3D printer san antonio

San Antonio 3D Printing Service

High quality and large scale 3D printing service in San Antonio, Texas. Get high quality 3D printed parts in no time.

No signup required.

Contact us

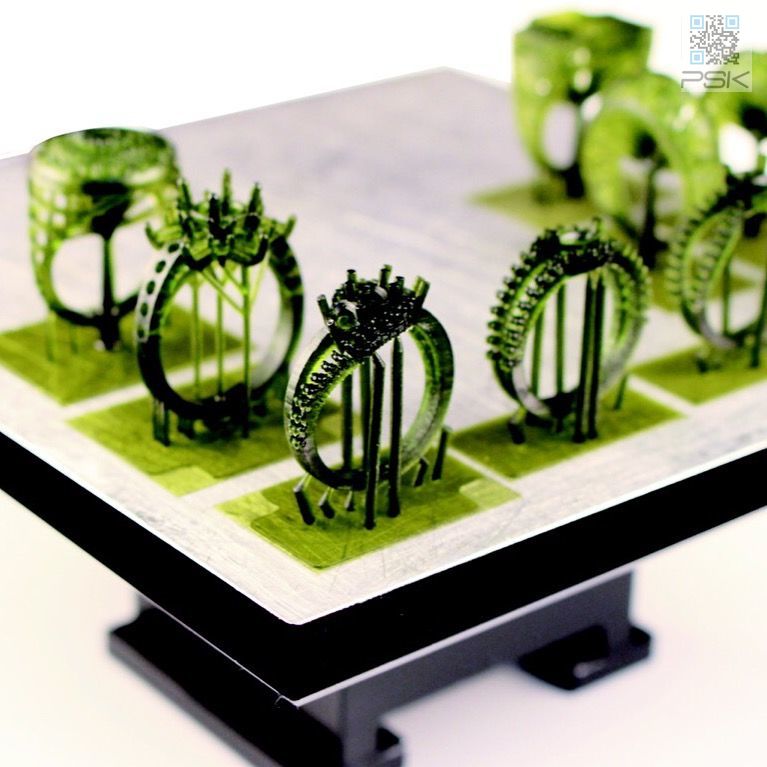

3D printing projects we did for our clients in San Antonio, Texas

3D printing materials that we offer

Looking for a material that isn't listed here? Shoot us an email at [email protected]

ABS

ABS plastic is a strong and durable material. They're ideal for prototyping mechanical parts. For prototypes that require high-precision, consider CNC machining ABS or printing in other materials. For production parts, we suggest using injection molding instead.

Nylon PA12

Nylons is a strong and durable material that is also flexible. Ideal for live hinges and functional parts.

Standard Resin

Perfect for complex 3d models that require high details and smooth finishing.

SOMOS Resin

SOMOS resin is the industrial version of standard resin.

It's perfect for almost any 3d that require smooth finishing and high details. We recommend this material for any projects such as high-detailed models, architecture, art sculptures and engineering prototypes.

SOMOS Waterclear 10122 Resin

Somos® WaterClear Ultra 10122 is a clear resin that produces colorless, functional and accurate parts that simulate an acrylic appearance. Parts produced from Somos® WaterClear Ultra 10122 exhibit excellent water and temperature resistance.

What makes PrintAWorld different from the other San Antonio 3D printing companies

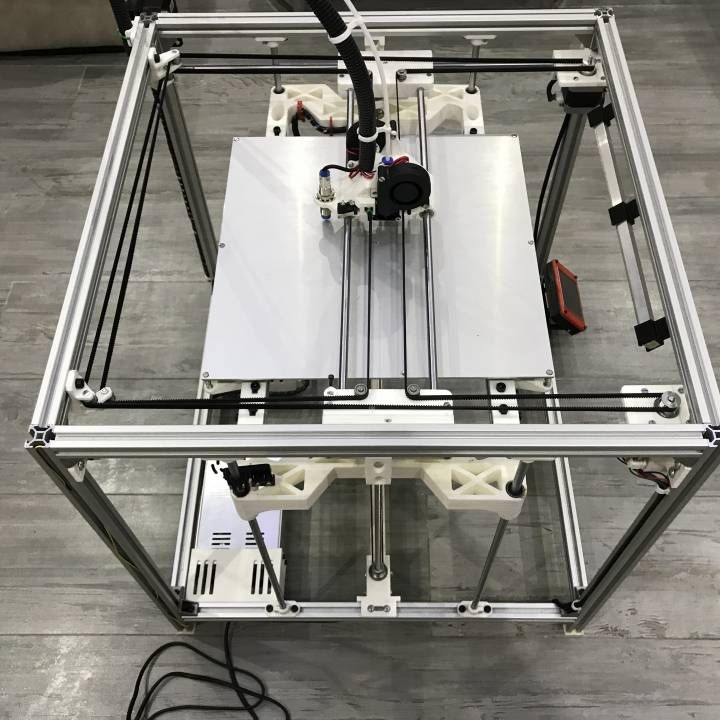

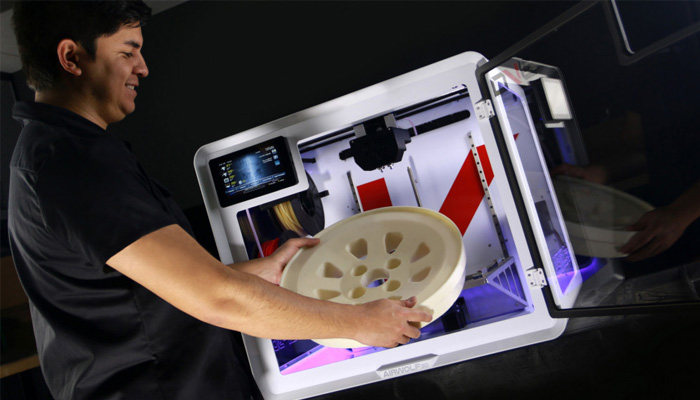

Get access to industrial 3D printers

High resolution and large scale 3d printers are expensive. At PrintAWorld, you'll get the benefits of industrial 3d printing without the cost that comes with it.

Get expert help

We'll help you every step of the way from fixing your file to figuring out the best way to get your project done within budget and time.

Fast turnaround

On a tight deadline? Need it over the weekend? We can help you get your 3d printing project done in no time.

How our 3D printing service in San Antonio works

0

1

.

Send us a few information

The material you need, quantities and a short description of your project. If you're unsure, don't sweat it. We will guide you to the perfect solution!

0

2

.

Upload a 3D File

Send us your.stl or .obj files. Don't have a file ready? We also provide a professional 3D modeling service.

0

3

.

Receive a quote

You'll get an email and a call from us immediately so we can talk about the best and most cost effective way to approach your project.

No minimum order quantities!

No minimum order quantities!0

4

.

Pay and print

Once the quote is approved we will start 3D printing your idea. We'll keep you updated and we'll make sure the result is exactly what you want or even more. No minimum orders.

0

5

.

Shipping or pickup

We offer nationwide delivery or you can pick it up from one of our local studios near you.

3D printing technologies that we use

These 3D printing technologies are what powers our 3D printing process

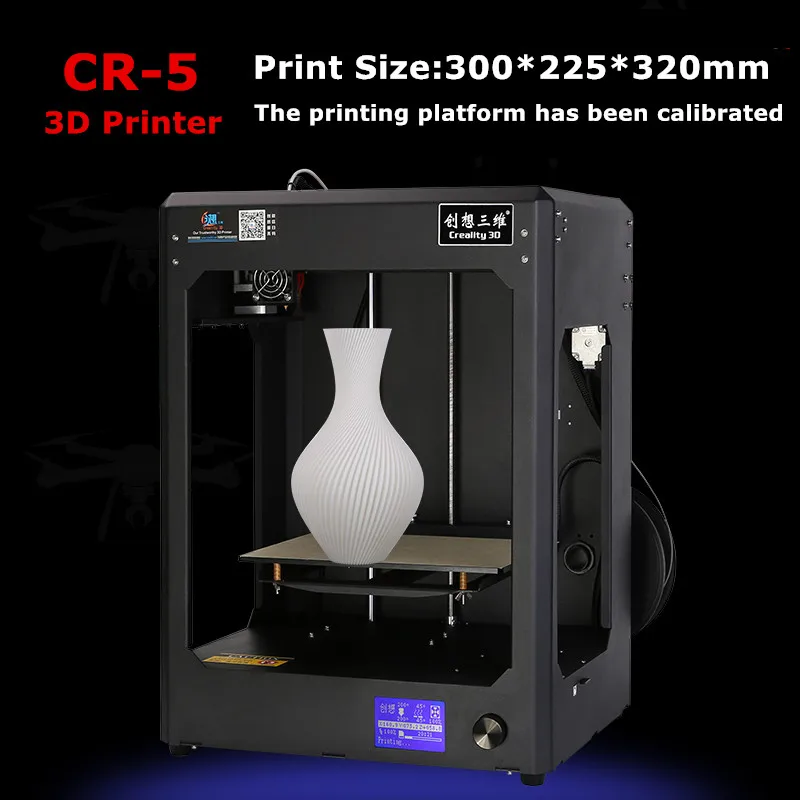

Fused Deposition Modeling (FDM)

We use Fused Deposition Modeling (FDM) for low-cost and simple 3d printed parts. We don't use this process as much because we find the quality lacking and the amount of post processing work involved negates the money you save from low material cost. This is good for prototyping but for manufacturing end products, they might not be cost effective as there are better printing methods. If you want to produce low-cost end use parts at a large volume, injection molding might be a better solution.

This is good for prototyping but for manufacturing end products, they might not be cost effective as there are better printing methods. If you want to produce low-cost end use parts at a large volume, injection molding might be a better solution.

Selective Laser Sintering (SLS)

Selective laser sintering is another great additive manufacturing technology for rapid prototyping. SLS allows us to 3d print objects in different materials such as nylon and metal at large volume without the need for supports. SLS greatly reduces the time spent for post-processing.

Stereolithography (SLA)

Stereolithography allows us to 3d print accurate and high resolution prototypes . We us this process to create functional prototypes that are highly detailed. We recommend SLA for almost any 3d printing projects because we believe it produces the highest quality prints.

Multi-Jet Fusion (MJF)

Multi Jet Fusion is what helps us 3d print end-use production in 24 hours.

F.A.Q

Do you offer delivery?

Yes, we can ship anywhere in San Antonio, Texas and surrounding states.

3D Printing Service for San Antonio, Texas

CapabilitiesCustom Online 3D Printing ServiceTexasSan Antonio

High Quality San Antonio, Texas 3D Printing | 60+ Materials Available

Endless Options

Choose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

Easy to Use

Get your parts delivered right to your door without the hassle of sourcing, project management, logistics, or shipping.

Quality Assurance

Our number one job at Xometry is making your custom parts to your specifications.

Your San Antonio, Texas 3D Printing Service: 3D Prototypes and Production Parts

A Global Leader in Industrial-Grade 3D Printing

Xometry is an industry-leading 3D printing service. Whether you need prototypes or production parts, we can make them for you in as fast as a day. We are your one-stop-shop for accurate, precise custom 3D printed parts at a low cost. Upload your 3D CAD file to get a quote and lead time within seconds. We use the latest additive manufacturing processes to build affordable functional prototypes & end-use parts in over 60 metals and plastics.

We are your one-stop-shop for accurate, precise custom 3D printed parts at a low cost. Upload your 3D CAD file to get a quote and lead time within seconds. We use the latest additive manufacturing processes to build affordable functional prototypes & end-use parts in over 60 metals and plastics.

We offer eight high-quality 3D printing processes including selective laser sintering, fused deposition modeling, stereolithography, direct metal laser sintering, polyjet, Carbon DLS, binder jet metal, and HP Multi Jet Fusion. We use commercial and industrial-grade printers such as Stratasys Fortus 900mc and Fortus 450 FDM, EOS Polymer Laser Sintering (SLS) and DMLS, Concept Laser, SLM Solutions, 3D Systems, ExOne, and more.

Xometry's High Quality 3D Printing Services

Selective Laser Sintering (SLS)

Selective Laser Sintering (SLS) is a powerful 3D printing technology that produces highly accurate and durable parts that are capable of being used directly in end-use, low-volume production, or for rapid prototyping.

An additive manufacturing layer technology, SLS involves the use of a high power laser (for example, a carbon dioxide laser) to fuse small particles of plastic powders into a mass that has a desired three-dimensional shape. The laser selectively fuses powdered material by scanning cross-sections generated from a 3-D digital description of the part (for example from a CAD file or scan data) on the surface of a powder bed. After each cross-section is scanned, the powder bed is lowered by one layer thickness, a new layer of material is applied on top, and the process is repeated until the part is completed.

Download the SLS Design Guide.

Stereolithography (SLA)

Stereolithography (SLA) is a robust 3D printing technology that produces extremely accurate and high-resolution parts that are capable of being used directly in end-use, low-volume production, or for rapid prototyping.

SLA is an additive manufacturing process that focuses an ultraviolet (UV) light on a vat of photopolymer resin. It offers higher resolution printing than many other 3D printing technologies, allowing customers to print parts with fine details and surface finishes. SLA 3D printing is a highly-versatile platform for making custom parts in prototype and production settings; often acting as a stand-in for injection-molded plastic parts.

It offers higher resolution printing than many other 3D printing technologies, allowing customers to print parts with fine details and surface finishes. SLA 3D printing is a highly-versatile platform for making custom parts in prototype and production settings; often acting as a stand-in for injection-molded plastic parts.

Xometry offers both standard and high-resolution options for fine detail parts, and can also print larger sized parts and products, with some materials offering up to a 58" inch build area. In addition, Xometry's manufacturing partner network allows us to offer a larger variety of materials than other 3D printing companies - we offer a wide range of both Accura and Somos brand materials.

Download the SLA Design Guide.

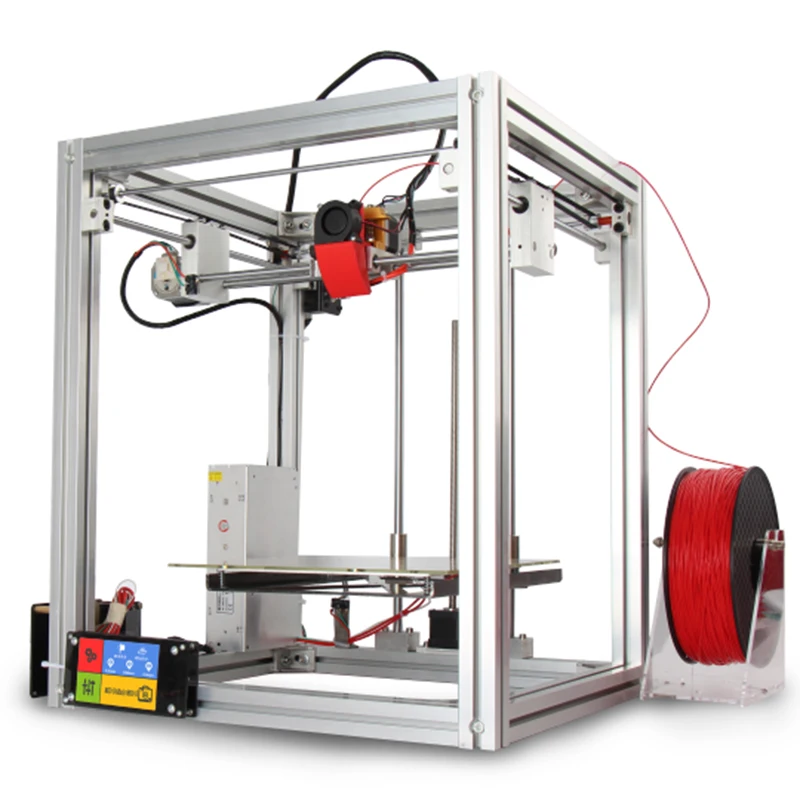

Fused Deposition Modeling (FDM)

Fused Deposition Modeling (FDM) is a 3D printing technology widely known for its speed, accuracy, and competitive cost. A machine precisely extrudes melted plastic filament to create a part. Parts are very rigid, especially compared to Selective Laser Sintering (SLS), which makes them a great fit for projects with a rigidity requirement. Xometry's FDM solution offers large build volumes up to 24″ x 36″ x 36″, a variety of colors, and a diverse selection of production-grade thermoplastics — from ABS to Polycarbonate to Ultem.

Xometry's FDM solution offers large build volumes up to 24″ x 36″ x 36″, a variety of colors, and a diverse selection of production-grade thermoplastics — from ABS to Polycarbonate to Ultem.

Download the FDM Design Guide.

HP Multi Jet Fusion (HP MJF)

HP Multi Jet Fusion is a new 3D printing technology that produces highly accurate and durable parts that are capable of being used directly in end-use, low-volume production, or for rapid prototyping. Since the process uses well-established 2D printing ink-jetting, it has remarkably fast layer times compared to other powder bed fusion technologies.

Download the HP Multi Jet Fusion Design Guide.

PolyJet 3D (PJ3D)

PolyJet 3D is a 3D printing technology known for its customizable material properties and excellent surface finish. It works by jetting UV curable resin onto a build tray in a process that is somewhat similar to inkjet printing. PolyJet 3D printing offers one of the most advanced industrial 3D printing solutions available, producing parts with incredible precision and speed. It also supports a wide variety of build materials including rigid and rubber-like plastics. Xometry's PolyJet solution has a maximum build envelope of 19.3 × 15.4 × 7.9 in. (490 × 390 × 200 mm) in a variety of colors and materials.

It also supports a wide variety of build materials including rigid and rubber-like plastics. Xometry's PolyJet solution has a maximum build envelope of 19.3 × 15.4 × 7.9 in. (490 × 390 × 200 mm) in a variety of colors and materials.

Download the PolyJet 3D Design Guide.

Direct Metal Laser Sintering (DMLS)

Direct Metal Laser Sintering (DMLS) is an 3D metal printing technology that builds prototype and production metal parts from a CAD file using a laser to selectively fuse a fine metal powder in either stainless steel or aluminum materials. A DMLS machine is capable of producing highly complex features and all-in-one assemblies using metal materials that would be difficult to achieve with subtractive manufacturing techniques.

Our DMLS metal 3D printing service typically offers build volumes up to 250 x 250 x 325 mm, but we may be able to accommodate larger part volumes upon request in the quote. (See our Manufacturing Standards for more details) A good first step is to find out the cost of the parts you need using DMLS and compare them to other 3D printing processes and CNC machining.

Download the DMLS Design Guide.

Carbon DLS™

Carbon DLS™ uses digital light projection, oxygen-permeable optics, and programmable liquid resins to produce products with end-use durability, resolution and surface finish. This 3D printing technology is called Digital Light Synthesis™, or DLS for short. Another legacy term for the process is Continuous Liquid Interface Production (CLIP). Along with Carbon’s custom liquid resins, DLS unlocks new business opportunities and product designs previously impossible, including mass customization and on-demand inventory of end-use products.

Carbon bridges, and sometimes substitutes, for processes like Urethane Casting and Injection Molding service production, because the materials are urethane-based or epoxy-based, giving excellent mechanical properties. There are even elastomer and silicone resins that outperform most additive manufactured rubber-like materials.

The typical build area is 7.4” x 4. 6” x 12.8”. Parts with dimensions exceeding 4” x 4” x 6” will require manual review.

6” x 12.8”. Parts with dimensions exceeding 4” x 4” x 6” will require manual review.

Download the Carbon DLS Design Guide.

Metal Binder Jetting

With binder jetting, an inkjet print head quickly deposits a bonding agent onto a thin layer of powdered particles -- either metal, sand, ceramics or composites. This process is repeated, layer-by-layer, using a map from a digital design file, until the object is complete. Binder jetting is offered through our Digital RFQ Marketplace through Xometry's partnership with ExOne.

Download the Binder Jetting Design Guide.

Locations near San Antonio, Texas

Austin

TexasCorpus Christi

TexasLaredo

TexasCollege Station

TexasWaco

TexasAbilene

TexasFort Worth

TexasArlington

TexasGrand Prairie

TexasBrownsville

TexasIrving

TexasDallas

TexasGarland

TexasPlano

TexasFrisco

TexasTyler

TexasMcKinney

TexasOdessa

TexasLubbock

TexasShreveport

Louisiana

Ready to start making custom 3D printed parts?

Free STL file SAN ANTONIO SPERS LOGO・3D printer design for download・Cults

Droid R2 D2.

0.72 €

Nocton/Crosier Zython 3D Staff (BIG JIM/CIPSA).

2.41 €

Hanging planter for home or office.

0.72 €

Christmas tree (3 levels and fast building). nine0004

0.72 €

Sandpaper for pedicure.

Free

Best 3D Printer Files in Home Category

Folding Hook

2.07 €

Super Mario Cookie Cutters set of 7

1,50 €

Lamp, architecture, home, decoration, interior, design

5.64 €

Can holders

Free

rotate_lamp

1. 60 €

60 €

Mandalorian Yoda cookie cutters

1.88 €

IKEA Hack - Korken Jar Label

Free

nine0005Bestsellers in the Home category

Another quick-change toilet roll holder

1 €

Waste bin with hinged lid

3.20 €

Snowman in underwear

2.35 €

Another quick change paper towel holder

1 €

tealight holder ver.b

1 €

GYRO BEER STAND 2

2.14 €

Bear wine holder

2.35 €

Notepad

2. 60 €

60 €

KUPPA, THE HAIRY FLEXI GNOME TO PRINT IN PLACE WITH HANDS UP

2.35 €

Wall shelf "Oyster mushroom"

2,40 €

Wall shelf "Tinder Fungus"

2.40 €

Super cute paw pen cup

1.31 €

Kawaii dim sums in a cute basket

1.53 €

nine0003 Modular storage box system with quick print5.65 €

Ornamented tea holder

€2.82 -25% 2.11 €

Wall shelf "Amanita mushroom"

2,40 €

Do you want to support Cults? nine0025

Do you like Cults and want to help us continue our journey on our own ? Please note that we are a small team of 3 people, so it is very easy to support us in maintaining activities and creating future developments of . Here are 4 solutions available to everyone:

Here are 4 solutions available to everyone:

-

AD: Disable your AdBlock banner blocker and click on our banner ads.

-

AFFILIATION: Shop online by following our affiliate links here Amazon.

-

DONATIONS: If you want, you can donate via PayPal here.

-

* INVITE FRIENDS: * Invite your friends, discover the platform and great 3D files shared by the community!

3D printed ear surgery performed in the USA

News

Follow the author

Subscribe

Don't want

3

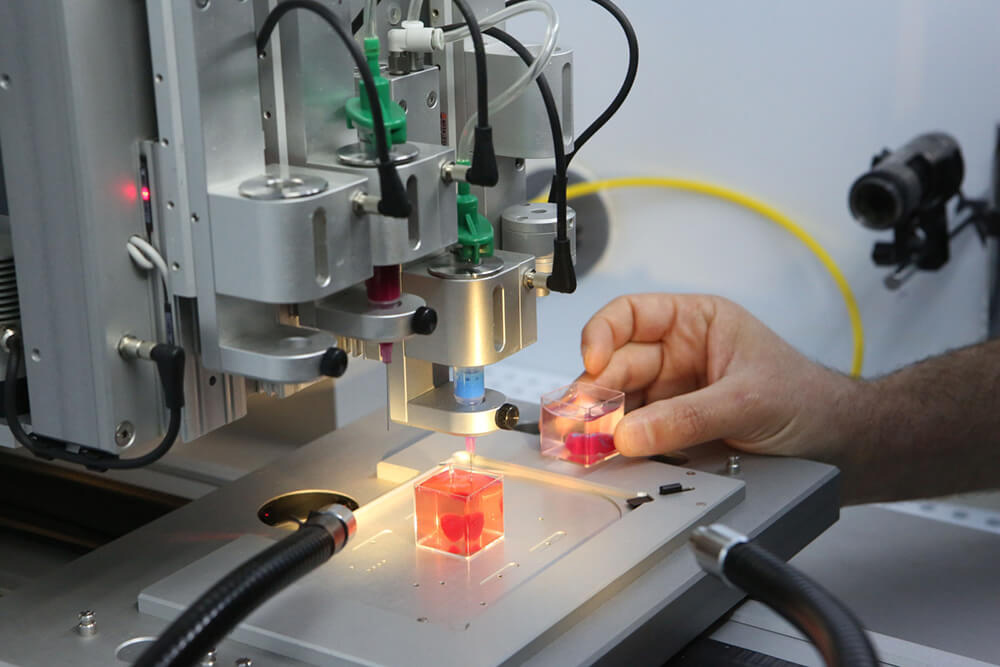

New York-based 3DBio Therapeutics and the Microtia Institute in San Antonio have begun clinical trials of auricles grown from living cells using biomedical 3D printers.

AuriNovo Organic Implant was developed by regenerative medicine research company 3DBio Therapeutics. The implant is printed with a cell mass obtained from samples of cartilage tissue of the patient - a twenty-year-old woman with microtia, that is, a congenital ear defect. The operation was performed by Dr. Arturo Boniya, a specialist in reconstructive surgery and founder and director of the Microtia Institute in San Antonio, Texas. nine0006

The operation was performed by Dr. Arturo Boniya, a specialist in reconstructive surgery and founder and director of the Microtia Institute in San Antonio, Texas. nine0006

AuriNovo implants are designed as an alternative to traditional implants made from either rib cartilage or polyethylene. Developed by 3DBio Therapeutics, the technique allows to simultaneously reduce invasiveness and obtain completely organic implants with minimal risk of rejection. The structure of the auricle is formed by a hydrogel 3D printer and seeded with a cell mass grown from cartilage tissue samples of the patient. In this case, the shell was modeled from a specular 3D scan of the left ear. The bulk of the time is spent on cell cultivation and implant maturation; directly 3D printing of the auricle took only about ten minutes. The resulting implant was implanted under the skin. nine0006

The operation took place in March, the patient is still under observation, and the authors promise to publish details when the study is completed. Clinical trials involve eleven people aged six to twenty-five.

Clinical trials involve eleven people aged six to twenty-five.

Do you have interesting news? Share your developments with us, and we will tell the whole world about them! We are waiting for your ideas at [email protected].

bioprinting an ear 3DBio AuriNovo

Follow author

Follow

Don't want

3

Article comments

More interesting articles

12

Subscribe to the author

Subscribe

Don't want

3MF is a file format designed to replace the STL with improved usability and enhanced functionality.