3D printer small business

Best 3D Printer for Small Business 2022: Top Pro-Grade Printers

Whether you’re looking to dive into professional 3D printing for the first time or level up an existing print farm, we’re here to nudge you in the right direction with our guide to the best 3D printers for small businesses.

Nowadays, a business-ready printer needs to do more than generate affordable high-quality parts and prototypes; it must actively improve productivity and streamline workflows. Below, you’ll find a curated selection of the most reliable and user-friendly mid-range printers on the market today that provide value to fledgling and established businesses alike.

Our picks are tried-and-tested workhorses fit for applications from fast-prototyping to end-use part fabrication and everything in between. Let’s dive in.

Best 3D Printers for Small Business

3DSourced is reader-supported. When you buy through links on our site, we may earn an affiliate commission. Learn more

Formlabs Form 3+ / 3L – professional resin printer

- Form 3+ price: $3,499 — Available at Dynamism here

- Form 3L price: $10,999 — Available at Dynamism here

The resin Formlabs 3+ and Formlabs 3L printers are designed from the ground up for the fast-paced, productivity-focused activities of small businesses that aim to circumvent outsourcing. They allow companies to easily bring streamlined, affordable prototyping and functional, end-use part fabrication in-house.

Print quality is nothing short of industry-quality with fast, precision printing that stands out for the richness of its features and flawless surface finish. These printers excel in fields that require highly accurate and functional parts such as jewelry making, hybrid visual effects production, engineering, medicine, and miniature/figurine making.

Read more: the best resin 3D printers

The two printers are fundamentally the same machines, except the FormLab 3L offers a larger 335 × 200 × 300 cm build volume and two light processing units to make up for the larger build platform. If your activities involve larger models or prototypes, or you need to batch print bigger quantities of smaller parts, we recommend the FormLab 3L. Otherwise, the FormLab 3+ offers the same reliable precision and speed at a more palatable price.

The Formlabs Form 3+ and 3L’s productivity focus extends to the surrounding ecosystem for a seamless end-to-end workflow. You can switch between 30 different resin types, each with its characteristics and properties, in a matter of seconds via Formlab’s easy swappable cartridges. Formlabs Form Wash and Form Cure accessories completely automate the post-processing of resin print with set-and-forget functionality.

You can switch between 30 different resin types, each with its characteristics and properties, in a matter of seconds via Formlab’s easy swappable cartridges. Formlabs Form Wash and Form Cure accessories completely automate the post-processing of resin print with set-and-forget functionality.

Formlabs PreForm SLA software is stacked with automated features such as adaptive layer thickness, mesh repair, and support generation for genuine one-click printing. Cloud-based dashboard monitoring and print management also mean you can scale up with multiple printers or queue up several prints from anywhere with little hassle.

Investing into the complete Formlabs ecosystem doesn’t come cheap, which may be prohibitive to some businesses. In that case, the Prusa SL1S Speed is an excellent lower-priced alternative. As it carries the Prusa name, you’re buying into 3D printing royalty here. It’s fast, easy to use, delivers professional-level print quality, and keeps running costs low.

Ultimaker S5 / S5 Pro Bundle

- Ultimaker S5 price: $6,355 — Available at Dynamism here / Matterhackers here

- Ultimaker S5 Pro Bundle Upgrade: $3,685 — Available at Dynamism here / Matterhackers here

The Ultimaker S5 and S5 Pro are workhorse FDM productivity printers for high-precision rapid prototyping of functional parts destined for the arts, medicine, engineering, automotive, consumer good production lines, and architecture, to name a few.

Much like Ultimaker’s consumer-grade printers, both the S5 and S5 Pro have ease-of-use baked in, emphasizing hassle-free throughput improvement while keeping down costs. At the center of this is a dual extrusion system, compatibility with a broad range of filaments, effortless network printer control, and near-zero onboarding one-click printing through Ultimaker’s Digital Factory software.

Thanks to desirable and identical specification sheets, the Ultimaker S5 and S5 Pro produce industry-grade prints, notably for a level of detail and smoothness run-of-the-mill FDM printers rarely achieve. The Ultimaker S5 and S5 Pro deliver durable, accurate parts such as pre-fabrication mockups, prototypes, functional parts, tools, and proof-of-work concepts.

The Ultimaker S5 Pro is an S5 with an enclosed, temperature-controlled material station tacked on. The station filters out toxic fumes while maintaining a dust and humidity-free environment through a robust air filtration system to keep materials in an optimum state.

Additionally, the station can house up to six different front-loaded filament spools simultaneously. Automatic material handling manages spool changeovers and run-out switching to ensure printing continues uninterrupted. It’s genuinely hands-off printing.

While smaller than its S5 sibling in footprint and build volume, the Ultimaker S3’s more affordable price tag, tighter footprint, and identical specifications make it a solid choice for smaller businesses with less cash to spare.

Raise3D Pro2 / Pro2 Plus

- Pro2 price: $3,999 — Available at Dynamism here / Matterhackers here

- Pro2 Plus price: $5,999 — Available at Dynamism here / Matterhackers here

Touted by Raise 3D as the ‘best industrial-grade 3D printer’ under the sun, the Raise3D Pro2 and its pricier counterpart, the Pro2 Plus, offer fast, high-detail printing backed by a durable and production-line-sturdy frame. They would both be reliable additions to a productivity-focused small business looking for a robust and versatile manufacturing and rapid-prototyping solution.

Standout features include dual extruders, a comprehensive HEPA air filtration system, and management of the entire printing process from end-to-end through the RaiseCloud software, allowing you to juggle a flock of printers remotely with ease.

The Raise3D Pro2 and Pro2 Plus material compatibility is extensive, with support for PLA, ABS, HIPS, PC, TPU, TPE, PETG, ASA, PP, PVA, Nylon, and Glass Fiber Infused, Carbon Fiber Infused, Metal Fill, Wood and Fill.

With the same underlying hardware and specifications as the Raise3D Pro2, the Raise3D Pro2 Plus splits in build volume. It ups the single extrusion build volume to 305 x 305 x 605 mm and dual extrusion volume to 280 x 305 x 605 mm, adding verticality for taller prints.

It’s also worth mentioning the Raise3D E2 in passing. A smaller footprint and build volume allied to an IDEX system see the Raise3D E2 take on the form of a desktop printer. A strong pick for small design studios that don’t need as much print area as that offered by the industrial-geared Pro2 machines.

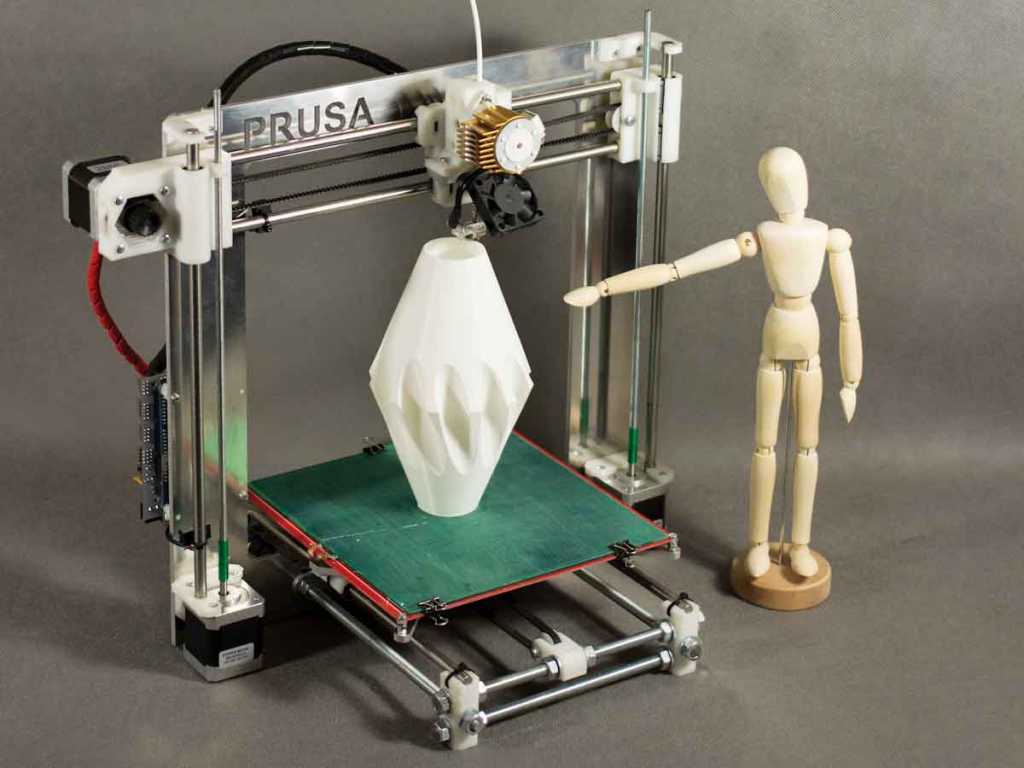

Prusa i3 MK3S+ – Best Low-Cost 3D Printer for Small Business

- Price: $999 — Available at Prusa store here

A darling among amateur makers across the globe, the Prusa i3 MK3S+ slides into our list as a low-cost savior for the smallest businesses put off by the exorbitant price tags of the Form 3+ and Ultimaker S5.

Even though the Prusa i3 MK3S+ is a workhorse in its own right, this isn’t a manufacturing tool or design powerhouse like the other best 3D printers for small businesses we’ve handpicked. The footprint is considerably smaller than most professional-grade printers for business use. If you operate out of your home, the Prusa i3 MK3S+ won’t take over an entire room.

Smaller and less ambitious, we see it as a dependable accessory for companies wanting to quickly pump out the odd high-quality prototype or focus on small, high-detail, limited-run parts.

The Prusa i3 MK3S+ does just that, but without sacrificing the quality of the finished product. The print results flirt with those you’d expect from the other printers on our list, but at a fraction of the cost. A trove of integrated fail-safe tools and sensors guarantees easy printing with all-around quality hardware to match and decent material compatibility, including PLA, PETG, ASA, PC, HIPS, and more.

The print results flirt with those you’d expect from the other printers on our list, but at a fraction of the cost. A trove of integrated fail-safe tools and sensors guarantees easy printing with all-around quality hardware to match and decent material compatibility, including PLA, PETG, ASA, PC, HIPS, and more.

Straightforward printing and software are equally appealing for fledgling businesses dabbling in 3D printing for the first time. You won’t be bogged down having to juggle a fleet of printers via a cloud-based management system.

Desktop Metal Studio System – Best Metal 3D Printer for Small Business

Matter-of-fact naming aside, the Desktop Metal Studio System swoops in as a solid, bleeding-edge metal printing solution suitable for prototyping, manufacturing, automotive design, consumer goods, and even small, one-off parts destined for heavy industry applications.

As the name implies, it’s desktop-friendly with the same approach applied to the native Fabricate software. The software covers all aspects of part creation, reducing tricky, oft-complex, not to say daunting, metallurgy to a well-guided, step-by-step process. Much like the other printers on our list, Fabricate operates with workflow in mind, and you can easily manage and monitor multiple printers for steady and productive printing.

The software covers all aspects of part creation, reducing tricky, oft-complex, not to say daunting, metallurgy to a well-guided, step-by-step process. Much like the other printers on our list, Fabricate operates with workflow in mind, and you can easily manage and monitor multiple printers for steady and productive printing.

It’s genuinely remarkable how it simplifies the creation of difficult-to-machine parts with a high level of geometric complexity. The results often rival traditional casting in density and accuracy, all while allowing for finicky undercuts and internal channels, delivering an excellent surface finish with every print.

The Desktop Metal Studio System metal printer comes accompanied by a sintering furnace in an office-friendly package. The latter features temperature profiles to match the material type and build, so you’re guaranteed industrial-strength sintering with every print. Printing is also far less messy than most powder-based metal systems with plenty of safety features, not least a fully enclosed chamber.

Things to Consider When Buying a 3D Printer for Small Business

Software and Workflow

Time is money as the hackneyed expression goes, and the software hitched to a 3D printer plays a massive part in determining workflow and efficiency. Whether you’re looking to scale your production, fill an order rapidly, or reduce hands-on tinkering to increase productivity, look to robust software suites that allow for cloud-based multiple printer monitoring and management.

One-click printing, Wi-Fi connectivity, automated slicing processes – these are all worth considering if productivity ranks as a top consideration. Intuitive UIs and baked-in ease-of-use are equally important for efficiency.

Materials

When shopping around for a 3D printer for your small business, pay close attention to material compatibility, especially if your applications necessitate more exotic and abrasive filament types. Generally, professional printers offer broader compatibility than hobbyist printers, with PLA, ABS, PETG, and flexibles as standard.

You may also want to consider a dedicated metal or resin printer if these materials feature in your printing plans. Dedicated machines tend to produce better results with their chosen filament focus than jack-of-all-trades printers.

Resolution

The resolution, often referred to as layer height, is a measurement expressed in mm (or microns) that defines the thickness of each printed layer. The lower the resolution, the better the details and textures.

For a small business, anywhere 20 to 100 microns should be sufficient for most applications. If you want the most accurate results, look to resin printers, high-resolution machines that excel at printing feature-rich, detailed parts.

Size and Build Volume

Build volume refers to the available print area or, in other words, dictates the maximum size of a print. The best 3D printers for small business have larger build volumes than standard consumer printers, but it’s worth checking if they have a sufficiently large build volume if you plan to build large prototypes or plan to batch print.

The printer’s physical footprint is likely less of a consideration, but it’s worth considering if you plan to piece together a print farm and have limited space in your workshop, lab, or office.

Use Case

Though most professional 3D printers work for various applications, we recommend investigating whether this or that machine is well-suited to your favored use case. A compact printer like the Prusa i3 MK3S+ works well in a small home office environment to print out small prototypes and limited-run parts.

The Desktop Metal Studio System is ideal for one-off metal parts for heavy industry. The Ultimaker S5 Pro offers easy printing of multiple filament types, swapping between them automatically as required to create complex, detailed parts. You get the idea; ensure a printer is suited to your needs.

Small Business 3D Printer FAQs

What Is The Best 3D Printer for Starting a Small Business at Home?

Although 3D printers, even professional-grade machines, have shrunk in size considerably since the early days of the technology, they are still bulky machines. With space-saving in mind along with keeping costs down, we recommend the Prusa i3 MK3S+ as the best 3D printer for starting a small business at home. The Prusa i3 MK3S+’s print quality comes close to that of printers three times its price, and its compact size, along with a sleek orange and black color scheme, blends into a home office environment.

With space-saving in mind along with keeping costs down, we recommend the Prusa i3 MK3S+ as the best 3D printer for starting a small business at home. The Prusa i3 MK3S+’s print quality comes close to that of printers three times its price, and its compact size, along with a sleek orange and black color scheme, blends into a home office environment.

What Is The Best Metal 3D Printer for Small Business?

Several printers on our list enable 3D printing with metal, but once rises above the rest – the Desktop Metal Studio System. The printer is designed from the ground up to work exclusively with metal for various professional applications. The results are excellent, and the Fabricate software greatly streamlines the usually complex art of metallurgy. It also ships with a furnace to land perfect industry-level sintering.

What Is The Best Resin 3D Printer for Small Business?

We recommend the Formlabs Form 3+ and Formlabs Form 3L for small businesses looking to work exclusively with resin. As ecosystem printers, they have all bases covered from design to post-processing, which helps establish a solid productivity-focused workflow. The print results are excellent, brimming with fine detail and smooth surface finish. Opt for the Formlab Form 3L if you want more build volume to print larger parts or to speed up batch printing.

As ecosystem printers, they have all bases covered from design to post-processing, which helps establish a solid productivity-focused workflow. The print results are excellent, brimming with fine detail and smooth surface finish. Opt for the Formlab Form 3L if you want more build volume to print larger parts or to speed up batch printing.

Other articles you may be interested in:

- The best industrial 3D printers

- The best commercial and professional 3D printers

- How to start a 3D printing business

- Things to 3D print and sell

- The best 3D printers under $2,000

- The best 3D printers under $5,000

- The best large format resin 3D printers

Getting Started with 3D Printing for Your Small Business — Creality Experts

If you are thinking about using 3D printing for your design business, architecture firm, or other small business, it can be overwhelming to know where to start. With so many technologies to choose from which range widely in cost and capability, you’ll first need to think about the types of parts you’ll be printing and how they will be used. A few common examples of 3D printing applications for small businesses include:

A few common examples of 3D printing applications for small businesses include:

Creating design prototypes for fit or other testing

Custom tools or jigs to improve workflows and efficiency

Creating display models, demos, or customer gifts

Small-run manufacturing of highly customized parts

In this article, we’ll take a look at when it makes sense to hire a 3D printing service versus buying your own 3D printer, and help you get started with each of these options.

Note: Creality Experts receives a commission for items you purchase from this page, at no additional cost to you. For more information, please see our affiliate link policy.

Should I Hire a Service or Purchase a 3D Printer?

Before looking at purchasing a 3D printer, you should consider whether hiring a 3D printing service makes more sense for your application. As you might expect, the cost of hiring a service is significantly more than purchasing raw materials to use with your own machine, but allows you to avoid the upfront costs of purchasing a 3D printer.

When to hire a 3D printing service

If your application has more rigid requirements for material properties, which is typical for end use parts, hiring a service may be the most economical way to incorporate 3D printing into your process. Typically, for these parts you’ll need to use more advanced 3D printing technologies such as SLS Nylon or Multi-Jet Fusion, where the lowest cost machines can cost $20,000 or more, and often have a large footprint and ventilation requirements. Lower cost 3D printers can print parts for some applications, but typically are not capable of printing engineering-grade plastics. Additionally, the Fused Deposition Modeling (FDM) technology used by more affordable printers prints parts in thin layers. This introduces anisotropy in strength, where parts are stronger in some dimensions than in others. While these drawbacks are not an issue for some end use applications, such as display models, prototypes, or custom jigs, lower cost FDM printers are typically not suited for end use manufacturing.

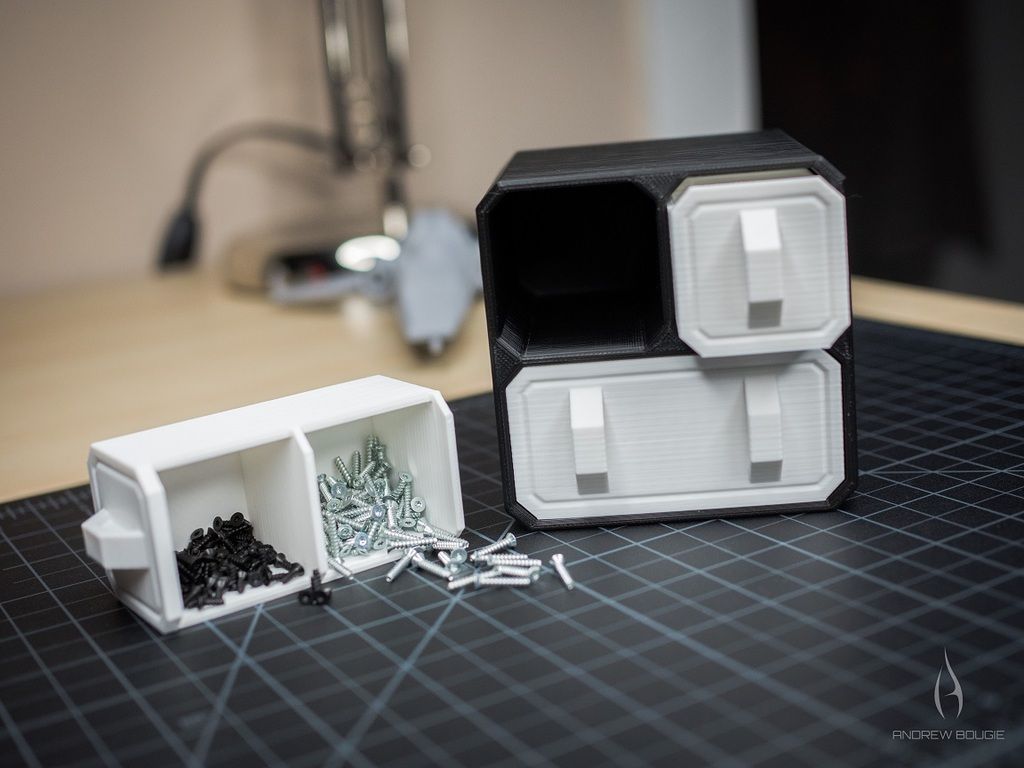

FDM 3D printing is a great choice for internal-use parts and jigs, such as this electronics enclosure for a custom tool.

3D printing excels at smaller production runs since there are no upfront tooling costs, but it does typically cost more per part to order a single part vs multiple due to the overhead required to set up the print job. However, this upfront cost is far less than the tooling costs traditional manufacturing, and 3D printing is often more affordable in the 100-1000 quantity range.

It is easy to get a quote for 3D printing your parts very quickly; most printing services offer an instant quoting tool which analyzes the 3D model file you provide. As long as you can export your design files to a compatible format such as STL or OBJ, you can quickly get an idea of the cost for 3D printing various quantities of your part.

When to buy your own 3D printer

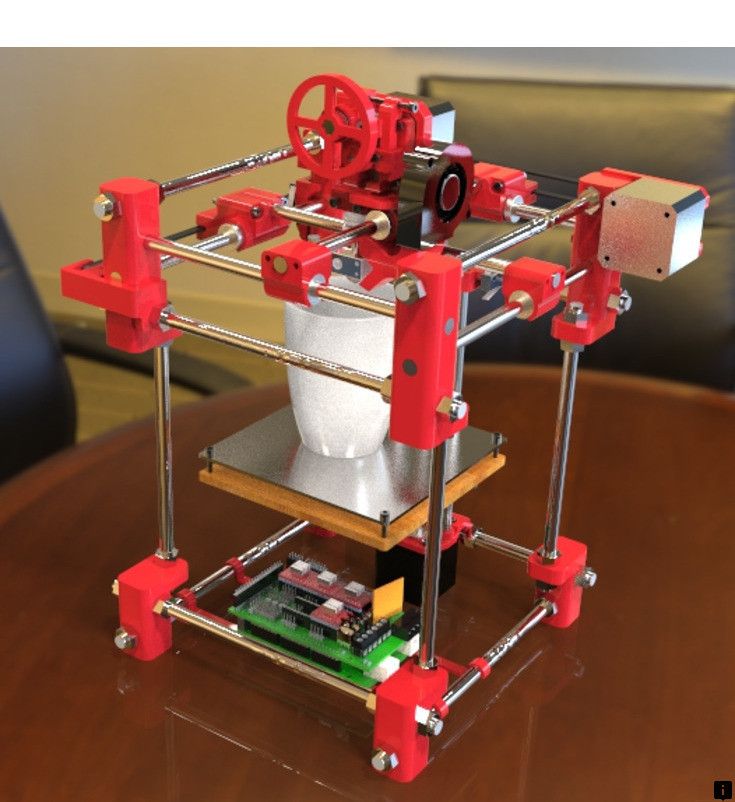

FDM printers are capable of producing detailed models, like this concept architectural model.

If your 3D printed parts do not have specific material requirements, such as creating early prototypes, jigs for your manufacturing process, or display models, purchasing a 3D printer becomes much more attainable. For these types of work, it’s reasonable to use a consumer FDM 3D printer, which provide impressive capability for a very low price. Most consumer 3D printers range from $200 - $1000 in price and are compact enough to fit on a desk. The drawbacks of FDM are typically not a concern for these types of parts, and having your own 3D printer offers a major benefit in addition to lower cost—reduced iteration time. When designing a product for testing, it is critical to minimize the iteration cycle.

Though ordering 3D printed parts from a service is much faster than traditional manufacturing, it will still typically take 3-5 business days to receive most orders from a service. This can add a lot of time to iteration, and discourages rapid iteration on an idea. With a 3D printer in-house, you can print testing prototypes very quickly, typically in 4-6 hours for midsized parts, which will allow you to quickly try designs, test them in the real world, and improve your design.

With a 3D printer in-house, you can print testing prototypes very quickly, typically in 4-6 hours for midsized parts, which will allow you to quickly try designs, test them in the real world, and improve your design.

Pioneer Woman Cookware uses 3D printing to produce early prototypes for look and feel testing to iterate quickly on their products.

Owning a 3D printer can also allow you to “prototype your prototype”. For example, if you are designing a part with rigid strength requirements which will eventually be manufactured using injection molding, you may need a high strength nylon prototype for final testing. However, many tests such as fitment and usability testing can be completed using a part with lower strength. For these cases, you can quickly and cheaply iterate on the design to complete this testing, then order a prototype from a 3D printing service once you have a finalized design.

FDM 3D printers typically have tolerances of ± 0. 15% , however the tolerances are larger for small features, with a lower limit of ± 0.2 mm. While this can be an issue for parts that have tight fit tolerances and smaller features, this is not typically a concern for design testing or display models. In addition, FDM 3D printers have very repeatable output, so you can compensate for any tolerance issues by adjusting your model dimensions and can reasonably expect subsequent prints to maintain these adjustments.

15% , however the tolerances are larger for small features, with a lower limit of ± 0.2 mm. While this can be an issue for parts that have tight fit tolerances and smaller features, this is not typically a concern for design testing or display models. In addition, FDM 3D printers have very repeatable output, so you can compensate for any tolerance issues by adjusting your model dimensions and can reasonably expect subsequent prints to maintain these adjustments.

Getting started with your own 3D printer

Note: Creality Experts receives a commission for items you purchase from this page, at no additional cost to you. For more information, please see our affiliate link policy.

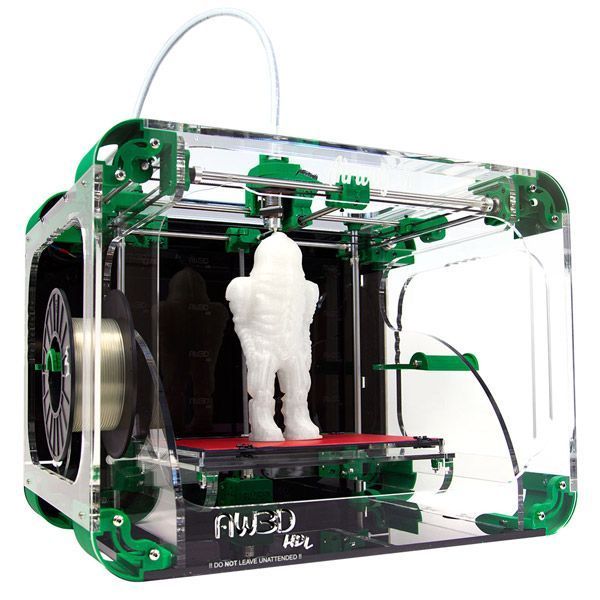

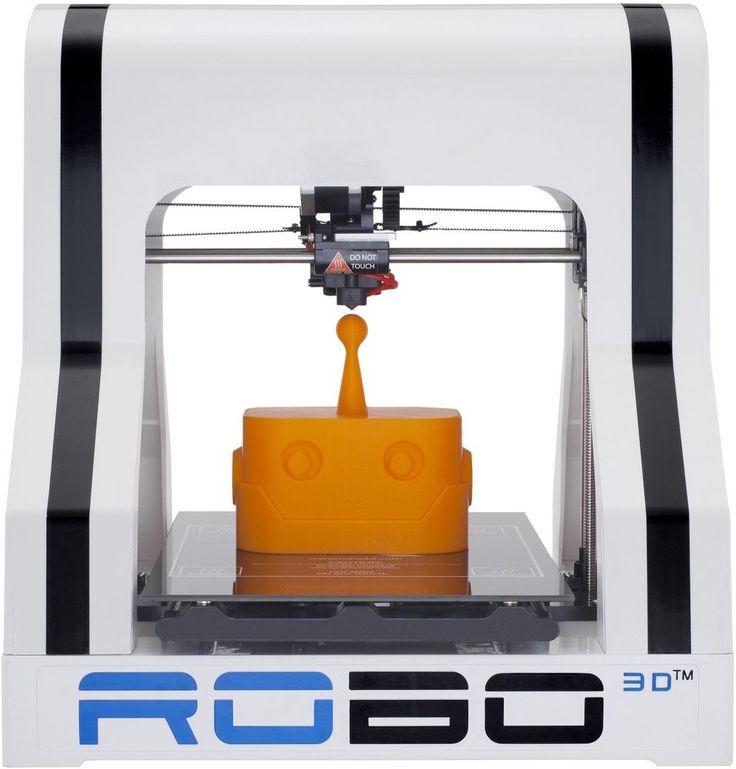

The Creality Ender 3 Max 3D printer balances ease of use and low cost, and can start producing quality parts quickly.

If you are looking to purchase your own 3D printer, starting with a fully or nearly assembled machine will reduce the amount of time you’ll need to spend on setup. The Creality Ender 3 Max (Amazon link) is a great low cost 3D printer that is easy to assemble and offers a large build volume of 300 mm x 300 mm x 300 mm (Most standard FDM printers are 200 mm x 200 mm x 200 mm). This larger size can open up a lot of options for what you are able to print.

The Creality Ender 3 Max (Amazon link) is a great low cost 3D printer that is easy to assemble and offers a large build volume of 300 mm x 300 mm x 300 mm (Most standard FDM printers are 200 mm x 200 mm x 200 mm). This larger size can open up a lot of options for what you are able to print.

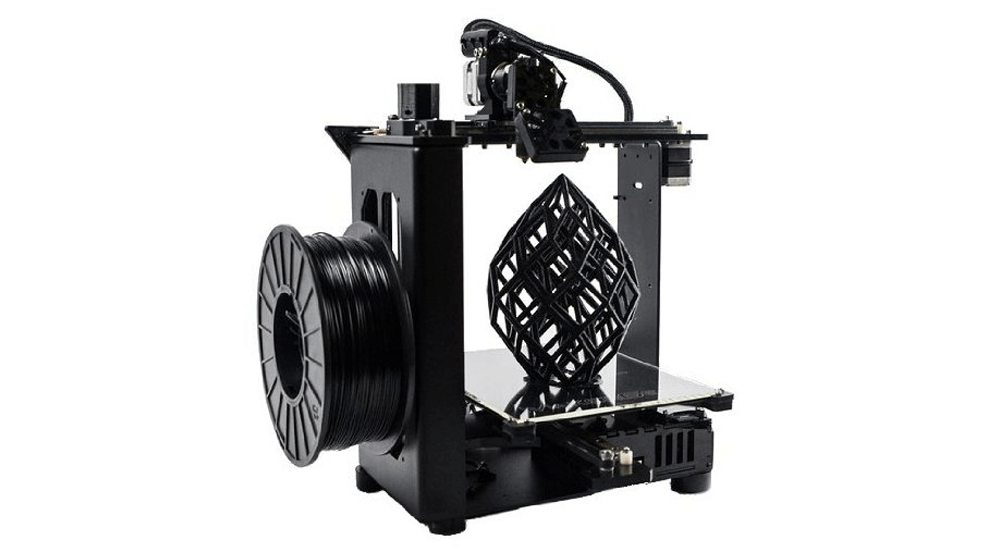

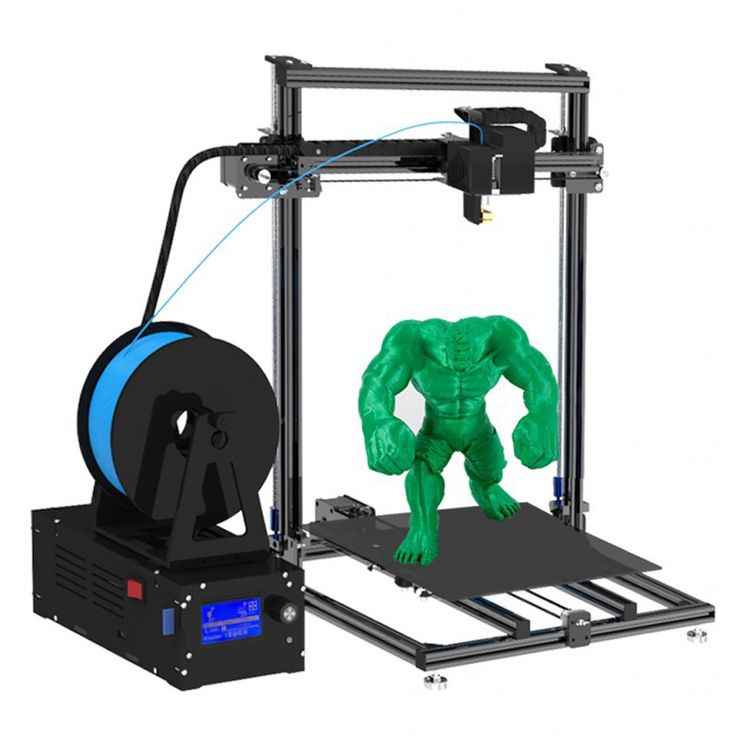

the CR-10s Max is a great 3D printer for larger life size prototypes, such as this full sized wheel rim used for fit testing

If you are looking to print even larger parts, the Creality CR-10 Max (Amazon link) offers a 450 mm x 450 mm x 470 mm build area at a much lower price point than other FDM printers of its size. Like the Ender 3 Max, this printer is mostly pre-assembled and does not require any calibration out of the box.

Every 3D printer will require occasional maintenance, but most maintenance processes are fairly simple and can be accomplished using the basic tools that are included with the printer. Common repairs include:

In addition to the 3D printer itself, you’ll also need to purchase the plastic filament used to build the parts. The most common material for FDM printers is PLA, a corn-based plastic which has great properties for 3D printing. It contracts very little as the part cools, resulting in very little part warping and excellent dimensional accuracy. PLA offers good strength for general use parts, but is not suitable for high stress or high temperature applications. There are many brands of PLA available, and we recommend the following brands from our experience:

The most common material for FDM printers is PLA, a corn-based plastic which has great properties for 3D printing. It contracts very little as the part cools, resulting in very little part warping and excellent dimensional accuracy. PLA offers good strength for general use parts, but is not suitable for high stress or high temperature applications. There are many brands of PLA available, and we recommend the following brands from our experience:

Overture PLA - an affordable general purpose filament with many color options

Hatchbox PLA - a premium brand that offers a great matte surface finish, excellent for showing off fine details

For more information about the types of filament you can use with a 3D printer and recommended brands for each type, see our filament guide.

You’ll also need to choose a slicer software to use with your 3D printer. The slicer software allows you to import a 3D model in common formats such as STL or OBJ and configure them for 3D printing. The Slicer software generates a GCODE file, which contains instructions used by the 3D printer to produce the part. Fortunately, there are many free slicer options available, and we suggest downloading one before you purchase a 3D printer to get an idea how to prepare a 3D model for 3D printing. Our top slicer choice is Cura, which is available for download on Ultimaker.com. While Ultimaker produces their own 3D printers, Cura is widely used with many brands of 3D printers, and printing profiles are available for nearly all FDM 3D printers on the market.

The Slicer software generates a GCODE file, which contains instructions used by the 3D printer to produce the part. Fortunately, there are many free slicer options available, and we suggest downloading one before you purchase a 3D printer to get an idea how to prepare a 3D model for 3D printing. Our top slicer choice is Cura, which is available for download on Ultimaker.com. While Ultimaker produces their own 3D printers, Cura is widely used with many brands of 3D printers, and printing profiles are available for nearly all FDM 3D printers on the market.

Exploring 3D printing services

Treatstock allows you to instantly compare prices from multiple 3D printing services for a variety of material options.

There are many 3D printing service son the market today, but a great place to start your search is treatstock.com, which offers a number of technology options from a network of 3D printing services in your area. Even if you are in the research phase, their instant quote tool allows you to quickly get an idea of the price and timeline for getting parts. Unlike other services, you can communicate directly with the company actually printing the parts before you order, so you can make sure there are no issues or concerns with manufacturing.

Even if you are in the research phase, their instant quote tool allows you to quickly get an idea of the price and timeline for getting parts. Unlike other services, you can communicate directly with the company actually printing the parts before you order, so you can make sure there are no issues or concerns with manufacturing.

If you are looking to take advantage of more premium 3D printing technologies, such as full color multi-jet fusion, services such as hubs.com and xometry.com have these technologies available. While these sites provide instant quotes, you won’t be able to communicate directly with your manufacturer.

Next Steps

Now that you know the basics, we encourage you to continue researching the available options; there is a lot to learn about 3D printing! The best way to get started is to experiment with different options, such as getting a quote from a service like treatstock.com, or downloading a slicer like Cura to get an idea what you can expect when printing parts yourself. Whichever route you go, 3D printing is a great tool to have in your arsenal and may be the tool your business needs to improve efficiency or produce parts more economically.

Whichever route you go, 3D printing is a great tool to have in your arsenal and may be the tool your business needs to improve efficiency or produce parts more economically.

Which 3D printer to choose for business

3D printed business models

3D printing is making its way into more and more areas of life these days. At the same time, the demand for 3D printing remains at a high level and the demand for products produced by additive methods is constantly higher than the supply. In a situation of such a shortage, a far-sighted businessman decides to enter this market in order to earn money by satisfying this request.

For new players in the 3D printing market, the choice of niche is closely related to the choice of technology, technique, and, sometimes, even specific models of 3D printers.

It is important that we are talking about business - a sphere of life in which everything can be found at a price expressed in the amount of money, which means that there are general requirements that apply to equipment. Maximum reliability allows you not to spend on repairs, which means it is worth the investment. The presence of all certificates for the equipment is required by the state from the business. The maximum level of after-sales service allows the entrepreneur not to learn 3D printing, but simply to do the business for which he created his business. The cost of the 3D printer itself is not decisive in choosing a particular machine; in various areas, the payback period for investing in such equipment can be both short and almost instantaneous.

Maximum reliability allows you not to spend on repairs, which means it is worth the investment. The presence of all certificates for the equipment is required by the state from the business. The maximum level of after-sales service allows the entrepreneur not to learn 3D printing, but simply to do the business for which he created his business. The cost of the 3D printer itself is not decisive in choosing a particular machine; in various areas, the payback period for investing in such equipment can be both short and almost instantaneous.

In general, there are several models for using a 3D printer for profit.

-

The company is introducing 3D printing to help existing processes.

-

The company switches to the production of a product using additive technologies

-

And there are companies that deal exclusively with printing, and the very idea of their business and their product is tied to additive technologies.

Let's see what 3D printing technologies are used in different models of companies on the market, as well as how to choose the right 3D printer for the business in your chosen niche!

Business 3D Printer

Modernization of existing business and technical processes is the key to the success of any enterprise. Not surprisingly, with the advent of new technologies, production strategies can be revised and even radically changed.

With the cost of additive technologies becoming cheaper, more and more enterprises are looking for ways to optimize their production using 3D printing. Sometimes, the optimization process leads to quite interesting results.

3D printing in production

Machine production is a method that allows you to get the most profit, and therefore the most interesting from a business point of view. Production line machines require constant maintenance and regular replacement of worn out parts. Usually, the process of replacing a part when it breaks down is as follows - a service employee localizes the malfunction, diagnoses the cause of the failure of a particular part, and orders a new part from the manufacturer according to the catalog. It’s good if the supplier has such spare parts in stock, but it happens that you have to wait until the spare part you need is produced.

It’s good if the supplier has such spare parts in stock, but it happens that you have to wait until the spare part you need is produced.

From the moment of ordering to receipt, it can take from a week to months. All this time the machine is idle, and in our time of widespread use of conveyor chains, this can mean idleness of the whole chain of machines. Moreover, for some machine tools, spare parts cannot be obtained in principle - they can be discontinued, and sometimes it turns out that the company - the manufacturer of the machine has already gone bankrupt and there will be no new parts for the existing machine in principle.

Possible production losses in this case can reach amounts comparable to the value of the enterprise.

But what if the part you need can be obtained without ordering it from the machine manufacturer? The increase in the availability of 3D printing has led more manufacturers to create 3D printing departments based on their service departments. Such a department consists of several 3D modelers, several 3D printers and several 3D printers.

Such a department consists of several 3D modelers, several 3D printers and several 3D printers.

Such 3D printers must meet several requirements - machine parts must be strong enough, the cost of maintaining a 3D printer fleet must be reasonable, and the 3D printer must be able to produce both the spare part itself and models to obtain parts using more expensive methods.

Such requests are met by 3D printers using FDM and LCD technology.

Picaso 3D Designer X Pro

One of the bestsellers in this category is the Picaso 3D Designer X Pro printer. The defining advantages here are the omnivorousness of this model - you can print both ABS, PLA, PETG, Flex, Nylon, as well as more specific and composite plastics - and the ability to print simultaneously with two materials.

Phrozen Transform Standard

Phrozen Transform Standard is also a good choice. Huge build area - 292x165x400 mm, print speed up to 10mm/hour and high-intensity ParaLED system allow this printer to quickly and accurately print parts, including those from specific polymers.

Architectural 3D printing

In architecture, the ability to present a material model of the proposed project to the customer is of great importance. There is little to promote acceptance; a positive decision, such as the opportunity to inspect and feel live at least a model of a building or apartment. For the production of such models in architectural bureaus and studios, there are large departments. A few years ago, next to the powerful computers of architects, there were workshops for the manual production of models from papier-mâché and other materials that are little associated with modern technology;

Affordable 3D printing has taken the manufacturability of the production of architectural models to a whole new level! Moreover, it turned out to be extremely simple to integrate 3D printing technologies into the work of an architectural bureau - engineers in this direction have already specialized in working with one or another software product related to the creation of 3D models, it only remained to bring this work to its logical conclusion - a layout.

The requirements for 3D printers for architectural offices are primarily related to the ability to produce large layouts. Strength here is not as important as the ability to convey the characteristic features of the project as accurately as possible - after all, the layout is a reduced copy, which means all the details will be tiny. These requirements are met by FDM 3D printers.

Raise3D Pro2 Plus

A good choice for an architecture studio is the Raise3D Pro2 Plus 3D printer. A large construction area, coupled with precision, through the use of high-quality components and optimal kinematics, allow you to carry out large-scale projects. The ability to print with two materials at the same time makes the implementation of projects easier and allows you to simplify the post-processing of finished models.

BigRep Studio

For particularly demanding architects, BigRep Studio will be a pleasure to work with. Resume printing from the same place after a power outage, remote control and print management make it possible to install this truly large machine in its dedicated room. Well, if necessary, put it in the office, it will pass through the door, since the manufacturer provides the opportunity to disassemble it into 2 halves.

Well, if necessary, put it in the office, it will pass through the door, since the manufacturer provides the opportunity to disassemble it into 2 halves.

Advertising and exhibitions

The advertising business is probably one of the most demanding of novelty. The new attracts attention, and that's what advertisers do. The media that conveys the advertising message is of high importance. Today, any new way to attract a potential client is in demand.

A special area of this business is the organization of stands for exhibitions and similar events. It often happens that there is very little time to implement an idea, and success is achieved due to the possibility of implementing the maximum range of such ideas.

So in advertising, 3D printing is in demand in a huge number of its manifestations. Here the creation of handouts, and layouts of future projects, and noticeable signs of pylons and posters. Different 3D printing methods are suitable for different areas of the advertising business, FDM and LCD are very much in demand. One of the fastest growing areas of advertising using 3D printing is signage. A 3D printer creates an almost finished product - all that remains is to connect the backlight and electronics. This allows, firstly, to implement ideas that are too costly to implement by other methods, and secondly, to significantly simplify the tailor made approach to the customer - each customer wants his own, unique sign. The requirements for such equipment are special. The size is of course very important, the sign must be highly visible, which means the print area must be suitable - wide and long, but not too high. Printing speed is more important than quality, you can't see small inaccuracies from afar. Signs are most often placed on the street, which means that it is important that the products are resistant to use in different weather conditions, which means that it is necessary to be able to print with suitable plastics.

One of the fastest growing areas of advertising using 3D printing is signage. A 3D printer creates an almost finished product - all that remains is to connect the backlight and electronics. This allows, firstly, to implement ideas that are too costly to implement by other methods, and secondly, to significantly simplify the tailor made approach to the customer - each customer wants his own, unique sign. The requirements for such equipment are special. The size is of course very important, the sign must be highly visible, which means the print area must be suitable - wide and long, but not too high. Printing speed is more important than quality, you can't see small inaccuracies from afar. Signs are most often placed on the street, which means that it is important that the products are resistant to use in different weather conditions, which means that it is necessary to be able to print with suitable plastics.

Flashforge AD1 Channel Letter

The Flashforge AD1 Channel Letter 3D printer is perfect for solving such problems. Its huge printable area allows you to print signs that will be visible from a great distance. The high-speed extrusion system will make this process relatively fast, and the ability to print in multiple colors makes the need for post-processing much lower. The use of such a machine allows not only to meet the requirements of the most fastidious customers, but also to significantly reduce the cost of production.

Its huge printable area allows you to print signs that will be visible from a great distance. The high-speed extrusion system will make this process relatively fast, and the ability to print in multiple colors makes the need for post-processing much lower. The use of such a machine allows not only to meet the requirements of the most fastidious customers, but also to significantly reduce the cost of production.

Jewelry 3D Printer

Since ancient times, jewelry has been considered one of the most profitable. The history of jewelry creation dates back many centuries and goes back to the time of the birth of the Homo Sapiens species. Many techniques in this area of production have been preserved for decades, and are in many ways an art. But even in this area, we see that additive technologies help to realize more and more projects and ideas.

The meaning of the word “jewelry” itself is associated with miniature, precision and painstaking work. A lot of time and effort is spent on creating each piece of jewelry, which as a result can easily turn out to be a masterpiece of art. 3D printing helps to facilitate the production of highly detailed blanks, making the work of the craftsman easier. Most often, models are printed, according to which such semi-finished products are subsequently smelted. The achievements of modern technologies bring their quality to the level of an almost finished product. For this, of course, the SLA 3D printing method is used - with its help you can create the most detailed models. The requirements for such 3D printers are related to the maximum resolution of finished models, as well as the ability to use materials created for subsequent transformation into metal, for example, by direct casting.

3D printing helps to facilitate the production of highly detailed blanks, making the work of the craftsman easier. Most often, models are printed, according to which such semi-finished products are subsequently smelted. The achievements of modern technologies bring their quality to the level of an almost finished product. For this, of course, the SLA 3D printing method is used - with its help you can create the most detailed models. The requirements for such 3D printers are related to the maximum resolution of finished models, as well as the ability to use materials created for subsequent transformation into metal, for example, by direct casting.

Phrozen Sonic XL 4K

A good example of a suitable 3D printer for jewelry is the Phrozen Sonic XL 4K LCD technology. The maximum resolution of 4K allows you to create the most detailed models, and the ParaLED system significantly reduces the time of their production.

Phrozen Sonic Mighty 4K

For workshops dealing with more miniature production, the Phrozen Sonic Mighty 4K may be sufficient. Although the build area is smaller and the ergonomics of the machine are not as well thought out, this printer performs well enough to be a rational choice when looking for a 3D printer for a small workshop.

Although the build area is smaller and the ergonomics of the machine are not as well thought out, this printer performs well enough to be a rational choice when looking for a 3D printer for a small workshop.

Sculpture

A striking example of a paradigm shift in production in our time is sculpture. Many people remember the saying of the great Michelangelo Buonarroti “I take a stone and cut off all that is superfluous.” How exactly the master defines the fundamental principle of subtractive technologies! Modern developments help to make the process of creating masterpieces more connected with working with the head than with the hands.

In our time, the sculptor has the opportunity not only to work with material objects, but to almost completely rid himself of such work. A chisel and hammer can replace a computer and a 3D printer. The requirements for the machine in this bundle are mainly related to the area of \u200b\u200bconstruction - sculptures can often be large. There is also a need for printing with different materials to implement projects that are complex in terms of 3D printing. It is important that the finished model can be processed by classical methods. Suitable 3D printing methods are FDM and SLA.

There is also a need for printing with different materials to implement projects that are complex in terms of 3D printing. It is important that the finished model can be processed by classical methods. Suitable 3D printing methods are FDM and SLA.

CreatBot D600 Pro

The CreateBot D600 Pro 3D printer becomes a frequent inhabitant of the studios of successful architects. A huge build area, the ability to print with two materials at the same time make this machine ready for the implementation of projects of increased complexity. The presence of a special table cover, as well as a special compartment for drying plastics, makes the process as comfortable as possible and does not require extra space.

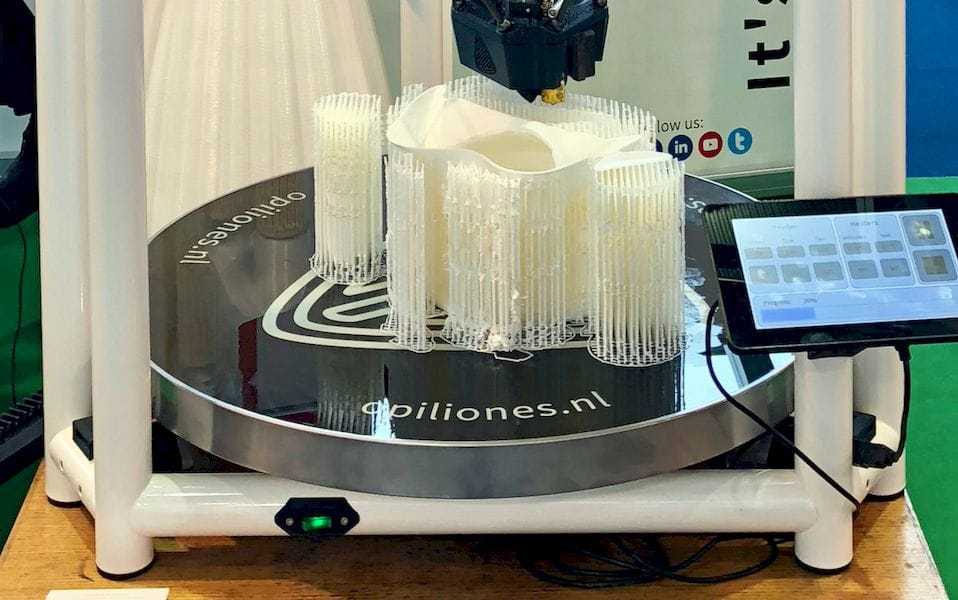

Peopoly Phenom XXL

For more detailed sculpting tasks, it will be useful to look at the Peopoly Phenom XXL 3D printer. The gigantic build area, coupled with the use of MSLA technology, makes this machine stand out from other printers in this price range.

Business converted to use a 3D printer

There are several periods of the so-called “breakthrough development of production” in history. One of the last can be called the Great Industrial Revolution in England. This revolution was made possible and resulted from the invention of a new method of production - production with an improved steam engine. Living during even such a revolution, it is difficult to realize the significance of a single invention or new technology for future generations. But even these difficulties do not prevent us from reasonably calling modern additive manufacturing methods revolutionary, of great importance, and changing entire business sectors.

Today we see a huge number of companies that, while remaining fundamentally in the same area, are changing the entire production line of their product, based on the new opportunities that 3D printing provides.

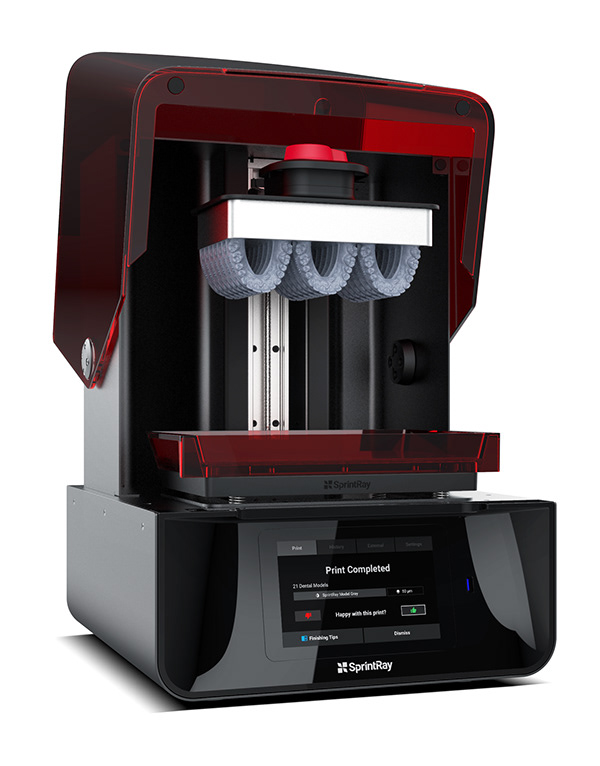

Dental 3D printers

For me personally, going to the dentist is always stressful. Despite the fact that in our time, sitting in the dentist's chair and not feel real negative sensations, memories of visits to doctors in childhood encourage us to think less about the existence of problems with teeth. Perhaps you do the same. It is also possible that for this reason, you, like me, do not notice strong changes in this area of \u200b\u200bmedicine. And they are really huge and, in my opinion, even a little magical.

Despite the fact that in our time, sitting in the dentist's chair and not feel real negative sensations, memories of visits to doctors in childhood encourage us to think less about the existence of problems with teeth. Perhaps you do the same. It is also possible that for this reason, you, like me, do not notice strong changes in this area of \u200b\u200bmedicine. And they are really huge and, in my opinion, even a little magical.

Modern technologies have made it possible to change the correction of such a frequent feature of dental clinic clients as malocclusion. In the days before 3D printing, overbite was corrected with braces or braces. This process was very pleasant, required a lot of attention from the client, and also forced to replace the usual tools, such as a toothbrush, with specific and inconvenient ones. For many, wearing braces was also unpleasant from an aesthetic point of view.

Why did people make such sacrifices? A metal brace attached to the teeth puts pressure on them in a certain direction, forcing them to shift towards the medically correct position. After a few months of wearing, the braces literally push the teeth where the dentist has determined.

After a few months of wearing, the braces literally push the teeth where the dentist has determined.

This is what the aligners look like

3D printing has changed the approach to the process itself so much that a patient undergoing a course of bite changes practically does not change his habits and lifestyle! This technology is called aligners (from the English allign, align). Now the dentist takes a 3D map of your teeth, a special program calculates the necessary changes and creates 3D images of special onlays for teeth, which are subsequently cast from special materials according to 3D printed models. The patient puts on such linings before going to bed and takes them off in the morning. The accuracy of manufacturing is so high that it allows the maximum dosage of pressure on certain teeth, forcing them to move into place in the most natural and imperceptible way. The absence of the need to specially maintain such pads, the invisibility of the process to others, and the comfort make this technique very popular. The purchase of what kind of 3D printers will allow you to enter the dental services market? The main requirement is medical neutrality, the machine itself, plastics, production quality must be such that use in medical institutions is justified. An important issue is the availability of the necessary specific certificates. Mandatory ability to produce high-precision models.

The purchase of what kind of 3D printers will allow you to enter the dental services market? The main requirement is medical neutrality, the machine itself, plastics, production quality must be such that use in medical institutions is justified. An important issue is the availability of the necessary specific certificates. Mandatory ability to produce high-precision models.

One of the leading printer manufacturers for this market segment is Formlabs.

Formlabs Form 3

The Formlabs Form 3 3D printer allows you to create high-quality models using a wide range of plastics. Particular attention to issues related to the possibility of using printers from this company in medical institutions allows you to be sure of their safety. Ergonomics and ease of use make it possible to concentrate even more on the really important things - helping the patient.

Formlabs Form 3L

For dental clinics that have already increased their production volumes and the need for even more advanced equipment is clearly overdue, the Formlabs Form 3L 3D printer will be a rational choice. The advantages of this machine will not only be an increased build area, but also closed-loop calibration and simplified component replacement.

The advantages of this machine will not only be an increased build area, but also closed-loop calibration and simplified component replacement.

3D printing in modern orthotics

Will it be news to you that the left and right legs of each of us are of different lengths? And will it be news to you that this can affect your life much more than just complications with the choice of trousers? It turns out that the individual characteristics of a person associated with the length of the legs can be the cause of many diseases, including mental ones, such as depression. Orthopedists help to get rid of problems associated with the peculiarities of the bones, muscles and joints of the patient. Quite often, the healing technique of interaction is based on the principle that we discussed in the previous part of the article - gentle movement and maintenance of body parts in a medically correct place in the body. For example, if the disease is due to the fact that leaning on legs of different lengths, you have a curvature of the spine, the orthopedist prescribes insoles of different thicknesses for you, thereby leveling the difference in the length of your body supports. And here 3D printing helps a lot with its accuracy, and most importantly, the ability to manufacture to individual sizes. Basically, in this area of medicine, solutions based on FDM technology are used. Machines capable of printing with various plastics, including elastic and hypoallergenic, are required. The ability to print products immediately in pairs is welcome.

And here 3D printing helps a lot with its accuracy, and most importantly, the ability to manufacture to individual sizes. Basically, in this area of medicine, solutions based on FDM technology are used. Machines capable of printing with various plastics, including elastic and hypoallergenic, are required. The ability to print products immediately in pairs is welcome.

Raise3D E2

These requirements are met by the Raise3D E2 3D printer. Automatic printing of products in pairs, the ability to use elastic materials for printing, convenient operation, and a filter make this model a good choice for an orthopedic clinic.

Cosplay

Many of us love masquerades. Probably one of the most exaggerated ways to dress up is cosplay (from the English costume play - costume play). Changing clothes, applying make-up, using additional accessories, cosplayers sometimes become almost like a copy of the heroes of movies, cartoons or comics. And if a pipe and a bowler hat can be enough to become Commissioner Maigret, then in order to turn into Iron Man or Wonder Woman, you need to create many elements of the costume from scratch. 3D printing helps with this. Cosplayers create such impressive costumes on a 3D printer that it is very difficult to guess about the use of 3D printing in their production. At the same time, if earlier costumes were created mainly with the help of papier mache and similar technologies, today most of the cosplay costumes are made using additive technologies. FDM is more commonly used, but LCD methods are also in demand.

3D printing helps with this. Cosplayers create such impressive costumes on a 3D printer that it is very difficult to guess about the use of 3D printing in their production. At the same time, if earlier costumes were created mainly with the help of papier mache and similar technologies, today most of the cosplay costumes are made using additive technologies. FDM is more commonly used, but LCD methods are also in demand.

A cosplay 3D printer should be able to print large models as quickly as possible. Plastics used are different, but mostly inexpensive, accessible, and easy to process.

Anycubic Chiron

Cosplayers starting to print costume details often look at the Anycubic Chiron 3D printer. This is an inexpensive machine that allows you to print with affordable plastics and create models that fit into a large print area of 400x400x450mm. An additional advantage of the model is its high maintainability and unpretentiousness in maintenance.

Anycubic Photon Mono

To create accessories and details requiring more detail, purchase the Anycubic Photon Mono. The main advantage of this machine, of course, is its price. At the same time, the print resolution, although it does not reach the height of professional models, is at a level more than sufficient for use in cosplay.

The main advantage of this machine, of course, is its price. At the same time, the print resolution, although it does not reach the height of professional models, is at a level more than sufficient for use in cosplay.

Pure 3D printing business

Speaking about the various niches in the market that have been created by new technological opportunities, one cannot fail to mention those companies whose business appeared as a result of the advent of 3D printing and cannot exist without it. It happens that such companies were initially engaged in something else, but then they saw the economic feasibility of switching to a new business model. There are many companies that were originally created and designed for entrepreneurship based on 3D printing. Due to the fact that additive technologies literally burst into all areas of our lives like an avalanche, it may seem that they are indistinguishable from the companies described in the previous parts of this article. Looking closely, you can see that they make a profit exclusively by doing 3D printing.

Prototyping

Personally, 3D printing has always seemed to me to be a way to create some kind of device or device parts. Moreover, it was important that if I made a mistake in calculations or taking measurements, I could always quickly correct the computer model and get a new version of the required component in the shortest possible time. Abroad for a long time, and now in our country, there are companies on the market that are engaged exclusively in the production of prototypes. Quite often it turns out that this is a subsidiary of some kind of laboratory or research center. Depending on the area in which these prototypes are used, 3D printing techniques and requirements for 3D printers can be different. Most often this is FDM printing, which must be accurate. A prototyping 3D printer should be easy to operate and maintain.

PICASO 3D Designer X

In our country, the PICASO 3D Designer X 3D printer is in great demand. The high printing accuracy of this printer is combined with a compact body with the ability to dry plastic in the process. Working with various plastics is facilitated by the system of profiling print parameters for each plastic - if you don’t like how the model was printed, you can print it with another plastic without using a computer, it’s enough to have a profile for it. Ergonomics, ease of monitoring the printing process, a high degree of automation add significant advantages to the scales of this printer.

Working with various plastics is facilitated by the system of profiling print parameters for each plastic - if you don’t like how the model was printed, you can print it with another plastic without using a computer, it’s enough to have a profile for it. Ergonomics, ease of monitoring the printing process, a high degree of automation add significant advantages to the scales of this printer.

Flash Forge Finder

The FlashForge Finder 3D printer is used to create low-level prototypes and to teach the 3D printing process. Also, the low cost and bright appearance make this printer an attractive purchase for studios and circles, where children get acquainted with additive technologies.

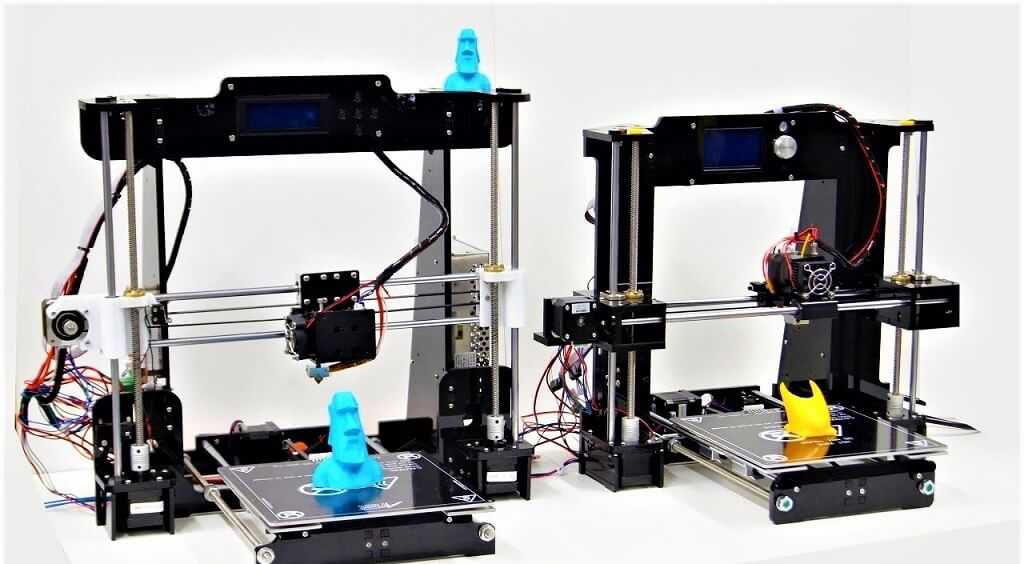

Custom 3D printing

You can print on a 3D printer a huge, almost infinite number of types of things. And some of them need to be printed in one copy and that's it. Someone needs 3D printing not constantly, but not often or even very rarely. Custom 3D printing companies are helping to meet the needs of these potential customers. Usually a full service is provided - model development, 3D printing and processing. Often these companies have many 3D printers, and they are located in the same room. Such assemblies are called 3D printed trusses. The technologies that are presented on such farms are FDM and LCD. The fact is that the requirements for printers here are formed mainly in terms of the price of the printer, the cost of maintenance and reliability. For the fastest return on investment in a 3D-printed farm, inexpensive printers are purchased for it in batches - the more unification, the easier it is to work.

Usually a full service is provided - model development, 3D printing and processing. Often these companies have many 3D printers, and they are located in the same room. Such assemblies are called 3D printed trusses. The technologies that are presented on such farms are FDM and LCD. The fact is that the requirements for printers here are formed mainly in terms of the price of the printer, the cost of maintenance and reliability. For the fastest return on investment in a 3D-printed farm, inexpensive printers are purchased for it in batches - the more unification, the easier it is to work.

Creality3D Ender 3

The Creality3D Ender 3 3D printer holds the undisputed leader in terms of affordability/quality ratio in this market segment. Its cost, decent print quality, acceptable reliability and high maintainability make it possible to recoup investments in creating a farm based on such machines in the shortest possible time. Without a doubt, this is one of the best 3D printers for 3D printed farm!

Anycubic Photon Mono X

It is not uncommon for 3D printed trusses to purchase multiple Anycubic Photon Mono X 3D printers to enable collaboration with customers who require a radically different level of detail. The reliable linear guides, high level of consumables unitization, and low maintenance seem to be a strong point. arguments in his favor.

The reliable linear guides, high level of consumables unitization, and low maintenance seem to be a strong point. arguments in his favor.

Multiple cases

It's always interesting to hear success stories. Let me give you a few real cases as an example.

3D printer - creator of scarce spare parts

There is an AUCHAN plant in the Tambov region. On the production lines of this enterprise, most of the machines are foreign. The machines use a huge number of plastic parts, some of which are considered consumables and are ordered from the manufacturer with a margin.

In particular, there is a line for the production and processing of plastic containers. For the washing machine on this line, the plant regularly ordered washer nozzles in Europe.

One terrible day for the manufacturer, on another machine of this line, a plastic part failed, without which the line stood up. After contacting the supplier, it turned out that this particular part was out of stock. We would have to wait for a new delivery for at least 2 months, and during this time the line would be idle. In such a case, the production would suffer big losses.

We would have to wait for a new delivery for at least 2 months, and during this time the line would be idle. In such a case, the production would suffer big losses.

The management decided to turn to a 3D printing studio to urgently create a scarce part based on a failed one. The part was created in the shortest possible time, production resumed its work, although there was a loss, it turned out to be completely incomparable with what it could have been.

Seems like a success story. But it was not all success!

In the process of negotiations with the contractor, it turned out that it is possible to quickly produce a large range of parts for this line, in particular, washer nozzles. At the same time, with the same quality of parts, the cost of these consumables turned out to be much lower. Such production made it possible to abandon logistics costs, free up storage space, and the cost of the part itself turned out to be corny lower. As a result, prototypes were presented, and then finished parts. The company was incorporated into UK Bekar and now this small 3D printed farm is doing contracts on a full-time basis for a large manufacturer. Everyone was a winner!

The company was incorporated into UK Bekar and now this small 3D printed farm is doing contracts on a full-time basis for a large manufacturer. Everyone was a winner!

Legs of different lengths and what does 3D printing have to do with it

I had a terrible boss at one of my previous jobs. He always found fault with no reason, voiced conflicting demands, in general, it was uncomfortable to work, and I thought about quitting.

But I didn't quit, and here's why.

It turned out that the boss was such a radish simply because he was haunted by constant headaches. He went to different doctors, to no avail. He made a visit to the next doctor when I was just starting work in the company. It was a turning point, he went to the orthopedist. In Germany. There, in a few days, they determined that he had headaches from the fact that the pelvis was displaced. And the pelvis is displaced because one leg is longer. Special insoles were prescribed and produced right in the clinic.

I remember that Thursday when he returned from his trip. I was shocked that he gave the bonus to our entire department, including me. Yes, and in person, it seemed that he had been replaced. Completely different, better person!

This story led him to invest in the creation of a laboratory for the production of such insoles in Russia based on the existing center of orthopedics. So to speak, I bought myself personal manufacturers of insoles. On this technological base, it was possible to produce, among other things, shoes designed taking into account the individual characteristics of the customer's foot. Subsequently, he sold this business, some of the specialists work in the Perseus Ortho center.

How the desire to help his wife turned into a business

And finally, a description of the case in which I took a personal part.

Alexander is my neighbor. Worked in a company that was engaged in deliveries abroad. We crossed paths with him on the topic of 3D printing, he bought himself an Ender 3 and printed all sorts of toys, trinkets and useful details. His wife Marina, as a hobby, baked various cookies, and sold them a little through Instagram. After 2018, the company went bankrupt and Alexander found himself out of a job. He was looking for a new job via the Internet, and Marina asked him to find on the Internet and buy a form for cutting cookies - the goddaughter asked her to bake cookies in the form of a unicorn for her birthday. After a long search, Sasha decided that it was easier for him to model this form himself and print it on a 3D printer than to find the right one. Within one day, the work was done, the cookies were baked, the goddaughter was happy, the photos of the cookies were posted on Instagram.

His wife Marina, as a hobby, baked various cookies, and sold them a little through Instagram. After 2018, the company went bankrupt and Alexander found himself out of a job. He was looking for a new job via the Internet, and Marina asked him to find on the Internet and buy a form for cutting cookies - the goddaughter asked her to bake cookies in the form of a unicorn for her birthday. After a long search, Sasha decided that it was easier for him to model this form himself and print it on a 3D printer than to find the right one. Within one day, the work was done, the cookies were baked, the goddaughter was happy, the photos of the cookies were posted on Instagram.

I heard this story some time later, when Alexander asked me to help him complete an order for 3D printing. It turned out that Marina was literally inundated with questions about cookies, and subsequently, with orders for cutting molds. In just a couple of weeks, the number of orders for modeling and printing exceeded the capabilities of Sasha's printer, and he turned to me.

The ending of this story is good, Sasha has been creating and printing forms to order for some time. For this, a powerful computer and 6 printers were purchased. A year later, the business was sold and Alexander left for Canada for permanent residence.

Finalizing

3D printing helps companies of a completely different profile occupy a variety of niches in the market. At the same time, there are many free niches, and often the prospect of using 3D printing in a certain area is not so obvious.

The success stories associated with the use of additive technologies are numerous, from the aerospace industries to the creation of toys.

The presented cases help you look at the existing order of things a little differently. It makes economic sense to check how 3D printing can help the business you run. It may be profitable to enter a new sector of the market with the help of 3D printing. In any case, the ability to understand the choice of 3D printers for business can be an additional benefit.

Good luck in building your successful business using a 3D printer and good adhesion!

The best 3D printer for small business: features of choice

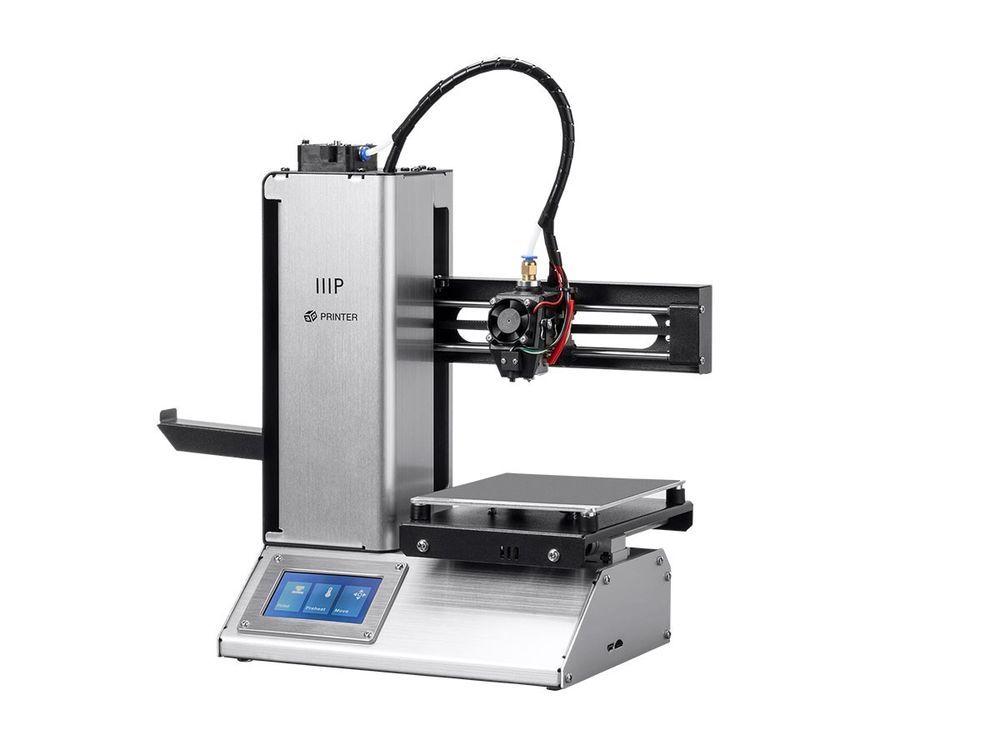

Modern technologies open up additional opportunities for earning. So, for example, a 3D printer for a small business will allow you to combine an interesting and favorite pastime with work. However, the success of the case will largely depend on the correct choice of device. Consider the main parameters that will help you choose the best 3D printer for a small business.

The main parameters to consider when choosing a 3D printer for small business

Let's look at the main selection criteria that will help you buy the best 3D printer for your small business.

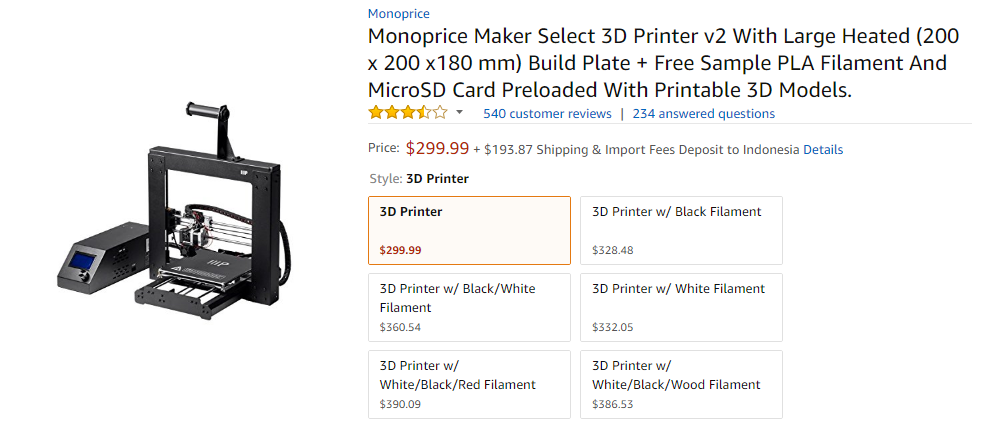

Price. Modern manufacturers of 3D printers offer devices in the most diverse range. If using the device it is planned to produce unique models of the highest quality, then products cheaper than $ 1000 should not even be considered. An equally important parameter is the cost of consumables. As a rule, for a bobbin with a plastic thread, you will have to pay 35-60 dollars per kilogram. The price is affected by the type of plastic, its quality and color. When choosing the best 3D printer for a small business, it is imperative to take note of its manufacturer. The reason is simple - in the future, a certain part may be required for it, but if there are practically no official representatives, it will be extremely difficult to order it.

An equally important parameter is the cost of consumables. As a rule, for a bobbin with a plastic thread, you will have to pay 35-60 dollars per kilogram. The price is affected by the type of plastic, its quality and color. When choosing the best 3D printer for a small business, it is imperative to take note of its manufacturer. The reason is simple - in the future, a certain part may be required for it, but if there are practically no official representatives, it will be extremely difficult to order it.

Types of plastics used. Plastics used in home 3D printers are made from petroleum products, sugarcane or corn. In the first case, ABS plastic is made, in the second - PLA plastic. The first option is distinguished by high durability and resistance to elevated temperatures, the second is environmentally friendly, it is used for the manufacture of plastic toys for small children, as well as dishes. The best option for a printer is a device that can print both types of plastics.

Maximum dimensions of manufactured products. Budget models of devices allow the manufacture of parts whose side does not exceed 120 mm. When buying a 3D printer for $3,000, you can produce products that can reach 30 cm² in volume and weigh 5 kg. It is also necessary to take into account the possibility of the required products to be glued or assembled from elements. In the latter case, the maximum dimensions of the structure are not limited by the dimensions of the products manufactured by 3D printers.

Print nozzle size. An important parameter when choosing a device for 3D printing is the maximum resolution. To date, you can buy 3D printers that can apply material with a thickness of 50 microns - it cannot be distinguished by the human eye. This allows you to "print" products of perfect smoothness. Cheap devices will allow you to get a resolution of 250 microns. But to open a home production, you can purchase a printer with a nozzle size of 100 microns. However, it must be remembered that the higher the quality of the “print”, the more time it takes.

However, it must be remembered that the higher the quality of the “print”, the more time it takes.

Multicolour "printing" possible. Only expensive 3D printers can make multi-color prototypes. Their design provides for several print heads. When performing a task, they are combined. Such devices will allow you to get the result of the highest quality. If it is possible to tint products manually, this will achieve considerable savings. Alternatively, you can make a design from various components, for the production of each of them you can change the color of the thread.

3D printers ideal for small businesses

Ever since 3D printing technology has been around, it has grown in popularity and development. To date, it has weaknesses, such as size limitations and low prototyping speed. Therefore, when expanding your business and increasing needs, one 3D printer is not enough, you will have to purchase additional equipment.

However, developments do not stand still.