3D printer nozzle brush

Brushes for cleaning nozzles of 3D printers FFF/FDM.

fter a certain use of a 3D printer, preventive maintenance must be carried out, within which is the cleaning of the parts that make up the 3D printer. The cleaning brushes (nylon, brass and steel) are ideal for cleaning all the components and surfaces that make up the 3D printer. Thanks to its suitable brushing area (10x33 mm) and the ergonomic grip zone (170 mm), the cleaning brushes can access any corner of the 3D printer with great ease and thus reduce time and money in maintenance.

The cleaning brushes are made of three materials: nylon, brass and steel. With this range of materials cleaning on any surface is ensured and without causing damage or scratches on the element to be cleaned.

The nylon cleaning brush is common for removing dirt, especially dust and chips from any material, from delicate surfaces such as upholstery, fabrics, glass or other. In 3D printing the nylon brush is used on cables and electronic components or to remove dirt and filament chips from the interior, where adhesion of dirt to the printer is minimal. With this type of brush it is ensured not to damage any surface.

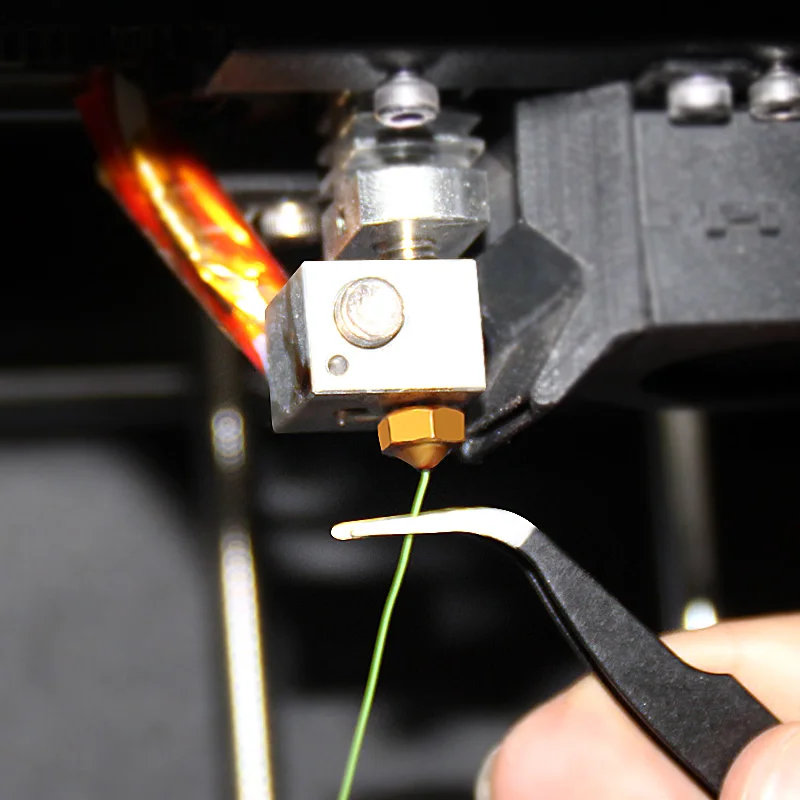

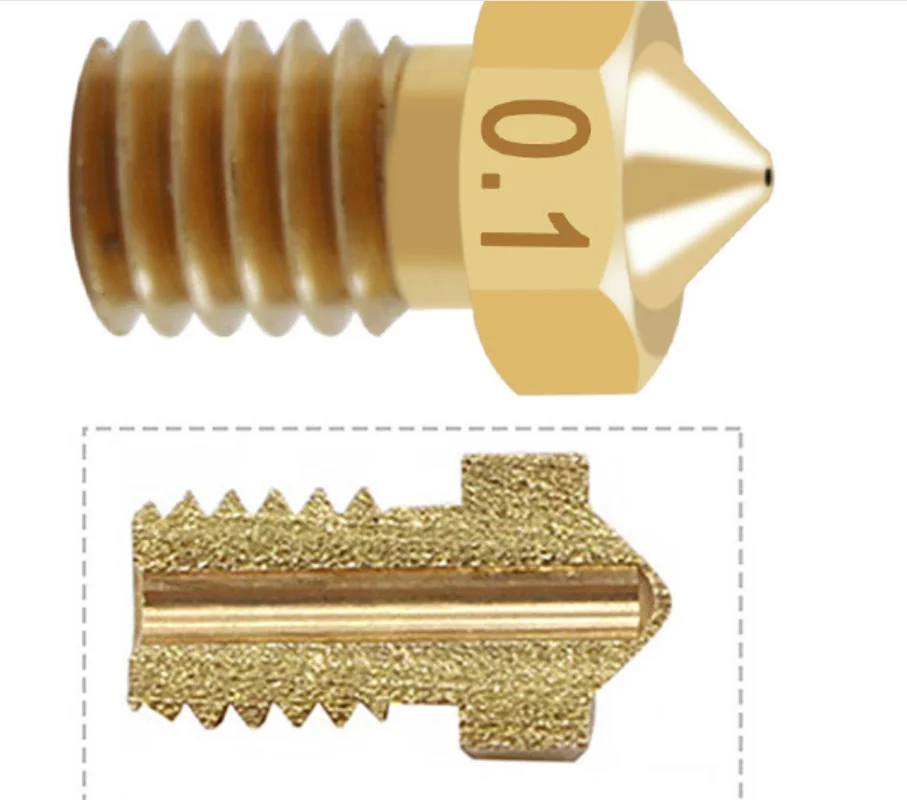

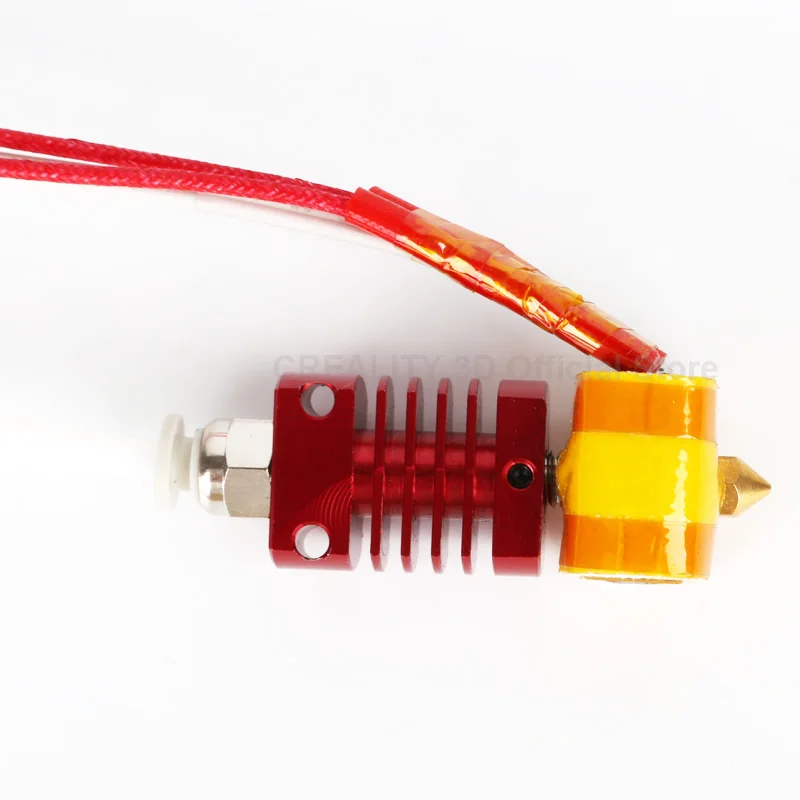

The brass cleaning brush is ideal for removing dirt or molten material from relatively hard surfaces, such as steel or high-strength plastics. This brush is ideal for removing traces of filaments, such as PLA or ABS, which can accumulate in the drive pinion of the extruder or on the outside of the nozzle. To perform this cleaning, the nozzle pmust be heated above the softening point of the material to be removed. For example, if you want to clean a nozzle traces of PLA, you must heat the nozzle t 100 ° C, once that temperature is reached you just have to pass the brass brush over the nozzle, without applying excessive force, and in few repetitions the nozzle it will be clean again.

The steel cleaning brush is the one that has the highest hardness of the three. It is likely that many users of a 3D printer after many hours of use are found with the brass nozzle completely filled with molten material or that a failed print has caused the same effect. In this case, the same process must be carried out as with the brass brush, but being very careful with the force applied for cleaning. Once removing more dense dirt it is recommended to use the brass brush to achieve an impeccable cleaning. With hardened steel nozzles the steel brush should be used, since the brass brush is not hard enough to remove dirt from the surface.

Image 3: Steel cleaning brushTherefore, with this pack of 3 brushes ensures the correct cleaning of the vast majority of elements of a 3D printer.

To avoid damage to the areas that you wish to clean, you must choose the cleaning brush correctly. To ensure that the cleaning brush (nylon, brass or steel) is adequate, it is recommended to make a test on a corner to avoid damage.

To ensure that the cleaning brush (nylon, brass or steel) is adequate, it is recommended to make a test on a corner to avoid damage.

| Kit content | 1x nylon brush 1x brass brush 1x steel brush |

|---|---|

| Brush length | 170 mm |

| Brushing area | 10 x 33 mm |

| HS Code | 8203.2 |

Free STL file X Gantry Nozzle Cleaning Brush・3D printing template to download・Cults

Clusterflake 2020 Fuck Corona Ornament

€2.54

Cutest Plague Doctor Earrings

€0.91

Pixel 7 TPU Case With Camera Protection

€1.98

QuickThrow Holster For Yo Yo

€4.76

Snap Off Box Cutter 18mm Magnetic Jack Knife

€1. 28

28

Flowerpot Earrings

€1.44

Perseverance Mars Rover Ear Saver

€1.30

Drawer Knife Organizer

Free

Best 3D printer files of the Tools category

Calibrate & Reverse axis check 30mm

Free

Corner Clamp

Free

Saginau face shield optimized in material

Free

Prop Guard for 250mm Drone Protection Propeller with Stand

Free

Reusable Respirator Mask with eyes protection with diposable filter

Free

Tent Stake Bundle

Free

Tiko Hanging Spool Holder

Free

3D printing optimized multifunctional stand

€6. 50

50

Best sellers of the category Tools

Chill Buddy Lighter Case

€0.95

3D Printed Strain Wave Gear (Harmonic Drive)

€4.99

Fast-Print Paint Bottle Rack (6 Sizes)

€2.91

phone ring holder

€0.90

Printer Drawers For Ikea Lack Table

€1.99

Armadillo - Flex Wire Conduit

€1.72 -50% €0.86

FLSUN v400 display holder

€4.99

PRECISION DIAL INDICATOR 3D PRINTING DIY

€1.90

ENDER 3 S1/PRO SPRITE, 4020 FAN CR TOUCH NO Y OFFSET

€1. -15% €1.66 96

96

Ender 3, 3 V2, 3 pro, 3 max, dual 40mm axial fan hot end duct / fang. CR-10, Micro Swiss direct drive and bowden compatible. No support needed for printing

€1.62

PET-Machine, make Your own filament from plastic bottles at home!

€50 -70% €15

Scissor Paint Rack

€5.30

Fire Hydrant Stash Container

€1.92

GEARS & TRACTION MECHANISM

€9.61 -40% €5.76

PRECISION CALIPER 3D PRINTING DIY

€3. 11

11

Spartan 4mm Hex tool bit holder

€1.80

Would you like to support Cults?

You like Cults and you want to help us continue the adventure independently? Please note that we are a small team of 3 people, therefore it is very simple to support us to maintain the activity and create future developments. Here are 4 solutions accessible to all:

ADVERTISING: Disable your AdBlock banner blocker and click on our banner ads.

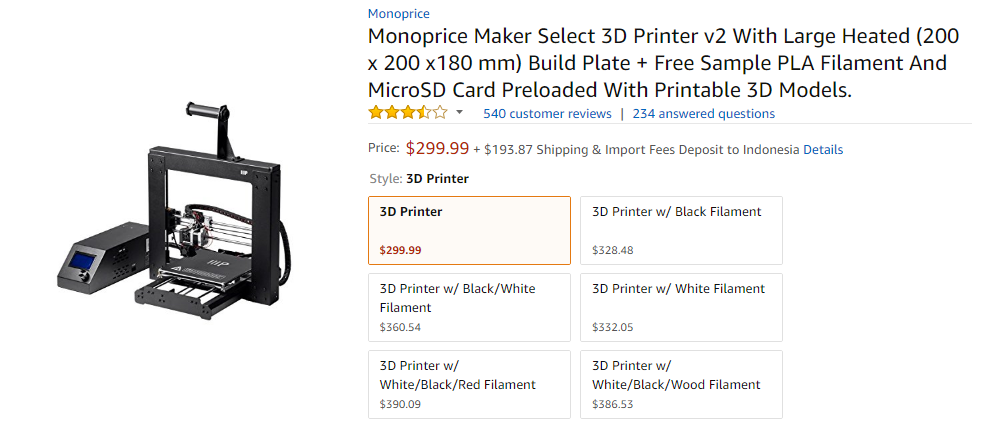

AFFILIATION: Make your purchases online by clicking on our affiliate links here Amazon.

DONATE: If you want, you can make a donation via PayPal.

WORD OF MOUTH: Invite your friends to come, discover the platform and the magnificent 3D files shared by the community!

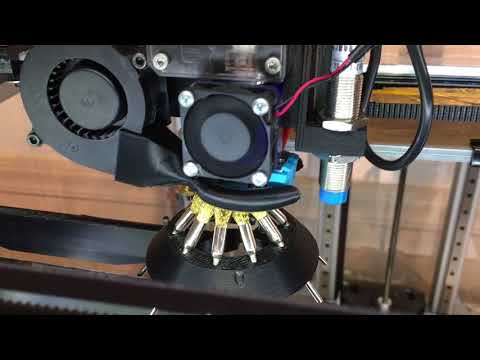

Printer nozzle cleaning brush.

3D printing.

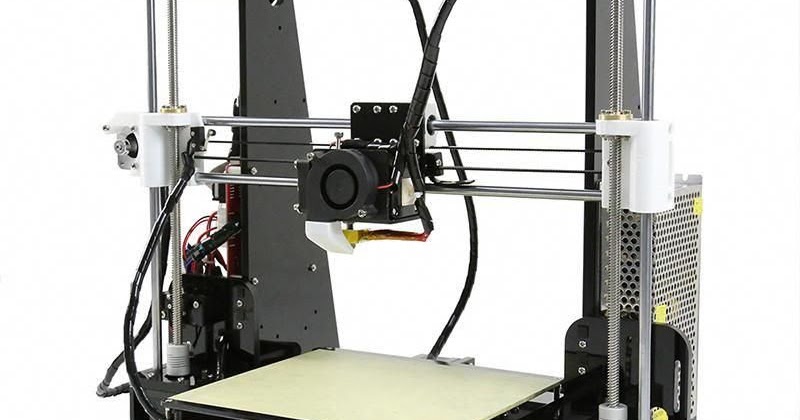

3D printing. I came up with the idea of automating printing. This time I will tell the story of how I designed and installed the printer nozzle cleaning brush before printing. In short, why is this needed at all: when you start printing the next part, the process begins with warming up the printer table. As the table heats up, the printer nozzle starts to heat up. As the nozzle heats up, a certain amount of plastic begins to flow out of it, which is already loaded into the printer. Previously, I always had to be on duty near the printer, when printing was started, and tear off plastic streaks with tweezers on the go. After installing the brush and making small adjustments in the pre-print control program, the nozzle cleans itself against the brush. First, the table and nozzle are heated, then the nozzle rubs against the brush, and only then does printing begin. I got the brush ready. It was a suede shoe brush. In the center there is a metal brush of medium hardness and along the edges a row of bristles made of fishing line. I cut out the middle of the brush, where the metal villi are. This will be the cleaning element.

I cut out the middle of the brush, where the metal villi are. This will be the cleaning element.

Development of a 3D model of the brush holder.

For precise positioning of the brush in the working area of the printer, it is necessary to make a special holder. For starters, this is a small box the size of my brush.

Then I close the bottom of the box.

Holder dimensions have been carefully taken from the side of the printer table. The holder should be easy to remove and install.

I extend the holder profile to the full width of the part.

And finally, I add a few fillets.

Preparing and printing the brush holder.

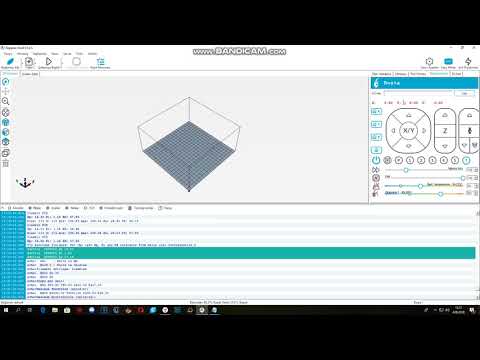

Loading the model into the slicer. I am preparing to print with a resolution of 250 microns. Greater precision is not needed here.

This is the print result.

The brush is inserted into the holder with little effort. Does not need fixing.

How it works.

The holder snaps onto the side of the printer table. The nozzle cleaning brush is installed.

The dimensions of the holder are chosen in such a way that the nozzle passes through the center of the brush exactly in the zero coordinate along the X axis (this is the horizontal axis from left to right) and from 150 to 180 mm along the Y axis (this is the longitudinal axis away from us).

In the preliminary program, I wrote the code:

G0 Z50 F7000; I raise the nozzle to a safe height of 50 mm G28; park the print head in all axes G0 Z50 F7000; raise the head again by 50 mm M190 S110; I heat the table to 110 degrees and wait until it heats up G0 Y200 Z80 X180 F7000; move nozzle Y200 Z80 X180 speed 7000 M109 S240; I heat the nozzle to 240 degrees and wait until it heats up G0 Z27 X0 F7000; move head Z27 X0 speed 7000 ; I start moving the nozzle on the cleaning brush G0 Y140 F7000; move towards me G0 Y200 F7000; move away from me G0 Y140 F7000; move towards me G0 Y200 F7000; move away from me G0 Y140 F7000; move towards me G0 Y200 F7000; move away from me G0 Y0 F7000; move head X0 Y0

After the preliminary program, the printing process (main program code) starts.

Weight immediately after printing.

Weight after removal of technological elements.

The automation doesn't stop there. This is just the first part. I'll tell you what happened next in one of the following publications.

| STL project files can be downloaded here |

Print Settings:

| Total Weight of Finished Parts (grams) | 10.46 |

| Print time (hours:minutes) | 00:44 |

| Plastic rod length (mm) | 3286 |

| Nozzle temperature (degrees C) | 230 |

| Table temperature (degrees C) | 105 |

| Plastic type | ABS |

| Nozzle diameter (mm) | 0.4 |

| Print resolution (micron) | 250 |

| Fill (percentage) | 100 |

3D modeling, 3D printing, Repetier-Host, Slic3r, Solidworks

- ← Kia Picanto wiper cap.

3D printing.

3D printing. - Nissan Xtrail wiper cap. 3D printing. →

Copper brush for cleaning the 3D printer nozzle (id 77743738)

Characteristics and description of

-

-

Purpose of spare part

For printer

-

Weight

17 g.

-

It often happens that in preparation for printing, the plastic can bend and melt on the outer surface of the nozzle or heating block, squeezing the plastic out of the threaded connection, neglected the printer and all the plastic safely envelops the hot elements, clean this burnt plastic can be done in many ways, but faster and more efficient is a compact copper brush.

Weight: 17 g;

Size: 176*8*20 mm.

Attention! (The characteristics and appearance of the product may differ from the description presented on the site)

Was online: Today

Seller Atyrau. Seller Online store of robotics and radio components SmartParts. kz

kz

Last online: Today

Available

30+ bought

from 1 160 Tenge.

wholesale prices

-

SATU Protects

Delivery

Payment and Warranty

We buy

spare parts and components for 3D devices

Consumables for 3d devices

Accessories for mobile phones

Coilers and cooling systems

Accessories for photo-, video cameras

Computer accessories

Accessories for TVs and Projectors

Game consoles and components

Metric fasteners

9000 9000 cables for electronics 9000 mobile phonesPrinters, scanners, MFPs and accessories

Quadcopters

Chargers for portable equipment 9Ol000

Copper brush for cleaning the nozzle of a 3D printer and other products in the Spare parts and accessories for 3D devices category are available in the Satu kz online store catalog in Kazakhstan at low prices.