3D print usa

Shapeways: 3D Printing Service Online

3D Printing Service

Create and customize. Streamline and save. Break down design barriers and scale your business with Shapeways 3D printing services.

Why 3D Printing?

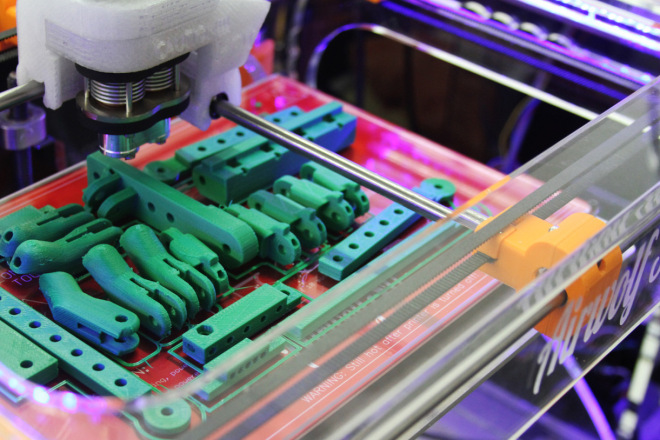

Reduce Assembly Time

Don’t waste time putting products together! Rely on 3D printing to make complex geometries that can be printed as one piece—or consolidated in one build.

Fast Turnaround

Working on a project for a customer that has to be just right? Get models back fast, and 3D print new iterations, if needed, for final feedback and production.

Reliable Quality

Proprietary processes, expert 3D printing operators, and inspections are our secrets to delivering exceptional, quality products every time.

Parts 3D Printed

3D Printing Technologies

Materials and Finishings

Countries Shipped

Customers Served

Cutting Edge Technologies

Manufacture high-quality products in over 90 of the best materials and finishes, from plastics to metals.

HP Multi-Jet Fusion

- Nylon 12 with a smooth and finished surface

- Exhibits incredible strength, durability and stiffness

- Supports complex geometries and thin features Learn More

ExOne Binder Jetting

- Steel infused with Bronze

- Supports large parts

- Strong metal with an industrial look and feel Learn More

Our Services

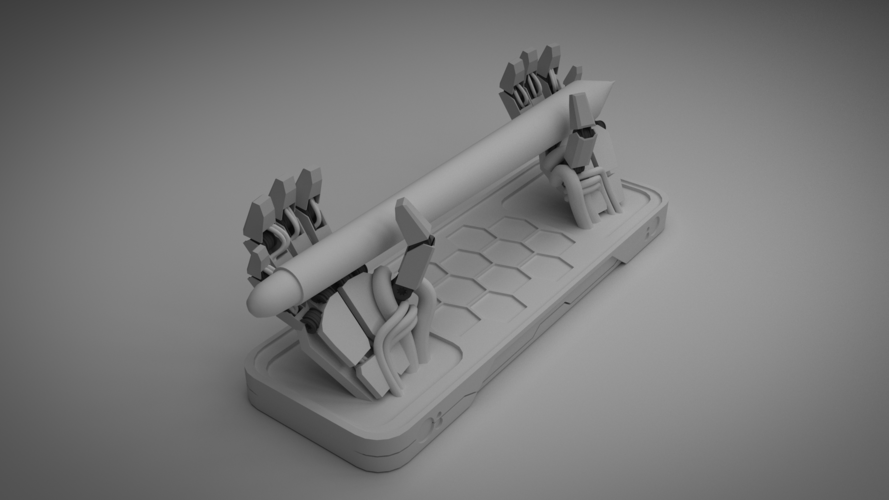

Production Parts

Upload customized models for 3D printing service—ensuring durability and strength in materials that result in end-use products meant to last. Learn More

Rapid Prototyping

Take the guesswork out of product development with 3D printing services for high-performance models used in meetings, testing, and perfection of final parts. Learn More

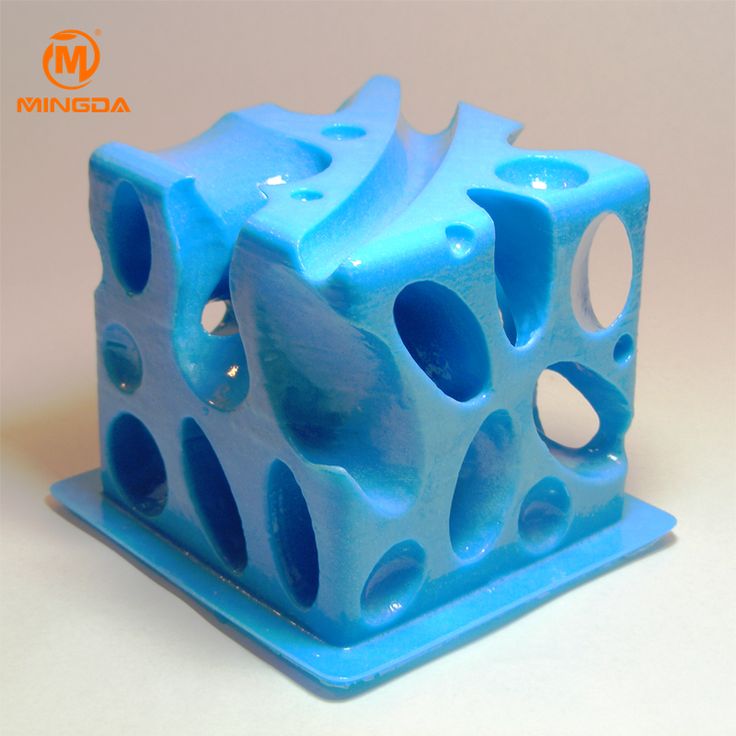

Finishing

Whether designers prefer polishing, smoothing, dyeing–or a combination of finishing techniques–Shapeways 3D printing services can perfect those final touches with shine, gloss, and color. Learn More

Learn More

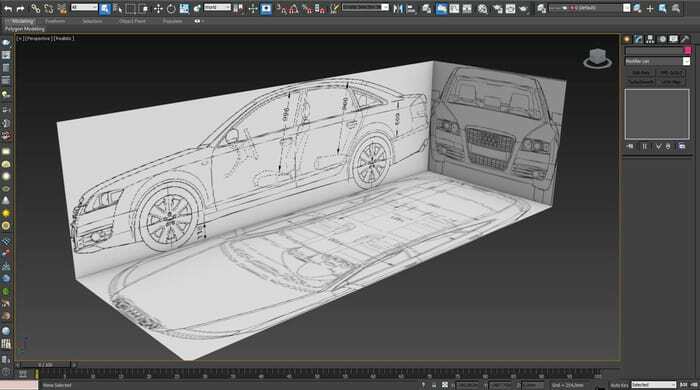

Professional Design Services

Bring your idea to life with 3D file design and optimization. Through our partnership with ZVerse, every customer has access to expert 3D Design solutions for any project need. Learn More

Rapid Prototyping

Our high quality printing enables you to assess factors such as ergonomics, usability, manufacturability, and material testing. Learn More

E-commerce Integrations

Launch your business through our marketplace by connecting to the Shapeways platform through our API, Shopify, or Etsy E-commerce Integrations. Learn More

Materials

Nylon 12 [Versatile Plastic]

Nylon 12 [Versatile Plastic] is a durable nylon plastic that can be used for a wide range of applications, both for prototyping and for end products. Printed using Selective Laser Sintering (SLS) 3D printing services, when thin, it's flexible enough for hinges and springs and when thick, strong enough for structural components. Learn More

Learn More

Accura 60

Accura 60 is a translucent and rigid acrylate-based plastic. Shapeways 3D prints this material using a large-format Stereolithography (SLA) printer capable of producing small to large parts with high resolution and detail as well as smooth surfaces with limited layer lines. Learn More

Stainless Steel 316L

Stainless Steel 316L is manufactured using ExOne’s ‘Triple Advanced Compaction Technology’ with Binder Jetting. Unlike our Steel that is infused with bronze, this material is a single alloy, composed of pure Stainless Steel. Learn More

Nylon 12

Nylon 12 (Versatile Plastic) is a durable nylon plastic that can be used for a wide range of applications, both for prototyping and for end products. Printed using Selective Laser Sintering (SLS), when thin, it's flexible enough for hinges and springs and when thick, strong enough for structural components. Learn More

Accura 60

Accura 60 is a translucent and rigid acrylate-based plastic. It is 3D printed using a large format stereolithography (SLA) printer capable of producing small to large parts with high resolution and detail as well as smooth surfaces with limited layer lines. Learn More

It is 3D printed using a large format stereolithography (SLA) printer capable of producing small to large parts with high resolution and detail as well as smooth surfaces with limited layer lines. Learn More

Stainless Steel 316L

Stainless Steel 316L is manufactured using ExOne’s "Triple Advanced Compaction Technology" with a binder jetting system. Unlike our Steel that is steel infused with bronze, this material is a single alloy, 100% Stainless steel 316L. Learn More

Testimonials

I like the ease of use in the Shapeways platform, being able to 3D print on-demand orders for the first time, and most of all–being able to scale my business. In the beginning years ago I basically had the change in my pocket and a credit line at my bank so I couldn’t order a ton of things, and you never know what’s going to sell.”

Steven Jaworski

Owner | Voytek Medical

During the process, we used Shapeways capabilities to 3D print many prototypes. That meant we had the option to iterate very quickly, print objects, and test them to see if they were working correctly in terms of complexity, or too much complexity. ”

”

Yonatan Assouline

Manager & Co-Founder | Flamingo Works

Shapeways was really great when we worked together before, which led us to reach out again. It’s been so helpful to talk with them about what we could do in every aspect of 3D printing and finishing, and it saved us a lot of time in experimentation.”

Nathan Lachenmyer

Director of Technology | Sitara Systems

I like the ease of use in the Shapeways platform, being able to 3D print on-demand orders for the first time, and most of all–being able to scale my business. In the beginning years ago I basically had the change in my pocket and a credit line at my bank so I couldn’t order a ton of things, and you never know what’s going to sell.”

Steven Jaworski

Owner | Voytek Medical

During the process, we used Shapeways capabilities to 3D print many prototypes. That meant we had the option to iterate very quickly, print objects, and test them to see if they were working correctly in terms of complexity, or too much complexity. ”

”

Yonatan Assouline

Manager & Co-Founder | Flamingo Works

Shapeways was really great when we worked together before, which led us to reach out again. It’s been so helpful to talk with them about what we could do in every aspect of 3D printing and finishing, and it saved us a lot of time in experimentation.”

Nathan Lachenmyer

Director of Technology | Sitara Systems

Previous Next

Recent Articles

Trusted by Businesses Around the World

Design, Upload, and 3D Print Your Files

Design, Upload, and 3D Print Your Files

3D print with Shapeways by creating complex products previously impossible with traditional manufacturing. Create sophisticated 3D printed ideas and designs, upload 3D print files, and expedite product development.

From a sketch to the final 3D printed product, Shapeways allows you to choose advanced 3D printing materials, technology, and feedback for 3D print files. This ensures quality manufacturing for assembly and fit, functionality, and high-performance parts for applications like aerospace or medical.

This ensures quality manufacturing for assembly and fit, functionality, and high-performance parts for applications like aerospace or medical.

Upload a File

Contact Sales

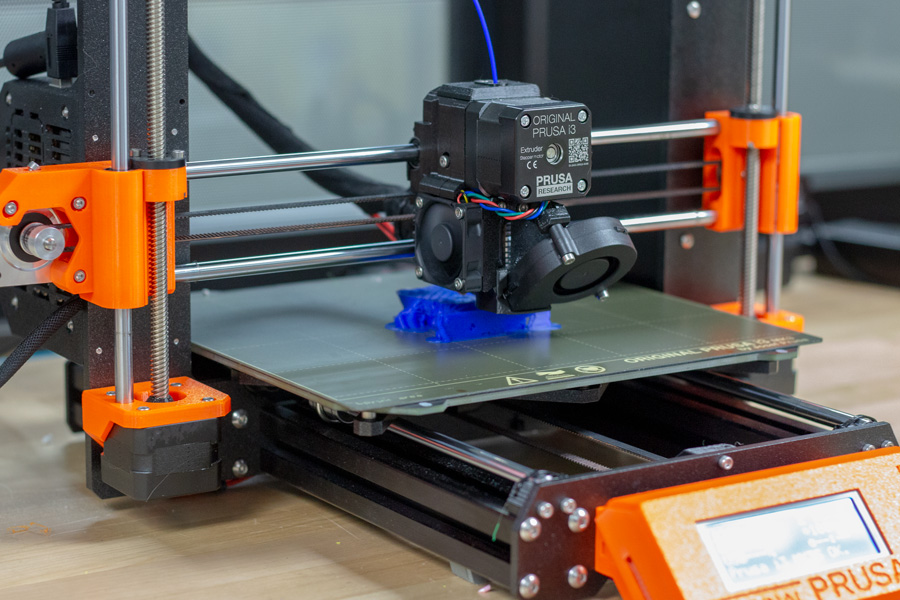

Have a 3D File Ready?

Create your 3D model and upload the 3D print file to Shapeways. Don’t have a 3D file? Shapeways can help.

Shapeways 3D prints and post-process your product.

Your 3D print is shipped expediently and arrives ready to use!

Upload a Model to 3D Print

Whether you are uploading 3D models for jewelry or automotive parts, Shapeways instantly analyzes the 3D file for printability. While most 3D models are uploaded successfully, if an issue arises, Shapeways file fixers can help regenerate the 3D file or provide customized feedback. Inspections, proprietary processes, and expert 3D printing operators lead to exceptional products.

Explore Materials

Proper selection of 3D printing materials is key as they must be compatible with 3D printing technology and optimized for project requirements. From plastics to metal, Shapeways offers over 90 materials and finishes–and additive manufacturing services for any project.

From plastics to metal, Shapeways offers over 90 materials and finishes–and additive manufacturing services for any project.

3D Print Design Tips

While excellence in product development depends on optimized modeling, prototyping, and quality management, 3D printing design guidelines play a critical role in the outcome of every 3D printed part. Check out the following resources for assistance in taking your 3D design from concept to market.

Services for Your Business

- Use Shapeways 3D printing services to create complex 3D printed products for you.

- Receive 3D printed parts quickly, print new iterations, or rapid prototypes as needed.

- Rely on expert 3D printing operators and inspections for delivery of quality products.

- Choose from a range of additive manufacturing and traditional manufacturing options, designed to scale any business.

- Drop ship your 3D prints to over 130 countries.

Contact Sales

First Name*

Last Name*

Email*

Phone*

Company

Title

Country*

--None--AfghanistanAlbaniaAlgeriaAndorraAngolaAnguillaAntigua and BarbudaArgentinaArmeniaArubaAustraliaAustriaAzerbaijanBahamas, TheBahrainBangladeshBarbadosBelarusBelgiumBelizeBeninBermudaBhutanBoliviaBosnia and HerzegovinaBotswanaBrazilBruneiBulgariaBurkina FasoBurundiCambodiaCameroonCanadaCape VerdeCentral African RepublicChadChileChinaColombiaComorosCongo, Democratic Republic of theCongo, Republic of theCosta RicaCroatiaCyprusCzech RepublicDenmarkDjiboutiDominicaDominican RepublicEcuadorEgyptEl SalvadorEstoniaEthiopiaFaroe IslandsFijiFinlandFranceFrench GuianaFrench PolynesiaGabonGambia, TheGeorgiaGermanyGhanaGibraltarGreeceGreenlandGrenadaGuadaloupeGuamGuatemalaGuernseyGuineaGuinea-BissauGuyanaHaitiHondurasHong KongHungaryIcelandIndiaIndonesiaIraqIrelandIsraelItalyIvory CoastJamaicaJapanJerseyJordanKazakhstanKenyaKiribatiKorea, SouthKuwaitKyrgyzstanLaosLatviaLebanonLesothoLiberiaLibyaLiechtensteinLithuaniaLuxembourgMacauMacedoniaMadagascarMalawiMalaysiaMaldivesMaliMaltaMarshall IslandsMauritaniaMauritiusMexicoMicronesiaMoldovaMonacoMongoliaMontenegroMontserratMoroccoMozambiqueNamibiaNepalNetherlandsNetherlands AntillesNew CaledoniaNew ZealandNicaraguaNigerNigeriaNorfolk IslandNorthern Mariana IslandsNorth KoreaNorwayOmanPakistanPalauPalestinian TerritoryPanamaPapua New GuineaParaguayPeruPhilippinesPolandPortugalPuerto RicoQatarRomaniaRussiaRwandaSaint Kitts and NevisSaint LuciaSaint Vincent and the GrenadinesSamoaSan MarinoSaudi ArabiaSenegalSerbiaSeychellesSierra LeoneSingaporeSlovakiaSloveniaSolomon IslandsSouth AfricaSpainSri LankaSudanSurinameSvalbard and Jan MayenSwazilandSwedenSwitzerlandTaiwanTajikistanTanzaniaThailandTimor-LesteTogoTongaTrinidad and TobagoTunisiaTurkeyTurks and CaicosTuvaluUgandaUkraineUnited Arab EmiratesUnited KingdomUnited StatesUnited States Minor Outlying IslandsUruguayUzbekistanVanuatuVatican CityVenezuelaVietnamVirgin Islands (British)Virgin Islands (US)Wallis and FutunaYemenZambiaZimbabwe

How can we help?*

Choose an optionI'm interested in repeating ordersI'm interested in batch productionI want to design a one-time prototypeI'm new to 3D printing and need guidanceI’m interested in custom packagingOther/general questions

Description

By entering your email address, you grant Shapeways permission to send you messages about Shapeways and Shapeways services. You may unsubscribe from these messages at any time by using the unsubscribe link. Your information is protected by the Shapeways Privacy Statement.

You may unsubscribe from these messages at any time by using the unsubscribe link. Your information is protected by the Shapeways Privacy Statement.

Please check recaptcha box

| 3DNews Technologies and IT market. News at the cutting edge of science In the United States, 3D printing technology has been developed... 03.12.2022 [14:06], Gennady Detinich Caltech engineers have developed a method to 3D print metals and alloys at a resolution that, in some cases, is an order of magnitude smaller than previously possible. The minimum element size has been reduced to 40 microns, paving the way for the production of tiny components for microelectronic mechanical systems (MEMS) that can be applied to a wide range of devices, from sensors to chip heat dissipation systems. nine0007 Image Source: Bob Paz Traditionally, metal 3D printing relies on layer-by-layer sintering of metal powders with a laser beam. The model is still created layer-by-layer on a 3D printer, but not from laser-heated powder metal, but from a polymer hydrogel with layer-by-layer fixing with ultraviolet light. After creating the model, it is placed in an aqueous solution of metal salts, in which metal ions penetrate into the hydrogel. After saturation of the model with salts, the model is annealed. The annealing temperature is chosen below the melting point of the metal, but it is still high enough (700–1100 °C) to completely burn out the hydrogel. nine0007 After annealing, a metal model remains with an element resolution even lower than that of a hydrogel matrix. Annealed copper model 3D Architech was formed by Caltech to license the new printing technology to anyone interested. Biotechnology, chip cooling, sensors, robotics - all these disciplines and many others need to mass-produce miniature metal products that cannot be made in the traditional way - casting, milling, forging, and so on. nine0007 Source: If you notice an error, select it with the mouse and press CTRL+ENTER. Related materials Permanent URL: News Hardware, nanotechnology, cutting edge science, 3D technology, Tags: 3d printing, caltech ← В past To the future → |

Alquist 3D-printed a house in which a family settled for the first time in the USA - Future on vc.

ru

ru =1&hash=51c56212e9092b635425bc8151f2ff967b4d31f32b20ff184112a8c0df9d8e7a","title":"\u041f\u0440\u0438\u043d\u0446\u0438\u043f \u00ab\u0431\u043e\u043b\u044c\u0448\u0435 \u043e\u043f\u044b\u0442\u0430 \ u2014 \u043b\u0443\u0447\u0448\u0435 \u0431\u0438\u0437\u043d\u0435\u0441\u00bb \u0443\u0441\u0442\u0430\u0440\u0435\u043b. \u0421\u043e\u0433\u043b\u0430 \u0441\u0438\u0442\u0435\u0441\u044c?","buttonText":"\u0412\u044b\u0441\u043a\u0430\u0437\u0430\u0442\u044c\u0441\u044f","imageUuid":"7e8d6699-f4e1-5068-b3e1-a6f0a319d5b0","isPaidAndBannersEnabled":false}

Future

DTF

Construction took 12 hours instead of the nominal four weeks.

20 155 views

The house was printed by Alquist, which uses 3D printing technology for "exceptional design", reducing the cost of construction and infrastructure. In the future, the company plans to build not only single-family homes, but also multifamily, mixed-use, and nursing homes across the US. nine0007

April Stringfield and her 13-year-old son received the keys to the first 3D-printed house as part of a charity program to support low-income families, according to CNN.

The 111-square-meter facility was printed in the Williamsburg, Virginia area in 12 hours, at least four weeks ahead of the standard construction schedule.

Three-bedroom, two-bathroom structure based on a fast-setting concrete frame. According to the developers, the material has long-term advantages - it retains temperature well and is resistant to damage. Printers have reduced construction costs by 15%. nine0007

A Raspberry Pi-based computer is responsible for monitoring home systems.

At the same time, the high thermal conductivity of metals makes it difficult to increase the resolution - heating occurs quickly, and no matter how you focus the laser, more powder is sintered in the projection area than the digital model provides. Scientists from Caltech solved this problem in an interesting way - at the stage of printing a model, they proposed to abandon metals and a laser. nine0007

At the same time, the high thermal conductivity of metals makes it difficult to increase the resolution - heating occurs quickly, and no matter how you focus the laser, more powder is sintered in the projection area than the digital model provides. Scientists from Caltech solved this problem in an interesting way - at the stage of printing a model, they proposed to abandon metals and a laser. nine0007  And if the method of direct laser 3D printing can create metal parts with a minimum resolution of 100 microns, then the use of a matrix increases the resolution of printing metal models up to 40 microns. It is twice as thin as a human hair.

And if the method of direct laser 3D printing can create metal parts with a minimum resolution of 100 microns, then the use of a matrix increases the resolution of printing metal models up to 40 microns. It is twice as thin as a human hair.