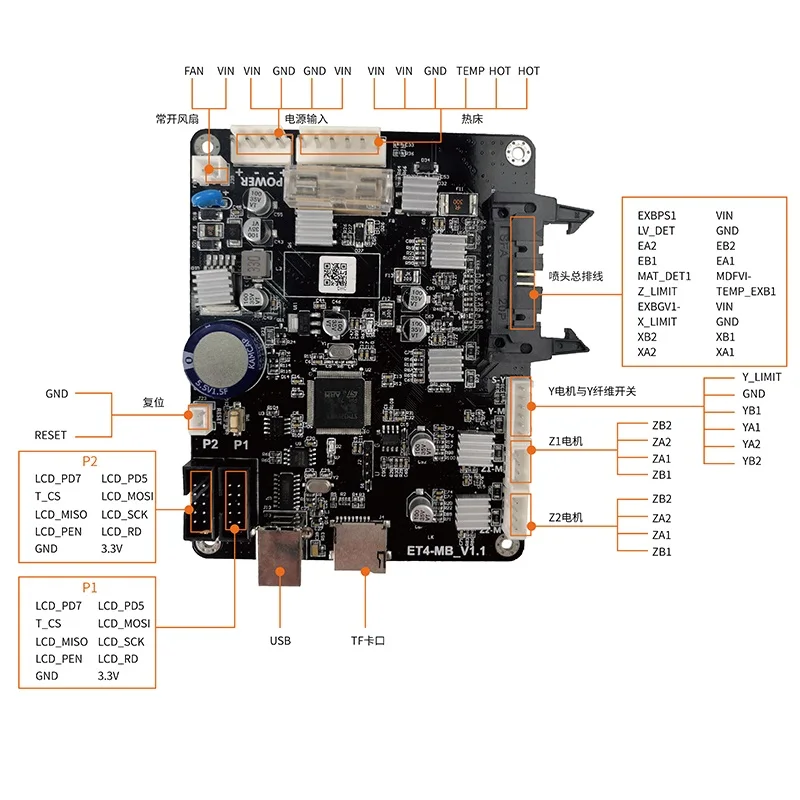

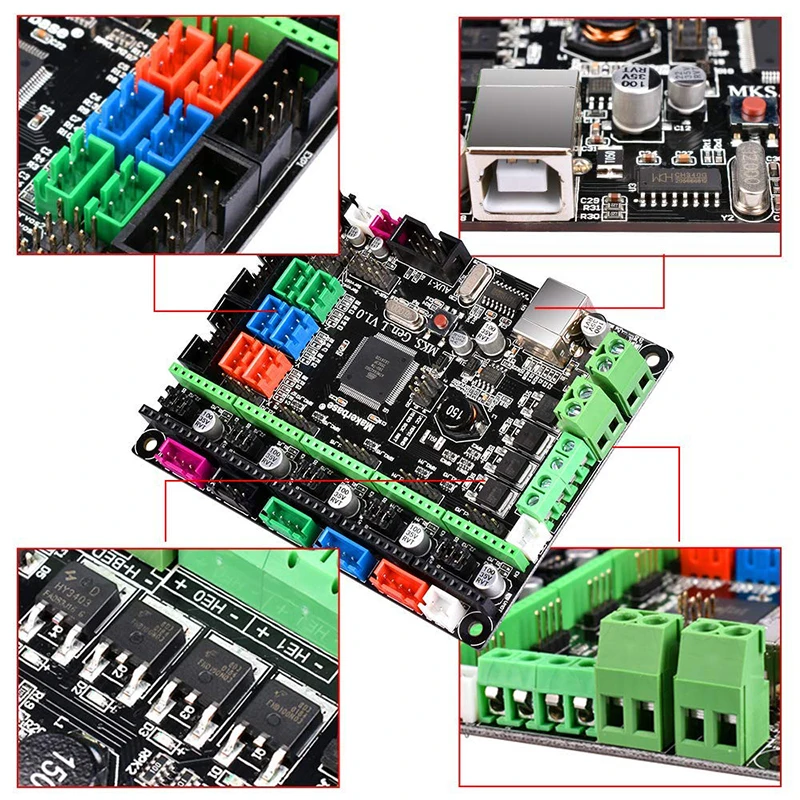

Motherboard for 3d printer

6 Best 3D Printer Controller Boards In 2022

- Last Updated: December 13, 2022

- Jackson O'Connell

The controller board on a 3D printer is arguably the most important part of a machine. Just like you can’t function without a brain, a 3D printer can’t function without this integral circuit board.

The controller board, sometimes known as a motherboard or mainboard, is responsible for processing and carrying out all of the commands sent to the machine. Without it, your 3D printer is just a bunch of motors, sensors, and probes, sitting on a metal frame, doing absolutely nothing.

The controller board varies from printer to printer (often based on brand), and some are better than others for reasons we’ll explain later. Luckily, you can usually replace the board on your printer to improve printing performance, usability, or other factors.

In the sections below, we’ll explain more about 3D printer motherboards and how they vary. We’ll then dive into our review of some of the best controller boards on the market that you can use on your machine.

Enjoy!

BTT SKR Pro V1.2

Check Latest Price

BTT SKR Mini E3 V2.0

Check Latest Price

Duet 2 Wi-Fi V1.04

Check Latest Price

Table of Contents

- Best 3D Printer Controller Boards At A Glance

- What Is A 3D Printer Controller Board?

- Why Change Your 3D Printer’s Board?

- What To Consider When Buying a Controller Board?

- Processor

- Number of Ports

- Compatibility

- Stepper Drivers

- Quality

- Price

- Best 3D Printer Controller Boards

- 1. BTT SKR Mini E3 V2.0 (Best Overall)

- 2. Duet 2 Wi-Fi V1.04 (Best Premium Choice)

- 3. BTT SKR Pro V1.

2 (Best Value)

2 (Best Value) - 4. Creality V4.2.7

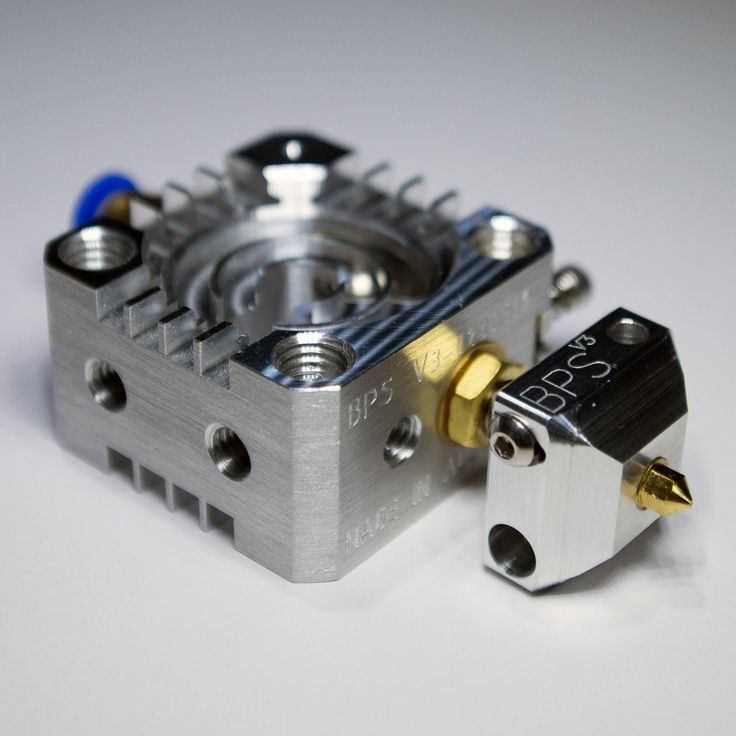

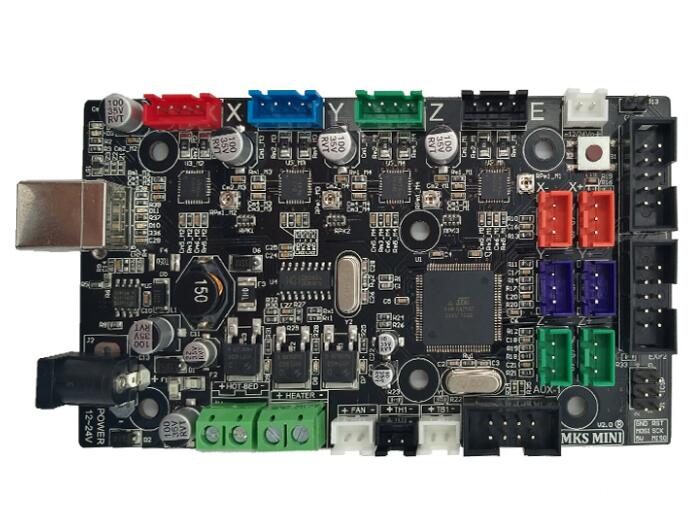

- 5. MKS Robin E3D

- 6. Smoothieboard (V1)

- Conclusion

Best 3D Printer Controller Boards At A Glance

1. BTT SKR Mini E3 V2.0 (Best Overall)

2. Duet 2 Wi-Fi V1.04 (Premium Choice)

3. BTT SKR Pro V1.2 (Best Value)

4. Creality V4.2.7

5. MKS Robin E3D

6. Smoothieboard (V1)

What Is A 3D Printer Controller Board?

A 3D printer controller board is a type of microcontroller meant for a 3D printer. As a microcontroller, the board’s sole purpose is processing commands, known as G-code for 3D printers, and following them.

Every electronic component – motors, sensors, probes, etc. – is wired to the different ports on the board. When the processing chip on the motherboard reads a G-code command, it gives power to the specific motor ports to carry out the command. And, when data needs to be used, it takes it from the sensor ports, like an automatic bed leveling sensor if your printer has one.

And, when data needs to be used, it takes it from the sensor ports, like an automatic bed leveling sensor if your printer has one.

The board is also where the firmware program is running. If you’re unfamiliar with the term, firmware helps bridge the digital and physical realms of 3D printing by giving the controller board a way to decode the G-code commands so it can carry them out. Firmware also contains certain features and capabilities like linear advance and meshes for automatic bed leveling.

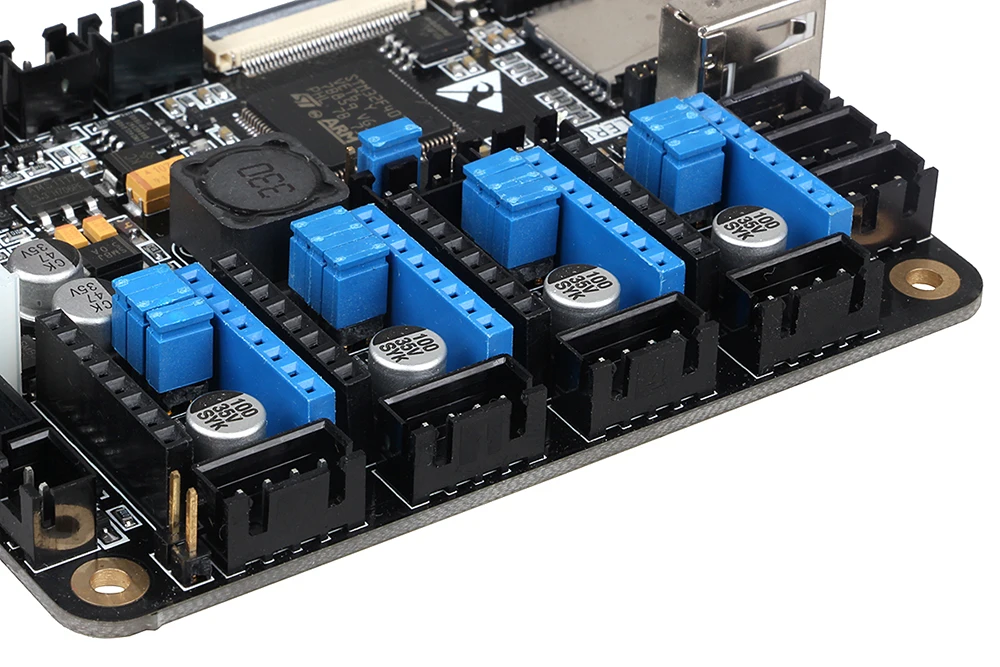

3D printer controller boards also have something called stepper motor drivers. These components of the board are responsible for the rotation of the motors connected to the board. Stepper motor drivers directly impact the noise level produced by the motors as well as their accuracy and precision.

Some boards have integrated stepper motor drivers, which means they can’t be changed and are built into the board. However, other, more customizable boards, have stepper motor driver ports that allow you to use your own drivers.

But most of this explanation isn’t what you’ll be needing in your day-to-day 3D printing activities. The main thing you need to know about a controller board is that it has different ports to support different hardware, and each controller board is different.

Why Change Your 3D Printer’s Board?

Source: Youtube Design Prototype TestSo, why change your 3D printer’s controller board?

Well, as we said, each board is different, and some are better than others, offering enhanced features. This might mean more ports, a faster processor chip, or support for different firmware programs, which can all directly or indirectly improve the printing and usability of your machine.

Perhaps the most common reason to switchboards is to enable a certain upgrade that requires an extra port. This includes adding a second Z-axis stepper motor or an automatic bed leveling sensor.

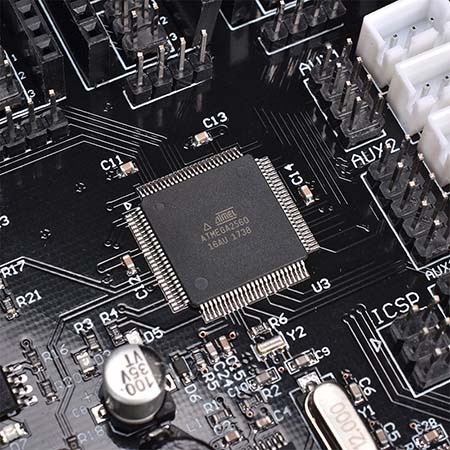

Another reason is for a better processor chip to get better prints. For example, motherboards that have a 32-bit processor architecture are known to yield smoother prints compared to 8-bit boards.

Yet another example is to get a quieter printing experience by switching to a motherboard with newer stepper motor drivers than your old board. Check out our review of the best quiet 3D printers here.

What To Consider When Buying a Controller Board?

3D printer controlled boards are pretty complex, with many different features onboard. As such, there are quite a few considerations to keep in mind when looking for a controller board for your machine.

In this section, we’ve gone over what we considered when picking out the best controller boards for this list.

Processor

Our first consideration was the processor on the controller boards. In the early days of 3D printing, the typical motherboard had an 8-bit microprocessor, but, now a 32-bit processor is the new standard. All of our selections have a 32-bit architecture as we wanted to make sure they can all handle the latest firmware features, like linear advance.

Number of Ports

The second consideration is the number of ports, including both motor and sensor ports. All of the controller boards on this list feature the necessary four (X, Y, Z, E) motor ports, but some go above and beyond with extra stepper motor ports to allow for more upgrades.

All of the controller boards on this list feature the necessary four (X, Y, Z, E) motor ports, but some go above and beyond with extra stepper motor ports to allow for more upgrades.

As for the sensor ports, each of the included controller boards has a sensor port for an automatic bed leveling sensor, and many have ports for a filament runout sensor as well.

Compatibility

Our third consideration was the popularity and compatibility of the controller boards. While a board can be unpopular and a good option, typically, the more popular a 3D printer controller board is, the more firmware programs support the board. We made sure at least a few different firmware programs could run on each of the included controller boards.

Stepper Drivers

Fourth, the stepper motor drivers were another thing we kept in mind when looking at the controller boards. If the board had integrated drivers, we made sure they were at least decently quiet. And, if the board had open driver ports, we made sure they supported some of the more recent TMC drivers as these types of drivers are most popular.

Quality

Fifth, the manufacturer of the product also matters, and we didn’t forget about it. A quick search on AliExpress will bring up many 3D printer boards that seem good on paper, but, when they arrive, they perform poorly. We made sure each of the controller boards we’re calling the “best” come from the best and most reputable manufacturers around.

Lastly, we reviewed the price of each of the listed products to make sure they all were in reach for the average hobbyist. We can’t be comparing $2,000 boards to $50 boards cuz’ that wouldn’t make sense.

Best 3D Printer Controller Boards

Now that we’ve gone over what a 3D printer controller board is, it’s time to get into the options. We’ve scoured the market and handpicked the best boards for you, reviewing each in the sections below.

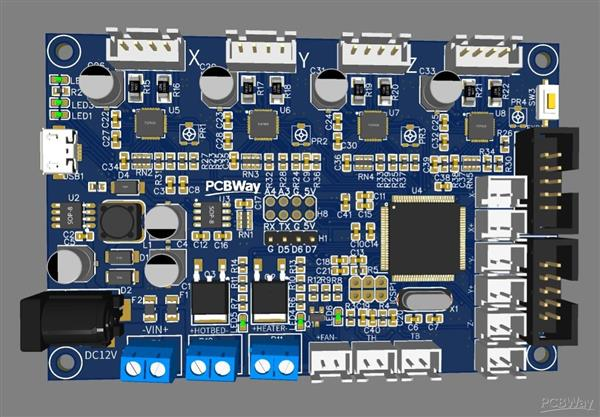

1. BTT SKR Mini E3 V2.0 (Best Overall)First up, the BTT SKR Mini E3 V2.0 is a very powerful 3D printer motherboard developed by the experts at BigTreeTech (BTT). Hence its name, the SKR Mini, has a pretty small footprint and can fit in consumer-grade printers like the Ender 3.

Hence its name, the SKR Mini, has a pretty small footprint and can fit in consumer-grade printers like the Ender 3.

What’s most appealing about the board, however, isn’t its size but rather its 32-bit architecture.

Moreover, the board has a powerful processor chip that runs an astounding 72-MHz, which is much faster than almost any stock board on consumer 3D printers. This will allow you to run larger and more feature-heavy firmware programs like Marlin 2.0 for your machine.

If that doesn’t get you excited, the board also provides five stepper motor ports and even a port dedicated to an automatic bed leveling sensor. This will allow you to make upgrades to your printer, like dual Z-axis motors and auto bed leveling, without having to ask, “Can my motherboard handle this?”.

Additionally, the device features onboard TMC2209 stepper motor drivers. While the 2209s aren’t the latest drivers in the game, they will provide a decently-quiet printing experience, not counting for the noise from the fans.

On this note, the Mini E3 also has three fan ports, which certainly isn’t a lot but is standard for today’s boards. A few other features of this board is a micro-USB connector, a micro-SD card slot for printing storage, and support for a touchscreen LCD.

- 5 stepper motor ports, automatic bed leveling sensor port

- 32-bit architecture and 72-MHz processor chip

- Support for touchscreen LCD and large firmware packages

- Micro-USB and micro-SD card connectivity options

- TMC2209 stepper motor drivers built-in

- Only three fan ports

- The stepper motor drivers are somewhat old

Check Latest Price

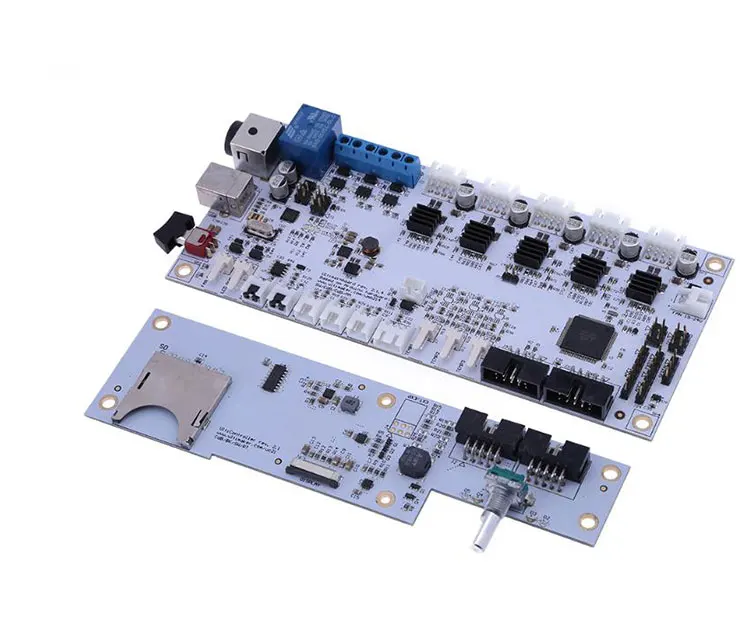

2. Duet 2 Wi-Fi V1.04 (Best Premium Choice)

Duet 2 Wi-Fi V1.04 (Best Premium Choice) Duet3D is on the pricier side of the consumer 3D printing market but they still make the cut.

Their Duet 2 Wi-Fi V1.04 board is a great option, especially for DIY 3D printers where the hardware isn’t made by just one manufacturer. That’s because the board is completely open-source, so you can use basically any motors, sensors, or other electronic attachments and, with some configuration, get them to work with the board.

As indicated by the name of this product, the Duet 2 Wi-Fi has an onboard Wi-Fi module that allows you to control your printer remotely. This means you can use Duet3D’s default online interface to start/stop prints, send G-code commands, set temperatures, and more.

It’s like an OctoPrint server built into the board!

And, when it comes to ports, the Duet 2 has got you covered with five motor ports to allow for an extra Z-axis motor. There are also plenty of other ports to allow for a Duet3D-developed PanelDue touchscreen LCD, two hot ends, a heated bed, and five endstops. And don’t forget about your automatic bed leveling sensor (e.g. BLTouch) or filament runout sensor because those can also both fit on this board.

And don’t forget about your automatic bed leveling sensor (e.g. BLTouch) or filament runout sensor because those can also both fit on this board.

And, in the unlikely scenario that you are still a few ports short, you can purchase Duet3D’s expansion board, which connects to the Duet 2 Wi-Fi and provides a few more motor and sensor ports.

As for the processor, it just makes sense that Duet3D used a powerful 32-bit chip on this monster of a board.

The drivers on the board are also exceptional and Duet3D opted for TMC2660 stepper drivers, which are some of the latest in the game. On top of keeping your printer quieter than quiet, these high-quality drivers allow for 256 microstepping. This feature ensures a super high level of accuracy and precision in stepper motor movements, improving the quality of prints.

Besides the close to $200 price tag, another major downside of this board is its massive size, which comes with offering the number of ports it does. The Duet 2 Wi-Fi isn’t a board that will fit into your Ender 3, Anycubic Mega, or really any other consumer-grade 3D printer. You’ll have to make a custom fitting (many 3D printable options online) to fit the board on your printer.

The Duet 2 Wi-Fi isn’t a board that will fit into your Ender 3, Anycubic Mega, or really any other consumer-grade 3D printer. You’ll have to make a custom fitting (many 3D printable options online) to fit the board on your printer.

- Built-in WiFi support and an online control interface

- Many motor ports for more upgrades

- Many sensor and attachment ports to support ABL and runout sensors

- TMC2660 stepper drivers and 256 microstepping

- 32-bit processing

- Optional expansion port board

- Very large; hard to fit on a regular 3D printer

- Very expensive

- Duet3D makes it difficult to run certain firmware programs (e.

g. Marlin)

g. Marlin) - Only a few LCDs are supported by the board

Check Latest Price

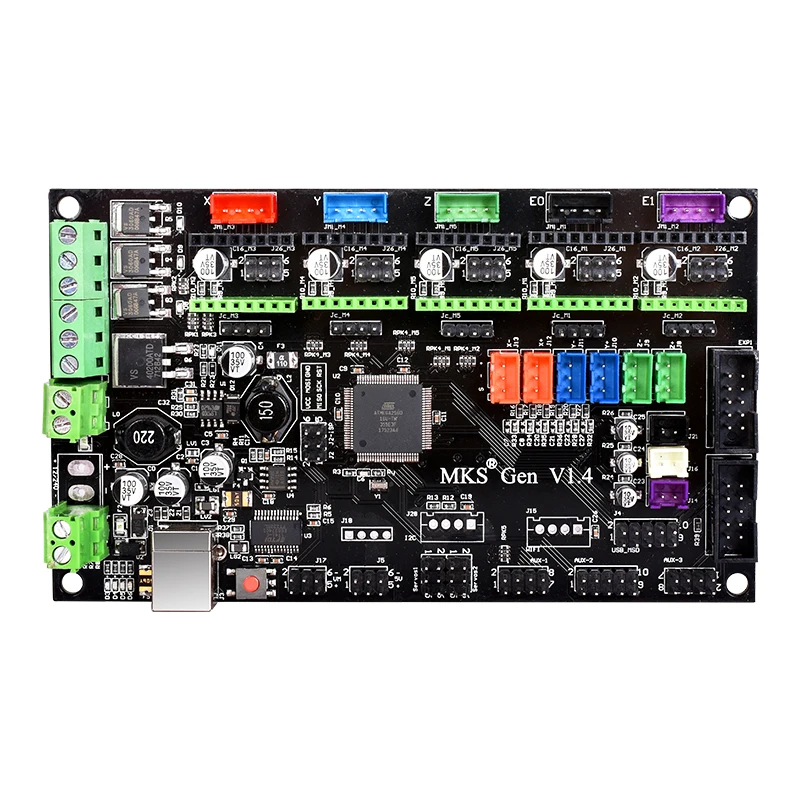

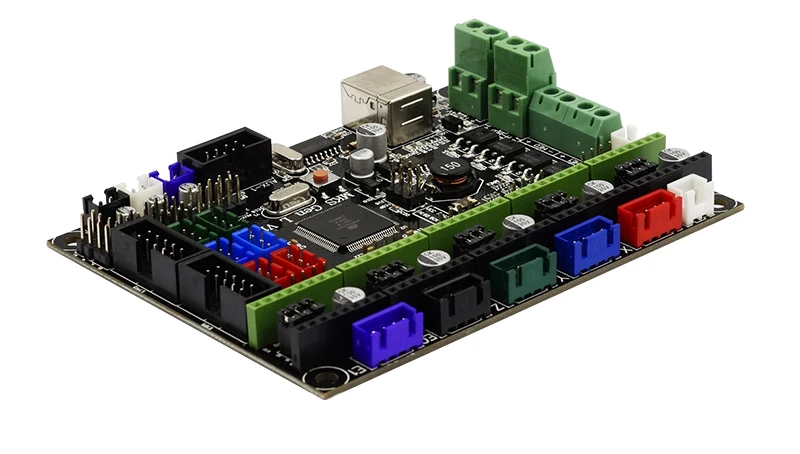

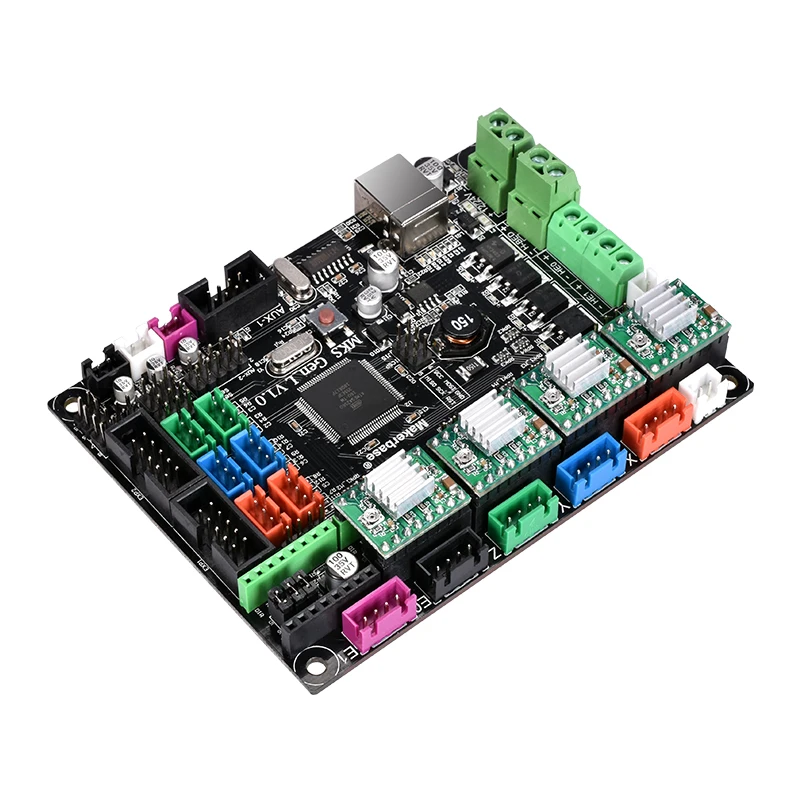

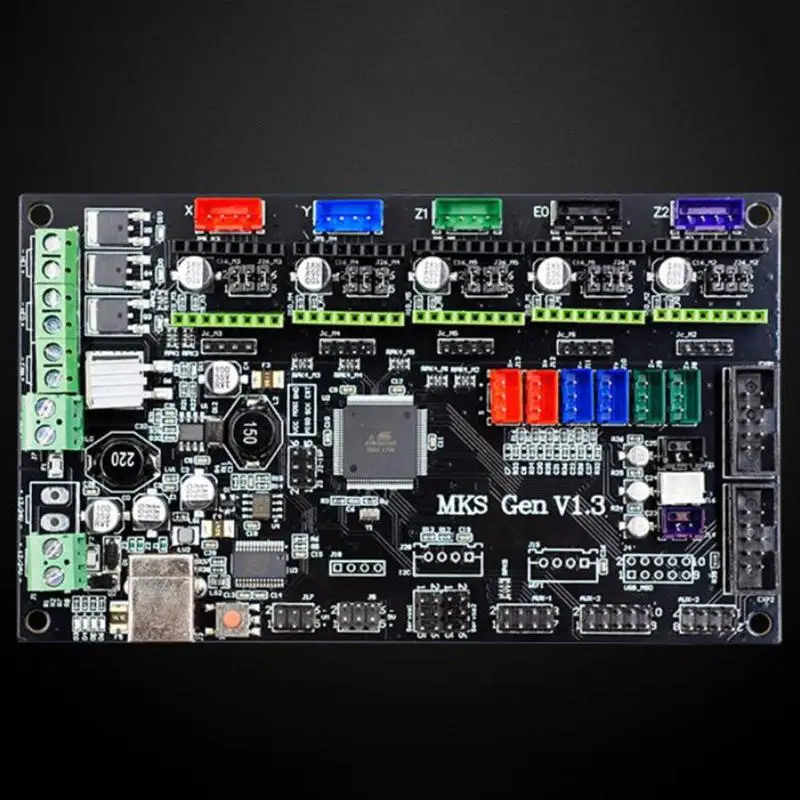

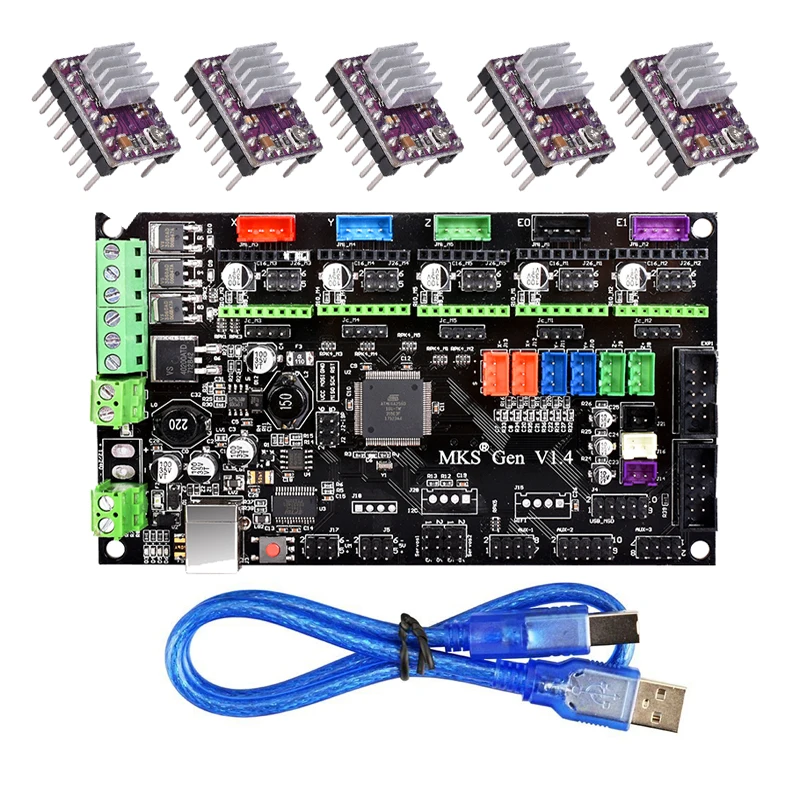

3. BTT SKR Pro V1.2 (Best Value)Another board from BigTreeTech is the BTT SKR Pro V1.2. The board is called “Pro” because it has more features and better features than most of BTT’s other boards. Unlike the Duet 2 Wi-Fi, though, this board is a normal size and can fit in most printers like the Ender 3.

But don’t be misled by the pretty regular size of the board as the SKR Pro V1.2 is far from normal. Boasting seven motor ports, the Pro V1.2 is a great option for dual-extrusion printers, where you need two extruder motors and two X-axis stepper motors. Alternatively, you can use the extra motor ports to have dual Z-axis motors to improve the quality of your prints.

Surprisingly, despite having seven motor ports, the Pro V1. 2 only has six driver ports for the stepper motors. That’s because one of the drivers is meant to run both of the motors in the Z-axis motor ports.

2 only has six driver ports for the stepper motors. That’s because one of the drivers is meant to run both of the motors in the Z-axis motor ports.

On this note about the drivers, the Pro V1.2 has open stepper motor driver ports, meaning you can fit whatever compatible stepper drivers you want. While this means the price of the board (which isn’t too much) isn’t the full price because you have to buy drivers, this allows you to choose what drivers you want based on how quiet and accurate you need your stepper motors to be.

Overall, the SKR Pro V1.2 is the board to get if customization is your middle name. Moreover, the board supports a lot of different drivers, firmware programs, and LCDs. The many ports on the board allow for basically whatever upgrade you want.

- Open-ended stepper drivers

- Wide support for firmware programs, LCDs, stepper drivers

- Seven motor ports

- 32-bit processor

- Wi-Fi module

- Small footprint

- Somewhat expensive

- Cable management can be difficult

- You have to buy the drivers separately

Check Latest Price

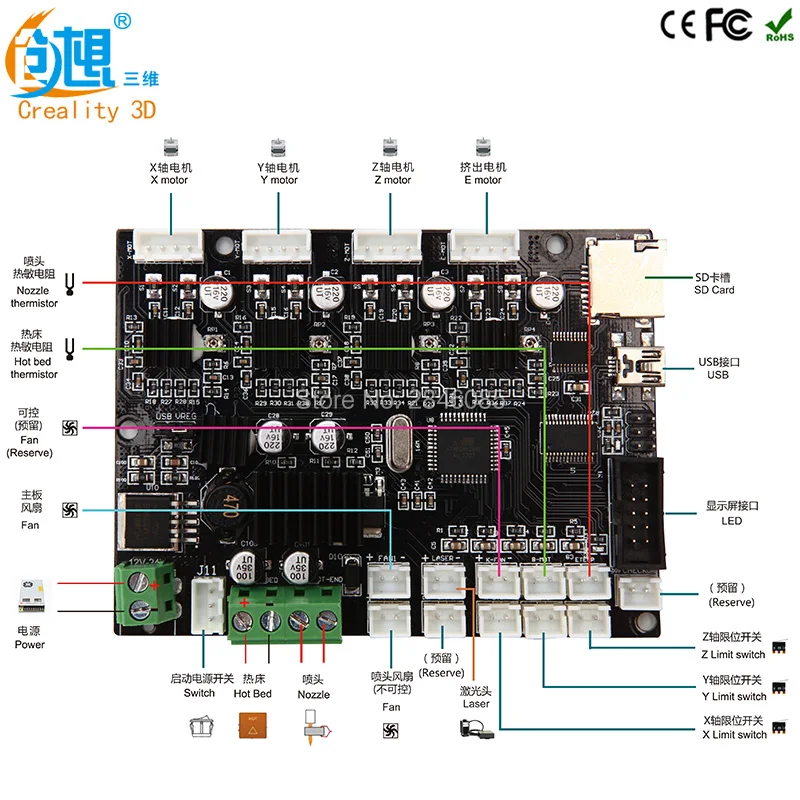

4. Creality V4.2.7

Creality V4.2.7 Creality is one of the largest names in the consumer 3D printing industry, with tens of the most popular printers on the market under its belt. Creality also makes a fair amount of optional upgrades for their printers, like the Creality V4.2.7 board.

The V4.2.7 was originally developed as a “silent” board for Creality’s Ender 3 V2, but it can be used on whatever printer you want as long as the parts are compatible.

As an Ender 3 enthusiast myself, I can honestly tell you that this board has improved my printing experience a lot.

First off, the 32-bit processor and decently-large EEPROM (storage space) on the V4.2.7 allow you to run feature-heavy firmware programs like Marlin 2.0. The board also has a built-in bootloader that allows you to flash new firmware programs through the micro-SD card slot.

But, in my opinion, the most beneficial part of the V4.2.7, is its integrated TMC2225 drivers.

The drivers quiet your printer so much to where you can really only hear the light humming of the fans. While these drivers can only reach 32 microstepping, which isn’t as accurate as some of the later TMC drivers, it’s still good enough to make parts very accurate.

While these drivers can only reach 32 microstepping, which isn’t as accurate as some of the later TMC drivers, it’s still good enough to make parts very accurate.

It’s also worth mentioning that the board is pretty small and can fit in many consumer-grade printers like all Creality printers as well as some non-Creality machines too. Sadly, the board only has four motor ports, so you can’t run two extruders or two Z-axis motors.

However, this 32-bit 3D printer board has specific ports for an automatic bed leveling sensor and a filament runout sensor, making installing those upgrades super easy.

- TMC2225 drivers for very quiet printing

- Small size; fits in most Creality printers

- Firmware flashing is possible through the micro-SD card slot

- Not too expensive

- 32-bit processor

- Ports for an ABL sensor and a filament runout sensor

- Microstepping capabilities aren’t super good

- Only four motor ports

Get Discount (Official Store)

Check Latest Price

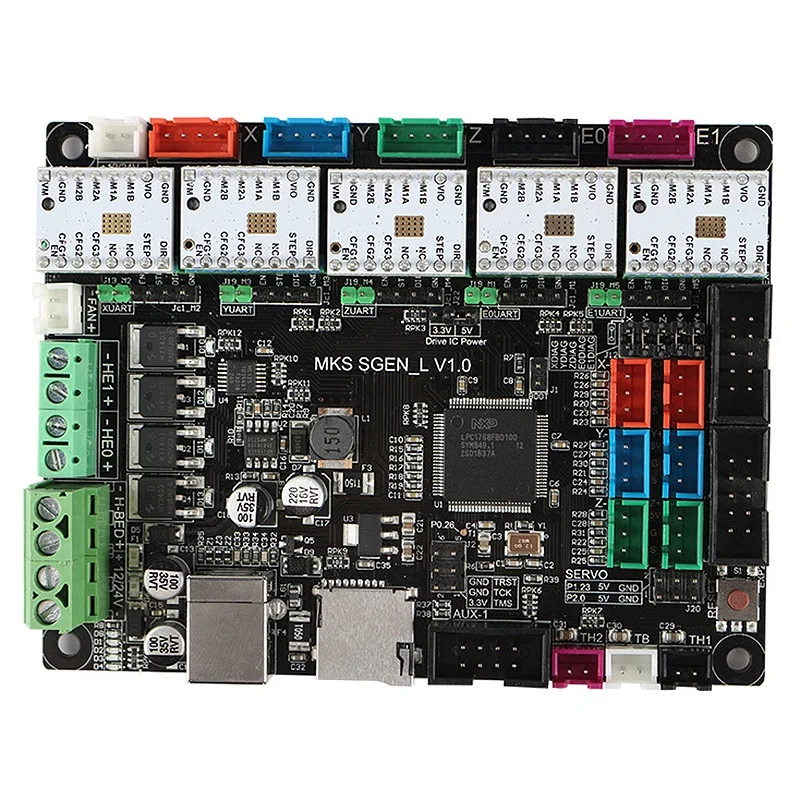

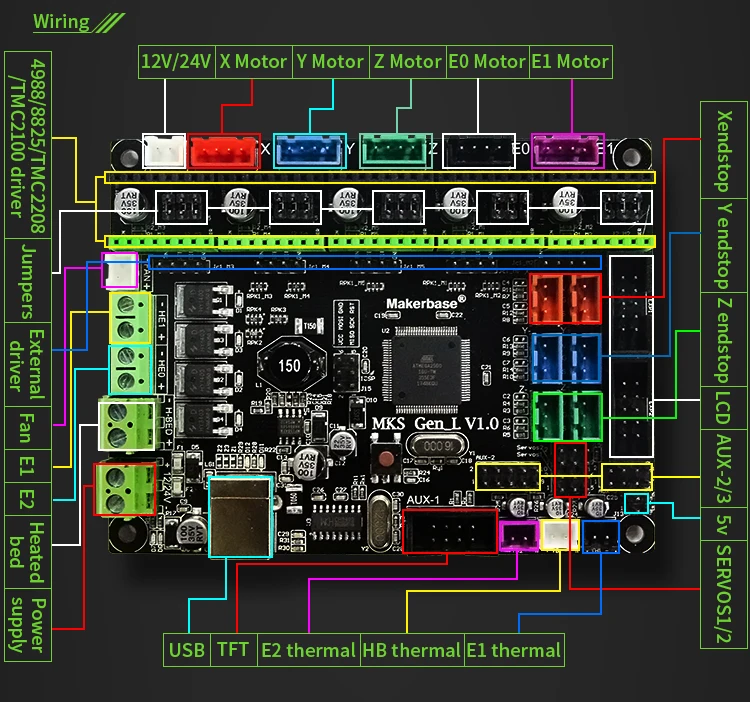

5. MKS Robin E3D

MKS Robin E3D Our last board comes from the experts at Makerbase, who make the MKS line of motherboards for 3D printers. The MKS Robin E3D isn’t the most popular board from Makerbase, but I think it’s very underrated and deserves a lot more credit for what it offers.

First off, the board has six motor ports to allow for both dual Z-axis motor and single-headed dual extrusion. Alternatively, you could build an independent dual-extrusion printer with the same number of motor ports.

However, this isn’t the only good part about the Robin E3D, and I think the open-ended stepper motor driver ports are another one of its main benefits. While the market seems to dislike the open-ended driver boards, they allow you to basically control the price of the machine because drivers make up a large part of the cost for most boards.

The E3D supports many different drivers, and you can put some TMC2209s on the board to achieve low noise and also have the option to run linear advance if you’re using Marlin firmware.

On a note about firmware, you should be able to change your board’s firmware through the micro-SD card slot, and most firmware programs are compatible (e.g. Marlin).

The board also supports many sensors, like ABL and filament runout ones. You can also connect a touchscreen LCD to the board and use Makerbase’s default TFT interface to control your printer through the screen.

The board is just a bit bigger than the default boards found on most consumer printers like the Anycubic Mega and Ender 3, so upgrading will require a fitted mount. However, it won’t be too hard as there are some 3D printable models online that work.

- Open-ended stepper drivers

- Small footprint

- Supports many sensors and attachments, like ABL, filament runout, and TFT screens

- Supports many different firmware programs

- Six ports for stepper motors

- Requires modifications to fit in most printers

- You have to buy your own stepper drivers

Check Latest Price

6. Smoothieboard (V1)

Smoothieboard (V1) While not as popular as the mass-manufacturing companies like BTT, MKS, and Creality, Smoothieware sure knows how to make a good motherboard. Smoothieware’s v1 Smoothieboard is the company’s flagship product and it launched on Kickstarter a few years ago, passing its target goal by about $100,000.

Perhaps the main reason this board is so revered is that it’s basically the only one ever made by an organization that develops 3D printer firmware. As such, the Smoothieboard v1 is optimized to run Smoothieware, which is the name of the firmware program that Smoothieware makes.

Yeah, it’s very confusing to talk about!

While the board is usually unavailable due to its lack of popularity, it doesn’t really need to be super popular when it has a native firmware program that it’s optimized for. But still, the board has a decent amount of other features too, like its 32-bit ARM processor which handles the rather-large Smoothieware firmware package.

The board comes in a few variations, like the 3X, 4X, and 5X, which have 3, 4, and 5 motor ports, respectively. While this isn’t too many motors, the 4X and 5X versions should be great for your printer and you might be able to use the 3X for a different type of CNC-style machine.

- Optimized to run Smoothieware

- 6 endstop ports and 6 other ports for fans, heaters, and more

- Ethernet port for internet connection

- Powerful 32-bit ARM processor

- Unavailable on many sites

- Relatively expensive

- Doesn’t have too many motor ports

- Pretty old integrated stepper motor drivers (Allegro A5984, 32 microstepping)

- Doesn’t run other firmware programs

Check Latest Price

Conclusion

Just like you wouldn’t want to have an outdated brain, you don’t want to use an outdated motherboard on your 3D printer. And, while you can’t easily replace your brain, upgrading your controller board isn’t too difficult.

And, while you can’t easily replace your brain, upgrading your controller board isn’t too difficult.

There are many different controller boards on the market today, and each has different stepper drivers, processors, motor ports, sensor ports, attachment ports, and firmware support. As such, the best 3D printer controller board for you depends on what features you plan on using or upgrades you plan on making.

If you just want to make the switch from an 8-bit to a 32-bit microcontroller board, but don’t plan on making too many upgrades, I would suggest going with the Creality V4.2.7. This board has a great 32-bit chip, can handle the latest firmware programs, and has a few extra sensor ports, but is nothing fancy.

Now, if you want to go all out and make as many upgrades as possible, the Duet 2 Wi-Fi is more up your alley. The many ports on the board, combined with the optional expansion board and onboard Wi-Fi module, make it a great option for those looking to explore the upgrade capabilities of their machine.

Buy a controller board for your 3D printer in the USA | 3D printing experts

About 3D printer controller boards

A controller board or a motherboard is the heart of a machine. This special unit manages and links the machine’s components to one another. The motherboard oversees the processes, ensuring that your 3D printer or laser engraver is operating to its full capacity. Check that the motherboard is compatible with your 3D printer or CNC machine as some items are manufactured for certain brands. Easily find a high-quality motherboard for your machine in our collection.

Select a controller board for your 3D printer

So, how do you go about selecting a controller board?

Choosing a mainboard depends on the kind of device you are working with and also what the tasks that you intend on having the device perform. The most important feature to consider is the firmware that supports the mainboard. There are many different types available like Marlin, MK4duo, and RepRapFirmware. Do take into account that certain mainboards will come with the manufacturer’s firmware installed, for example, Creality and Klipper.

Do take into account that certain mainboards will come with the manufacturer’s firmware installed, for example, Creality and Klipper.

Another consideration is the amount of axis that you would like to be supported by the mainboard and the number of extruders you will be able to hook up to your 3D printer. The speed of the main processor is also determined by your choice. The higher the MHz the faster your machine can run. Furthermore, ensure that the peripherals you would like to incorporate into your machine are supported by the controller board. This concerns the fan outputs, external stepper drivers, thermistors, thermocouples, SD cards, and LCD/touch screens. It can also be that you want to set up another circuit for the heated bed, allowing you to provide more power to your machine. Decide which voltage is required to run your machine as higher voltages will give more power for the heaters and stepper motors. The most commonly supported voltages are 12-24V. The expandability of the motherboard will also be different. Some will accept certain add-ons, like Duet 3D known for electronic devices with various innovative expandability options.

Some will accept certain add-ons, like Duet 3D known for electronic devices with various innovative expandability options.

3D printer motherboard firmware

Firmware is an essential part of the motherboard and acts as the connection between all components. A firmware will function based on the scripts and programs designed by developers. This can vary depending on a device and its intended function. Without firmware, devices would not know what to do and in fact, would not function at all. Firmware can be found in all devices like TVs, washing machines, and security cameras. Firmware processes the inputs and controls the outputs in 3D printers and CNC machines. An example of an input is the file provided by the slicer software with G-code instructions which is then executed by the firmware.

Updating a 3D printer’s firmware

Updating firmware is possible however there are many factors to take into consideration. Compatibility is very important since not all motherboards support the same types of firmware. There are many reasons to update your firmware, however, it is advised to do this if really required. For example, if you need to fix some bugs and your machine keeps crashing. If you feel like you are missing out on the necessary features that your project or activity requires, this is also a good reason to look into updating your firmware. In case you would like to fully replace your motherboard, it is very possible that you will also have to change the firmware as well, especially if the previous firmware does not match.

There are many reasons to update your firmware, however, it is advised to do this if really required. For example, if you need to fix some bugs and your machine keeps crashing. If you feel like you are missing out on the necessary features that your project or activity requires, this is also a good reason to look into updating your firmware. In case you would like to fully replace your motherboard, it is very possible that you will also have to change the firmware as well, especially if the previous firmware does not match.

Do you have questions about controller boards? Please let us know through our customer service team, we are happy to help!

Frequently asked questions

How can I upgrade the firmware of my 3D printer?

Connect your 3D printer to your computer with a USB cable or download the compatible firmware onto your USB and plug it into your 3D printer. Always check the manual as this can depend on the 3D printer. There is a series of firmware to select from like Marlin, MK4duo, or RepRapFirmware. Make sure that your firmware is compatible with your 3D printer’s mainboard.

Make sure that your firmware is compatible with your 3D printer’s mainboard.

What is the best 3D printer controller board?

The best controller board for your 3D printer depends on the kind of machine and the firmware that is supported. Decide what kind of peripherals will make your machine complete and determine the features and operations you need to perform, this will majorly outline which mainboard to select. Find your 3D printer and see the available upgrades for your machine on the product pages.

What is a 3D printer controller board?

A 3D printer’s controller board or motherboard is often referred to as the heart of the machine. It is a special unit that oversees and manages all operations of a 3D printer or CNC machine. The firmware is located in a mainboard that connects all components to the same place for inputs and output commands.

What controllers do 3D printers use?

A 3D printer is controlled by the firmware. The firmware receives input from the slicer software with G-code commands for the 3D printer. The 3D printer is then instructed on where to place the extruder and when, or how much filament to extrude at a certain temperature appropriate for the material or model being printed.

The firmware receives input from the slicer software with G-code commands for the 3D printer. The 3D printer is then instructed on where to place the extruder and when, or how much filament to extrude at a certain temperature appropriate for the material or model being printed.

How do I choose a 3D printer mainboard?

A controller board should be selected based on the intended functions for your 3D printer. Choose a 3D printer mainboard that supports the peripherals best for optimal operation. There are many aspects to take into account like the overall setup, voltages, and expandability options. We list upgrades for specific 3D printers on the details page in our 3D printer section.

Board for a 3D printer: choosing a control motherboard

When buying or assembling a 3D printer with your own hands, special attention should be paid to the device's motherboard. Since this component is responsible for printing products in general. Consider what functions the motherboard performs, what types of this component exist, and what parameters you need to pay attention to when choosing it.

3D Printer Motherboard

Controller Motherboard is the main control element for extruder, motor, sensor and heated filament bed in any 3D printer. nine0003

Motherboard is executing user-specified commands. After the internal set of elements of the microchip converts electrical impulses into mechanical movements of stepper motors. As a result, a three-dimensional computer model will be printed layer by layer on the working surface of a 3D printer.

Choosing a control board

Among the most popular motherboards for 3D printers, there are five models:

- Arduino Mega 2560 + Ramps 1.4. nine0018

- Melzi.

- Lerdge X.

- Duet.

- Rumba.

Let's take a closer look at the features, pros and cons of each board.

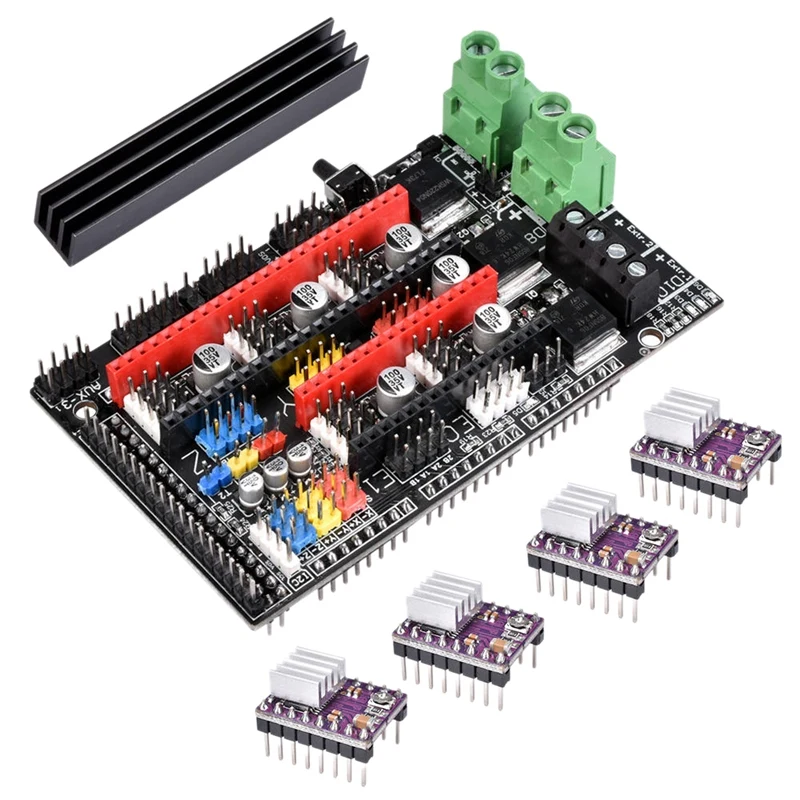

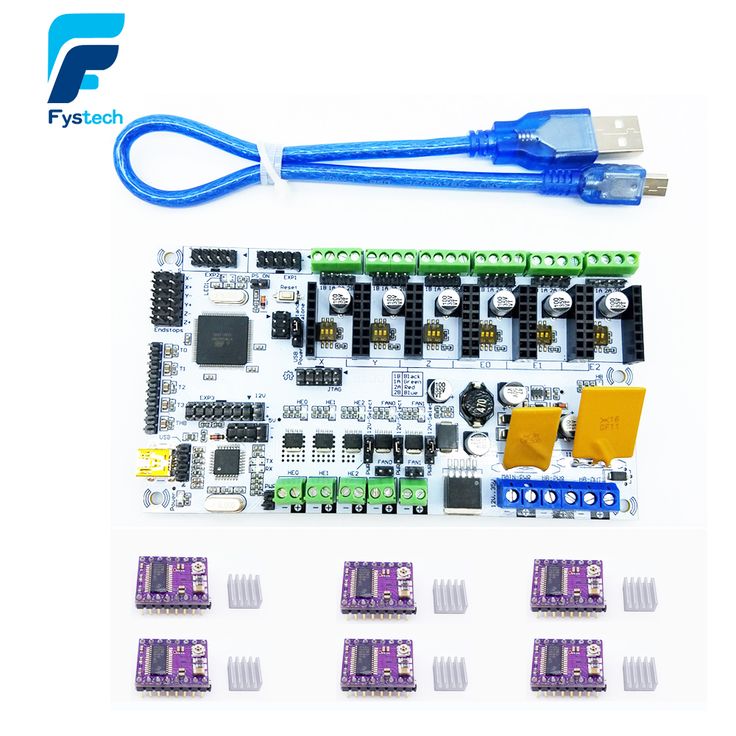

Arduino Mega 2560 + Ramps 1.4

Board with Ramps 1.4 component operates from 5 V. It is equipped with five slots for installing stepper motors. At the same time, three slots allow the motors to control the axes of the printer, and the other two to drive the extruders. In addition, the board contains many additional pins for controlling various elements, such as a table auto-level sensor, axle limit switches, servos, etc.

In addition, the board contains many additional pins for controlling various elements, such as a table auto-level sensor, axle limit switches, servos, etc.

To control all the printer's built-in electronics, the board contains contact pads into which the Ramps shield component is inserted.

The three main advantages of the board are:

- low price;

- a wide range of interchangeable components that can be replaced in the event of a breakdown;

- additional pins for controlling various printer components.

The board has only one significant drawback - its bulky design. nine0003

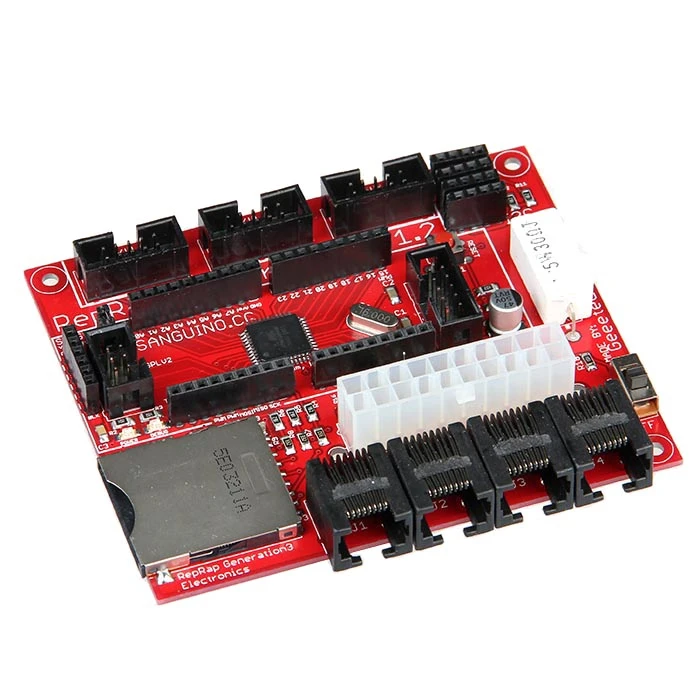

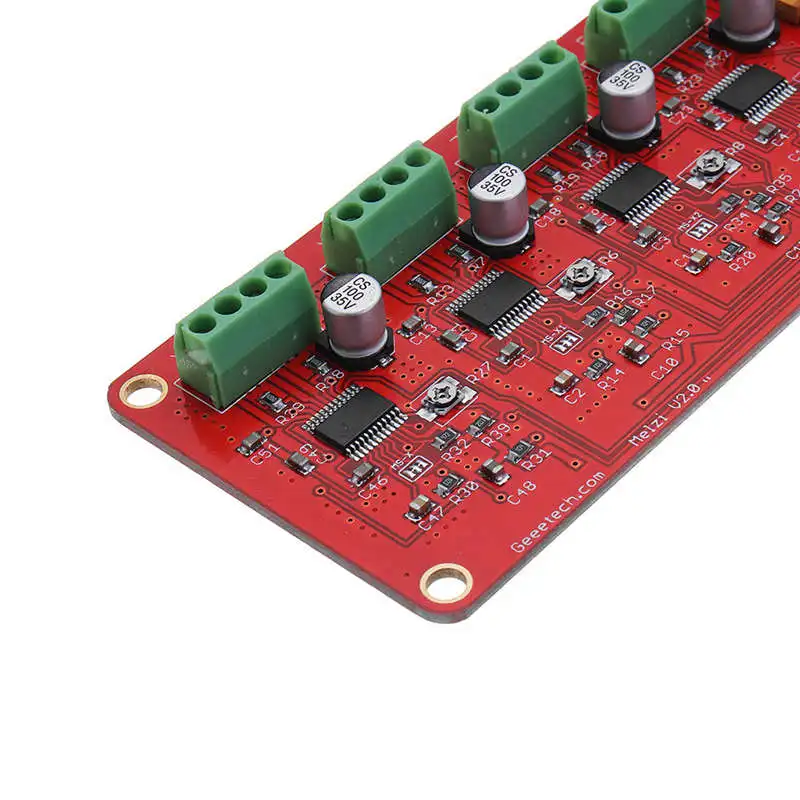

Melzi

The Melzi motherboard is equipped with four stepper motor controllers, three of which are located on the XYZ axis and one on the extruder. This model is sold already with customized firmware. Therefore, the user only needs to correctly connect the wires to the output connectors.

You can print 3D objects using a memory card via a micro-USB connector or by connecting the card directly to a computer.

The Melzi board is ideal for the beginner building a printer for the first time. Since it does not require additional calibrations and can be used immediately after purchase. However, the motherboard also has significant drawbacks:

- no display can be connected to the board;

- You can reflash the motherboard only through the ISP port, but this will take a lot of time and a layer of special knowledge;

- If the motor controller fails, it cannot be replaced.

Lerdge X

Lerdge X is a motherboard with a 32-bit STM32F407 chip that allows you to quickly read lines of code. The device is additionally equipped with four drivers and a color display with touch control. The board supports only one extruder and it is not possible to install a second one if necessary. nine0003

Before using the board, you need to calibrate it, set the dimensions of the working area, adjust the temperature sensors of the extruder and table, and set the speed parameters of each motor.

You can print files using a flash drive, memory card or via a computer.

Pros of using the Lerdge X board:

- motherboard fits any type of printer;

- board chip supports various kinds of popular slicers; nine0018

- built-in display with touch screen.

The disadvantage of using the board is that only one extruder can be used.

Duet

The Duet board is equipped with its own open source firmware, which is available for free to any user on Github.com. The 32-bit Atmel SAM3X8E chip is responsible for the stable operation of the motherboard.

Built-in device drivers allow four extruders to print simultaneously. For more convenient control, the user can install a touch screen with a diagonal of 4.3, 5 and 7 inches. nine0003

Pluses of the board:

- free firmware;

- four extruders available at the same time;

- two board configurations to choose from (Ethernet or Wi-Fi).

Duet motherboard cons:

- Before installing the board, it requires full configuration and firmware.

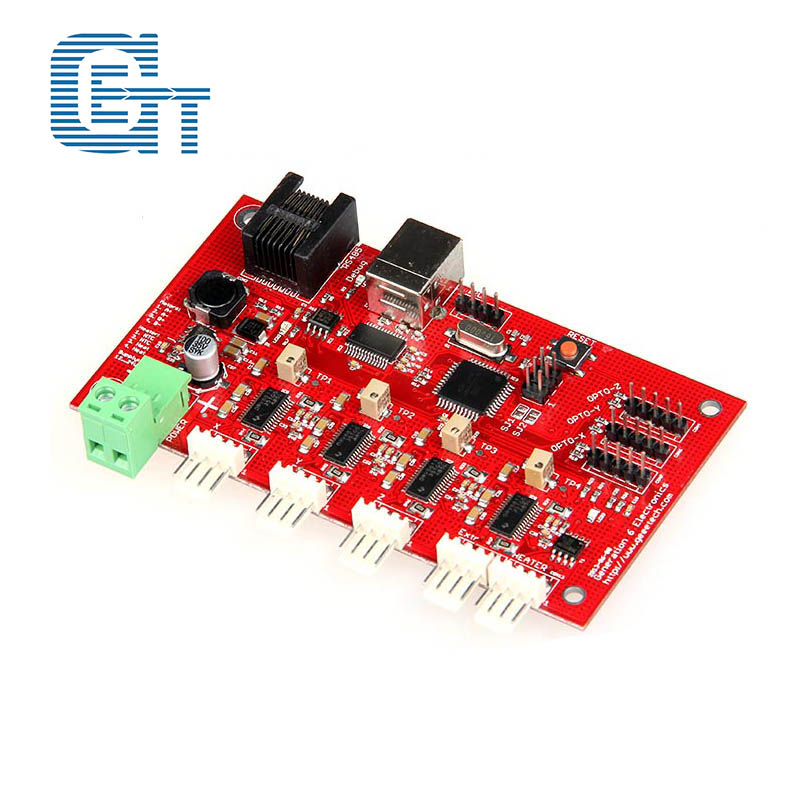

Rumba

The Rumba 8-bit motherboard allows the 3D printer to use three extruders at the same time. However, installing them separately will not work, but you can only install a Diamond Hotend multi-extruder with support for three filaments. nine0003

This type of board is based on the Arduino processor. It comes with Marlin firmware installed. If the user needs to reflash the board, then for this you can use the standard mini-USB connector.

Among the advantages of Rumba are:

- the presence of connectors for connecting a display and a slot for a memory card;

- removable motor drivers that can be easily replaced if broken;

- simple flashing if necessary. nine0018

The main disadvantage of the motherboard is that for printing with multiple filaments, you will need to purchase an additional multi-extruder.

What to look for when choosing a 3D printer board?

When choosing a motherboard for installation in a 3D printer, the user is advised to pay attention to six device parameters:

- The number of supported extruders. Ideally, there should be four or more. In this case, full color printing will be available. nine0018

- Integrated or plug-in drivers. It is desirable that the drivers in the board are removable. Since in the event of a breakdown, they can be easily removed and repaired or replaced in the event of a complete malfunction.

- Number of engines. It is recommended that the board has at least four motors, ideally six.

- Wi-Fi available. The built-in module will allow you not to constantly connect the printer to the computer each time you print.

- Firmware support. It is desirable that the board supports various types of firmware. Both paid and free. nine0148 Help. Each specific type of board can support one or more types of firmware.

Their number depends on the board manufacturer. For example, Arduino boards support Marlin, Marlin Kimbra, Marlin RichCattell, Repetier-Firmware, Teacup, Aprinter, Sprinter firmware. Arduino Due motherboards can work with Marlin4Due, Marlin Kimbra v4.2.x, Repetier-Firmware, RepRap Firmware. And 32-bit ARM processors are compatible with Smoothie Project and Redeem firmware.

Their number depends on the board manufacturer. For example, Arduino boards support Marlin, Marlin Kimbra, Marlin RichCattell, Repetier-Firmware, Teacup, Aprinter, Sprinter firmware. Arduino Due motherboards can work with Marlin4Due, Marlin Kimbra v4.2.x, Repetier-Firmware, RepRap Firmware. And 32-bit ARM processors are compatible with Smoothie Project and Redeem firmware. - The presence of protection against incorrect inclusion of elements.

In this article, we have listed only the most popular motherboards for 3D printers. However, on the electronics market there are boards for any user requests, the choice of which can be guided by the recommendations presented above.

- March 29, 2021

- 5161

Get expert advice

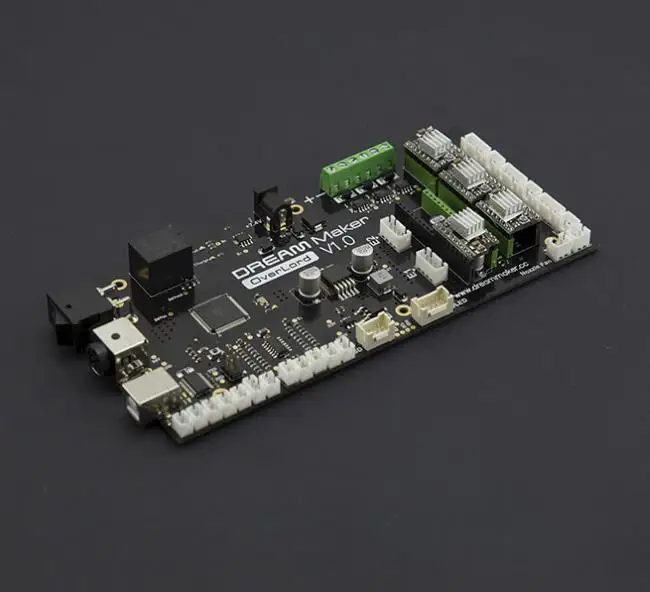

Ideal 3d printer motherboard. Part 1.

3D printing

Hi friends.

Have you ever missed a feature on your printer motherboard?

New Year is coming soon, time to make wishes.

I propose to describe what an ideal printer motherboard is for you, such a concentration of desires, everything you can want from a control board. nine0003

And maybe Santa Claus will hear us)

Here is our list of features that seem to be the most important in the first place:

- 4 extruders (for CMYK full-color printing, if you need more - write why you need more and how much)

- drivers are only interchangeable, no soldered once and for all on the board

- 2 drivers each for X and Y (often you need two for Y, there are also plans for the second X)

- 6 motors for Z (4 need often, let it be 6 so that exactly enough, if you know the design where you need more - write)

- 4 segments for the heating table (to enable a large table of several segments, and not include all 4 for the sake of a small detail)

- of course 32 bits, on STM32F4 chip so expensive to make it an option)

- support for all existing popular firmware (marlin, repeater, etc.

, write if you use some other one)

, write if you use some other one) - support for all existing screens (discount, full graphic, MKS TFT (wifi module for you can no longer buy it at the price of half the board, it will be on board the board itself)), maximum compatibility with existing boards

- separate motor power supply (nothing needs to be done to switch to 24V)

- protection against improper switching on of elements (+/- power supply, limit switches that burned chips when turned on incorrectly - all this will not happen, write more popular fatal errors of incorrect switching on, worth considering)

This is a second order list, it is not yet clear if anyone needs it:

- limit switch for each motor (including all 6 Z motors) - each can be parked separately to its point, all synchronous motors as double Y or six Zs drive together until the first triggered, then each parks separately. Some firmware can do this and we have not yet decided whether it is necessary

- Bluetooth (it’s not clear if anyone needs it at all if there is wifi, but there are such topics, write if necessary, wifi doesn’t cancel this and won’t make it much more expensive)

- separate power supply for heating table segments and extruders from its own line, but it is not yet clear whether this will pile up the board too much and whether someone needs it)

- microstep switches are not under the driver, but on the side - there was a problem picking out all the Z drivers to change the microstep, but it is not clear whether it is worth piling up with this fee, write if you also want them on the side

The main idea is to describe the board, to which nothing needs to be added, a total solution for existing 3D printing technology, for any application.

If you know someone who needs such a fee or can add wishes - tell him.

And just repost please, the more people read, the more wishes Santa Claus will take into account)

Subscribe to the author

Subscribe

Don't want

10

Article comments

More interesting articles

15

Subscribe to the author

Subscribe

Don't want

Dear friends!

The eve of the winter holidays is a great occasion to thank...

Read more

arelav

Loading

01/07/2023

1010

13

Subscribe to the author

Subscribe

Don't want

This project was created a year and a half ago.