3D printing in florida

World’s First 3D Printed Home Showroom In Florida - Now Open

Above: Apis Cor 3D printed homes in Florida/Image Source: Florida InsiderApis Cor, one of the world’s leading construction 3D printing company, has opened up the world’s first 3D printed home showroom in Florida, US. The showroom, located in a warehouse in Brevard County, Florida, showcases the most recent 3D printing technology, which has the potential to totally change the home-building and architecture industries.

At Apis Cor’s Avenue Viera facility, a 3D printing robot “Frank” greets visitors to the world’s first 3D printed home showroom. He comes from an exceptional family, since his predecessor printed and completed the Guinness Book, World’s Largest 3D Printed Building on Earth.

Above: Apis Cor opens first 3D printed home showroom in Florida/Image Source: Florida InsiderThe 3D printed home showroom allows the general public to get an inside look at the emerging technology that may be a commonplace in the near future.

“I definitely think 3D printing is a pillar in the construction industry, right now. The innovation is needed, and another great benefit of it is it replaces human error. People can kind of go around and look at the wall samples and see that it’s very similar to traditional concrete masonry block construction. And see how windows are implemented,” she continued.

– Jennifer McKinney, Apis Cor’s Business Operation Manager

Brevard-based Apis Cor, a non-traditional construction company, is responsible for Frank’s existence. According to Apis Cor, any home design is possible, and there are no restrictions on a home’s square footage, wall shapes, or even height. With the click of a button, two-story buildings can be printed.

Above: Frank, the 3D printing robot/Image Source: Apis CorProponents of 3D printed home technology claim that it addresses a number of industry-wide issues such as waste, labour shortages, and environmental impacts. They also claim that 3D printed homes can be completed quickly.

“I like the fact that it’s so durable. In different parts of the country we are seeing storms, the tornadoes that went through Kentucky, are not far from where we live,” Ohio resident Jan Stockton said while visiting.

Traditional construction sites are typically littered with leftover materials and scraps, but Apis Cor claims that its 3D home printing will eliminate the majority of that waste. As a result, 3D-printing initiatives will be greener and more efficient than traditional construction methods.

McKinney added, “We just print what we need and even if there’s a little bit here and there, we can reincorporate it back into the home.”

Homes will start at $300,000, according to McKinney, but the sky is the limit. A $7,000 deposit will reserve a 3D printed home and will be applied to the total price of the house once construction begins in 2023.

Before expanding across the country, the company plans to focus on building homes in Florida.

About Manufactur3D Magazine: Manufactur3D is an online magazine on 3D Printing. Visit our Global News page for more updates on Global 3D Printing News. To stay up-to-date about the latest happenings in the 3D printing world, like us on Facebook or follow us on LinkedIn and Twitter.

Visit our Global News page for more updates on Global 3D Printing News. To stay up-to-date about the latest happenings in the 3D printing world, like us on Facebook or follow us on LinkedIn and Twitter.

3D Printing Service Florida | Instant Quotes Online

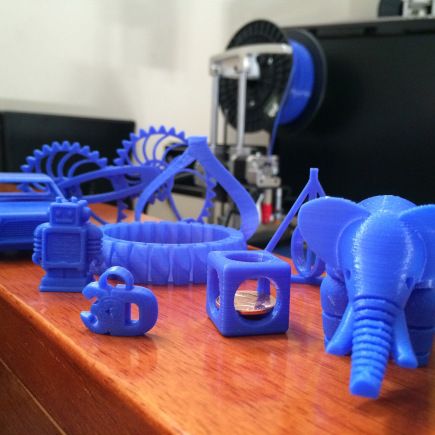

Our 3D printing capabilities

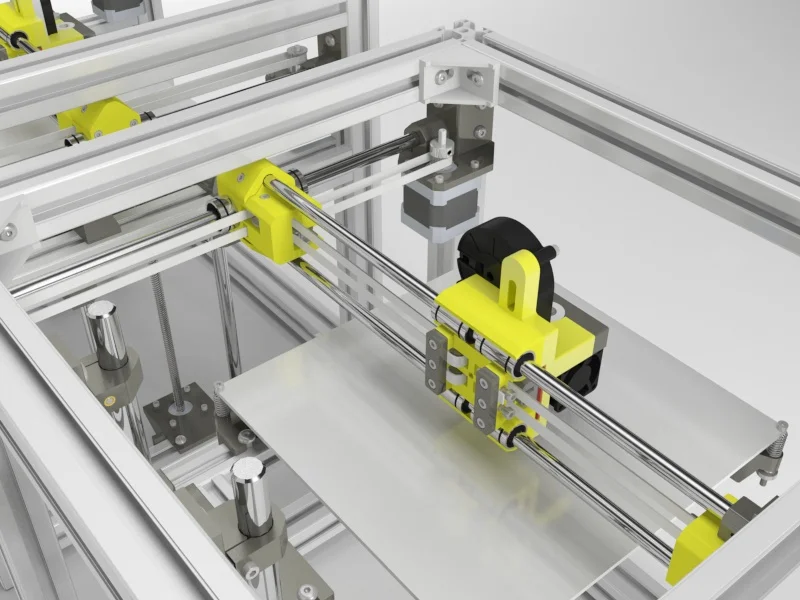

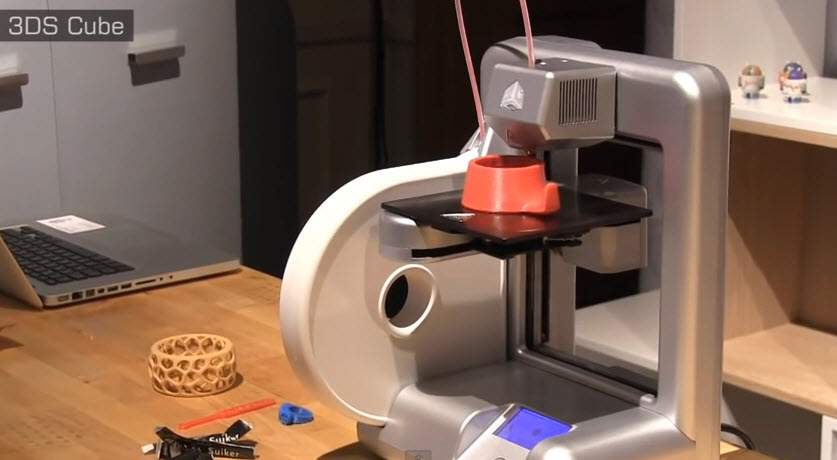

We have over 90 3D printing shops in our network and are well known for manufacturing high-quality parts at competitive prices, from rapid prototyping with Fused Deposition Modeling (FDM) to functional end parts made with Selective Laser Sintering (SLS) or Multi Jet Fusion (MJF).

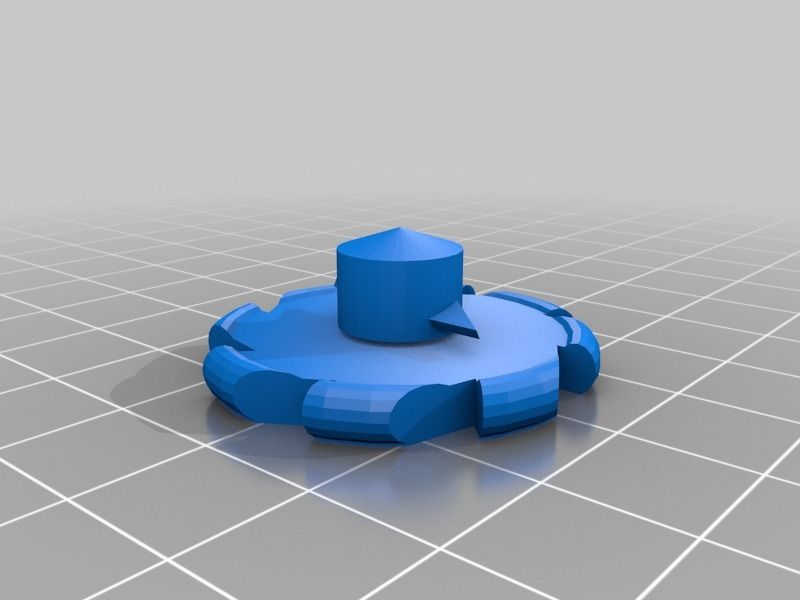

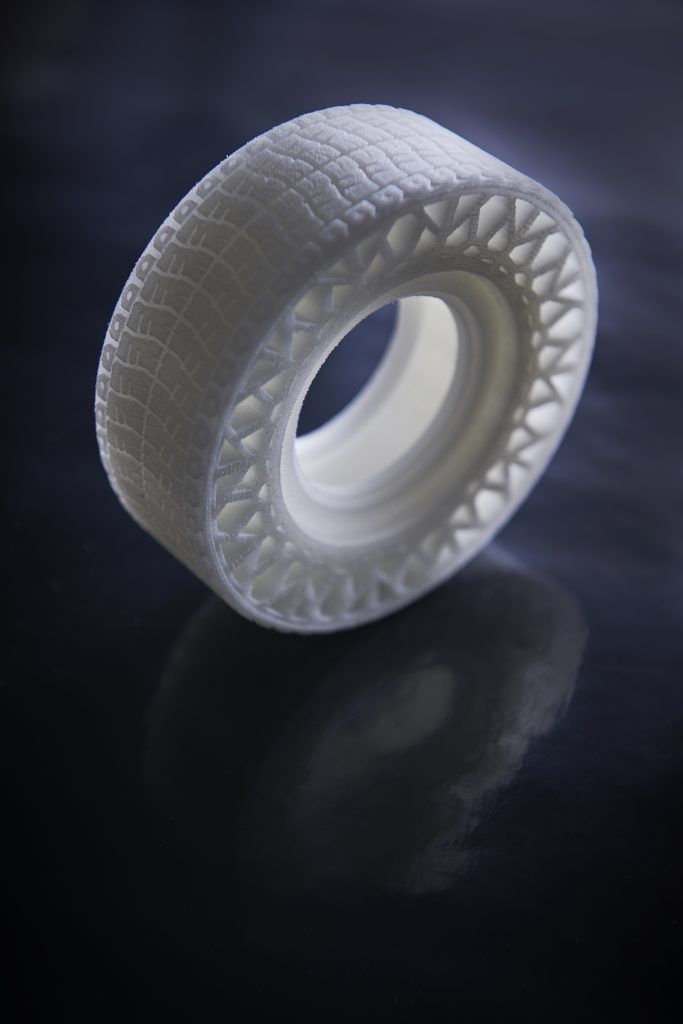

Gallery of 3D printed parts manufactured by Hubs

With over 65,000 customers from every industry, including aerospace, defense, robotics, medical, machinery, automotive and electronics, we have extensive experience meeting a diverse range of 3D printing requirements, from prototyping to production: Visual aids, concept models, injection-molding prototypes, form-fit & function prototypes, tooling and casting patterns, jigs, grips and fixtures, and durable end parts.

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22. 18 18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29. 83 83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22. 18 18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29. 83 83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22. 18 18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29. 83 83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22. 18 18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29. 83 83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22. 18 18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29. 83 83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22. 18 18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29. 83 83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22. 18 18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29. 83 83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22. 18 18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29. 83 83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22. 18 18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29. 83 83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22. 18 18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29. 83 83 |

| Industry | Aerospace |

Instant, online 3D printing quotes

-

Upload a CAD to start (STEP, STP, IGES, IGS, SLDPRT, 3DM, SAT, STL, OBJ or X_T)

-

Price updates in real-time as you change materials, lead time, etc..

-

No hidden costs. Our instant quotes are not just indications, but the actual price, and include shipping and customs up front.

Learn about how our quoting algorithm works

Our ordering process

Receive instant quote

Upload your CAD to our online quoting platform

Confirm specs

Configure your part specifications and select a lead time that suits your schedule

Production

We select the best manufacturer for your order, and production begins immediately

Quality control

We take full responsibility for making sure your parts are manufactured according to our standards

Delivery

Our 3D printing service has been rated 4.

9/5

9/5 Over 216 customers are satisfied with our 3D printing service.

“Perfect prints. everything turned out great. ”

“Parts turned out just like we wanted and arrived on time!”

“Would definitely use this service again! Fast, Great quality, matched my design perfectly.”

“quality print job. fast turnaround. will recommend and use again.”

“Super fast service! Prints came out great!”

“The prints are perfect. Ordered and received within a weeks time. Fast, reliable, and quality product and service.”

“Parts print well, but wait time is a bit long.”

“Very quick service. Short, sweet, and to the point. No complaints on my end”

“Very accommodating and helpful as always!”

“Awesome print quality, affordable pricing, rapid turn-around time, and very fast shipping! Will definitely use again for future 3D printing needs!”

“Excellent work, and much faster than expected!”

“Fantastic parts with great communication and updates!”

“Very friendly, quick, and sent pictures and updates of item before sending. 🖒🖒”

🖒🖒”

“Work very fast, good communication, very nice.”

“Andrew is a great manufacturer to deal with. He is responsive and professional, and the parts look great! Thanks!”

“Was great. Product looks amazing. One problem... I sent the older version of the prototype so I have to reorder the new version.. not your fault totally mine. But I get to keep really cool prototype”

“Loved it! Very prompt service & replies. ”

“Fast service, quality prints, will use again.”

“Great prints and communication! Perfectly balanced as everything should be. ”

“Only a couple minor print errors, overall the parts are what I need and fit together perfectly.”

“Fast, built to specification, and affordable.”

“Great work on these parts! I'm really happy with the customer service you guys provided as well. ”

“My Go to place for all my printing needs, especially when my printer dies and I need new parts to bring it back to life. Thanks Guys!”

“Great experience! Turn around was much faster than previous orders (from other providers). Excellent experience! Thanks!!!!”

Excellent experience! Thanks!!!!”

“This was in my opinion a complicated print and it turned out really good.”

Show more reviews

Show less reviews

Teams build better parts

Create your Hubs team and start collaborating

Read more

The Hubs Standard - consistent quality, every time

Hubs takes the stress out of manufacturing by guaranteeing the quality and consistency of every part. Each order is dimensionally and visually inspected to make sure it meets the Hubs Standard.

3D printing materials

We can generate instant 3D printing quotes for 25+ plastics. For metal 3D-printed parts, you can request a quote from our parent company, Protolabs.

Available materials

SLS

PA 12 Glass filled PA 12

Desktop FDM

Prototyping PETG Prototyping ASA Prototyping TPU Prototyping ABS Prototyping PLA

Desktop SLA

Formlabs Standard Resin Formlabs Clear Resin Formlabs Tough Resin 2000 Formlabs Rigid Resin 4000 Formlabs Grey Pro Resin Formlabs Flexible Resin 80A Formlabs High Temp Resin Formlabs Durable Resin

MJF

HP PA 12 Glass filled HP PA 12

Industrial FDM

Markforged Onyx ABSplus Stratasys ULTEM 9085 Stratasys Stratasys ASA ABS M30 Stratasys ULTEM 1010 Stratasys

Industrial SLA

Accura 25 (PP-like) Accura ClearVue Accura Xtreme White 200 (ABS-like)

3D printing locations near Florida

Lakeland, FL Winter Haven, FL Zephyrhills, FL

Brandon, FL Riverview, FL Wesley Chapel, FL

Tampa, FL Poinciana, FL Town 'n' Country, FL

Kissimmee, FL

The 3D Printing Handbook

No one understands 3D printing like us - our founders literally wrote the book. Click here to download the sample chapters.

Buy the book from Amazon

FAQ's

How much does your 3D printing service cost?

The cost of your 3D printed parts depends on factors such as part volume, part complexity, choice of material, which 3D printing technology is used, and if any post processing is required. For more details on these cost factors, see our article on the cost of 3d printing. To check the cost of your 3D printed part, simply upload a CAD (.STL) file and select your material and 3D printing technology to receive a quote within seconds.

How do you guarantee the quality of my prints?

Your parts are made by experienced 3D printing shops within our network. All facilities are regularly audited to ensure they consistently meet the Hubs quality standard. We include a standardized inspection report with every order and offer a First Article Inspection service on orders of 100+ units.

We have partners in our network with the following certifications, available on request: ISO9001, ISO13485 and AS9100.

Follow this link to read more about our quality assurance measures.

How do I select the right 3D printing process for my prints?

You can select the right 3D printing process by examining which materials suit your need and what your use case is.

By material: if you already know which material you would like to use, selecting a 3D printing process is relatively easy, as many materials are technology specific.

By use case: once you know whether you need a functional or visual part, choosing a process is easy.

For more help, read our guide to selecting the right 3D printing process. Find out more about Fused Deposition Modeling (FDM), Selective Laser Sintering (SLS), Multi Jet Fusion (MJF) and Stereolithography (SLA).

How can I reduce the cost of my 3D prints?

In order to reduce the cost of your 3D prints you need to understand the impact certain factors have on cost. The main cost influencing factors are the material type, individual part volume, printing technology and post-processing requirements.

The main cost influencing factors are the material type, individual part volume, printing technology and post-processing requirements.

Once these have been decided, an easy way to further cut costs is to reduce the amount of material used. This can be done by decreasing the size of your model, hollowing it out, and eliminating the need for support structures.

To learn more, read our full guide on how to reduce the cost of 3D printing.

Where can I learn more about 3D printing?

Our knowledge base is full of in-depth design guidelines, explanations on process and surface finishes, and information on how to create and use CAD files. Our 3D printing content has been written by an expert team of engineers and technicians over the years.

See our complete engineering guide to 3D printing for a full breakdown of the different 3D printing technologies and materials. If you want even more 3D printing, then check out our acclaimed 3D printing handbook here.

We have an extensive range of online resources developed to help engineers improve their capabilities.

Introductory guides

Design guides

Material guides

Applications

CAD & file preparation

Post processing & finishing

Our other manufacturing capabilities

CNC machining

CNC machining

Milling (3-, 4- & full 5-axis), turning and post-processing

-

50+ metals and plastics & 10 surface finishes

-

Tolerances down to ±.0008” (0.020 mm)

-

Lead times from 5 business days

See our CNC machining services

Put your 3D printed parts into production today

Get an instant 3D printing quote

Florida 3D Printing Show

Archive

Subscribe Author

Subscribe

Don't Wish

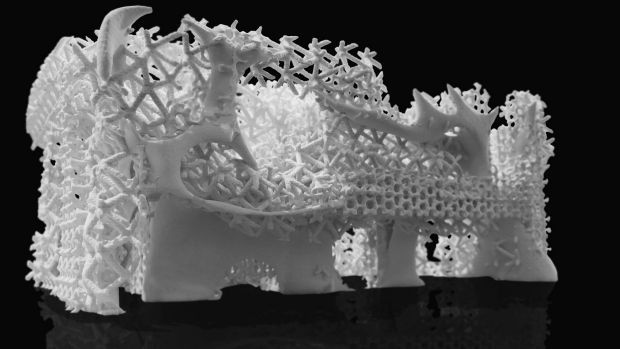

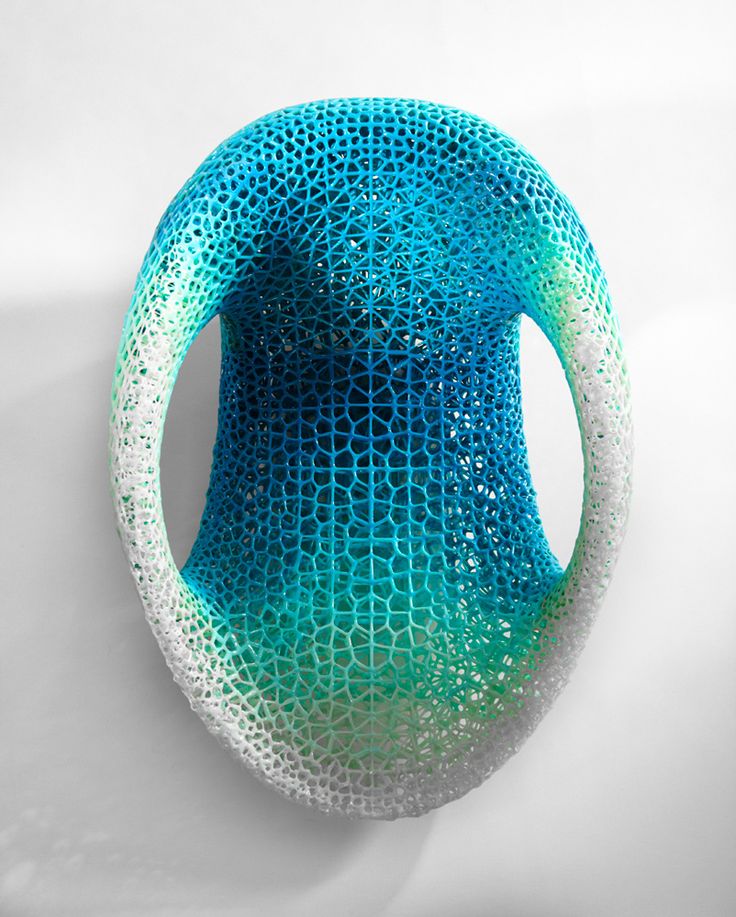

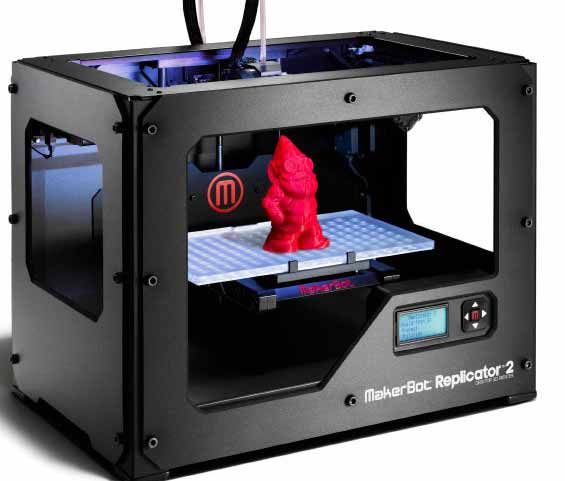

On June 14, Florida will host MOSI's 3D Printing Show. The exhibition will highlight the world of 3D printing in all its applications, from toys to medicine. This event aims to show all the possibilities that 3D printers give us today. Visitors to the exhibition will be lucky enough to look into the world of the future through the prism of 3D printing, in its live demonstrations.

The exhibition will highlight the world of 3D printing in all its applications, from toys to medicine. This event aims to show all the possibilities that 3D printers give us today. Visitors to the exhibition will be lucky enough to look into the world of the future through the prism of 3D printing, in its live demonstrations.

MOSI also cooperates with the Salvador Dalí Museum. The two museums will have their own displays in the exhibition areas and will make special offers to visit their exhibitions for visitors to this event. MOSI will offer a 50% discount to anyone who presents a ticket from the Salvador Dalí Museum.

The exhibition will feature the following sections:

3D Archeology

AIST will show how ancient artifacts are brought to life in amazing detail using this technology. They will also show how scientists are using 3D scanning to better identify people, places and animals found in excavations.

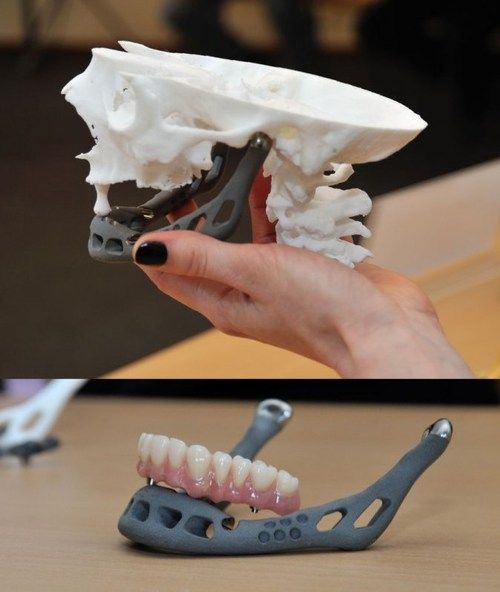

3D medicine

Guests will be invited to view 3D printed medical objects, including printed body parts and prostheses. Visitors will be able to clearly see that 3D printing is already revolutionizing modern medicine.

Visitors will be able to clearly see that 3D printing is already revolutionizing modern medicine.

3D science and technology

Visitors to the exhibition will be able to understand how 3D printing helps scientists and researchers working in the most remote places on Earth. All guests will also have the opportunity to learn how this technology helps in solving crimes, building houses and cars, and sending replacement parts to space stations.

3D printing in everyday life

This section will demonstrate the benefits that 3D printing can bring to everyday life. Such amenities will include printing out parts for a dishwasher, or printing an extra dining area for unexpected guests. Also, this section will show how the world of fashion began to change with the advent of 3D printing: new design ideas that have become feasible with the advent of this technology will be demonstrated.

3D Live Show

This section will provide visitors with a variety of fun activities, including 3D scanning, musical performances using 3D printed tools, and a step-by-step demonstration of the development of 3D printing technology.

The MOSI Admission, which will include an exhibition of 3D printing technology and an IMAX film screening, will cost $22.95 for adults, $20.95 for seniors (60+), and $18.95 for children.

Article prepared for 3DToday.ru

Follow author

Follow

Don't want

More interesting articles

7

Subscribe to the author

Subscribe

Don't want

So, you are thinking about the possibility of making money on 3D printing. How realistic is this? Quite, although the way...

Read more

four

Follow author

Follow

Don't want to

One of the most promising and least developed areas of 3D printing is bioprinting. Whole a...

Read more

3

Follow the author

Follow

Don't want

Not so long ago we told about an interesting engineering and architectural project directly related to the example of. ..

..

Read more

Tallahassee is building the first house using 3D printer technology

Home News Techno Tallahassee builds first 3D printer home

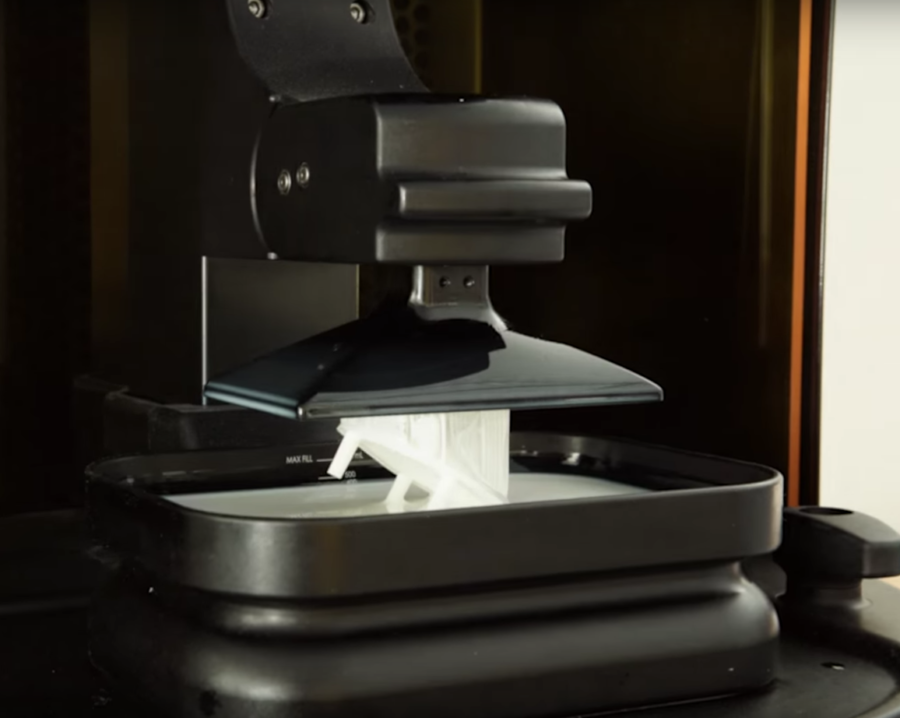

In Griffin Heights, Tallahassee, Precision Building and Renovating is building the first house entirely printed on a giant 3D printer. Construction began on Thursday, July 29.

“I even pinched myself. I still find it hard to believe that this is actually happening, ”said 39-year-old Kindra Light (Kyndra Light) co-owner of Precision Building and Renovating.

Together with her husband, James Light, they have been looking for a modern and economical way to build affordable housing. And the couple chose a 3D printer from Printed Farms, which has access to technology from a Danish corporation called COBOD.

And the couple chose a 3D printer from Printed Farms, which has access to technology from a Danish corporation called COBOD.

They first bought land in the Griffin Heights area. Then the couple entered into an agreement for the construction. And now passers-by and specially flown experts are watching how a huge machine lays out the walls of the future house layer by layer.

Work began on Thursday 29 July. The scheduled completion date for construction is Friday evening, August 6th. The giant printer builds up to two feet of wall a day.

A huge metal structure has been installed on the site, which covers the construction site. A small “nose” moves along it, which applies a special Laticrete concrete solution layer by layer.

As a result, the building is "wavy", but this only adds to its individuality. After the solution hardens, it takes some more time to shrink and deliver the furniture. After 6-8 weeks, the owner will be able to move into his unusual home.