Photon 3d printing

Anycubic Photon - LCD/DLP/SLA 3D Printer

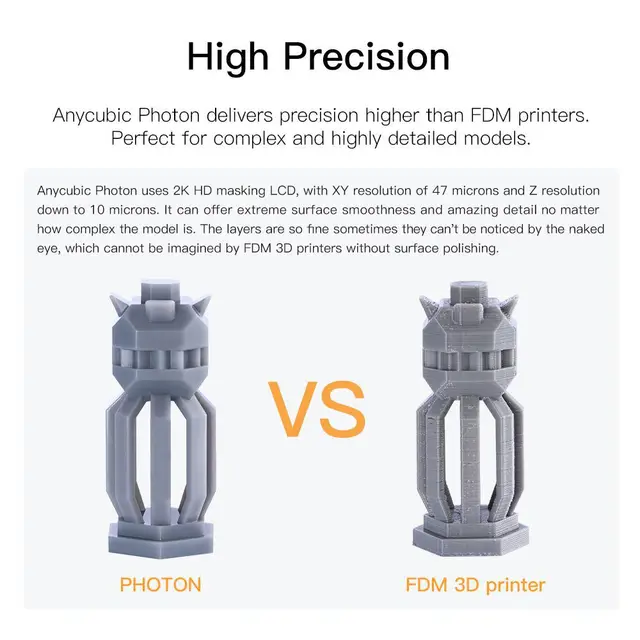

The colorful touch screen equipped with Photon system and bring new functions. You could pre-view the model in SD card just like you saw pictures in Windows OS. Real-time display printing process function is available now. 2560*1440(2k)HD LCD make the details down to few micrometers.

- Touch Screen

- Easy manipulation, real-time previews of printing status.

- Unique Resin Vat

- Easily adjust and replace the FEP film to save your cost of use.

- Off-line Print

- the Photon supports offline print with built-in operational system, improve print stability.

- Easy Leveling

- 3-step Leveling.

- Technical Specifications

- ● Printing Technology: LCD-based SLA 3D Printer

- ● Light-source : UV integrated light(wavelength 405nm)

- ● XY DPI : 47um (2560*1440)

- ● Y axis resolution : 1.

25um

- ● Layer resolution : 25 ~ 100um

- ● Printing speed : 20mm/h

- ● Rated Power : 40W

- ● Printer size: 220mm*200mm*400mm

- ● Printing volume : 115mm *65mm *155mm (4.52″*2.56″*6.1″)

- ● Printing material : 405nm photosensitive resin

- ● Connectivity :USB

- ● Package Weight: 6.6kg

- 2k LCD Screen

- 2560*1440 HD LCD, printing details down to few micrometers.

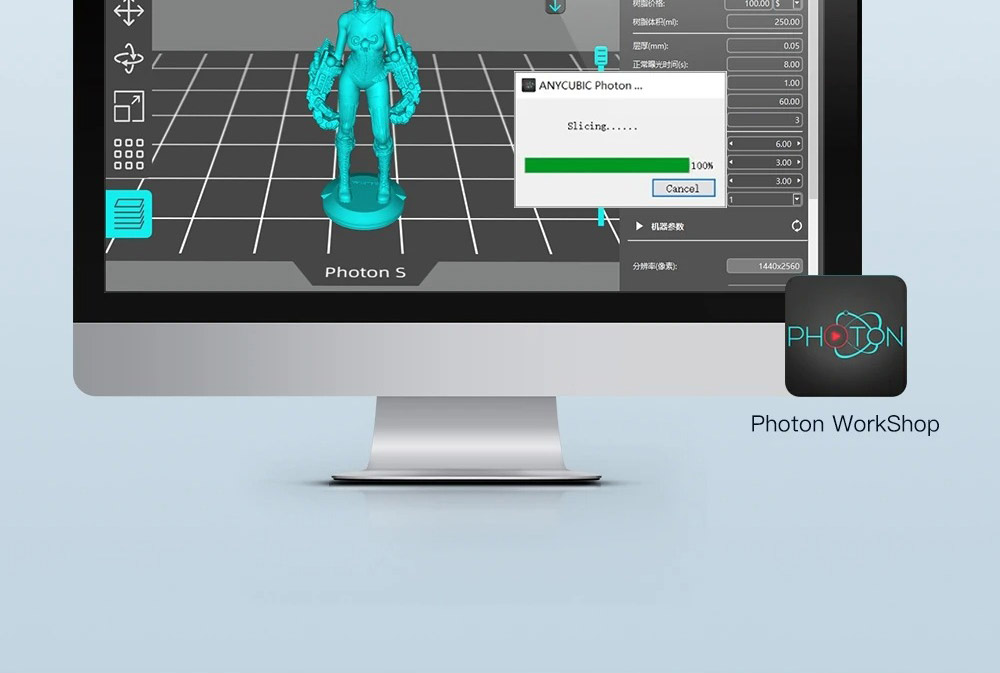

- Quick Slicing

- Self-developed slicer software, quick to slice and easy to use.

- Easy Leveling

- Lower the platform down to the screen; Feel the resistance when pulling the paper in-between; Tighten one screw; Leveling done.

Package List

Srews(M5)*5

Scraper

Tool set

USB Drive

Glove

Resin Vat

User manual

Funnel

Power cord

|

|

| |

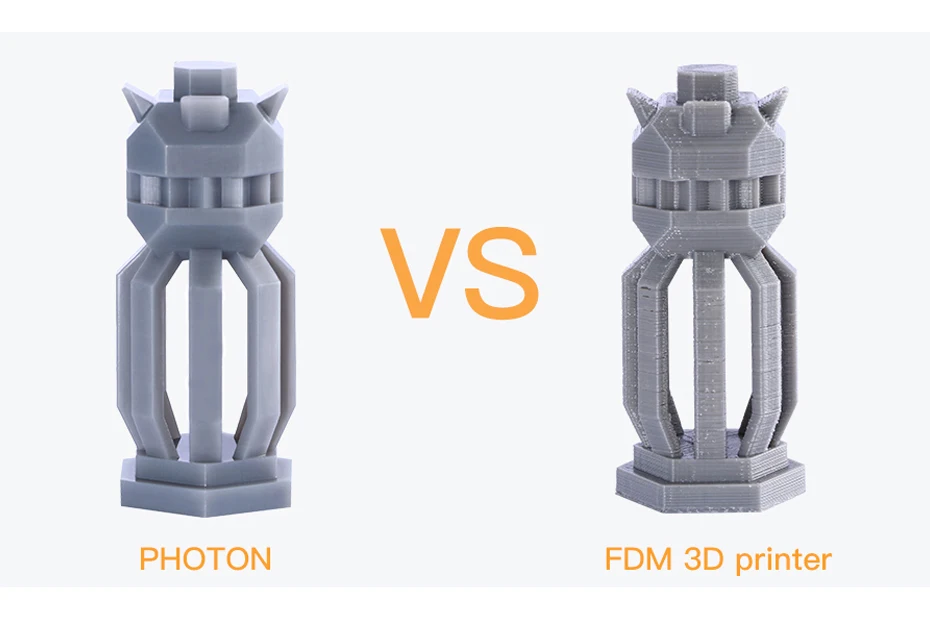

| Printing Technology | LCD-based SLA Printing | LCD-based SLA Printing | FDM (Fused Deposition Modeling) |

| XY Resolution | 3840*2400 px | 5760*3600 px | None |

| Build Volume | 132mm*80mm*165mm | 197mm*122mm*245mm | 245*245*260mm |

Max. Printing Speed Printing Speed | 50mm/h | 80mm/h | 100mm/s |

| Print Materials | 405nm UV Resin | 405nm UV Resin | PLA, ABS, PETG, Wood |

| Z axis Accuracy | 0.01mm | 0.01mm | 0.002mm |

-

- Photon

- LCD-based SLA

- Build Area: 115x65x155mm

- Filament:405nm UV Resin

- Diffusion Illuminant

- Single Z-axis

-

- Photon S

- LCD-based SLA

- Build Area: 115x65x165mm

- Filament:405nm UV Resin

- Matrix Illuminant

- Double Z-axis

-

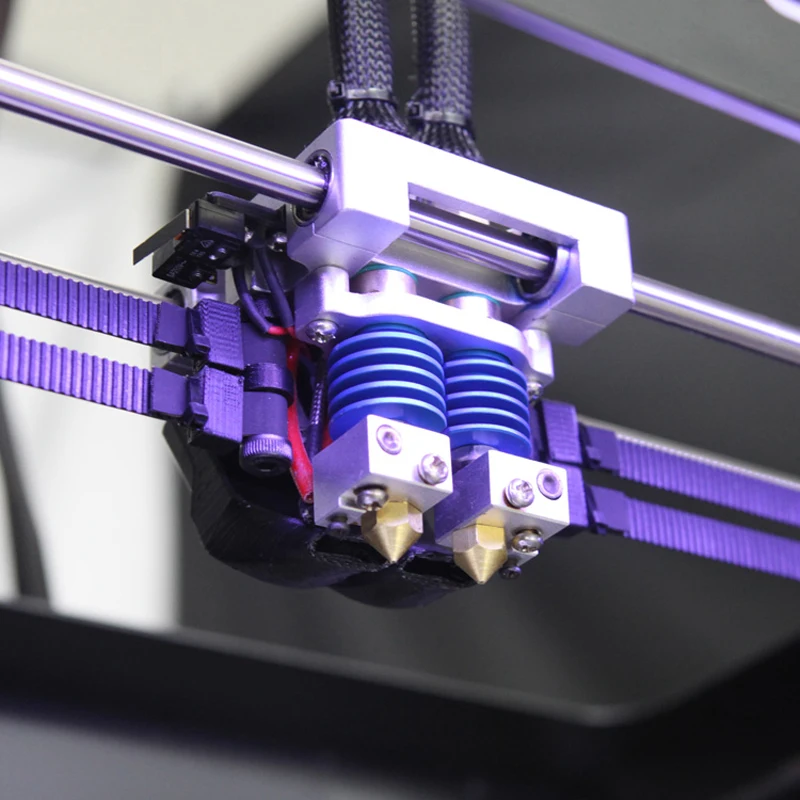

- 4Max Pro

- FDM (Fused Deposition Modeling)

- Build Area: 270x205x205mm

- Filament: PLA, ABS, HIPS, PETG,

Wood and TPU - Titan Extruder

Suspended Filament Rack - Single Z-axis

Anycubic Care

Firmware

1. V5.0.2 [ChangeLog]

V5.0.2 [ChangeLog]

(Photon Upgraded Only)

2. V4.2.19

Driver

/

Slicer

V2.1.26-Mac

V2.1.26-Win X86

V2.1.26-Win X64

Manual

Test model

1. Test_model_1

2. Test_model_2

Manual

1. Photon_Manual_en

please click on it to download.

Service

We offer excellent after-sales service. Please click here for details.

Anycubic Photon Series LCD-Based SLA Resin 3D Printers – ANYCUBIC 3D Printing

Anycubic Photon Series LCD-Based SLA Resin 3D Printers – ANYCUBIC 3D Printing Skip to contentSort SortFeaturedBest sellingAlphabetically, A-ZAlphabetically, Z-APrice, low to highPrice, high to lowDate, old to newDate, new to old

- Anycubic Photon M3 Series

- Anycubic Photon Series🆕

- Anycubic DLP Series🆕

- Anycubic Wash & Cure Station

- Anycubic AirPure

Quick view

Anycubic Photon M3 Premium

ANYCUBIC

from $639. 00

00

Save $100

Quick view

Anycubic Photon Mono 4K

ANYCUBIC

Regular price $289.00 Sale price from $189.00

Save $230

Quick view

Anycubic Photon Mono X

ANYCUBIC

Regular price $529.00 Sale price from $299.00

Save $100

Quick view

Anycubic Photon Mono X2

ANYCUBIC

Regular price $429.00 Sale price from $329.00

Save $280

Quick view

Anycubic Photon Mono X 6K

ANYCUBIC

Regular price $689.00 Sale price from $409.00

Save $60

Quick view

Anycubic Photon M3

ANYCUBIC

Regular price $299.00 Sale price from $239.00

Save $140

Quick view

Anycubic Photon M3 Max

ANYCUBIC

Regular price $1,099. 00 Sale price from $959.00

00 Sale price from $959.00

Save $270

Quick view

Anycubic Photon M3 Plus

ANYCUBIC

Regular price $699.00 Sale price from $429.00

Save $80

Quick view

Anycubic Photon D2

ANYCUBIC

Regular price $679.00 Sale price from $599.00

Save $20

Quick view

Wash & Cure Machine 2.0

ANYCUBIC

Regular price $149.00 Sale price from $129.00

Save $30

Quick view

Anycubic Wash & Cure Plus Machine

ANYCUBIC

Regular price $249.00 Sale price from $219.00

Sold Out

Quick view

Anycubic Photon Mono SE

ANYCUBIC

$419.00

Save $310

Quick view

Anycubic Photon Ultra

ANYCUBIC

Regular price $599. 00 Sale price from $289.00

00 Sale price from $289.00

Sold Out

Quick view

Limited Edition Photon Mono X 6K

ANYCUBIC

Regular price $659.00 Sale price $429.00

Sold Out

Quick view

Anycubic Photon Mono

ANYCUBIC

$269.00

Sold Out

Quick view

Anycubic Photon Mono SQ

ANYCUBIC

$169.00

Sold Out

Quick view

Wash & Cure Machine

ANYCUBIC

Regular price $219.00 Sale price $69.00

Sold Out

Quick view

Anycubic Photon

ANYCUBIC

from $279.00

Sold Out

Quick view

Anycubic Photon S

ANYCUBIC

$379.00

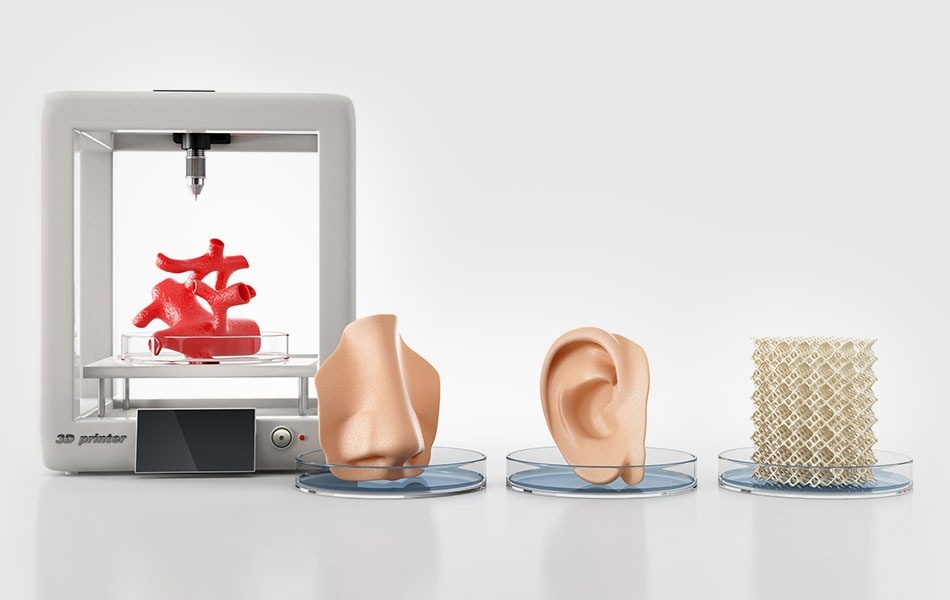

Photopolymer 3D printer

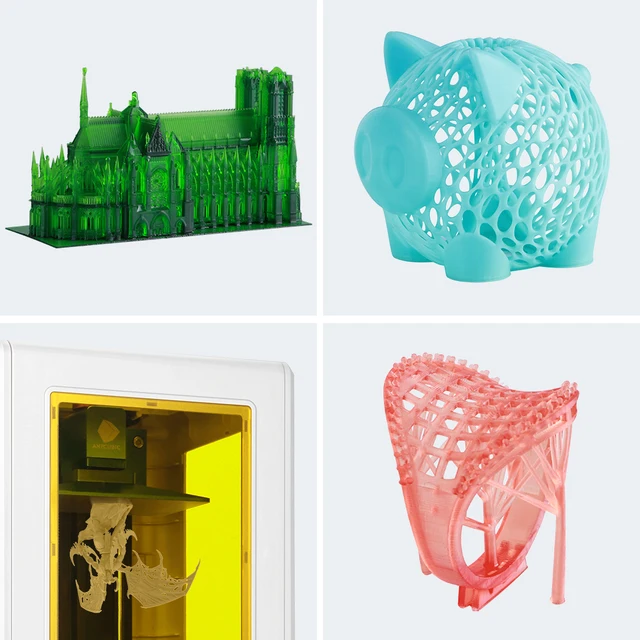

3D printers can be sorted not only by the printing technologies used, but also by the consumables used. In this section, we will look at devices that use photopolymer resins to build models.

In this section, we will look at devices that use photopolymer resins to build models.

- 1 Consumables

- 2 Laser stereolithography (SLA)

- 3 Projector stereolithography (DLP)

- 4 Multi-jet (MJM and PolyJet)

- 5 3D pens

- 6 Additional illumination

Consumables

Photopolymer resins are liquid polymers that harden when exposed to light. As a rule, such materials are sensitive to the ultraviolet range, which determines the design of photopolymer printers. One of the common design elements is a transparent colored cap or housing made of a material that filters ultraviolet radiation. This is done both to protect the user's eyes and to protect the supplies inside the printer from exposure to sunlight and background lighting. nine0003

Photopolymer resin loaded into Form 1 3D printer

The physical properties of resins after polymerization vary widely. Both rigid and flexible options are available, transparent and matte. A wide selection of colors is also available. Resin consistency and exposure times also vary, so a range of compatible media should be considered when choosing a printer.

Both rigid and flexible options are available, transparent and matte. A wide selection of colors is also available. Resin consistency and exposure times also vary, so a range of compatible media should be considered when choosing a printer.

The last aspect to consider when choosing a material is its toxicity. There are both quite toxic options and biologically safe ones. nine0003

The cost of consumables can be considered the Achilles' heel of photopolymer printing. The plants themselves are already reaching quite acceptable price levels, but it is still quite difficult to find inexpensive photopolymer resins. It is hoped that the proliferation of inexpensive photopolymer printers will lead to an increase in the production of consumables and lower prices.

Laser Stereolithography (SLA)

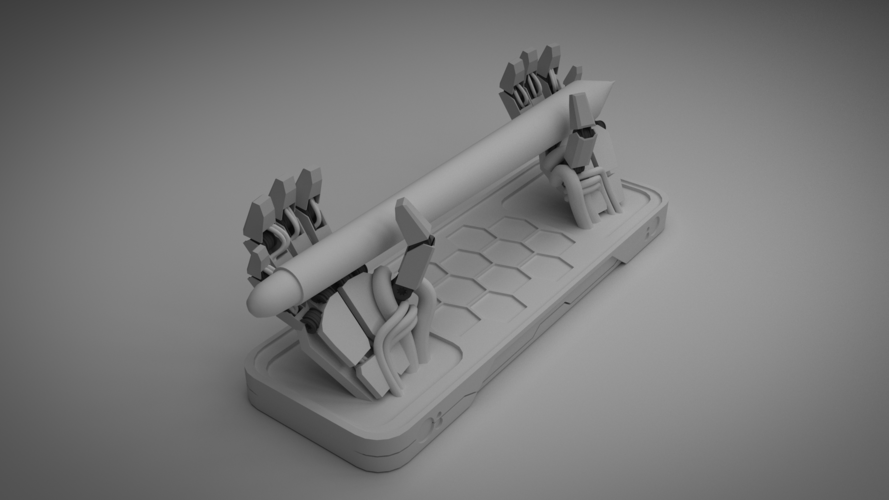

SLA Model

The firstborn of photopolymer printing and modern 3D printing in general. The technology was developed in 1984 by Charles Hall, who later founded 3D Systems.

SLA printers use laser emitters to cure the photopolymer supply.

A typical SLA printer consists of a consumable tray sitting under a build platform driven vertically by a raise/lower mechanism.

Alternatively, the cuvette itself can be driven - what matters is the relative movement of the platform and the container. Above the cuvette is a laser emitter and a mirror system for deflecting the laser beam. nine0003

During the printing process, the platform is immersed in the consumable for the thickness of one layer of the digital model.

Since photopolymer resins can be quite thick, a leveling mechanism is often used to speed up the process.

SLA printer operation scheme

After leveling, the process of illumination of the material begins. Illumination is produced by laser irradiation. Most photopolymer resins are designed to cure (polymerize) when exposed to ultraviolet light, which determines the choice of laser frequency. The movement of the beam along the X and Y axes is determined by the operation of the deflecting mirrors. nine0003

The movement of the beam along the X and Y axes is determined by the operation of the deflecting mirrors. nine0003

After the drawing of the layer is completed, the platform is immersed in the material for the thickness of one more layer, and the process is repeated with the drawing of the next layer of the digital model.

Model building animation

SLA printing takes quite a long time, and printers using this method tend to have relatively small build areas.

This is mainly due to the high cost of laser emitters: printing large objects with a single laser will take too much time, and installing additional emitters and mirrors will complicate the design, increase the dimensions of the installation and raise the price to an unacceptable level for most users. nine0003

Despite the success of this technology, projected stereolithography is considered to be a more promising, although very similar method.

Projector Stereolithography (DLP)

Formlabs Form 1 Desktop DLP Printer

A close relative of laser stereolithography, this method uses digital LED projectors instead of laser machines with mirror deflection systems. The method became popular due to the development of technology for the production of low-cost high-resolution digital projectors by Texas Instruments. nine0003

The method became popular due to the development of technology for the production of low-cost high-resolution digital projectors by Texas Instruments. nine0003

Layers are illuminated using a digital projector that highlights patterns of the entire layer, which distinguishes this method from SLA, where the "picture" emerges progressively using an ultraviolet laser.

A similar approach has previously been used on SGC-type units, but this technology used physical photomasks, making the process expensive, time consuming, slow and noisy.

FTI continues to exist, a development of SGC that is almost indistinguishable from DLP printing, as it also uses digital LED projectors. nine0003

DLP printer design

Simultaneous illumination of an entire layer using projectors can significantly speed up the printing process even compared to SLA printers that have a high scanning speed (ie beam movement).

In addition, these printers are less sensitive to rough physical impact due to the absence of delicate mirror systems.

The absence of mechanical mirror systems improves accuracy. Finally, the cost of projectors sets them apart from laser systems. nine0003

Projection size can be quite significant, reaching the average of popular FDM printers.

An interesting feature of DLP printers is the ability to "reverse" or "reverse" printing.

In this case, the projector is installed under a transparent (material choice for transparency in relation to ultraviolet light) cuvette, and the platform does not sink into the material, but gradually rises, pulling out the layers of exposed polymer. nine0003

This approach eliminates the alignment mechanism and achieves even higher Z resolution than SLA printers.

In addition, the size of models in height is not limited by the depth of the cuvette, which favorably affects the dimensions of the printer and the possibility of increasing the build area.

Multi-jet printing (MJM and PolyJet)

3D Systems ProJet 3500HDMax MJM printer

MJM and PolyJet technologies are practically indistinguishable from each other. The name difference comes from the respective patents: Multi Jet Modeling is owned by 3D Systems, while PolyJet is owned by rival Stratasys. nine0003

The name difference comes from the respective patents: Multi Jet Modeling is owned by 3D Systems, while PolyJet is owned by rival Stratasys. nine0003

The very principle of multi-jet polymer printing was developed by the Israeli company Objet, which eventually became a division of Stratasys.

Multi-jet printing technology combines features of 3D inkjet printing (3DP) and projection stereolithography (DLP).

How the MJM PolyJet printer works

Models are built by spraying photopolymer using linear arrays consisting of multiple nozzles.

The applied layer is immediately exposed to ultraviolet lamps - as a rule, two processes occur simultaneously.

By the time the array reaches the end of the build chamber, the previously deposited material is hard enough to print a new layer.

Composite models created on the ProJet 3500 DP dental printer

This approach allows to achieve very high printing speed, but is characterized by high design complexity, which negatively affects the cost of such installations and limits their distribution to professional use. nine0003

nine0003

One of the advantages of MJM and PolyJet technologies is the ability to create composite structures from photopolymer resins with different physical characteristics.

It is therefore possible to create models with easily removable supports, use multiple colors and use flexible and rigid materials in parallel within the same model.

3D Pens

CreoPop 3D Pen

Recently, there has been a craze for hand-held printing devices called 3D pens. At the moment, there are three main options for such devices: drip-jet pens (DOD), called BioPen and used in the development of new methods for treating damaged tissues, FDM 3D pens, which are manual extruders (essentially similar to the usual hot glue guns, but using thermoplastics) and developments in 3D-drawing with photopolymer resins.

CreoPop 3D pen was the first "handheld resin printer". The design of this device is quite simple, because the most complex function, positioning, is performed by the user himself. The pen only extrudes resin through the tip surrounded by LED emitters. nine0003

The pen only extrudes resin through the tip surrounded by LED emitters. nine0003

CreoPop 3D pen in action

This way the resin hardens immediately after application, allowing you to literally draw on air.

The advantage of such handles over FDM-analogues is the low operating temperature – there are no heating elements in the device. As a result, with such pens you can even draw on the skin.

In addition, a wide range of photopolymer resins with different physical properties can be used with such devices, which greatly expands the range of possible applications. At a minimum, this is a relatively inexpensive, but entertaining toy. nine0003

The only drawback is the relatively high cost of consumables, but such devices are unlikely to require large volumes of photopolymer resin when used in everyday life.

Additional Lighting

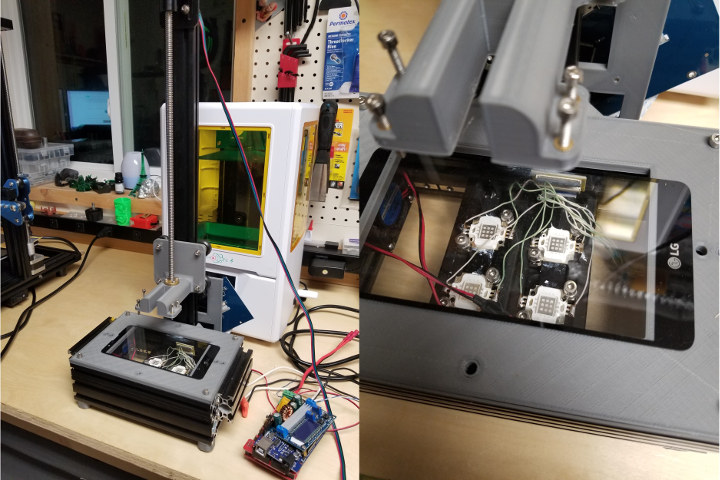

Final Lighting of Resin Models in a Homemade Camera

Full curing of models can take quite a long time, so models during SLA and DLP printing are only partially polymerized, sufficient to maintain the physical shape of the part. nine0003

nine0003

After production, the models are usually placed in chambers equipped with ultraviolet lamps until fully cured. Of course, if possible, you can simply lay out the models in the sun - the effect will be the same.

Just keep in mind that ordinary glass practically does not transmit ultraviolet light, so exposure to sunlight must be direct.

If desired, a UV-transparent quartz glass container can be used. nine0003

Go to the main page of the Encyclopedia of 3D Printing

Nano-Resolution 3D Printing of Silicon Electronics / Sudo Null IT News During the sintering process, they are converted into either glass or cristobalite. Source: Rice University Laboratory of Nanomaterials, Nanomechanics, and Nanodevices

Rice University engineers demonstrate the ability to 3D print glass and crystal nanostructures to build electronics or photonic devices in a bottom-up fashion. nine0003

Materials scientists at Rice University create silicon nanostructures using a sophisticated 3D printer, demonstrating a bottom-up method for building micro-scale electronics as well as mechanical and photonic devices.

Weaving of intricate microscopic structures of crystals or glass is now possible. At the same time, it is also possible to print products on a 3D printer that allow doping and adjustment of crystal structures for various purposes.

A related study by Jun Lu, professor of materials science and nanoengineering at the George R. Brown School of Engineering, was published in the journal Nature Materials. nine0003

The modern electronics industry is built around silicon, the basic semiconductor substrate that has been used for decades to build microprocessors. The results of the study overcome the limitations of top-down manufacturing technology by turning the entire process on its head with a 3D printer.

"It's very difficult to create complex, three-dimensional geometric structures with traditional photolithography techniques," Lu says. “In addition, it is not environmentally friendly, since the process requires the use of a large amount of chemicals and is multi-stage.And even with all these technological efforts, some structures cannot be created.” nine0023 "In principle, we can print arbitrary 3D shapes, which will play an important role in the creation of exotic photonic devices." he added.

In the lab, a two-photon polymerization process is used to print structures with lines only a few hundred nanometers wide, which is smaller than the wavelength of light.

“Conventional polymerization uses polymers and photoinitiators, molecules that absorb light to generate free radicals,” Rice University graduate and co-author Boyu Jang explains a process that uses UV light to cure materials in 3D printing and dentistry . nine0023 “In our process, photoinitiators absorb two photons at the same time, which requires a lot of energy,” he says. “Only a very small peak of this energy causes polymerization, which eventually covers a tiny area, allowing us to go beyond the diffraction limit of light.”

To implement such a printing technique, the laboratory specialists had to develop a unique ink. Zhang and his colleague Xiven Wen created resins containing silica nanospheres doped with polyethylene glycol, giving them the property of solubility. nine0003

After printing, the structure is cured by high temperature sintering, which removes all polymers from the product, leaving amorphous glass or polycrystalline cristobalite.

"When heated, the material goes through phases of transformation from glass to crystal, and the higher the temperatures, the more ordered the crystals become." Lou says.

The lab also demonstrated doping the material with various rare salts to make the end products photoluminescent, a property required for optical applications. The next goal is to improve the process to realize 3D printing with a resolution of less than 10 nanometers. nine0003

Rice University researcher Hua Guo, research scientists Guanhui Gao and Xian Zhang, Rice University alumni Youshun Zhao, Qiyi Fang and Christine Nguyen; Tsinghua University graduate Fan Ye, University of Houston graduate Shuai Yue, currently working at the Chinese Academy of Sciences; and Jiming Bao, professor of electrical and computer engineering at the University of Houston.