDF format, which pictorially describes the differences between the scan data and the CAD data.

CAD Model for Reverse Engineering

Laser scanning is the fastest, most accurate, and automated way to acquire 3D digital data for reverse engineering. Again, using specialized software, the point cloud data is used to create a 3D CAD model of the part’s geometry. The CAD model enables the precise reproduction of the scanned object, or the object can be modified in the CAD model to correct imperfections. Laser Design can provide a surface model or the more complex solid model, whichever results are needed for the application.

The CAD model enables the precise reproduction of the scanned object, or the object can be modified in the CAD model to correct imperfections. Laser Design can provide a surface model or the more complex solid model, whichever results are needed for the application.

Have additional questions? Check out our Glossary, sign-up for our eNewsletter, watch the 3D Laser Scanning Video or ask a question of your own!

scopes and overview of models / Sudo Null IT News

3D laser scanning - creating a digital model of a physical body using a laser beam. The technology is non-contact, works at close and long distances, eliminates damage to objects during scanning. The principle of operation of 3D laser scanners: a directed laser beam is reflected from the surface of an object, forming a cloud of points. Each point has its own coordinates in space. The software identifies them and creates a finished 3D digital model based on this data. nine0003

From the overview you will find out where laser scanning is used and what equipment is used to solve related problems.![]()

Purpose of laser scanners

Source: newequipment.com

Compared to traditional measurement methods, laser scanners have an important advantage - they can digitize objects with complex surfaces and work in hard-to-reach places for humans. The main areas of application of devices are input and output quality control in production, inspection of working devices in order to prevent and eliminate defects, reverse engineering and other areas. nine0003

Construction, renovation and renovation of objects

Source: ellisdon.com

During the preparation of the building design, it is necessary to evaluate the features of the site and the cost of the forthcoming works. With the help of 3D laser scanners, a landscape model is created, on the basis of which further work is carried out. During the construction process, intermediate control of the geometry of future buildings is required: walls, corners, openings, etc. Laser scanning copes with this task more accurately and faster than conventional measuring technologies. nine0003

Laser scanning copes with this task more accurately and faster than conventional measuring technologies. nine0003

The basis for an exterior or interior renovation is often an accurate digital model, on the basis of which changes and additions to the current interior or exterior are planned. Laser scanners are also indispensable in this area.

Road networks and transport

Source: autodesk.com

Laser scanning is becoming an integral part of the planning and creation of urban and suburban road networks, tunnels, pedestrian sections, railways, ports. The technology is used to assess the current state of coatings, plan and estimate the cost of repairs, to obtain models of perennial structures, such as bridges. The equipment is involved in the design, manufacture, repair and tuning of cars, air transport and ships. nine0003

Public utilities

Source: 3dscanner.es

With the help of 3D laser scanners, it became possible to quickly digitize and document engineering communications. Scanning significantly saves time during maintenance and reconstruction. The devices work remotely, minimizing the risks of people when working in adverse conditions and in hard-to-reach areas.

Scanning significantly saves time during maintenance and reconstruction. The devices work remotely, minimizing the risks of people when working in adverse conditions and in hard-to-reach areas.

Oilfield installations

Source: ramboll.com

Oil production complexes located in the water require constant monitoring of work processes. Objects are regularly exposed to adverse and changeable environmental influences: winds of different strengths and directions, currents, temperature changes, etc. 3D laser scanning is becoming an integral part of the inspection of oil production installations. The equipment allows you to quickly identify and fix deformations and other damage, control wear, calculate the timing of scheduled maintenance, and prevent accidents. nine0003

Forensic examination

Source: faro.com

Photographs and manual measurements in investigative processes and forensic examinations are being replaced by 3D laser scanning. The devices create three-dimensional models of accident sites with accurate fixation of the location of objects and the distances between them. The data is used in the process of pre-trial and litigation.

The devices create three-dimensional models of accident sites with accurate fixation of the location of objects and the distances between them. The data is used in the process of pre-trial and litigation.

Other applications

Source: news.microsoft.com

3D laser scanners facilitate and optimize workflows in the following areas:

- In cartography and geodesy - when creating terrain plans, maps, geographic information systems (GIS).

- In archeology - in the restoration and preservation of ancient artifacts.

- In paleontology, to create missing parts of excavated skeletons.

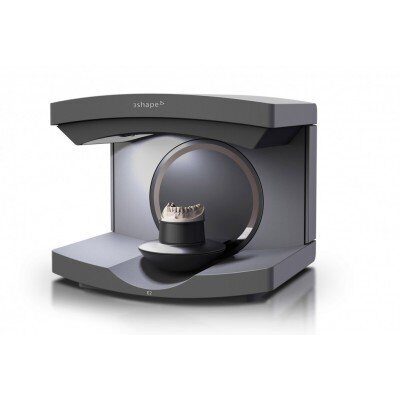

- In medicine, including plastic surgery and dentistry. nine0080

- home

- Products/Solutions nine0267 Laser scanners

- Scanners

- Leica RTC360 3D laser scanner nine0073

- The compact, highly automated, intuitive and user-friendly RTC360 solution includes a powerful 3D laser scanner, the Leica Cyclone FIELD 360 mobile app for edge computing, such as automatic real-time registration of scanned data, and Leica Cyclone REGISTER 360 software for office work , with which you can easily implement the resulting 3D model into your workflow.

- Capture scans, including stunning HDR images, in less than two minutes. nine0073

- Automatic recording of movements between survey points to pre-register scan data in the field without manual intervention.

- Augment the collected data with informative tags with hints for optimal planning and information about the real conditions on the site, which will help your colleagues to better understand the situation.

- Upload collected data from Cyclone FIELD 360 directly to Leica TruView Cloud to quickly share design data before import and registration. nine0073

Overview of models and manufacturers

FARO Focus

Source: ifworlddesignguide.com

FARO is one of the popular manufacturers of laser scanning devices. The new Focus3D S-series instruments stand out from other scanners in lightness and compact size, as well as the ability to work in bright sunlight and keep in touch with the location using GPS.

The FOCUS 3D S 150 scanner works at a distance of up to one hundred and fifty meters, with an accuracy of up to ±2000 microns at a maximum distance. The device is used in design, architecture and construction, for digitizing equipment and other objects. nine0003

You can learn more about this model on the website.

Source: youtube.com

Focus3D S 350 scans with the same accuracy as the previous device, but the distance to the measurement object is increased to 0.35 km. The device is designed for outdoor use.

Source: kkgeosystem.blogspot.com

SHINING 3D

Source: shining3d.com

FreeScan is a line of well-known Chinese manufacturer of digital equipment SHINING 3D. These are universal laser handheld 3D scanners FreeScan X5 (X5+), FreeScan X7 (X7+) weighing up to 1 kg, with an excellent set of professional features. nine0003

nine0003

Basic parameters:

Specifications

Creaform

Source: foundry-planet.com

Creaform's SCAN 3D range is characterized by high scanning quality combined with ease of use. Portable laser scanners HandySCAN 3D, MetraSCAN 3D have a clear interface, do not require special skills and complex user training.

Instrument features:

ScanTech

Handheld range

Source: cmmxyz.com

The HandHeld Prince series uses blue and red laser beams to scan large and small objects with high accuracy. Scanners can operate in bright sunlight and low light conditions. Due to its compact size, high speed and detail, the equipment is widely used in reverse engineering, quality inspection, digitization of museum, archaeological and other objects. nine0003

Key features:

Composite series

Source: twitter. com

com

In addition to the dual scan mode, the KSCAN20 is equipped with a photogrammetry system, thanks to which the working area of the device is 2.5 m * 3 m with an accuracy of 35 µm / m.

Blue and red lasers provide high-speed scanning of up to 650,000 measurements per second with a resolution of 0.01 mm.

Key Features:

3D Laser Scanner Applications

Reduce construction costs and time with FARO Focus

Source: autodesk.com

US construction company Gilbane invested $60,000 in the purchase of a FARO Focus-S 350 laser scanner, software and employee training. At first glance, the amount seems too large for a small-scale firm. But, after making calculations, the company's management came to the conclusion that the investments would pay off in the shortest possible time. nine0003

According to Gilbane's director of 3D design, John Tocci Jr., after introducing the expensive new technology, the company began to use the equipment even in areas where it was not originally planned. The specialists managed to save $30,000 for one hour of Focus-S 350 and Autodesk Revit software.

The specialists managed to save $30,000 for one hour of Focus-S 350 and Autodesk Revit software.

Source: autodesk.com

Building a digital model of air ducts and other systems made it possible to avoid errors during the installation of physical objects, which could take several weeks. The use of FARO Focus in the assembly of plumbing, electrical and mechanical installations helped to optimize costs at all stages of work

Case “Modernization of the building of the University of Miami”

Source: elevar.com

At the time of the start of work, the architects had drawings made 85 years ago, and a little more than 4.5 thousand square meters of the old building. Using a 3D laser scanner, Gilbane digitized the training areas in one day. Modernization of load-bearing structures, as well as the main utility systems: plumbing, electrical and ventilation, was based on data obtained from scanning. nine0003

nine0003

Quality Inspection with ScanTech

Source: 3d-scantech.com

The advantage of metal stamping over forging and casting is the lower weight and thickness of the resulting parts. The use of molds gives high accuracy and maximum compliance of the obtained parts with the specified characteristics, but does not completely exclude deviations and deformations. Which, in turn, can lead to difficulties in assembling finished products and reducing product quality. Therefore, constant quality inspection is a necessary part of production. nine0003

Understanding the manufacturer's tasks, ScanTech suggested checking the quality of stamped parts using the PRINCE laser scanner. The ability to switch between blue and red laser modes allowed the device to combine the functionality of traditional portable and metrological 3D scanners. The mode of operation with an active beam of a red laser provides fast digitization of objects. In the case of increased requirements for accuracy and detail, turn on the blue laser beam mode. nine0003

In the case of increased requirements for accuracy and detail, turn on the blue laser beam mode. nine0003

The photo shows the stages of work:

1. Installing markers - takes about two minutes.

Source: 3d-scantech.com

2. Digitizing a part takes about three minutes.

Source: 3d-scantech.com

Source: 3d-scantech.com

3. Deviation detection - lasts 3 minutes.

Source: 3d-scantech.com

The digital model shows the parameters and deviations, allows you to correct errors at the design stage. The case clearly shows that the process required a minimum of time and effort. nine0003

Using FARO 3D scanners on Justin Timberlake's world tour

Source: disguise.one

Timberlake's "Man of the Woods" program features scenery brought to life on stage. First, the ScanLAB team digitized a number of corners of the forest in the US state of Oregon. Laser projectors then directed images over the auditorium and stage, painting amazing pictures of the Portland landscape on translucent canvases suspended in the air. nine0003

First, the ScanLAB team digitized a number of corners of the forest in the US state of Oregon. Laser projectors then directed images over the auditorium and stage, painting amazing pictures of the Portland landscape on translucent canvases suspended in the air. nine0003

Source: faro.com

Two Faro Focus X 330 laser scanners, Faro Scene 6.2 software were used to prepare visual effects. In total it took 40 digital copies and 1 working day in the concert hall.

Source: www.esa.int

Considering the limited preparation time, the large surface areas for displaying the image and the corresponding need for high image resolution, creating visual effects in a short time without using the chosen technology was impossible. nine0003

Selection guide for 3D laser scanners

In the review, we introduced you to the equipment of market leaders with an excellent reputation. All the devices described have high performance, so we recommend that you pay attention to these devices for use in various fields:

All the devices described have high performance, so we recommend that you pay attention to these devices for use in various fields:

FARO Focus: Focus3D S350, Focus 3D S150.

Creaform: MetraSCAN 350 (350 Elite), MetraSCAN 750 (750 Elite), HandySCAN Black (Black Elite).

SHINING 3D: FreeScan X5 (X5+), FreeScan X7 (X7+). nine0008 ScanTech: KSCAN20, PRINCE 775, PRINCE 335.

Results

Source: 3d-scantech.com

The cases discussed clearly prove that the use of 3D laser scanning optimizes workflows in many areas. The range of tasks solved with the help of 3D laser scanners is constantly expanding.

Buy a professional 3D laser scanner in Top 3D Shop — experienced specialists will help you choose the most suitable equipment, software for your business, and offer a project to modernize production. nine0003

Leica RTC360 3D Laser Scanner | Leica Geosystems

Use automatic on-site pre-registration of point cloud data for real-time quality control, increased productivity and better decision making on site

Document and digitize your environment in 3D with the Leica RTC360 3D reality capture solution. Increase productivity on site and in the office with fast, accurate, portable and easy-to-use hardware and software. With the RTC360 3D Laser Scanner, a skilled technician can overcome any design challenge with accurate and reliable 3D models to unlock the full potential of any site. nine0003

Quick

The new Leica RTC360 laser scanner captures reality in 3D at a speed never seen before. Capturing up to 2 million points per second and using advanced HDR image capture, the scanner generates colorful 3D point clouds in less than two minutes.

Automated, labelless data logging in the field based on VIS technology and convenient automatic data transfer from site to office further speed up field work and increase productivity. nine0003

Automated, labelless data logging in the field based on VIS technology and convenient automatic data transfer from site to office further speed up field work and increase productivity. nine0003

Adaptive

Thanks to its portable design and foldable tripod, the compact and lightweight Leica RTC360 fits into a regular backpack. On the object, one click of a button is enough to scan the environment without any additional settings.

Fine

nine0008 Low noise in the acquired data means better image quality – you get crisp, detailed scans that are ready for a variety of industries. Combined with the Cyclone FIELD 360 automated data logging software in the field, the Leica RTC360 delivers amazing accuracy that can be verified on site.

Pre-registration in the field

The Cyclone FIELD 360 app, part of the RTC360 solution, bridges the gap between on-site 3D data collection and on-site registration of laser scan data in the office with Cyclone REGISTER 360.

User can automatically capture, register, and control scan and image data on site . The easy-to-learn and user-friendly graphical interface offers visual aids for complex calculations, making it easy for even beginners to master. nine0003

User can automatically capture, register, and control scan and image data on site . The easy-to-learn and user-friendly graphical interface offers visual aids for complex calculations, making it easy for even beginners to master. nine0003 Previous Next

Scanning options

The RTC360 3D Laser Scanner automatically captures movement between survey points to pre-register scanned data on the spot. Juergen Mayer spoke about the latest developments in an interview with The Reporter.:quality(80)/images.vogel.de/vogelonline/bdb/841500/841567/original.jpg) nine0003

nine0003

Introduction to the RTC360

The latest Leica RTC360 3D reality capture solution, unveiled at HxGN LIVE 2018, combines a high-performance laser scanner with a mobile application for capturing and pre-logging real-time scan data.

From hardware to software

Geosystems specialists optimize every link of the workflow in both software and hardware solutions to increase the efficiency and productivity of field work and data processing in the office. nine0003

Leica RTC360: 3D reality capture solution

Leica Cyclone FIELD 360 mobile-device app

Downloads

Videos

EXPERT ADVICE

nine0084 Examples of using

Podcasts

Introducing the Leica RTC360 3D Laser Scanner

3D environments in a matter of minutes - an outlook on recent reality capture technology

3D reality capture - new opportunities, greater understanding

Transforming Ayacucho into a digital city

nine0084 Services

myWorld - Customer Portal

Active Customer Care

Customer Support Packages

Similar products

Laser scanners

Leica BLK360 laser scanner

Leica ScanStation P40 / P30

Leica ScanStation P50

Software

Leica Cyclone

Leica Cyclone REGISTER

Leica Cyclone REGISTER 360

Leica CloudWorx

Leica TruView

Leica JetStream

Accessories

Accessories for 3D laser scanners 9003

contact-for-laser-scanning

As of v7. 0.1, Safari exhibits a bug in which resizing your browser horizontally causes rendering errors in the justified nav that are cleared upon refreshing. nine0003

0.1, Safari exhibits a bug in which resizing your browser horizontally causes rendering errors in the justified nav that are cleared upon refreshing. nine0003

As of v7.0.1, Safari exhibits a bug in which resizing your browser horizontally causes rendering errors in the justified nav that are cleared upon refreshing.

CONTACT US

The High-Definition Surveyor - Blog

Learn how Leica Geosystems laser scanning solutions are helping professional to shape the future of our world. nine0003

Learn how Leica Geosystems laser scanning solutions are helping professional to shape the future of our world.

Read More

The power of scanning

Quality is a tradition, built deep within our DNA. We have a commitment to excellence and exceptional attention to detail. nine0003

The power of scanning

Quality is a tradition, built deep within our DNA. We have a commitment to excellence and exceptional attention to detail.

WATCH NOW

Educational articles and analytics

What is 3D Reality Capture and how is it applied in your industry? nine0003

What is 3D Reality Capture and how is it applied in your industry?

learn more

Comparison table of laser scanners

Which laser scanner is right for you?

Which laser scanner is right for you?

download now

Reality Capture Newsletter

Click here to subscribe to our regular newsletter and stay up-to-date on all the latest reality capture news.