3D printer repair los angeles

Repairs — LA 3D Printer Repair

"I'm glad we found you!"Is a compliment we get often from operators we help.

We’re glad you found us!

Problems are solved efficiently and affordably, we are pleased to provide a valuable service you can depend on.

Trust us with your 3D printer and we won't let you down.

If you need help, simply send us the details using one of the options below, and we’ll take care of the rest.

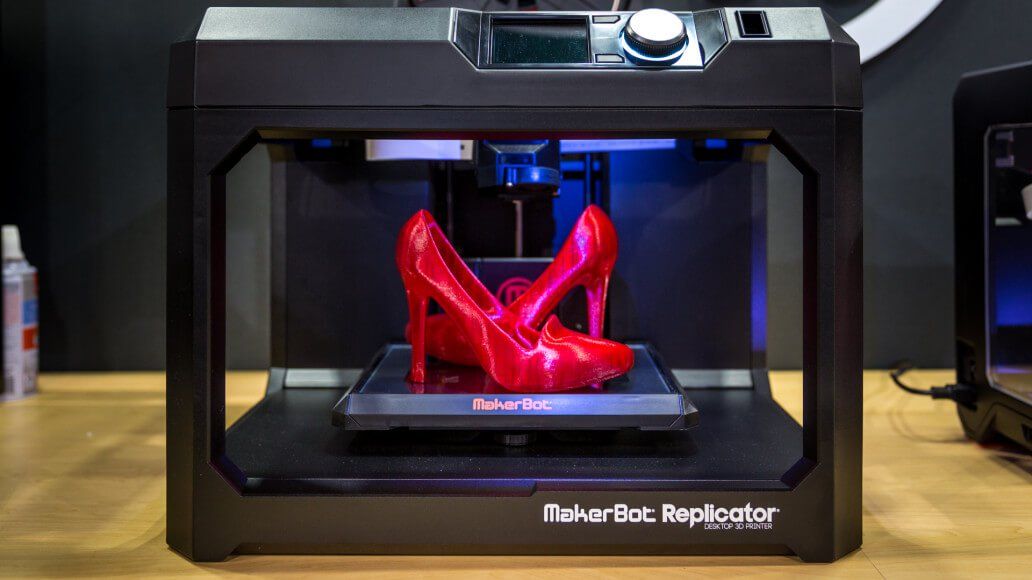

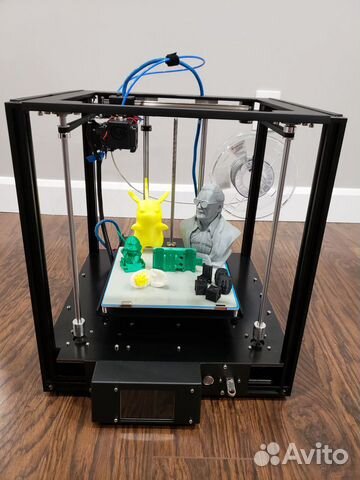

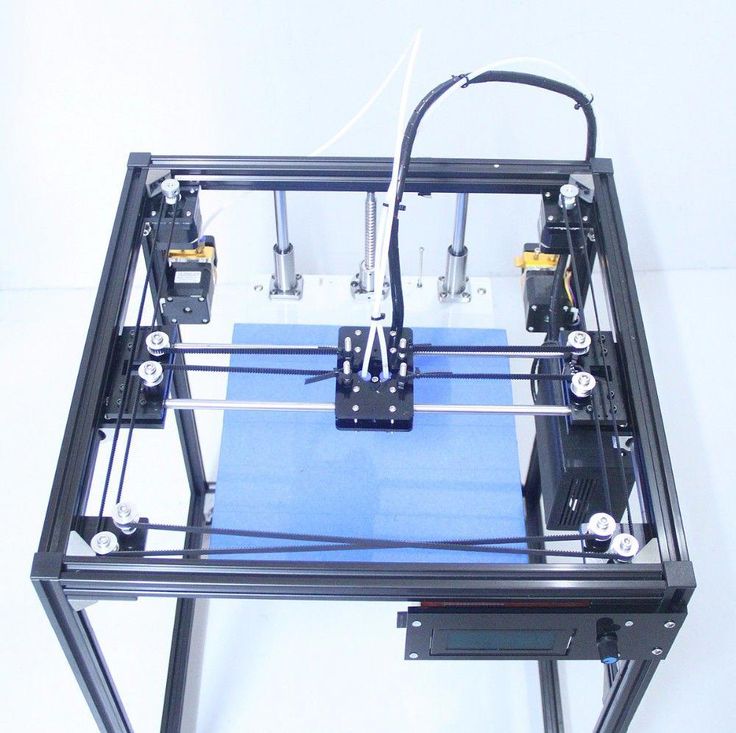

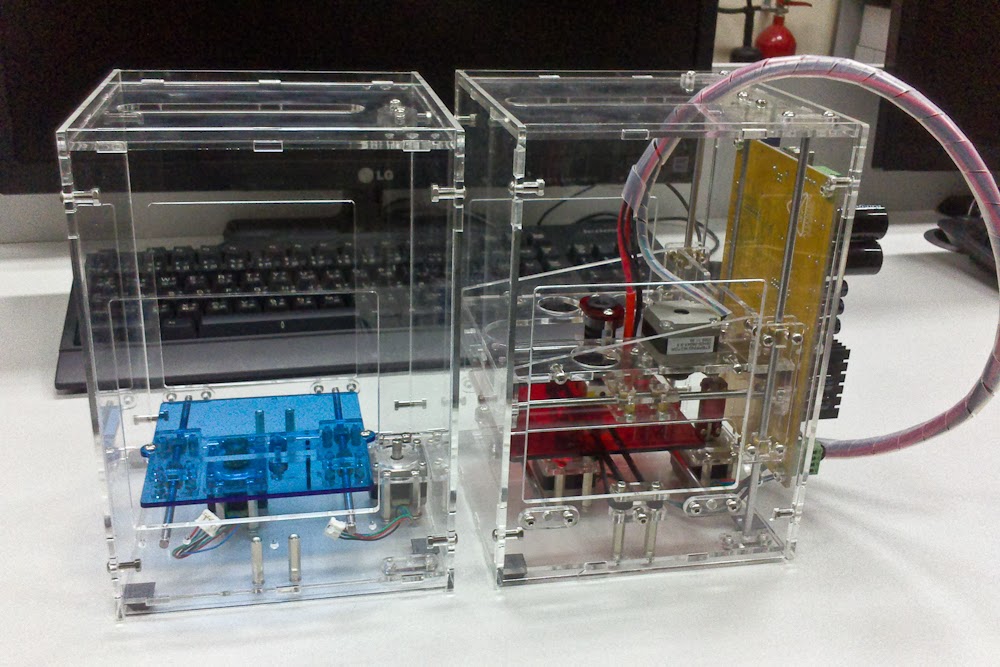

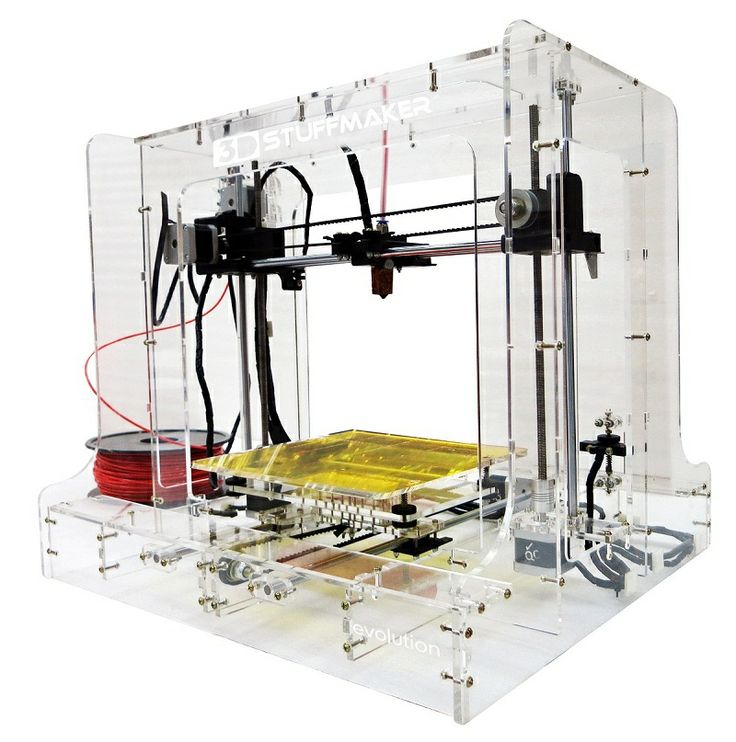

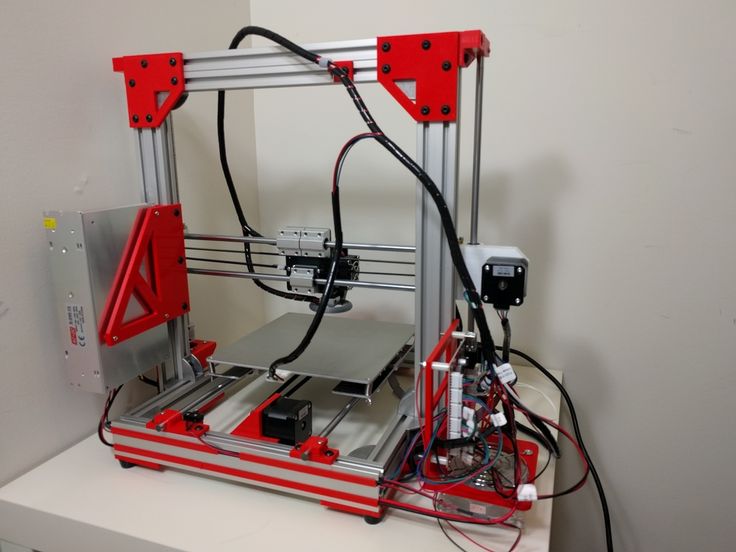

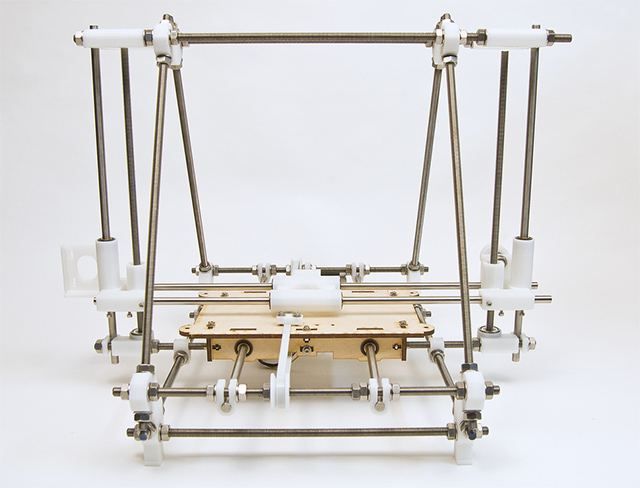

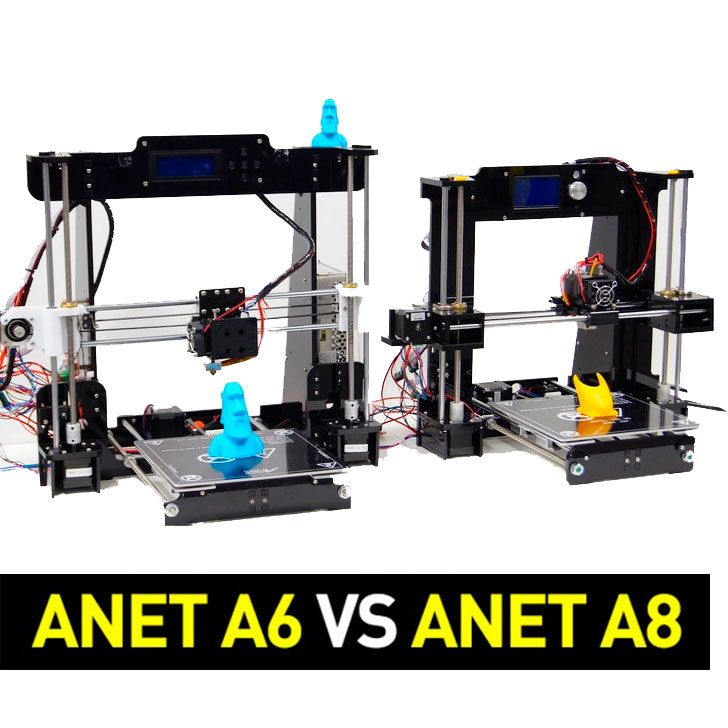

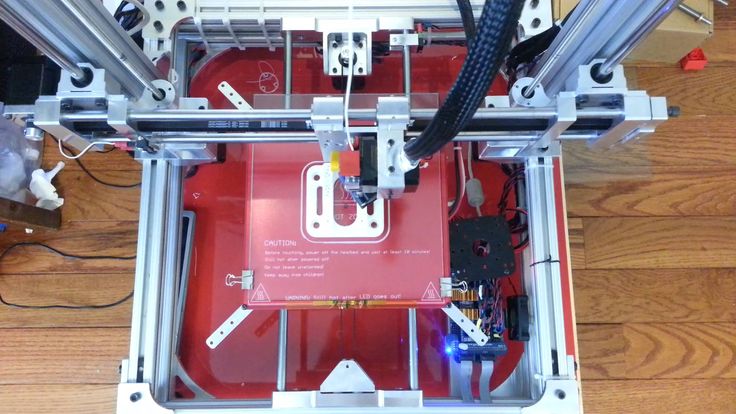

We fix a lot of printers, here’s a small selection of our work:

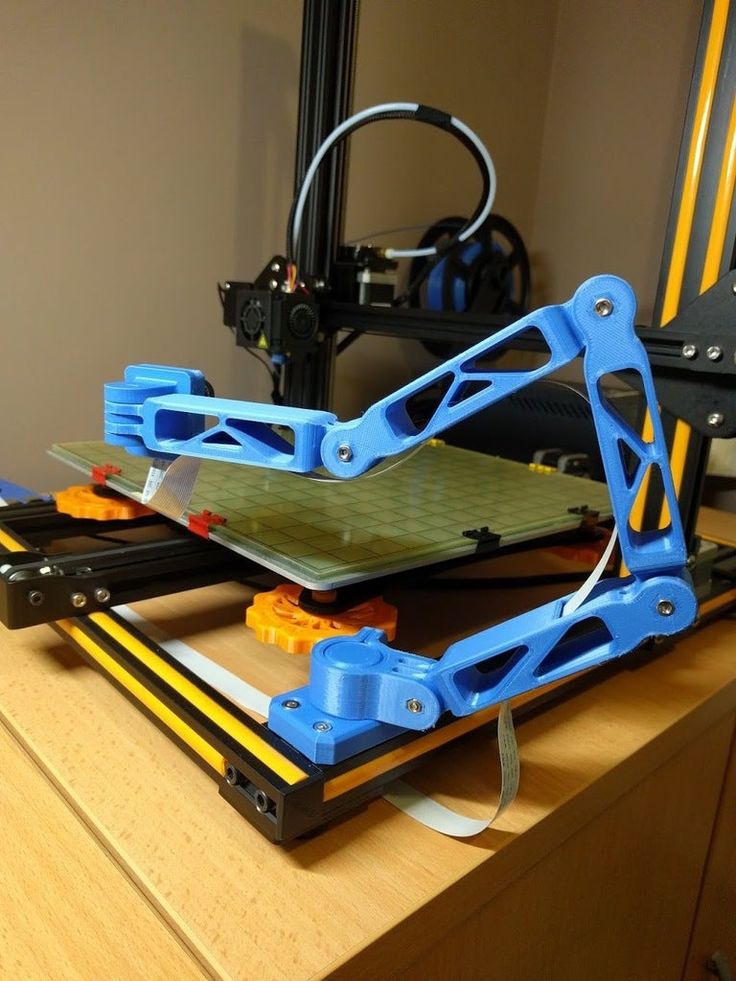

We have several in-house designed drop-in upgrades which we only sell directly, you won't find these anywhere else.

3D Printer problems need 3D Printed solutions.

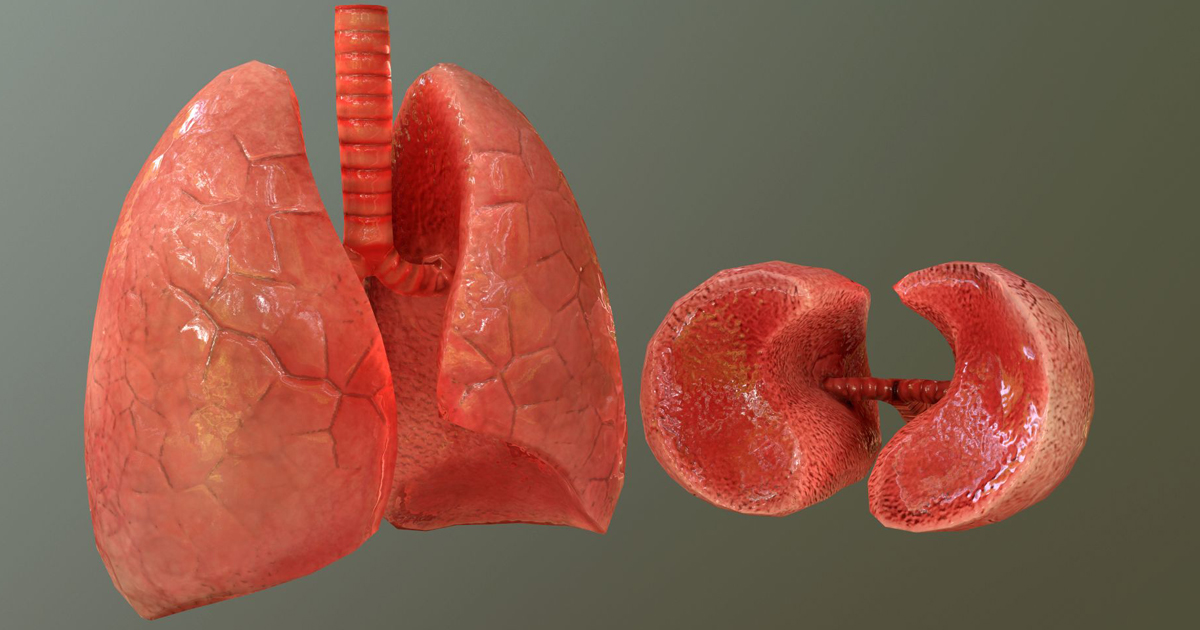

Visual aids help illustrate problems to our customers, we don't just fix, we educate.

It's the sentiment that counts, not the grammar. 👍🏻

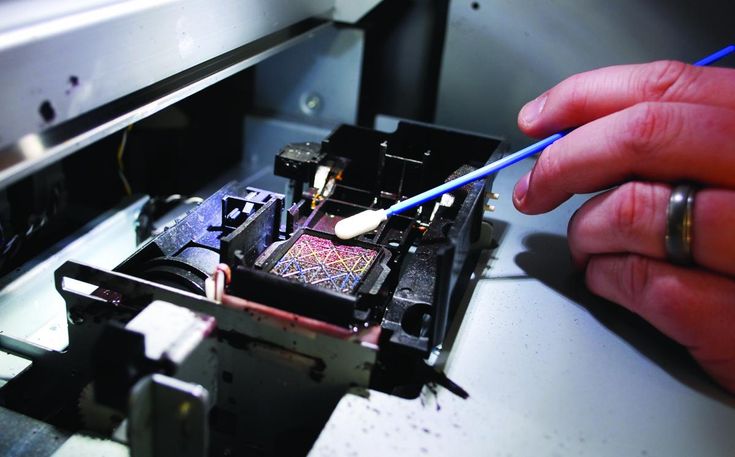

This TERRIBLE guidance from a reputable publication is in direct conflict with the assembly manual for the product which it clones - demonstrates a complete lack of familiarity with the fundamentals, and shows how treacherous "advice" in this market can be.

We have undertaken some lubricous projects, such as a complete, comprehensive retrofit for the MakerBot Replicator chassis to implement Marlin, complete with internalized PSU, and re-designed LCD enclosure.

A Prusa MK3, "totaled" in a topple, completely restored and upgraded to MK3S with MMU2S.

We have solutions borne out of years of experience summed up in simple terms.

We design parts on-demand to address problems, this simple adapter permits clean wire routing on Prusa MK2S printers.

Detail of Hemera mount repair with epoxied square nuts held via improvised SCAD jig.

It is illegal for a manufacturer to refuse service on an opened a device exposing "VOID" stickers, they are meaningless.

Failed Solid State Relay, likely poor QC; the mating of heat-spreader was fouled by a blob of solder, causing accelerated life.

Fouled drive pulleys from various Creality printers, obviously made of brass cheese.

You can spend a lot of money on upgrades and get frustrated making them work, whatever your situation, we will make you proud.

A batch of failed mosfets off a ChithuBoard, we will perform board level repairs where feasible.

Filament scrap stuck in a drive pulley from the Y-Axis of a Prusa MK2S causing head-crashes.

We regularly see bare wires on even new printers, this is generally "ok" but it's a shop standard to always use crimped ferrules to secure stray wire strands that might short.

Lots of nozzles - quality parts, the right nozzle for the application, and regular maintenance will keep you printing, indefinitely.

Incorrectly oriented "trap nuts" might work, but it's wrong, and every printer that earns our sticker leaves the shop right.

A common extruder idler lever failure we have seen recently on Creality printers, bad/no QC.

Self-service doesn't always go as planned, but we can get you out of even a serious jam with zero hassle.

Correct hotend maintenance is absolutely essential to long-term success with your printer and will avoid "showstoppers".

Customer commission E3D Volcano install on Creality CR-10S Pro

Our Prusa MK3S 3D printing farm doing 3D printing things.

You can indeed achieve near-resin caliber prints, with a standard FDM printer and a stock 0.4mm nozzle.

Once in a while, we get to just relax...

A severely heat-creeped Prusa extruder, incorrect hotend service cascading to take out other parts, we replaced the melted components, mended the fan wires, no big deal. Rapidly recovered and restored into working service at minimal cost.

The MMU2S is a grossly under-appreciated and misunderstood product, we have repaired more than anyone, and used our experience to produce "The MMU2S Theory of Operation" to help operators get their grips with it.

We perform regular commissioning of customer printers, like this RailCore 300ZLT.

The Prusa "wall of pride", Prusa is the only company *constantly* improving a product rather than sell you a new model. It prints its own upgrades - that should be the standard, not the exception.

3D Printing Service for Los Angeles, California

CapabilitiesCustom Online 3D Printing ServiceCaliforniaLos Angeles

High Quality Los Angeles, California 3D Printing | 60+ Materials Available

Endless Options

Choose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

Easy to Use

Get your parts delivered right to your door without the hassle of sourcing, project management, logistics, or shipping.

Guaranteed Quality

We back every part we ship with the Xometry Quality Guarantee. Our number one job at Xometry is making your custom parts to your specifications.

Your Los Angeles, California 3D Printing Service: 3D Prototypes and Production Parts

A Global Leader in Industrial-Grade 3D Printing

Xometry is an industry-leading 3D printing service. Whether you need prototypes or production parts, we can make them for you in as fast as a day. We are your one-stop-shop for accurate, precise custom 3D printed parts at a low cost. Upload your 3D CAD file to get a quote and lead time within seconds. We use the latest additive manufacturing processes to build affordable functional prototypes & end-use parts in over 60 metals and plastics.

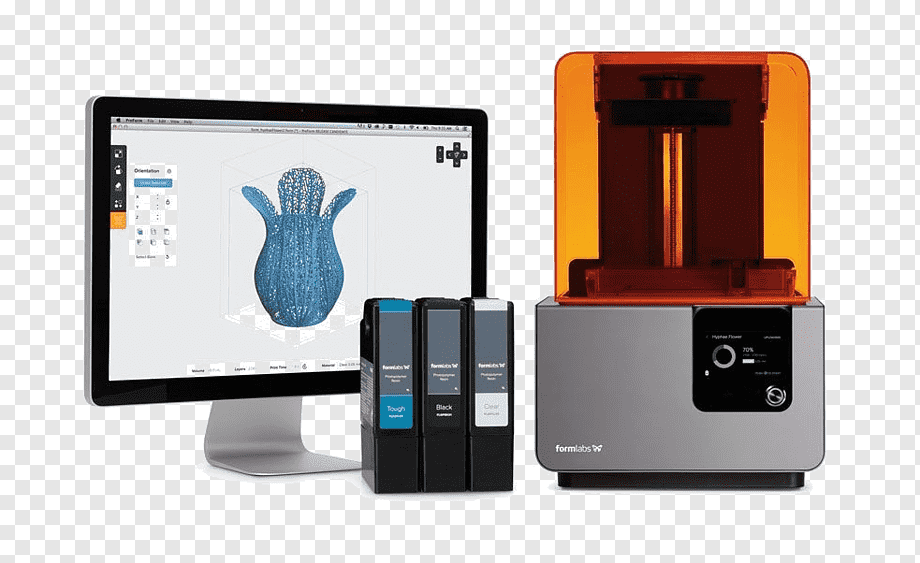

We offer eight high-quality 3D printing processes including selective laser sintering, fused deposition modeling, stereolithography, direct metal laser sintering, polyjet, Carbon DLS, binder jet metal, and HP Multi Jet Fusion. We use commercial and industrial-grade printers such as Stratasys Fortus 900mc and Fortus 450 FDM, EOS Polymer Laser Sintering (SLS) and DMLS, Concept Laser, SLM Solutions, 3D Systems, ExOne, and more.

Los Angeles 3D Printing - Industries and Applications

3D printing, a form of additive manufacturing, is a tremendous manufacturing asset to businesses and organizations in Los Angeles, California. If you're looking to better understand how 3D printing could add value to your project or industry, Xometry can assist you with your goals.

According to Thomasnet.com®'s 2022 sourcing data, the top six most popular manufacturing industries in Los Angeles are Software & Technology, General Manufacturing, Aerospace & Defense, Food & Beverage, Electronics, and Automotive. Here's how 3D printing can support local manufacturing in Los Angeles in some of these popular sectors:

- General manufacturing: Considered a necessary utility tool that the majority of manufacturing companies are employing, 3D printing is a low-cost and invaluable manufacturing solution used in many avenues, from parts of the production line and making jigs and fixtures to creating custom tooling for laser marking.

It also allows for rapid prototyping to test design concepts ahead of production runs, thus reducing risk and eliminating costly design flaws. Top automotive companies are eager to leverage this technology, i.e., BMW, which uses Xometry for custom assembly of purpose-designed soft-touch handheld jigs. One case study showed that these improved-quality, lighter-weight, 3D printed products not only reduce fatigue but they also reduce scrap rate, too. Additive manufacturing is also starting to become a substitute process for injection molding, particularly for low-volume projects that require complex tooling from plastic or metal. As 3D printing creates parts directly from the CAD model one layer at a time, it offers cost advantages by eliminating the upfront expenses of creating tooling or molds, such as with die casting, injection molding, or CNC machining.

It also allows for rapid prototyping to test design concepts ahead of production runs, thus reducing risk and eliminating costly design flaws. Top automotive companies are eager to leverage this technology, i.e., BMW, which uses Xometry for custom assembly of purpose-designed soft-touch handheld jigs. One case study showed that these improved-quality, lighter-weight, 3D printed products not only reduce fatigue but they also reduce scrap rate, too. Additive manufacturing is also starting to become a substitute process for injection molding, particularly for low-volume projects that require complex tooling from plastic or metal. As 3D printing creates parts directly from the CAD model one layer at a time, it offers cost advantages by eliminating the upfront expenses of creating tooling or molds, such as with die casting, injection molding, or CNC machining. - Aerospace and defense: 3D printing is already being utilized in aerospace and, though not yet heavily adopted in defense, has the potential to provide enormous value in the sector.

3D printing applications in aerospace mainly revolve around reducing foreign object debris (FOD) by consolidating part count, while also reducing the weight of components thereby significantly reducing costs. Freeform aerospace designs via additive can also benefit through topology optimization, a method utilizing mathematical tools to augment the distribution of the designs’ material. For defense, 3D printing can simplify the life cycle support of any product, specifically for low-volume repairs or replacements of highly custom legacy products that are no longer manufactured. In addition to using this technology for the creation of advanced weapon systems like drones and weaponry, additive manufacturing can reduce the downtime from repairs through rapid response, with the potential for real-time 3D printing base replacement units for the military. Though there is still a lot of discovery yet to take place in relation to legacy parts, it is an interesting avenue with a lot of potential for the defense sector.

3D printing applications in aerospace mainly revolve around reducing foreign object debris (FOD) by consolidating part count, while also reducing the weight of components thereby significantly reducing costs. Freeform aerospace designs via additive can also benefit through topology optimization, a method utilizing mathematical tools to augment the distribution of the designs’ material. For defense, 3D printing can simplify the life cycle support of any product, specifically for low-volume repairs or replacements of highly custom legacy products that are no longer manufactured. In addition to using this technology for the creation of advanced weapon systems like drones and weaponry, additive manufacturing can reduce the downtime from repairs through rapid response, with the potential for real-time 3D printing base replacement units for the military. Though there is still a lot of discovery yet to take place in relation to legacy parts, it is an interesting avenue with a lot of potential for the defense sector.

- Food and beverage: On the manufacturing side of food and beverage, 3D printing is gaining traction as a valuable utility, with the potential to become so much more. Though general mass-market kitchenware isn’t 3D printed, the prototypes for these products very likely are, as well as other essential items in the sector such as food packaging, utensils, or spare parts for food production lines. 3D printed foods have long been the topic of fervent interest, with advancements such as the first commercial 3D chocolate printer that is set to change the game for bakeries and chocolatiers everywhere. But there are a few limitations, the main one being cleanability as a 3D printed surface with micropores is not smooth enough to be considered food-grade. The addition of chemical vapor smoothing for the post-processing of 3D printed products has, however, made it possible to get closer to food processing with 3D printing than ever before.

- Electronics: Additive manufacturing in this sector largely focuses on the 3D printing of plastics to produce custom enclosures with bespoke individual functions.

IoT devices and wire routings that would be difficult and cumbersome to traditionally manufacture with standard tooling can be directly printed with metal or even substituted with a high-performance polymer in a short amount of time. Manufacturers of customized electronics and other products, from wearables to bridge- and high-fidelity tooling, are also turning to this technology.

IoT devices and wire routings that would be difficult and cumbersome to traditionally manufacture with standard tooling can be directly printed with metal or even substituted with a high-performance polymer in a short amount of time. Manufacturers of customized electronics and other products, from wearables to bridge- and high-fidelity tooling, are also turning to this technology. - Automotive: Additive manufacturing has been used in the automotive industry for decades with manufacturers choosing to 3D print automotive prototypes for early-stage research and testing. Today, major automakers — Ford, BMW, GM, and many more — have adopted 3D printing within their manufacturing operations for the rapid creation of purpose-built components such as handheld jigs, grips, custom fixtures, thermoforming tools, and molds. In some cases, additive manufacturing has been used within automotive for installed components, especially when mass configuration or personalization is desired, as this allows companies to keep costs low and avoid future losses by printing only samples and low volumes.

The additive manufacturing and material market is rampantly growing and is estimated to reach US$61.1 Billion by the year 2027. With the technology being so prolific, providing endless options, and the opportunity to greatly add to and advance your business, let Xometry cater to all your industrial-grade 3D printing needs.

Xometry's High Quality 3D Printing Services

Selective Laser Sintering (SLS)

Selective Laser Sintering (SLS) is a powerful 3D printing technology that produces highly accurate and durable parts that are capable of being used directly in end-use, low-volume production, or for rapid prototyping.

An additive manufacturing layer technology, SLS involves the use of a high power laser (for example, a carbon dioxide laser) to fuse small particles of plastic powders into a mass that has a desired three-dimensional shape. The laser selectively fuses powdered material by scanning cross-sections generated from a 3-D digital description of the part (for example from a CAD file or scan data) on the surface of a powder bed. After each cross-section is scanned, the powder bed is lowered by one layer thickness, a new layer of material is applied on top, and the process is repeated until the part is completed.

After each cross-section is scanned, the powder bed is lowered by one layer thickness, a new layer of material is applied on top, and the process is repeated until the part is completed.

Download the SLS Design Guide.

Stereolithography (SLA)

Stereolithography (SLA) is a robust 3D printing technology that produces extremely accurate and high-resolution parts that are capable of being used directly in end-use, low-volume production, or for rapid prototyping.

SLA is an additive manufacturing process that focuses an ultraviolet (UV) light on a vat of photopolymer resin. It offers higher resolution printing than many other 3D printing technologies, allowing customers to print parts with fine details and surface finishes. SLA 3D printing is a highly-versatile platform for making custom parts in prototype and production settings; often acting as a stand-in for injection-molded plastic parts.

Xometry offers both standard and high-resolution options for fine detail parts, and can also print larger sized parts and products, with some materials offering up to a 58" inch build area. In addition, Xometry's manufacturing partner network allows us to offer a larger variety of materials than other 3D printing companies - we offer a wide range of both Accura and Somos brand materials.

In addition, Xometry's manufacturing partner network allows us to offer a larger variety of materials than other 3D printing companies - we offer a wide range of both Accura and Somos brand materials.

Download the SLA Design Guide.

Fused Deposition Modeling (FDM)

Fused Deposition Modeling (FDM) is a 3D printing technology widely known for its speed, accuracy, and competitive cost. A machine precisely extrudes melted plastic filament to create a part. Parts are very rigid, especially compared to Selective Laser Sintering (SLS), which makes them a great fit for projects with a rigidity requirement. Xometry's FDM solution offers large build volumes up to 24″ x 36″ x 36″, a variety of colors, and a diverse selection of production-grade thermoplastics — from ABS to Polycarbonate to Ultem.

Download the FDM Design Guide.

HP Multi Jet Fusion (HP MJF)

HP Multi Jet Fusion is a new 3D printing technology that produces highly accurate and durable parts that are capable of being used directly in end-use, low-volume production, or for rapid prototyping. Since the process uses well-established 2D printing ink-jetting, it has remarkably fast layer times compared to other powder bed fusion technologies.

Since the process uses well-established 2D printing ink-jetting, it has remarkably fast layer times compared to other powder bed fusion technologies.

Download the HP Multi Jet Fusion Design Guide.

PolyJet 3D (PJ3D)

PolyJet 3D is a 3D printing technology known for its customizable material properties and excellent surface finish. It works by jetting UV curable resin onto a build tray in a process that is somewhat similar to inkjet printing. PolyJet 3D printing offers one of the most advanced industrial 3D printing solutions available, producing parts with incredible precision and speed. It also supports a wide variety of build materials including rigid and rubber-like plastics. Xometry's PolyJet solution has a maximum build envelope of 19.3 × 15.4 × 7.9 in. (490 × 390 × 200 mm) in a variety of colors and materials.

Download the PolyJet 3D Design Guide.

Direct Metal Laser Sintering (DMLS)

Direct Metal Laser Sintering (DMLS) is an 3D metal printing technology that builds prototype and production metal parts from a CAD file using a laser to selectively fuse a fine metal powder in either stainless steel or aluminum materials. A DMLS machine is capable of producing highly complex features and all-in-one assemblies using metal materials that would be difficult to achieve with subtractive manufacturing techniques.

A DMLS machine is capable of producing highly complex features and all-in-one assemblies using metal materials that would be difficult to achieve with subtractive manufacturing techniques.

Our DMLS metal 3D printing service typically offers build volumes up to 250 x 250 x 325 mm, but we may be able to accommodate larger part volumes upon request in the quote. (See our Manufacturing Standards for more details) A good first step is to find out the cost of the parts you need using DMLS and compare them to other 3D printing processes and CNC machining.

Download the DMLS Design Guide.

Carbon DLS™

Carbon DLS™ uses digital light projection, oxygen-permeable optics, and programmable liquid resins to produce products with end-use durability, resolution and surface finish. This 3D printing technology is called Digital Light Synthesis™, or DLS for short. Another legacy term for the process is Continuous Liquid Interface Production (CLIP). Along with Carbon’s custom liquid resins, DLS unlocks new business opportunities and product designs previously impossible, including mass customization and on-demand inventory of end-use products.

Carbon bridges, and sometimes substitutes, for processes like Urethane Casting and Injection Molding service production, because the materials are urethane-based or epoxy-based, giving excellent mechanical properties. There are even elastomer and silicone resins that outperform most additive manufactured rubber-like materials.

The typical build area is 7.4” x 4.6” x 12.8”. Parts with dimensions exceeding 4” x 4” x 6” will require manual review.

Download the Carbon DLS Design Guide.

Metal Binder Jetting

With binder jetting, an inkjet print head quickly deposits a bonding agent onto a thin layer of powdered particles -- either metal, sand, ceramics or composites. This process is repeated, layer-by-layer, using a map from a digital design file, until the object is complete. Binder jetting is offered through our Digital RFQ Marketplace through Xometry's partnership with ExOne.

Download the Binder Jetting Design Guide.

Ready to start making custom 3D printed parts?

3D Printing for Vintage Car Restoration and Repair

Jay Leno is an American Emmy award-winning comedian, television host, and owner of one of the finest, if not the finest, car collections in the world. Based in Burbank, California, the Big Dog Garage collection includes over 200 cars and 100 motorcycles. The area of the premises allotted for finished cars is 1600 square meters. But that's not all, because in the garage there are several buildings reserved for maintenance, repair and restoration, where several mechanics are constantly working.

Based in Burbank, California, the Big Dog Garage collection includes over 200 cars and 100 motorcycles. The area of the premises allotted for finished cars is 1600 square meters. But that's not all, because in the garage there are several buildings reserved for maintenance, repair and restoration, where several mechanics are constantly working.

Jay Leno is considered one of the most respected auto journalists in the United States. Not only does he have one of the largest car collections in America, but he also restores and restores rare models. It is important that all cars and motorcycles in the garage are full-fledged, efficient specimens, ready to hit the road at any time.

Even with all the attention the team puts into keeping the cars running, some parts will inevitably break. Finding replacement parts for classic and hand-built cars, some over 100 years old, is next to impossible, and making new ones using traditional methods can become very costly and time consuming.

Jay Leno and his team do not solely rely on traditional methods, but instead use advanced technology to solve this problem. By incorporating 3D scanning, reverse engineering and 3D printing into their workflow, they create both end-use parts and tooling for automotive injection molding. Not only does the technology provide huge benefits for vintage vehicles, but it is also invaluable for unique and custom vehicles that do not have mass-produced parts.

For over 10 years Jay Leno's team has worked closely with major 3D printer manufacturers Stratsys and 3D Systems. Big Dog Garage engineers use the company's Stratsys DimensionSST 1200 and Fortus250 3D printers. They also use Stratsys Direct Manufacturing and 3D Systems On Demand 3D printing services. In his show "Jay Leno's Garage", Jay shared his experience of using 3D printing technologies to restore cars.

November 2019 Big Dog Garage Joins Stratasys Performance Partner Program

As part of the partnership, Stratasys will provide Jay Leno's auto repair companies with access to its 3D printers to produce custom parts. In particular, one of the most popular models 3D printer Stratasys for the automotive industry Fortus 450mc with FDM Nylon12 Carbon Fiber. 3D printing using carbon fiber allows you to create strong, rigid and lightweight products. FDM Nylon 12CF combines Nylon 12 and carbon fiber to achieve the highest flexural strength and stiffness to weight ratio of any Stratasys FDM material. The unique properties of the material allow it to be used for replacing metal components, for making lighter tools, for functional prototyping and for printing final products.

In particular, one of the most popular models 3D printer Stratasys for the automotive industry Fortus 450mc with FDM Nylon12 Carbon Fiber. 3D printing using carbon fiber allows you to create strong, rigid and lightweight products. FDM Nylon 12CF combines Nylon 12 and carbon fiber to achieve the highest flexural strength and stiffness to weight ratio of any Stratasys FDM material. The unique properties of the material allow it to be used for replacing metal components, for making lighter tools, for functional prototyping and for printing final products.

According to the TV presenter, the use of 3D printing technologies of in the automotive industry will significantly accelerate its development. The ability to recreate any part, regardless of its rarity or complexity of geometry, makes it easy to carry out repairs of any complexity.

You can buy a Stratasys Fortus 450mc 3D printer, see it in operation or order a test print from the official Stratasys dealer in Russia - Jetcom.

Would you like to know more?

View our catalog of industrial 3D printers or contact us for help with choosing the right equipment for your tasks: +7 (495) 739-09-09

scanners throughout Russia

Call!

Free call from Russia

Tomsk

+7(3822) 25-59-25

Sot. Megaphone

+7 (923) 401-31-00 9000

or write:

CIS marketing department:

9000 You can call free to us from your city by dialing additionally in tone dialing: 64008

Australia, Melbourne +61 (39) 111-24-60

Australia, Sydney +61 (28) 880-04-33 9004 Austria, National +43 (720) 775-512

Argentina, Buenos Aires +54 (11) 521-70-773

Belgium, Mobile +32 (466) 900-986

Bulgaria, Burgas 398 +3 Brazil, Rio de Janeiro +55 (21) 404-200-67

UK, London +44 (203) 769-01-65

Guatemala, Guatemala +502 (2) 375-00-15

Germany, Berlin +49 (305) 201-42-42

Denmark National 45 (7) 873-09-60

Israel, Jerusalem +972 (2) 569-50-85

Israel, Tel Aviv +972 (3) 374-12-78

Ireland, National + (76) 888-92-44

Iceland, Reykjavik +354 (5) 395-011

Spain, Barcelona +34 (93) 164-17-78

Spain, Madrid +34 (91) 082-27-97

Kazakhstan, Nur-Sultan (Astana) +77 (172) 472-839

Canada, Montreal +1 (514) 819-05-77

Canada, Toronto +1 (647) 496-82-62

Canada, Toronto +1 (437) 800-55-03

Cyprus, Nicosia +357 (22) 030-216 Colombia Bogota +57 (1) 580-03-35

Kyrgyzstan, Bishkek +996 (312) 962-693

Latvia, Riga +371 (67) 88-15-29

Lithuania, Vilnius tel:+370 (5) 259-61-71

Mexico, Mexico City +52 (55) 852-62-722

New Zealand, Wellington +64 (4) 889-49-10

Panama, Panama +507 (836) 77-75

Poland, Warsaw +48 (22) 602-21-91

Russia, Belgorod +7 (4722) 777-170 9015 Russia +7 (4732) 007-316

Russia, Yekaterinburg +7 (3432) 264-777

Russia, Kazan +7 (8432) 071-650

Russia, Kaliningrad +7 (4012) 92-08-66

Russia, Krasnodar +7 (861) 217-6-777

Russia, Krasnoyarsk +7 (391) 989-77-79 Russia , Moscow - bronze

Russia, Omsk +7 (3812) 99-16-40

Russia, Perm +7 (3422) 33-83-05

Russia, Rostov-on-Don 9+7 (863) 308-17-60

Russia, Ryazan +7 (4912) 29-40-35

Russia, Samara +7 (846) 970-77-77

Russia, St.

Learn more