3D printed lungs

3D Systems and United Therapeutics Unveil 3D Printed Lung Scaffold

3D printing news News 3D Systems and United Therapeutics Unveil 3D Printed Lung Scaffold

Published on June 16, 2022 by Clemens M.

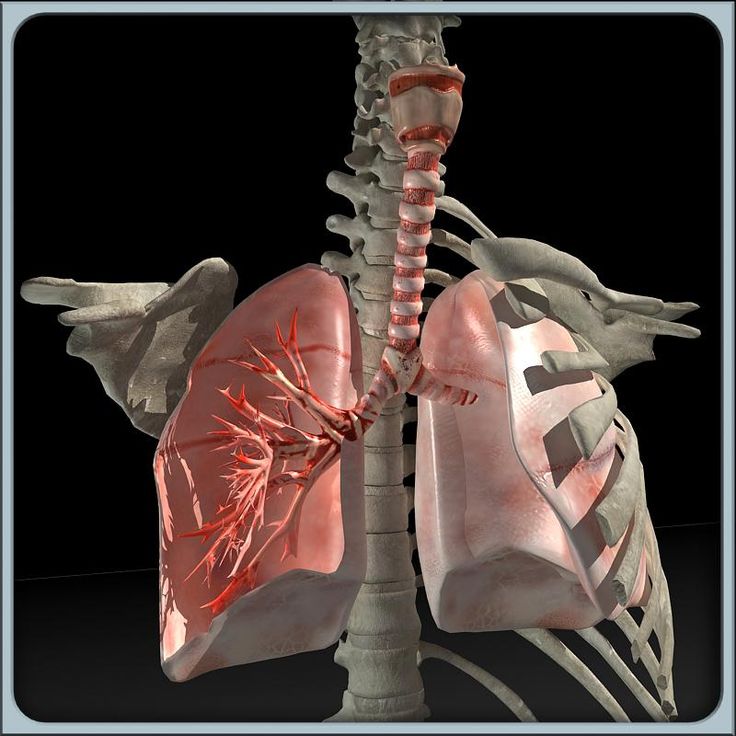

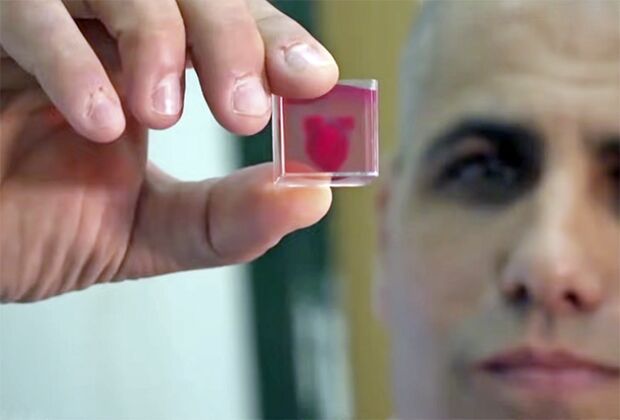

In a collaboration between United Therapeutics and 3D Systems, researchers have succeeded in developing a complex 3D-printed human lung scaffold. The lung scaffold was unveiled at the LIFE ITSELF conference in San Diego and is considered to be the most complex object ever created using additive manufacturing. The lung scaffolds, which have already been animal tested, are planned to be made in the future with the patient’s own stem cells.

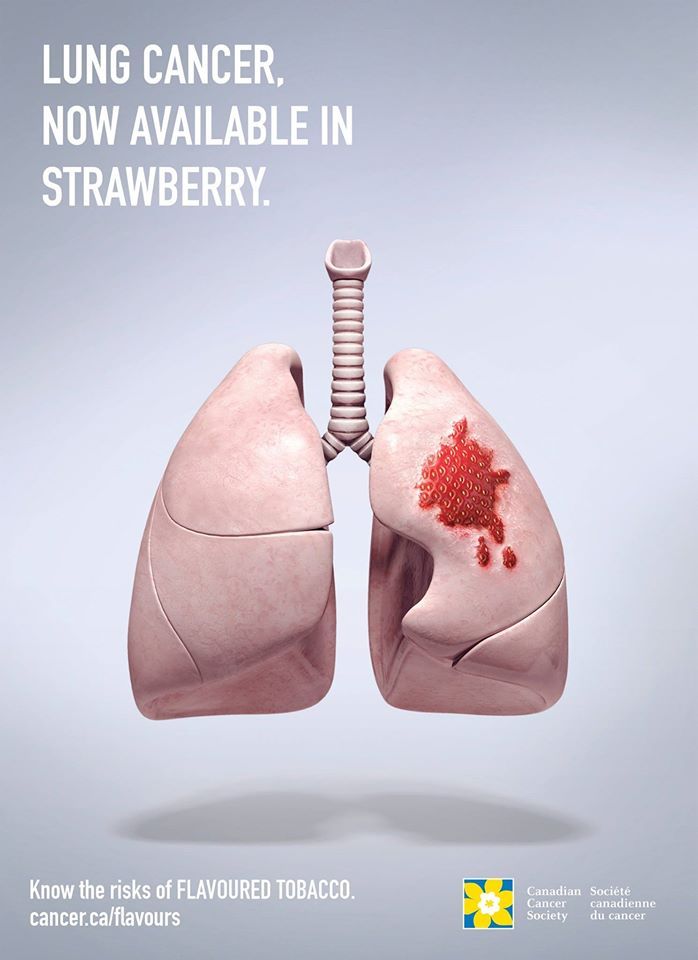

Lately, you’ve probably heard a lot about the various applications of bioprinting. This new form of 3D printing using living cells is becoming increasingly important in medicine. For example, a surgeon in the USA has recently successfully transplanted an ear implant made from human cells. Most famously, it is expected to be able to create fully functional organs for human beings. Though this is not yet possible, steps like this lung scaffold chose the immense advancements which have already happened thanks to 3D printing.

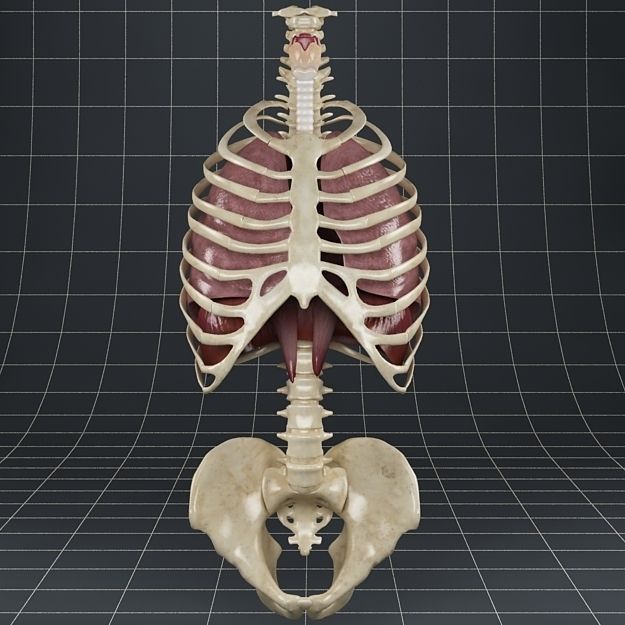

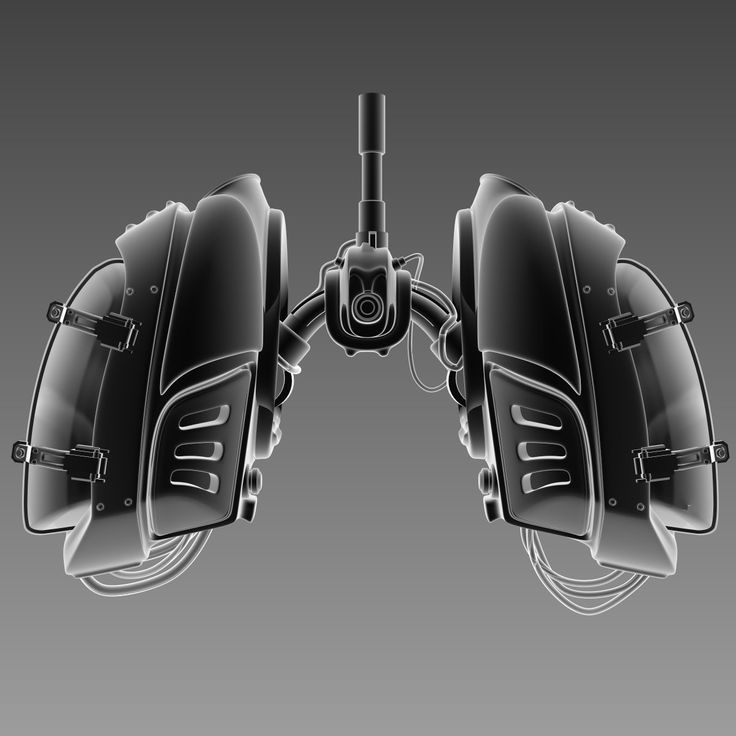

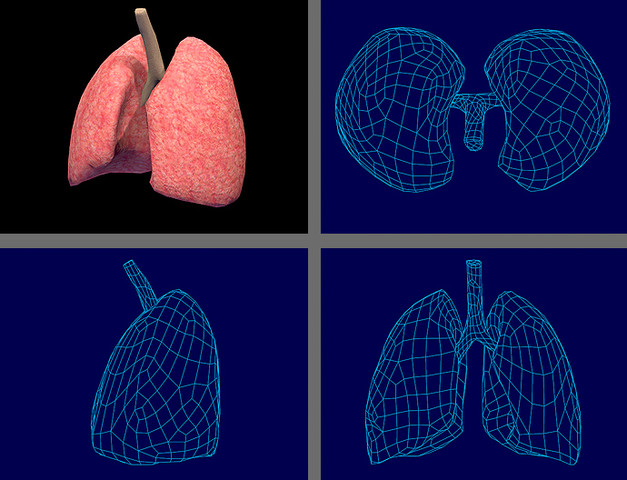

3D printed lung scaffold (photo credits: 3D Systems)

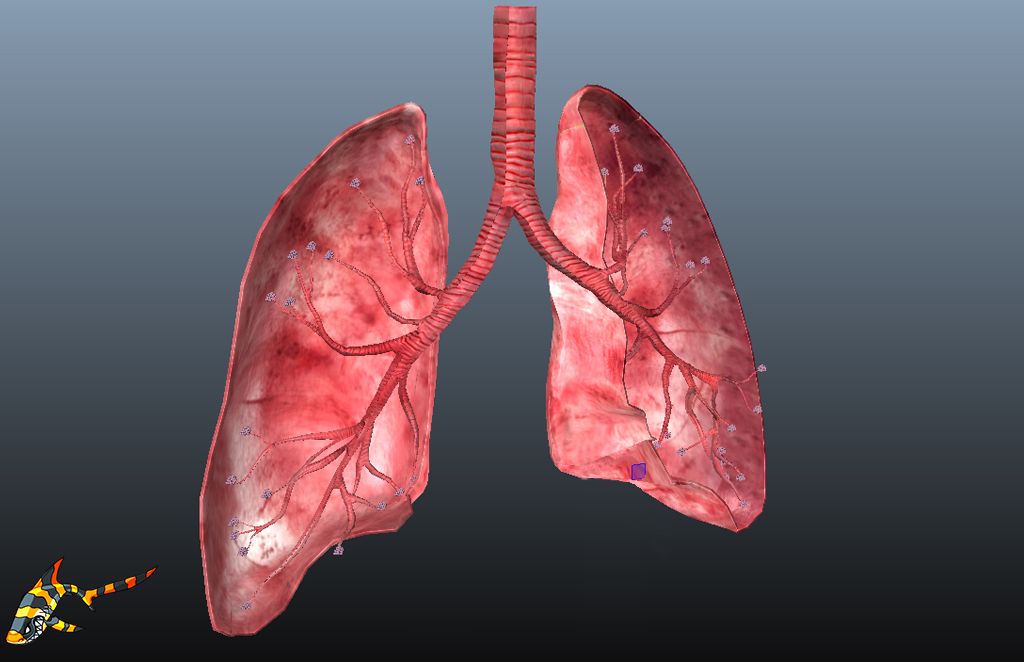

The Structure of the 3D Printed Lung Scaffold

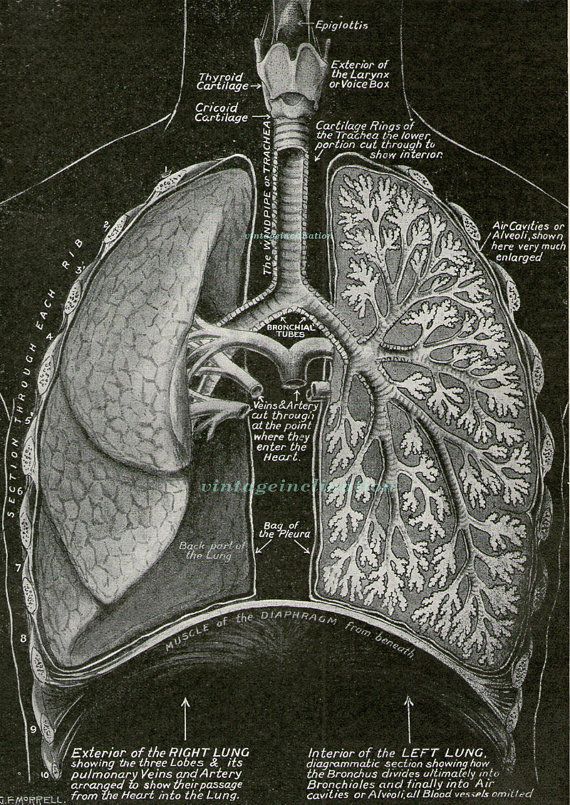

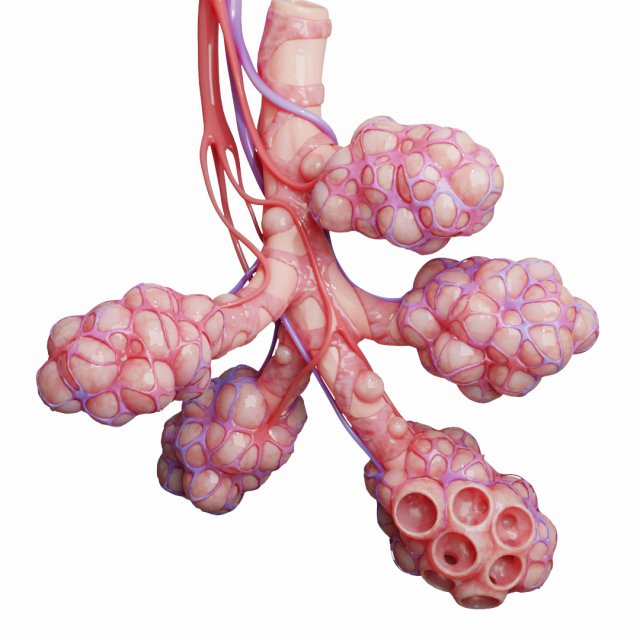

The 3D printed lungs consist of a record 44 trillion individual parts (voxels), which are distributed over 4,000 kilometers (~2500 miles) of lung capillaries and 200 million alveoli. United Therapeutics scientists, therefore, plan to cellularize these 3D printed lung scaffolds with patients’ own stem cells. This method may make it possible to create compatible, transplantable human lungs in the future. By using each patient’s own stem cells, the bioprinted lungs would carry a significantly lower risk of rejection, thus not requiring immunosuppression which can be very dangerous for the patient. The newly developed advanced photopolymer-based bioprinting technology called Print to Perfusion could enable this type of donor organ to be manufactured in as little as three weeks.

According to Dr. Martine Rothblatt, chief executive officer of United Therapeutics, these 3D-sculpted lung scaffolds have already been tested in animal models, which have demonstrated the successful gas exchange of the lung scaffolds. Rothblatt commented, “With the continued hard work of dedicated scientists and engineers at United Therapeutics and 3D Systems, we hope to have these personalized, manufactured lungs cleared for human trials in under five years.”

The goal of the collaboration, she said, is also to create an unlimited supply of transplantable lungs in the future. For example, they would already use a process called ex vivo lung perfusion. This could increase the supply of transplantable lungs by extending the period of viability of human donor lungs by several hours. This method has successfully prolonged over 230 lives to date.

The demand for donor organs is steadily increasing. In 2021, for example, 2,524 patients in the U.S. received a lung transplant, according to the U. S. Health Resources and Services Administration. As of June 3, 2022, there were also 1,075 patients in the U.S. on the waiting list to receive a donor’s lung. Meanwhile, more than 150,000 Americans die each year from lung disease, including many waiting for a transplant. You can find out more about the project HERE.

S. Health Resources and Services Administration. As of June 3, 2022, there were also 1,075 patients in the U.S. on the waiting list to receive a donor’s lung. Meanwhile, more than 150,000 Americans die each year from lung disease, including many waiting for a transplant. You can find out more about the project HERE.

Do you think 3D printed lung scaffolds could replace human donor organs in the future? Let us know in a comment below or on our Linkedin, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

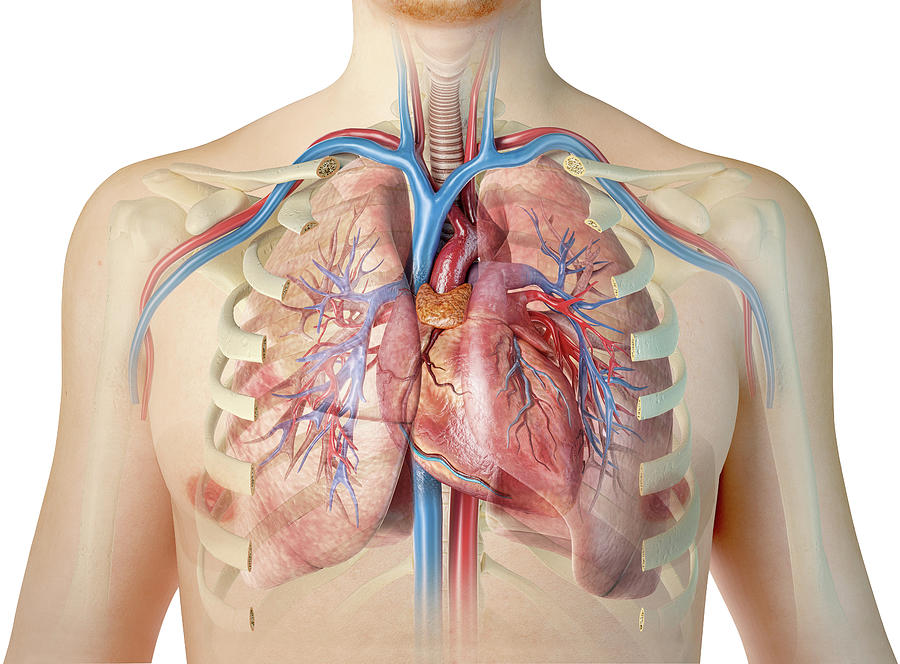

*Cover Photo Credits: yodiyim/Fotolia

United Therapeutics creates 3D printed lung scaffold

United Therapeutics Corporation said it has – in partnership with 3D Systems Corporation – produced the world’s most complex 3D-printed object, a human lung scaffold.

The human lung scaffold was demonstrated at the LIFE ITSELF Conference, held recently in San Diego, Cal.

Martine Rothblatt, United Therapeutics’ chairperson and CEO, and Chuck Hull, 3D Systems’ co-founder, executive vice president, and chief technology officer for regenerative medicine, explained to conference attendees that these 3D-printable lung scaffold designs consisted of a record 44 trillion voxels (similar to a 3D pixel) that lay out 4,000 kilometers of pulmonary capillaries and 200 million alveoli.

Scientists at the US-headquartered United Therapeutics plan to cellularize the 3D-printed scaffolds with a patient’s own stem cells to create tolerable, transplantable human lungs that should not require immunosuppression to prevent rejection.

“Last week, it was exciting to show the public our 3D-printed human lung scaffold, but we’re thrilled to share that our 3D-printed lung scaffolds are now demonstrating gas exchange in animal models. We are regularly printing lung scaffolds as accurately as driving across the United States and not deviating from a course by more than the width of a human hair,” Rothblatt said.

She added the goal is to have personalized, manufactured lungs cleared for human trials in less than five years.

Content continues below

Related Content

Rothblatt added, “Our goal is to create an unlimited supply of transplantable lungs in the future. Even today, we are using a process called ex-vivo lung perfusion to add to the supply of transplantable lungs by extending by several hours the period of assessment and viability for human donor lungs, resulting in over 230 lives extended to date.”

Lung transplants

According to the U.S. Health Resources and Services Administration, 2,524 patients in the U.S. received a lung transplant in 2021 and there are 1,075 patients on the U.S. lung transplant waiting list as of June 3, 2022. More than 150,000 Americans die from lung disease each year.

Hull said: “The reveal at LIFE ITSELF represents the culmination of our efforts with United Therapeutics that includes not only 3D-printed lungs, but two additional organs under development, kidneys and livers. These lung designs can be printed in as little as three weeks using our latest advanced photopolymer-based bioprinting technology we call Print to Perfusion.”

These lung designs can be printed in as little as three weeks using our latest advanced photopolymer-based bioprinting technology we call Print to Perfusion.”

United Therapeutics

United Therapeutics is the first publicly traded biotech or pharmaceutical company to take the form of a public benefit corporation.

Its mission is to find a cure for pulmonary arterial hypertension and other life-threatening diseases. The company has received U.S. Food and Drug Administration (FDA) approval for five medicines to date.

Last month, the FDA approved the company’s Tyvaso DPI (treprostinil) inhalation powder. This is used treating pulmonary arterial hypertension and pulmonary hypertension associated with interstitial lung disease to improve exercise ability. Tyvaso DPI is the only dry powder inhaler approved by the FDA for use in these conditions.

Content continues below

Related Content

The use of 3D printing isn’t new, although bioprinting is a growing category. According to Mordor Intelligence, the global 3D bioprinting market was valued at $724.2M in 2020, but is expected to reach $2.4B by 2026.

According to Mordor Intelligence, the global 3D bioprinting market was valued at $724.2M in 2020, but is expected to reach $2.4B by 2026.

Cover image: Shutterstock

3D Printed Lungs: Human Trials Over Five Years

Biotech company United Therapies has just revealed to the public its roadmap to build what it calls "the world's most complex 3D printed object." Frame for the lungs (framework in technical jargon). A lung that could become the standard for transplants in the future.

And according to the company, it may not be very far away. United Therapeutics and 3D Systems, a 3D printer manufacturer, have already made a lung scaffold that can be used in animal models. The next steps include generating them from patients' stem cells to make them portable and transplantable human lungs.

Five years from now

Dr. Martin Rothblatt , President and CEO of United Therapeutics, is very pleased. “Our lung scaffolds show that they can work, and we can make them with incredible speed and precision: compared to design, the final product can deviate by the size of a human hair. ”

”

"Through the hard work of dedicated scientists and engineers, we hope to have approval to test these custom printed lungs in less than five years."

Human vascular model created using 3D Systems' Print to Perfusion process. Image via United Therapeutics.3D printed lung scaffold

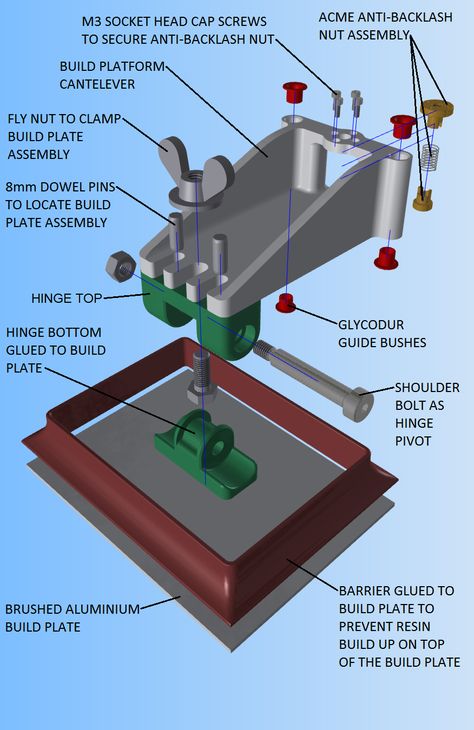

For many years, 3D Systems and United Therapeutics have been working on developing their process called Printing in Perfusion. Un Plan Allow Print high resolution 3D scaffolds that can be perfused with living cells to create tissue.

This process allows the printing of large, highly detailed, vascularized hydrogel scaffolds that could potentially open up a number of new tissue applications. The huge advances in this technology have caused quite an earthquake.

Investments in regenerative medicine, acquisitions of companies related to 3D printing and bioprinting, and other initiatives allowed us to come to the first unexpected result. Creating an "air pocket" that can function like a lung in animal models is a milestone.

Creating an "air pocket" that can function like a lung in animal models is a milestone.

Printed lungs: human clinical trial over five years

A 3D printed lung scaffold that can replace lungs for transplantation is an all-time record. 44 trillion voxels are distributed to form the shape of 4,000 km of pulmonary capillaries and 200 million alveoli. Time will make these structures nearly perfect, and it is no coincidence that both companies are already developing other organs such as the kidneys and liver.

With bioprinting techniques, if this technology were already widespread today, a bioprinted lung could be produced in less than three weeks.

Can you imagine how much faster it will work in just 5 years, when hopefully it will be safe enough for human testing?

An unlimited supply of lungs

Obtaining an infinite number of organs in a short time that does not require immunosuppression and does not cause rejection will be a real breakthrough.

Clinical trials (marked year: 2027) will be the first step towards the future of 3D printed organs made from the patient's own cells, safe and fully transplantable.

50 cool things to print on a 3D printer / Sudo Null IT News

No ideas for 3D printing? Tired of worthless trinkets? Here is a list of 50 cool really useful things for 3D printing.

Like us, you are fascinated by the possibilities of 3D printing. But, unfortunately, the horizon is littered with trinkets, trinkets and other unnecessary things. We are in danger of being buried under a heap of useless rubbish.

Throw off the shackles of mediocrity! Let's create really useful things! Here is a list of cool things that you can make on a 3D printer right now. Prove to your family and loved ones that this wonderful technology can be used daily and in practice.

No access to 3D printer? No problem. Just upload your files to our 3D printing price comparison system and choose the best price, ONLINE!

Download from ThingiVerse

Cool 3D Printing Item #30: Wine Bottle Guard

Download from MyMiniFactory7 Download from0005

Cool thing for 3D printing No. 31: Pocket ashtray

download from Myminifactory

Cool Press No. 32: Rod holder

3D Printable Cool Item #33: Apple Remote Stand

Download from MyMiniFactory

3D Printable Cool Item #34: Key Holder

Download with Myminifactory

Cool thing for 3D printing No. 35: Holder of cutlery for people with disabilities

Download from Myminifactory

Twist Twisting Passing No. 36: Cove wine bottle

Download from MyMiniFactory

Cool thing for 3D printing #37: Paper cup holder

download from Myminifactory

Cool thing for 3D Press No. 38: Case for blades

38: Case for blades

download from Myminifactory

Cool thing for 3D Press No. 39: Holder for a children's bottle 9004 from MyMiniFactory

Cool 3D Printable Item #40: Towel Rack

Download from MyMiniFactory

Cool 3D Printable Item #41: Holder for a glass

Download with Myminifactory

Cool thing for 3D Press No. 42: Holder for a phone in the shower

download from Myminifactory 9000 9000 for beer glasses

Download from MyMiniFactory

Cool thing for 3D printing #44: MacBook Pro stand

download from Myminifactory

Cool thing for 3D printing No. 45: Protection for SD-Cart

download from Myminifactory

Cool Press No. 46: BATERIOUS 9000 9000 Download from MyMiniFactory

3D Printable Cool Item #47: Ice Cream Cone Holder

Download from MyMiniFactory

Printable Cool Item #40056 shower set

download from Myminifactory

Cool Suck No.

The Hobb Knob is a small pen with a label to describe the items in the drawers. Now you will never lose your socks!

The Hobb Knob is a small pen with a label to describe the items in the drawers. Now you will never lose your socks!  Print it out and give it to your grandmother. She will appreciate this gesture.

Print it out and give it to your grandmother. She will appreciate this gesture.  " Do you have such a business card? Find her a pair in the form of this business card holder, printed in its entirety (yes, already with a hinged lid). Instructions for adding a custom logo are included.

" Do you have such a business card? Find her a pair in the form of this business card holder, printed in its entirety (yes, already with a hinged lid). Instructions for adding a custom logo are included.

It is especially suitable for kitchen plants. The next time you buy fresh herbs for cooking, transplant them into this neat device and they'll stay fresh all week long.

It is especially suitable for kitchen plants. The next time you buy fresh herbs for cooking, transplant them into this neat device and they'll stay fresh all week long.  It’s great if you have water limits set in the height of summer.

It’s great if you have water limits set in the height of summer.  28: Protection for disk

28: Protection for disk