Is 3d printing pla toxic

How Toxic Are ABS & PLA Fumes? 3D Safety Examines VOCs

0Shares

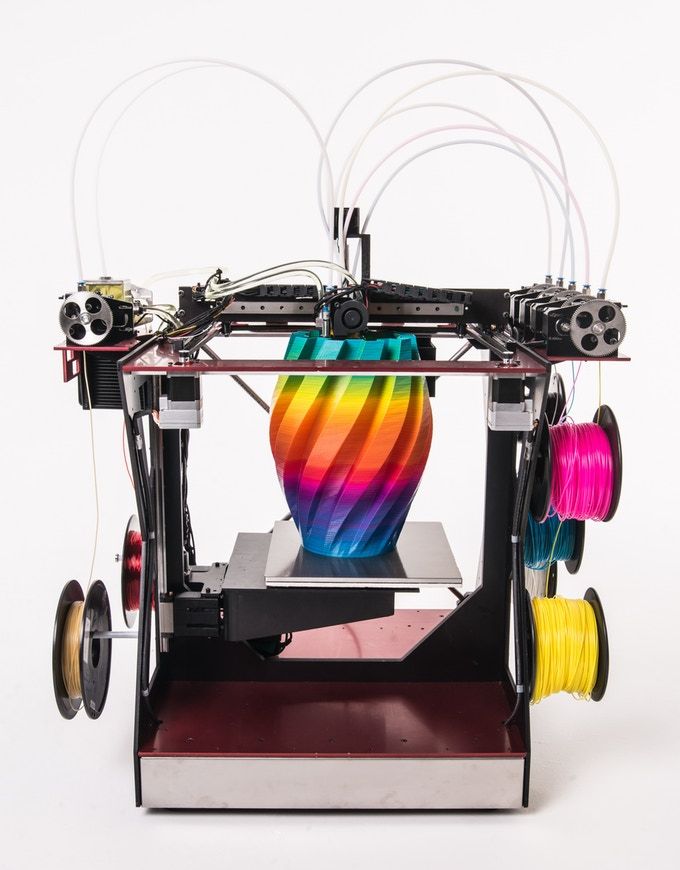

While everyone knows the unpleasant odor from ABS cannot possibly be healthy to breathe in, most of us generally do not really care. However, not only ABS, but also PLA, may release toxic fumes known as VOCs (Volatile Organic Carbon). Not all VOCs are actually toxic, but some may be, especially for younger users. Before this becomes a serious health issue, a new study conducted by 3Dsafety.org, in collaboration with Italian 3D printer manufacturer WASP, has analysed the exact quantities of toxic VOCs – as well as potentially dangerous nanoparticles – released during filament extrusion, in order to assess the potential health risks.

The new study, presented by Dr. Fabrizio Merlo and Dr. Eng. Stefano Mazzoni, starts off from other previous research conducted in the early 90’s, which demonstrated that during the fusion and processing of plastic materials, several toxic particles are released as gases, including ammonia, cyanidric acid, phenol, and benzene, among others.

The lab tests showed that ABS is significantly more toxic than PLA, but that the corn-based polymer is not exempt form dangerous emissions, especially if extruded at temperatures higher than 200°C. Furthermore (as may be expected), the same material spools, when acquired from different resellers, release very different quantities of VOCs, even if used in the same 3D printer and under the same parameters of speed and temperature.

A second critical aspect is that relating to the emission of nanoparticles, that is, particles with a diameter smaller than .1 micron, which can be absorbed directly by the pulmonary alveolus and the epidermis. In this case, the emissions, when using ABS, vary from 3 to 30 times those that occur when using PLA filament. The test also demonstrated that the time necessary for the nanoparticle concentration in the air to go back to standard levels was between 10 and 30 minutes after the extrusion processes stopped. Through a photo-ionization technology, the study (which has been published on 3Dsafety. org and will progressively be updated with further information) was also conducted on nylon, polystyrene, PET and other materials.

org and will progressively be updated with further information) was also conducted on nylon, polystyrene, PET and other materials.

Among the effects that the absorption of toxic VOC’s and nanoparticles can cause to humans, the most common are pulmonary pathologies, such as bronchitis, tracheitis, asthma. In some cases, these substances can also cause certain types of cancers, so this is not something to be taken lightly. The solution, however, is not too complicated. 3Dsafety.org, in collaboration with WASP, is working to increase awareness as to the potential risks of toxic emissions from filament, while several practical tips can be implemented right away.

For example, working in well ventilated rooms: the ideal solution would be using an air ventilation system capable of moving three times the room’s volume of air in one hour. This means that a room measuring 100 cubic meters should have a system capable of displacing 300 cubic meters of air in one hour. When using closed-chamber 3D printers, it may be possible in the near future to implement an active carbon filtration device, and the team is actively working toward development of a device specifically tailored for 3D printers, which can be regulated according to the type of filament material used.

Certainly this does not mean we should all just stop using 3D printers. However, dealing with the potential health risks of 3D printing materials early is the best way to make sure this technology evolves in a way that we can maximise its benefits and limit any risks involved.

Davide Sher

Davide was born in Milan, Italy and moved to New York at age 14, which is where he received his education, all the way to a BA. He moved back to Italy at 26 and began working as an editor for a trade magazine in the videogame industry. As the market shifted toward new business models Davide started working for YouTech, the first iPad native technology magazine in Italy, where he discovered the world of additive manufacturing and became extremely fascinated by its incredible potential. Davide has since started to work as a freelance journalist and collaborate with many of Italy’s main generalist publications such as Corriere della Sera, Panorama, Focus Italy and Wired Italy: many of his articles have revolved around the different applications of 3D printing.

Are 3D Printer Filament Fumes Toxic? PLA, ABS & Safety Tips – 3D Printerly

There’s no doubt about the excellence of what 3D printers have brought to the world but one crucial thought comes to mind when the danger that these machines impose is in question. This article concentrates on acknowledging whether filaments used for 3D printing are toxic to health or not.

3D printer filament fumes are toxic when melted at very high temperatures so the lower the temperature, generally the less toxic a 3D printer filament is. PLA is known as the least toxic filament, while Nylon is one of the most toxic filaments out there. You can reduce toxicity with an enclosure and air purifier.

To put it into layman terms, 3D printing is a procedure that involves thermal decomposition. This means that when the printing filament is melted at an exceeding amount of temperature, it’s bound to give off toxic fumes and release volatile compounds.

These bi-products therefore, do pose a health concern towards users. The intensity with which they can prove to be harmful, however, varies due to a number of reasons which will be discussed later on in this article.

The intensity with which they can prove to be harmful, however, varies due to a number of reasons which will be discussed later on in this article.

How Can 3D Printer Filament Spoil Our Health?

The rate at which the thermoplastics start emitting dangerous particles is directly proportional to temperature. Higher temperature means that a higher amount of these threatening particles is emitted and a higher risk is involved.

Side by side, it is to be pointed out that the actual toxicity may vary from filament to filament. Some are more noxious, while others are less.

According to a study conducted by ACS Publications, some filaments release Styrene which is assumed to be a carcinogen. Styrene is subject to cause unconsciousness, cephalgia, and weariness.

In addition, the toxic fumes released from the melted plastic, often tend to target the respiratory system and possess the capacity of causing direct damage to the lungs. Moreover, there’s also a risk present for cardiovascular diseases as toxins enter the bloodstream.

Inhaling the particles given off by thermoplastics aggravate the chance of asthma furthermore.

To look into the matter closely, we need to understand what precisely is the danger and in what form. Not only this, but general information on the most popular printing filaments and their safety concerns is about to come next as well.

The Toxicity Explained

Better understanding the concept of why thermoplastics can be fatal for human life will help decipher the whole phenomenon.

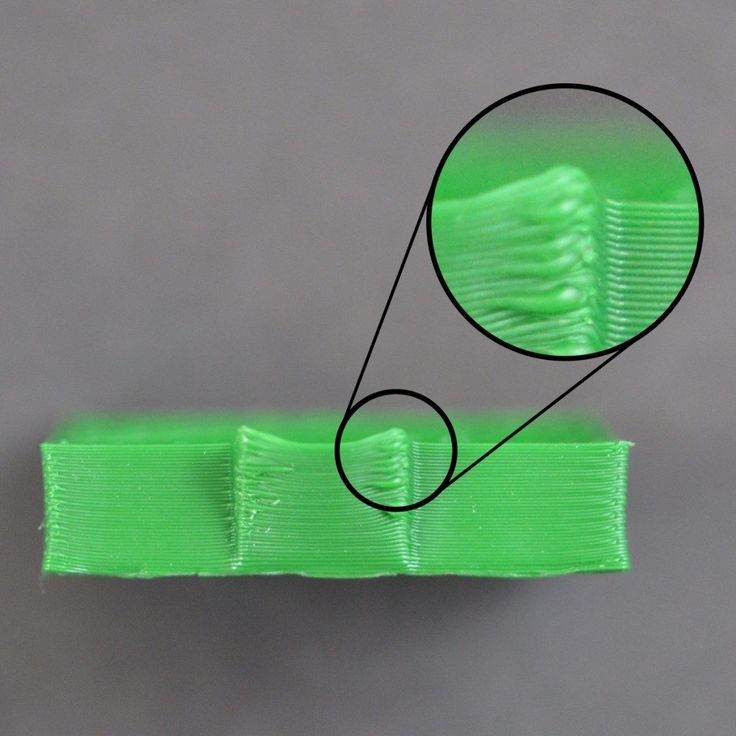

Basically, a 3D printer works wonders printing layer over layer, but in doing so, it pollutes the air. How it does that, is primary for us to focus on.

When thermoplastics are melted at high temperatures, it starts emitting particles that can have negative consequences on the indoor quality of air, therefore causing air pollution.

Pinpointing this form of pollution, it has been revealed that there are two main types of particles that come into being during printing:

- Ultrafine Particles (UFPs)

- Volatile Organic Compounds (VOCs)

Ultrafine particles have a diameter of up to 0. 1 µm. These can enter the body with ease and target the lung cells specifically. There are also a number of other health risks concerned with the intrusion of UFPs in the human body such as various cardiovascular disorders and asthma.

1 µm. These can enter the body with ease and target the lung cells specifically. There are also a number of other health risks concerned with the intrusion of UFPs in the human body such as various cardiovascular disorders and asthma.

Volatile organic compounds such as Styrene and Benzene also put the users of 3D printers at risk since they have a connection with cancer. The Environmental Protection Administration (EPA) also categorizes VOCs as agents of toxicity.

Research conducted by the Georgia Institute of Technology in collaboration with Weizmann Institute of Science in Israel took measures to show beyond doubt, the negative impact of particle emission from 3D printers.

For this purpose, they made the concentration of particles coming from 3D printers to come in contact with human respiratory cells and rat immune system cells. They found out that the particles provoked a toxic response and influenced the cell’s potentiality.

Talking about the filaments in specific, the researchers took PLA and ABS; two of the most common 3D printing filaments out there. They reported that ABS proved to be more fatal than PLA.

They reported that ABS proved to be more fatal than PLA.

The reason for this is because of the fact that more emissions are produced as the temperature rises for the filaments to melt. Since ABS is a printing material that takes ample number of degrees to melt, it’s liable to give off more fumes than PLA which melts at a lower temperature.

With that being said, it’s quite surprising that a lot of people are oblivious of the health risks associated with 3D printing.

Many users have reported headaches, dizziness and fatigue after spending some time with their printers, only to find out later upon research, that the main cause for their ailing health was the constant exposure.

Five Most Common Filaments & Toxicity

Elucidating the topic additionally, we’ll look into and discuss the 5 most commonly used printing filaments, their composition, and if they mean any peril.

1. PLA

PLA (Polylactic Acid) is a unique thermoplastic filament that is derived from natural resources like sugarcane and corn starch. Being biodegradable, PLA is the go-to choice for printing enthusiasts and experts.

Being biodegradable, PLA is the go-to choice for printing enthusiasts and experts.

As PLA is the type of filament that melts at a lower temperature, around 190-220°C, it’s less prone to warping and is less resistant to heat.

Although breathing in the fumes of any plastic can’t be good for anyone whatsoever, as compared to the infamous ABS, PLA comes out on top in terms of emission of toxic fumes. This is mainly because it doesn’t require intense conditions to be extruded out onto the printing bed.

Upon thermal decomposition, it breaks down into lactic acid which is generally harmless.

PLA has been regarded as environment-friendly, although it may be more brittle than ABS and also less tolerable to heat. This means that a hot day in summer with elevated conditions could cause the printed objects to deform and lose shape.

Check out OVERTURE PLA Filament on Amazon.

2. ABS

ABS stands for Acrylonitrile Butadiene Styrene. It is one of the most common printing filaments out there used for forming objects needed to be able to tolerate high temperatures. Although it’s termed as a non-biodegradable plastic, ABS filament is ductile and heat-resistant.

Although it’s termed as a non-biodegradable plastic, ABS filament is ductile and heat-resistant.

However, ABS with its common use over the years, has started to raise several eyebrows opposed to its safety measures.

Since ABS amounts to melting at very high temperatures, particularly between 210-250°C, it starts emitting fumes that have reported to cause discomfort to users.

Not only a slight bother, prolonged exposure can cause eye irritation, respiratory problems, headaches and even fatigue.

Check out SUNLU ABS Filament on Amazon.

3. Nylon (Polyamide)

Nylon is a thermoplastic widely known in the printing industry for its prime durability and pliability. It requires heating between 220°C and 250°C to reach optimal performance.

A heated print bed is required for nylon-based filaments to ensure good adhesion and low chances for warping.

Despite Nylon being far stronger than ABS or PLA, an enclosed print chamber is highly necessary to minimize health risks. Nylon is suspected to give off a VOC called Caprolactam which is toxic to inhalation and able to cause grave damage to the respiratory system.

Nylon is suspected to give off a VOC called Caprolactam which is toxic to inhalation and able to cause grave damage to the respiratory system.

Therefore, constantly working in an environment where the filament is nylon-based is sure to be alarming and precaution is advised.

Check out OVERTURE Nylon Filament on Amazon.

4. Polycarbonate

Polycarbonate (PC) is arguably, one of the strongest printing materials available on the market. What PLA or ABS lack to offer, Polycarbonate verily provides.

They possess phenomenal physical properties and are on the front lines in the making of heavy-duty objects like bulletproof glass and construction materials.

Polycarbonate has the ability to be bent in any form without cracking or breaking. Moreover, they are extremely resistant to high temperatures.

Nevertheless, having high-temperature tolerance also means that they have increased chances to warp. Therefore, an enclosure over the printer and a preheated platform is a must when printing with PC.

Talking about safety issues, Polycarbonate also emits a considerable number of particles that could do a number on a person’s health. Users have reported that staring at the object being printed with PC too long starts stinging the eyes.

Check out Zhuopu Transparent Polycarbonate Filament on Amazon.

5. PETG

Polyethylene Terephthalate revised with glycolisation has given birth to PETG, a filament on the rise to gaining popularity purely because of its non-polluting properties and high capabilities.

PETG boasts a glossy and smooth finish to the objects, making it highly convenient and a great alternative to PLA and ABS.

Additionally, many PETG users have provided positive feedback that they have experienced little to no warping and the filament makes it easier to adhere to the printing platform as well.

This makes it a huge contender in the marketplace as it is also water-resistant and is commonly used in the manufacture of plastic water bottles.

Check out HATCHBOX PETG Filament on Amazon.

Tips on How to Reduce Toxicity Exposure From Filament

As soon as people are let known about the toxicity of some of the most commonly used filaments, they are all going to ask the same question, “What do I do now?” Fortunately, the precautions aren’t exactly rocket science.

Proper Ventilation

Most printers come with highly specialized carbon filters beforehand to minimize the emission of fumes. Regardless of that, it’s entirely up to us to evaluate and set the correct printing conditions.

It’s always recommended to print in a place where there is a good ventilation system installed, or somewhere in the open. This helps in filtering the air and expelling the fumes away.

Limiting the Exposure

It’s a good idea making sure that your 3D printer is in an area that people aren’t constantly exposed to. Rather a designated area or room that people don’t have to access to get to a desired area.

The goal here is to limit exposure to the particulates and harmful emissions that come from your 3D printer.

The Dos and Don’ts

The Do’s

- Setting up your 3D printer in a garage

- Using a non-toxic printer filament

- Keeping general awareness of the threat some thermoplastics pose

- Replacing your printer’s carbon-based filter consistently, if any

The Don’ts

- Setting up your 3D printer in your bedroom or living room with poor ventilation

- Not researching thoroughly about the filament you use

- Letting your printer run overnight in the same place where you sleep

Examined the toxicity of ABS and PLA

fumesAnyone who manufactures products on the 3D printer knows that ABS plastic does not have the most pleasant smell, and inhaling such fumes is harmful to health. Know something they know, but, apparently, no one thinks about it seriously.

ABS and PLA are quite common plastics for printing and at the same time quite harmful. The vapors emitted by them are called volatile organic substances. Even if not every one of them is toxic, it is harmful for the child's body and adolescents in any case. nine0005

The vapors emitted by them are called volatile organic substances. Even if not every one of them is toxic, it is harmful for the child's body and adolescents in any case. nine0005

The developers of the resource 3Dsafety.org have teamed up with WASP, the Italian team behind 3D printers. Their main goal is to calculate the exact number of toxic volatile elements that 3D printing plastics release during processing. Based on this, it will be clarified what health risk the emitted nanoparticles carry.

Doctors Fabrizio Merlo and Stefano Mazzoni presented the results of the study. Much of their work is based on an earlier one published in the early 19th century.90s. Even then, it was found that ammonia, phenol and benzene are released during the melting of plastic.

The results of the work showed that ABS is more toxic than PLA, but there are a number of nuances. At 200°C, PLA becomes as toxic as ABS. The second feature is that one material purchased from different manufacturers will have a different degree of toxicity, even if the settings (print speed, temperature) of the 3D printer are the same for several different brands of plastic.

No less important is the moment associated with nanoparticles. These elements are less than 1 micron in diameter. At such sizes, they easily penetrate the lungs and linger in the epidermis. Taking into account the latter factor, the use of ABS plastic is 3-30 times more dangerous than the use of PLA.

Scientists have calculated the time it takes for nanoparticles in the air to reach a safe rate, and it turned out that this interval is from 10 to 30 minutes after the printing process is completed. nine0005

What causes the inhalation of harmful fumes? A person is threatened with lung pathology, asthma, as well as treatable, but unpleasant bronchitis. The greatest danger is the occurrence of cancer.

It all looks intimidating, however, the researchers share the secret to solve this problem. First of all, 3Dsafety.org and WASP started spreading the word about possible risks. And they also developed a number of recommendations that you can follow today.

So, the room in which the object is printed must be well ventilated. Ventilation, which would renew the air several times per hour, would be ideal. If the working area is 100 m3, then the ventilation must handle three times more. nine0005

In the future - 3D printers , which would have their own carbon filtration system. The developers have already taken up the implementation of this idea. In this case, the cleaning system will be customizable.

The results of the research are troubling, but that doesn't mean we should stop using 3D printing technology. It is important to take steps to reduce the risks.

Source: 3dpulse.ru

nine0001

Technician

Subscribe to the author

Subscribe

Don't want

17

All fans of 3D printing are familiar with the unpleasant smell of ABS plastic, and most people understand that inhaling these fumes is most likely harmful to health it's really worrisome. However, not only ABS, but also PLA can be a source of toxic fumes called volatile organic compounds (VOCs).

However, not only ABS, but also PLA can be a source of toxic fumes called volatile organic compounds (VOCs).

Not all VOCs are toxic, although some may be particularly dangerous to children and adolescents. The 3Dsafety.org team, together with the Italian 3D printer manufacturer WASP, has determined the exact amount of toxic VOCs, as well as potentially dangerous nanoparticles, that are formed during the 3D printing process and assessed the associated health risks. nine0005

The new study, presented by Dr. Fabrizio Merlo and Dr. Stefano Mazzoni, builds on previous work published in the early 90s. Past research has shown that melting and mixing plastic releases fumes of toxic substances such as ammonia, cyanuric acid, phenol and benzene.

Laboratory studies have shown that ABS plastic is much more toxic than PLA, but the latter is not without the risk of hazardous fumes, especially if the operating temperature exceeds 200°C. In addition, as expected, it turned out that the same material purchased from different manufacturers has different VOC content, even when used in the same 3D printer at constant speed and temperature settings. nine0005

nine0005

Another critical risk factor is related to nanoparticles, ie particles less than 1 micron in diameter, which can penetrate directly into the lung alveoli and epidermis. In this case, the risk score for ABS is 3 to 30 times higher than for PLA. The tests also revealed that the time it takes for nanoparticles in the air to return to normal levels is 10 to 30 minutes after the end of the 3D printing process.

Inhalation of toxic VOCs and nanoparticles most often causes lung pathologies in humans, such as bronchitis, tracheitis, asthma (class, I just have asthma). In some cases, these substances can also cause cancer, so this topic should be taken seriously. However, solving the problem is not that difficult. 3Dsafety.org and WASP are working together to get the potential risk out to as many people as possible, and there are a few best practices you can start following now. nine0005

In particular, the researchers advise working in well-ventilated areas: ideally, it would be a ventilation system that can change the entire volume of air in the room three times per hour.