3D printer phenom

Phenom Prime by Peopoly

Roll over image to zoom in Click on image to zoom

Save $1,090.00

Peopoly

Country: US

US

EU

UK

Other

Product: Prime

Kit: None

None

Panel & 2x FEP & 2KG Deft White

Curing Box Pro

4KG Deft White

4KG Deft Grey

Variant

US / Prime / None - $1,709.00US / Prime / Panel & 2x FEP & 2KG Deft White - $1,979. 00US / Prime / Curing Box Pro - $1,943.00US / Prime / 4KG Deft White - $1,755.00US / Prime / 4KG Deft Grey - $1,755.00EU / Prime / None - $1,709.00EU / Prime / Curing Box Pro - $1,979.00UK / Prime / None - $1,709.00UK / Prime / Curing Box Pro - $1,979.00Other / Prime / None - $1,709.00

Share this product

An Introduction Video for Prime

Prime review at 3D Printed Props

Faster, Sharper, Rock Solid MSLA Printing

*Available in stock for immediate shipping!

Introducing Phenom Prime, it boasts an all-new 5448 × 3064 resolution (5.5K HD) panel with a best-in-class 51 um pixel pitch. The monochrome panel has a significantly higher light transmission rate that leads to an over 70% reduction in exposure time. When used in conjunction with Peopoly Deft resin and Peopoly FEP film, users can expect a 100% increase in speed over the current Phenom. Prime also has 3 times longer LCD panel expected lifespan than Phenom and sports the newly designed cooling system to handle the heat from printing. With a build volume of 276 × 155 x 400 mm, Phenom Prime is 400% bigger than Form3 and 500% faster when printing at full capacity. Read more coverage on All3DP

With a build volume of 276 × 155 x 400 mm, Phenom Prime is 400% bigger than Form3 and 500% faster when printing at full capacity. Read more coverage on All3DP

MSLA is much faster than other resin technology when printing a large object or a full plate of small objects because the entire layer is cured of resin. Peopoly’s customized light engine has even more light distribution than other printers using MSLA technology and a cooling system to improve print results while extending the life of the mask.

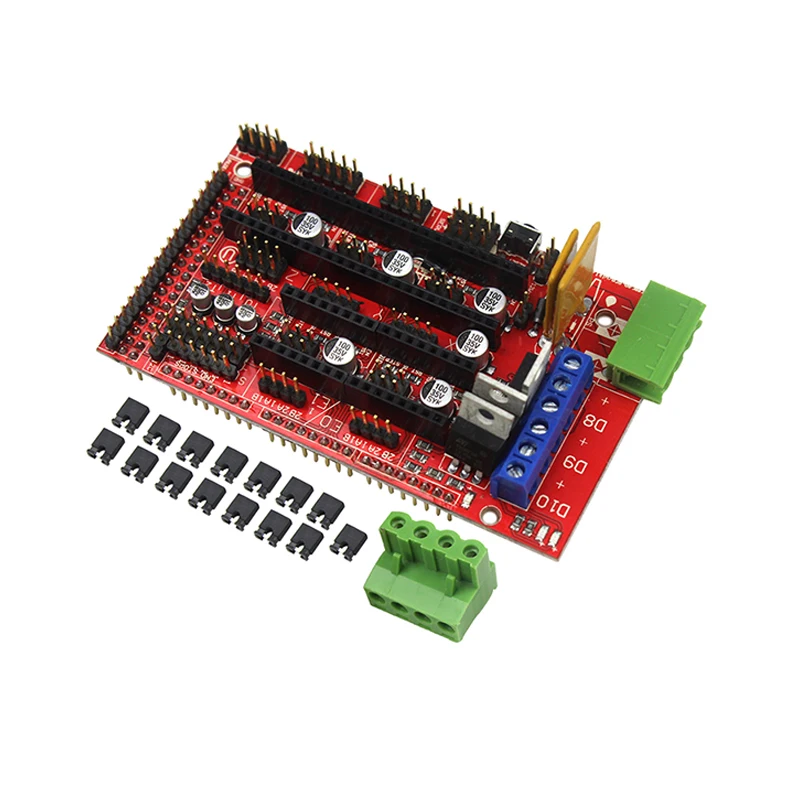

Phenom Prime is also powered by the latest Chitu System controller board that can output up to 8K with faster processors. The upcoming CHITUBOX Pro software will have many advanced features and is the best slicer choice for Phenom Prime and Chitu Systems board.

Details

- Printer Size: 452x364x780 mm

- Print volume: 277 × 156x 400 mm

- Resolution: 51 um

- Technology: MSLA 3D Printing

- Vat Volume: 2. 5 kg

5 kg

- Additional FEP film x1

- Panel Lifespan: 1200 on average using recommended resin and settings

Additional Consumables

Phenom Forge by Peopoly

Roll over image to zoom in Click on image to zoom

Save $550.00

Peopoly

Country: US

US

CA

EU

UK

Other

Product: Forge

Kit: None

None

Panel and 2x FEP

Curing Box Pro

2x Deft White

2x Deft Grey

2x Nylon-Like

Variant

US / Forge / None - $1,349. 00US / Forge / Panel and 2x FEP - $1,523.00US / Forge / Curing Box Pro - $1,557.00US / Forge / 2x Deft White - $1,394.00US / Forge / 2x Deft Grey - $1,394.00US / Forge / 2x Nylon-Like - $1,412.00CA / Forge / None - $1,349.00EU / Forge / None - $1,529.00EU / Forge / Curing Box Pro - $1,737.00UK / Forge / None - $1,709.00UK / Forge / Curing Box Pro - $1,889.00Other / Forge / None - $1,529.00Other / Forge / Panel and 2x FEP - $1,703.00Other / Forge / Curing Box Pro - $1,737.00Other / Forge / 2x Deft White - $1,574.00Other / Forge / 2x Deft Grey - $1,574.00Other / Forge / 2x Nylon-Like - $1,592.00

00US / Forge / Panel and 2x FEP - $1,523.00US / Forge / Curing Box Pro - $1,557.00US / Forge / 2x Deft White - $1,394.00US / Forge / 2x Deft Grey - $1,394.00US / Forge / 2x Nylon-Like - $1,412.00CA / Forge / None - $1,349.00EU / Forge / None - $1,529.00EU / Forge / Curing Box Pro - $1,737.00UK / Forge / None - $1,709.00UK / Forge / Curing Box Pro - $1,889.00Other / Forge / None - $1,529.00Other / Forge / Panel and 2x FEP - $1,703.00Other / Forge / Curing Box Pro - $1,737.00Other / Forge / 2x Deft White - $1,574.00Other / Forge / 2x Deft Grey - $1,574.00Other / Forge / 2x Nylon-Like - $1,592.00

Share this product

An Introduction Video for Forge

Order now for immediate shipping.

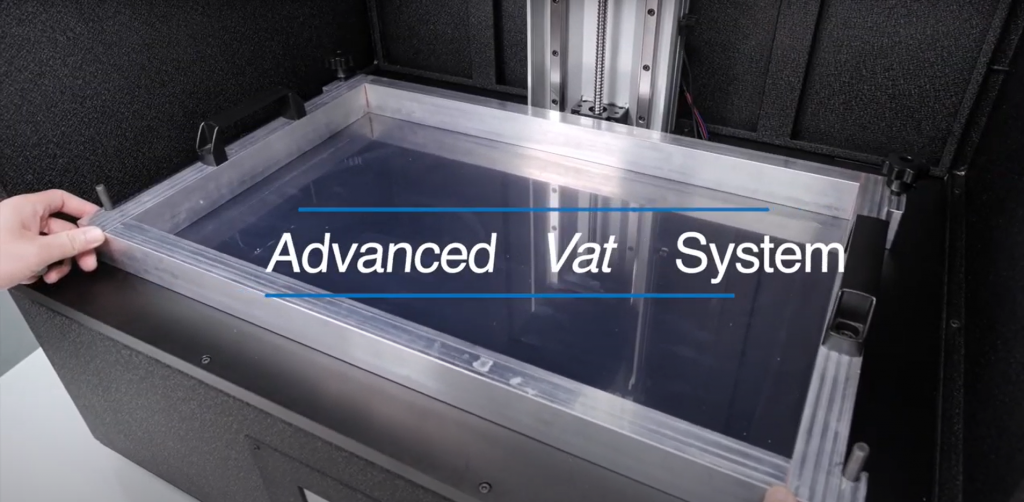

Introducing Forge, a production-grade large-format MSLA printer built for workshops and factories. It is the only large MSLA printer with heated Vat, the highest contrast monochrome screen, and the most accurate parallel light source. It is powered by the all-new Vlare Core controller with features that will make printing easier, faster, and more accurate. Read more coverage on All3DP

It is powered by the all-new Vlare Core controller with features that will make printing easier, faster, and more accurate. Read more coverage on All3DP

Key Features

- Build Volume 288 x 163 x 350mm

- High Contrast (500nit) 6K Monochrome Panel for even better resolution and excellent life span.

- Vlare Core controller board with Open File Format support and onboard EMMC storage

- Build-In masking function for more even light distribution

- Slicer options: Lychee Slicer, Tango Voxeldance, and Vlare Slicer

- WiFi and Infrared Camera for remote monitoring and management

- Temperature-Controlled Vat for more consistent printing

- Fleet management functions for print farm

- Advanced Parallel LED for higher resolution

- More power-efficient, less fan noise design with UL Certified power source.

- Highly customizable with add-ons like air duct vent, chamber heater, LED strip, and more.

- All new Nylon-Like Tough resin to work with Forge printer

Forge is shipped in two boxes and requires 30-60 minutes of assembling to connect the top and the bottom part of the printer. The assembling does not require any special tools or soldering.

For users who print for productions, speed and ease of use are often as important as resolution if not more so. The flat build plate allows for quick removal and cleaning, unlike a perforated plate. The heated vat ensures printing consistency and avoids reprint that costs time and money. Users can swap a new film or a new panel in under 20 minutes instead of an hour. And most components can be accessed by removing one panel for quick maintenance.

Details

- Printer Size: 470x 360x 640mm

- Print volume: 288 x 162 x 350mm

- Resolution: 50 um

- Technology: MSLA 3D Printing

- Vat Volume: 2. 5 kg

5 kg

- Physical Weight: 30KG

- Shipping Weight: 43KG

- Additional FEP film x1

- Panel Lifespan: 1200 on average using recommended resin and settings

Additional Consumables

3D printing phenomenon / 3D, 3D printing, weapons, clothes, fashion, design, art

3D printing is not something fantastic “from the future”. Already today, a 3D printer is available not only in certain printing houses, but also in stores where you can buy them for home use. However, 3D printing these days is still able to surprise many people who have not yet discovered this type of industry. What is 3D printing? What are its areas of application? Why is 3D printing so relevant today?

How did 3D printing come about?

The emergence of a 3D printer is preceded by a long history of the creation of this device. The best minds around the world tried to contribute to the development of 3D printing methods. Officially, its inventor is considered to be an engineer named Chuck Hull. Of course, he did not invent the 3D printer. But the American scientist managed to create the progenitor of modern devices - a "installation for stereolithography." It happened not so long ago, at 1986 year.

Officially, its inventor is considered to be an engineer named Chuck Hull. Of course, he did not invent the 3D printer. But the American scientist managed to create the progenitor of modern devices - a "installation for stereolithography." It happened not so long ago, at 1986 year.

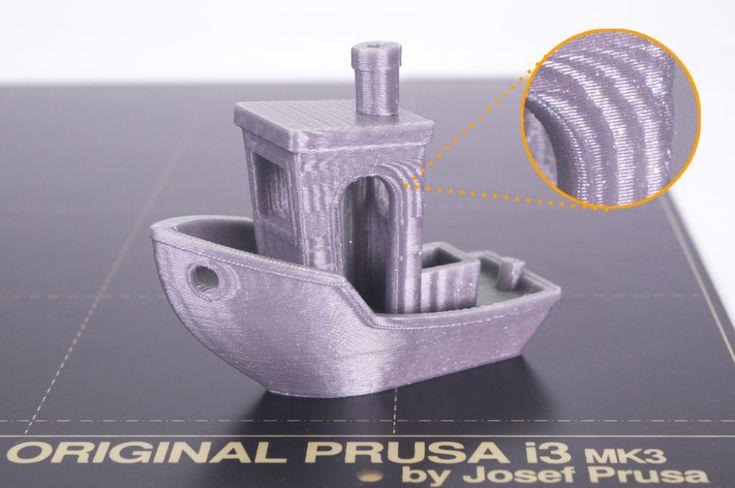

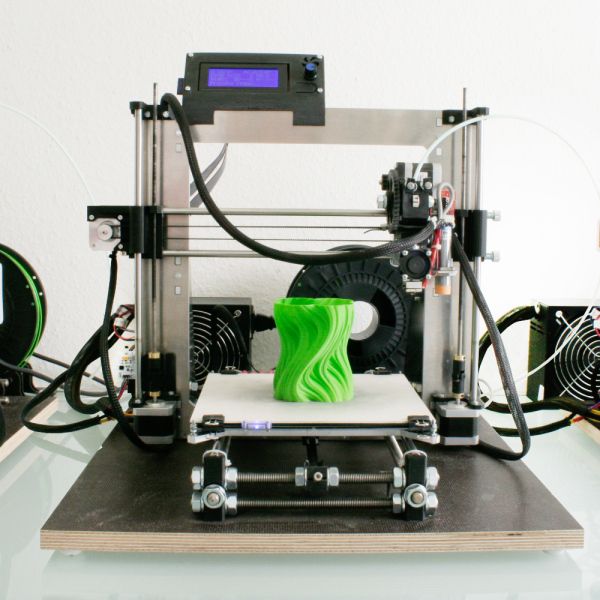

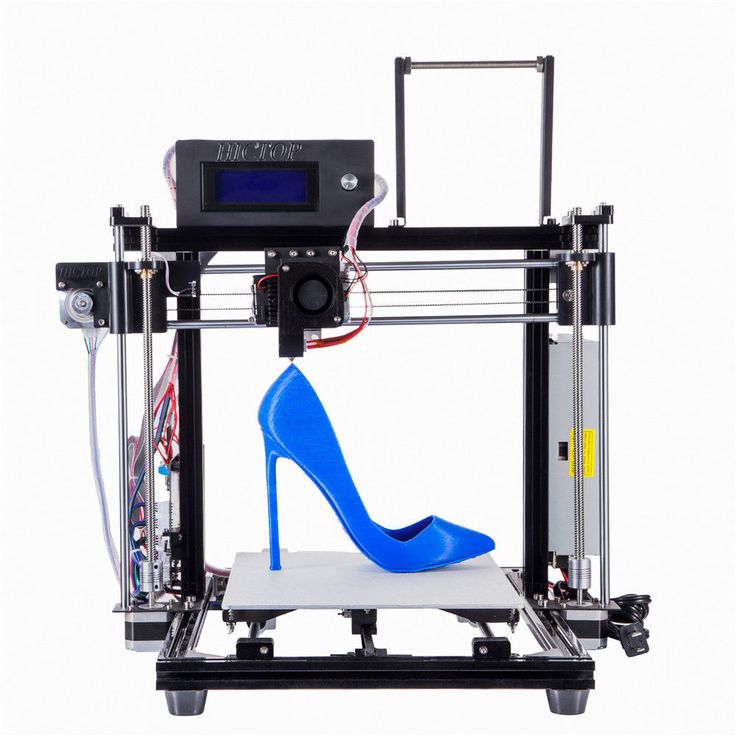

Two years later, inventor Scott Crump came up with "FDM" technology, which became the basis for 3D printers designed to print small items in a matter of quantity. In other words, this technology provided the modeling of objects using the decomposition of melting materials. Already in 1995, the Massachusetts Institute of Technology officially introduced the term "3D printing", and a year later another term appeared - "3D printer". This was the name of the device created by 3D Systems (model Actua 2100).

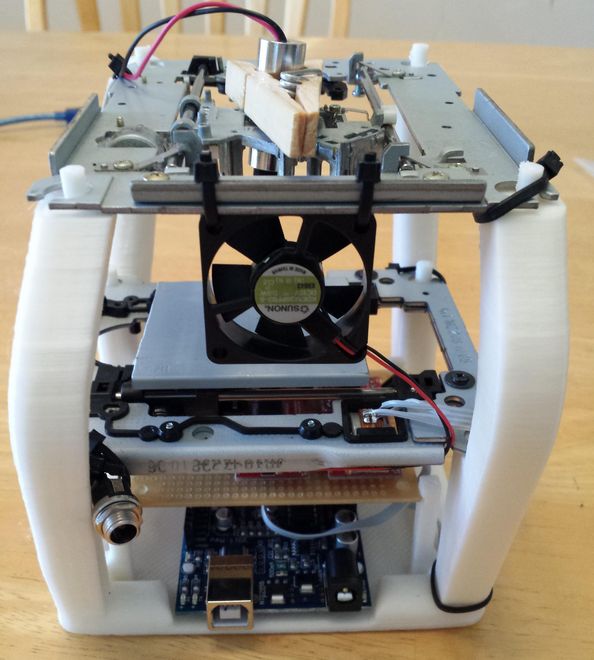

Initially, 3D printers were characterized by low power, and the created models had a number of errors. High print quality was achieved after ten years of improvement. So, in 2005, high-quality printers began to be produced, and three years later, the famous “Reprap” appeared - a 3D printer that could reproduce itself. Until 2008, only ABS plastic was used as a printing material. Manufacturers believed that this was the best material option, most suitable for 3D printing.

Until 2008, only ABS plastic was used as a printing material. Manufacturers believed that this was the best material option, most suitable for 3D printing.

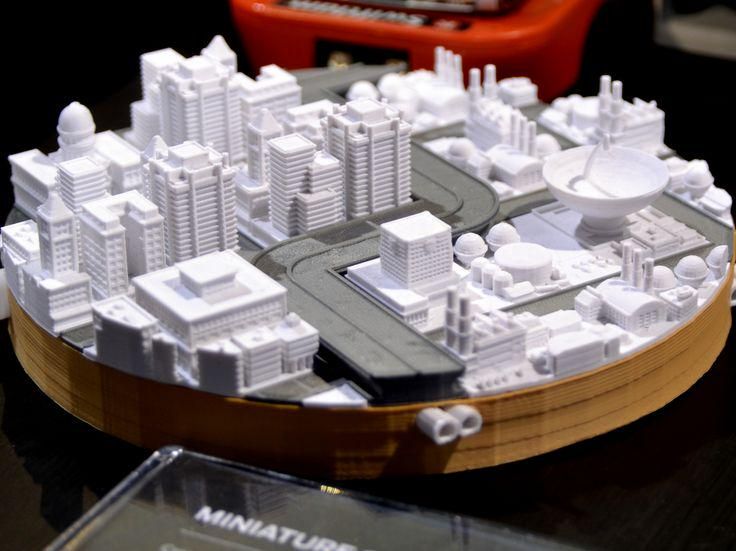

But that all changed after the release of the Connex 500 by Objet Geometries. This printer may have used different materials during operation. Today there are about a hundred different types of materials used. The capabilities of modern 3D printers are amazing: you can create any objects. Printed models are always solid and durable, and the volume is achieved due to the layering of the model. Today, printing a three-dimensional model of a toy, cup or car can be done quickly and easily.

What does Obama's speech look like in 3D?

The 2013 3D Printshow featured the work of Gilles Azzaro, a French artist who managed to 3D print the sound of Barack Obama's speech. According to the artist, the time for 3D printing of the president's speech was twenty-seven and a half hours.

The resulting model made it possible to reproduce the exact sound of Obama's voice while the scanner beam slid over the printed model. The markings of the model were so accurately reproduced that they made it possible to reproduce the sound, taking into account all the nuances and features of the president's voice.

The markings of the model were so accurately reproduced that they made it possible to reproduce the sound, taking into account all the nuances and features of the president's voice.

How to 3D print an office?

The authorities of the United Arab Emirates, in particular, Minister Muhammad al-Gergawi, decided to implement the idea of creating a three-dimensional model of the office space. According to the project, it should be a building with an area of just over one hundred and eighty square meters. The building should consist of one floor.

A six-meter three-dimensional printer, according to the project, will be able to create such a model in layers, thanks to which, in the future, the time for construction work will be reduced by seventy percent.

In addition, the construction of building models using 3D printers will reduce labor costs by more than half. The planned office building will presumably also feature furnishings (also 3D printed). There will be a museum of the future and a platform for exhibitions.

There will be a museum of the future and a platform for exhibitions.

How to print a suit?

Victoria's Secret, a renowned lingerie brand, donated $12 million to the project in 2013, spending much of that money to create a three-dimensional snow queen costume for the show's main figure, Lindsey Elingson.

The image of the American model was created by scanning her figure. Then, 3D printing specialist B. Rotenberg created a crown, wings and other elements using a 3D printer. The result is a rather extravagant costume, emphasizing the status of the queen.

How to grow a houseplant with a 3D printer?

Marijuana cultivation is legal in some states of America, while it is illegal in other states. Today, using a 3D printer, you can print a special installation for high-quality marijuana growth. 3D printing technology, in tandem with hydroponic garden systems company 3Dponics, resulted in a Lego-like structure.

It consists of three elements such as tub, bowl and lid. To create a special design, you need to download the exact parameters of the parts on an information carrier, print them on a 3D printer, and then assemble all the parts in one installation. Thanks to this invention, the cultivation of "weed" has become quite easy: you only need to occasionally water medicinal marijuana with water.

How to print human organs?

Several Chinese scientists in 2013 were able to 3D print an analogue of human kidneys. The resulting organ exactly corresponded to real healthy human kidneys. This discovery could save many people by curing them of various kidney diseases. As statistics show, more than twenty-five million inhabitants of the United States of America suffer from such diseases. Over time, the number of patients increases.

However, until now, scientists have not been able to cope with the only problem of replacing diseased kidneys with printed analogs: the latter have a short service life. Kidneys created with a 3D printer can only function for four months. Research is currently underway to help increase the lifespan of artificially created kidneys.

Kidneys created with a 3D printer can only function for four months. Research is currently underway to help increase the lifespan of artificially created kidneys.

How to 3D print a car?

In 2013, Korecologic released a car model that consisted mainly of 3D printed parts. It was the Urbee 2, which was an improvement on the first 3D-car printed in 2010.

The Urbee 2 is made of plastic and weighs only 500 kilograms. There is a gasoline engine, as well as two electric motors. Each of them is responsible for a specific axis of the machine. The printed car is capable of speeds up to one hundred and twelve kilometers per hour. The battery charge is enough to overcome sixty-four kilometers.

What are the possibilities of 3D printing?

In 2011, as an alternative to NASA's robotic moon base project, ESA proposed using 3D printers to construct buildings. Using the Monolite D-Shape printer model, it will be possible to build three and a half cubic meters of a building every hour. This means that the average building will be built in about a week.

This means that the average building will be built in about a week.

Can I print my pistol?

In 2012, Defense Distributed came up with a plan to create a 3D printed plastic handgun. The Liberator is a pistol model released a year after the plan was drawn up. This type of weapon consists of sixteen parts, and only one of them is made of metal. The pistol is loaded with one cartridge. Easily replaceable barrel is designed for 11 shots.

A bullet fired from this gun can crush the skull and easily damage body tissues. Weapons that anyone could print using a 3D printer began to pose a huge danger to society. Metal detectors cannot detect such a pistol, so it is almost impossible to calculate the printed weapon.

It wasn't until November 2013 that a law was passed prohibiting the manufacture of weapons using 3D printers. Now only those who have a license to do so ("Federal Firearms License") can get such a pistol.

The Phenomenon of Creative Thinking

3D Printing in the Production of Spectacular P. O.S. Materials

O.S. Materials

Non-standard advertising structures in the form of extenders on traditional billboards, large-format replicas of products and products near store facades or eye-catching installations of complex shape in the design of exhibition stands have long been regarded as a proven effective tool for attracting increased attention of the audience. Considering all this, Massivit 3D Printing Technologies (Israel) has developed a technology with which sculptures, enlarged models of various objects and original P.O.S. displays can be quickly manufactured and installed in supermarkets, shopping centers, hotels, cinemas and exhibition pavilions.

“3D branding is an approach that harmoniously and effectively combines interior design and brand positioning,” says Avner Israel, CEO of Massivit 3D Printing Technologies. “3D branding makes an impression in several dimensions at the same time, which affects the potential buyer much more than standard advertising graphics. ”

”

Developed by Massivit 3D Printing Technologies, large objects over 3 cubic meters can be printed. The system is optimized for the visual communications industry. With it, you can create a variety of complex three-dimensional shapes: for example, this machine, in particular, successfully printed a three-dimensional model of the famous Strati car developed by Local Motors.

Massivit 1800 is equipped with GDP technology - gel printing, which is distributed in a special way according to the design layout. In an hour, the printer is able to reproduce 3D models up to 35 cm high with high accuracy. The gel curing device that the printer is equipped with causes the gel to be converted into a solid form very quickly, which makes 3D printing in extra large format possible. The maximum dimensions of a 3D print that can be created with the Massivit 1800 are 1.5 x 1.2 x 1.8 m. The printer also has the ability to print two products at the same time, which can significantly save time on the production of three-dimensional models.

The photosensitive gel used in the Massivit 1800 printer cures when exposed to UV light. This provides higher performance than the common use of thermoplastic in 3D printers with a smaller printable area. For example, it takes just five hours to make a full-length mannequin with the Massivit 1800. With parallel printing of another figure, the time to print one product is halved. The developer sees this printer capability as a huge advantage for display manufacturers, who are often required by corporate customers to complete orders on extremely tight deadlines, and the order includes a visual demonstration of their latest products. The Massivit 1800 printer can also be used to print decorative ceilings and exclusive complex wall coverings.

The first Massivit press has already been installed in Israel at E.S. Digital, which specializes in large format printing, visual communications, signage and P.O.S. materials. “With the new printer, we are able to offer our customers even more ways to capture the attention of their audience and enhance the impact of their advertising and promotional campaigns: we can add a new dimension to traditional marketing,” emphasizes Eyal Shemesh, CEO of E. S. digital.

S. digital.

New opportunities for laser engraving

Dan Shapiro, who eventually founded and led Glowforge, took a different look at familiar equipment such as laser engraving machines and realized the opportunity to implement new, demanded capabilities in it. Just four days after it started accepting applications for the 3D laser printer he developed, the company's profit reached nearly $3.5 million. The idea of creating such a system began to emerge from Dan Shapiro, who had access to a laser engraver, at the moment when his children asked him to make toys for them using a machine. Having tried a laser engraver in this case, Dan was not satisfied: it took too much time to bring most of the designs to life, at the same time, using an engraving machine was both difficult and unsafe for his children. He decided to search the market for more suitable solutions and found that they did not exist at all. As a seasoned entrepreneur who already had experience selling his business to Google, Shapiro set out to build an affordable and easy-to-use laser cutting machine. Investors shared his enthusiasm and invested more than 9 years in starting a new business.million dollars.

Investors shared his enthusiasm and invested more than 9 years in starting a new business.million dollars.

Technologically, Dan Shapiro's development is a CNC laser engraver, although it is implemented as a laser 3D printer.

The machine manufactured by Glowforge is capable of processing leather, paper, fabrics, various plastics and cardboard and producing finished products at the touch of a button. The machine is also capable of engraving on acrylic, plywood and even food.

One of the strengths of the Glowforge 3D laser printer is its ability to automatically recognize what kind of material or object is in the processing area before the machine starts engraving and cutting. This prevents the risk of costly mistakes, for example, when engraving the metal case of a laptop.

The Glowforge 3D Laser Printer is 94 cm wide, 50 cm deep and 20 cm high. The machine is equipped with autofocus for high-precision 3D printed products, two cameras for previewing designs, and technology for replaying created hand-drawn drawings and images.

The printer is aimed at creative users who want to bring their creative ideas to life in a very short time. Images can be loaded into the machine from software packages such as Adobe Photoshop or Adobe Illustrator without the need for professional CAD software, making the Glowforge even more attractive to users with no experience with laser engravers.

Views: 1730

Knowledge base

Materials science

Encyclopaedic information on all types of materials used in advertising production

Printing theory

Required information for those who produce or order digital large format printing

Q&A

Answers to questions you can ask!

Abbreviation

Explanation of almost all abbreviations that appear in the description of advertising materials

Glossary of Terms

Advertising Industry Terminology A to Z, A to Z

Other publications of section

See all publicationsMirror stand based on the LiDAR scanner principle

February 07, 2022 Industrial Fiction

Sometimes, to make even a small space look spectacular, it is enough to apply creative thinking and appropriate materials.