What does the 3d printer do

3D Printing: What It Is, How It Works and Examples

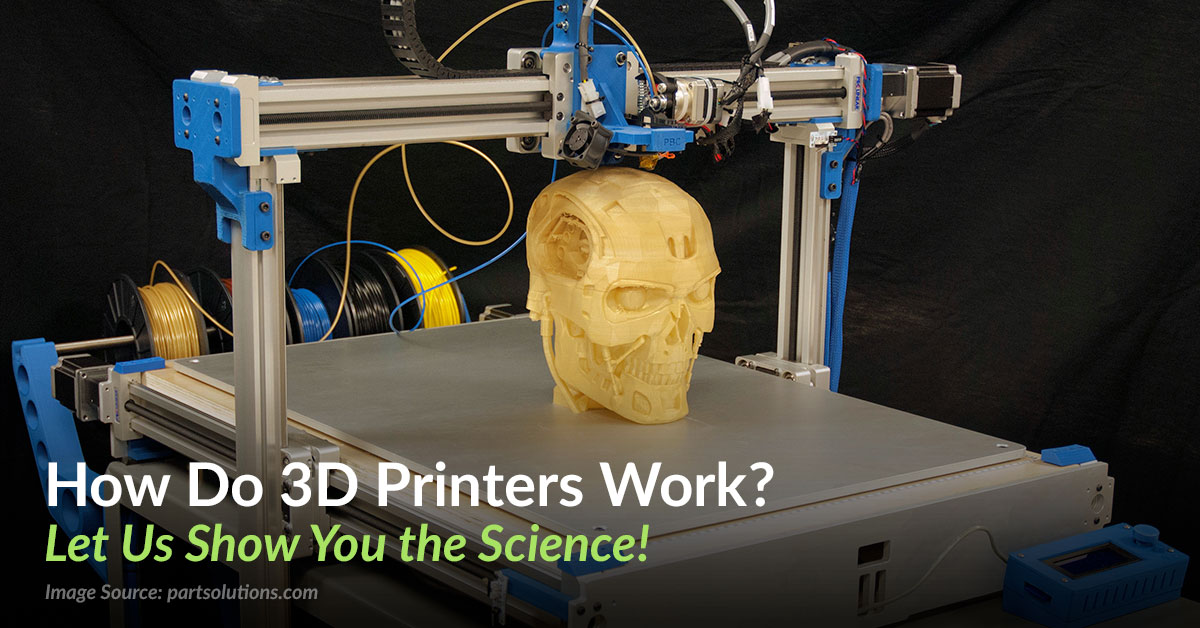

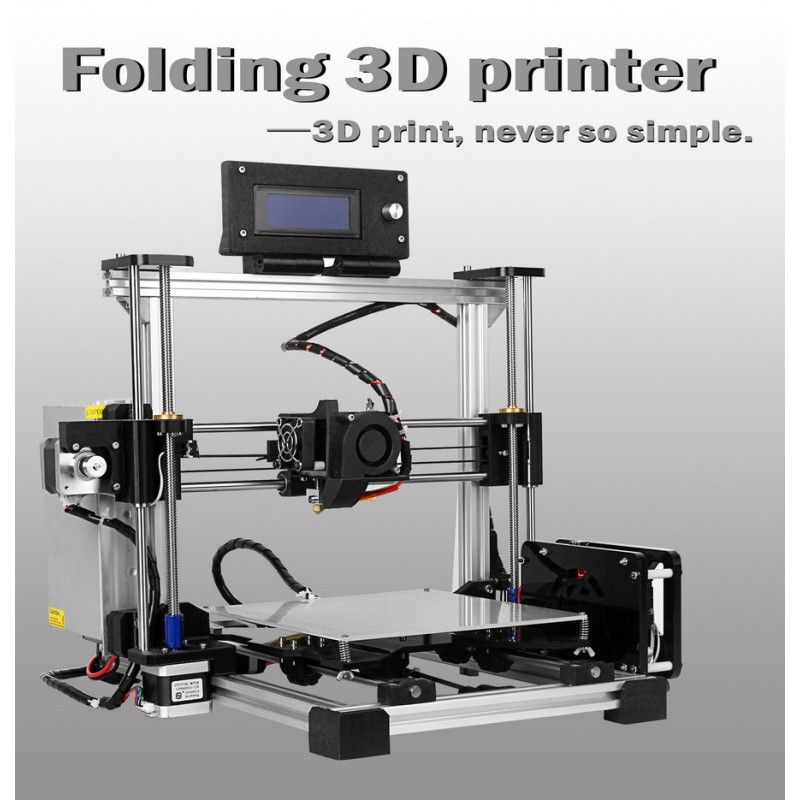

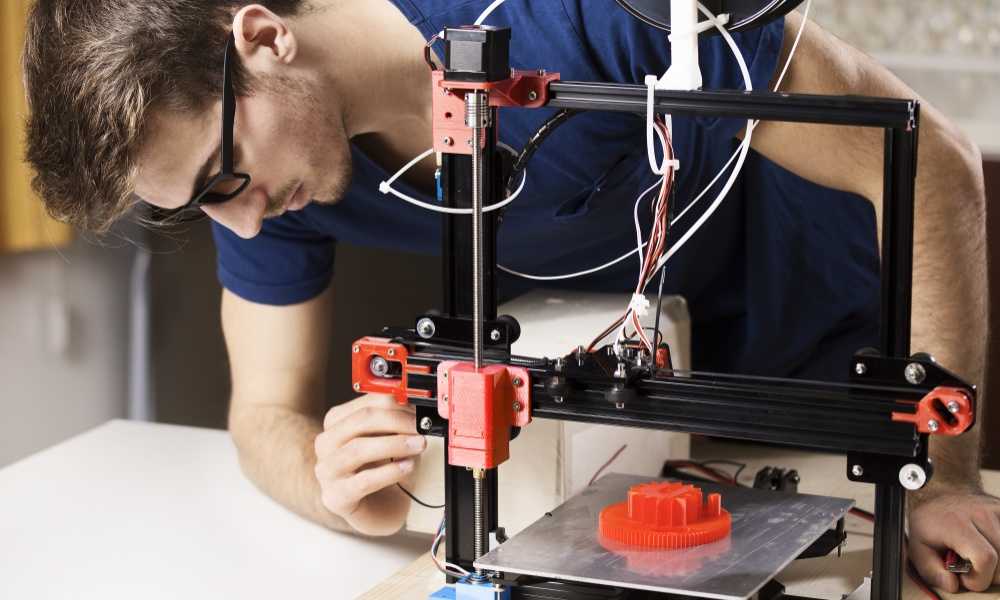

3D printers might seem like they're right out of a science fiction movie, but they're proving to be useful in a variety of industries. | Image: ShutterstockHow Do 3D Printers Work?

3D printing is part of the additive manufacturing family and uses similar methods to a traditional inkjet printer — albeit in 3D. Additive manufacturing describes the process of creating something in layers, adding material continuously until the final design is complete. This term most often refers to molding and 3D printing.

It takes a combination of top-of-the-line software, powder-like materials and precision tools to create a three-dimensional object from scratch. Below are a few of the main steps 3D printers take to bring ideas to life.

How Does a 3D Printer Work?

3D printers are related to additive manufacturing. 3D printers use computer-aided design to understand a design. When a design is ready, a material that can be dispensed through a hot nozzle or precision tool is printed layer by layer to create a three-dimensional object from scratch.

3D Modeling Software

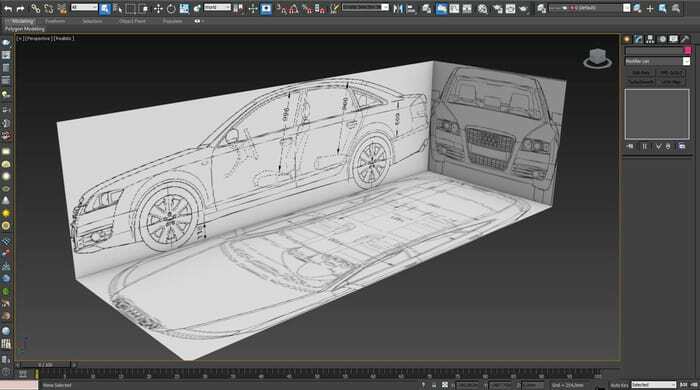

The first step of any 3D printing process is 3D modeling. To maximize precision — and because 3D printers can’t magically guess what you want to print — all objects have to be designed in a 3D modeling software. Some designs are too intricate and detailed for traditional manufacturing methods. That’s where CAD software comes in.

Modeling allows printers to customize their product down to the tiniest detail. The 3D modeling software’s ability to allow for precision designs is why 3D printing is being hailed as a true game changer in many industries. This modeling software is especially important to an industry, like dentistry, where labs are using 3D software to design teeth aligners that precisely fit to the individual. It’s also vital to the space industry, where they use the software to design some of the most intricate parts of a rocketship.

3D PRINTERS USE MODELING AND SLICING SOFTWARE TO GUIDE THE PRINTER IN CREATING EACH OBJECT. Video: Digital Trends

Slicing the Model

Once a model is created, it’s time to “slice” it. Since 3D printers cannot conceptualize the concept of three dimensions, like humans, engineers need to slice the model into layers in order for the printer to create the final product.

Slicing software takes scans of each layer of a model and will tell the printer how to move in order to recreate that layer. Slicers also tell 3D printers where to “fill” a model. This fill gives a 3D printed object internal lattices and columns that help shape and strengthen the object. Once the model is sliced, it’s sent off to the 3D printer for the actual printing process.

The 3D Printing Process

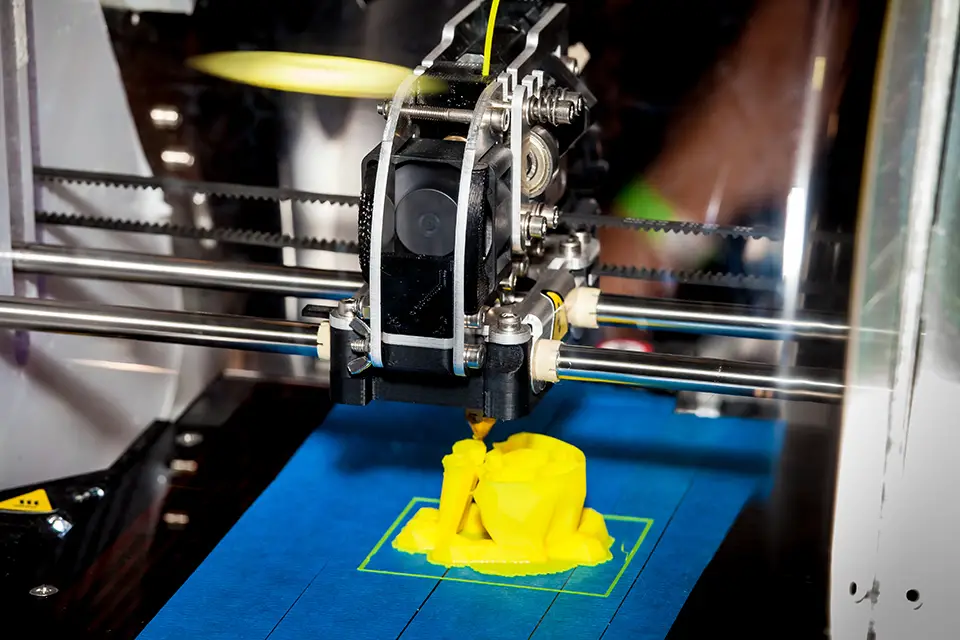

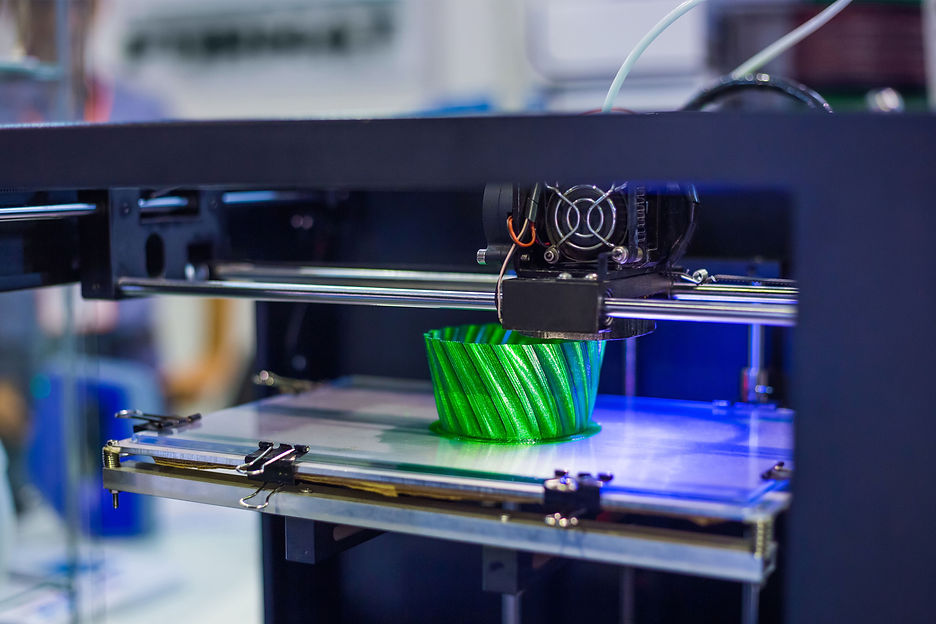

When the modeling and slicing of a 3D object is completed, it’s time for the 3D printer to finally take over. The printer acts generally the same as a traditional inkjet printer in the direct 3D printing process, where a nozzle moves back and forth while dispensing a wax or plastic-like polymer layer-by-layer, waiting for that layer to dry, then adding the next level. It essentially adds hundreds or thousands of 2D prints on top of one another to make a three-dimensional object.

The printer acts generally the same as a traditional inkjet printer in the direct 3D printing process, where a nozzle moves back and forth while dispensing a wax or plastic-like polymer layer-by-layer, waiting for that layer to dry, then adding the next level. It essentially adds hundreds or thousands of 2D prints on top of one another to make a three-dimensional object.

3D Printing Materials

There are a variety of different materials that a printer uses in order to recreate an object to the best of its abilities. Here are some examples:

Acrylonitrile Butadiene Styrene (ABS)

Plastic material that is easy to shape and tough to break. The same material that LEGOs are made out of.

Carbon Fiber Filaments

Carbon fiber is used to create objects that need to be strong, but also extremely lightweight.

Conductive Filaments

These printable materials are still in the experimental stage and can be used for printing electric circuits without the need for wires. This is a useful material for wearable technology.

This is a useful material for wearable technology.

Flexible Filaments

Flexible filaments produce prints that are bendable, yet tough. These materials can be used to print anything from wristwatches to phone covers.

Metal Filament

Metal filaments are made of finely ground metals and polymer glue. They can come in steel, brass, bronze and copper in order to get the true look and feel of a metal object.

Wood Filament

These filaments contain finely ground wood powder mixed with polymer glue. These are obviously used to print wooden-looking objects and can look like a lighter or darker wood depending on the temperature of the printer.

The 3D printing process takes anywhere from a few hours for really simple prints, like a box or a ball, to days or weeks for much larger detailed projects, like a full-sized home.

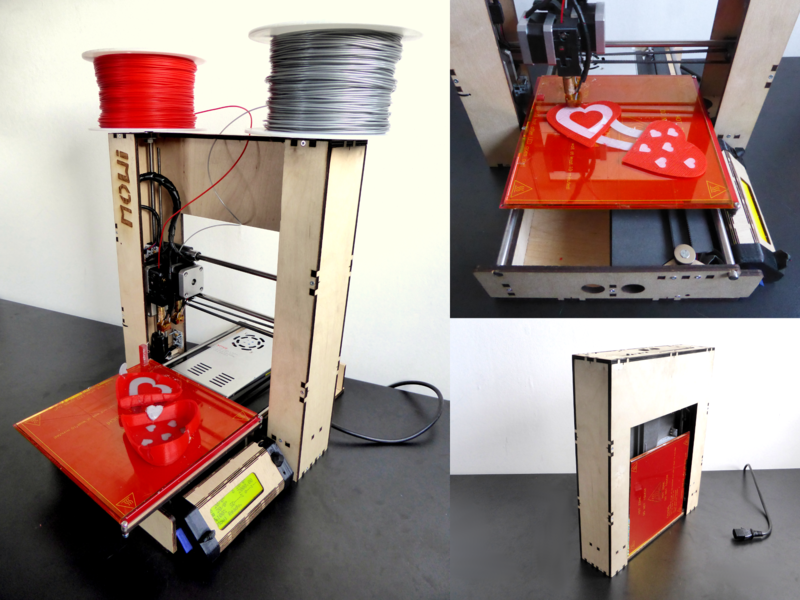

How Much Do 3D Printers Cost?

The cost of 3D printers vary based on the size, specialty and use. The cheapest 3D printers, for entry level hobbyists, typically range from $100 to $500. More advanced models can range between $300 and $5,000. Industrial 3D printers can cost up to $100,000.

More advanced models can range between $300 and $5,000. Industrial 3D printers can cost up to $100,000.

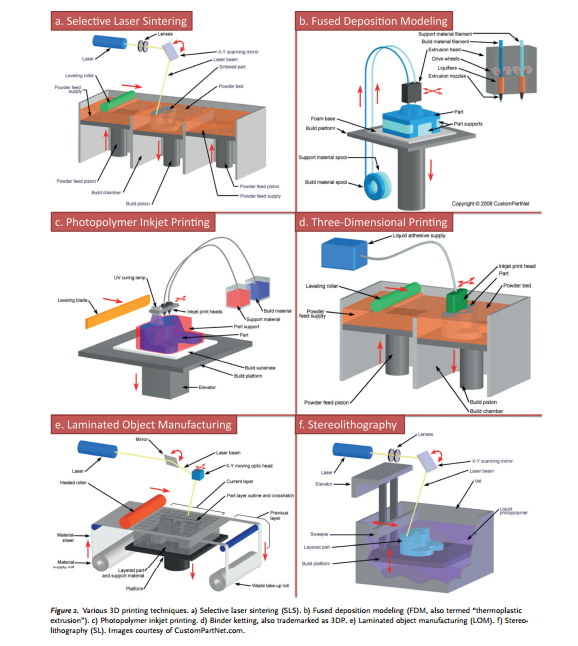

3D Printing Processes and Techniques

here are also different types of 3D printers depending on the size, detail and scope of a project. Each different type of printer will vary slightly on how an object gets printed.

Fused Deposition Modeling (FDM)

FDM is probably the most widely used form of 3D printing. It’s incredibly useful for manufacturing prototypes and models with plastic.

Stereolithography (SLA) Technology

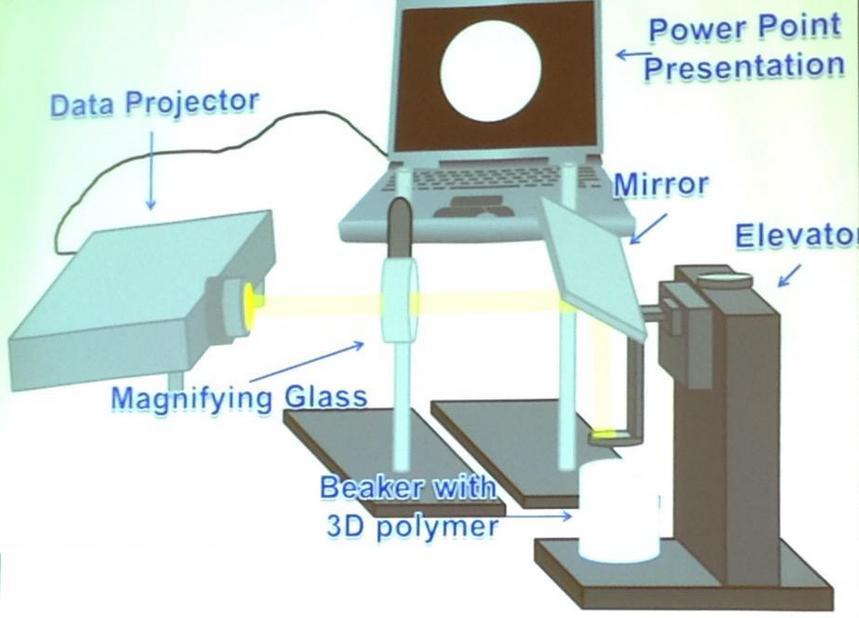

SLA is a fast prototyping printing type that is best suited for printing in intricate detail. The printer uses an ultraviolet laser to craft the objects within hours.

Digital Light Processing (DLP)

DLP is one of the oldest forms of 3D printing. DLP uses lamps to produce prints at higher speeds than SLA printing because the layers dry in seconds.

Continuous Liquid Interface Production (CLIP)

CLIP is amongst the faster processes that use Vat Photopolymerisation. The CLIP process utilizes Digital Light Synthesis technology to project a sequence of UV images across a cross-section of a 3D printed part, resulting in a precisely controlled curing process. The part is then baked in a thermal bath or oven, causing several chemical reactions that allow the part to harden.

The CLIP process utilizes Digital Light Synthesis technology to project a sequence of UV images across a cross-section of a 3D printed part, resulting in a precisely controlled curing process. The part is then baked in a thermal bath or oven, causing several chemical reactions that allow the part to harden.

Material Jetting

Material Jetting applies droplets of material through a small diameter nozzle layer-by-layer to build a platform, which becomes hardened by UV light.

Binder Jetting

Binder Jetting utilizes a powder base material layered evenly along with a liquid binder, which is applied through jet nozzles to act as an adhesive for the powder particles.

Fused Deposition Modeling (FDM)

FDM, also known as Fused Filament Fabrication (FFF), works by unwinding a plastic filament from a spool and flowing through a heated nozzle in horizontal and vertical directions, forming the object immediately as the melted material hardens.

Selective Laser Sintering (SLS)

A form of Powder Bed Fusion, SLS fuses small particles of powder together by use of a high-power laser to create a three-dimensional shape. The laser scans each layer on a powder bed and selectively fuses them, then lowering the powder bed by one thickness and repeating the process through completion.

The laser scans each layer on a powder bed and selectively fuses them, then lowering the powder bed by one thickness and repeating the process through completion.

Multi-Jet Fusion (MJF)

Another form of Powder Bed Fusion, MJF uses a sweeping arm to deposit powder and an inkjet-equipped arm to apply binder selectively on top. Next, a detailing agent is applied around the detailing agent for precision. Finally, thermal energy is applied to cause a chemical reaction. Direct Metal Laser Sintering (DMLS) also utilizes this same process but with metal powder specifically.

Sheet Lamination

Sheet Lamination binds material in sheets through external force and welds them together through layered ultrasonic welding. The sheets are then milled in a CNC machine to form the object’s shape.

Directed Energy Deposition

Directed Energy Deposition is common in the metal industry and operates by a 3D printing apparatus attached to a multi-axis robotic arm with a nozzle for applying metal powder. The powder is applied to a surface and energy source, which then melts the material to form a solid object.

The powder is applied to a surface and energy source, which then melts the material to form a solid object.

How Do 3D Printers Work? Plus, How 3D Printing Is Being Used Now

Every editorial product is independently selected, though we may be compensated or receive an affiliate commission if you buy something through our links. Ratings and prices are accurate and items are in stock as of time of publication.

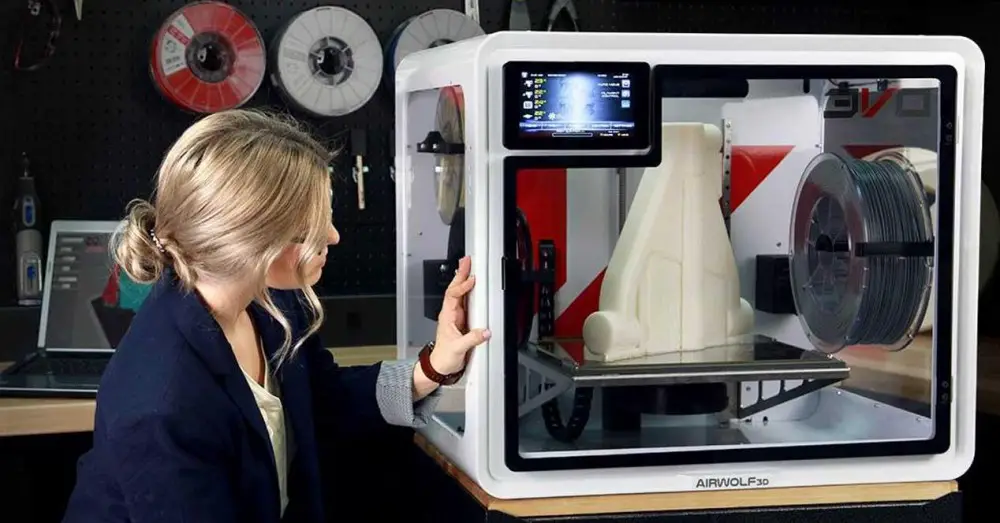

Imagine being able to use a home printer to create your own decor, musical instruments or cameras. Or what if manufacturers could print customizable car parts, or doctors didn’t have to worry about donor lists and could simply print the organs their patients needed? This and so much more is possible with 3D printing—and it’s happening now. But how do 3D printers work, and can anyone use them?

While the mechanisms may be complicated, the technology is becoming more affordable and accessible, and it’s surprisingly eco-friendly. Neil Gershenfeld, director of MIT’s Center for Bits and Atoms, says that there’s a “maker movement” happening right now. “If you asked the average person if they want access to computer-controlled manufacturing tools, they would probably shrug,” he says. “But if you ask if you want to be able to make custom furniture in your house and design toys for your children? That is an entirely new world of possibility.”

“If you asked the average person if they want access to computer-controlled manufacturing tools, they would probably shrug,” he says. “But if you ask if you want to be able to make custom furniture in your house and design toys for your children? That is an entirely new world of possibility.”

The 3D printing market is expected to triple to nearly $45 billion globally by 2026, and the Biden administration is touting 3D printing, or additive manufacturing, as a way to address supply chain shortages and help American families. “3D printing technology is incredible,” President Biden said in May 2022. “It can reduce parts lead times by as much as 90% and slash material costs by 90% and cut energy use in half. That all helps to lower the costs of making goods here in America.”

How, exactly? Here’s what you need to know about 3D printing—from how it’s currently being used with real-life robots to how it relates to the future of recycling and sustainable living.

On This Page

What is a 3D printer?

kynny/Getty Images

In the end, 3D printers are literally just printers. But instead of printing words on paper, they print 3D objects, layer by layer, and can make them out of everything from carbon fiber and powders to plastic and metal. They can also combine different materials in their production—for example, metal objects that have plastic components, such as wind turbine blades and engine parts—eliminating the need for multiple machines (and workers) to produce an object. This can ultimately lower costs for companies, collapse the time frame to create a product and eliminate waste.

But instead of printing words on paper, they print 3D objects, layer by layer, and can make them out of everything from carbon fiber and powders to plastic and metal. They can also combine different materials in their production—for example, metal objects that have plastic components, such as wind turbine blades and engine parts—eliminating the need for multiple machines (and workers) to produce an object. This can ultimately lower costs for companies, collapse the time frame to create a product and eliminate waste.

And 3D printers aren’t just relegated to factory floors. Consumers can also make good use out of them at home. “It’s exciting because it places manufacturing into the hands of the user,” says David Bourell, a professor of mechanical engineering and materials science and engineering at the University of Texas at Austin. “By way of analogy, many years ago, taking a photograph required a professional photographer. As photography advanced, people could take photographs themselves, which exploded photographic advances. [Here], a user can create and build without involving anyone else, which nurtures innovation and creativity.”

[Here], a user can create and build without involving anyone else, which nurtures innovation and creativity.”

When was 3D printing invented?

As a concept, 3D printing has been around since 1945. That’s when sci-fi writer Murray Leinster published his short story “Things Pass By,” which described a machine with a moving arm that could turn drawings into 3D objects created out of melted plastic. The Teletype Corporation, which invented inkjet printers in the ’60s, experimented with primitive 3D printers utilizing melted wax in 1971, but it wasn’t until the 1980s that the first actual 3D printer was created.

Physicist Charles Hull came up with the idea in 1983, when using UV light to harden coatings on a tabletop, and patented the technology in 1986. At the time, he referred to the process as “stereolithography.” Meant to be used in research-and-development labs and manufacturing plants, it grew out of a general frustration with slow production times and the need for small parts in new designs.

Hull went on to start a company called 3D Systems and expanded his patents to include non-liquids. Carmakers, hospitals and aerospace companies expressed immediate interest in the promise of this invention. In 2014, Hull was inducted into the National Inventors Hall of Fame.

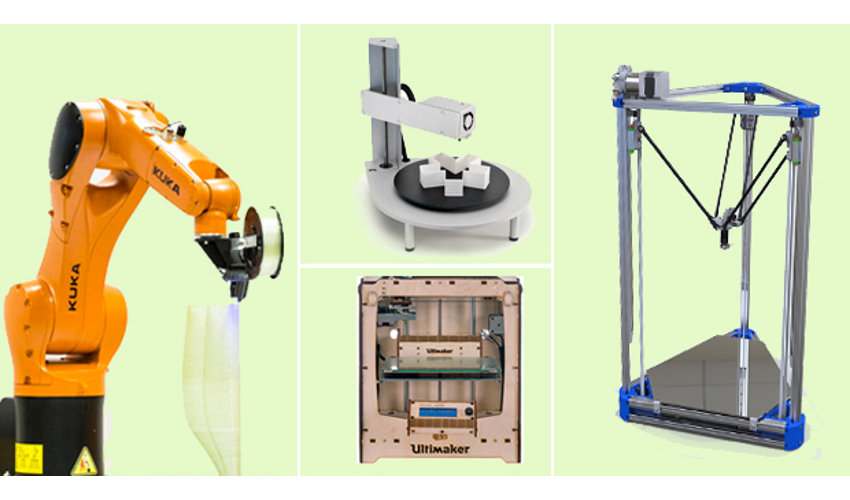

How many kinds of 3D printers are there?

picture alliance/Getty Images

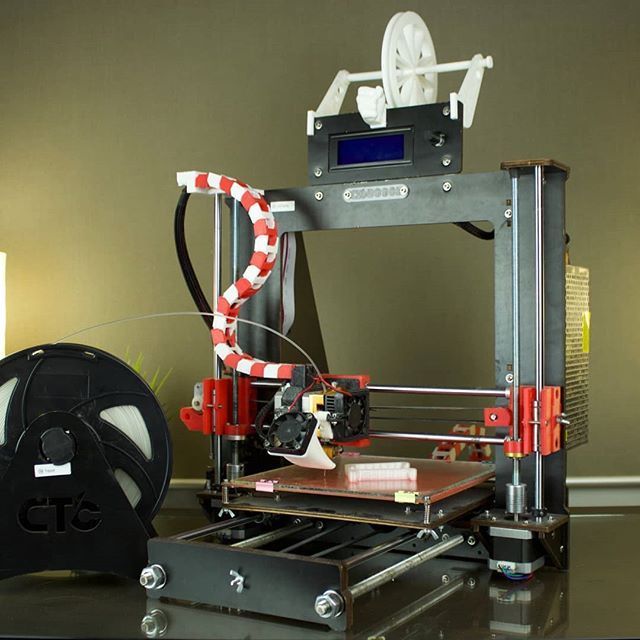

You need to know a few things before we answer the question “How do 3D printers work?” For starters, 3D printers come in a variety of sizes and shapes, ranging from some able to fit on a desk to much bigger construction models used to make 3D-printed walls and foundations for small houses.

There are seven types of 3D printers, each with its own specific use. Fused deposition modeling (FDM) is the most popular because of its high accuracy, low cost and large material selection. FDM printers can be used to make everything from safety whistles to earbud cases to pencil holders, and this is generally what you’d get if you were to buy a 3D printer for home use.

“The process is so simple,” says Denis Cormier, a professor of industrial and systems engineering at the Rochester Institute of Technology. “They are essentially a more expensive hot-melt glue gun. A large percentage of those machines are used by hobbyists due to low cost and simplicity.” Some of the more interesting things that can be created with this kind of printer include 3D printed cars, unmanned aerial vehicles and 3D electric guitars.

Here’s a brief overview of the other 3D printers available:

- Stereolithography: An industrial printing process used to create prototypes for products in development, medical models and computer hardware, stereolithography creates products in a layer-by-layer fashion. It is fast, but it can be expensive.

- Digital light processing: This type of 3D printing uses digital micromirrors and a projected light source. It is popular in the dental, medical and jewelry industries.

- Selective laser sintering: SLS uses laser as its power and heat source to sinter powdered materials.

It is used for rapid prototyping and the low-volume production of component parts.

It is used for rapid prototyping and the low-volume production of component parts. - Selective laser melting: Similar to selective laser sintering, selective laser melting uses a bed of powder with a source of heat to create metal parts. It is used in the production of aerospace industrial components, motor parts and dental and medical engineered equipment such as implants and prosthetics.

- Laminated object manufacturing: Considered a fast and inexpensive way to 3D print objects with a variety of materials, laminated object manufacturing is largely used for rapid prototyping, as opposed to production. Since designers can quickly create a scale model with this type of 3D printing, they often use it present new concepts to investors, customers and clients.

- Digital beam melting: This may be the most complex type of 3D printing, and it requires a skilled practitioner to use electron beam melting technology. It is often used to print components for the automotive, aerospace, defense and medical industries.

How much is a 3D printer?

Believe it or not, a hobbyist can score a 3D printer for between $300 and $500. Of course, the more involved 3D printers aren’t cheap, and the more specialized and complex the field, the higher the costs. A professional 3D printer used to make furniture, food or industrial products can cost anywhere between $1,000 and $10,000, though some in the automotive, medical and aerospace industries—especially those that utilize more advanced AI—run upwards of $500,000 to $1 million. And that price tag doesn’t take into account the costs of the materials, operation and maintenance. According to All3DP, an online printing magazine, just a kilogram of metal powder can cost up to $600.

How do 3D printers work?

RD.com, Getty Images

As noted earlier, 3D printers work via a process known as additive manufacturing, which utilizes computer-aided design, or CAD. This is a technical way of saying that a 3D printer uses a computer program to build an object layer by layer. While each 3D printer works slightly differently, the basic concept begins by designing the object you want to print on a computer. The modeling software is incredibly precise, and it creates a 3D model of your design. Rhino is one of the most popular 3D printing programs on the market right now.

While each 3D printer works slightly differently, the basic concept begins by designing the object you want to print on a computer. The modeling software is incredibly precise, and it creates a 3D model of your design. Rhino is one of the most popular 3D printing programs on the market right now.

When you print your creation on a 3D printer, it comes out in slices. Each small layer sticks together to form a single object from the bottom up. Each overlapping thin layer can be rather complex and can even include moving parts like hinges and wheels. This process continues until the model is complete.

The most common material from which 3D printers build objects is thermoplastic filament, which is essentially the “ink” in these printers. This material is known for its flexibility and durability. Other materials 3D printers use include plastics, powders, resins and metals. Because the 3D printer creates only what the program tells it to create, as opposed to crafting it from bulk raw materials, this type of production can reduce waste, creating more sustainability within businesses and causing a positive ripple effect for the environment.

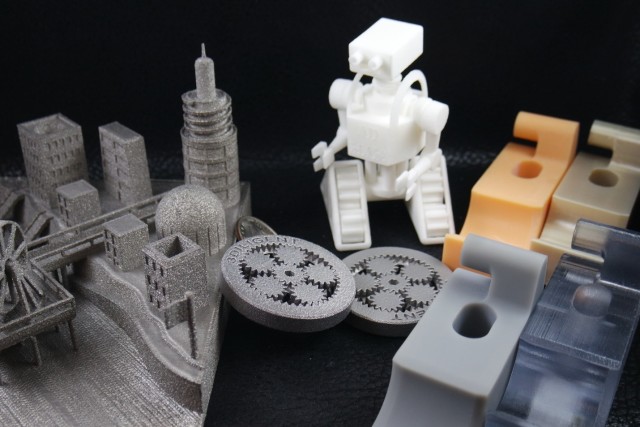

What can you make with a 3D printer?

Theoretically speaking, you can make anything with a 3D printer, though its main uses are in manufacturing and prototyping, construction, medicine and education. Currently, we have the ability to make telescopes, cameras, metal parts for machines, plastic toys, ceramic cups, stoneware vases and even cakes—yes, cakes you can actually eat! Hobbyists can create the nonindustrial items at home, and many are even selling their wares online as a side hustle. Right now, the most popular 3D printed objects include costumes, accessories, props, miniature figures and planters.

3D printers were also a pivotal tool at the height of the COVID-19 pandemic, when PPE was in short supply. Hospitals relied on 3D printers to supply their staff with gowns, masks and respirators, as well as to create parts for ventilators. One Seattle high school student even ran a mask factory from his home using a 3D printer.

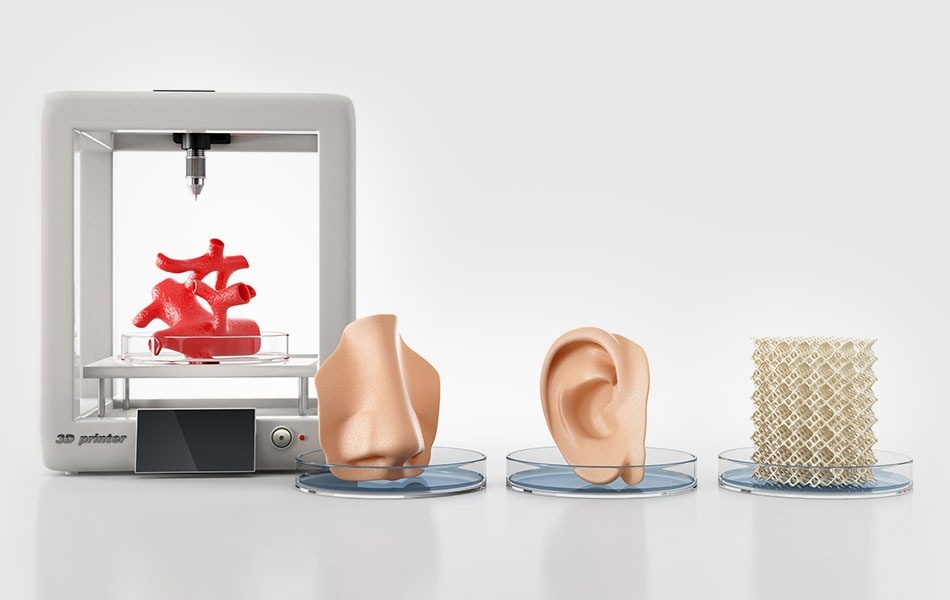

The advances in medicine are arguably among some of the most exciting, with scientists able to create prosthetics and implants via 3D printing. They can also create actual body parts like ears from stem cells, collagen and structural proteins in the human body called fibrin; this process is known as bioprinting, though much of it is still in the testing phases. Additionally, researchers can test pharmaceuticals easily and ethically with tissue created from 3D printers.

They can also create actual body parts like ears from stem cells, collagen and structural proteins in the human body called fibrin; this process is known as bioprinting, though much of it is still in the testing phases. Additionally, researchers can test pharmaceuticals easily and ethically with tissue created from 3D printers.

via merchant

Comgrow Creality Ender 3 3D Printer

Shop Now

via merchant

Sunlu PLA 3D Printer Filament

Shop Now

via merchant

Labists 3D Printer for Kids

Shop Now

What does the future hold for 3D printing?

In the future, designers and hobbyists may not be asking the question “How do 3D printers work?” because 3D printers will likely be so interwoven in our daily lives. Today, kids are being taught about 3D printing in elementary school, and many local libraries currently have the machines available, as do stores like UPS and Staples.

Honestly, the possibilities are endless in the aerospace, electronic, medical, energy and automotive industries, where 3D printers will become even more vital tools. While this can be handy when it comes to cars, which can be customized for buyers, it is even more essential in the medical field. While we’re still probably 10 to 15 years away from 3D printed organs like kidneys, this scientific advancement is most definitely on the horizon.

And consider the opportunities in space, where the defense and aerospace 3D printing market is expected to reach $5.58 billon by 2026. In the future, 3D printing could transform space exploration and space tourism by allowing astronauts to create objects they need on demand—while in space. Imagine a future in which buildings and food are created in space!

When will you be able to print nearly anything at home? We’re getting there. “We are at the doorway of a manufacturing age,” Bourell says, “which I believe may have comparable impact as the Information Age. ”

”

Get Reader’s Digest‘s Read Up newsletter for more humor, cleaning, travel, tech and fun facts all week long.

Sources:

- Neil Gershenfeld, director of MIT’s Center for Bits and Atoms, who teaches a popular 3D printing course

- David Bourell, professor of mechanical engineering and materials science and engineering at the University of Texas at Austin

- Pen and Plastic: “The different types of 3D printing technology”

- Denis Cormier, professor of industrial and systems engineering at the Rochester Institute of Technology

- Hubs: “3D printing trend report 2022”

- New York Times: “Doctors Transplant Ear of Human Cells, Made by 3-D Printer”

- Redshift: “History of 3D Printing: It’s Older Than You Think”

- Easy Rhino 3D: “100 Useful Things You Can Make with a 3D Printer”

- Redshift: “What Material Does a 3D Printer Use? Plastic, Metal, and More”

- Interesting Engineering: “The Future of Medicine: 3D Printers Can Already Create Human Body Parts”

- Globe Newswire: “Aerospace 3D Printing Market Worth USD 5.

58 Billion by 2026 at 25.7% CAGR”

58 Billion by 2026 at 25.7% CAGR” - Biofabrication: “Recent advances in 3D bioprinting of musculoskeletal tissues”

Popular Videos

ⓘ

How a 3D printer works, what can be printed on a 3D printer

The 3D printer is a technology that allows you to create real objects from a digital model. It all started in the 80s under the name "rapid prototyping", which was the goal of the technology: to create a prototype faster and cheaper. A lot has changed since then, and today 3D printers allow you to create anything you can imagine.

Contents:

- What is 3D printing? nine0012

- How does a 3D printer work?

- What can be printed?

The 3D printer allows you to create objects that are almost identical to their virtual models. That is why the scope of these technologies is so wide.

What is 3D printing?

3D printing is an additive manufacturing process because, unlike traditional subtractive manufacturing, 3D printing does not remove material, but adds it, layer by layer—that is, it builds or grows. nine0005

nine0005

- In the first step of printing, the data from the drawing or 3D model is read by the printer.

- Next is the sequential overlay of layers.

- These layers, consisting of sheet material, liquid or powder, are combined with each other, turning into the final form.

With limited production of parts, 3D printing will be faster and cheaper. The world of 3D printing does not stand still and therefore there are more and more different technologies competing with each other on the market. The difference lies in the printing process itself. Some technologies create layers by softening or melting the material, then they provide layer-by-layer application of this same material. Other technologies involve the use of liquid materials, which acquire a solid form in the process under the influence of various factors. nine0005

In order to print something , you first need a 3D model of the object, which you can create in a 3D modeling program (CAD - Computer Aided Design), or use a 3D scanner to scan the object you want print. There are also easier options, such as looking for models on the internet that have been created and made available to other people.

There are also easier options, such as looking for models on the internet that have been created and made available to other people.

Once your design is ready, all you need to do is import it into the Slicer, a program that converts the model into codes and instructions for a 3D printer, most of the programs are open source and free. The slicer will convert your project into a gcode file ready to be printed as a physical object. Simply save the file to the included SD card and insert it into your 3D printer and hit print. nine0005

The whole process can take several hours and sometimes several days. It all depends on the size, material and complexity of the model. Some 3D printers use two different materials. One of them is part of the model itself, the other acts as a prop that supports parts of the model hanging in the air. The second material is subsequently removed.

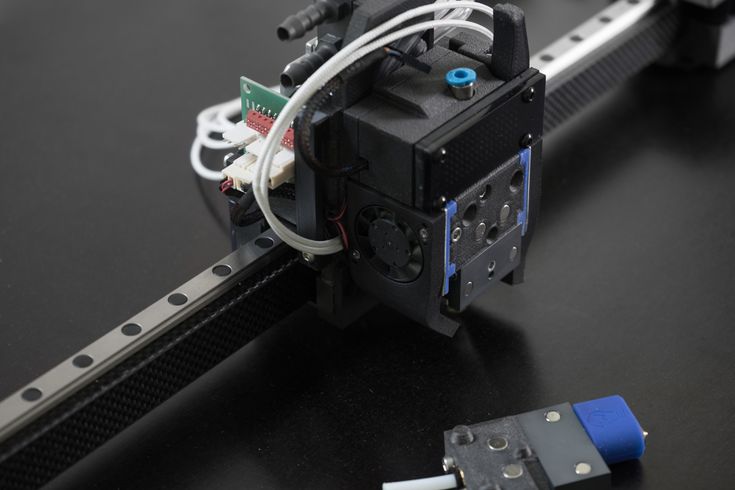

How does a 3D printer work?

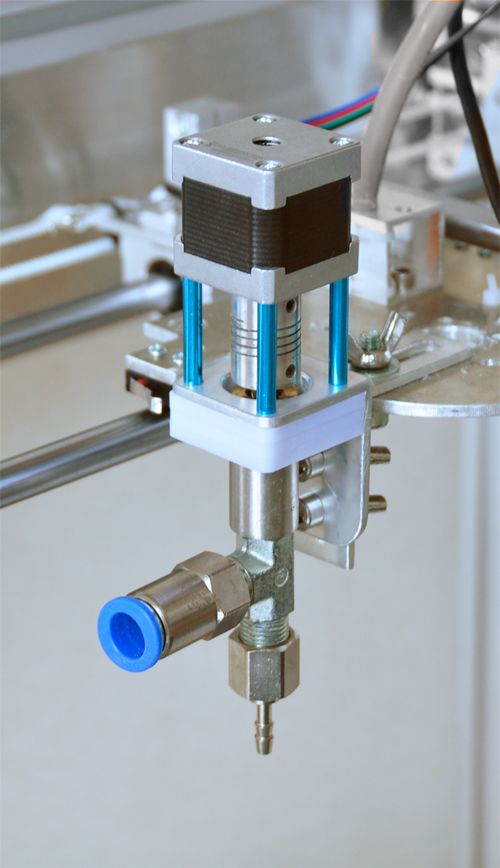

Although there are several 3D printing technologies, most create an object by building up many successive thin layers of material. Typically desktop 3D printers use plastic filaments (1) which are fed into the printer by the feeder (2) . The filament melts in the print head (3) which extrudes the material onto the platform (4) creating the object layer by layer. Once the printer starts printing, all you have to do is wait - it's easy.

Typically desktop 3D printers use plastic filaments (1) which are fed into the printer by the feeder (2) . The filament melts in the print head (3) which extrudes the material onto the platform (4) creating the object layer by layer. Once the printer starts printing, all you have to do is wait - it's easy.

Of course, as you become an advanced user, playing with the settings and tweaking your printer can lead to even better results.

What can be 3D printed? nine0021

The possibilities of 3D printers are endless and they are now becoming a common tool in fields such as engineering, industrial design, manufacturing and architecture. Here are some typical use cases:

Custom Models

Create custom products that perfectly fit your needs in terms of size and shape. Do something that would be impossible with any other technology.

Rapid Prototyping

3D printing allows you to quickly create a model or prototype, helping engineers, designers and companies get feedback on their projects in a short time.

Complex geometry

Models that are hard to imagine can be easily created with a 3D printer. These models are good for teaching others about complex geometry in a fun and useful way.

Cost reduction

The cost of 3D printing end-use parts and prototypes is low due to the materials and technology used. Reduced production time and material consumption as you can print models multiple times using only the material you need. nine0005

How to choose and buy a 3D printer? →

3D printer: what is it and how does it work? | GeekBrains

https://gbcdn.mrgcdn.ru/uploads/post/1999/og_image/501bb6c82a53bb3bc2a0fee73b0c9e9e.png

In 2011, a printer filled with a human kidney TED printed directly during a TED conference. Two years ago, Adidas announced a new sneaker that can be 3D printed in 20 minutes. And recently, Elon Musk's SpaceX successfully tested the spacecraft's engines, which were also printed on a 3D printer. nine0005

In today's world, 3D printing is not an amazing technology of the future, but a well-studied reality. It is used in architecture, construction, medicine, design, production of clothing and footwear and other areas. At the request of "3D printer", search engines give out hundreds of drawings and prototypes of varying complexity - from a soap dish and a table lamp to a car engine and even a residential building.

It is used in architecture, construction, medicine, design, production of clothing and footwear and other areas. At the request of "3D printer", search engines give out hundreds of drawings and prototypes of varying complexity - from a soap dish and a table lamp to a car engine and even a residential building.

Anyone can buy a printer and print a smartphone case, but not everyone goes beyond 3D printing from a drawing. In this article, we will tell you when 3D printing appeared, how the technology can be applied and what its prospects are. nine0005

How the 3D printer came to be

Let's not bore you too much with the dates and briefly retell the history of 3D printing.

A precursor to 3D printing. In the early 1980s, Dr. Hideo Kodama developed a rapid prototyping system using photopolymer, an acrylic-based liquid substance. The printing technology was similar to the modern one: the printer printed the object according to the model, layer by layer.

First 3D printing. The production of physical objects using digital data was demonstrated by Charles Hull. At 19In 84, when computers were not much different from calculators, and ten years before the release of Windows-95, he invented stereolithography, the forerunner of 3D printing. The technology worked like this: under the influence of an ultraviolet laser, the material solidified and turned into a plastic product. The form was printed on digital objects, and this became a boom among developers - now it was possible to create prototypes at a lower cost.

The production of physical objects using digital data was demonstrated by Charles Hull. At 19In 84, when computers were not much different from calculators, and ten years before the release of Windows-95, he invented stereolithography, the forerunner of 3D printing. The technology worked like this: under the influence of an ultraviolet laser, the material solidified and turned into a plastic product. The form was printed on digital objects, and this became a boom among developers - now it was possible to create prototypes at a lower cost.

The first 3D printer. Source: habr

The first manufacturer of 3D printers. Two years later, Charles Hull patented the technology and opened the 3D Systems printer company. It released the first machine for industrial 3D printing and is still leading the market. True, then the printer was called differently - an apparatus for stereolithography. nine0005

The popularity of 3D printing and new technologies. In the late 80s, 3D Systems launched mass production of stereolithographic printers. But by that time, other printing technologies had also appeared: laser sintering and deposition modeling. In the first case, the powder was processed by the laser, not the liquid. And the majority of modern 3D printers work according to the fusing method. The term "3D printing" came into use, the first home printers appeared.

But by that time, other printing technologies had also appeared: laser sintering and deposition modeling. In the first case, the powder was processed by the laser, not the liquid. And the majority of modern 3D printers work according to the fusing method. The term "3D printing" came into use, the first home printers appeared.

A revolution in 3D printing. At the beginning of the 2000s, the market split into two directions: expensive complex systems and those that are available to everyone for printing at home. The technology began to be used in specific areas: for the first time, a bladder was printed on a 3D printer, which was successfully implanted. nine0005

Kidney Test Print. Source: BBC

In 2005, the first high-quality color 3D printer appeared, creating kits for itself and "colleagues".

How a 3D printer works

Basically, 3D printers consist of the same parts and are similar in design to conventional printers. The main difference is obvious: a 3D printer prints in three planes, and in addition to width and height, depth appears.

Here are the parts of the 3D printer, not counting the body:

- extruder, or print head - heats up the surface, measures the exact amount of material using a gripping system and extrudes semi-liquid plastic, which is fed in the form of threads;

- desktop (it is also called a working platform or printing surface) - on it the printer forms parts and grows products;

- linear and stepper motors - drive parts, are responsible for the accuracy and speed of printing;

- clamps - sensors that determine the print coordinates and limit moving parts. They are needed so that the printer does not go beyond the desktop, and make printing more accurate; nine0012

- frame - connects all elements of the printer.

Schematic of a 3D printer. Source: Lostprinters

All of this is computer controlled.

How products are created

An additive 3D printing process is responsible for creating a three-dimensional product - this is when layers of material are superimposed on each other, from bottom to top, until a copy of the form in the drawing is obtained. This is how plastics are printed. And photopolymer printing works on stereolithography (SLA) technology: under the influence of a laser emitter, photopolymers harden. In addition to plastic and photopolymer resins, modern 3D printers work with metal clay and metal powder. nine0005

This is how plastics are printed. And photopolymer printing works on stereolithography (SLA) technology: under the influence of a laser emitter, photopolymers harden. In addition to plastic and photopolymer resins, modern 3D printers work with metal clay and metal powder. nine0005

Printing consists of continuous cycles that repeat one after another - one layer of material is applied to the next, and the print head moves until the finished object is on the working surface. The printer itself removes print waste from the desktop.

How a 3D drawing works

The printer prints a product according to a 3D drawing: it is created on a computer in a special program, then saved in STL format. This file is output to the cutting program for the printer - it helps to set the model of the physical properties of the product, such as density. Next, the program converts the model into instructions for the extruder and uploads it to the printer, which starts printing the product. nine0005

nine0005

3D drawing is easy to make at home - read the instructions on habr.

How to program a 3D printer

Brief instructions for setting up the printer:

- Select a 3D model. You can draw the product yourself in a special CAD editor or find a ready-made drawing - the Internet is full of models of varying complexity.

- Prepare 3D model for printing. This is done by the slicing method (slice - part). For example, in order to print a toy, its model must be “split” into layers using slicer programs and transferred to the printer. Simply put, a slicer shows the printer how to print an object: which contour to move the print head, at what speed, what thickness of layers to make. nine0012

- Transfer model to printer. From the slicer, the 3D drawing is saved to a file called G-code. The computer downloads the file to the printer and starts 3D printing.

- Monitor printing.

Whether printed products can be used

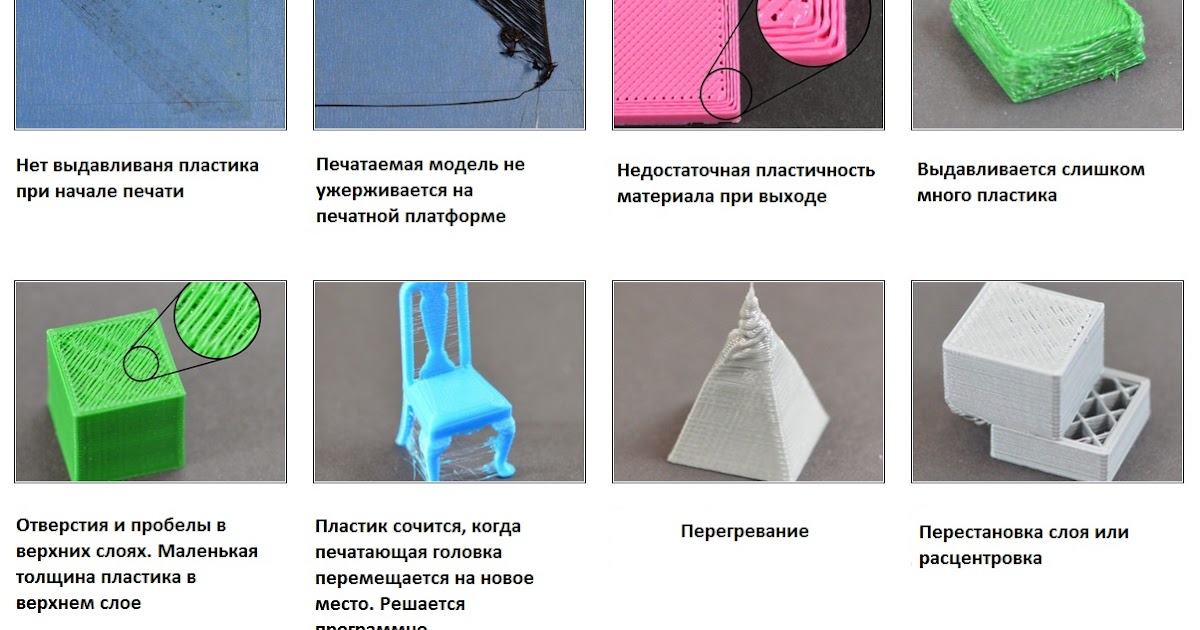

Depends on the quality of the media, printer and end product. Often home printers do not accurately convey the shape and color of an object. Plastic products need additional processing: sometimes they are printed with burrs and defects, and almost always with a ribbed surface. nine0005

Often home printers do not accurately convey the shape and color of an object. Plastic products need additional processing: sometimes they are printed with burrs and defects, and almost always with a ribbed surface. nine0005

Product after and before processing. Source: 3D-Today

There are several ways to finish the surface - not all are suitable for home use:

- mechanical processing - hand sanding, deburring;

- chemical - immersion in acetone, sandblasting, applying a special solution with a brush.

What can be printed with a 3D printer

The Internet is full of collections with instructions for printing 3D products. 3D-Today publishes photos of the work of printer owners, from small parts to sculptures. Three years ago, Habré posted a list of "50 cool things to print on a 3D printer." Make3D wrote about larger projects like printing cars, weapons, solar panels, and prosthetics. nine0005

There are a number of promising areas where 3D printing is already being applied.

Making models according to your own sketches. Konstantin Ivanov, the creator of the 3DPrintus service, in an interview with Afisha said that 3D printing will lead to the flourishing of customizable things: anyone can assemble and print the desired product online. For example, make a model of a robot and order its printing on an industrial printer, create and print your own design of wedding rings or shoes. Examples of such projects are Thinker Thing and Jweel. nine0005

Rapid prototyping. The most popular area in which 3D printing is used. Test models of prostheses, prototypes of medical corsets, bas-reliefs, Olympic equipment are made on 3D printers.

Prototypes of children's prostheses, 3D printing. Source: 3D-Pulse

Complex geometry. The 3D printer can easily handle the production of models of any shape. A few examples:

- an Australian university explored the possibilities of a 3D printer and printed a stool in the shape of a fingerprint; nine0005

- A Danish chef won a haute cuisine competition: he 3D printed miniature dishes of complex shapes from seafood and beetroot puree;

One of the chef's winning dishes. Source: 3D-Pulse

Source: 3D-Pulse

- A German institute has developed a system for accelerated 3D printing - in 18 minutes, the printer produces a complex geometric product 30 cm high. It usually takes printers an hour to print pocket figures.

3D printing technology

Briefly about the main methods of 3D printing.

Stereolithography (SLA). In a stereolithographic printer, a laser irradiates photopolymers and forms each layer according to a 3D drawing. After irradiation, the material hardens. The strength of the product depends on the type of polymer - thermoplastic, resins, rubber.

Stereolithography does not support color printing. Other drawbacks include slow operation, huge size of stereolithographic setups, and you can't combine multiple materials in one run. nine0005

This technology is one of the most expensive, but guarantees accurate printing. The printer applies layers with a thickness of 15 microns - this is several times thinner than a human hair. Therefore, with the help of stereolithography, dental prostheses and jewelry are made.

Therefore, with the help of stereolithography, dental prostheses and jewelry are made.

Industrial stereolithography machines can print huge products, several meters in length. Therefore, they are successfully used in the production of aircraft, ships, defense industry, medicine and mechanical engineering. nine0005

Selective laser sintering (SLS). The most common method for sintering powder materials. Other technologies are direct laser sintering and selective laser melting.

The method was invented by Carl Descartes in the late eighties: his printer printed by layer-by-layer drawing (sintering). A powerful laser heats up small particles of material and moves along the contours of the 3D drawing until the product is finished. The technology is used to manufacture not whole products, but parts. After sintering, the parts are placed in an oven where the material burns out. SLS uses plastics, ceramics, metals, polymers, fiberglass in powder form. nine0005

The athlete is wearing New Balance shoes, which were made using laser sintering. Source: 3D-Today

Source: 3D-Today

SLS technology is used for prototypes and complex geometric parts. For printing at home, SLS is not suitable due to the huge size of the printer.

FDM or Fused Deposition Modeling. This 3D printing method was invented by American Scott Crump. FDM works like this: the material is fed into the extruder in the form of a thread, where it heats up and is fed to the worktable in microdroplets. The extruder moves along the working surface in accordance with the 3D model, the material cools down and solidifies into the product. nine0005

Advantages - high product flexibility and temperature resistance. For such printing, different types of thermoplastics are used. FDM is the most inexpensive among 3D printing technologies, which is why printers are popular for home use: for making toys, souvenirs, and jewelry. But mostly fusing modeling is used in prototyping and industrial production - printers quickly print small-scale batches of products. Refractory plastic items are made for the space industry. nine0005

nine0005

3D inkjet printing. One of the first methods of three-dimensional printing - in 1993, it was invented by American students when they improved a conventional paper printer, and soon the technology was acquired by the same company 3D Systems.

Inkjet printing works like this: a binder is applied to a thin layer of material along the contours of the drawing. The print head applies the material along the boundaries of the model, and the particles of each new layer stick together. This cycle is repeated until the product is ready. This is one of the types of powder printing: earlier inkjet 3D printers printed on plaster, now they use plastics, sand mixtures and metal powders. To make the product stronger, after printing it can be impregnated with wax or fired. nine0005

Items printed using this technology are usually durable, but not very durable. Therefore, with the help of inkjet printing, souvenirs, jewelry or prototypes are made. This printer can be used at home.

These candies were made on a ChefJet 3D confectionery inkjet printer that uses water, sugar, chocolate and food coloring instead of plastic. Source: 3Dcream.ru

Inkjet technology is also used in bioprinting, where living cells are layered on top of each other and thus organic tissues are built. nine0005

Where 3D printing is used

Mainly in professional fields.

Construction. 3D printers print walls from a special cement mixture and even houses with several floors. For example, back in 2014 Andrey Rudenko printed a 3 × 5 meter castle on a construction printer. Such 3D printers can build a two-story house in 20 hours.

Medicine. We have already mentioned the printing of organs, and 3D printers are also actively used in prosthetics and dentistry. Impressive examples - with the help of 3D printing, doctors managed to separate Siamese twins, and a cat without four legs was given prostheses that were printed on a printer. nine0005

nine0005

Learn more about 3D printing in medicine in the article published by 3D-Pulse.

Space. 3D printing is used to make equipment for rockets and space stations. Another technology is used in space bioprinting and even in the work of lunar rovers. For example, the Russian company 3D Bioprinting Solutions will send live bacteria and cells into space, which will be grown on a 3D printer. Amazon founder Jeff Bezos unveiled a prototype lunar module with a printed engine, and space startup Relativity Space is building a rocket 3D printing factory. nine0005

Aviation. 3D parts are printed not only for spacecraft, but also for aircraft. Engineers at the US Air Force Lab can 3D print aircraft components, such as a fuselage skin element, in about five hours.

Architecture and industrial design. 3D printers print models of houses, neighborhoods and villages, including infrastructure: roads, trees, shops, lighting, transport. As a material, an inexpensive gypsum composite is usually used.