3D printer marketing

Why 3D Printing Could Be The Next Big Thing In Marketing

Young woman operating a 3D printerIn the last decade, 3D printing has been used in different sectors, including manufacturing, education, aerospace, and medicine. But despite the rising popularity of this technology in many industries, the marketing space seems slow to adopt its use. Even so, the success of several promotional campaigns using 3D printing has opened the eyes of brand managers and decision-makers to the exciting possibilities of using this tech in marketing.

For now, many brands who want to use 3D printing may not be able to invest in the machines or technology directly. Instead, it’d be more feasible for them to buy finished 3D-printed marketing materials from B2B companies that make them. In essence, many companies offering 3D printing services would be like managed service providers (MSP) that offer turnkey IT solutions to other businesses of all shapes and sizes.

Contents

- 1 3D Printing In Marketing

- 1.

1 Innovative Method To Introduce A Product

- 1.2 Low-Cost Advertising Materials

- 1.3 New Potential For Customization And User Interaction

- 1.4 Exciting Opportunity To Present Products To Customers

- 1.

- 2 Bottom Line

Suppose you’re a B2B company offering 3D printing or managed IT services to other companies. In that case, you need a robust MSP marketing services provider if you want to grow your business and improve recurring revenues. After all, 3D printing enterprises and IT service providers shouldn’t be that far off from each other regarding marketing requirements.

As the economy begins to take off, more businesses will need to boost their marketing. And 3D printing technology is in the perfect position to take advantage of the situation, at least in the marketing sphere. That said, a B2B company offering 3D printing services—or any business, for that matter—can expect that 3D printing is the next big thing in marketing goods and services. Below are the reasons why:

Below are the reasons why:

Launching a new product can be a terrifying moment for a business because you don’t have a clue whether the public will love it or not. For a business startup with limited capital, taking on substantial working capital business loans to fund manufacturing and marketing will make much more sense only after getting feedback from their target market.

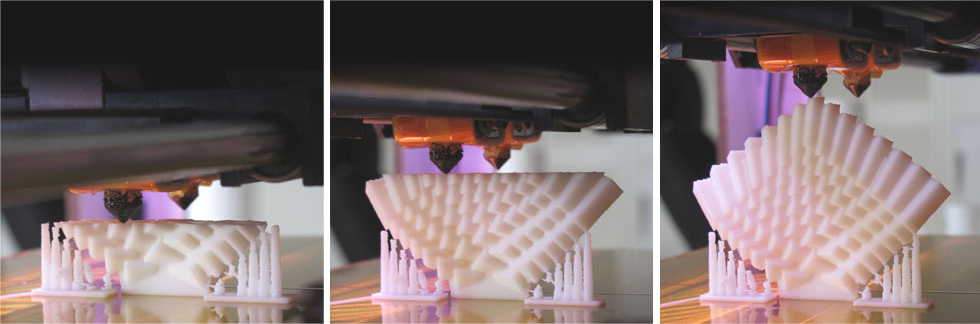

With 3D printing technology, you can make prototypes and launch promotional campaigns on a smaller scale to see what people think of your new product. You can then use the initial feedback to aid further product development. So, instead of spending a huge chunk of capital creating molds or machines to launch new products, companies could save a lot of money by first using 3D printing to build prototypes before investing in large-scale manufacturing.

Low-Cost Advertising MaterialsOne of the reasons why experts predict that 3D printing is the next big thing in marketing is the technology’s ability to build marketing materials for shop displays and other promotional items at a low cost. If you participate in a trade fair, you can use 3D printing to create beautiful and intricate displays to make you stand out.

If you participate in a trade fair, you can use 3D printing to create beautiful and intricate displays to make you stand out.

This strategy is also effective in the construction and real estate industry. For instance, Dubai plans to construct 25% of its buildings via 3D printing by 2030. While that may be a lofty goal for any private property company, you can still take advantage of the technology by creating scaled replicas of the buildings and real estate development you’re selling. Through these 3D printed models, you’ll enable customers to see even the most intricate details of your projects.

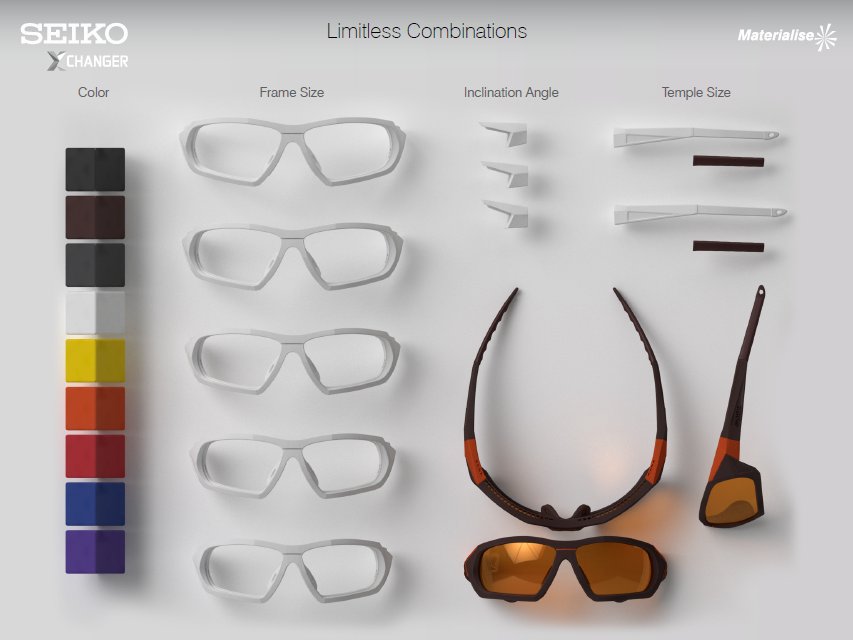

New Potential For Customization And User InteractionOne of the most significant marketing potentials of 3D printing is product customisation. How often have you walked into a shop and wished that you could change the colour or tweak the design of the item you’re holding? With 3D printing, you can provide customers with an opportunity to make the product design their own, or at least have a say on the colour or shape of the product.

Aside from customization, 3D printing is also an excellent way to encourage user interaction. You could create marketing buzz by enabling users to design a new product or improve on an old one. This move could give you a pulse of what people need or what they like about your product. If you have the budget, you can 3D print the suggested designs from market participants and send them samples. You can bring a 3D printer and do the printing onsite to draw a massive crowd to your booth in a trade show.

Exciting Opportunity To Present Products To CustomersMany customers want to touch and see a product before they buy. Technology will significantly affect marketing over the next decade through 3D-printed physical samples that consumers can test and inspect. If you’re an online seller of high-ticket items, sending potential customers samples of your product is a cost-effective approach to encourage people to buy what you offer.

More and more large corporations around the globe have shown the different uses of 3D printing for their promotional and advertising campaigns. Thus, it’s not surprising that experts predict smaller brands and marketing service providers will adopt this relatively new technology for their marketing in the coming years.

Thus, it’s not surprising that experts predict smaller brands and marketing service providers will adopt this relatively new technology for their marketing in the coming years.

About Manufactur3D Magazine: Manufactur3D is an online magazine on 3D printing. which publishes the latest 3D printing news, insights and analysis from all around the world. Visit our 3D Printing Education page to read more such informative articles. To stay up-to-date about the latest happenings in the 3D printing world, like us on Facebook or follow us on LinkedIn.

Three Areas Holding Back The $10.6B 3D Printing Industry

Market research firm SmarTech Analysis recently released its data for the additive manufacturing (AM) industry. It determined that, in 2021, the 3D printing sector reached $10.6 billion in revenue, excluding the revenues associated with hardware maintenance contracts and post-processing equipment. The firm further projects that AM is expected to grow to over $50 billion by 2030.

The firm further projects that AM is expected to grow to over $50 billion by 2030.

The 3D printing industry is projected to reach over $50 billion by 2030, according to one market ... [+] research firm.

Image courtesy of SmarTech Analysis.This growth is closely pinned to the trend that large manufacturers will increasingly use the technology for mass production. However, in order for AM to reach wide-scale adoption, it will need to advance significantly in three crucial and interrelated areas: throughput, factory integration, and quality control. Fortunately for the industry, these are all also issues that are being actively addressed.

3D Printing Throughput

Due to its roots as a prototyping technology, 3D printing was never designed with mass production in mind. Instead, its ability to create complex shapes has been limited to one-off parts or small batch manufacturing. For that reason, firms across the 3D printing industry have been working to develop systems that can make many parts as rapidly as possible, a concept known as throughput.

Among the leaders in this regard is HP, which spent years researching the technology before finally unveiling technologies capable of rapid production both in plastics and metals. The 2D printing giant has ported its expertise in inkjet printheads over to 3D printing with a technology called Multi Jet Fusion (MJF). MJF is already being used to produce large batches of polymer parts for everything from eyewear to grocery bots.

Legor Group in Italy is using HP Metal Jet to 3D print functional stainless steel accessories for ... [+] the jewelry and fashion markets.

Image courtesy of Legor Group SPA.MORE FROMFORBES ADVISOR

This is just the beginning for the company, which is now rolling out its Metal Jet technology. A form of what is called “metal binder jetting,” Metal Jet deposits a liquid binder onto metal powder, creating a component that must then be sintered in a furnace. Customers as large as Volkswagen are investing in the technology with a plan to mass produce up to 100,000 metal components annually for consumer vehicles.

However, HP isn’t the only company in this quickly evolving space. A widely publicized startup called Desktop Metal is working to speed up metal binder jetting. GE, too, is working on its own version of the technology. Altogether, these companies are ushering in an era in which low-cost metal powders can be used to 3D print large numbers of parts in a single job, potentially changing the cost structure for metal 3D printing altogether.

This means that they will be taking on the established leaders in metal 3D printing, which typically rely on zapping high powered laser beams at expensive metal powders. These companies are working on increasing throughput, as well, by adding up to 12 lasers to their machines.

3D Printing Factories

While a fleet of 3D printers may be capable of manufacturing at volume, that doesn’t mean that they’ll necessarily fit into an existing factory operation. In large part, this is due to the fact that they lack mass production-level software.

Now, a handful of startups have emerged to take on the challenge of developing AM-specific software for manufacturing execution systems (MES). These tools make it possible to both manage a fleet of 3D printers and connect them to a company’s existing production software. They typically aid in the entire order-to-fabrication workflow. This means order quoting and tracking, print file preparation, print job monitoring and data collection, printer fleet queuing, quality control, and shipping.

MES software necessarily connects to a business’s existing software tools. This includes product lifecycle management (PLM), enterprise resource planning (ERP), and general IT software. While PLM might include a company’s preferred 3D modeling software, ERP will be made up of everything from payroll programs to tools for tracking overall finances.

MES platforms are now working to take all of the software that a manufacturer might already be working with and inserting 3D printing into the mix. However, they’re not just limiting themselves to AM. Many MES developers are looking to connect with other production equipment, such as CNC machines. Then, with the help of machine learning, the entire workflow can be improved automatically as data from each order and each machine job feeds back into the work cycle. Artificial intelligence is significantly adding to the capabilities of MES software.

However, they’re not just limiting themselves to AM. Many MES developers are looking to connect with other production equipment, such as CNC machines. Then, with the help of machine learning, the entire workflow can be improved automatically as data from each order and each machine job feeds back into the work cycle. Artificial intelligence is significantly adding to the capabilities of MES software.

3D Printing Quality Control

Perhaps the biggest obstacle to widespread AM adoption is quality control. This is because, with additive, each part is distinct. Every point on the build platform may be slightly different and even the slightest variation in a printing parameter may change the microstructure of the printed object.

In turn, an object printed at one angle will not be the same as one printed at another. And, because parts are built up layer by layer, it is difficult to validate the internal geometries of an item once printing is complete. As a result, the only true way to assure the quality of a printed object is with a CT scan, typically a cost-prohibitive method for inspecting multitudes of parts.

Fortunately, not only are newer CT scanning systems with lower price tags coming onto the market, but there are other tools that are being used to ensure the quality of printed parts. Among them is computer simulation. Companies like ANSYS have developed software that can anticipate any defects that occur during the printing process and compensate for them. Hexagon is taking this one step further by predicting issues at the microscopic level.

Meanwhile, firms like Sigma Labs and Additive Assurance have created hardware to monitor the build chambers of metal 3D printers to detect errors. Increasingly, these tools will enable active feedback so that the machines can quickly correct issues during the print process. When connected with MES software and 3D printing simulation, the equipment can learn from past errors and address them before they even happen in the future.

Altogether, these areas are advancing at incredible rates, in large part because manufacturers see the value in being able to produce objects from digital files on demand. As companies as large as Ford, GE, and Siemens look to 3D printing to produce quality end parts, they are driving the entire additive market to bend to their needs. To reach a whopping $50 billion by the end of the decade, the 3D printing industry has to be capable of making millions of parts for those customers.

As companies as large as Ford, GE, and Siemens look to 3D printing to produce quality end parts, they are driving the entire additive market to bend to their needs. To reach a whopping $50 billion by the end of the decade, the 3D printing industry has to be capable of making millions of parts for those customers.

3 tips for using 3D printing in your marketing campaign・Cults

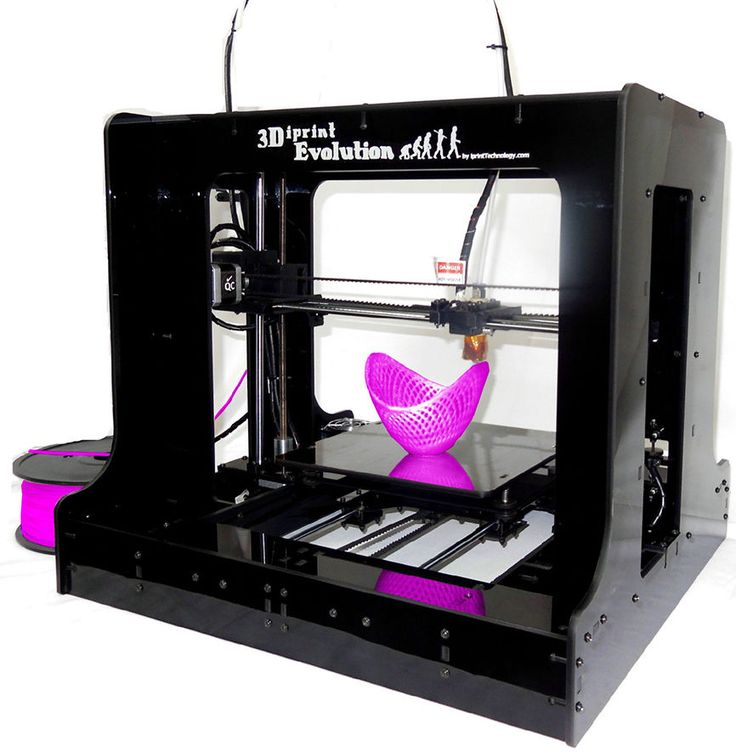

The role of additive manufacturing and 3D printing continues to grow as more industries jump into this trend.

AMFG statistics show that the global manufacturing market grew to more than $10 billion last year, a figure that will double every three years.

But while investment in 3D printing is growing rapidly, AMGF claims that 71% of companies still don't have enough knowledge about 3D printing and tend to opt for more traditional methods if they have a choice.

However, the lack of knowledge or relative novelty of 3D printing is not a problem for many industries that, in search of innovation, have chosen to capitalize on this technology. And it's not just manufacturing that benefits from 3D printing.

And it's not just manufacturing that benefits from 3D printing.

We have already analyzed the impact of 3D printing on education and how working with computer-aided design can help students gain hands-on experience and develop skills.

Another industry that has found its way into 3D printing is marketing. In it, marketing has found a lot of advantages, namely:

● Product innovation. With a model built in hours and different model scales, marketers are finding a new way to present a product.

● High level of personalization. New features can be easily added to personalize the product model.

● Low development cost. Modeling a product using 3D printing is cheaper than traditional prototyping methods.

B2B businesses in particular can benefit from 3D printing as this innovative approach to prototyping will attract more investors. Thus, the use of 3D printing in marketing can help a business to take the lead and outperform the competition.

Collaboration with Heineken

In 2015, we partnered with Heineken, a well-known Dutch company that decided to shift its marketing efforts to 3D printing.

On the occasion of the UEFA Champions League, we made 3D models of accessories for football fans - an ice bucket, coaster and bottle opener. All products have been created in Heineken's corporate color and logo.

Product is part of Heineken's #ChampionTheMatch marketing campaign marketing campaign. Product models can be downloaded and recreated on any 3D printer.

But not only individual companies use 3D printing in marketing.

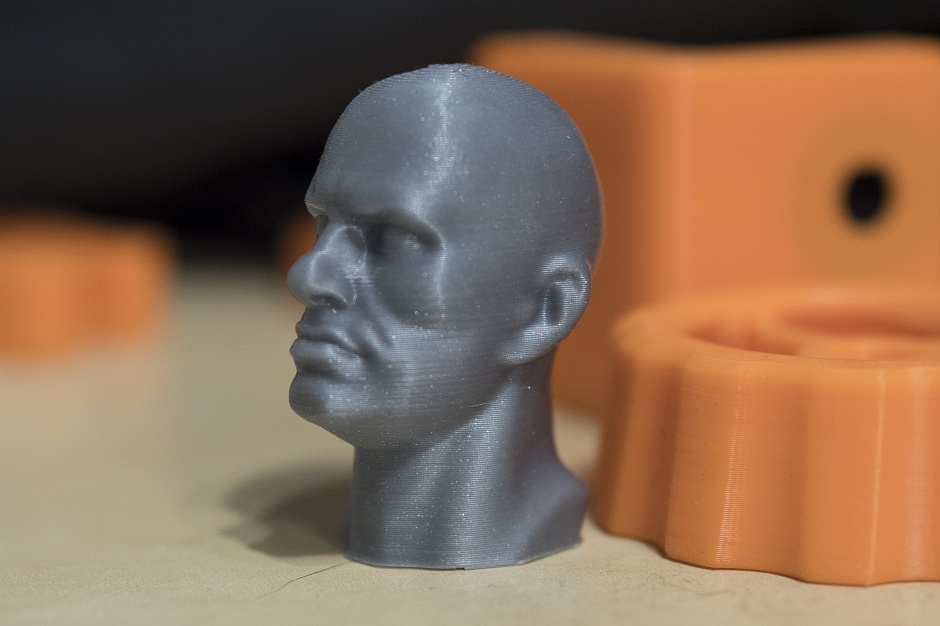

French presidential election

During the French presidential election, our company produced 3D bust models of all presidential candidates. Thus, we have used 3D printing to raise political awareness and remind voters and candidates that the future of France lies in innovative technologies.

As you can see, 3D printing can help your business reach millions of people and communicate powerful messages in an innovative way.

If you've finally decided to open the door to 3D printing and include it in your marketing campaign, here are some of our thoughts on how to do it effectively.

You must have heard about the importance of behind-the-scenes content in marketing. However, with 3D marketing, you can take it to the next level and allow consumers to take part in the creation of your product.

Thus, from passive observers, they turn into co-creators of your product.

Here's how Volkswagen incorporated the hands-on experience of 3D printing into its marketing campaign.

Back in 2012, to promote its Polo cars, Volkswagen launched a marketing campaign that allowed customers to create their own version of the Volkswagen Polo.

The marketing campaign was called "The Polo Principle" and at the end of the campaign, Volkswagen selected 40 of the most creative designs submitted by users and turned the campaign finale into a show in Copenhagen. The winning models were later turned into real cars.

The winning models were later turned into real cars.

What is the result?

3D printing allowed Volkswagen to introduce people to the process of designing a car by inviting them to become designers themselves. In this way, the campaign has successfully turned the usual behind-the-scenes content into an active, hands-on activity.

You can go one step further and allow consumers to customize the product to suit their preferences.

This way, you give them the opportunity to work on personalizing the product themselves, rather than doing it for them.

This is exactly what Nokia used in their marketing campaign for the Nokia Lumia 820. Users could create cases for this smartphone model because Nokia provided a 3D printing kit.

It was a smart move towards product customization. Nokia has moved from traditional approaches to customization to more innovative ones.

Nokia has moved from traditional approaches to customization to more innovative ones.

Is this marketing ploy appropriate?

According to statistics, he definitely deserves your attention. According to Prime Group, 61% of consumers say they would prefer customized products and designs over mass production. As a result, consumers are willing to pay more money for product personalization.

With 3D printing, you can take customization to the next level and let your customers realize their vision of your product.

The golden rule of marketing is to always provide value. Each element of a marketing campaign must be considered in terms of value.

Likewise, delivering value should be your top priority if you're including 3D printing in your marketing campaign.

An excellent example of how 3D printing can provide value to a marketing campaign is the Belgian insurance company DVV.

At the center of their marketing campaign, DVV has used one of the most annoying problems faced by its customers - the loss of keys.

Clients were required to create a 3D scan of their keys and store it on the DVV server. And if they lost their keys, they could download a copy file and print a new key using any available 3D printer.

DVV clients had constant access to a copy of the key, so in the event of a recurrence of an unpleasant situation, they could print as many copies of the keys as they wanted. This is a great example of an ongoing marketing campaign as the company provides a one-of-a-kind service that benefits its loyal customers.

When you think about using 3D printing in marketing, you may think of it more as a tool for fun than anything that can provide a real purpose.

However, our experience proves that 3D printing can go far beyond entertainment when it comes to marketing.

It can take product personalization to the next level and involve people in the production process. It can also add value to your services and even help you spread an important message, as our campaign did during the French presidential election.

There are still many unexplored marketing opportunities in 3D printing, but this technology has already proven to be very influential and opens up new innovative perspectives.

Biography of the author. Daniela McVicker is a blogger with extensive experience writing articles on UX design, content planning and digital marketing. She currently contributes to the TopWritersReview project, where she helps individuals and organizations improve their writing, design and web content planning skills. Her posts are always filled with examples and actionable content that readers can put into practice right away.

This page has been translated using machine translation. Suggest the best translation

Previous

ShareNext

Similar publications

Lately, Anycubic has been surprising with a series of new, innovative and affordable 3D printers, and the Photon Zero is no exception.

If you're throwing a game night, why not make it as interesting and fun as possible? If you want to beat the Joneses who live next door, then it's time to level up the game. You can make it with a 3D printer to take your game night to the next level.

Read more3D printing as a marketing tool / Sudo Null IT News

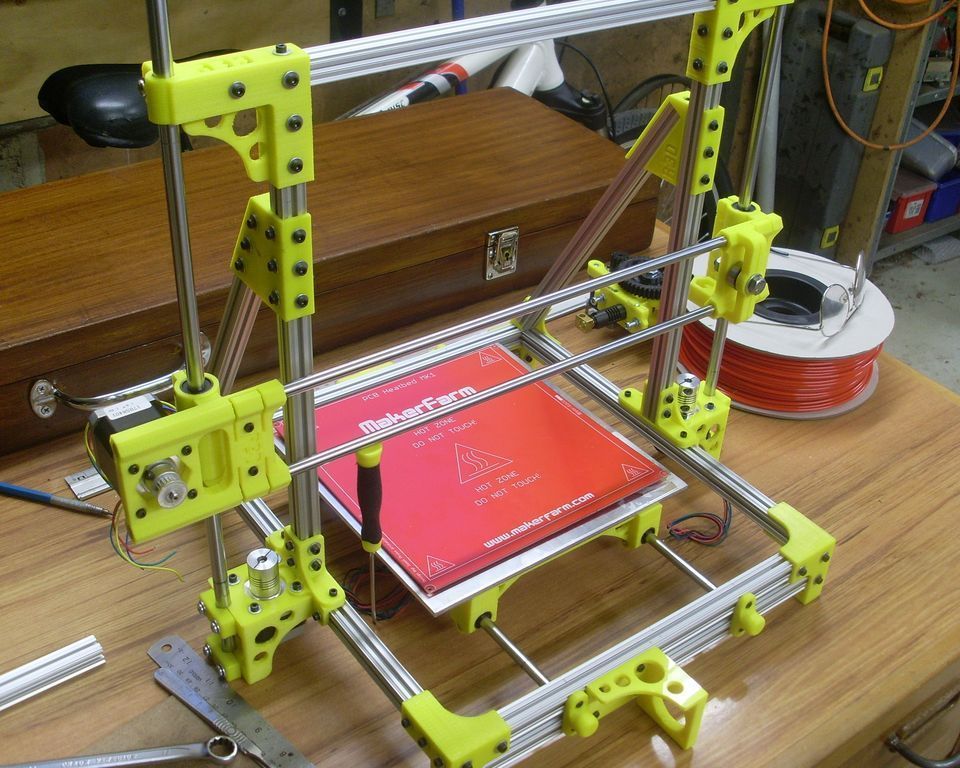

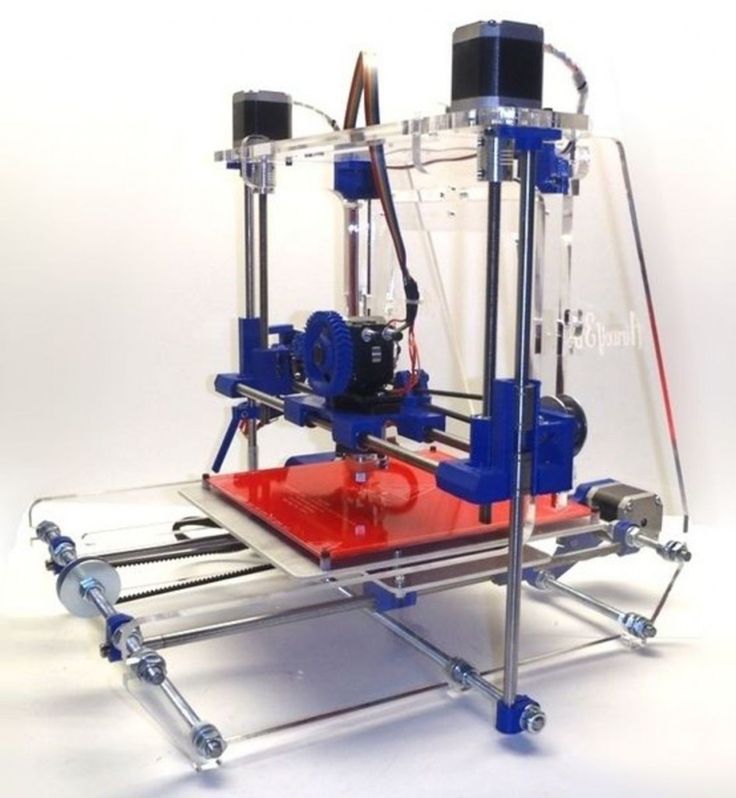

Although the history of 3D printing dates back to the 1980s, it is only in the current decade that 3D printers have become a widely available technology. They opened up new opportunities for small and large companies operating in various industries.

Over the past five years, people have tried to print buildings, prototype cars, medical implants, musical instruments, clothes, shoes, and even jewelry. For example, in the Netherlands, a bridge across one of the canals in Amsterdam is being prepared for printing. 3D printing is also being used by brands to promote their products. This is not at all surprising, since technological innovations of this caliber are able to interest a large audience. Here are some examples of the use of 3D printing in the promotional activities of brands in various fields.

This is not at all surprising, since technological innovations of this caliber are able to interest a large audience. Here are some examples of the use of 3D printing in the promotional activities of brands in various fields.

Print yourself and your family (Coca-Cola, ASICS and ASDA)

The most common use of 3D printing in promotional activities is at events where attendees can print miniature copies of themselves after being scanned. An example would be a 2013 Coca-Cola promotion in Israel promoting a new small bottle. The company held a competition in which participants had to create a mini-copy of themselves using a special mobile application. The winners were invited to the Coca-Cola plant, where real miniature copies of them were created (after a full scan of their bodies).

The same idea was used by ASICS to attract attention and promote the brand at the New York City Marathon in 2014. Previously, she invited registered participants to send their photo via e-mail (using a special website for this). The company then converted the first 500 images received into 3D models and printed them out. Athletes could pick up miniature versions of themselves at the ASICS booth. The marathon also featured a Twitter contest in which the 50 runners with the most tweets containing the #minimarathoner hashtag won miniatures of themselves.

The company then converted the first 500 images received into 3D models and printed them out. Athletes could pick up miniature versions of themselves at the ASICS booth. The marathon also featured a Twitter contest in which the 50 runners with the most tweets containing the #minimarathoner hashtag won miniatures of themselves.

For British supermarket chain ASDA, 3D printing became a standard service in 2015 at more than 50 of the brand's locations in the UK. This is the result of a successful experiment conducted in 2013 at selected locations (including York, Edinburgh and Manchester) and a nationwide 'tour' with a mobile scanner and printing equipment. The interest of visitors of ASDA supermarkets to the novelty was huge: the action attracted a large number of customers.

Thus, the decision was made to include scanning and 3D printing in the list of permanent services of photo studios located in the stores of this brand. The new service is being advertised in the same way as it was done for ordinary photography in the 19th century: customers are encouraged to immortalize important moments of their lives through unusual (at least for the target group) technology.

Huggies

The diaper brand Huggies also used 3D printing in its latest Brazilian campaign, doing so in a more humanistic manner than the examples above. An action was held on social media under the hashtag #CountingTheDays. Its main part was an Internet video showing the real story of a blind pregnant woman who, thanks to ultrasound scanning and 3D printing, was able to touch the face of her child even before his birth.

Obviously, this is an image campaign and an isolated case, but one can easily imagine that in the future such actions will be carried out on a larger scale. The promotion was very successful, with over 10 million views on YouTube within 2 months. In the case of Huggies, 3D printing has served as a key tool to evoke mother joy and audience emotion. Thus, the brand used modern technology to achieve its goals.

Volkswagen

Back in 2012, Volkswagen used 3D printing technology as the main focus of the Polo Principle campaign in Denmark. The company emphasized the use of VW 3D printers in the prototyping phase, encouraging the audience to design their own vehicles using tools on a dedicated website or pre-made graphics software templates. Among the projects submitted by users, the jury selected the best 40 and printed them especially for the fair at the Danish Design Center. The winner received a real car for use for two summer months (with a design developed by him personally). The action was carried out in social networks, as well as through commercials and Internet videos.

The company emphasized the use of VW 3D printers in the prototyping phase, encouraging the audience to design their own vehicles using tools on a dedicated website or pre-made graphics software templates. Among the projects submitted by users, the jury selected the best 40 and printed them especially for the fair at the Danish Design Center. The winner received a real car for use for two summer months (with a design developed by him personally). The action was carried out in social networks, as well as through commercials and Internet videos.

In the Polish campaign (April 2015) for the Volkswagen Passat, 3D printing technology also dominates. The protagonist of the video is a car advertising designer. He explains the benefits of using 3D printers (saving time and materials), praising their creativity and calling them "the technology of the future." By referring to innovation, Volkswagen creates a visible connection between its brand and 3D printing: since the company uses such “futuristic” solutions, it must be modern and innovative itself (although using this technology to create car prototypes has already become the standard).

Barnardo and Home for Christmas

Barnardo is a charity that helps children and young people in difficult circumstances. On the occasion of the Christmas holidays in 2012, Barnardo organized a fundraiser to support the homeless youth, encouraging people to donate money by organizing a contest, the prizes of which were miniature 3D models of philanthropists' houses placed in glass balls. To take part in this competition, it was enough to transfer any amount using a special website. Winners were chosen daily throughout the promotion.

The organization contacted them to confirm the details of the address and then used photos from the Google Maps platform to create 3D models of the houses. The lucky winners could send additional pictures to improve the accuracy of the match between the printed prototype and the original building.

The main idea of the campaign was to remind people what a joy it is to be at home for Christmas, pointing out that more than 75,000 young people were left homeless for the holiday. Using these messages, the organizers counted on the emotional reaction of the audience. At the same time, the use of personalized 3D printing was more pragmatic: a real reward was supposed to be an enticing motivator for donors.

Using these messages, the organizers counted on the emotional reaction of the audience. At the same time, the use of personalized 3D printing was more pragmatic: a real reward was supposed to be an enticing motivator for donors.

3D printing alone made it possible to create so many different models in such a short amount of time, and the media's mention of the use of innovative technology for charitable purposes only increased the success of this great initiative.

DVV insurance agency and digital key backup

In September 2013, the Belgian insurance agency DVV launched a new service dedicated to creating digital key models. The usefulness of such a solution is obvious: instead of having to call a locksmith, you just need to download and print the key using 3D technology. Files are stored in the cloud, which is not associated with personal data, so you don't have to worry about "leaks". Each time you download, you should also answer a personalized question. This is a good example of using modern technologies for the benefit of customers.

This is a good example of using modern technologies for the benefit of customers.

source: blog.netpeak.ua

Summary

3D printing is a relatively young technology, but modern advances can already be used to create quality products. Also, 3D printing today is of great interest from the public and therefore will serve as an effective tool for promoting and attracting attention to the brand. In addition, it is much easier to create personalized things with this technology, which makes a 3D printed product more attractive than a mass-produced one. As we saw from the examples in the text, it is an individual approach that makes the experience of participating in an advertising campaign unique and therefore important for its participant, who subsequently becomes a loyal client and buyer.

Souvenir products reflect the brand's image, and therefore require a responsible approach. When choosing 3D printing to promote a company, it is important to find a contractor who will fulfill such an order with high quality.