3D printing flowers

Flower best 3D printing files・Cults

GANESH FLOWER

€11.32

Giant Lego flower vase with white base, flower bricks, flowers

€1.70

Set 3 Modern 3d printable vase

€4.60

Bat Planter

€4

High Tech Planter

€4

Eared Planter

€4

Ribbed planter

€4

Striped Planter

€4

Set of Geometric Cups!!!

Free

lotus flower

€9.43

Set 3 3D Printed Flower Vases

€4.70

Jug Planter

€4

Spider web Planter

€4

Sunny planter

€4

DICE FLOWER VASE

€1 -50% €0. 50

Diamond floral star beaded coin pendant charm 3D print model

€5.66

Diamond floral star fashion ring US sizes 6 7 8 3D print model

€7.54

Flower Stl File

€3.30

Lily flower Stl File

€3.30

Hawaiian Flower COOKIE CUTTER - SUMMER TROPICAL COOKIE CUTTER STL FILE

€2.36

Peace flower Stl File

€3.30

set cutter daisys 7sizes

€2.01

Machinery planter

€5

5 Planters

€4

Square Rainbow planter

€4

Planter with glasses

€5

lotus flower ring

€0. 55

55

Triangle mini pot

€0.65

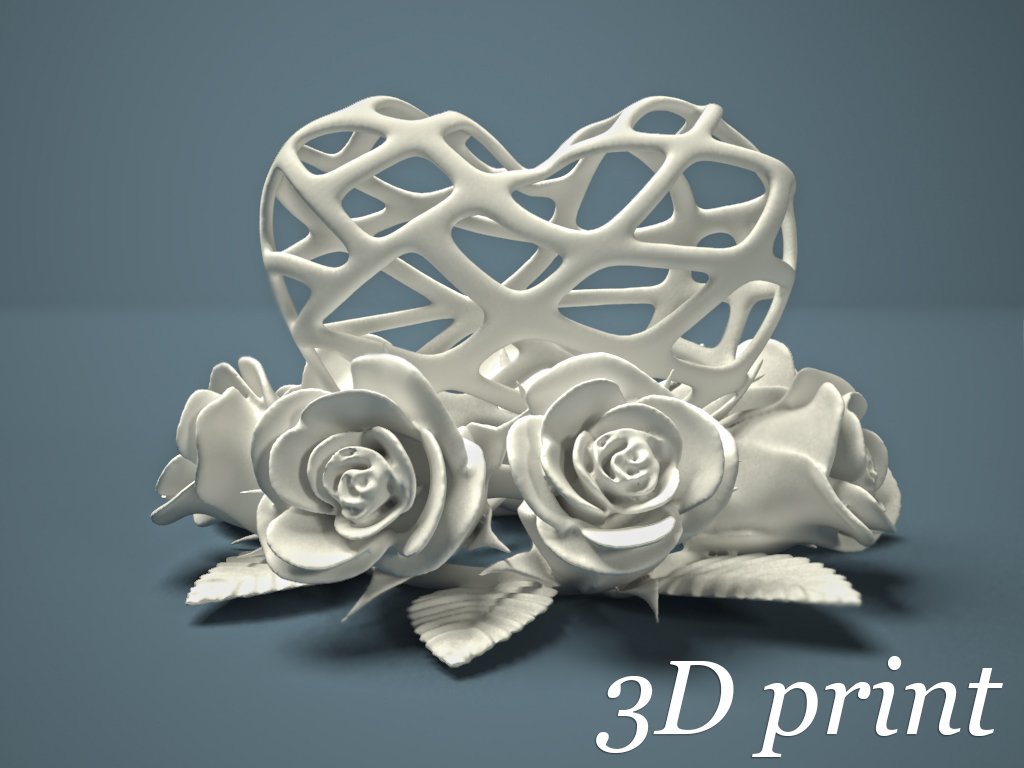

Valentine's Day Flower

€2.36

Valentine's Day Rose Flower

€2.36

Floral star 3mm diamond pendant charm with bail 3D print model

€4.24

Lilaloa Flower SAN VALENTINES DAY COOKIE CUTTER STL

€2.36

Set 3 models 3D Printed Vases

€4.60

Set of Kenetic Vases!

€0.94

Vase #001

€1.95

Fine Jewelry, Filigree Flower Ring

€12.50

Planter

€0.50

Multiple greenhouse pots - Multiple pots under greenhouse

€2. -20% €2 50

50

Flower Stl File

€3.30

Flower Stl File

€3.30

Flower Stl File

€3.30

Flower Stl File

€3.30

Flower Stl File

€3.30

Flower Stl File

€3.30

Flower Stl File

€3.30

Flower Stl File

€3.30

Flower Stl File

€3.30

Flower Stl File

€3.30

Flowers - Collections - glitchpudding

by glitchpudding, last updated

*Maybe send some real ones, too.

2939 3770

937 1387

897 1126

1217 1586

293 297

3656 4562

2620 2898

887 1023

365 358

186 241

438 593

281 220

Color 3D printing: some theory and practice

Technical

Subscribe to the author

Subscribe

Don't want

27

Briefly about RGB and CMYK color schemes. A little practice of mixing colors without a printer. We measure the color after mixing the plastics.

A little practice of mixing colors without a printer. We measure the color after mixing the plastics.

A bit of theory

Many are already familiar with the RGB scheme - it consists of three components, each of which is responsible for a certain part of the visible spectrum (red, green and blue). This scheme is more applicable to radiation sources in the visible spectrum. Depending on the spectrum and its level of radiation, we perceive the total radiation in the form of some kind of color. For example, if the spectrum of all three ranges is present in the radiation, then we see white. If the spectrum contains only red and green, we perceive it as yellow. Everything is simple here. nine0003

Now CMYK (the picture is taken from the same site) - many people are also familiar with this scheme. Only this scheme is no longer applicable to radiation sources, but to objects that reflect or absorb a certain part of the visible spectrum. These objects are all that we see around us in the presence of lighting. And, as we see it, it depends on the lighting. What is the fundamental difference? Yes, the difference is just in the difference ... Components C yan, M agenta, Y ellow, K ey color (Blac K ) actually describe the color that is obtained when a certain part of the radiation spectrum is completely absorbed. Cyan is a color that has no red component in its spectrum, i.e. There is only blue and green part of the spectrum. Magenta - the green part of the spectrum is missing. Yellow - the blue part of the spectrum is missing. The surface from which light is reflected absorbs part of the radiation, which goes into heating the surface of the object (most of it). Therefore, a black object (absorbs all radiation) heats up more than a white object (reflects all radiation) under the same illumination. nine0003

And, as we see it, it depends on the lighting. What is the fundamental difference? Yes, the difference is just in the difference ... Components C yan, M agenta, Y ellow, K ey color (Blac K ) actually describe the color that is obtained when a certain part of the radiation spectrum is completely absorbed. Cyan is a color that has no red component in its spectrum, i.e. There is only blue and green part of the spectrum. Magenta - the green part of the spectrum is missing. Yellow - the blue part of the spectrum is missing. The surface from which light is reflected absorbs part of the radiation, which goes into heating the surface of the object (most of it). Therefore, a black object (absorbs all radiation) heats up more than a white object (reflects all radiation) under the same illumination. nine0003

Colored plastic contains dyes that are responsible for the absorption of one or another part of the radiation spectrum. If you mix two plastics of different colors, you get a third color. If you mix plastics with dyes that absorb red, green and blue radiation, you get black (ideally).

If you mix plastics with dyes that absorb red, green and blue radiation, you get black (ideally).

A bit of practice

For mixing, you need plastic of different colors, cut into pieces of the same length, for a more convenient conversion of the percentage of a particular color. You also need a manual “mixer” - a soldering iron with a clean tip and temperature control is suitable here. Well, in order to “measure” the color, you need a spectrophotometer, which will show what part of the white spectrum is reflected from the surface. I have an X-Rite ColorMunki Photo and use it. nine0003

I must say right away that for proper mixing you need the “correct” CMYK plastics, and I don’t have them, so I took them from BestFilament’s PLA 3D pen kit.

To begin with, I chose colors close to CMYK and checked their color. It was necessary to check all the colors, but I did not see the point in checking the color that I did not need.

The result can be seen on the pictures:

Here I checked the mixing of white and black - the result is expected. The result is an almost even (R, G, B almost the same) gray color. nine0003

The result is an almost even (R, G, B almost the same) gray color. nine0003

Yellow - in theory there should be only R (203) and G (179) components, but we see the presence of a blue (47) component.

It was supposed to be magenta, but in practice we observe the presence of a green (93) component.

I thought that cyan is blue, but after reading a little and understanding it, I realized that it should be blue-green. Taking the blue plastic, you can see a good absorption of the red component. It's almost blue-green, only twice as much blue as green. nine0003

Now I'm trying to mix different not true CMYK…

It's almost done - I got green color, mixing yellow and not cyan, but blue.

Here I added all the colors and a little black - I got almost gray. Too much blue.

I added less blue - I got almost pure gray.

I mixed blue and pink and got some kind of blue.

Conclusions

- Mixing turns out - you have to try (measure the color) different plastics and look for real CMYK. nine0070

- Plastic makers will need to tinker a bit to get pure CMYK.

- If you learn how to mix plastics in the printer, you will need only CMYK and white in order to get a model of any color. Here, in fact, not every color can be obtained. Yes, and all sorts of transparent and luminous plastics will be mixed in different ways.

- Color printing requires color calibration, ie. you will need to create color profiles for each combination of CMYK plastics. At least for different manufacturers of plastics. nine0070

Follow author

Follow

Don't want

27

3D color printing - how it works

3D color printing - how it worksColor 3D printing - how it works

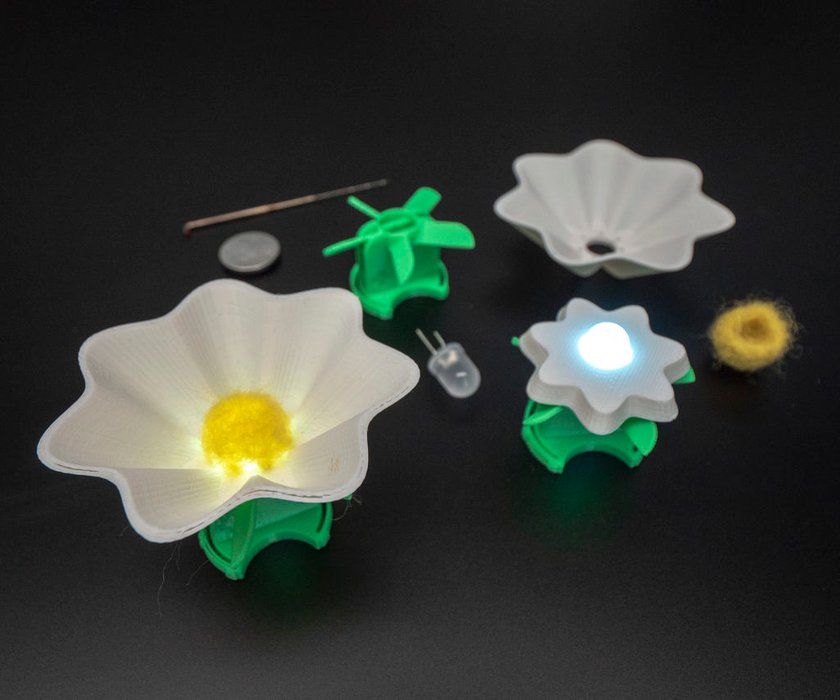

3D printing is a layer-by-layer method for virtually anything, from simple figurines to jewelry, weapons, and aerospace parts. Three-dimensional printing has long been an integral part of the creation of complex architectural and technological objects. Now 3D printing is actively developing and reaching the user level - fast and high-quality production of objects gives 3D technologies significant competitive advantages over traditional production methods. And color 3D printing opens up a lot of opportunities for creating various products in all their color diversity. nine0003

Three-dimensional printing has long been an integral part of the creation of complex architectural and technological objects. Now 3D printing is actively developing and reaching the user level - fast and high-quality production of objects gives 3D technologies significant competitive advantages over traditional production methods. And color 3D printing opens up a lot of opportunities for creating various products in all their color diversity. nine0003

Today, the most commonly used color 3D printing material is gypsum, a material that allows printing photorealistic color models at a resolution of 600×540 dpi. Gypsum is ideal for 3D printing figurines, figurines, game characters, artwork, decorative and art objects, architectural models, corporate souvenirs and more. In general, the material can be described as hard, hard, brittle and slightly rough, perfect for stationary models. nine0095 The color 3D printing process is as follows:

- First, a 3D model is created using special software such as: SolidWorks, Maya, Sketchup, Blender or any other similar software.

- The model is then sliced into separate images corresponding to each printed layer. The starting material for printing is gypsum powder, which is applied in an even layer on the base surface.

- The printheads move in a horizontal plane, layer by layer applying a glue-like substance and a tint of a predetermined color to a certain area of the future model. The cycle is repeated until the 3D model is "grown". nine0070

- After printing is completed, the finished product is carefully removed from the printer and cleaned of excess powder using a jet of compressed air.

- Next, the object is completely immersed in glue, which fills all the micro-holes of the model, giving it the final hardness, color saturation and gloss. And the unused powder is automatically recycled and can be reused for 3D printing.

3D printing is much faster than standard production technologies, and the products produced by professional 3D printers are of high quality, high precision and have a wide range of applications.

Learn more