3D print workshop

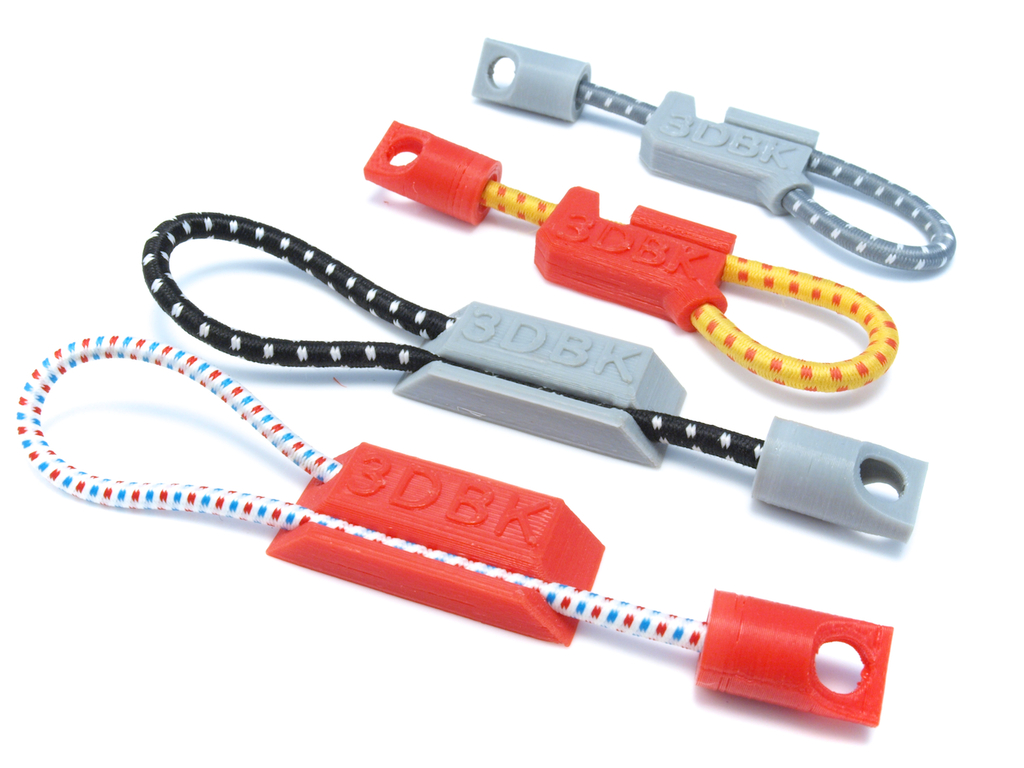

3D printed workshop equipment: organizing your stuff

Welcome to the first part of our series on 3D printed workshop equipment. Today we will focus on tidying up our man caves (or woman caves ;-)) with the help of 3D printing.

Actually, your workshop doesn’t really have to look like a cave anymore nowadays. In DIY stores, you can find a neat selection of holders, organizers, racks, and containers. However, chances are you might want to opt for 3D printing, even though it will always be more expensive and time-consuming than buying ready-made stuff.

The customizing and personalizing aspects might be well worth it – pick your favorite color, match the style of organizers you already have, and tailor everything to utilize all the available space…which is somehow never large enough.

Having everything in boxes or drawers is tidy and makes the dusting much easier, however, searching for the right tool in closed containers is time-consuming and distracting.

We really recommend having everything readily accessible, with each thing in its permanent place, preferably right in front of your eyes. Some sort of a wall-mounted storage system is ideal for this.

Mounting all the racks and holders directly on the wall is not very practical. Instead, you should screw or glue them to a desk and then attach the whole desk to the wall. It’s up to you whether you want to use plywood, chipboard, or solid wood.

Another option is a pegboard: a perforated panel with standardized holes. Again, there are various materials: metal, plastic, or hardboard.

There are various types of pegboards with different shapes, sizes, and spacing of the holes. If you want to use downloaded 3D models, plan ahead and make sure they are going to be compatible.

Where to get the models?Speaking of downloading 3D models, there is a whole category of organizers in the PrusaPrinters database. You will also find links to individual models and collections below.

Another option is modeling the parts of the storage system yourself. It might seem daunting at first, however, it is actually an ideal beginner’s project, and also a very rewarding one. All the boxes, racks, and holders are relatively simple geometrical shapes after all. In fact, practical thinking and patience to measure everything twice are going to be much more important than awesome 3D modeling tricks.

We are using the Fusion 360, which we consider a good beginner’s choice: it is very user-friendly for such a sophisticated piece of software.

By the way, consider checking out our article on parametric modeling. Storage systems are a typical application of the parametric approach – it is extremely useful to branch out various types and sizes from a basic model with just a few clicks.

Consider sharing the results of your work with others via PrusaPrinters and enjoy our new system of rewards!

If you don’t feel ready to start from scratch yet, you can begin with remixes and adjustments to existing models (for simple things like deleting pegs, adding holes, etc. , even Tinkercad will do) and slowly work your way through to your own creations.

, even Tinkercad will do) and slowly work your way through to your own creations.

Finally, let’s move on to the models for download and/or your inspiration.

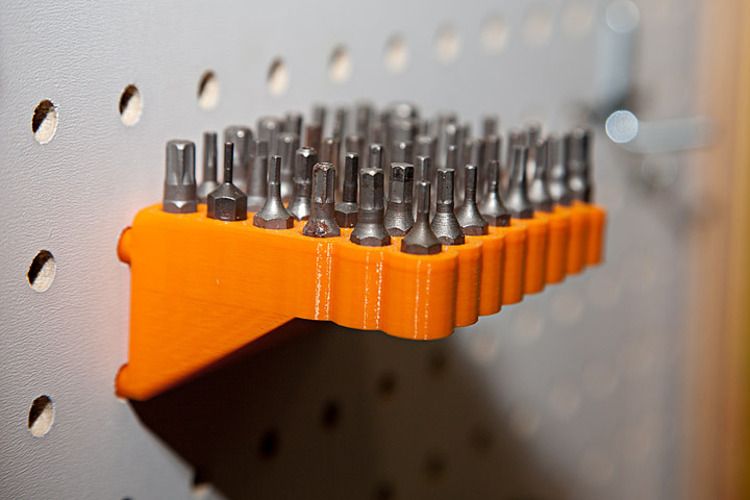

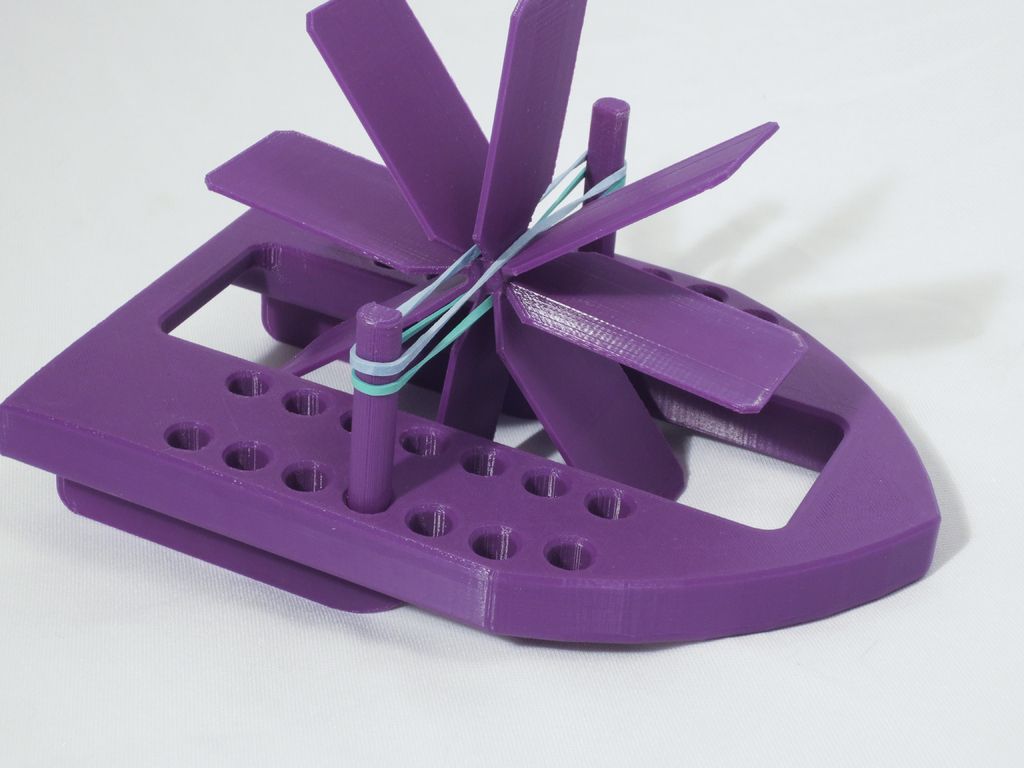

Screwdriver holder

This one is designed for a pegboard, but you can easily remove the peg mounts and model (or later drill) holes instead.

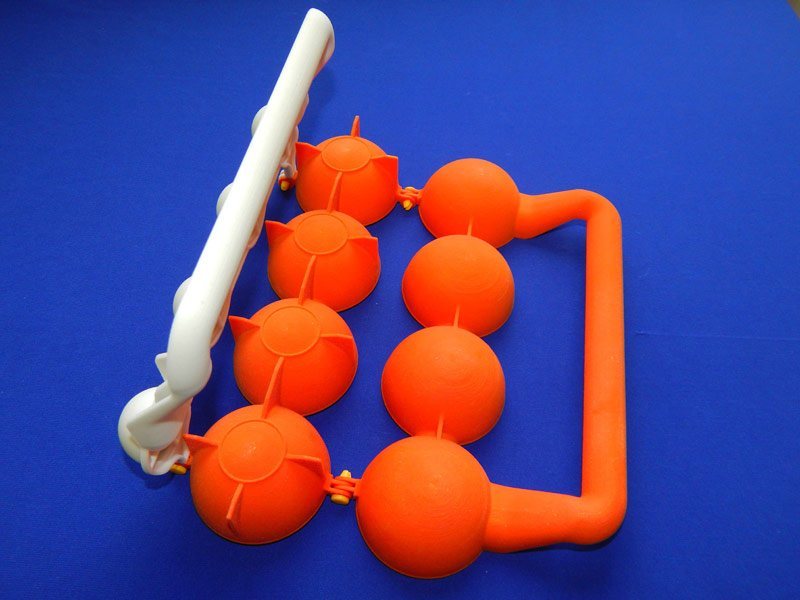

Pliers holder

Designed to be mounted on a board. Looks primitive, but there is really not much to improve. Works perfectly with pliers of various shapes and sizes.

Drill holders

Drill holders are especially useful as sifting through a pile of them to find a correct diameter is a major PITA. The holes are marked with numbers – it is just a matter of your discipline returning the drills to their correct places immediately 😉

Various paint holders

Organizing your paints is a topic on its own. Few painters and modelers remain faithful to one brand (neither is one brand suitable for all applications), so inevitably, over the years they end up with a motley assortment of oil paint tubes, spray cans, tins, bottles, and pedal bins (or whatever are the Citadel containers properly called ;-)). With 3D printing, you can mix and match your paint rack to accommodate everything efficiently, even if you have only a few pieces of each brand.

With 3D printing, you can mix and match your paint rack to accommodate everything efficiently, even if you have only a few pieces of each brand.

The Vallejo (or Vallejo-sized, like AK Interactive, etc.) paint holder comes in various sizes, from 2×3 to 9×6 bottles.

Organizing fasteners

Even though we earlier dismissed boxes and drawers for storing your tools, they are golden for all those nuts, screws, and other small bits. In the link above, there is a whole system of more than 60 models of all sizes that you can stack and attach to each other to completely fill your available storage space.

Here is an interesting organizer, upcycling plastic sides of empty Prusament spools.

By the way, the whole spool is reusable, even the paper tubes!

Last but not least, here is a collection of various small containers.

Our picksThis is a whole system we use in our own modeling workshop. It contains holders for paints, drill bits, small trays, but also less obvious, but useful things like a heat gun holster or a paper towel rack.

It contains holders for paints, drill bits, small trays, but also less obvious, but useful things like a heat gun holster or a paper towel rack.

And here is another collection of assorted prints we consider interesting and useful.

Stay tuned!We will soon follow up with another article (or two), this time focused on the tools themselves.

In the meantime, please feel free to share your tips and suggestions. Also, you can share photos of your workbench, no matter if it’s neatly organized, or…less so. Let the unofficial quest for the worst place of chaos and despair begin 😉

Happy printing!

Workshop best 3D printer files・Cults

038MT 16x AK Environmental Paint Unit

€2.83

040MT Open Shelf Unit

€2.83

039QT 8x AK Environment Paint Unit

€2.83

Badges Ateliers De Sotteville circa 1969-70

€0. 50

50

Box for drill bits/drills

€0.80

BEWARE OF MY HUSBAND

€1.41

Wireframe Deer STL

€3.04

Railway signal light

€0.80

Railroad

€1.49

Heavy Attack Walkers

Free

Heavy Attack Walker Library for Udo's Customizer

Free

Evil Destroyers

Free

Bamboo - Miniature Basing

€2.73

Attack Walkers

Free

Attack Walker Library for Udo's Customizer

Free

Modular, stackable boxes

€3. 20

20

Round drill holder

Free

1:18 Scale Workshop Desk with tools oil cans

€2

Workbench 1/24 Garage Diorama

€1

750p Add-on for Prime Space Soldiers Army for Grimdark Future

Free

Wall-mounted battery holder

€0.95

tool holder for dremel

€12.55 -66% €4.27

LED-bar Hinge Wall Mount for workshop lights from amazon

€4.16 -25% €3.12

750p Prime Space Soldiers Army for Grimdark Future

Free

FREE UPGRADES (with honours and markings) for Tribunus Celerum

Free

TRIBUNUS CELERUM for tabletop games, primary marines, space soldiers

€7. 99

99

Base expansion ring

€0.50

Workshop template 30

€0.65

oil plug for air compressor

€1.50

Small drawers

Free

Oil Barrel

Free

1/10 WORK BENCH (NO SUPPORTS)

€3.48

Falcon on the Hunt -Mini Diorama

€1

Router Dust Extraction Adapter

Free

750p Space Bugs Army for Grimdark Future

Free

Space Bugs - Boss Library for Udo's Customizer

Free

Space Bugs Library for Udo's Customizer

Free

Space Bugs - DNA Borrowers Library for Udo's Customizer

Free

Workshop crane

€3

Print in place folding Citadel Paint Pot Holder and mixing palette

€1. 36

36

Print in place folding Citadel double Paint Pot Holder

€1.36

Beware of the Cat sign

Free

1K Hijos Vortex Mutie-Monster

€7.52

Give-a-F**k-O-Meter

Free

Stranger Things

€1.41

Kinoko Tea Light Lantern - Soupcan13

€2.82

Prime Assault Soldiers for Grimdark Future

Free

1K Hijos Prime Magus Rojo (presupported)

€14.10

3D Printing Technologies - FDM, FFF, SLA, DLP, PolyJet, CJP, SLS, SLM

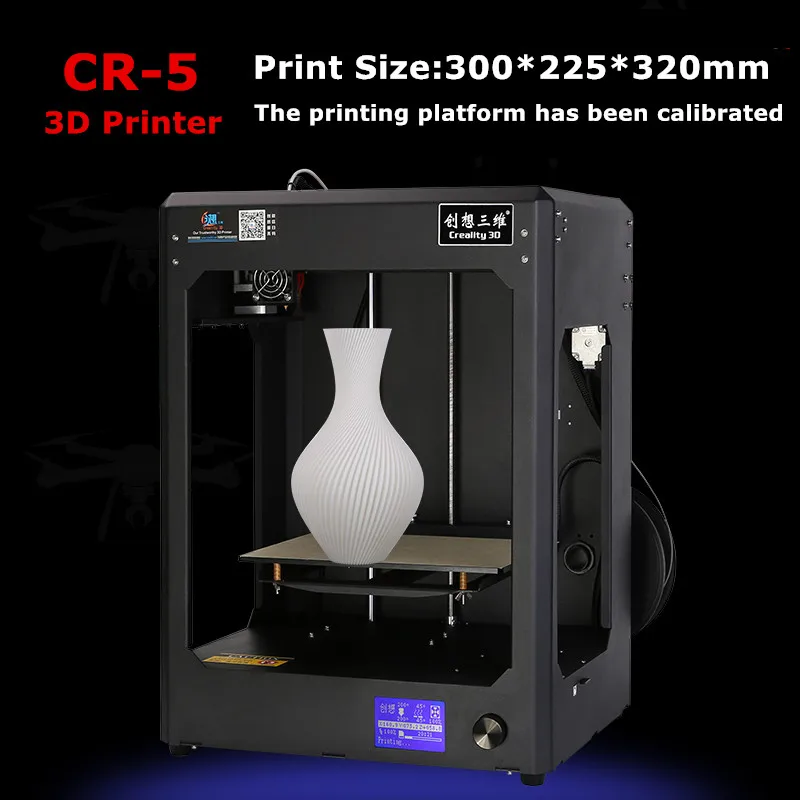

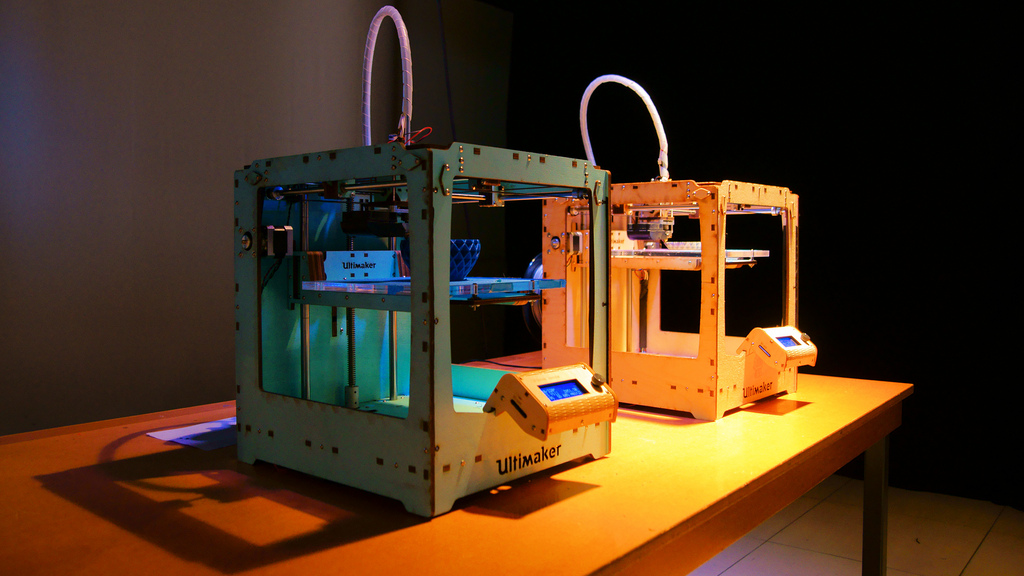

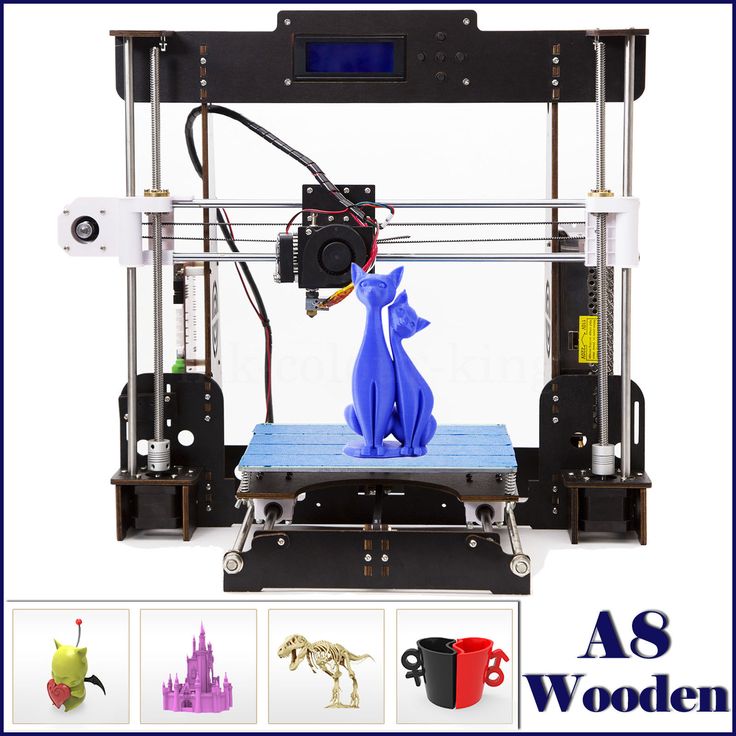

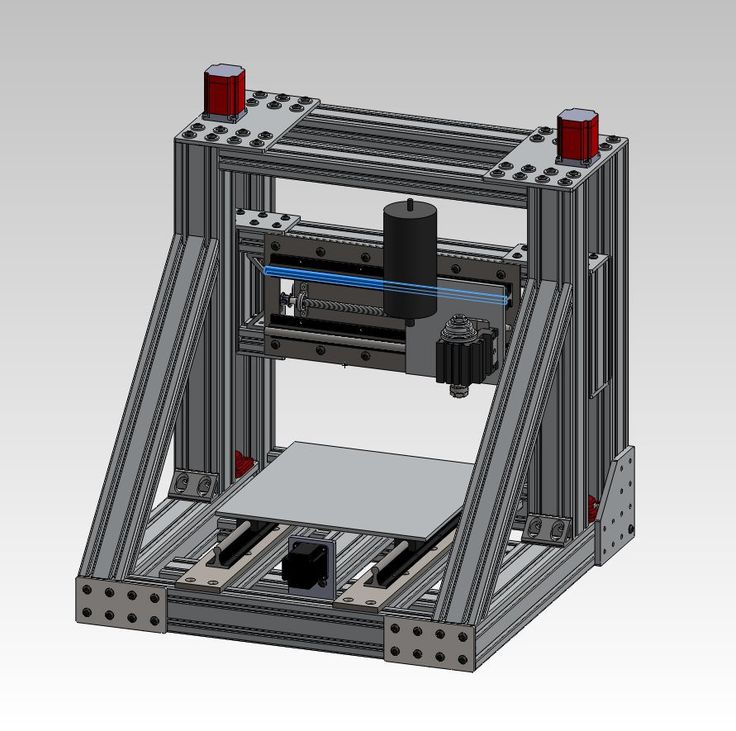

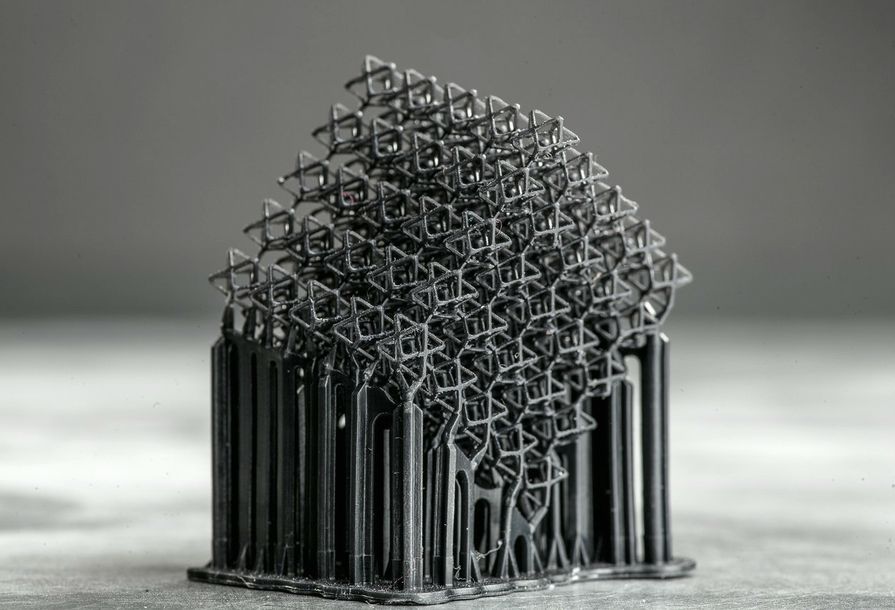

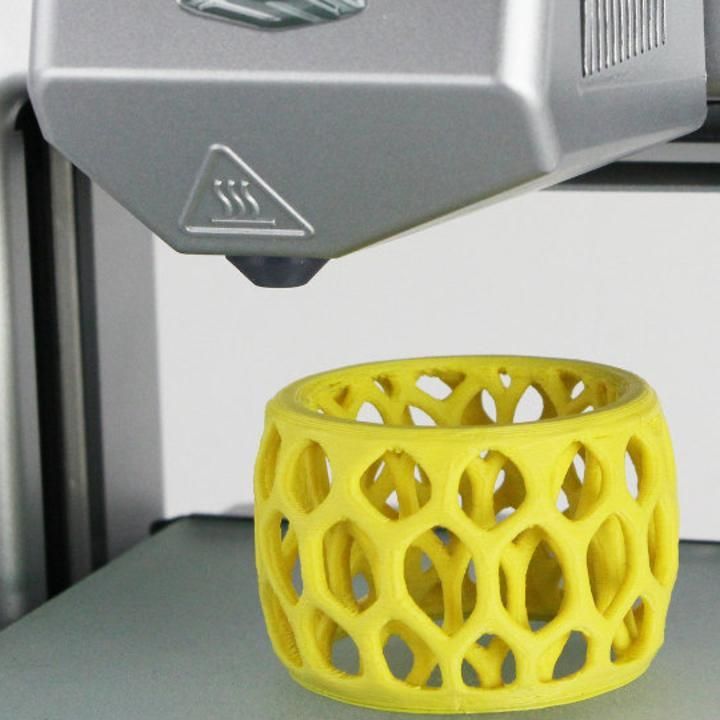

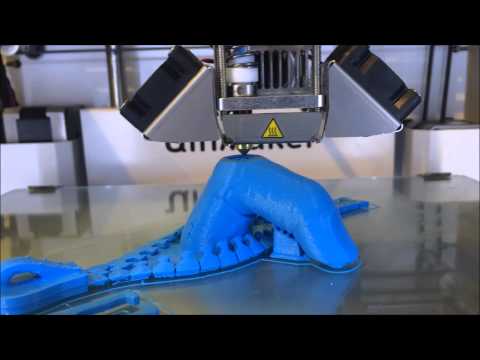

FUSED DEPOSITION MODELING PRINT TECHNOLOGY – + FDM

One of the most popular, simple and cheap 3D printing technologies is Fused Depsition Modeling. The technology was invented more than 20 years ago and implemented by Stratasys, and still it remains the most popular. The principle of building a prototype using this method is simple and clear. The simulated 3D object in STL format is transferred to the 3D printer software. After placing the model in a virtual working chamber (automatically or manually), cutting the model into horizontal layers, the 3D printing process begins. The extruder print head melts the filament, laying down layer by layer according to the model data. If necessary, before starting printing, auxiliary structures (supports) are automatically or manually placed on a virtual 3D model, which, after printing, can be removed with a special solution or manually. nine0007 There are many types of equipment that print using this technology. They differ in terms of accuracy, the number of print heads, the size of the working platform, the presence or absence of a closed working chamber, consumable options, etc. There are models that support the ability to use different materials when printing.

The technology was invented more than 20 years ago and implemented by Stratasys, and still it remains the most popular. The principle of building a prototype using this method is simple and clear. The simulated 3D object in STL format is transferred to the 3D printer software. After placing the model in a virtual working chamber (automatically or manually), cutting the model into horizontal layers, the 3D printing process begins. The extruder print head melts the filament, laying down layer by layer according to the model data. If necessary, before starting printing, auxiliary structures (supports) are automatically or manually placed on a virtual 3D model, which, after printing, can be removed with a special solution or manually. nine0007 There are many types of equipment that print using this technology. They differ in terms of accuracy, the number of print heads, the size of the working platform, the presence or absence of a closed working chamber, consumable options, etc. There are models that support the ability to use different materials when printing. There are also industrial FDM 3D printers and personal ones.

There are also industrial FDM 3D printers and personal ones.

The following materials can be used in FDM 3D printing: nine0005

- ABS

- PLA

- SBS plastic

- Nylon

- Polycarbonate

- HIPS support material

- PVA support material

- PETG plastic

- FLEX rubber-like plastic

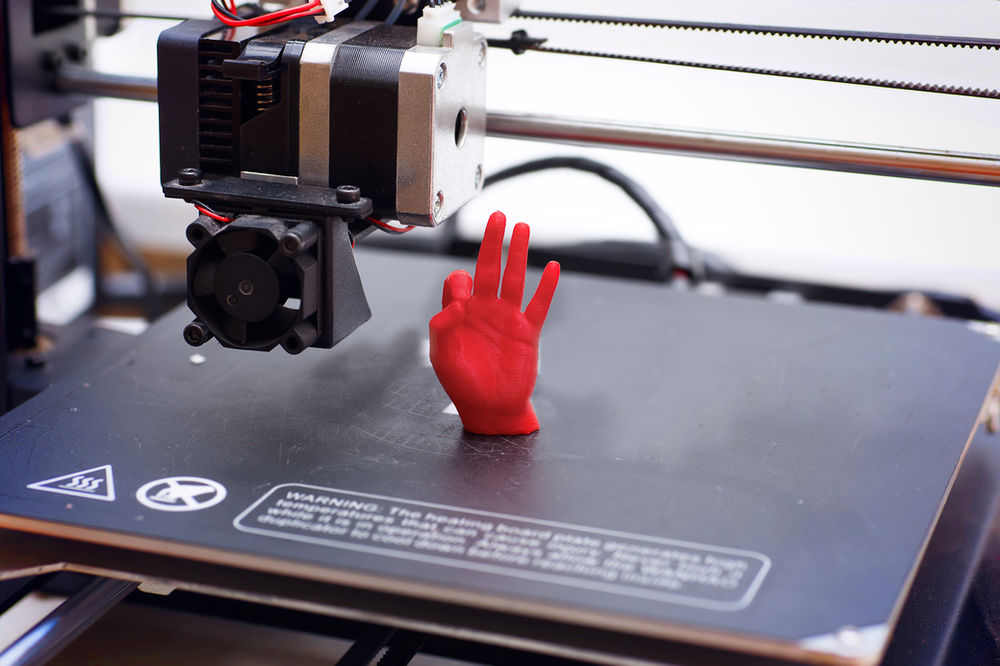

- RUBBER plastic with rubber properties

The most popular materials are ABS and PLA. Products printed using FDM technology are characterized by elasticity, strength and stable physical characteristics, depending on the selected material. The construction accuracy varies from 0.027mm to 1mm. As a rule, the printed object has a layered (ribbed) surface, the severity of which depends on the thickness of one layer. This effect can be eliminated by post-processing with chemicals or grinding. nine0007 The advantages of FDM 3D printing technology include sufficient speed and ease of manufacture of products, safety, high accuracy, a wide choice of materials, as well as ease of use and maintenance of equipment. In addition, consumables for printing in this way are affordable. All this together makes this technology the most highly competitive and affordable in economic terms.

In addition, consumables for printing in this way are affordable. All this together makes this technology the most highly competitive and affordable in economic terms.

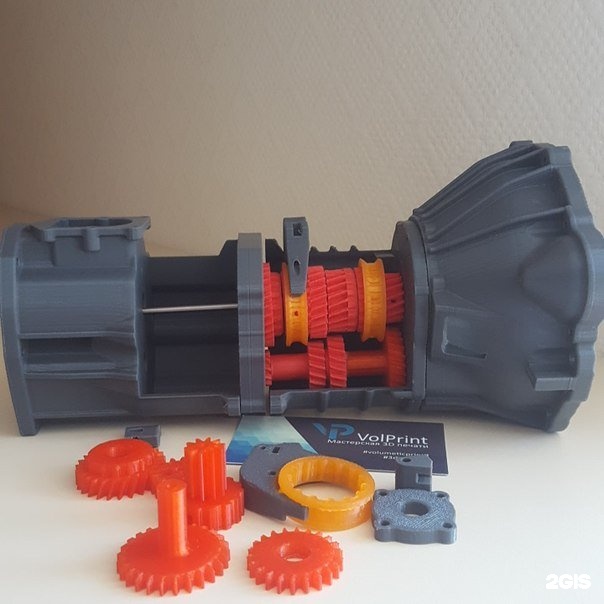

FDM 3D printing technology can be used for rapid prototyping and even small series production. Depending on the selected consumable material, this technology can be used to create parts of mechanisms, toys, interior items, jewelry, souvenirs and much more. The use of high-strength engineering thermoplastics makes it possible to apply this 3D printing method to products used in the aerospace industry. nine0007 Our company has several 3D printers working on this technology. You can order high-quality 3D printing using FDM technology from us with any of the available materials and in any available color option. We guarantee you the quality and efficiency of order execution of any degree of complexity.

To order 3D printing using FDM technology, you need to send us a file in STL format. Trust our professionalism and take advantage of the most affordable 3D printing.

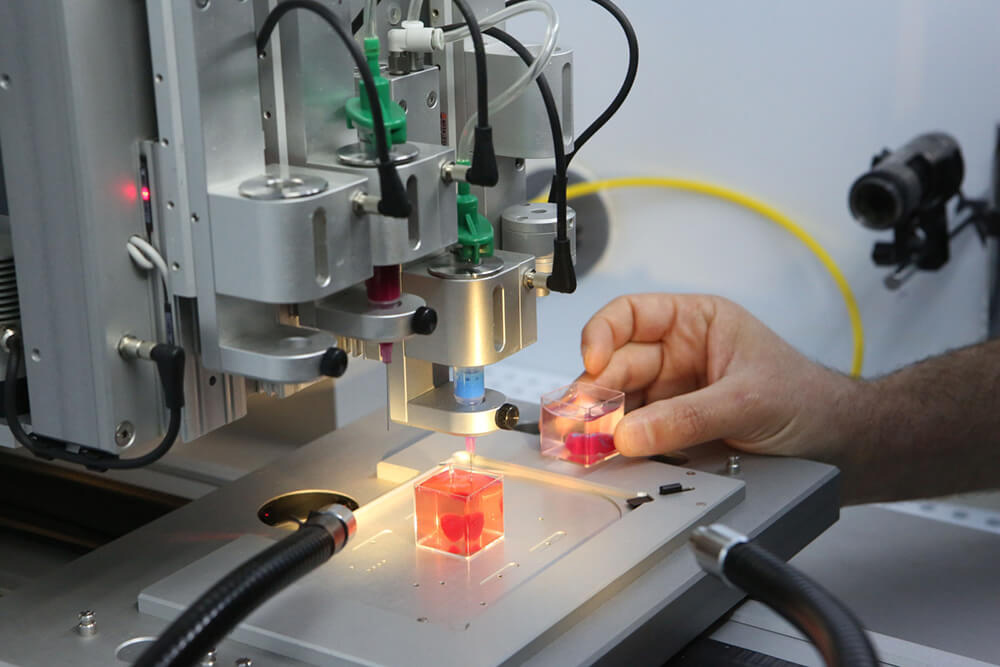

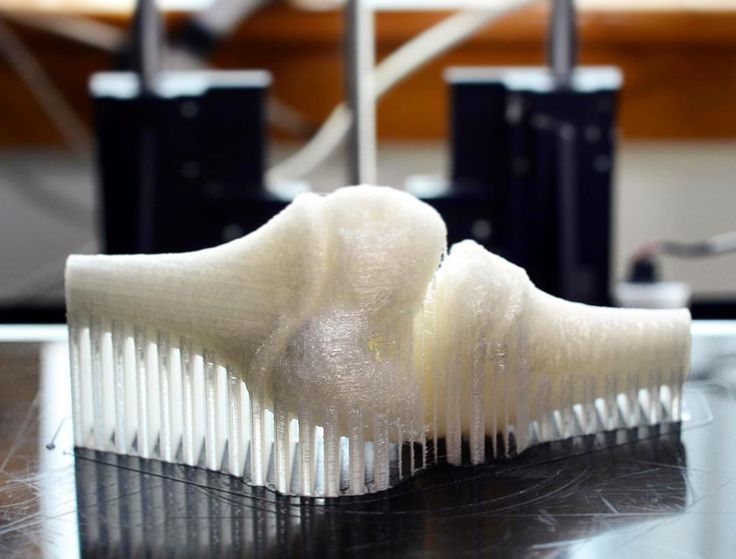

STEREOLITHOGRAPHY PRINT TECHNOLOGY – + SLA

SLA 3D printing technology or laser stereolithography is based on the layer-by-layer curing of a liquid photopolymer under the action of a laser beam. The technology was invented in 1986 by Charles W. Hull, who founded 3D Systems, which manufactures 3D printers that print using this technique.

Photopolymer, which in this case acts as a consumable, is a resinous substance that changes its properties under the influence of ultraviolet radiation - it polymerizes and hardens. In this case, the wavelength and time of exposure to radiation will depend on the environmental conditions and the specific material. nine0007 The principle of building a model using laser stereolithography technology at the initial level is similar to any other - the modeled object in STL format is loaded into the 3D printer software, placed in a virtual working chamber and cut into layers. Photopolymer resin is poured into a special container. It contains a working platform on which the part will be built. Initially, the working platform is set so that it is covered with the thinnest layer of photopolymer (0.05-0.13 mm). This will be the size of the layer when printed. Then the laser is turned on, it irradiates the areas that will later become parts of the finished product. As a result of irradiation, the material hardens and the working platform sinks to the extent of the layer. The algorithm repeats again until all programmed layers are exhausted. Then the finished product is immersed in a special bath, into which a composition is poured to remove excess elements. And at the end, the product is again irradiated so that it gains maximum strength. nine0007 Stereolithography, like most other 3D printing technologies, requires support. After printing is completed, they are removed manually.

Photopolymer resin is poured into a special container. It contains a working platform on which the part will be built. Initially, the working platform is set so that it is covered with the thinnest layer of photopolymer (0.05-0.13 mm). This will be the size of the layer when printed. Then the laser is turned on, it irradiates the areas that will later become parts of the finished product. As a result of irradiation, the material hardens and the working platform sinks to the extent of the layer. The algorithm repeats again until all programmed layers are exhausted. Then the finished product is immersed in a special bath, into which a composition is poured to remove excess elements. And at the end, the product is again irradiated so that it gains maximum strength. nine0007 Stereolithography, like most other 3D printing technologies, requires support. After printing is completed, they are removed manually.

The main advantages of stereolithography technology are the highest precision and the ability to create the smallest and thin-walled objects. The technique is distinguished by easy post-processing of products and their almost perfect surface. The disadvantage of this technology is the impossibility of using several materials at once. Color printing is also not possible. The properties of the model and its color will determine the initial characteristics of one photopolymer. In addition, the cost of such printing and equipment is not cheap. nine0007 Due to the fact that stereolithography allows you to get a model of almost any degree of complexity, the main scope of this 3D printing is research. And due to the highest accuracy and detail, this technique is used in medicine, in particular in dentistry. Also, printed models are in demand in art, jewelry, museum work and restoration. There are photopolymers that can be used to print molded models. The model printed on a 3D printer, in this case, is poured with molding sand and placed in an oven for annealing at a temperature of 1000 degrees. As a result, the polymer burns out without leaving a trace, and the resulting form can be used for pouring metal under vacuum.

The technique is distinguished by easy post-processing of products and their almost perfect surface. The disadvantage of this technology is the impossibility of using several materials at once. Color printing is also not possible. The properties of the model and its color will determine the initial characteristics of one photopolymer. In addition, the cost of such printing and equipment is not cheap. nine0007 Due to the fact that stereolithography allows you to get a model of almost any degree of complexity, the main scope of this 3D printing is research. And due to the highest accuracy and detail, this technique is used in medicine, in particular in dentistry. Also, printed models are in demand in art, jewelry, museum work and restoration. There are photopolymers that can be used to print molded models. The model printed on a 3D printer, in this case, is poured with molding sand and placed in an oven for annealing at a temperature of 1000 degrees. As a result, the polymer burns out without leaving a trace, and the resulting form can be used for pouring metal under vacuum. As the metal cools, the mold breaks and the metal part is removed. nine0007 In our company you can order 3D printing using SLA technology. We have in our arsenal professional 3D printers using this technology and a wide range of photopolymer resins with various characteristics for 3D printing. We guarantee you high quality and prompt execution of the order. To order 3D printing using the laser stereolithography method, you need to provide us with a file in STL format.

As the metal cools, the mold breaks and the metal part is removed. nine0007 In our company you can order 3D printing using SLA technology. We have in our arsenal professional 3D printers using this technology and a wide range of photopolymer resins with various characteristics for 3D printing. We guarantee you high quality and prompt execution of the order. To order 3D printing using the laser stereolithography method, you need to provide us with a file in STL format.

Get the most out of high-precision and highly detailed stereolithographic 3D printing. nine0007

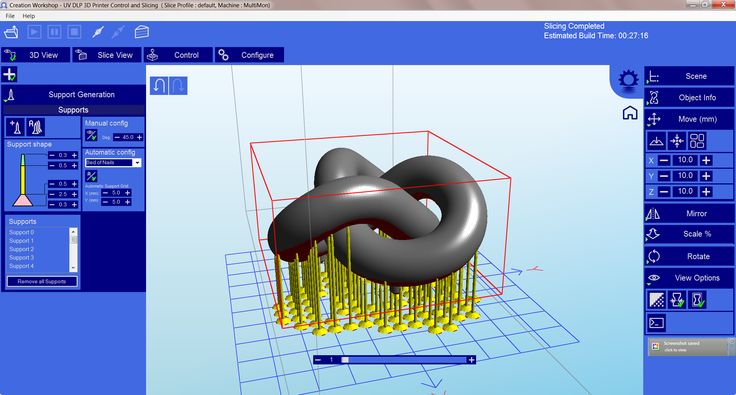

DIGITAL LIGHT PROCESSING PRINT TECHNOLOGY – + DLP

DLP 3D printing is one of the most accurate and fastest 3D printing methods. It is based on the technology that Larry Hornbeck invented for multimedia projectors. The peculiarity lies in the use of a special mirror matrix. Each individual pixel of this matrix is a microscopic mirror. nine0007 DLP stands for Digital Light Processing, which means "Digital Light Processing". Thus, this technology is one of the varieties of photopolymer 3D printing and photopolymer resin is used as a consumable. This resin is irradiated with projected light from the LEDs and hardens. The technology is very similar to stereolithography. However, with SLA 3D printing, each layer is, as it were, loomed with laser beams. And in DLP technology, the layer is completely projected onto a photopolymer using the same matrix with micromirrors, that is, this method is more like stamping. Thus, while maintaining the highest accuracy of 3D printing, it was possible to significantly increase its speed. At the moment, the speed of DLP printing is several times higher than FDM, SLM and SLA printing. For this reason, the DLP 3D printing technique is one of the most promising. nine0007 The thickness of one layer when printing using DLP technology is 10-15 microns, which is basically similar to the indicators for SLA 3D printing technology.

nine0007 DLP stands for Digital Light Processing, which means "Digital Light Processing". Thus, this technology is one of the varieties of photopolymer 3D printing and photopolymer resin is used as a consumable. This resin is irradiated with projected light from the LEDs and hardens. The technology is very similar to stereolithography. However, with SLA 3D printing, each layer is, as it were, loomed with laser beams. And in DLP technology, the layer is completely projected onto a photopolymer using the same matrix with micromirrors, that is, this method is more like stamping. Thus, while maintaining the highest accuracy of 3D printing, it was possible to significantly increase its speed. At the moment, the speed of DLP printing is several times higher than FDM, SLM and SLA printing. For this reason, the DLP 3D printing technique is one of the most promising. nine0007 The thickness of one layer when printing using DLP technology is 10-15 microns, which is basically similar to the indicators for SLA 3D printing technology. For comparison, the FDM method implies a minimum thickness of at least 50 microns.

For comparison, the FDM method implies a minimum thickness of at least 50 microns.

Since DLP printers are the main competitors of SLA printing, their application is about the same. They can print products for dentistry, jewelry, complex designs and even souvenirs. The technology is also in demand in the research area.

Photopolymers used in 3D printing with this method are diverse, and you can choose a material with the desired characteristics. For example, there are materials that mimic the properties of ABS plastic, hard engineering plastics, and even rubber. However, it is important to know that in some cases, under the influence of light, photopolymer products can crack and become brittle. This technology implies the impossibility of using several materials at once. Color printing is also not possible. The properties of the model and its color will determine the initial characteristics of one photopolymer. nine0007 However, there is also a drawback to DLP technology - as in the case of SLA 3D printers, the cost of equipment is very high, as in principle the price of photopolymers. Not every, even a large company, can afford such a 3D printer.

Not every, even a large company, can afford such a 3D printer.

But this does not mean at all that you will not be able to take advantage of the speed and advantages of DLP printing, because you have the opportunity to order 3D printing on such a 3D printer in our company. To do this, you just need to provide us with an STL file with the desired model. We guarantee you prompt execution of the order and high quality. nine0007 Enjoy high-quality, fast, high-precision DLP printing.

PRINT TECHNOLOGY LED DISPLAY – + LED

One of the varieties of DLP 3D printing technology is LED 3D printing. That is, this method is based on the same digital light processing (as Digital Light Processing stands for). However, in devices for LED 3D printing, instead of a mirror chipped matrix, there is an LED display that immediately highlights a whole layer on the material, like a kind of light stamp. Using an LED display allows you to increase the speed of 3D printing. So it takes about 10-15 minutes to 3D print 2.5 cm along the Z-axis, and it's really fast. Although the print speed in any case will directly depend on the thickness of one layer. nine0007 As a consumable material, a photopolymer resin is used, which polymerizes under the action of ultraviolet light, that is, it changes its qualities, passing from a semi-liquid state to a solid one. There are many options for photopolymers, among which there are materials that, after the polymerization process, imitate the characteristics of solid, including engineering plastics. There are also those that are very similar to classic rubber after hardening, that is, they have the same strength and elasticity indicators. You can also choose biocompatible photopolymers. When choosing a material for printing, you should be guided by the technical characteristics and scope of a particular photopolymer. nine0007 Like any other photopolymer 3D printing, LED technology is characterized by the highest precision and detail.

So it takes about 10-15 minutes to 3D print 2.5 cm along the Z-axis, and it's really fast. Although the print speed in any case will directly depend on the thickness of one layer. nine0007 As a consumable material, a photopolymer resin is used, which polymerizes under the action of ultraviolet light, that is, it changes its qualities, passing from a semi-liquid state to a solid one. There are many options for photopolymers, among which there are materials that, after the polymerization process, imitate the characteristics of solid, including engineering plastics. There are also those that are very similar to classic rubber after hardening, that is, they have the same strength and elasticity indicators. You can also choose biocompatible photopolymers. When choosing a material for printing, you should be guided by the technical characteristics and scope of a particular photopolymer. nine0007 Like any other photopolymer 3D printing, LED technology is characterized by the highest precision and detail. The thickness of one layer is only 10-15 microns. With its help, you can print thin-walled products, objects with complex geometry. Photopolymers practically do not shrink and do not change their geometry after hardening, and this is also an advantage, especially when it is necessary to print anatomically accurate models. The DLP LED 3D printing technology itself, although it provides for a layer-by-layer method for creating a model, still does not differ in pronounced layering of the finished model. The surface is almost perfectly smooth, requiring no additional processing. nine0007 If complex objects are printed, support must be used. They can be set in automatic or manual mode immediately before printing during the positioning of the model in the virtual working chamber. These supports are subsequently removed manually.

The thickness of one layer is only 10-15 microns. With its help, you can print thin-walled products, objects with complex geometry. Photopolymers practically do not shrink and do not change their geometry after hardening, and this is also an advantage, especially when it is necessary to print anatomically accurate models. The DLP LED 3D printing technology itself, although it provides for a layer-by-layer method for creating a model, still does not differ in pronounced layering of the finished model. The surface is almost perfectly smooth, requiring no additional processing. nine0007 If complex objects are printed, support must be used. They can be set in automatic or manual mode immediately before printing during the positioning of the model in the virtual working chamber. These supports are subsequently removed manually.

LED technology implies the impossibility of using several materials at once. Color 3D printing is also not possible. The properties of the finished prototype and its color will determine the initial characteristics of the photopolymer used. nine0007 The field of application of LED 3D printing is basically the same as the field of use of DLP printing, since this technology is, in fact, its improvement. The technology is in demand in the production of hearing aids and earmolds, in dentistry and orthodontics, as well as in jewelry. Due to the high accuracy and detail of 3D objects printed using this technology, products will also be in demand in the field of research and engineering activities.

nine0007 The field of application of LED 3D printing is basically the same as the field of use of DLP printing, since this technology is, in fact, its improvement. The technology is in demand in the production of hearing aids and earmolds, in dentistry and orthodontics, as well as in jewelry. Due to the high accuracy and detail of 3D objects printed using this technology, products will also be in demand in the field of research and engineering activities.

LED 3D printer is very expensive. However, this does not mean that its benefits are not available to you. You can order 3D printing using LED technology in our company. We offer you a large selection of photopolymer resins for printing and guarantee the high quality of models, in full compliance with the provided STL-file, and the prompt execution of the order. nine0007 Take full advantage of LED technology with our help.

POLYJET PRINT TECHNOLOGY – + PJ

PolyJet is a revolutionary 3D printing technology that is a powerful tool for high performance additive manufacturing. The technique was invented and patented by Stratasys. The operation of a PolyJet 3D printer is very similar to a conventional, well-known inkjet printer, but printing is carried out not on paper and not with simple ink, but on a special substrate in the chamber, and an acrylic-based liquid photopolymer acts as a material. nine0007 The PolyJet-enabled 3D printer is equipped with a special print head with nozzles. There can be several printheads, which allows you to print faster and even prototyping several objects at once. The printing process is carried out by dosed deposition of a photopolymer. One layer of 16 microns is sprayed at a time. Then this layer is exposed to an ultraviolet lamp and the photopolymer turns into a hard plastic. After that, the working platform with the substrate is lowered, and the algorithm is repeated again. When printing complex geometric shapes, a support material is used. For this technology, a special gel-like material has been created, which is easily removed with plain water or hands.

The technique was invented and patented by Stratasys. The operation of a PolyJet 3D printer is very similar to a conventional, well-known inkjet printer, but printing is carried out not on paper and not with simple ink, but on a special substrate in the chamber, and an acrylic-based liquid photopolymer acts as a material. nine0007 The PolyJet-enabled 3D printer is equipped with a special print head with nozzles. There can be several printheads, which allows you to print faster and even prototyping several objects at once. The printing process is carried out by dosed deposition of a photopolymer. One layer of 16 microns is sprayed at a time. Then this layer is exposed to an ultraviolet lamp and the photopolymer turns into a hard plastic. After that, the working platform with the substrate is lowered, and the algorithm is repeated again. When printing complex geometric shapes, a support material is used. For this technology, a special gel-like material has been created, which is easily removed with plain water or hands. nine0007 A key feature of PolyJet 3D printing technology is the ability to use multiple materials in one print run. At the same time, there are models of 3D printers that can mix photopolymers in various proportions, obtaining a variety of composite materials with certain characteristics. Also, this technology is characterized by the possibility of complex color reproduction. That is, it is possible to use color printing, the palette of which includes about 1000 colors and shades. In fact, it is the only additive manufacturing technology that supports these capabilities. nine0007 Other advantages of the method include: high printing speed, high accuracy and detail, perfect surface and generally excellent quality of printed objects. In addition, a wide range of materials allows you to create objects of almost any kind. More than 100 different photopolymer resins can be used as a base, mixing of which allows obtaining materials from transparent to completely opaque, from hard to elastic and rubbery.

nine0007 A key feature of PolyJet 3D printing technology is the ability to use multiple materials in one print run. At the same time, there are models of 3D printers that can mix photopolymers in various proportions, obtaining a variety of composite materials with certain characteristics. Also, this technology is characterized by the possibility of complex color reproduction. That is, it is possible to use color printing, the palette of which includes about 1000 colors and shades. In fact, it is the only additive manufacturing technology that supports these capabilities. nine0007 Other advantages of the method include: high printing speed, high accuracy and detail, perfect surface and generally excellent quality of printed objects. In addition, a wide range of materials allows you to create objects of almost any kind. More than 100 different photopolymer resins can be used as a base, mixing of which allows obtaining materials from transparent to completely opaque, from hard to elastic and rubbery. This is truly a new standard for realism in the most complex prints. PolyJet technology allows you to achieve perfect surface smoothness and imitate any even the most subtle texture. The camera of the PolyJet 3D printer is quite large, but if you need to print a large object, then it can be broken into parts, which are then simply glued together. nine0007 The only disadvantage of the technology is its high cost. The equipment is very expensive, and photopolymer resins are not cheap. But this does not mean that you cannot use this technology, because you have the opportunity to order 3D printing using PolyJet technology in our company. In a short time, we will implement your project on our own 3D printer. All you need is to provide us with the STL file.

This is truly a new standard for realism in the most complex prints. PolyJet technology allows you to achieve perfect surface smoothness and imitate any even the most subtle texture. The camera of the PolyJet 3D printer is quite large, but if you need to print a large object, then it can be broken into parts, which are then simply glued together. nine0007 The only disadvantage of the technology is its high cost. The equipment is very expensive, and photopolymer resins are not cheap. But this does not mean that you cannot use this technology, because you have the opportunity to order 3D printing using PolyJet technology in our company. In a short time, we will implement your project on our own 3D printer. All you need is to provide us with the STL file.

PolyJet 3D printing technology is truly limitless. nine0007

COLOR JET PRINTING TECHNOLOGY – + CJP

Color inkjet 3D printing - CJP (ColorJet Printing) technology - a patented technique invented by 3D Systems. It consists in layer-by-layer gluing and coloring of the powder gypsum composite. 3D printing of this type is based on a technique called 3DP, which is its improvement. nine0007 3D printing by this method is based on the use of two materials: base and binder. To create the base layer, a consumable of the main type is used. It consists of gypsum mixed with a polymer. And the binder is used for gluing and staining the layers.

It consists in layer-by-layer gluing and coloring of the powder gypsum composite. 3D printing of this type is based on a technique called 3DP, which is its improvement. nine0007 3D printing by this method is based on the use of two materials: base and binder. To create the base layer, a consumable of the main type is used. It consists of gypsum mixed with a polymer. And the binder is used for gluing and staining the layers.

ColorJet Printing 3D printer has two cameras. A gypsum composite is poured into one of them, and the second chamber is used to remove excess material. The model is "grown" in layers. A special roller distributes a thin layer of material on the working platform. The print head applies the adhesive and colors the main consumable particles. All this is carried out in accordance with the loaded mathematical 3D model. The working surface is lowered by the amount of the layer (0.1016 mm), and the roller again applies a layer of gypsum composite powder, and so on until the model is printed to the end. nine0007 ColorJet Printing technology has a relatively low cost of printed models. Its advantage is the absence of the need for supports, since the non-glued material will act as supporting structures. In addition, the material that was not used during printing can be reused. It turns out that this method of additive manufacturing is waste-free.

nine0007 ColorJet Printing technology has a relatively low cost of printed models. Its advantage is the absence of the need for supports, since the non-glued material will act as supporting structures. In addition, the material that was not used during printing can be reused. It turns out that this method of additive manufacturing is waste-free.

The CJP technology is the only one that uses the CMYK printing color palette. This palette includes 390 thousand colors and shades. The material is dyed during the gluing of the layer, resulting in details with excellent color reproduction.

The accuracy of building a model by this method is very high, the minimum printed element has dimensions of 0.1-0.4 mm. The thickness of the walls of the prototype, which will not collapse under their own weight, is 0.102-0.089 mm.

Models printed using ColorJet Printing technology have a typical gypsum rough surface, characterized by a high degree of hygroscopicity. The strength of the models is average. However, finished models are easy to sand, paint and glue. To improve the characteristics of the model and protect them from moisture, you can cover the surface with varnishes, waxes, resins, as well as all kinds of fixatives. nine0007 The technology can be used for 3D printing of architectural models, product presentations, souvenirs, miniatures, etc. Despite the fact that the products are of low strength, they allow you to visually evaluate the prototypes.

However, finished models are easy to sand, paint and glue. To improve the characteristics of the model and protect them from moisture, you can cover the surface with varnishes, waxes, resins, as well as all kinds of fixatives. nine0007 The technology can be used for 3D printing of architectural models, product presentations, souvenirs, miniatures, etc. Despite the fact that the products are of low strength, they allow you to visually evaluate the prototypes.

CJP 3D printer has impressive dimensions and is quite expensive, despite the fact that the cost of printed prototypes is low, not everyone can afford such pleasure. In our company, you can order 3D printing using ColorJet Printing technology. We guarantee you prompt execution of the order and full compliance of the prototype with the modeled object. All you need is to provide us with an STL file with a 3D model. nine0007 Take advantage of CJP 3D printing technology with our help and appreciate all its advantages in practice.

SELECTIVE LASER SINTERING PRINT TECHNOLOGY – + SLS

Selective, that is, selective, laser sintering is a 3D printing technology that was created back in 1979. However, for a long time it was not available to the market until DTM was created in 1996. In 2001, 3D Systems bought this company, and in 2014 the patent expired, and now this technology is available to a wide range of consumers. nine0007 The SLS 3D printing technique consists in the fact that the material is heated by a laser beam until the particles are sintered, that is, not completely. As a result, the model turns out not to be solid, but, as it were, “sintered” from individual tiny particles. If we consider the structure under magnification, then individual particles of the material will be visible, as if glued to each other.

However, for a long time it was not available to the market until DTM was created in 1996. In 2001, 3D Systems bought this company, and in 2014 the patent expired, and now this technology is available to a wide range of consumers. nine0007 The SLS 3D printing technique consists in the fact that the material is heated by a laser beam until the particles are sintered, that is, not completely. As a result, the model turns out not to be solid, but, as it were, “sintered” from individual tiny particles. If we consider the structure under magnification, then individual particles of the material will be visible, as if glued to each other.

The operation of a 3D printer that prints using SLS technology is as follows. Powder material is poured into the chamber. A 3D model in STL format is loaded into the software. The working platform is exposed and a thin layer of material (thickness about 120 microns) is applied to it, leveled with a roller. The laser sinters the powder particles according to the loaded model. After the layer is completed, the platform is lowered and a new layer of material is applied. The procedure will be repeated until the very last layer is completed. nine0007 Since there is unused material in the working chamber, the need for supports simply disappears, because complex and overhanging parts will be supported by unused material. This allows you to get models of any, even very complex geometry.

After the layer is completed, the platform is lowered and a new layer of material is applied. The procedure will be repeated until the very last layer is completed. nine0007 Since there is unused material in the working chamber, the need for supports simply disappears, because complex and overhanging parts will be supported by unused material. This allows you to get models of any, even very complex geometry.

Powder polymers, metals and their alloys, ceramics, glass, composite materials can be used as consumables. But in any case, the material must be in powder form. Due to the fact that the power of laser radiation can be adjusted, the degree of melting of the material can change, and, accordingly, the strength and uniformity of the structure of the resulting model. Currently, the most popular material for 3D printing using SLS technology is polyamide. This is a versatile powder material that can be used in almost any field. If powdered metal is used for printing, it is preheated to make printing faster and easier. nine0007 As a result of 3D printing, models are obtained with a surface that requires processing, in particular grinding. Models made of polyamide are sensitive to moisture, so they must be coated with a protective compound, such as moisture-resistant paint, if outdoor use is planned.

nine0007 As a result of 3D printing, models are obtained with a surface that requires processing, in particular grinding. Models made of polyamide are sensitive to moisture, so they must be coated with a protective compound, such as moisture-resistant paint, if outdoor use is planned.

Selective laser sintering shows excellent results when used in small-scale production, as well as for the manufacture of master models. This 3D printing technology is in demand in the aerospace industry, in manufacturing, etc. nine0007 The disadvantages of SLS 3D printing technology are the high cost of equipment. In addition, the powder material is potentially harmful to the human body, so a separate room with air conditioning and an air filter is equipped for such 3D printers. All this imposes difficulties for additive manufacturing using this technique. But this does not mean that you cannot take advantage of the possibilities of selective laser sintering technology, because our company provides professional 3D printing services on such equipment. You can order 3D printing using SLS technology from us. All you need is to provide us with a file with a 3D model in STL format. We guarantee you high quality printing in full accordance with the provided 3D model. nine0007

You can order 3D printing using SLS technology from us. All you need is to provide us with a file with a 3D model in STL format. We guarantee you high quality printing in full accordance with the provided 3D model. nine0007

SELECTIVE LASER MELTING PRINT TECHNOLOGY – + SLM

Selective (selective) laser melting - SLM is a 3D printing method from a mathematical CAD model, which is used to create 3D objects by melting metal powders. For this, high-power lasers are used.

Using this technology, it is possible to create precise metal parts that will later be used in various units and assemblies, including non-separable structures that change their geometry during use. This type of printing is becoming more and more widespread, because the parts created by this method are in many ways superior in their mechanical and physical characteristics to products produced by traditional methods. nine0007 The advantages of 3D printing using SLM technology are: the ability to solve the most complex production problems, including in the aerospace industry, where parts and assemblies have a hard load and serious requirements are imposed. Also, SLM printing is used in experimental and scientific and technical activities, where it is possible to significantly reduce the R&D cycle, because the most complex mechanisms and products can be created without serious equipment.

Also, SLM printing is used in experimental and scientific and technical activities, where it is possible to significantly reduce the R&D cycle, because the most complex mechanisms and products can be created without serious equipment.

The technology also allows you to print objects with internal cavities, which can significantly reduce the weight of products. nine0007 The essence of the method lies in the layer-by-layer application of metal powder on a special heated platform and its subsequent processing with a high-power laser, in accordance with the CAD model. The working chamber of the 3D printer, where the melting process itself takes place, is filled with argon or nitrogen. The choice of gas will depend on which consumable is selected for printing. Inert gas will be mainly consumed in preparation for printing, when the chamber is purged, because it is necessary to achieve conditions so that the percentage of oxygen in the chamber is no more than 0.15%. This is a necessary condition in order to avoid the oxidation of metals. Consumables can be: powdered metals and alloys. It can be tool or stainless steel, titanium and its alloys, aluminum, platinum, gold, as well as cobalt-chromium alloys. nine0007 The model is fused layer by layer. After the printing of the prototype is completed, it is removed from the chamber with the working platform and separated from it mechanically. In the future, it may require processing, because the surface of the product may not be ideal. However, the product will be very strong and uniform in structure, similar to cast.

Consumables can be: powdered metals and alloys. It can be tool or stainless steel, titanium and its alloys, aluminum, platinum, gold, as well as cobalt-chromium alloys. nine0007 The model is fused layer by layer. After the printing of the prototype is completed, it is removed from the chamber with the working platform and separated from it mechanically. In the future, it may require processing, because the surface of the product may not be ideal. However, the product will be very strong and uniform in structure, similar to cast.

One of the advantages of the technology is its economy and non-waste. After all, unsintered material can be reused. The thickness of one layer is 20-100 microns. Thus, SLM 3D printing is a very precise and highly detailed additive manufacturing technique. nine0007 The cost of 3D printers using this method is very high. And in general, their operation is by no means a simple matter, requiring special conditions. But you have a great opportunity to use 3D printing using selective laser fusion technology with the help of our company. All you need is just to order 3D printing using this technique in our company. To do this, you need to provide us with an STL file with a CAD model for printing.

All you need is just to order 3D printing using this technique in our company. To do this, you need to provide us with an STL file with a CAD model for printing.

Take advantage of the innovative method of creating high-precision metal products - SLM printing. nine0007

ELECTRON BEAM MELTING PRINT TECHNOLOGY – + EBM

One of the most reliable metal 3D printing methods is EBM printing or electron beam melting. This is an additive manufacturing technology that is used to create high-strength, comparable to cast, metal products. Pure (without impurities) metal powder acts as a consumable. Printing is carried out in a vacuum chamber, which minimizes the oxidation of the material, such as pure titanium. nine0007 Electron beam melting is very similar to SLS 3D printing technology, that is, selective laser melting. However, it does not use powerful lasers, but electron emitters, which serve as sources of powerful energy used to melt metal. So-called electron guns fire high power electron beams that fuse metal powder. The method is similar to other 3D printing methods - the layering of consumables. A layer of metal powder is applied, and electron beams, following the contour of the model, fuse the material. Then the algorithm is repeated again until all layers are created and a finished three-dimensional object is obtained in accordance with the mathematical 3D model. nine0007 As a result of such 3D printing, a high-density metal model is obtained, and the porosity of the structure is absent. This means that additional processing by the method of firing for a strong fusion of the material in the model is not required. And the model itself will have high strength characteristics initially, that is, it will not differ in any way from cast products.

So-called electron guns fire high power electron beams that fuse metal powder. The method is similar to other 3D printing methods - the layering of consumables. A layer of metal powder is applied, and electron beams, following the contour of the model, fuse the material. Then the algorithm is repeated again until all layers are created and a finished three-dimensional object is obtained in accordance with the mathematical 3D model. nine0007 As a result of such 3D printing, a high-density metal model is obtained, and the porosity of the structure is absent. This means that additional processing by the method of firing for a strong fusion of the material in the model is not required. And the model itself will have high strength characteristics initially, that is, it will not differ in any way from cast products.

Electron beam melting is printed at high background temperatures of 700-1000 degrees Celsius. This avoids a strong temperature difference between the already cooled printed layer and the fresh hot layer. Therefore, printed parts will not suffer from residual mechanical stress. This is how the highest possible strength of EBM-printed products is achieved. nine0007 This 3D printing technology is used to create high-precision titanium prostheses and implants, such as hip and knee implants, skull parts, etc. Titanium combines strength and biocompatibility.

Therefore, printed parts will not suffer from residual mechanical stress. This is how the highest possible strength of EBM-printed products is achieved. nine0007 This 3D printing technology is used to create high-precision titanium prostheses and implants, such as hip and knee implants, skull parts, etc. Titanium combines strength and biocompatibility.

EBM printing is also used in the aerospace industry. With the help of this technology, load-bearing structural elements of various devices (aircraft, rockets), as well as parts of their engines, are printed. For this purpose, strong and light powder metals are used. nine0007 EBM printing equipment is very expensive. However, you can order 3D printing using the technology of electron beam melting of powder metal. We are ready to fulfill your order in the shortest possible time, and we guarantee the high quality of printed products, in full accordance with the provided STL file.

Take advantage of high-precision and high-strength metal 3D printing - electron beam melting (EBM).

Custom ABS (ABS) FDM printing

Custom FDM ABS (ABS) printing nine0002 Printing with ABS (ABS) plastic using FDM technology to orderTechnology: 3D PRINT

loading ...

loading ...

loading ...

loading ...

loading ...

loading ...

loading ...

loading ...

loading ...

Loading ...

Loading ...

Price

no more than 12 o/cm 3

Cost per treatment

+ fifty o for processing 1 item

Printing time

from 1 to 3 days

0005

Processing cost

+ fifty o for processing 1 item

Printing time

We print on the day of order*

Calculate the cost

Price

no more than 25 o/cm 3

Cost for processing

+ fifty o for processing 1 item

Printing time

from 1 to 3 days

Calculate the cost

Price

no more than 70 o/cm 3

Processing cost

+ 500 o for processing 1 item

Printing time

from 5 to 7 days

Calculate the cost

Price

no more than 12 o/cm 3

Cost per treatment

+ fifty o for processing 1 item

Printing time

from 1 to 3 days

Calculate the cost

nine0002 Priceno more than 70 o/cm 3

Processing cost

+ 500 o for processing 1 item

Printing time

from 5 to 7 days

Calculate the cost

Price

no more than 25 o/cm 3

Cost per treatment

+ fifty o for processing 1 item

Printing time

from 1 to 3 days

Calculate cost

Price

no more than 25 o/cm 3

Cost per treatment

+ fifty o for processing 1 item

Printing time

We print on the day of the order*

Calculate the cost

Need an alternative?

More accurate

Photopolymer

Higher quality nine0005

Polyamide

Beneficial for series production

Molding plastic into silicone

Feedback form for calculating the cost of 3D printing

If you have a finished 3D model, upload it to the online form to calculate the cost of 3D printing.