Upwork 3d printing

Your Next Job May Be As a 3D Printing Consultant

According to freelance website Upwork, demand has risen sharply since last year for engineers with experience of all kinds in 3D printing and AM.

Ann R. Thryft | Sep 15, 2016

Last week, we heard from Design News Senior Editor Rob Spiegel that engineering job growth is moving slowly. Those figures are from the Bureau of Labor Statistics, so they're about as good as we can get. But the BLS doesn't measure the leading edge of what's happening in an industry, and when things are moving fast the categories they use don't always reflect today's world.

The BLS categories include aerospace, biomedical, chemical, civil, computer hardware, electrical, environmental, health and safety, industrial, materials, mechanical, mining & geological, nuclear, and petroleum engineers. Some of these didn't exist several years ago, it's true, but even today the bureau doesn't break out robotics engineering as a separate category, as we've discovered in previous reports.

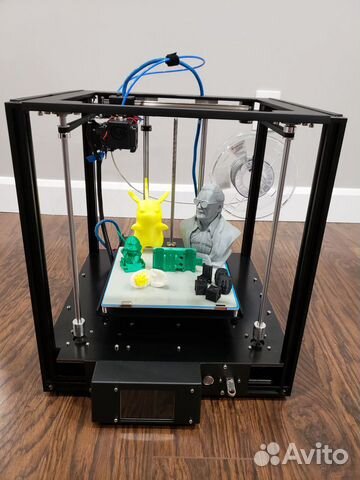

One area of engineering that's changing rapidly is reflected in how manufacturers are adapting to 3D printing and additive manufacturing (AM). Although the BLS categories may not reflect this yet, companies are looking for engineers with experience of all kinds in 3D printing and AM. According to Upwork, demand has risen sharply in the first half of 2016 versus the same period last year. The company, which bills itself as the world's largest freelance website, was created last year after the merger of Elance and oDesk.

3D Printing's Brave New World. Ann Thryft will lead a panel discussion on one of the hottest topics in manufacturing: 3D printing. Come hear "3D Printing: The Brave New World of Manufacturing" at the Embedded Systems Conference, Sept. 21-22, 2016 in Minneapolis. Register here for the event, hosted by Design News’ parent company, UBM.

During this period, demand for 3D printing-related skills increased between 83% and 227% depending on the category, Upwork's categories director Ryan Johnson told Design News. Since about half of the website's three million annual job postings are in IT and technology, including engineering, this represents a huge jump in demand. The site's engineering categories include mechanical, electrical, civil and structural, chemical, and software, among others, and the number of total freelancers listed on it exceeds 12 million.

Since about half of the website's three million annual job postings are in IT and technology, including engineering, this represents a huge jump in demand. The site's engineering categories include mechanical, electrical, civil and structural, chemical, and software, among others, and the number of total freelancers listed on it exceeds 12 million.

"We're seeing a lot of growth in engineering job requests related to additive manufacturing skills and knowledge," said Johnson. "As the costs of 3D printing come down, more companies are getting into AM, and they want to fill their talent gap for civil, structural, and mechanical engineers. They're looking for 3D modelers, 3D printer technicians, and design engineers, people who can contract with service bureaus to get prototypes made, or individuals doing models and prototyping."

During the first half of this year, demand for independent contractors to create the physical product and/or prototypes, or work with a service bureau to get it done, rose 94% over the same period last year, said Johnson. Demand for 3D rendering skills rose 83%, and for CAD and AutoCAD-related skills by 227%. That last category includes programs like AutoCAD, 3ds Max, and Google SketchUp. Demand for engineers skilled in SolidWorks for 3D printing rose by 94%, and for Rhinoceros 3D experts by 83%. Most of the engineering demand is in the design stage, where companies are looking for engineers with 3D modeling/design software skills, primarily in 3D model design for prototyping.

Demand for 3D rendering skills rose 83%, and for CAD and AutoCAD-related skills by 227%. That last category includes programs like AutoCAD, 3ds Max, and Google SketchUp. Demand for engineers skilled in SolidWorks for 3D printing rose by 94%, and for Rhinoceros 3D experts by 83%. Most of the engineering demand is in the design stage, where companies are looking for engineers with 3D modeling/design software skills, primarily in 3D model design for prototyping.

Upwork is seeing the most demand for these skills in several different industries. In consumer electronics, which accounts for about half of their currently posted jobs, wearables is a huge trend, said Johnson. Another is automotive, one example being a job requesting 3D printing skills related to motorcycle parts and accessories. In medical applications, engineering jobs posted on the site include medical wearables and 3D printouts of an ultrasound.

[image via Pressfoto / Freepik]

Ann R. Thryft is senior technical editor, materials & assembly, for Design News. She's been writing about manufacturing- and electronics-related technologies for 29 years, covering manufacturing materials & processes, alternative energy, and robotics. In the past, she's also written about machine vision and all kinds of communications.

Thryft is senior technical editor, materials & assembly, for Design News. She's been writing about manufacturing- and electronics-related technologies for 29 years, covering manufacturing materials & processes, alternative energy, and robotics. In the past, she's also written about machine vision and all kinds of communications.

TAGS: Design Software Materials Automotive Engineering Aerospace Consumer Electronics

Upwork

| Monthly Tech-Tip from Tony HansenSignUp | No tracking! No ads! That's why this page loads quickly! |

All Glossary

200 mesh |325 mesh |3D Design |3D Printer |3D Slicer |3D-Printed Clay |3D-Printing |Abrasion Ceramics |Acidic Oxides |Agglomeration |Alkali |Alkaline Earths |Amorphous |Apparent porosity |Artware |Ball milling |Bamboo Glaze |Base Glaze |Base-Coat Dipping Glaze |Basic Oxides |Batch Recipe |Bisque |Bit Image |Black Coring |Bleeding colors |Blender Mixing |Blisters |Bloating |Blunging |Bone China |Borate |Boron Blue |Boron Frit |Borosilicate |Breaking Glaze |Brick Making |Brushing Glaze |Calcination |Calculated Thermal Expansion |Candling |Carbon Burnout |Carbon trap glazes |CAS Numbers |Casting-Jiggering |Celadon Glaze |Ceramic |Ceramic Binder |Ceramic Decals |Ceramic Glaze |Ceramic Glaze Defects |Ceramic Ink |Ceramic Material |Ceramic Oxide |Ceramic Slip |Ceramic Stain |Ceramic Tile |Ceramics |Characterization |Chemical Analysis |Chromaticity |Clay |Clay body |Clay Body Porosity |Clay for Ovens and Heaters |Clay Stiffness |Co-efficient of Thermal Expansion |Code Numbering |Coil pottery |Colloid |Colorant |Cone 1 |Cone 5 |Cone 6 |Cone plaque |Copper Red |Cordierite Ceramics |Crackle glaze |Crawling |Crazing |Cristobalite |Cristobalite Inversion |Crucible |Crystalline glazes |Crystallization |Cuerda Seca |Cutlery Marking |Decomposition |Deflocculation |Deoxylidration |Differential thermal analysis |Digitalfire Foresight |Digitalfire Insight |Digitalfire Reference Library |Dimpled glaze |Dip Glazing |Dipping Glaze |Dishwasher Safe |Dolomite Matte |Drop-and-Soak Firing |Drying Crack |Drying Performance |Drying Shrinkage |Dunting |Dust Pressing |Earthenware |Efflorescence |Encapsulated Stain |Engobe |Eutectic |Fast Fire Glazes |Fat Glaze |Feldspar Glazes |Fining Agent |Firebrick |Fireclay |Fired Strength |Firing Schedule |Firing Shrinkage |Flameware |Flashing |Flocculation |Fluid Melt Glazes |Flux |Food Safe |Foot Ring |Forming Method |Formula Ratios |Formula Weight |Frit |Fritware |Functional |GHS Safety Data Sheets |Glass vs. Crystalline |Glass-Ceramic Glazes |Glaze Bubbles |Glaze Chemistry |Glaze Compression |Glaze Durability |Glaze fit |Glaze Gelling |Glaze laydown |Glaze Layering |Glaze Mixing |Glaze Recipes |Glaze Shrinkage |Glaze thickness |Globally Harmonized Data Sheets |Glossy Glaze |Green Strength |Grog |Gunmetal glaze |Handles |High Temperature Glaze |Hot Pressing |Incised decoration |Industrial clay body |Ink Jet Printing |Inside-only Glazing |Insight-Live |Interface |Iron Red Glaze |Jasper Ware |Jiggering |Kaki |Kiln Controller |Kiln Firing |Kiln fumes |Kiln venting system |Kiln Wash |Kovar Metal |Laminations |Leaching |Lead in Ceramic Glazes |Leather hard |Lime Popping |Limit Formula |Limit Recipe |Liner Glaze |Liner glazing |Liquid Bright Colors |LOI |Low Temperature Glaze |Majolica |Marbling |Material Substitution |Matte Glaze |Maturity |Maximum Density |MDT |Mechanism |Medium Temperature Glaze |Melt Fluidity |Melting Temperature |Metal Oxides |Metallic Glazes |Micro Organisms |Microwave Safe |Mineral phase |Mineralogy |Mocha glazes |Mohs Hardness |Mole% |Monocottura |Mosaic Tile |Mottled |Mullite Crystals |Native Clay |Non Oxide Ceramics |Oil-spot glaze |Once fire glazing |Opacifier |Opacity |Ovenware |Overglaze |Oxidation Firing |Oxide Formula |Oxide Interaction |Oxide System |Particle orientation |Particle Size Distribution |Particle Sizes |PCE |Permeability |Phase Diagram |Phase Separation |Physical Testing |Pinholing |Plainsman Clays |Plaster Bat |Plaster table |Plasticine |Plasticity |Plucking |Porcelain |Porcelaineous Stoneware |Pour Glazing |Powder Processing |Precipitation |Primary Clay |Primitive Firing |Propane |Propeller Mixer |Pugmill |Pyroceramics |Pyrometric Cone |Quartz Inversion |Raku |Reactive Glazes |Reduction Firing |Reduction Speckle |Refractory |Refractory Ceramic Coatings |Representative Sample |Respirable Crystalline Silica |Restaurant Ware |Rheology |Rutile Glaze |Salt firing |Sanitary ware |Sculpture |Secondary Clay |Shino Glazes |Shivering |Sieve |Sieve Shaker |Silica:Alumina Ratio |Silk screen printing |Sintering |Slaking |Slip Casting |Slip Trailing |Slipware |Slurry |Slurry Processing |Slurry Up |Soaking |Soluble colors |Soluble Salts |Specific gravity |Splitting |Spray Glazing |Stain Medium |Stoneware |Stull Chart |Sulfate Scum |Sulfates |Surface Area |Surface Tension |Suspension |Tapper Clay |Tenmoku |Terra Cotta |Terra Sigilatta |Test Kiln |Theoretical Material |Thermal Conductivity |Thermal shock |Thermocouple |Thixotropy |Throwing |Tony Hansen |Toxicity |Trafficking |Translucency |Transparent Glazes |Triaxial Glaze Blending |Ultimate Particles |Underglaze |Unity Formula | |Variegation |Viscosity |Vitreous |Vitrification |Volatiles |Warping |Water in Ceramics |Water Smoking |Water Solubility |Wedging |Whiteware |Wood Ash Glaze |Wood Firing |Zero3 |Zero4 |Zeta Potential

Crystalline |Glass-Ceramic Glazes |Glaze Bubbles |Glaze Chemistry |Glaze Compression |Glaze Durability |Glaze fit |Glaze Gelling |Glaze laydown |Glaze Layering |Glaze Mixing |Glaze Recipes |Glaze Shrinkage |Glaze thickness |Globally Harmonized Data Sheets |Glossy Glaze |Green Strength |Grog |Gunmetal glaze |Handles |High Temperature Glaze |Hot Pressing |Incised decoration |Industrial clay body |Ink Jet Printing |Inside-only Glazing |Insight-Live |Interface |Iron Red Glaze |Jasper Ware |Jiggering |Kaki |Kiln Controller |Kiln Firing |Kiln fumes |Kiln venting system |Kiln Wash |Kovar Metal |Laminations |Leaching |Lead in Ceramic Glazes |Leather hard |Lime Popping |Limit Formula |Limit Recipe |Liner Glaze |Liner glazing |Liquid Bright Colors |LOI |Low Temperature Glaze |Majolica |Marbling |Material Substitution |Matte Glaze |Maturity |Maximum Density |MDT |Mechanism |Medium Temperature Glaze |Melt Fluidity |Melting Temperature |Metal Oxides |Metallic Glazes |Micro Organisms |Microwave Safe |Mineral phase |Mineralogy |Mocha glazes |Mohs Hardness |Mole% |Monocottura |Mosaic Tile |Mottled |Mullite Crystals |Native Clay |Non Oxide Ceramics |Oil-spot glaze |Once fire glazing |Opacifier |Opacity |Ovenware |Overglaze |Oxidation Firing |Oxide Formula |Oxide Interaction |Oxide System |Particle orientation |Particle Size Distribution |Particle Sizes |PCE |Permeability |Phase Diagram |Phase Separation |Physical Testing |Pinholing |Plainsman Clays |Plaster Bat |Plaster table |Plasticine |Plasticity |Plucking |Porcelain |Porcelaineous Stoneware |Pour Glazing |Powder Processing |Precipitation |Primary Clay |Primitive Firing |Propane |Propeller Mixer |Pugmill |Pyroceramics |Pyrometric Cone |Quartz Inversion |Raku |Reactive Glazes |Reduction Firing |Reduction Speckle |Refractory |Refractory Ceramic Coatings |Representative Sample |Respirable Crystalline Silica |Restaurant Ware |Rheology |Rutile Glaze |Salt firing |Sanitary ware |Sculpture |Secondary Clay |Shino Glazes |Shivering |Sieve |Sieve Shaker |Silica:Alumina Ratio |Silk screen printing |Sintering |Slaking |Slip Casting |Slip Trailing |Slipware |Slurry |Slurry Processing |Slurry Up |Soaking |Soluble colors |Soluble Salts |Specific gravity |Splitting |Spray Glazing |Stain Medium |Stoneware |Stull Chart |Sulfate Scum |Sulfates |Surface Area |Surface Tension |Suspension |Tapper Clay |Tenmoku |Terra Cotta |Terra Sigilatta |Test Kiln |Theoretical Material |Thermal Conductivity |Thermal shock |Thermocouple |Thixotropy |Throwing |Tony Hansen |Toxicity |Trafficking |Translucency |Transparent Glazes |Triaxial Glaze Blending |Ultimate Particles |Underglaze |Unity Formula | |Variegation |Viscosity |Vitreous |Vitrification |Volatiles |Warping |Water in Ceramics |Water Smoking |Water Solubility |Wedging |Whiteware |Wood Ash Glaze |Wood Firing |Zero3 |Zero4 |Zeta Potential

Using the services of online freelancers connects potters and small ceramic producers to expert engineering talent at low cost.

Details

There are many freelancer websites online, this is the one we know. Services like these, that offer thousands of skills, will completely disrupt the world of engineering, putting inexpensive engineering talent at the service of everyone.

Upwork charges a percentage but other wise it is free (unless you need advanced features). It can be tempting to move your interaction with a consultant outside of Upwork, but the platform they provide to organize, pay and search is compelling enough that you will come back. Consultants are trying to build reputation, and you, as an employer need to do the same.

It will cost money to learn the system. The biggest mistakes you make early on will be failure to describe precisely what you want. Freelancers can be very anxious to please and will do more that you want (which often means not what you want). So break jobs up into small pieces, called Milestones, and pay at each stage (not by the hour). Some projects will go bad, the consultant will take you down an impractical path. That money will be lost, but think of it as saving you all the trouble and lost time. And it is education.

That money will be lost, but think of it as saving you all the trouble and lost time. And it is education.

If you just search for the skill you need the first hits may be charging $50 and hour. Refine the search to India or Asia it will drop to $5-10. Do not be intimidated by hiring people in Asia, the Middle East, Oceania and Africa. They will smash every preconception you have about ability, proficiency with English and motivation. And give you a respect for the kinds of university systems that have been developed around the world.

When posting a job follow instructions carefully. State clearly exactly what kind of person you need to do what kind of job. Learn enough of the jargon of the discipline so that you can correspond clearly with them. How do you pick the right one from the dozens who might respond? The one who is most specific about being able to help you. Many just send a resume while others will actually do some work on the job and submit that with their application. Don't pass up a keener like that. Once you find a good person, stick with them. That being said, sometimes you need to hire a pro, maybe they can do as much in an hour as someone else can in a week.

Don't pass up a keener like that. Once you find a good person, stick with them. That being said, sometimes you need to hire a pro, maybe they can do as much in an hour as someone else can in a week.

Be ready to work with their idiosyncrasies. They might disappear for a week without a word, later reporting they went to a religious festival. Deadline mentalities will not likely work well, be patient. Some have a short attention span but are very knowledgable, use them to solve specific issues. Once you make friends with someone, you can ask them a question anytime (using the messaging area) and they will often answer for free. Some people will return your money if they do not think they did a good enough job! Accept it, learn and move on.

Use your interaction with consultants as an educational experience, so that you can learn what they are doing and be independent. Consultants will often convince you to do something a different way that you intended. A better way. Once you build a relationship with someone, keep a contract open with them and each time you have a question you are confident they can answer, pay a bonus of $10 or $20 and then ask it. The answer will come quickly with many thanks. This is way better than googling!

The answer will come quickly with many thanks. This is way better than googling!

Who to be careful of people who do not share knowledge (e.g. how to do something in 3D software program). When you find someone good they will even make videos showing exactly how they did it. Watch out for people who do not communicate, they often think they know better and do the job in a completely different way than you want. And you do not need to deal with people who demand money, there is so much talent out there and so many really nice people you don't need to work with such ones. That being said, be generous when someone does a good job.

Create a folder on a cloud drive named "Upwork" and keep everything from each project in its own folder inside that.

Related Information

Getting a consultant on Upwork

Tap picture for full size

Notice I have done the search: "3d printing fusion 360". Initially it showed many North Americans, who typically charge $30-50/hr. But notice I have refined the search and specified India and Bangladesh. This cuts the price by half or three quarters. Notice that the highlighted consultant, although advertising as hourly, also does 'fixed price' work. And on the other jobs, notice how happy the client was and that he worked many more than the required hours (reducing the hourly earnings). At the prices Asian engineers charge you can afford to pay them plenty of bonuses (part of the Upwork system) to keep good relations. Their skills are exceptional, they will make you look good!

But notice I have refined the search and specified India and Bangladesh. This cuts the price by half or three quarters. Notice that the highlighted consultant, although advertising as hourly, also does 'fixed price' work. And on the other jobs, notice how happy the client was and that he worked many more than the required hours (reducing the hourly earnings). At the prices Asian engineers charge you can afford to pay them plenty of bonuses (part of the Upwork system) to keep good relations. Their skills are exceptional, they will make you look good!

Links

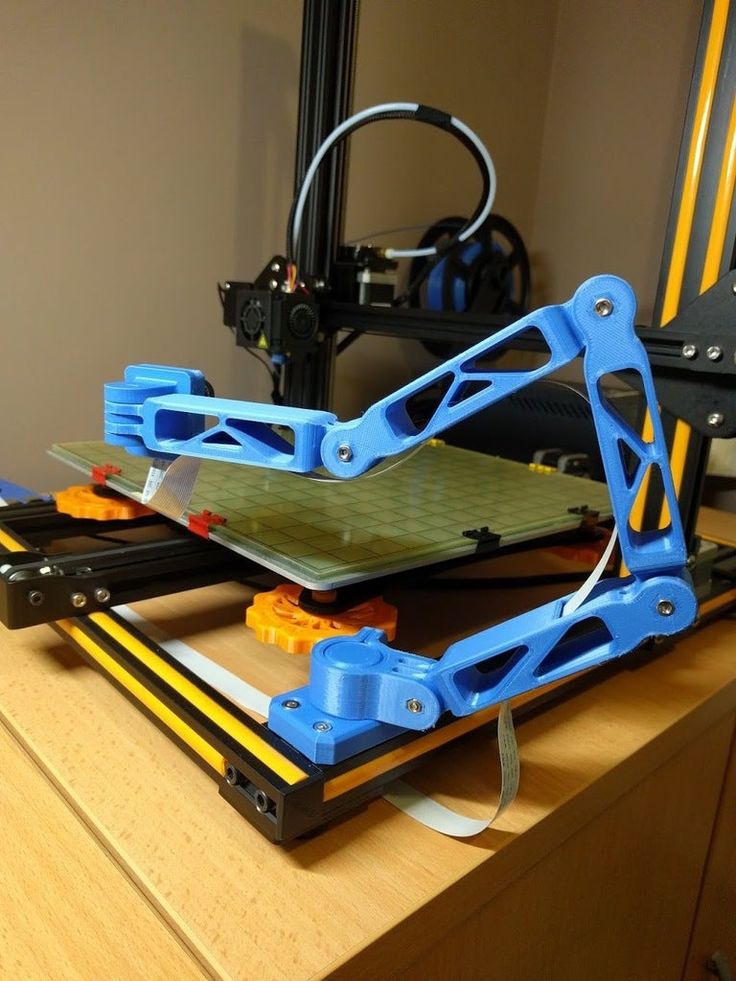

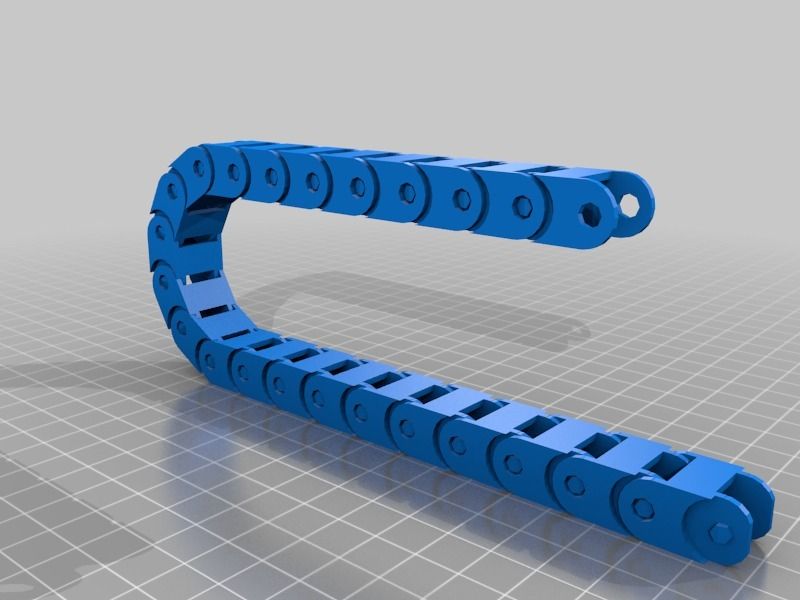

| Glossary | 3D-Printing Standard 3D printing technology (not printing with clay itself) is very useful to potters and ceramic industry in making objects that assist and enable production. |

|---|---|

| Projects | 2019 Jiggering-Casting Project |

| By Tony Hansen Follow me on |

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.

com, All Rights Reserved

com, All Rights Reserved Privacy Policy

Category 3D printing - all you need to know about 3d printing on a 3d printer - community of 3D printer owners 3DToday

All about 3D printing: technologies, techniques and curiosities, flavored with controversy.

3D printing

31

Subscribe to the author

Subscribe

Don't want

Hello, readers!

I have never published articles before, but I can't help but share my experience and the whole story. This reading will be something like an "adventure with printers" with elements of useful information.

I have been printing for more than a year, and during this time I have encountered quite a lot of different defects, both caused by unsuccessful upgrades (it seems to me that sooner or later all printer owners begin to “itch their hands”, somehow refine or improve . ..

..

Read more

3D printing

8

Subscribe to the author

Subscribe

Don't want

Another segment toy, this time I tried to hide the connecting elements of the model as much as possible, while not affecting the model's mobility. The end result is this fish. It prints easily, without supports, and is strong enough on its own.

Link to the model for dollars: https://cults3d.com/en/3d-model/game/prehistoric-toothpick

Link to the model for rubles: https://digital.wildberries.ru/offer/119390

Read more

Utmel

Loading

02/22/2023

1628

3D printing

8

Subscribe to the author

Subscribe

Don't want

Many people still think that 3D printing is only good for making knick-knacks. We decided to collect in one place brief descriptions of the main methods used in various fields - from 3D printing of souvenirs to the production of aerospace parts.

We decided to collect in one place brief descriptions of the main methods used in various fields - from 3D printing of souvenirs to the production of aerospace parts.

Read more

3D printing

10

Subscribe to the author

Subscribe

Don't want

Good day to all, student Tyoma, today we will talk about my next order for 3D printing and modeling of various things. So, let's begin.

After the announcement of special actions by the royal decree, a large number of suppliers left the Russian market, including people who produce electric curtain rods turned their backs to us. One fine day, a client came to us with an electric motor from the eminent Sompfy, with a plastic mechanism and a Chinese...

Read more

3D printing

5

Subscribe to the author

Subscribe

Don't want

After 2 years of use, I decided to reflash the bear from the drain. But I’m completely satisfied with the graphical interface with icons, I consider WiFi a necessity, I desperately need the icon of the printed part, and there’s no desire to put up with the prehistoric COLOR_UI printer. No, seriously, the blue color and the overall design is taken there only from nostalgic memories of this beauty:

But I’m completely satisfied with the graphical interface with icons, I consider WiFi a necessity, I desperately need the icon of the printed part, and there’s no desire to put up with the prehistoric COLOR_UI printer. No, seriously, the blue color and the overall design is taken there only from nostalgic memories of this beauty:

It just turned out that popular firmware for the 5th bear is supplied ...

Read more

Easybom

Loading

01/31/2023

5237

3D printing

eleven

Subscribe to the author

Subscribe

Don't want

This article is intended as a guide for beginner users of FDM/FFF 3D printers. In it, we will look at the main tools and techniques used in the post-processing of PLA models.

Read more

3D printing

3

Subscribe to the author

Subscribe

Don't want

Today, on January 24, 2023, UltiMaker introduced a new product to the world - UltiMaker S7.

The company has taken the best of the UltiMaker S5... and created something that will exceed all expectations! The new S7 FDM 3D printer is equipped with the latest technology to make 3D printing high quality models easier than ever.

What's new in UltiMaker S7?

• PEI Coated Flexible Worktable

• Integrated Air Manager...

Read more

3D printing

16

Subscribe to the author

Subscribe

Don't want

This project was created a year and a half ago. I printed it, but I have not collected it until today, somehow everything was not up to it. Yes, and there are many other projects that are unfinished, which I am gradually completing. Today it's the turn to present this wonderful tool to you.

Read more

3D printing

-5

Subscribe to the author

Subscribe

Don't want

Hello, Friends! With you 3DTool!

This year, at your request, we decided to launch a new section - guides, tutorials and reviews dedicated to various tricks of 3D printing, settings, characteristics, methods of working with devices. Over the years of working with this equipment, we have gained a lot of experience, developed our own approaches to improving the printing result, came up with various tricks to speed up and improve the process and are ready to share this knowledge with you!...

Over the years of working with this equipment, we have gained a lot of experience, developed our own approaches to improving the printing result, came up with various tricks to speed up and improve the process and are ready to share this knowledge with you!...

Read more

3D printing

16

Subscribe to the author

Subscribe

Don't want

Dear friends!

The approach of the winter holidays is a great occasion to thank you again for your trust and cooperation. The time of the New Year holidays, beloved by everyone, is approaching, when you can slowly take stock of the outgoing year and set goals for the new one, how to relax and spend time with loved ones.

Read more

- 1

- 2

- .

..

.. - 211

What is a 3D printer?

What is 3D printing and how it can be used! Interesting!

What is 3D printing

3D printing technology was patented in the 80s of the last century, but gained popularity relatively recently. New, promising techniques have been developed and the possibilities of 3D technologies have reached a completely new level. However, to this day, the technique is not known in all circles, and not everyone is aware of what 3D printing is. In today's article, we will try to explain in detail and in an accessible way what 3D printing is and where it is used.

New, promising techniques have been developed and the possibilities of 3D technologies have reached a completely new level. However, to this day, the technique is not known in all circles, and not everyone is aware of what 3D printing is. In today's article, we will try to explain in detail and in an accessible way what 3D printing is and where it is used.

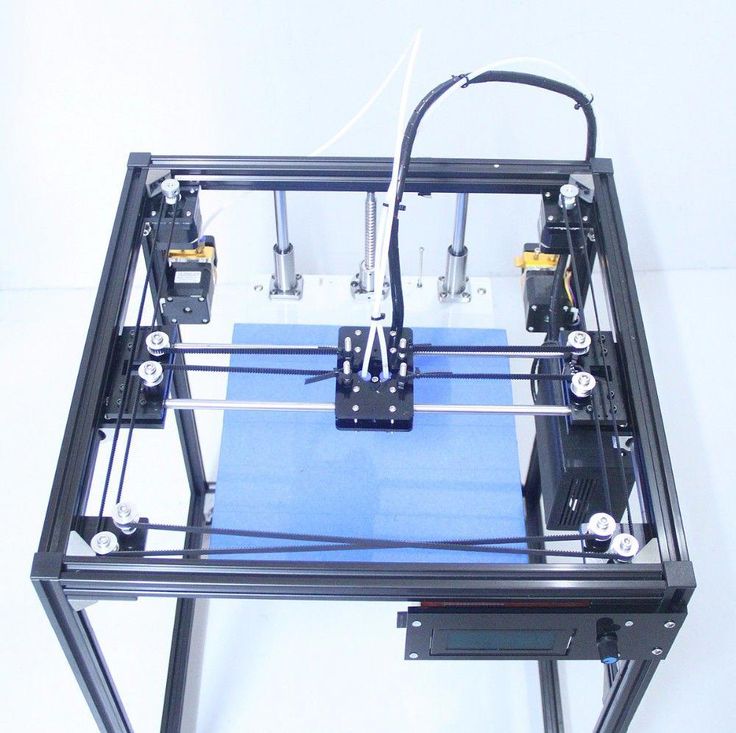

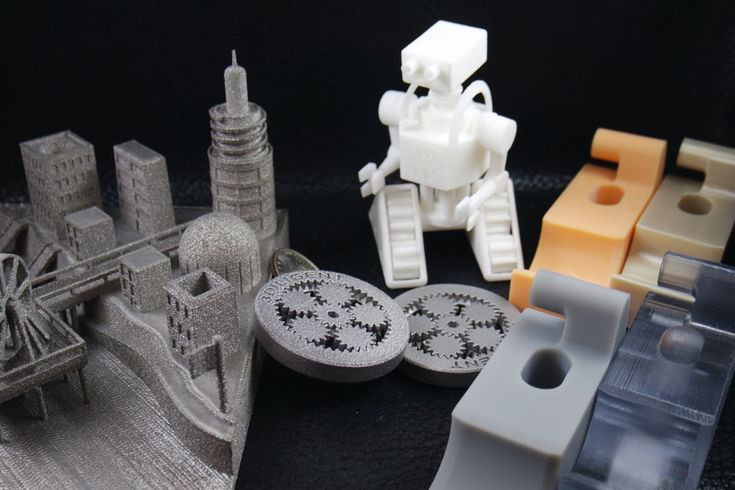

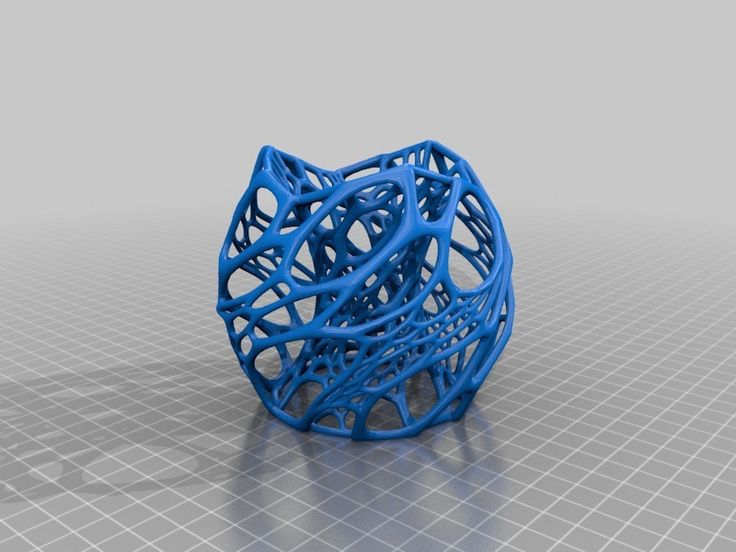

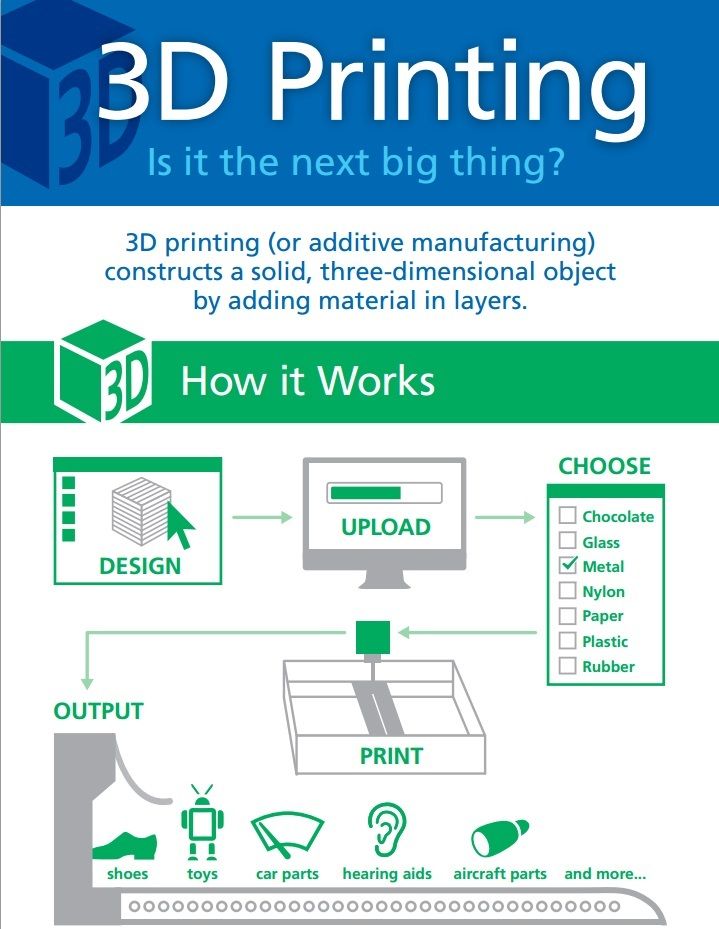

In short, 3D printing is a technique for manufacturing three-dimensional products based on digital models. Regardless of the specific technology, the essence of the process is the gradual layer-by-layer reproduction of objects.

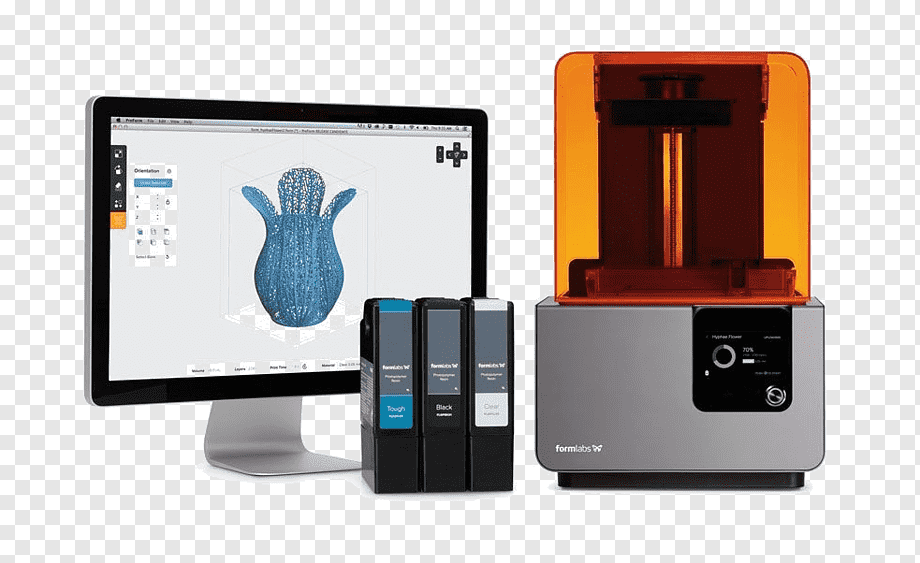

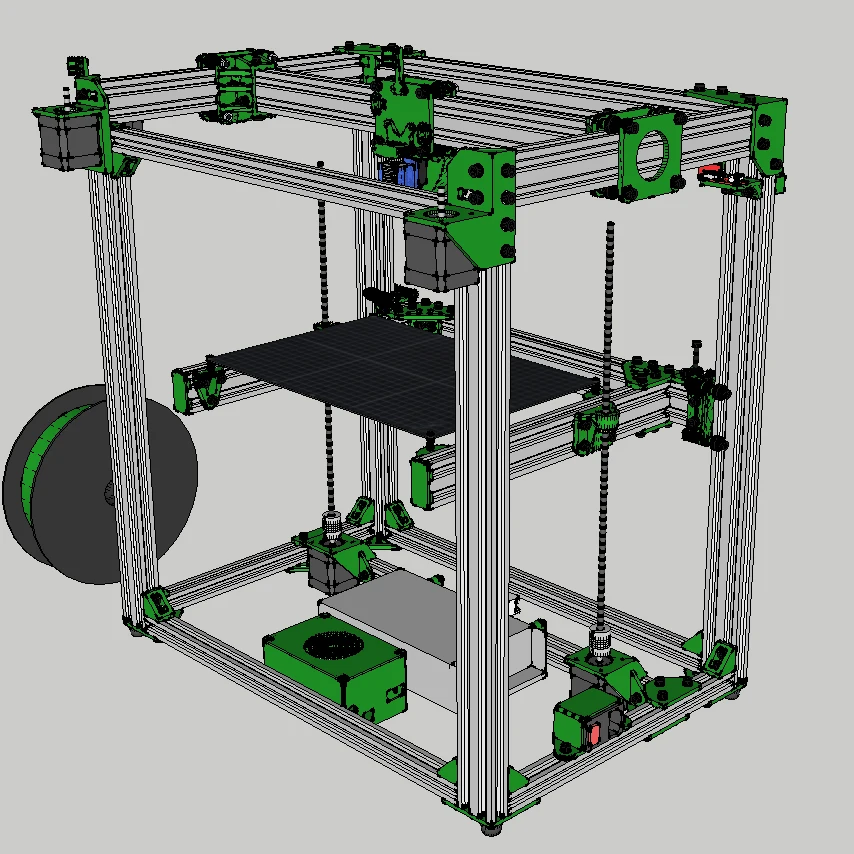

This process uses a special device - a 3D printer, which prints certain types of materials. More details about it are written here. Other names for the technology are rapid prototyping or additive manufacturing. Often the phrase "additive technologies" is used in the meaning of "3D technologies".

3D printing steps

To make it clearer what 3D printing is, let's take a look at the playback process step by step. Below are the specific stages of 3D printing. How it works:

Below are the specific stages of 3D printing. How it works:

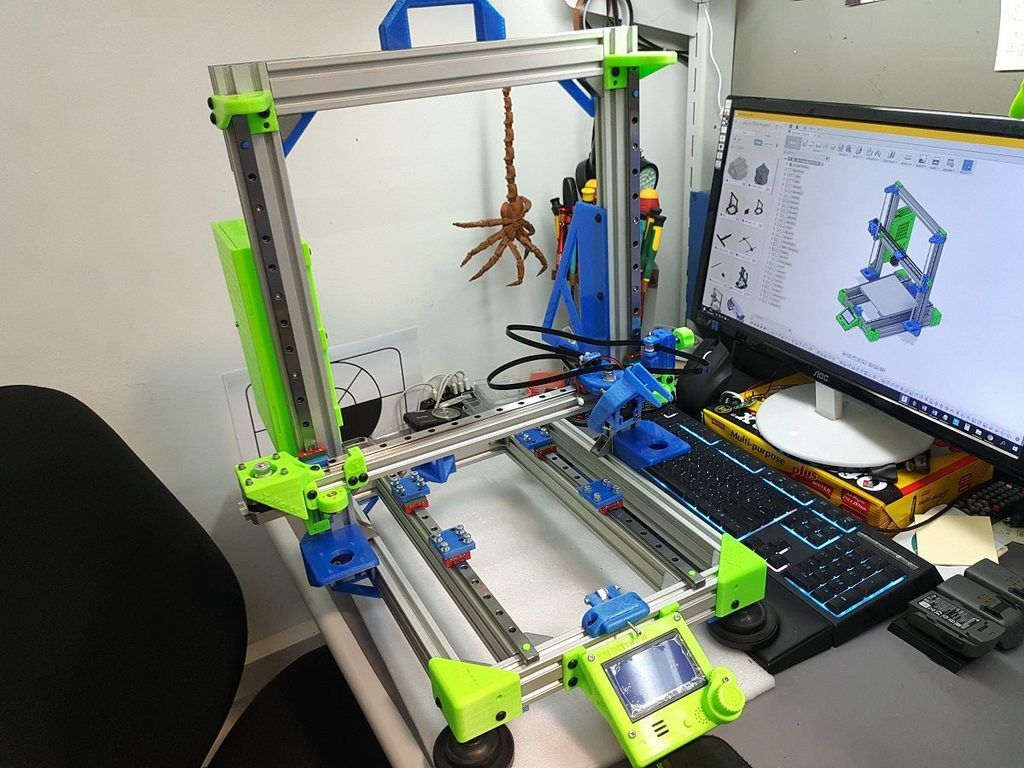

- 3D modeling of the required object is performed according to certain rules;

- The file with the digital model is loaded into the slicer program, which generates the control code for the 3D printer;

- Sets required 3D printing options;

- The code is written to a removable memory that connects to a 3D printer;

- The 3D model is reproduced.

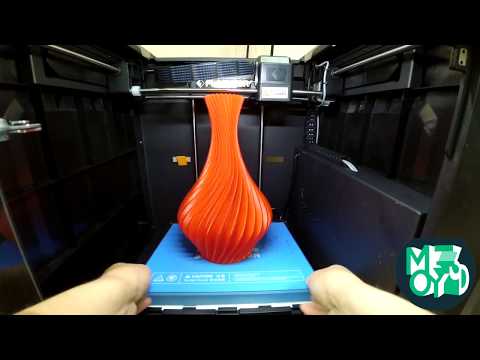

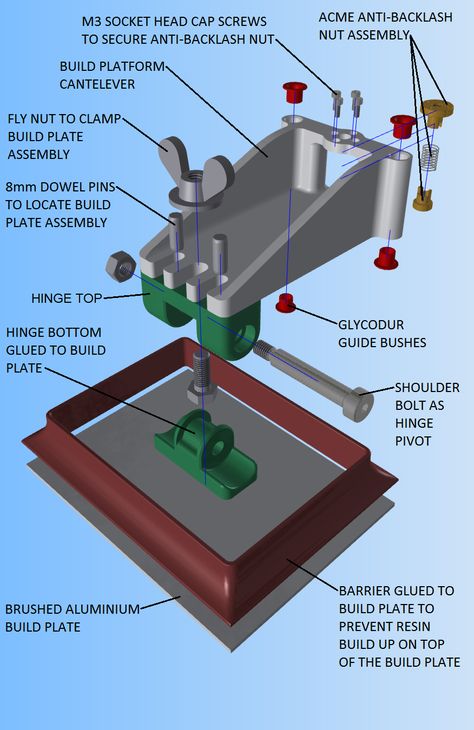

Objects are rendered gradually. According to the required shape, the selected material is applied layer by layer, forming the finished product. It is worth noting that the possibilities of 3D printing are almost limitless, that is, anything can be made. In some technologies, very thin overhanging elements are provided with supports, thanks to which they can be avoided from sagging.

Naturally, this is a very simplified description of the stages of 3D printing, but they give a very clear idea of the essence of the technique.

Other questions and answers about 3D printers and 3D printing:

- Basics What is 3D scanning?

- Basics What is a 3D model?

3D Printing Technologies

Different 3D printing technologies are used to reproduce different objects. They differ both in the consumables used, and in the speed and accuracy of printing. Here are the main 3D printing technologies:

- Fused deposition modeling (FDM) . One of the most common 3D printing technologies, used in most desktop 3D printers, and represents an ideal price / quality ratio. Printing occurs by layer-by-layer supply of a thread of molten plastic;

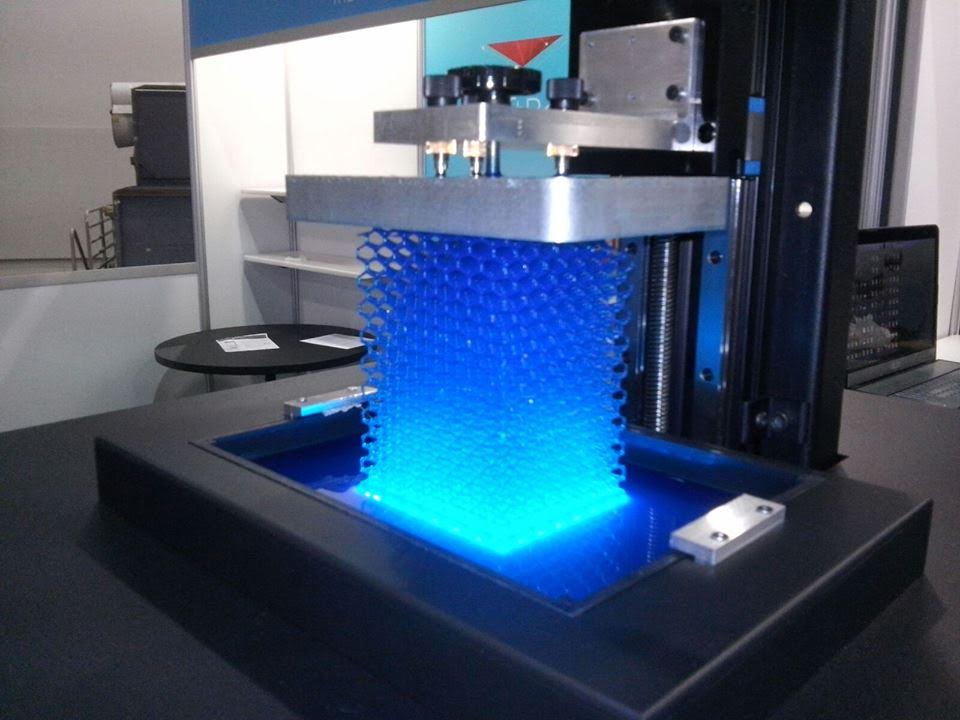

- Laser stereolithography (SLA) . The formation of the object occurs due to the layer-by-layer illumination of a liquid photopolymer resin by a laser, which hardens under the influence of radiation. One of the variations of this technology is DLP 3D printing. It uses a special projector instead of a laser.

Both 3D printing methods are used to create objects with a high degree of detail. In the case of DLP printing, speed is also an added advantage;

Both 3D printing methods are used to create objects with a high degree of detail. In the case of DLP printing, speed is also an added advantage; - Selective laser sintering (SLS) . Reproduction is performed by layer-by-layer melting of a special powder under the action of laser radiation. This 3D printing method is widely used in the industry for the manufacture of durable metal elements

3D Printing Applications

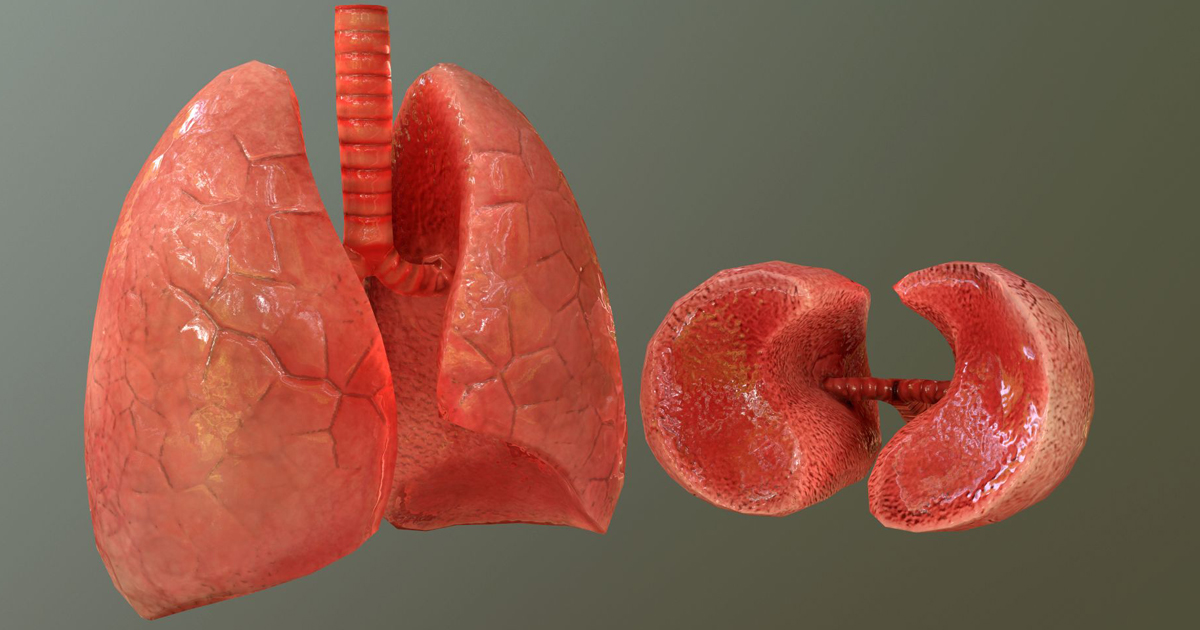

As you may have guessed by now, 3D printing is extremely versatile. The second name of the technology - rapid prototyping - speaks for itself. In the manufacture of prototypes and models of models, 3D printing can be simply indispensable. It is also a very cost-effective solution for small-scale production. In the aerospace and automotive industries, 3D technologies are already being used with might and main due to the high profitability and speed of manufacturing components. Culinary professionals are working on the development of 3D food printers, and in medicine, 3D printing has become something of a technology of the future. With the help of 3D bioprinting, it is planned to produce bones, organs and living tissues, but for now, implants and full-fledged medicines are printed on 3D printers. Desktop 3D printers can be used for domestic purposes: for repairs, making various household items, and so on. And designers, fashion designers, sculptors and artists appreciate the possibilities of 3D printing and 3D modeling as an unusual way to realize their talent.

With the help of 3D bioprinting, it is planned to produce bones, organs and living tissues, but for now, implants and full-fledged medicines are printed on 3D printers. Desktop 3D printers can be used for domestic purposes: for repairs, making various household items, and so on. And designers, fashion designers, sculptors and artists appreciate the possibilities of 3D printing and 3D modeling as an unusual way to realize their talent.

Well, that was a brief description of what 3D printing is. We hope we were able to provide the necessary information in an accessible way. If you have additional questions that we have not covered, write to us by e-mail and we, if necessary, will add your questions! Best regards, 3DDevice team.

We would also like to remind you about the possibility to order 3D printing, 3D scanning, 3D modeling or purchase of related equipment and consumables from 3DDevice with delivery throughout Ukraine. If you have any questions, please contact us at one of the phone numbers listed here.