3D printed plastic model kits

3d Printed Kit - Etsy.de

Etsy is no longer supporting older versions of your web browser in order to ensure that user data remains secure. Please update to the latest version.

Take full advantage of our site features by enabling JavaScript.

Find something memorable, join a community doing good.

( 1,000+ relevant results, with Ads Sellers looking to grow their business and reach more interested buyers can use Etsy’s advertising platform to promote their items. You’ll see ad results based on factors like relevancy, and the amount sellers pay per click. Learn more. )

Home - 3dsets.

2022

Discover the best

3D Sets products

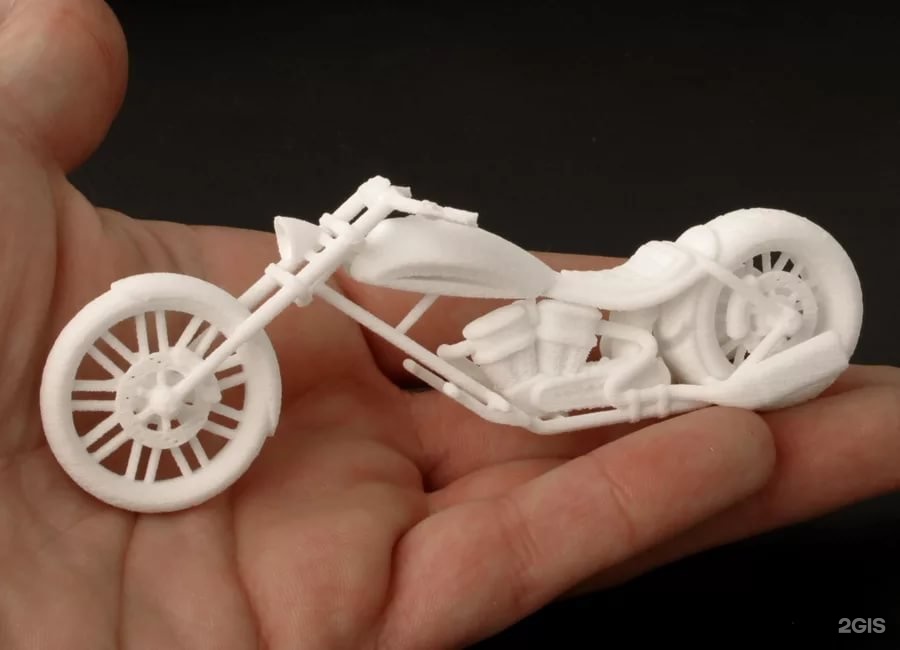

We specialize in crafting high-quality digital content for 3D printer enthusiasts. Our products are digital – you can 3D print and assemble them by yourself.

Print, Built and Enjoy!

…that’s our motto. And if anything breaks, don’t worry, you can always print new parts and continue to modify and perfect your design to your heart’s content. With our designs, the possibilities are endless.

Our designs use screws to hold the parts together, allowing for easy disassembly.

It’s all about joy…

learn how to enjoy 3D Sets product

1.

Buy & Download

3D Sets printing data

Browse through our e-shop and select your desired product. Once purchased, download the print files directly from our website in the “My Account” section.

Get ready for the next step: gather non-printable parts using our Build Guide links and stock up on filament. Bring your dream creation to life!

Bring your dream creation to life!

2.

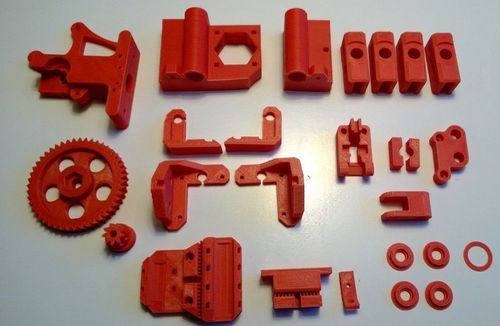

Print parts

on your own 3D printer

Our print files come in multiple formats to accommodate different printers and slicers:

- gcodes for Prusa MK3/Mini printer

- .3mf files compatible with common slicers (PrusaSlicer, Cura, Simplify3D…)

- .stl files for every part

The Build Guide includes instructions on when to use each parts set, allowing you to start assembling your model after the initial prints. Plus, your printer can continue to print other parts as you move forward with assembly, streamlining the process.

3.

Assemble parts

following the Build Guide

The Build Guide will guide you step-by-step through the building process with clear, easy-to-follow instructions. These instructions are available online and are regularly updated. They are primarily visual, using pictures to show the building process.

Join our 3D Sets community on Facebook for quick answers to any questions you may have and to share your building experience with other enthusiasts. Have fun building with “3D Sets”!

Have fun building with “3D Sets”!

4.

Upgrade & Rebuild

your model

However, completing your model is not the end of the journey! With “3D Sets” models, you have the opportunity to continue working on them over and over again. We offer a variety of accessories and upgrades that can be easily added to our products thanks to the built-in mounting slots. Our unique upgrade feature allows you to transform your current model into another one, saving you money in the process.

5.

Play & Enjoy

your 3D Sets model!

Now you can bring your creation into life! Connect the battery and bring it outside, to find out how it drives. Or just put it on the desk and study all functional details and mechanics. And in case anything breaks, you can easily replace it by 3D printing a new part, with no glue required as it is all held together with screws, allowing for quick repairs and getting you back on the road in no time.

4.

Upgrade & Rebuild

your model

However, completing your model is not the end of the journey! With “3D Sets” models, you have the opportunity to continue working on them over and over again. We offer a variety of accessories and upgrades that can be easily added to our products thanks to the built-in mounting slots. Our unique upgrade feature allows you to transform your current model into another one, saving you money in the process.

5.

Play & Enjoy

your 3D Sets model!

Now you can bring your creation into life! Connect the battery and bring it outside, to find out how it drives. Or just put it on the desk and study all functional details and mechanics. And in case anything breaks, you can easily replace it by 3D printing a new part, with no glue required as it is all held together with screws, allowing for quick repairs and getting you back on the road in no time.

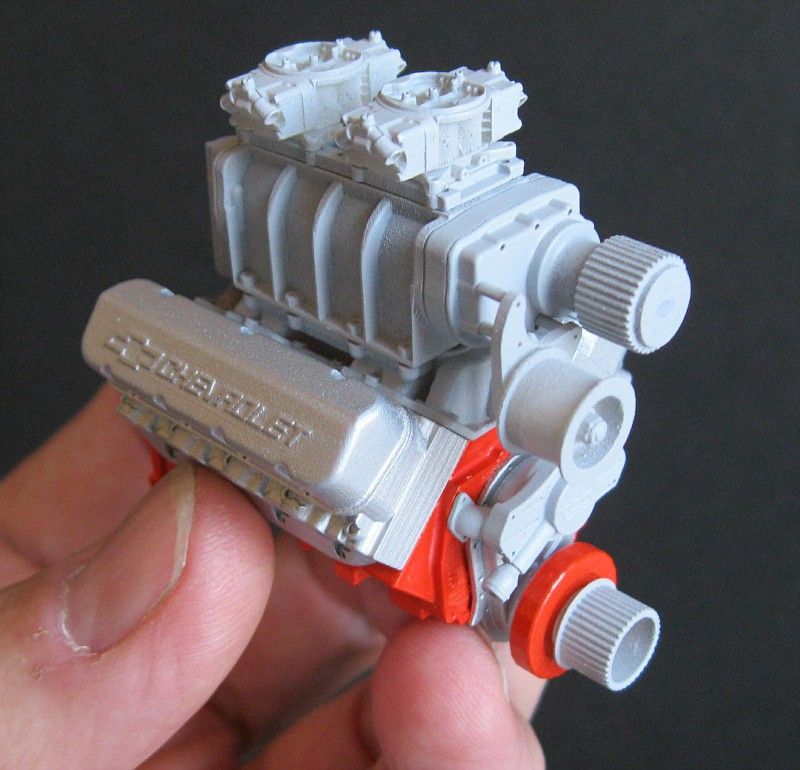

Product Showcase

Some great features about our products

Why to choose

3D Sets products?

We care about quality & experience

We have spent countless hours fine-tuning our products, ensuring that everything is tested and fits together perfectly. Assembling our models is truly a pleasure!

Assembling our models is truly a pleasure!

Enjoy free

updates

We are constantly working to improve our products, and if we release an upgraded version of a product you have already purchased, you will receive it – at no additional cost!

Join great

community

Whether you’re seeking advice, seeking inspiration, or want to share your experience, join us on Facebook, YouTube, or Instagram. Everyone is welcome to be part of our community!

They wrote about

3D Sets…

Thank you all for mentioning our products. We always want to deliver best quality and inovate.

-

“When you hold it in your hands, you feel like this is a machine that can drive through anything”

“3D Sets offers a selection of premium-quality off-road car models, which can be further enhanced with various accessories and upgrades. When you purchase one of the models from 3Dsets.com, you’re getting not only the STL files, but also pre-sliced G-Codes ready to be printed on the Original Prusa i3 MK3/S, along with a perfectly laid-out step-by-step guide and, of course, a shopping list.

”

”Prusa Research

-

“3D Sets offers a complete package”

“3D Sets offers a complete package, including the 3D printable model and instructions on how most effectively print and build your car with references and links where to get non-printable parts and 3D printing materials to make the building as efficient as possible. ”

Fillamentum

-

“The final results look stunning”

“Since each of the vehicles offered by 3D Sets has many 3D printed components, it’ll take you some time to 3D print it all. However, the final results look stunning. Because these models are specifically made for 3D printing and there are some nice details involved, making the RC cars feel as close to the real things as possible.”

All3DP

-

“The car’s gear box to me was the most amazing part of the build”

“Well, if you want a super well designed, well though out model with meticulous detail with 225 different printed pieces and 450 screws, and you’re going to love the process of building it, and then you want to end up with a model that has awesome grip and traction and ability to climb over obstacles but NOT something super fast, and if you want something that is highly customizable and something you’ll be able to work on and tinker with and keep improving then this is the model for you!”

RC Printer

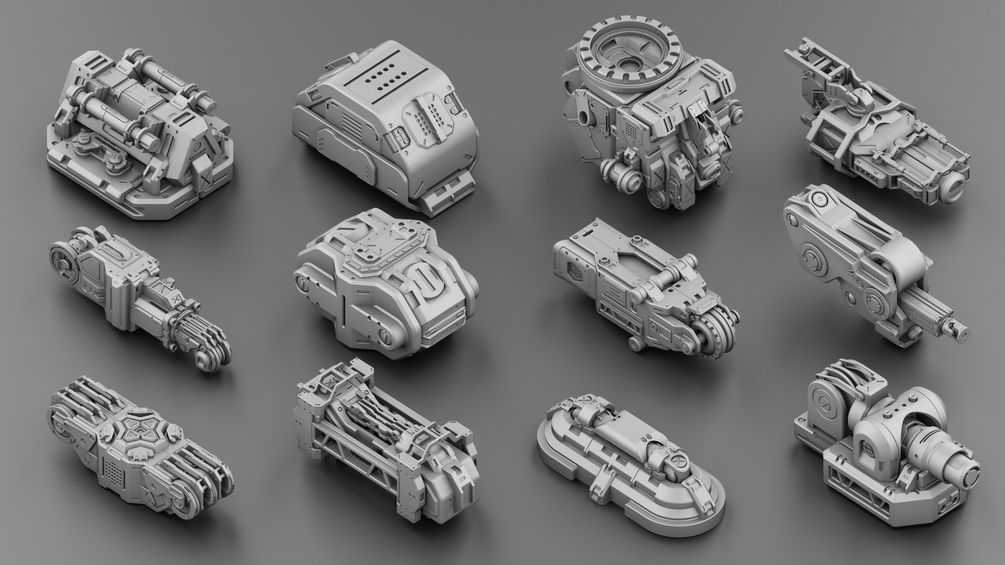

How to choose?

Consider your intended use:

We offer slower all-wheel drive 4×4 models for realistic terrain crawling and faster rear wheel drive 4×2 models for more action. We also have a variety of accessories for all models to enhance your models.

We also have a variety of accessories for all models to enhance your models.

- 4×4 crawlers

- Road and Buggy

- Max model lineup

- 3D Sets Mini 4×4

- Accessories

Some numbers…

3D Sets statistics in a nutshell13000+

members in 3D Sets Facebook group50+

premium quality products available3x

wrapped the Moon in used filament

Read about us and or work

3D Sets blogposts

See all Blog Posts

More from 3D Sets Instagram

3D Sets Instagram

U3Print GF PLA 3D Printer Kit (Black and White)

U3Print GF PLA 3D Printer Kit (Black & White)

Kit Contents:

1 U3Print GF PLA ANTHRACITE (Black) 1kg 1.75mm

White) 1kg 1.75 mm

Code: BUNDLE_u3_gf_pla_gf_petg Categories: U3Print, PLA (Polylactide), Plastic Kits Tags: Geek Filament, gf, PLA, u3print, budget, budget plastic, Plastic set, Filament

- Description

- Details

- Origin of goods

Description

Composition composition:

1 plastic coil U3PRINT GF PLA ANTHRACITE (Black) 1,75 mm

1 plastic plastic U3PRINT GF PLA Snow Flake 1 kg 9000 9000

Description plastic for 3D printer

U3Print GF PLA 1kg 1. 75mm

75mm PLA plastics of the budget GF series from U3Print have acceptable quality, a wide choice of colors and an affordable price, which makes them very attractive for use in home 3D printing, as well as for prototyping, making decorative models.

PLA plastics from U3Print are perfect for printing on open 3D printers. are not sensitive to drafts, have excellent adhesion to the printing table, do not emit harmful substances during printing.

The GF PLA series is great for printing small models, but for very long prints the manufacturer recommends using the HIGH PERFORMANCE (HP) series

| Brand | Geek Fil/lament |

| Weight kg | 1 kg |

| View | Budget plastics GeekFilament© |

| Thread diameter, mm | 1.75 |

| Material | Pure PLA |

| Tensile modulus, MPa | 2169.4 |

| Purpose | Prototyping, production of non-critical parts, decor |

| Density, g/cm3 | – |

| Tensile strength, MPa | 56. 4 4 |

| Tensile strength, MPa | 56.6 |

| Recommended print speed mm/s | 25-50 |

| Recommended temperature of the heated area, °C | 50-55 |

| Recommended extruder temperature, °С | 190-200 |

| Country of origin | Russia |

| Dryer | no |

| Shore D | 77 |

| Deformation temperature, °С | 56 |

| Type | PLA |

| Impact strength, kJ/m2 | 13 |

| Elongation at break, % | 3.3 |

| Tensile elongation, % | 3.26 |

| Shrinkage | quite low |

Origin of goods

Country of origin: Russia 118B, Klin, Moscow region, RF

Importer in the Republic of Belarus:

SP Shalashenko Evgenia Alexandrovna

Legal address: 222728, Minsk region. Dzerzhinsky district, Shatili village, st. Central, 4

Dzerzhinsky district, Shatili village, st. Central, 4

-

Quick View

-

Quick View

-

Quick View

- Sale!

Quick View

- U3Print, PLA

- BYN 48.00

- Add to cart

- Sale!

-

Quick View

-

Quick View

- U3Print, PETG

- BYN 50.00

- Add to cart

-

FDM 3D printing guide for beginners. Understanding Basic Terms

Getting started with 3D printers doesn't have to be intimidating. We have created this simple 3D printing guide for beginners to help all beginners understand the basic terms.

We have created this simple 3D printing guide for beginners to help all beginners understand the basic terms.

3D printing is a very general term. The media, especially mainstream marketing, portray 3D printing as the magical technology of the future, capable of reproducing complex objects.

But this approach makes it difficult to understand what 3D printing is from a technical point of view.

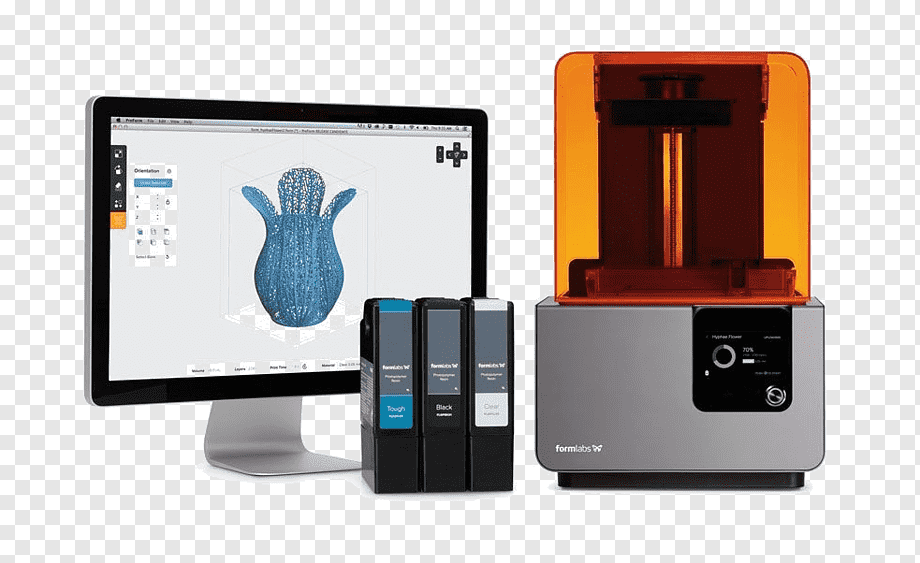

In reality, there are many different 3D printing technologies, but the most common for beginners is the layer-by-layer modeling method (FDM or FFF), which is the focus of this article.

Ender 3 V2 is one of the most popular hobbyist 3D printers.

FDM prints parts using thermoplastic, which is basically a filament of material that can melt, cool, and solidify. Details are built by stacking layers on top of each other.

This technology was created because people needed a way to quickly prototype parts. Even today, rapid prototyping is one of the biggest advantages of FDM and 3D printing in general. Not surprisingly, 3D printing is also gradually becoming a powerful manufacturing solution.

Not surprisingly, 3D printing is also gradually becoming a powerful manufacturing solution.

Before we get into the details of how FDM works, there is one more thing worth mentioning. If you have done some research on FDM, you may have noticed that some sources use the term "FFF" instead of FDM when referring to the technology. This is because FDM is a term originally patented by Stratasys and FFF is a non-proprietary generic abbreviation. Remember, this is the same technology, only the names are different. Today, most people use the term FDM.

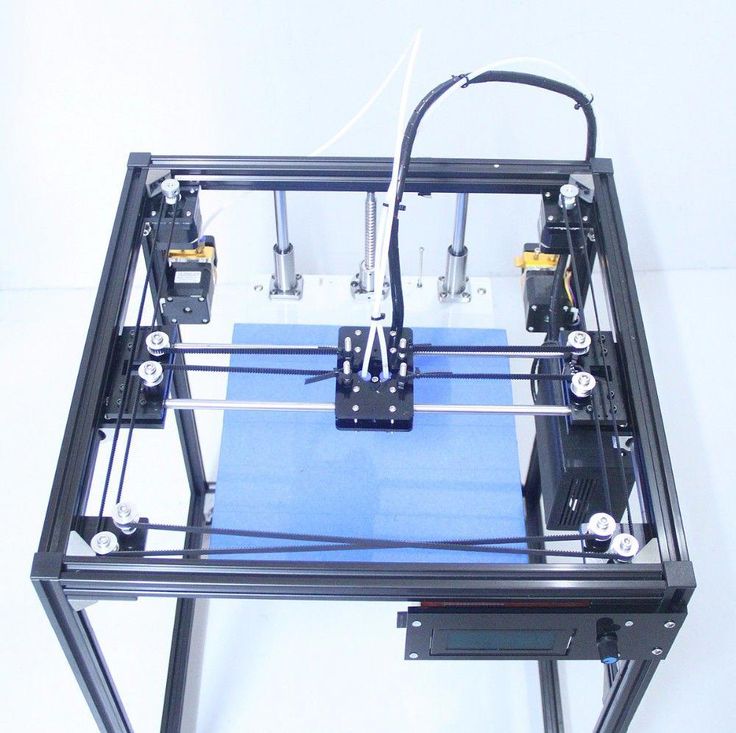

FDM 3D printing. How it works?

- 3D printer control interface

- 3D printing plastic (filament)

- Extruder

- Hotend (hot end)

- Fan (cooler)

- Print platform (table)

- 3D printing

The easiest way to understand how FDM works is to study the details of an FDM 3D printer. However, before we get into the specifics, it's worth mentioning that most 3D printers can move in three axes: X, Y, and Z. The X and Y axes are responsible for moving left, right, forward, and backward, while the Z is responsible for vertical movement.

The X and Y axes are responsible for moving left, right, forward, and backward, while the Z is responsible for vertical movement.

Now let's look at the main components of a 3D printer:

Control interface : Some modern 3D printers have a touch screen that is used to control the 3D printer. On older printers, a simple LCD with physical scrolling and a click wheel may be present instead of a touch interface. Depending on the model, an SD card slot and a USB port may also be present.

Print Bed : The bed or table of a 3D printer is essentially the surface on which parts are made. Platforms are most often made with heating to improve the adhesion of the part, but more on that later.

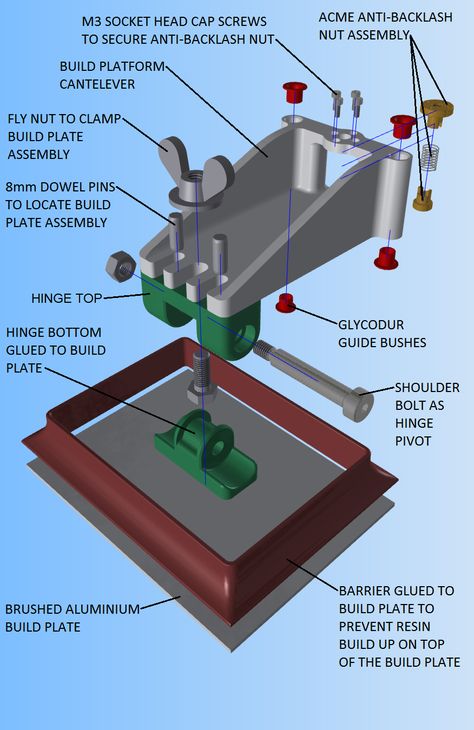

Extruder(s) : The extruder is the component responsible for melting and progressively depositing the plastic filament to build the model.

The extruder actually consists of two sub-components: hot and cold. The hot end or hot end contains a heater and nozzle that actually melts the filament, while the cold end consists of a motor, drive gears and other small components that push the filament into the hot end to melt.

There is a heatsink and fan between the hot and cold ends because it is necessary that the cold end stays cold to avoid jamming.

In addition to the heatsink fan, there is usually at least one other fan designed to cool the molten filament after it exits the extruder - this is commonly referred to as the parts cooling fan.

Print head : one or more extruders are installed on the print head (standard 3D printers have one extruder). At the top of the print head is a tube that feeds filament into the print head.

How a 3D printer prints.

The process starts when you send the 3D model file to the printer. After starting a print job, the nozzle starts to heat up. When the nozzle reaches the temperature required to melt the filament, the extruder draws the filament into the hot end in preparation for deposition modeling.

The printer is now ready to 3D print the part. The print head descends onto the build surface (platform) and begins to fuse the filament, which cools and solidifies shortly after exiting the nozzle thanks to the part cooling fans.

Plastic is applied one layer at a time, and after one layer is completed, the printhead moves up the Z-axis a short distance and the process is repeated until the part is completed.

Create, download and purchase 3D models.

Naturally, if you want to 3D print a part, you must have a 3D model of that part. 3D models are created using 3D modeling software commonly referred to as CAD (computer-aided design) software. Here are some examples of popular 3D modeling software:

- Autodesk's Fusion 360 (Free for non-commercial use)

- Blender (free)

- ZBrush (paid, but free trial available)

However, most newbies to 3D printing do not have the skills required to use such software. If so, don't worry because there are other solutions.

First, there are simpler CAD software options like Tinkercad, a program that almost anyone can use without any prior experience. This is an online application developed by Autodesk, one of the leading developers of CAD software.

Downloading files

With so many people having access to 3D printers in recent years, several sites have become repositories for 3D models.

Some of the most popular are:

- Thingiverse (free)

- MyMiniFactory (many free, some paid)

- Cults3D (free and paid)

- CGTrader (some free and most paid)

- PrusaPrinters (all free)

So anyone can get their hands on a model without any modeling skills.

Model preparation.

3D models must be prepared for 3D printing using special software that translates the model into machine instructions. This is done using slicing software, also called a slicer. 3D models are imported into a slicer, which then actually "cuts" the model into layers. The resulting files consist of a G-code, which is essentially a long list of instructions that a 3D printer follows to build a model.

G-code is the "language" of 3D printers and CNC machines. These files contain important parameters needed to create a model, such as print speed and temperature, wall thickness, infill percentage, layer height, and many others. In other words, 3D printing is impossible without G-code files!

In other words, 3D printing is impossible without G-code files!

Supports (support structures)

Another of the main functions of the slicer is the generation of support structures (supports). In particular, supports are needed for parts with attachments.

9The 0004 Slicer allows you to choose where to place the supports and how tight you want them to be. Some slicers even offer users the ability to select different types of support structures for easier removal or strength.Printer preparation.

Before you start printing on a 3D printer, there are a few mandatory steps to take:

Loading plastic: The extruder must be ready to extrude the filament before printing begins. The loading process begins with heating the hot end to the melt temperature, and then the filament is directly loaded into the heated extruder.

Platform Leveling: In order for the printer to successfully print an object, the table must be as level as possible.

Depending on the printer, platform calibration can be performed manually, semi-automatically or automatically.

Platform leveling is very important because, for example, if the nozzle is too far from the table, the first and most important layer will not adhere to the surface, resulting in you not being able to print your object.

Materials for FDM 3D printing.

As we already mentioned, FDM 3D printers use spools of plastic as part material. Filament is basically a thermoplastic specifically designed to melt and cool while maintaining its structural integrity.

3D printing filaments usually come in two diameters: 1.75mm and 3mm (or 2.85mm). Most 3D printers use 1.75 diameter plastic, which is why the variety of types and shades of 1.75 filament significantly exceeds 2.85.

We recommend that before you buy a 3D printer, be sure to clarify which filament it works with.

Converting the extruder from 2.85 to 1.75 is possible, but requires fiddling, time and additional accessories.

One of the best things about FDM 3D printers is that they can handle a wide range of plastics.

Here are just a few of the different types that are used in FDM 3D printing:

Standard:

- PLA

- ABS

- PETG

Engineering:

- Flexible (TPU, TPE)

- Nylon

- With additives (wood, metal, etc.)

- Polycarbonate (PC)

For supports:

- HIPS

- PVA

Among other things, FDM filament is one of the cheapest materials used in the world of 3D printing.

Post-processing of printed products.

Post-processing is the final steps you must take to complete your object.

Below we have listed some of the post-processing steps for a 3D printed part. You don't necessarily need to complete each of these steps.

Most often, post-processing is completed at the stage of removal of supports.

Support Removal : After printing, the support structures are mechanically removed by simply breaking them off. As a result, you can see marks left on the surface of the part.

If you have bought a 3D printer with two extruders, you can use special soluble plastics to print supports. In this case, you just need to place the object in water if you printed with PLA+PVA or in limonene if you printed with ABS+HIPS.

Sanding : Your part may still have imperfections (eg after removing supports). In this case, grinding comes into play. Light sanding of 3D printed parts can make the surface smoother.

Coloring : You will often print in one color. To add more colors, details or protection, you can paint your model!

Polishing or Smoothing : Epoxy is one way to smooth the surface of a printed part. For ABS, an acetone steam bath is often used. Under the influence of acetone vapors, ABS begins to dissolve and, if this process is stopped in time, you will get a smooth and glossy part.

Gluing : If you want to print a large 3D model that won't fit in your printer's build chamber, you can print the part in two or more parts and then glue them together.

Common 3D printer problems.

Let's discuss some of the most common problems beginners may encounter when using a 3D printer.

Warp : This problem occurs due to temperature differences during the 3D printing process. 3D Print Delamination - 5 Tips and Tricks to Avoid Delamination.

Plastic bleed (snot) : Thin extra filaments of plastic on your model may be caused by incorrect temperature or retraction settings. Some types of plastic, such as PETG, are more prone to free flow from the nozzle.

Nozzle Clog : Nozzle clogging is one of the most annoying problems of FDM 3D printers.

If you hear a strange printhead sound and no plastic comes out of the nozzle, the nozzle may be clogged. This can be caused, for example, by poor filament quality or incorrect temperature settings.

Layer Offset : This problem can be caused by vibrations and wobbles in your printer, insufficient X and Y belt tension, or excessively high print speeds.