Powder bed 3d printers

Who makes powder bed fusion 3D printers?

Home > Latest Articles > Who makes powder bed fusion 3D printers?

By Leslie Langnau Leave a Comment

To build parts one layer at a time, you need to convert various materials into a form that can fit a layer by layer build process. For the additive process of Powder Bed Fusion (PBF), polymers or metals need to be converted into a fine powder. Then, you need some way to bind layers of powder into specific shapes and geometries. Powder Bed Fusion systems typically use a light source, either lasers or electron beams, to melt or sinter the powder layer-by-layer.

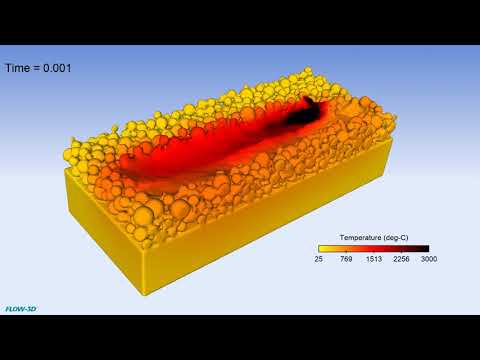

A review of the layer-by-layer process: The laser or electron beam moves over the powder in the powder bed, turning the powder into liquid or into a sufficiently liquid state so that when the affected powder cools it solidifies and adheres to the previous layer of powder. The light source affects a specific depth of powder, depending on the 3D printer’s specifications. After that, a new thin layer of powder is spread over that earlier layer, and sintered or melted to the previous layer to bond the layers, and the process repeats until a part is built. Most laser based PBF systems use an enclosed build chamber that is filled with an inert gas to prevent the potential of explosions, particular with metal powders.

Users will find a number of brand names to describe PBF. These include Direct Metal Laser Sintering (DMLS), Selective Laser Melting (SLM), Laser Powder Bed Fusion (LPBF), and Selective Laser Sintering (SLS). In some cases, the vendors’ processes vary a bit so a new label describes that. For example, you can’t melt plastic, but you can sinter it.

Here’s a look at which additive vendors offer PBF systems.

3D Systems metal 3D printers use Direct Metal Printing (DMP) to build parts. A high-precision laser solidifies metal powder.

The FormUp 350, from AddUp, is a metal 3D printer that uses what the company calls Laser Beam Melting (LBM). It works with stainless steel, nickel, titanium alloys and aluminium alloys.

It works with stainless steel, nickel, titanium alloys and aluminium alloys.

DMG Mori has two printers that use Direct Metal Laser Sintering (DMLS).

EOS operates in the polymer 3D printing market with Selective Laser Sintering(SLS) 3D printers, and in the metal industry with a range of Direct Metal Laser Sintering (DMLS) 3D printers.

GE Additive offers 3D printers originally from Arcam and Concept Laser. The Arcam printers use Electron Beam Melting (EBM). The Concept Laser systems operate with LaserCUSING technology, based on laser sintering of metals.

Renishaw offers four metal PBF systems. Its PBF is a form of laser melting.

SLM Solutions uses DMLS patented as Selective Laser Melting (SLM) on its range of additive systems. The 3D printers use multiple lasers for faster operation.

Trumpf has three printers with Laser Metal Fusion (LMF) technology (a process similar to DMLS). The company also offers two printers based on Laser Metal Deposition technologies.

The following vendors offer variations of powder bed fusion.

Australian manufacturer Aurora Labs uses an additive build method that can be categorized between powder bed fusion and direct energy deposition (DED) that it calls Multi-layer Concurrent Printing. It claims this technique speeds up the build process.

ExOne also offers a powder-based 3D printer, primarily working with sand for castings. It uses binders to build parts one layer at a time.

HP’s Metal Jet additive system includes a bed of powder, but it uses special chemical binders to build parts a layer at a time. It offers systems that work with polymers and metal materials.

After beginning with AM software, Velo3D recently launched its 3D printer Sapphire System that uses patented Intelligent Fusion technology, based on a powder bed.

Filed Under: FAQs

The Complete Guide to Laser Powder Bed Fusion in 3D Printing

Published on September 3, 2019 by Alexandrea P.

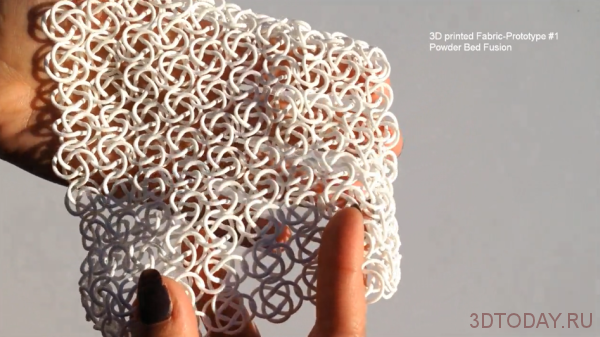

All technologies part of the Powder Bed Fusion (PBF) family use a build platform containing powder material to additively manufacture a part – the powder can be polymers or metals. It was during the 1990s that several companies began exploring Powder Bed Fusion (PBF) for metal: metal powder particles were melted using a heat source such as a laser or electron beam to form a more or less complex part, layer by layer. Today, we will focus on Laser Powder Bed Fusion (LPBF), which, as its name suggests, uses a laser to additively manufacture a metal part.

It was during the 1990s that several companies began exploring Powder Bed Fusion (PBF) for metal: metal powder particles were melted using a heat source such as a laser or electron beam to form a more or less complex part, layer by layer. Today, we will focus on Laser Powder Bed Fusion (LPBF), which, as its name suggests, uses a laser to additively manufacture a metal part.

In 1994, EOS patented its process called Direct Metal Laser Sintering (DMLS), while in 1995 the Fraunhofer Institute introduced the term SLM for Selective Laser Melting. The two techniques are similar, however to avoid any confusion we will use the term Laser Powder Bed Fusion (LPBF). The terms can seem confusing, DMLS uses the word sintering when in fact it works by melting. Similarly, PBF uses the word fusion, when you cannot melt a plastic, you can only sinter it. However, Selective Laser Sintering (SLS) is part of the PBF family.

Image via Fraunhofer ILT, Aachen, Germany

What you should remember is that the difference between sintering and melting is quite simple: melting involves moving from a solid to a liquid state thanks to the high-temperature of the heat source; sintering does not allow the material to reach its liquid state because the temperature of the heat source is not high enough. In the case of sintering metal, the metal particles are agglomerated together, but the result is a fairly weak part. To illustrate this point, let’s take the example of stacking apples: there will always be a gap between two fruits. The 3D printed parts will therefore have a low mechanical strength, unlike fusion (i.e. melting) where the material, because it reaches its liquid form, fills these holes.

In the case of sintering metal, the metal particles are agglomerated together, but the result is a fairly weak part. To illustrate this point, let’s take the example of stacking apples: there will always be a gap between two fruits. The 3D printed parts will therefore have a low mechanical strength, unlike fusion (i.e. melting) where the material, because it reaches its liquid form, fills these holes.

How does Laser Powder Bed Fusion work?

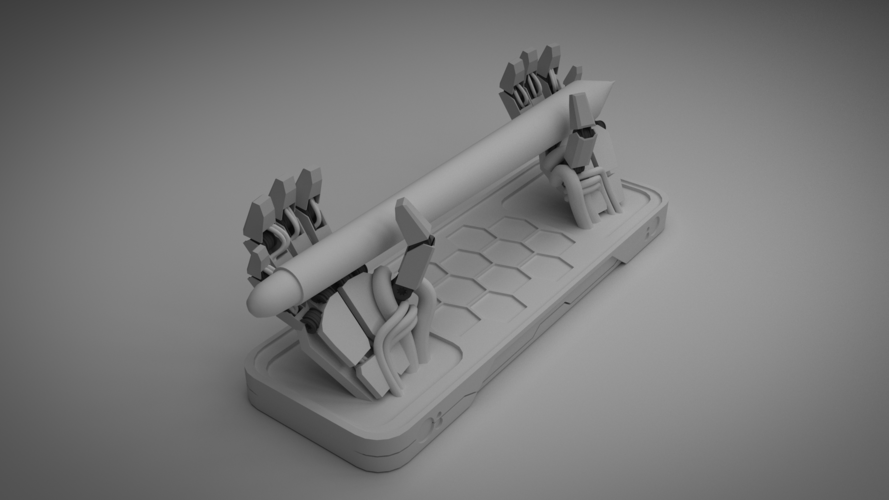

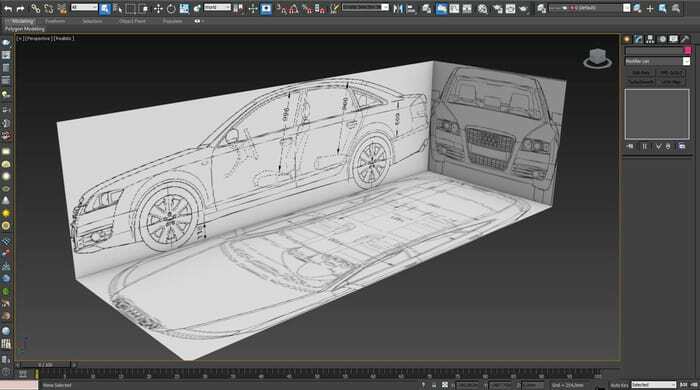

Like any 3D printing technique, the design of a part begins with the creation of the 3D model using CAD software. The part is then cut into a multitude of layers by a slicer – in this case, the thickness of a layer generally varies between 20 and 60 microns.

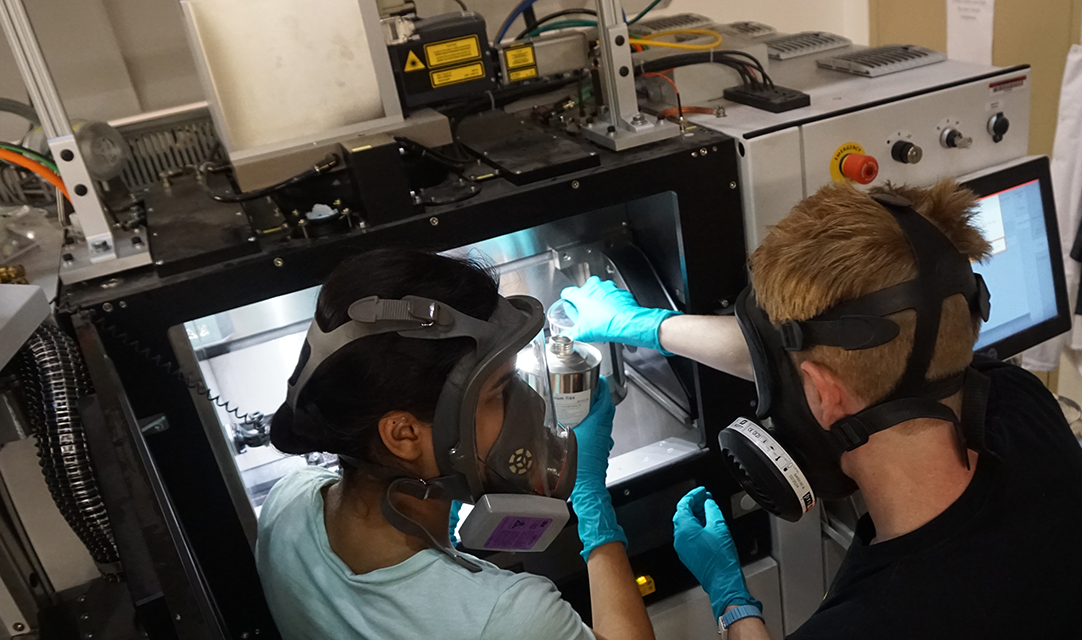

In order to start the printing process, the 3D printer fills its chamber with an inert gas and then heats it to the optimal printing temperature. A thin layer of powder is then applied to the build platform, according to the layer thickness previously defined by the software. The fiber optic laser (200/400 W) then scans the cross-section of the part, melting the metal particles together. When the layer is finished, the platform moves down, allowing another layer of powder to be added. The process is repeated until the final part is obtained.

The fiber optic laser (200/400 W) then scans the cross-section of the part, melting the metal particles together. When the layer is finished, the platform moves down, allowing another layer of powder to be added. The process is repeated until the final part is obtained.

The 3D printer must then be allowed to cool and the unmelted powder removed from the tray to see the printed part. The part is attached to the build plate thanks to printing supports; Unlike SLS technology, these supports are recommended because they reduce the warping and distortion phenomena observed at high temperatures. They are generally removed by cutting or machining methods or by wire electro-erosion. The parts can be heat treated to reduce residual stresses and improve mechanical properties. Further post-processing can involve CNC machining steps and polishing processes to offer a better surface quality.

Post-processing steps can be more or less important depending on the results you wish to achieve on your final part

Materials and Applications of Laser Powder Bed Fusion technology

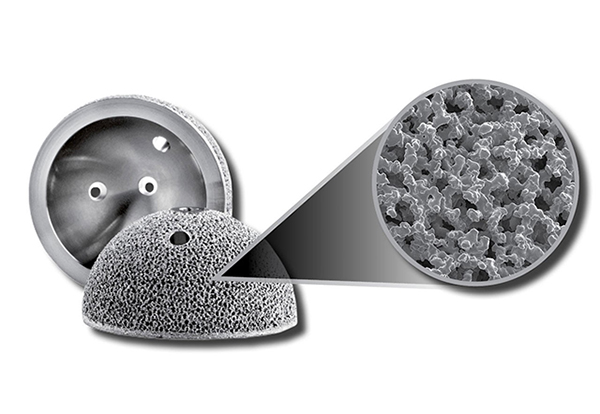

As you will have understood, LPBF uses metallic powders to design more or less complex parts. Metallic and alloy materials such as stainless steel, cobalt-chromium, aluminium, titanium and inconel are most often used. Some precious metals (gold, platinum, silver) are sometimes used, but almost exclusively in the jewellery sector. The strength of the parts obtained is comparable to that obtained by casting or machining techniques. LPBF is one of the few additive manufacturing technologies to be used in production.

Metallic and alloy materials such as stainless steel, cobalt-chromium, aluminium, titanium and inconel are most often used. Some precious metals (gold, platinum, silver) are sometimes used, but almost exclusively in the jewellery sector. The strength of the parts obtained is comparable to that obtained by casting or machining techniques. LPBF is one of the few additive manufacturing technologies to be used in production.

The aerospace, automotive and medical (especially dental) sectors are very fond of this technology. It offers a geometric complexity that is impossible to achieve using conventional manufacturing methods while reducing their final weight and the number of components to be assembled using techniques such as topology optimisation. This results in shorter production times and very resistant custom parts. However, metal 3D printers and metal powders are very expensive and do not allow the manufacture of very large parts.

A 3D printed metal part | Image via Mercedes-Benz

The Main Market Players

One of the technology pioneers is the German EOS with its EOS M range, which offers a complete production solution for any industrial company. The company was joined by 3D Systems in 2013 following the acquisition of the French company Phenix Systems, which specializes in the development of DMLS machines. Of course, the German company SLM Solutions, but also Trumpf, Renishaw and the Italian company Sisma are some important players. If you are looking for more manufacturers of LPBF 3D printers, have a look at our listing of the main market players of metal AM systems HERE.

The company was joined by 3D Systems in 2013 following the acquisition of the French company Phenix Systems, which specializes in the development of DMLS machines. Of course, the German company SLM Solutions, but also Trumpf, Renishaw and the Italian company Sisma are some important players. If you are looking for more manufacturers of LPBF 3D printers, have a look at our listing of the main market players of metal AM systems HERE.

Was this guide useful? Let us know in a comment below or on our Facebook and Twitter pages! Sign up for our free weekly Newsletter, all the latest news in 3D printing straight to your inbox!

Machine tool Powder bed and inkjet head 3D printing Manufacturing Selective laser melting, honeycomb technology, metal, 3D Printing, selective Laser Melting png

Machine tool Powder bed and inkjet head 3D printing Manufacturing Selective laser melting, honeycomb technology, metal, 3D printing, selective laser melting pngtags

- metal,

- 3D printing,

- selective laser melting,

- seal,

- printer,

- bed powder and inkjet head 3d printing,

- production,

- machine,

- laser scanning,

- laser cut,

- laser,

- dmg Mori Aktiengesellschaft,

- additive Production,

- honeycomb technology,

- png,

- transparent,

- free download

About this PNG

- Image size

- 630x472px nine0043 File size

- 140.

49KB

49KB - MIME type

- Image/png

resize PNG

width(px)

height(px)

License

Non-Commercial Use, DMCA Contact Us

- Inkjet printing press Large-format printer Printing press, printer, electronics, digital, banner png 3908x2620px 1.96MB

- Laser cutting Laser engraving Computer CNC machine, textile, engraving, machine png 676x653px 290.15KB

- Paper 3D printer Xerox Printer, printer, electronics, computer, business png 1024x580px 454.4KB

- Laser cutting Laser engraving Fiber laser, others, angle, furniture, laser png 700x505px 317.4KB

- Machine Heidelberger Druckmaschinen Printing press Laser cutting, printer, electronics, banner, digital Printing png 3264x2448px 2.43MB

- Printer paper CMYK color model, Printer, supplies, electronics, happy Birthday Vector Images png 2430x2422px 291.84KB

- Laser cutting Laser engraving 3D printing, others, angle, rectangle, 3D Printing png 700x700px 19.87KB

- Hewlett-Packard Laser printing Printer HP LaserJet Pro P1102, hewlett-packard, electronics, computer, monochrome png 640x481px 281.27KB

- Hewlett Packard Enterprise Inkjet printing HP Slate 500 Laptop Laser printing, HP printers, angle, electronics, computer png 790x856px 635.58KB

- Large-format printing printer Dye-sublimation printer MIMAKI ENGINEERING CO., LTD., others, ink, lithography, printer png 1186x1023px 369.19KB

- Rapid prototyping 3D printing Prototype Computer Icons, printing, rectangle, black, business png 900x900px 11.85KB

- Machine tool Laser cutting Laser processing, plotter, engraving, computer Numerical Control, machine png 1500x1500px 1.32MB

- photocopier machine business stationery copier, copier, angle, people, canon png 1000x1000px 299.

65KB

65KB - Selective laser sintering machine 3D printing Selective laser melting, printer, electronics, public Relations, industry png 1200x748px 266.11KB nine0006

- Hewlett-Packard Multifunction Printer HP LaserJet Pro MFP M227 Laser printing, Multifunction printer, canon, electronic Device, fax png 1000x750px 166.47KB

- Hewlett Packard Enterprise printer Laser printing Toner cartridge HP LaserJet, printer, white, electronics, ink Cartridge png 2898x2280px 1.16MB

- Laser cutting Laser engraving 3D printing, Laser cutting, electronics, engraving, electronic Device png 802x401px 204.53KB nine0006

- Laser cutting Fiber Laser Laser engraving, cutting machine, engraving, metal, metal png 900x600px 357.18KB

- Label printer Barcode printer Thermal printing, printer, electronics, label, retail png 755x756px 471.57KB

- Laser cutting Computer Icons Metal, laser, angle, rectangle, service png 1200x1200px 54.17KB

- Large-format printer Offset printing Vinyl banners Digital printing, printer, ink, electronics, digital png 1024x625px 430.24KB nine0006

- Metal, Laser Cutting, Computer Numerical Control, Machine Tool, Fiber Laser, CNC Router, Sheet Metal, Laser Engraving, Laser Cutting, Computer Numerical Control, Computer Monitor Accessory png 1067x497px 235.

22KB

22KB - Dot-matrix printing Epson dot-matrix printer, printer, electronics, computer, electronic Device png 1130x1188px 306.42KB

- Laser cutting Machining, Laser cutting, symmetry, monochrome, steel png 640x640px 161.21KB nine0006

- Laser cutting 3D printing Industry, technology, electronics, text, service png 512x512px 4.92KB

- Xerox multi-function printer copier Paper, printer, angle, electronics, ink Cartridge png 469x500px 154.71KB

- Multi-function printer Hewlett Packard Enterprise HP LaserJet HP Deskjet, HP Printers, electronics, black, electronic Device png 742x742px 204.

63KB

63KB - Multi-function printer copier Konica Minolta scanner, printer, electronics, electronic Device, fax png 600x840px 477.22KB nine0006

- Barcode printer Label printer Zebra Technologies Printing, zebra, electronics, animals, label png 945x945px 205.87KB

- Machine tool Laser cutting Laser engraving, technology, angle, electronics, material png 1498x1497px 698.22KB

- 3D printing Selective laser sintering Selective laser melting Material, powders, angle, electronics, material png 960x500px 90.64KB

- 3D printing Metal Selective melting laser printer, printer, electronics, material, metal png 800x633px 488.

57KB nine0006

57KB nine0006 - 3D printing filament 3D Kreator Business, printer, 3D Computer Graphics, people, small Appliance png 662x668px 361.91KB

- 3D printing Metal 3D Systems Manufacturing, metal surface, steel, material, metal png 940x940px 294.63KB

- Textile Folding Machine Woven fabric, textile, office, fabric png 700x611px 414.62KB

- Paper printer Laser printing Toner, Cartoon printer, cartoon Character, supplies, ink Cartridge png 2252x1574px 646.74KB nine0006

- 3D printing Stereolithography Formlabs Fused filament fabrication, printer, electronics, 3D Computer Graphics, orange png 1200x800px 389.

91KB

91KB - 3D printing 3D modeling Printer Paper, printer, blue, angle, electronics png 800x600px 7.27KB

- Laser printing Printer driver Multi-function printer, printer, computer Network, electronics, monochrome png 619x473px 192.26KB

- Laser engraving Laser cutting Epilog Laser, others, engraving, business, laser png 800x626px 375.51KB nine0006

- Multi-function printer Small office/home office Inkjet printing, SCAN, electronics, canon, office png 3000x2823px 2.57MB

- Robot welding Robot welding Machine KUKA, address, electronics, metal, industry png 1000x1200px 1.

58MB

58MB - Canon paper Printer driver Inkjet printing, Inkjet Printers, computer Network, ink, electronics png 3100x2300px 845.09KB

- Printer Laser printing Toner refill Toner cartridge, printer, ink, electronics, ink Cartridge png 600x600px nineteen7.65KB

- Laser engraving Laser cutting, laser, miscellaneous, angle, laser png 1244x1052px 736.67KB

- Manufacturing Support Implementation Technical Support Computer project, others, angle, service, computer png 591x591px 38.79KB

- 3D Circle, 3D Printing, Manufacturing, Digital Light Processing, Stereolithography, Selective Laser Melting, Powder Coat And Inkjet Head 3D Printing, Manufacturing, 3d Computer Graphics, 3d Printing, Area png 1728x1728px nine0.

22KB

22KB - Laser printing Ricoh paper Printer copier, Monochrome laser printer copier MFP, electronics, monochrome, printer png 500x500px 70.47KB

- Machine tool Laser cutting Fiber laser Laser engraving, Laser cutter, machine Shop, automotive Exterior, machine png 750x392px 241.5KB

- Machine tool Laser cutting Laser engraving, others, miscellaneous, textile, machine png 2477x1859px 883.13KB

complete guide to quick production

Contents

- 1 What is rapid production? Definition

- 2 A Brief History of Rapid Manufacturing

- 3 How does Rapid Manufacturing work?

- 4 Fast Production Types

- 4.1 1. Fusion Powder Bed

- 4.

2 2. Material Blasting

2 2. Material Blasting - 4.3 3. Photopolymerization of VAT.

- 4.4 4. Sheet lamination.

- 4.5 5. Material extrusion

- 4.6 6. Directed energy deposition

- 4.7 7. Binder spraying

- 5 Which materials can be processed with rapid production?

- 6 Benefits of rapid production

- 6.1 1. Reduces development time

- 6.2 2. Reduces production cost.

- 6.3 3. Quality products and parts

- 6.4 4. Easy to make changes.

- 6.5 5. Minimum loss of resources

- 7 Roche Industry: reliable and fast manufacturing services

What is fast manufacturing? Definition

Fast production can be defined in different ways. We can define it as a set of development processes that are designed not to reduce development time and at the same time reduce product development time.

Another way to define fast manufacturing is the use of 3D software, which is linked to a set of equipment to speed up the manufacturing process. This explains the name "Rapid" as the whole process is faster than conventional production. nine0059

This explains the name "Rapid" as the whole process is faster than conventional production. nine0059

Alternatively, rapid prototyping can be thought of as methods of making solid objects by transferring requirements sequentially from one step to the next. This method is used with the aim of using speed while minimizing the cost of production.

A Brief History of Rapid Manufacturing

Rapid Manufacturing is a relatively new technology in the manufacturing world. It is derived from 3D printing and rapid prototyping processes.

In the early days, 3D printers were introduced to reduce production time. They ensure that the time span between design and prototyping is much shorter. nine0059

3D printing and rapid manufacturing technologies were tested in the 1980s. The first fast manufacturing patent was filed in 1980. Although it encountered some resistance, it was not until 1986 that this production method became commercial.

Rapid production has improved a lot in recent years. Now it is used for the manufacture of complex products and components. It is also applicable to a wide range of industries.

Now it is used for the manufacture of complex products and components. It is also applicable to a wide range of industries.

How does rapid production work? nine0173

When learning the basics of fast manufacturing, it's important to understand how it works.

Like any other type of 3D printing, rapid production involves the combination of a CAD system and a machine. The two work together to reach their desired goal.

First, a 3D CAD design of the product is created using computer software. To create a design, various programs or programs are used, among which Autocad and ProEngineer are the most common. There are many alternative programs that can help. nine0059

The 3D design is then cut into layers of different thicknesses according to your requirements. The profiles are then saved in a specific format, which in most cases is STL machine data.

Another computer program converts STL data into machine data. This information is then transferred to a running machine where fabrication techniques and other metal working methods are performed.

This process is repeated several times to create each layer of the machine or product. nine0059

The last step of quick manufacturing entails the removal of the machined part of the machine. Tilting and polishing can be done to improve the appearance of the machine part.

Here are some of the key steps that take place in the rapid manufacturing process:

Molding material from liquid to solid : During the casting process, the material changes from liquid to solid. The liquid is poured into the die and as it cools it takes on the shape of the preform. nine0059

Then the newly formed object will be extracted from the form.

Rolled, stamped and forged : External forces and working techniques are applied to the material. These actions are designed to change the design, shape, and even dimensions of the product.

These actions are designed to change the design, shape, and even dimensions of the product.

Metalworking : Material cut to desired product characteristics. Various metal cutting tools such as grinders and lathes are used to perform this task. The cutting process is precise as it is controlled by the computer. nine0059

Joining parts : Shaping and forming methods are used to weld machined parts. There are also programs that are used to manage this task.

Rapid production types

Rapid production is not a single process. There are seven different categories of this type of production, the difference is to take care of the different needs of the products.

These are seven types of fast production:

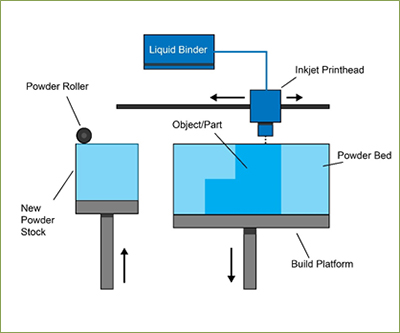

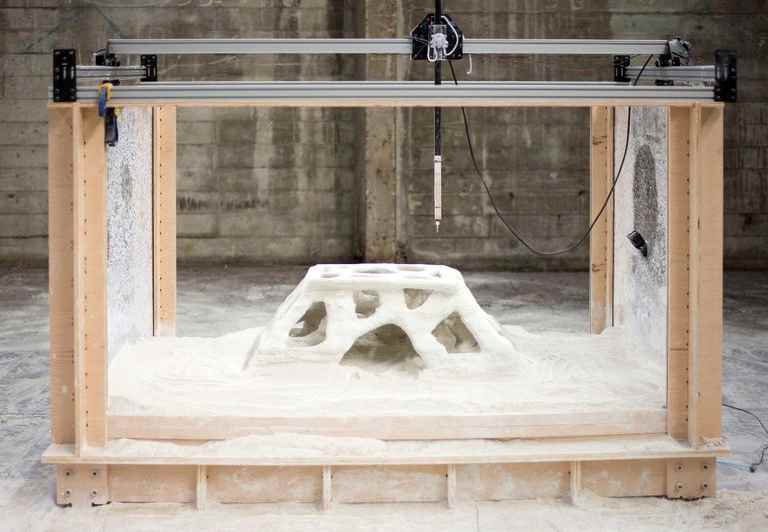

1. Fusion Powder Bed

There are various processes covered by powder bed fusion technology. These are direct metal laser sintering (DMLS), selective laser melting (SLM), selective laser sintering (SLS), and electron beam melting (EBM).

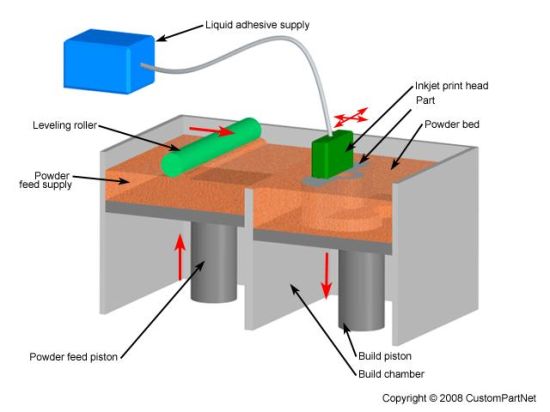

Powder Bed Fusion uses an electronic or laser beam to cut and reshape material. All PBF metal processing processes involve the application of powder to previous layers. | A roller or blade is used to distribute the powder. nine0059

There are several reasons why powder bed fusion is the preferred fast manufacturing method. One of them is that it is suitable for different types of prototypes. This method is also cheaper than the fastest fabrication methods.

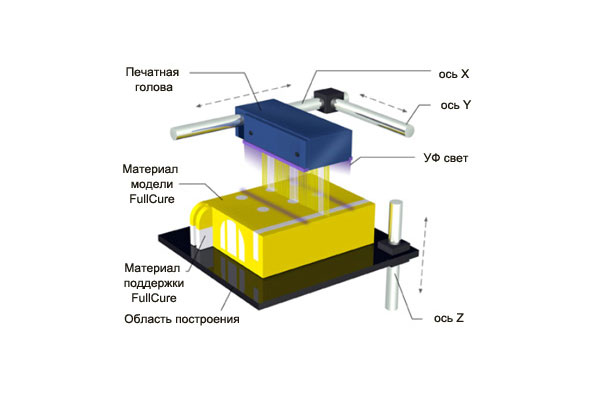

2. Material blasting

This rapid fabrication method can be compared to creating an object or product in 2D.

Hot metal material is poured onto a platform or building surface. Then it will harden, forming a product consisting of several layers. Then these layers will be strengthened with ultraviolet rays. nine0059

One of the main advantages of this method is the high accuracy it shows. You can also apply multiple layers of material to an object. This method is mainly used in the production of plastics and polymers.

3. Photopolymerization of VAT.

This is a form of fast manufacturing process that uses vat resin with liquid resin to create a model. Models of this type still use different layers, and UV radiation plays a major role in the curing of the resin. nine0059

This method differs from powder methods as it does not have structural support during the construction phases. Resins are cured either by photopolymerization or by exposure to UV light.

One of the key advantages is high accuracy. It is also a time saving method. The method is ideal for the manufacture of resins and polymers.

4. Sheet lamination.

In the context of fast manufacturing, sheet lamination is used to refer to a method of processing laminated objects or ultrasonic fast manufacturing. Both methods use sheets and tapes. nine0059

For ultrasonic production, metal strips or sheets are melted in an internal welding process. For the manufacture of laminated products, layers of metals are joined together with an adhesive material.

Like other rapid production methods, sheet lamination involves sequential processing of each layer. This means that each layer is processed before moving on to the next layer.

Sheet lamination can be used on both metals and plastics. It is also used in the manufacture of paper. nine0059

5. Extrusion of material

This is considered the most affordable method of rapid production. It is typically used for base builds where material is drawn through a nozzle, heated, and then deposited in layers.

Nozzle is designed for horizontal movement while platform moves up and down to receive material. The pressure at which the material exits the nozzle must be kept constant to keep the layers uniform.

This method is used for a variety of materials, including plastics, ABS, and even some metals.

6. Directed energy deposition

This method is commonly known as laser-engineered shaping, while others call it 3D laser cladding. This method is used when you want to add a new material to an already existing product or object.

In this process, the material nozzle can move freely in all axes. The material may be in the form of a powder or a molten form. nine0059

As a fast production method, material extrusion cannot be used for plastics, polymers and ceramics. It is only suitable for some metals such as titanium.

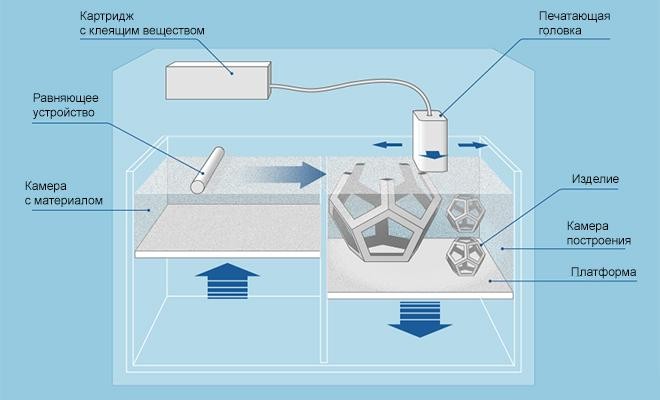

7. Binder Spray

It's just another word for 3D printing. Binder spraying is a popular fast manufacturing method for several reasons. It is versatile, durable and very effective.

This method uses both liquid and powder forms. The binder, which is in liquid form, will act as a glue, holding the layers of powder together. The printhead is designed to move in all axes of the design. nine0059

Because it is a versatile production method, binder jet spraying is used to produce various types of materials. Among them are metals, glass, ceramics, plastics, polymers and others.

Which materials can be processed with rapid production?

Let's say you're planning to use rapid manufacturing for your products. What types of materials are suitable for this process?

What types of materials are suitable for this process?

Here is a list of materials or media that can be processed using the rapid production method. nine0059

Metals: You can have a wide range of metals that can be processed using the rapid production method. The most common metals include, among others, steel, cobalt, chromium, aluminum, titanium.

Metals processed with this manufacturing method can be used for their respective applications.

Ceramics such as silica, porcelain and carbide

Resins such as ABS, polycarbonate (PC), epoxy, polyamide and others. nine0059

If you are not sure whether metal or plastic is suitable for fast production, consider asking the fast production experts. They will help you evaluate the viability of this method in your material.

The benefits of fast manufacturing

As a manufacturer, should you consider using fast manufacturing for your products?

Over the years, rapid production has proven to be a viable production method. Here are some of the benefits manufacturers can get from using it:

Here are some of the benefits manufacturers can get from using it:

1. Reduces development time

Manufacturers choose the fast manufacturing method because it saves time. As the name suggests, this production method focuses on mass production within a limited time frame.

Instead of waiting months for your projects to be completed, you will receive finished parts and components within days.

You will also save time as parts are produced by other companies. This means that activities at your workplace will continue without interruption. nine0059

2. Reduces production cost.

There is no doubt that rapid production is a cost-effective method for manufacturing various parts and components. You will be able to produce parts without high costs.

This can be achieved in many ways. For example, you do not have to buy equipment and tools for fast production. The fast food company already has the equipment to work with.

The ability to produce large volumes of products in a short time allows you to reduce the cost of production. nine0059

nine0059

3. Quality products and spare parts

Despite the maximum speed, fast production is characterized by high precision. The material layers are exactly aligned with each other. This means that the product of the process is likely to have a minimum of flaws.

4. Easy to change.

Fast production is very flexible. This makes it possible to change the characteristics of the product without any adverse effects on the entire production process.

Implementing appropriate changes to most production methods can be a challenge. You may have to spend more to make a small change.

5. Minimal wastage of resources

As we have seen, various methods of rapid production are quite effective when it comes to the use of materials. They ensure that no material is wasted during the entire process.

In addition, this method does not waste other resources that are used in the production process. nine0059

Roche Industry: reliable and fast manufacturing services

Would you like to improve the quality of your products? Or, if your market share has increased, it's time to switch to a fast production method.