Alcohol 3d printer

3DJAKE Isopropyl Alcohol, 1 liter

Effective cleaning agent for 3D printers and models

332 Customer Ratings

Bestseller

3DJAKE Isopropyl Alcohol

9,99 €

(9,99 € / l, Price shown includes 19% VAT. - )

Content: 1 l

Delivery by Wednesday, 08 March if you order by Monday at 07:00.

In stock

Quantity:

There are only 2703 items of this product left in our warehouse. More are on the way! The delivery date could be affected if you order more than this quantity.

Free shipping in Germany from 49,90 €.

Features & Advantages

- Isopropyl Alcohol 99.9%

- Very effective

- Good cleaning properties

Item no.: AOE-ISO-1L, Content: 1 liter, EAN: 9120099285339

DescriptionIsopropyl Alcohol (2-propanol or rubbing alcohol) is a clear, powerful cleaning agent for 3D printed parts, building boards and general applications.

Isopropyl Alcohol for building boards

IPA is effective in cleaning the 3D printer building board and leaves no traces or residues. To work, it can be diluted to 70% Isopropyl Alcohol and 30% distilled water. For its maximum potential, it can also be used at high concentrations.

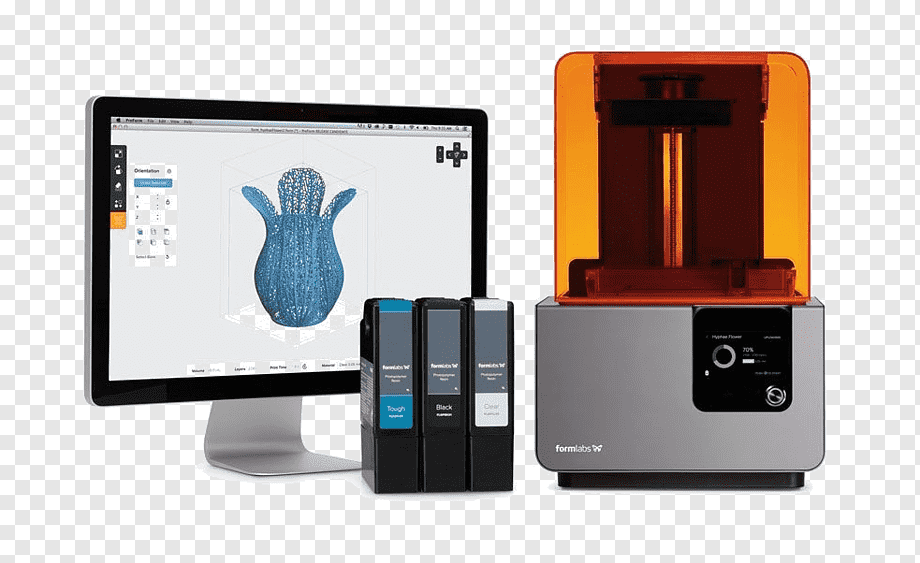

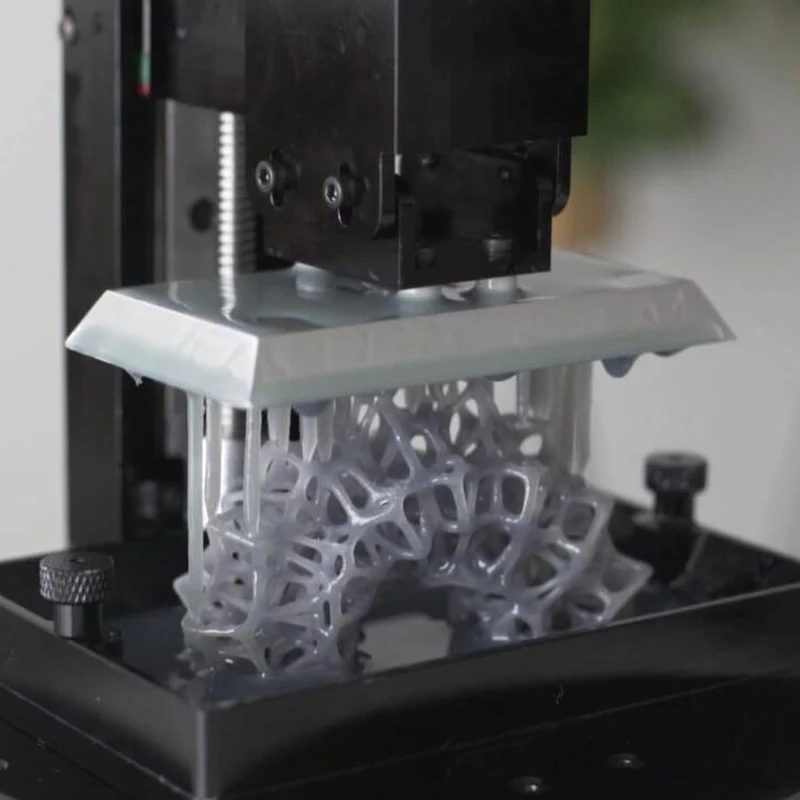

Isopropyl Alcohol for SLA and DLP prints

Isopropyl Alcohol removes and dissolves uncured resin from DLP and SLA prints and can be used to clean finished DLP and SLA 3D printed parts. Because of its rapid evaporation, it dries quickly. Therefore the container should not be open longer than necessary.

Because of its rapid evaporation, it dries quickly. Therefore the container should not be open longer than necessary.

Signal word: Danger

Precautionary statements:

- P210 - Keep away from heat, hot surfaces, sparks, open flames and other ignition sources. No smoking.

- P233 - Keep container tightly closed.

- P305+P351+P338 - IF IN EYES: Rinse cautiously with water for several minutes. Remove contact lenses, if present and easy to do. Continue rinsing.

Hazard statements:

- h325 - Highly flammable liquid and vapour

- h419 - Causes serious eye irritation

- h436 - May cause drowsiness or dizziness

Questions & Answers about 3DJAKE Isopropyl Alcohol

Receive answers from other customers who purchased this product. Please forward any other order-related questions to our Customer Service Team.

Please forward any other order-related questions to our Customer Service Team.

Customer Reviews

-

Daniel Souza

19 February 2023

Verified purchase

"Verified Purchase" indicates that the rating was given by customers who actually bought this product from us. However, anyone who has a customer account with us can give a rating. Close this note

-

dave

03 December 2022

Verified purchase

"Verified Purchase" indicates that the rating was given by customers who actually bought this product from us. However, anyone who has a customer account with us can give a rating. Close this note

-

Fred

28 August 2022

Verified purchase

"Verified Purchase" indicates that the rating was given by customers who actually bought this product from us. However, anyone who has a customer account with us can give a rating.

Close this note

Close this note

Related products

-

3DJAKE Resin Cleaner- Low odour

- Ease of use

- Suitable for ultrasonic cleaners

-

Elegoo Washing Tank- Replacement container

- For thorough cleaning

-

Anycubic Wash & Cure Plus- For larger resin prints

- 2-in-1 solution

- Powerful cleaning device

-

Elegoo Mercury Plus 2.0- Cleaning and curing

- Intelligent curing control

- 360° treatment

-

Creality UW-01- 2-in-1 solution

- Easy use

- 360 ° treatment

Customers also bought

-

3DJAKE Nozzle Cleaning Set- Good quality

- Comprehensive set

- Easy cleaning

-

3DJAKE Resin Filter Set- Easy cleaning

- Separates resin from particles

- Easy to use

-

3DJAKE Mini Wire Brush Set- 3-Piece Set

- With mini brush heads

- Rubber handles

-

3DJAKE ecoResin Light Grey- Budget-friendly

- Low odour

- Fast curing

-

3DJAKE Adheasy Spray- Easy application

- In a large 400ml can

- For heated and unheated building boards

How to Wash Resin Prints

3D Insider is ad supported and earns money from clicks, commissions from sales, and other ways.

It was not so long ago when resin-based 3D printing was described as “not for beginners.” While resin printing is not technically difficult, it can be quite a messy activity. One step that can potentially make a mess is washing.

Uncured resin has to be rinsed off using 99% isopropyl alcohol. It’s best to do this using either a commercial rinsing station or DIY rinsing vats or basins. Five to ten minutes of rinsing should be enough. More importantly, be sure to wear the proper protective equipment as contact with uncured resin can be very harmful. Also, practice proper disposal methods for any item or solution that has come in contact with uncured resin.

Check out our detailed guide on how to properly and safely wash your resin prints

Why do you need to wash resin prints?

Resin 3D printing has often been criticized as a very messy process. This mostly comes down to having to handle the liquid resin. Not only can this resin create a mess by dripping or spilling, but it’s also a toxic compound.

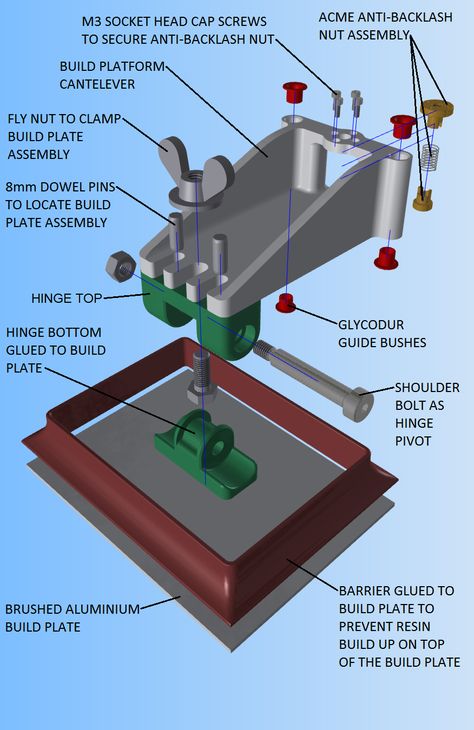

Right after resin printing, the resin is still in a “green” state. While it has been cured enough to maintain its form, it still has not reached the level of optimum strength and rigidity. Moreover, there will inevitably be a lot of excess resin on its surface. If your model is hollow, then there will also be resin inside the model even if it has drain holes.

Rinsing the excess resin ensures that the fine details of your 3D printed model are retained after curing. It also makes the model much easier and safer to handle as it removes the potentially dangerous uncured resin.

DIY vs. brand-name washing systems

At this point, you have two options – to buy a commercially available rinsing station or come up with a DIY solution. Obviously, the DIY method is much cheaper but is less convenient than buying a pre-assembled rinsing station. Both these methods will require that you have a healthy stock of 99% isopropyl solution. You’re going to need a lot.

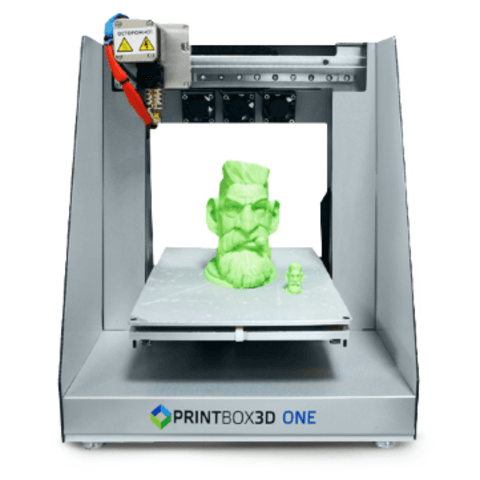

Commercial rinsing stations

Most of the big brands that offer resin 3D printers also offer 2-in-1 rinsing and curing stations. These are standalone devices that have built-in UV lamps and turntables.

These are standalone devices that have built-in UV lamps and turntables.

The rinsing step often involves submerging the model and build plate over a container with isopropyl solution while a rotating mechanism agitates the solution. This is very effective. Some models even include brackets that can be attached to the build plate so that your hands never need to come in contact with the uncured resin.

There are two limitations to this approach. The first is that these commercial rinsing stations are made to be compatible with specific resin printer models. This means that the rinsing vats are measured specifically to the build plate of the printer. An example is the ELEGOO Mercury 2-in-1 Washing and Curing Machine paired with ELEGOO Mars resin printer.

The second drawback is that you will likely be spending more on a commercial resin washing station. Most of these products cost a little more than $100. On the flip side, the fact that these products provide both washing and curing solutions makes them quite a good deal. If you need both, then you should consider getting a pre-assembled 2-in-1 washing and curing station.

If you need both, then you should consider getting a pre-assembled 2-in-1 washing and curing station.

DIY rinsing stations

If you just need a resin washing station, then it seems more practical to just make one yourself. Resin washing isn’t a complex operation, and you can make do with just about any plastic container large enough to submerge your resin prints.

We recommend having two such containers. The idea is that one of these will be the primary wash while the other will be the finishing wash. The primary wash will inevitably end up with a higher concentration of uncured resin and will have to be replaced more frequently. The finishing wash will help rinse out any residual resin with a relatively fresher batch of isopropyl alcohol.

To minimize handling of the uncured print, we also recommend using plastic strainers as a sort of false bottom for the washing containers. This will allow you to lift the uncured print without having to touch them with your hands or straining them with tweezers or tongs. It would be better if the strainers can be lifted without having to submerge your hands in the isopropyl solution.

It would be better if the strainers can be lifted without having to submerge your hands in the isopropyl solution.

How long should you wash in isopropyl alcohol?

The rule of thumb is that five to ten minutes should be enough to remove any uncured resin from the print if washing is coupled with agitation. However, this washing time can be extended for exceptionally large prints or those that have large hollow spaces or channels. A maximum of twenty minutes can be observed but is rarely necessary.

After washing, the next step would be to cure the resin prints. This can be done in a UV box or under direct sunlight. Curing in a UV box is recommended as it can be done in less than 5 minutes. If you plan to make lots of resin prints, a UV box is certainly worth the investment.

Safety measures

We cannot stress enough that uncured resin is harmful, both to people and the environment. Handling uncured resin is probably the most daunting thing about resin printing. You can get used to it eventually, but you will always have to be diligent about practicing these safety measures.

You can get used to it eventually, but you will always have to be diligent about practicing these safety measures.

Wear the proper PPE

When handling uncured resin, you will at least need to have gloves and eye protection. Nitrile gloves typically fare better than latex gloves, but these should still be treated as disposable after every use. Heavy-duty latex gloves might last longer but these will eventually still deteriorate after repeated contact with uncured resin. Any proper pair of safety glasses should do.

It’s also worth mentioning that you should dress appropriately when working with resin prints. If possible, wear long pants and fully covered footwear. You will want some protection for the bottom half of your body in case some of the resin spills or drips.

If you have to work with your resin printer for extended periods, then you may also want to wear some breathing protection to protect yourself from fumes. Make sure to use breathing protection that is rated for chemical vapors.

Be wary of spills

On the topic of spills and drips, you will have to accept that they will inevitably happen. Make sure that your workspace is equipped to handle such an accident. Get rid of any carpeted surfaces or any material that would be impossible to clean up if resin were to get in them.

Have towels on hand to clean up any spills quickly. It’s best to wipe surfaces with some isopropyl alcohol to remove any possible residue. You can also consider laying down some paper towels before transferring the print to the washing station to make clean-up easier.

Keep pets and children away

Make sure that your resin printer is in an isolated location where kids and pets cannot just wander in. This does not need much explanation – knowing the hazards of uncured resin should already be enough of a warning to prevent kids and pets from touching or ingesting it.

Isolate anything that comes in contact with uncured resin

Whenever you rinse your resin prints, keep an inventory of every single thing that comes in contact with uncured resin. This list should include your gloves, build plate, rinsing solution, and any towels you used to clean up spills. If you use a spatula or tweezers to remove the finished print from the build plate, then these should also be in the list.

This list should include your gloves, build plate, rinsing solution, and any towels you used to clean up spills. If you use a spatula or tweezers to remove the finished print from the build plate, then these should also be in the list.

These items should either be washed with isopropyl alcohol before reuse or treated properly before disposal. Tools in contact with uncured resin should be designated and used exclusively for this purpose.

Proper disposal of excess resin and rinsing solution

Proper waste disposal is a discipline that must be developed by anyone who goes into resin 3D printing. Since uncured resin is harmful to the environment, it must not be disposed of in its raw form. This applies to any other object that comes in contact with the uncured resin. This includes gloves, cleaning towels, empty resin bottles, and the isopropyl solution used to rinse the prints.

The most common way to handle any uncured resin is to simply cure it under direct sunlight. Cured resin is no longer dangerous. This is fairly simple to do for tools and equipment such as gloves and towels. Once the resin residue has hardened, the materials should be safe to dispose of along with the standard household waste.

Cured resin is no longer dangerous. This is fairly simple to do for tools and equipment such as gloves and towels. Once the resin residue has hardened, the materials should be safe to dispose of along with the standard household waste.

Disposing of the isopropyl alcohol solution can take considerably longer. You will want to expose the entire solution under direct sunlight. This will result in both the curing of the resin in the solution and the evaporation of isopropyl alcohol.

At the end of the process, you should end up with minimal isopropyl and some bits of solidified resin. You can wait for the alcohol to completely evaporate or just filter out the solid plastics from the solution. Isopropyl alcohol can be safely disposed of on the sink.

If you’re very lucky, your local recycling facility may even be equipped to handle uncured resin. These facilities likely handle other hazardous household materials like paints, adhesives, inks, and other cleaning products. It would be best to give them a call and ask for advice on how the hazardous waste should be contained before being handed over.

Final thoughts

Washing is one of those extra steps that are unique to resin-based 3D printing. The actual washing step is quite simple, but what complicates it is that you will be handling toxic uncured resin. This complication is likely one of the biggest culprits for the reputation of resin printing as a more difficult 3D printing option.

Resin washing does not have to involve complex equipment. Some plastic containers will do, although going for commercially made washing stations is equally as valid. What is more important is practicing safety guidelines on the handling and disposal of uncured resin.

Warning; 3D printers should never be left unattended. They can pose a firesafety hazard.

Amazing facts about 3D printing: how tea and beer are related to 3D printing, what does dental fillings have to do with it, why hairspray and PVA glue are used in 3D printing.

3D printing seems to have already firmly entered our lives, but at the same time, most people have about the same idea about it as about the structure of a spaceship.

And some facts about 3D printing can surprise you a lot.

- Sweet tea and dark beer for 3D printing.

- What is PVA glue used for in 3D printing?

- Why are dental fillings and office stamps sisters of photopolymer 3D printing?

- 3D printing plastic is made from corn

- 3D printer is CNC machine

- Fancy Printing: Office Paper

Sweet tea and dark beer for 3D printing.

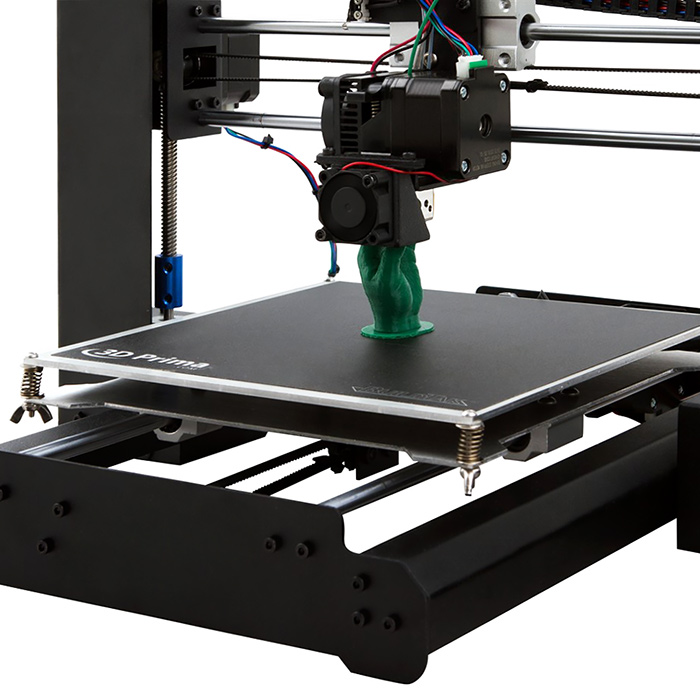

How does the simplest 3D printer work? The plastic is heated inside to the desired temperature and squeezed out, like toothpaste from a tube, onto a special “table”.

It's hard to believe, but, as we found out by experience, in order to fix the product on the table during printing, sweet tea (5-6 tablespoons of sugar) or beer, always dark, are best suited. You can also use glue stick for paper and ... hairspray. Of course, not every varnish or glue will work perfectly, but some will work very well. ..

..

The fact is that 3D printing is a relatively young field, and here you often have to improvise.

What is PVA glue used for in 3D printing?

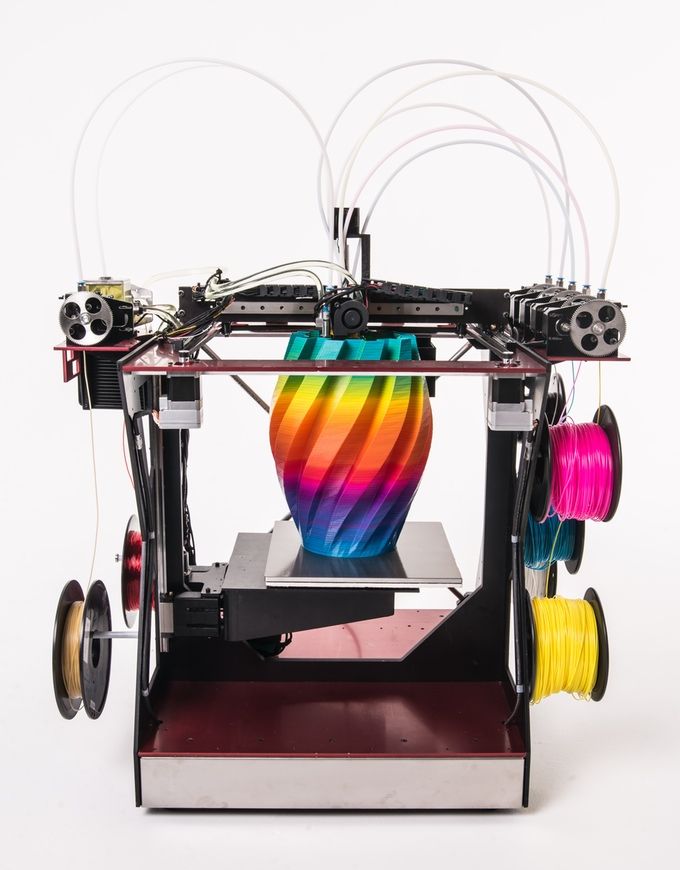

3D printing has found an unusual use for PVA glue. The fact is that it not only adheres well to plastic, but also dissolves easily in water, so it serves as an excellent support for overhanging parts. Thin plastic support sticks are necessary so that strongly protruding parts do not deform during printing, but subsequently they are very troublesome to remove. If the 3D printer has a second nozzle, hardened PVA glue can be fed into it instead of plastic. As soon as the product is ready, it remains to throw it into the water - the PVA will gradually dissolve, and we will get a beautiful model without the hassle and worries!

Why are dental fillings and office stamps sisters of photopolymer 3D printing?

What can these seemingly completely different things have in common? Material.

Photopolymer is a gel that cures when exposed to light (laser or LED).

Do you remember how the dentist used a special lamp when placing a light filling on you? The fact is that this seal is a photopolymer, which hardens under the influence of an LED, and then grinds by hand.

A photopolymer 3D printer works in a similar way, only it grows the model, layer by layer.

And where does the office stamp for documents? For its manufacture, a photopolymer is also used. First, a negative (mirror reflection) is printed on paper on a conventional printer, and then it is translucent - this is how a stamp cliché is created, which is glued to the snap.

Plastic for 3D printing is made from corn

You may have heard that buttons were once made from ordinary cottage cheese: when hardened, it becomes very durable. And PLA plastic is made from corn and is used, for example, for the production of dishes or confectionery molds. Outwardly, it practically does not differ from the usual one, but at the same time it is completely environmentally friendly, it can even be swallowed without harm to health. However, the above does not mean, for example, that PLA is able to decompose in a week of exposure to the street - it can serve for years even in the open air.

However, the above does not mean, for example, that PLA is able to decompose in a week of exposure to the street - it can serve for years even in the open air.

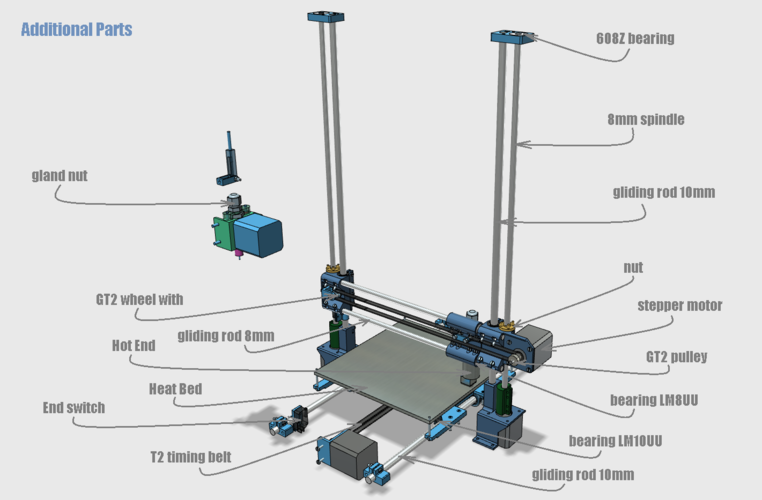

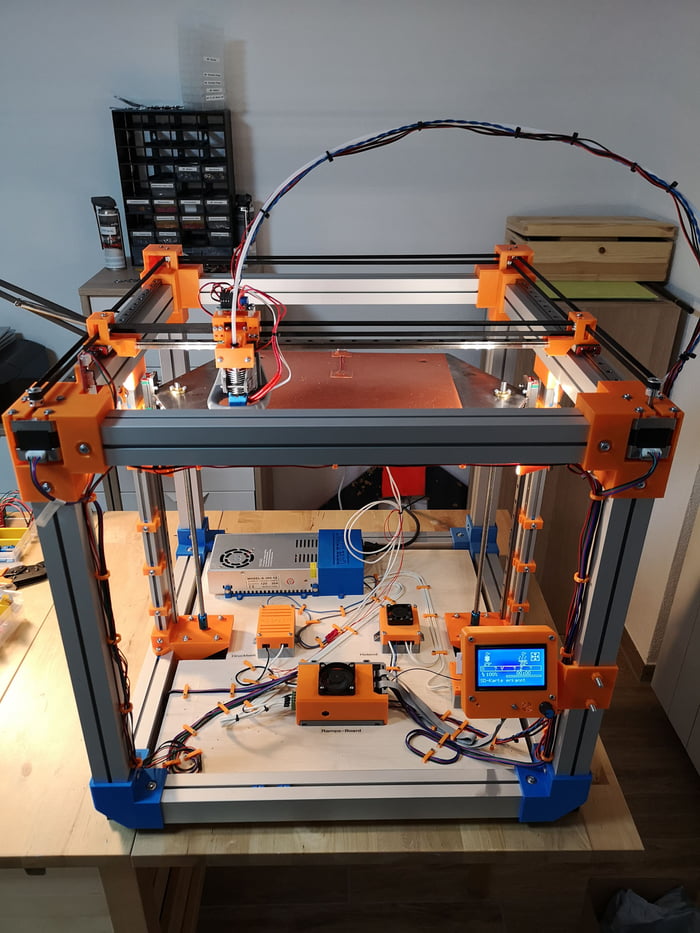

A 3D printer is a CNC machine

The principles of modern 3D printing appeared long before the printers themselves. But how did this become possible? It turns out that all the main technologies and methods used in 3D printing came from CNC machine tool building. A CNC machine is a computer numerically controlled machine.

CNC machines, which appeared in the middle of the last century, differ from 3D printers only in technology and (or) the principle of manufacturing a part. So a 3D printer from a scientific point of view is a CNC machine.

Unusual printing methods: office paper

Among the variety of 3D printing methods, there are quite unusual ones. For example, the Mcor printer has the following printing principle: you place a stack of ordinary office paper in the tray, the printer takes one sheet, cuts the outline of the future part on it, and glues each next sheet to the previous one and then paints it. The result is, for example, a detailed colored figurine. But if you try to break it, you will see a stack of glued office paper inside ...

The result is, for example, a detailed colored figurine. But if you try to break it, you will see a stack of glued office paper inside ...

SLA. Photopolymer solvents and its utilization.

3D printing

For a short experience of owning an SLA printer, I encountered a number of problems and questions in practicality. Even before becoming a happy owner of 'additive technologies' (really innovative, yeah), I already knew that isopropyl alcohol is used to post-process parts made from photopolymer. A little later, on foreign sites, I found the use of the word alcohol, that is, also alcohol, but in a more generalized concept (most likely, ethyl?). I also noticed in some places the sale or use of a 'specially developed composition for post-processing parts made of photopolymer', the composition of which, unfortunately, was not indicated anywhere =)

With a small supply of solvents and chemicals in the closet and on the balcony, I hasten to share my experience, and also look forward to your 'chemical' experience with this sometimes smelly, tarry 'greasy' substance in the comments.

- Ethyl alcohol 95%. This is not vodka, it smells much more unpleasant. When in contact with the skin, it dries it insanely in the literal sense, be sure to use protection. Dissolves liquid photopolymer very quickly. After ethyl treatment, the part has a soft touch and 'damp' surface that disappears after backlighting even in the presence of oxygen, or simply after a day of air drying on an indoor shelf. May form a whitish coating on the surface. Since alcohol is very volatile and has its own unique concentrated aroma, the 'liquid', in which something has already been rinsed, smells simply irresistible, since polymer particles are picked up by alcohol vapors and rush right into the brain itself. I also noticed that the container from under the 'defiled' alcohol has a viscous dirty film on the walls.

- A solution of ethyl alcohol in water. Up to a concentration of at least 1: 1, nothing really washes. At 50% alcohol content, the part is still washed from the non-polymerized polymer for a long and tedious time (taftology, yeah).

Otherwise, all the same application features as in the case of a 95% ethyl solution, with the exception of a slightly less strong smell.

Otherwise, all the same application features as in the case of a 95% ethyl solution, with the exception of a slightly less strong smell. - Isopropyl alcohol and its solutions. Haven't tried it, but it's been described everywhere. According to the description, the application features are the same as with ethyl alcohol. Only the smell of isopropyl is much stronger, I think that my scent is not ready for this.

- Petrol. Not at all. A drop of photopolymer does not dissolve in gasoline, but at the same time floats freely along the bottom without sticking to anything. Gasoline seems to lubricate the surface, tearing off the photopolymer from it. Gasoline, for example, cleans a dirty printer display well - the polymer is absorbed into rags, and gasoline reduces the adhesion of this 'stick'.

- Kerosene. Doesn't dissolve. Due to its oily properties, it pretty much stains objects by itself, since degreasing with gasoline is required after it. In the furnace - there it makes the soul warmer from him.

- Dichloromethane. I read somewhere about using this chemical to wash the photopolymer, but I haven’t tried it myself.

- Acetone. However, it dissolves. Perhaps a little slower than alcohol, but this is not so important. The surface of the part after acetone is clean, dry, hard - there is no that soft and loose layer on the surface. Does not leave a whitish tint on surfaces. With a short exposure (several minutes), I did not notice a negative effect on the polymerized layers. A container with a 'dirty' solution, in which the parts have already been rinsed, does not have a coating on the walls. Smelly, but the smell is not so disgusting compared to alcohol, as for me. And if we take the smell of a 'dirty' solution of acetone with a polymer, then its smell is much more tolerable than the same alcohol. Degreases the skin, but chemically for the skin is not as dangerous as alcohol.

I chose acetone as the solvent. Habitual smell, easy availability in stores, affordable price, surface quality after washing, the practicality of cleaning the container, greater safety for the skin of the hands - these are its beneficial aspects. Hazard class 4 is the same as for alcohols, but the MPC of acetone is still less than alcohol, which requires more vigilance when working with it.

Hazard class 4 is the same as for alcohols, but the MPC of acetone is still less than alcohol, which requires more vigilance when working with it.

Now about disposal. For enterprises, of course, their own requirements for waste disposal, but the photopolymer, it seems, does not belong to hazardous waste and can be safely disposed of as household waste.

- Liquid collection. Drain everything into a large or not very large container (bottles, cans) and throw it away as household waste. Perhaps, from the side of soil pollution, it is better to burn this solution in the air - in this way, the decay products will be able to rearrange faster in nature.

- Drain to sewer. That they just don’t pour into it. We are all guilty of this. But it is still better to refrain from such a method. An alcohol solution, when drained into the sewer, leaves a smell from it for the next day. From this side, the acetone solution is just a fairy tale - it was drained, rinsed with water and truncated; it will smell for about 30 minutes and not a trace is left, acetone is water-soluble.

I can be extremely wrong in any statements, therefore I look forward to criticism and your precious experience, which will help to conduct more efficient and safe activities when working with SLA printers. How are you processing the workpiece? How do you dispose of garbage?

Follow author

Follow

Don't want

15

Article comments

More interesting articles

31

Subscribe to the author

Subscribe

Don't want

Hello readers!

I have never published articles up to this point, but the experience gained and all ...

Read more

5

Subscribe to the author

Subscribe

Don't want

After 2 years of use, I decided to reflash the bear from the drain.