3D printer thermistor replacement

3D Printer Thermistor Guide – Replacements, Problems & More – 3D Printerly

The thermistor on your 3D printer serves an important function, though some people can get confused on what exactly it does, and how it helps out. I wrote this article to set people on the right path on thermistors so they can understand it better.

In this article, we are going to explain all about thermistors to you. We’ll show you everything you need to know, from how to calibrate your thermistor to how to change.

So, let’s get started with a simple question, “What do thermistors do?”.

What Does a Thermistor Do in a 3D Printer?

A thermistor is an important component in FDM printers. Before we talk about its job, let’s define what a thermistor is.

Thermistors – short for “Thermal Resistors”- are electrical devices whose resistance varies with temperature. There are two types of thermistors:

- Negative Temperature Coefficient (NTC) Thermistors: Thermistors whose resistance decreases with increasing temperature.

- Positive Temperature Coefficient (PTC) Thermistors: Thermistors whose resistance increases with an increase in temperature.

The sensitivity of thermistors to changes in temperatures makes them suitable for temperature-sensitive applications. These applications include circuit components and digital thermometers.

How Is A Thermistor Used In 3D Printers?

Thermistors in 3D printers serve as temperature sensing devices. They are found in temperature-sensitive areas like the hot end and the heated bed. In these areas, they monitor the temperature and relay the data back to the micro-controller.

The thermistor also serves as a control device. The printer’s micro-controller uses the thermistor’s feedback to control the print temperature and keep it within the desired range.

3D printers mostly use NTC thermometers.

How Do You Replace & Attach a Thermistor to a 3D Printer?

Thermistors in 3D printers are very fragile instruments. They can break or lose their sensitivity easily. Thermistors control important parts of the printers, so it’s necessary to make sure they are in tiptop shape all the time.

They can break or lose their sensitivity easily. Thermistors control important parts of the printers, so it’s necessary to make sure they are in tiptop shape all the time.

Thermistors in 3D printers are often in hard to reach areas, so removing them can be a bit tricky. But don’t worry, as long as you exhibit caution and follow the steps carefully, you will be fine.

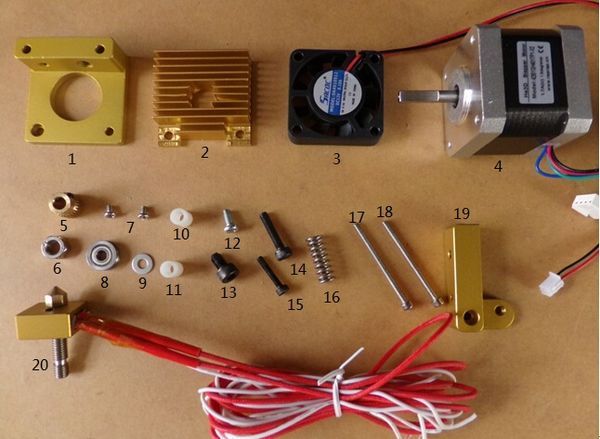

Two main 3D printer components contain thermistors- The hot end and the heated print bed. We’ll be taking you through the steps for replacing thermistors in both.

What You’ll Need

- Set of screwdrivers

- Tweezers

- A set of Allen keys

- Pliers

- Kapton tape

Replacing the Thermistor on Your Hot End

When replacing a thermistor in the hot end, unique procedures exist for different printers. But for most models, these procedures are the same with a little variation. Let’s go through them:

But for most models, these procedures are the same with a little variation. Let’s go through them:

Step 1: Consult the datasheet for your printer and get the appropriate thermistor for it. You can find more information about this in the article.

Step 2: Before you start, make sure you follow the appropriate safety tips.

- Make sure the 3D printer is powered down and disconnected from all power sources.

- Ground yourself if necessary.

- Make sure the hot end is cooled to room temperature before you attempt to disassemble it.

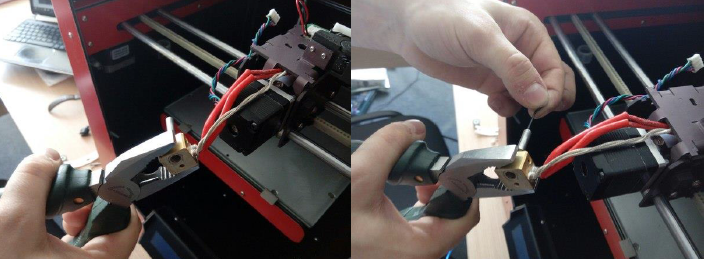

Step 3: Remove the hot end from the printer’s frame.

- This might not be necessary if the thermistor’s position is accessible from the outside.

- Remove all the screws holding the hot end and its wires in place.

Step 4: Remove the old thermistor from the hot end.

- Loosen the screw holding it in place on the bloc and remove it.

- Sometimes, there can be caked plastic on the block preventing this. You can use a heat gun to melt this away.

Step 6: Disconnect the thermistor from the micro-controller.

- Open the processing unit of the printer.

- Access the micro-controller and remove the thermistor connection with a tweezer.

- Be careful to make sure you remove the right wire. Consult your manufacturer’s specifications to make sure you know the wire to remove.

Step 7: Install the new thermistor

- Plug the end of the new sensor into the micro-controller.

- Carefully place the head of the new thermistor in its hole in the hot end.

- Screw it in place lightly. Be careful not over-tighten the screw so as not to damage the thermistor.

Step 8: Finish up

- Cover up the printer’s processing unit.

- You can use the Kapton tape to hold the wires firmly together to avoid movement.

- Re-attach the hot end to the printer’s frame.

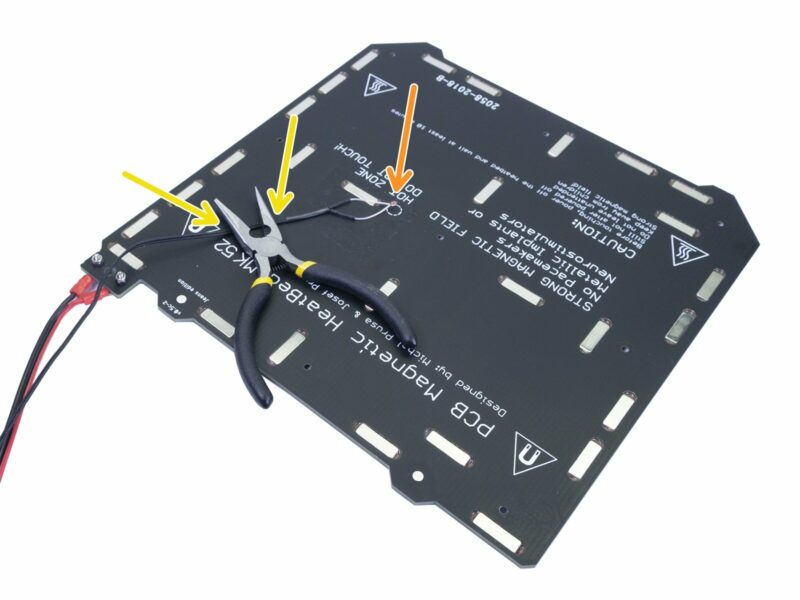

Replacing the Thermistor on Your Print Bed

If your 3D printer comes with a heated print bed, there’s a good chance that it also has a thermistor there. The steps for replacing the thermistor on a print bed varies from model to model, but it’s mostly similar. Let’s how you how to:

Step 1: Follow the appropriate safety tips before starting.

Step 2: Remove the print bed

- Disconnect the print bed from the PSU (Power Supply Unit).

- Remove all the screws holding it to the frame of the printer.

- Lift it up and away from the frame

Step 3: Remove the insulation covering the thermistor.

Step 4: Remove the thermistor

- The thermistor can be arranged in many ways. It can be secured to the bed with Kapton tape or secured with a screw.

- Remove the screws or the tape to free the thermistor.

Step 5: Replace the thermistor

- Cut off the legs of the old thermistor from the sensor’s wire.

- Attach the new thermistor to the wire by joining them together.

- Cover the connection with electrical tape

Step 6: Finish up

- Attach the thermistor back to the bed

- Replace the insulation

- Screw the print bed back onto the frame of the printer.

How Do You Check the Resistance of a Temperature Sensor?

Resistance is not a value that can be measured directly. To find the thermistor’s resistance, you’ll have to induce current flow in the thermistor and measure the resulting resistance to it. You can do that with a multimeter.

Note: It’s a thermistor, so the reading will vary across temperature. It’s best to take your reading at room temperature (25℃).

Let’s go through the steps on how to check the resistance.

What You’ll Need:

- A multimeter

- Multimeter probes

Step 1: Expose the legs of the thermistor (strip away the fiberglass insulation).

Step 2: Set the Multimeter range to the rated resistance of the thermistor.

Step 3: Apply the multimeter probes to both legs, and the multimeter should display the resistance.

Most 3D printing thermistors have a resistance of 100k at room temperature.

How to Calibrate Your 3D Printer Thermistor

An uncalibrated thermistor is very bad for 3D printing. Without accurate temperature measurement and control, the hot end, and the heated bed cannot function properly. So, as part of routine maintenance, you should make sure your hot end is always calibrated properly.

Let’s show you how to do it:

What You’ll Need:

- A thermocouple equipped multimeter

Step 1: Test the multimeter’s thermocouple.

- Boil a small amount of water.

- Dip the thermocouple into the water.

- It should read 100℃ if it’s accurate.

Step 2: Open the printer’s firmware.

- In the printer’s program file, there’s going to be an Arduino file controlling the hot end.

- You can check with your manufacturer or on online forums to find the file’s location for your printer.

Step 3: Attach the multimeter’s thermocouple to the hot end.

- Find a space between the hot end and the nozzle and stick it in.

Step 4: Open the temperature table in the firmware.

- This is a table containing the values of thermistor resistance versus temperature.

- The printer uses this file to determine the temperature from the resistance measured.

- Copy this table and delete the temperature column in the new table.

Step 5: Fill out the table.

- Set the hot end to the temperature value in the old table.

- Measure the correct temperature reading on the multimeter.

- Input this reading to the resistance value on the new table corresponding to the value on the old table.

- Repeat these steps for all resistance values.

Step 6: Replace the table.

- After finding the accurate temperature for all the resistance values, delete the old table and replace it with the new one.

How Do You Know If a Thermistor is Bad on a 3D Printer?

The signs of a malfunctioning thermistor vary from printer to printer. It can be as clear as a diagnostic message flashing on the printer’s interface, or it can be as bad as a thermal runaway.

We’ve compiled a list of some of the most common signs that indicate a problem with your 3D printer’s thermistor. Let’s go through them:

Thermal Runaway

Thermal Runaway is the worst-case scenario for a bad thermistor. It occurs when a faulty sensor supplies the wrong temperature to the printer. The printer then keeps transmitting power to the heater cartridge infinitely until it melts the hot end down.

The printer then keeps transmitting power to the heater cartridge infinitely until it melts the hot end down.

Thermal runaway can be very dangerous. It can result in fires that can destroy not just your printer but the surrounding areas. Luckily, most manufacturers have included firmware safeguards in place to prevent this from occurring.

Higher Than Usual Print Temperatures

Materials usually come with recommended print temperatures. If the printer requires a higher temperature than the rated temperature to extrude the materials, the thermistor can be faulty.

You can run a diagnostic test on the thermistor to find out.

Symptoms of a faulty thermistor can also include:

- A large number of print errors due to temperature issues.

- Wild variations in temperature readouts.

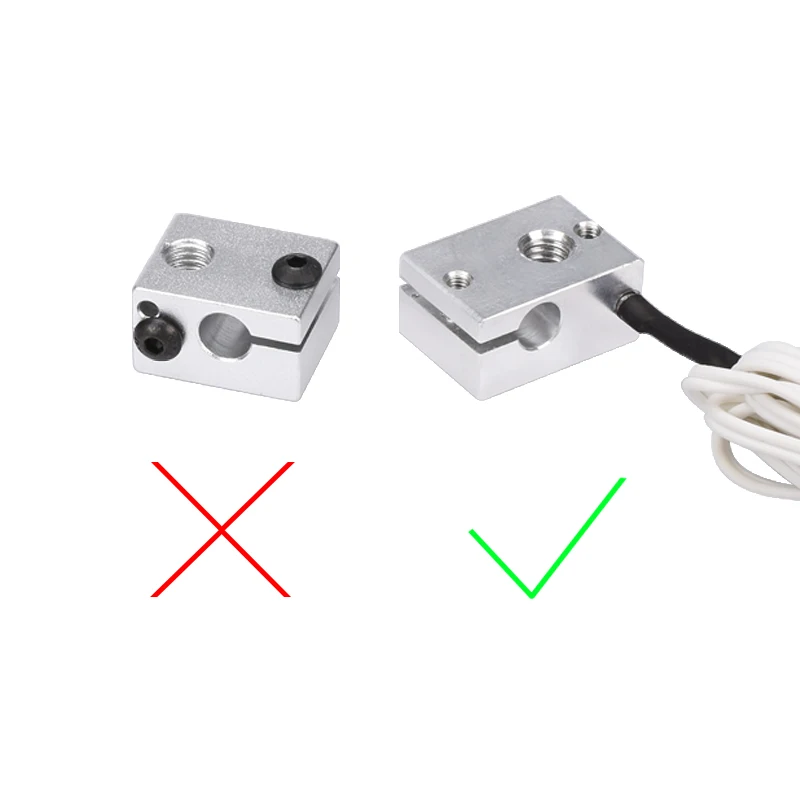

If your thermistor cracks, it is going to fail so you want to prevent that from happening. Most times, a thermistor would break due to the screw that holds them being too tight, which shorts them out.

The screw should be slightly loose, at around half a turn back from being tight on there, since the thermistor just needs to be held in place rather than securely pressed against the hotend.

The good thing is that thermistors are fairly cheap.

Best Thermistor Replacement for Your 3D Printer

When selecting a thermistor for your 3D printer, there are some key factors to consider to get the right one. Let’s go through them.

The most important of these factors is resistance, the resistance of the thermistor matters. It determines the range of temperature the thermistor will be able to measure. 3The resistance of 3D printer thermistors is mostly 100kΩ.

The temperature range is another important factor. It determines the magnitude of temperature your thermistor will be able to measure. An acceptable temperature range for an FDM printer should be between -55℃ and 250℃.

Finally, the last factor you should look at is the build quality. The thermistor is only as good as the materials used in building it. The materials can have a high effect on sensitivity and durability.

The materials can have a high effect on sensitivity and durability.

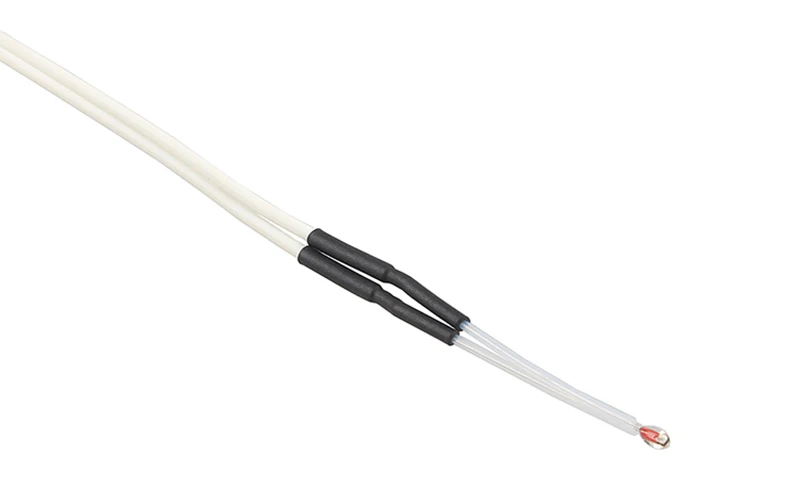

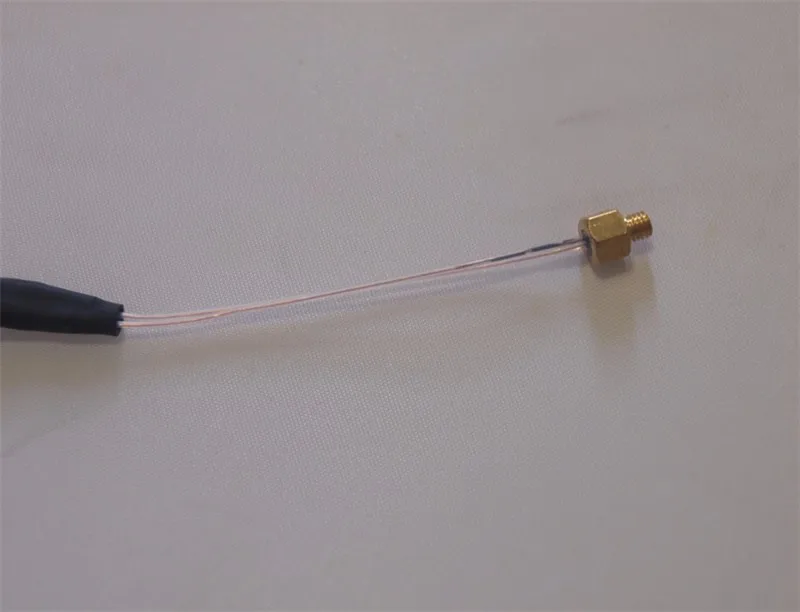

To get the best quality, it’s advisable to go for aluminum thermistors with suitable insulation like fiberglass for the legs. This is because aluminum is very conductive to heat while fiberglass is not.

Using all the factors listed above as a yardstick, we’ve compiled a list of some of the best thermistors on the market for your 3D printer. Let’s have a look at it.

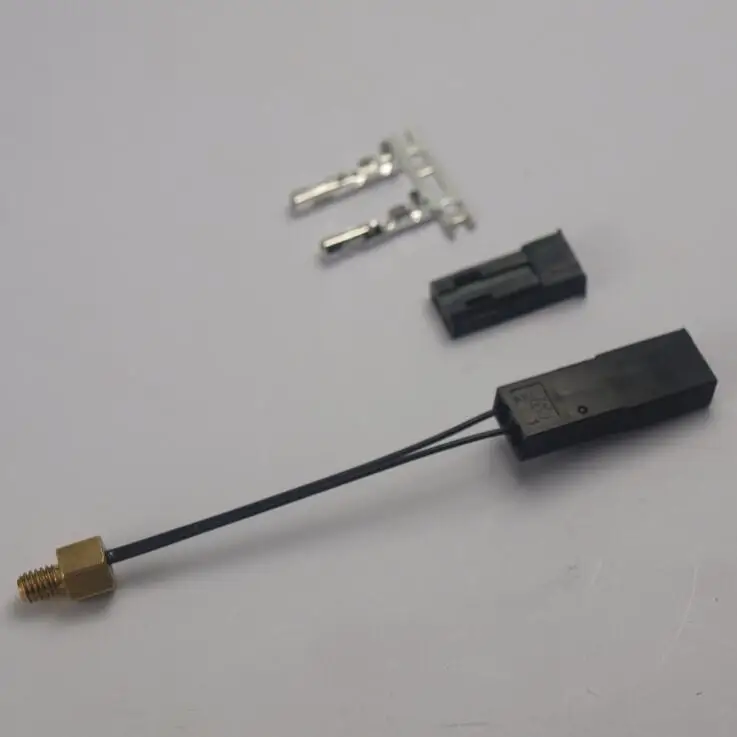

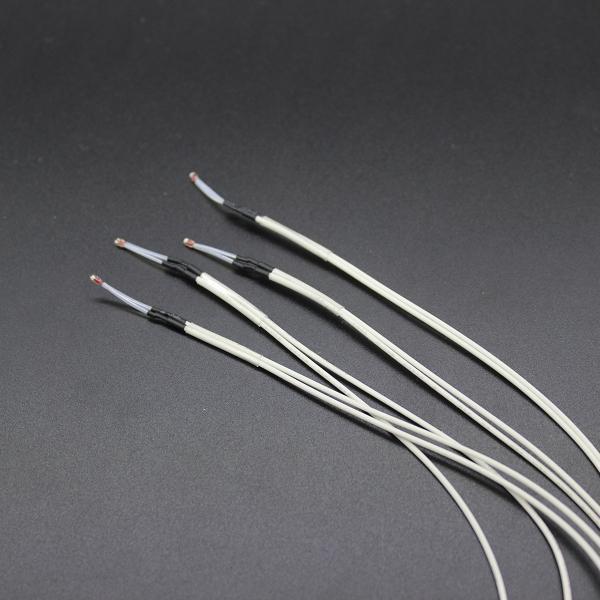

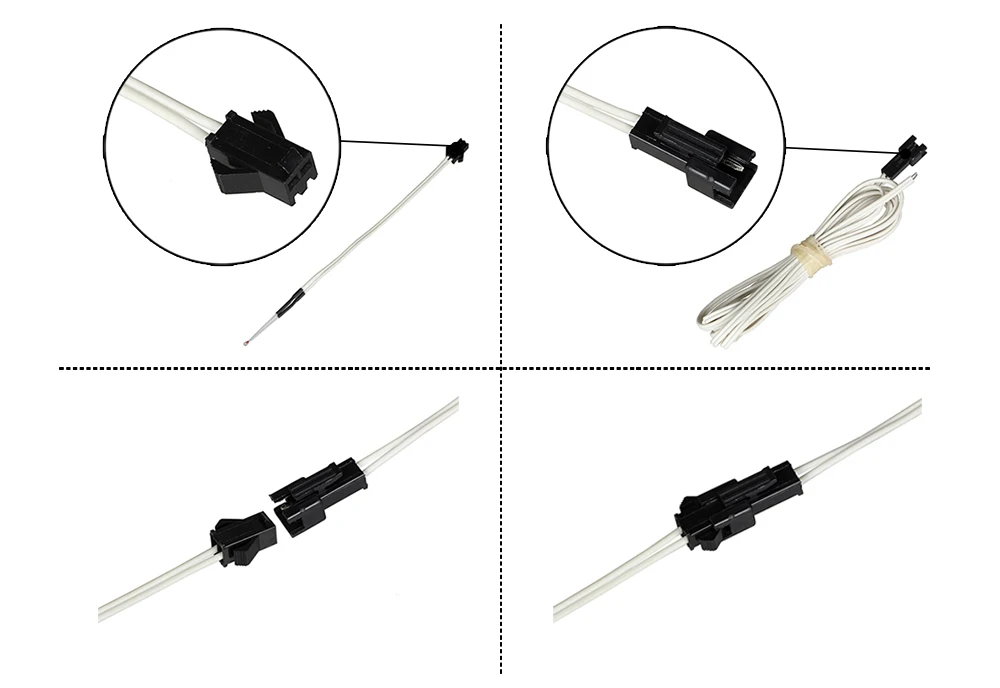

HICTOP 100K ohm NTC 3950 Thermistors

Many people mention just how useful the HICTOP 100K Ohm NTC 3950 Thermistors are after using it on their 3D printers. There is more than enough length for it to suit your needs and is a perfect job for your 3D printer.

You should make sure that your firmware is set correctly beforehand.

If you’ve had the thermistors on your Ender 3, Anet 3D printer or many others out there, then this should work very nicely for you.

These thermistors can fit on a Prusa i3 Mk2s bed without issues. The temperature range is okay to go up to 300°C, then after that kind of temperature, you’ll need a thermocoupler.

The temperature range is okay to go up to 300°C, then after that kind of temperature, you’ll need a thermocoupler.

Creality 3D Printer NTC Thermistor Temp Sensor

Another set of thermistors that you can go for are the Creality NTC Thermistors, which list down the Ender 3, Ender 5, CR-10, CR-10S and more. Basically any 3D printer that takes a thermistor is good to go with these.

It’s used perfectly with your heated bed or extruder as you desire.

It has the standard 2-pin female connector with a wire length of 1m or 39.4 inches. The package comes with 5 thermistors with a temperature accuracy ±1%.

You should set the temp sensor number to “1” in Marlin for the best results.

If you’ve had some type of minimum temperature error on your 3D printer, these can definitely come to the rescue.

Most people had a positive experience with these, where they fit and work fine, as well as having spares just in case.

One user who purchased an Ender 5 Plus had temperature readings of -15°C or 355°C max. temperature change their thermistor to these and solved the issue.

temperature change their thermistor to these and solved the issue.

Some people have complained that they can come up a little short on the Ender 3, and required the wiring for the fans and heater cartridge to be looped above the assembly to use the sleeve and keep it together.

You can splice the thermistor, then solder it in if needed.

Others have used it as a direct plug replacement on the Ender 3 though.

3D Printer Thermistors - 3DJake International

Sort byRelevanceBestsellersCustomer ReviewsPrice, Low to HighPrice, High to LowNew arrivalsHighest Discount

-

E3D Thermistor- Easy connection

- Cartridge style

- With extension cord

-

Creality Hotend Thermistor 3 Model types- Original spare part

- Available for various 3D printers

-

E3D PT1000 Temperature Sensor- For high temperatures

- Accurate measurement

- Easy installation

-

BondTech PT1000 RTD Temperature Sensor- Platinum-based resistor

- Robust sensor in thin-film construction

- -50 ° C - 500 ° C

-

BondTech DDX Thermistor Adapter- For Copperhead and Mosquito heating block

-

Qidi Tech Hotend Thermistor 6 Model types- Original spare part

- By Qidi Tech

-

Slice engineering 300°C Thermistor- From room temperature to 300 ° C

- 3 mm connection

- High compatibility

-

Creality Thermistor Kit- Easy installation

- High precision

- For hotend & heated bed

-

Artillery Thermistor 5 Model types- Original spare part

-

BondTech HeatLink Cable JST XHP-2- For numerous 3D printers

- Easy to use

-

BondTech HeatLink 300C Thermistor- Easy to use

- For numerous 3D printers

- Plug & Play

-

E3D Prusa Thermistor- Spare thermistor

- Especially for Prusa

-

E3D 100k Ohm NTC Thermistor - Semitec- Spare part for V5 hot ends

-

E3D PT100 Amplifier Board- Upgrade for PT100 sensor

- More accurate temperature measurement at high temperatures

-

E3D PT100 Temperature Sensor- Highest precision

- Suitable for high temperatures

- Up to 500 ° C

-

Qidi Tech High Temp Hotend Thermistor- Original spare part

- From Qidi Tech

-

BondTech Molex MX-50-57-9002 HeatLink Cable- Easy to use

- For numerous 3D printers

- Plug & Play

-

BondTech HeatLink cable JST SMP-02V-BC- Easy to use

- For numerous 3D printers

- Plug & Play

-

MINGDA Thermistor- Original spare part

- For MINGDA 3D printers

-

BondTech HeatLink Cable JST XH-2- For numerous 3D printers

- Easy to use

-

3D Solex Temperature Sensor PT100 UM2 / +- Tested & Approved

- High-quality

- Length: 134 cm

-

Zortrax Thermocouple + Heater- Original spare part

-

E3D V6 PT100 Upgrade Kit- High precision

- Temperatures up to 500 ° C

- Easy to use

-

E3D Thermistor Replacement Kit- Package for changing the thermistor

All prices incl. VAT.

VAT.

PID calibration or what to do after replacing the heater or thermistor

In this article we will talk about how to calibrate the PID of a 3D printer after replacing the heater, thermistor, and in some cases the heating block.

As you know, nothing is absolutely identical in nature, including two absolutely identical thermistors, heating blocks and heaters. Well, it is quite logical that after replacing them, the 3D printer starts printing somehow wrong. This is due to the wrong PID. nine0005

What is a PID? Wikipedia tells us the following:

The Proportional-Integral-Differentiating (PID) controller is a device in a feedback control loop. Used in automatic control systems to generate a control signal in order to obtain the required accuracy and quality of the transient process. The PID controller generates a control signal that is the sum of three terms, the first of which is proportional to the difference between the input signal and the feedback signal (error signal), the second - the integral of the error signal, the third - the derivative of the error signal.

Source

In simple terms, these are 3 coefficients that the microcontroller uses to control the heating, in our case, the extruder. These coefficients are unique for each bundle of heater and thermistor, respectively, when one of them is replaced, the coefficients also change.

Therefore, after replacing the heater or thermistor, it is necessary to calibrate the PID for the correct operation of the 3D printer. nine0005

It is worth considering that most 3D printer manufacturers do not calibrate the PID of each printer, but use some average values that will work on a particular printer, as God wills.

So, it is necessary to calibrate the PID of the extruder in the following cases:

- On a new 3D printer

- When replacing thermistor

- When replacing heater

- When replacing the heating block (not always)

Let's figure out how to do this using the Marlin firmware as an example. nine0005

Marlin firmware already has a built-in automatic PID calibration mechanism, as well as the ability to change coefficient values without 3D printer firmware.

The only condition under which this will work is that the non-volatile EEPROM is unlocked.

Let's analyze the PID calibration process without flashing using the example of the Anycubic Mega-S 3D printer

Attention! not on all models of 3D printers EEPROM is unlocked. Check this before performing this operation. nine0004

You do the following steps at your own risk. We are not responsible for no result, negative result.

For PID calibration we need.

- Pronterface Program You can also use Repiter Host, but Pronterface is more convenient.

- USB cable for connecting 3D printer to PC

- Drivers for 3D printer. They need to be installed.

If you have CURA slicer running, close the program, or even better, restart your computer. nine0004

Connect the 3D printer to the PC with a cable.

Launch the Pronterface software and connect to the 3D printer. To do this, select the COM port on which the 3D printer was detected, select the connection speed and press the button CONNECT

In our case, this is COM5 speed 250 000

various texts will run in the right part of the window:

If instead of a conscious text you see some kind of gibberish, then you have chosen the wrong connection speed. Pick it up experimentally. nine0005

Pick it up experimentally. nine0005

If nothing appears in the window on the right except for the text Connecting..., then the computer for some reason cannot communicate with the printer (the port is incorrect, there is no driver, there are problems with the cable, etc.)

After we have successfully connected to the 3D printer, in the command input line, you need to enter the command for auto PID calibration. It looks like this:

M303 E0 C10 S240

Where M303 is the command to calibrate PID

E0 is the number of the extruder for which the PID is being calibrated

C10 is the number of heating/cooling cycles, based on which the 3D printer microcontroller will calculate the optimal PID

S240 is the temperature at which the calibration will be performed. It is recommended that you choose the temperature at which you print most often.

We enter the command in the line for entering commands, press the SEND button and wait for the result of the execution. You will have to wait a few minutes. nine0005

You will have to wait a few minutes. nine0005

During the execution of the command, the window will display approximately the following values. This means that the printer is calibrating.

After the end of the calibration process, the printer may make a sound with a squeaker (if it can), and the window will look like this:

. Now let's transfer them to the 3D printer's memory. nine0005

To do this, execute the following command:

M301 P14.62 I1.08 D49.42

equal to define DEFAULT_Kp parameter obtained during calibration)

I1.08 – coefficient i (its value is equal to define DEFAULT_Ki parameter obtained during calibration)

D49.42 – coefficient d (its value is equal to define DEFAULT_Kd parameter obtained from during calibration)

You will get your own values.

Paste the command into the pronterface command line and press the button SEND

Command execution result:

Command M500 save the new PID values in the 3D printer memory.

To check that everything worked out for us, turn off the 3D printer and disconnect the cable from the PC.

In a minute, turn on the 3D printer and connect its cable to the computer. Again, through the Pronterface program, connect to the 3D printer and execute command M503

If as a result of executing the command in the output window we received the PID values obtained during calibration:

This means that the PID calibration process was completed successfully.

As you can see, after replacing the heater or thermistor, it is not necessary to reflash the 3D printer to change the PID values.

You can get acquainted with the range of spare parts for the extruder and not only in the catalog, section “Hotend parts”

(Solution) Replacing the original Ultimaker temperature sensor?

You need the thermocouple , not the thermistor. Also, as you say, Ultimaker Original+ and Ultimaker 2 (which both use version 2. x.x boards) use PT100 1 .

x.x boards) use PT100 1 .

According to this message, on the E3D thermocouple mount on the UMO+ , type k thermocouple will perform:

I'm switching to E3D V6 on my UMO and decided to use the type k thermocouples sold by e3d with the standard/original UMO amplifier board. nine0005

Or, to be more precise, from this post on REPLACING THERMOCOUPLE SENSOR, this is thermocouple 3 mm k-type :

I would ask the salesperson to measure the thermocouple so that it is really 3mm. I've never used a thermocouple so I have no idea. I know some AliExpress sellers did sell me a pt100 with 3.05mm (it doesn't fit) so it's a good idea to ask for a photo with the caliper before paying.

The thermocouple in question on AliExpress was: SWMAKER Thermoelement Typ K (TC) für Ultimaker Original 3D Drucker 3mm K thermoelement type für Ultimaker Original 3D Drucker, ~$10

Or this one, much more expensive at 33 euro, original Ultimaker thermocouple sensor (out of stock):

Usually you won't need to make any changes because your UMO already works with a thermocouple. nine0005

nine0005

So, assuming you have an AD595 amplifier and not a MAX6675, make sure you have

#define TEMP_SENSOR_0 -1

set in config.h

//==================================== ===================================== //=============================Thermal Settings ================= =========== //=============================================== ============================ // //--NORMAL VALUE-4.7kΩ!-- 1kΩ can be used on the hotend sensor using the correct resistor and table // //// Temperature sensor settings: // -2 - thermocouple with MAX6675 (sensor 0 only) // -1 - thermocouple with AD59five // 0 is not used // 1 - Thermistor 100K is the best choice for EPCOS 100K (4.7K) // 2 - thermistor 200 K - ATC Semitec 204GT-2 (4.7 K) // 3 - Mendel thermistor (4.7 K) // 4 is a 10k thermistor!! don't use it for quick access. This gives poor resolution at high temperature. !! // 5 - thermistor 100K - ATC Semitec 104GT-2 (used in ParCan and J-head) (4.7K) // 6 is 100K EPCO - Not as accurate as Table 1 (created using a fluke thermocouple) (4.7k) // 7 - 100k thermistor Honeywell 135-104LAG-J01 (4.7k) // 71 is a Honeywell 100k 135-104LAF-J01 (4.7k) thermistor // 8 - 100k 0603 SMD Vishay NTCS0603E3104FXT (pullup 4.7k) // nine-100k GE Sensing AL03006-58.2 K-97-G1 (4.7k pull-up) // 10 is a 100K RS thermistor 198-961 (4.7K) // 11 is 100k beta-3950 1% thermistor (4.7k) // 12 - 100k 0603 SMD Vishay NTCS0603E3104FXT (4.7k removable) (calibrated for Makibox hottable) // 13 is 100k Hisen 3950 1% up to 300°C for "Simple ONE" and "Hotend All in ONE" hotends // 20-circuit PT100 found in Ultimainboard V2.x // 60-tool manufacturer 100k Works Thermistor Kapton Desk beta=3950 // // 1k ohm pull-up tables - This is not normal, you would have to change your 4.7K to 1K // (but provides more accuracy and more stable PID) // 51 is the 100k thermistor - EPCOS (1k removable) // 52 - Thermistor 200k - ATC Semitec 204GT-2 (1k removable) // 55 is the 100k thermistor - ATC Semitec 104GT-2 (used in ParCan and J-head) (1k removable) // // 1047 is Pt1000 with 4k7 pullup // 1010 is Pt1000 with 1k pull-up (non-standard) // 147 is Pt100 with 4k7 pullup // 110 is Pt100 with 1k pull-up (non-standard) #define TEMP_SENSOR_0 -1 nine0232

However, according to questions about thermocouple and thermistor, UMO board is 1.

5.7 and can use NTC100K thermistors and (possibly but not clear) 4.7K resistor:

First, we have to complete the task with the Sainsmart UM kit with this UM 1.5.7 board.

We also bought E3D V6 printheads which have ntc 100k thermistors already installed in Marlin. Since board V1.5.7. works with a thermocouple, the question arose of how to connect it. I already got an answer to just connect the signal and GND to the board, but I'll have to look for resistors behind the headers. Is it true that I need a different resistor for each type of thermistor? nine0005

However, for simplicity, it is probably best to stick with a 3 mm k-type thermocouple.

Footnote

1 Apparently, for these reasons, starting from this post, about REPLACING THE THERMOCOUPLE SENSOR:

UMO has an "old" 1.5 x board which is a shield for the Arduino Mega, with Pololu/Allegro stepper drivers connected to it (e.

Learn more