3D printing facts for kids

What is 3D Printing? - Facts For Kids, Science

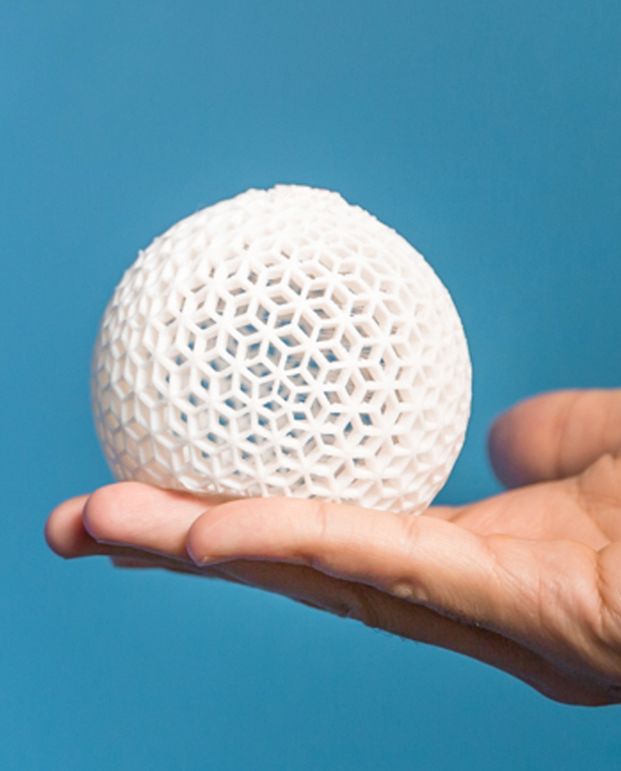

3D Printing, Image Credit: Flickr User fdecomite, via CC

There is a unique technology that has come up recently. It is very useful and a lot of fun to play with. No, It’s not just a new video game or a new phone. It has to do something with the way you print. Can you guess what it is? It’s a brand new technology called 3D printing!

What is 3D printing?

It’s a kind of technology that allows you to create three-dimensional objects. We talk of three dimensions when you can not only see the shape but feel and touch the object. It is pretty amazing! Consider your printer spewing out an object instead of a picture on a piece of paper.

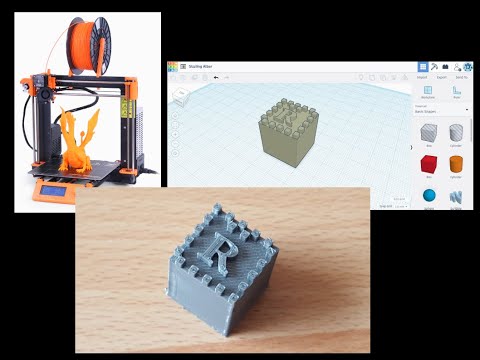

A 3D Printer by New York company Maker Bot Industries, Image Credit: makerbot.com

How does it work?

Well, it’s quite easy to understand. In fact, it is so easy to understand that it’s a wonder that people didn’t discover it sooner. Imagine taking something that’s easy to mold – like playdoh. Or mashed potatoes if you like being messy. Now think of some object you want to create. First you start with the bottom layer. And then add on a layer at a time to create it. Keep adding on until you get what you needed to make. Bingo! You end up with a three-dimensional object! It’s that simple to work with.

How is it useful?

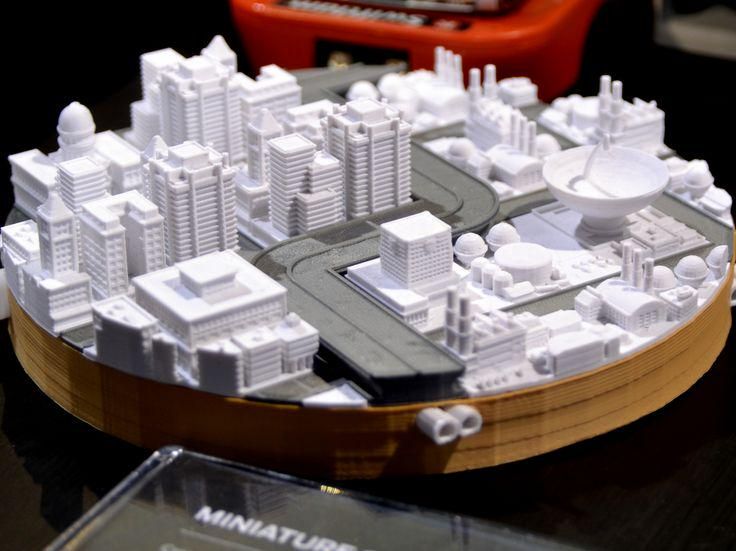

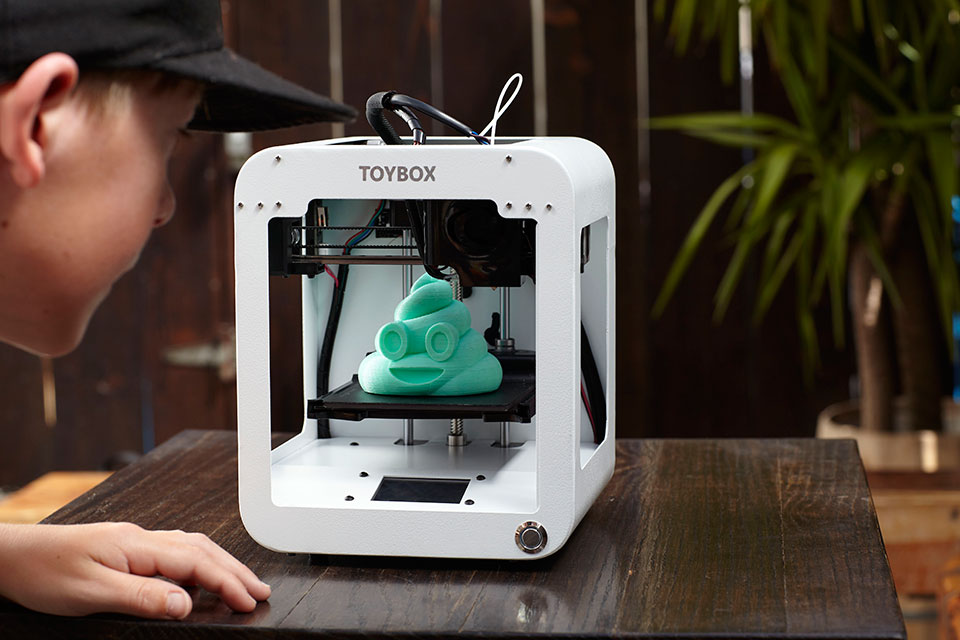

To begin with, a 3D printer can turn your drawings into 3D objects. You can also make toys and puzzles. Yes, with a 3D printer you can make all sorts of toys! Do you like building things and putting them together? Then you can make off brand lego blocks that can click together easily. You can make clothes for your dolls, or armor and weapons for your action figures. You can even make your own line of toys and sell them online.

A figurine, printed from a 3D printer, Image Credit: shapeways.com

Do your parents let you have a phone of your own? With 3D printing, you can print beautifully designed phone case and customize it to how you want it to look. Whether it has your favorite cartoon characters on it, or something silly your friends will laugh at.

Whether it has your favorite cartoon characters on it, or something silly your friends will laugh at.

A phone case via 3d printing, Image Credit: shapeways.com

Imagine having a 3D printer at home, or school! You can create things to help with school work. And with additional 3D models your school projects can become easier to understand. You’ll find that your only limit will be your imagination!

3D printing is beginning to get used in many big organizations. Recently, NASA tried its hand at creating a part of its rocket engine using this technology. Some big auto companies are using it to make new models of cars. Doctors are even trying to create organs using 3D printing!

So you see 3D printing is not just a child’s play. It is a technology that is here to stay!

Kinooze Learning

Publishing news and facts, re-imagined and written for kids. Since 2012.

Since 2012.

Related posts

Amazing Brain Facts For Kids

January 29, 2020Kinooze Learning

Interesting River Nile Facts

January 26, 2020Kinooze Learning

Fun Penguin Facts

January 20, 2020Kinooze Learning

Shopping Carts of the Future

March 23, 2016Shweta Sinha

What is 3D Printing? - beanz Magazine

What is 3D Printing?

By Tim Slavin / Coding Concepts Articles for Kids / February 2015 Issue

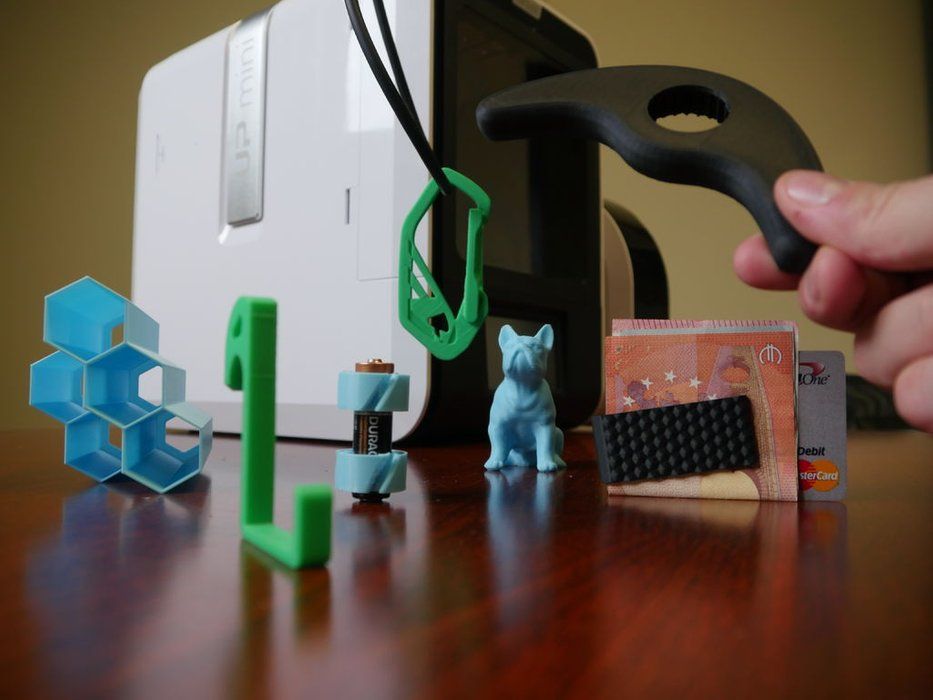

Creative Tools on Flickr

A basic introduction to 3D printing with concepts, examples, and a glossary of 3D terminology.

This article provides a high level overview of 3D printing. While the technology has been around for twenty five years or so, it was used primarily by engineers to create prototypes. More recently, 3D printing technology has become available to more people at a lower cost to create objects on demand locally.

While the technology has been around for twenty five years or so, it was used primarily by engineers to create prototypes. More recently, 3D printing technology has become available to more people at a lower cost to create objects on demand locally.

A Basic Definition of 3D Printing

We all know what printing is so let’s begin with the 3D part of 3D printing. 3D is shorthand for three-dimensional. When you print a page on a printer, there are only two dimensions: the front of the page and the back of the page. Three-dimensional printing adds a third dimension, volume.

3D printing uses a printer to create three-dimensional objects, for example, a cup or Yoda doll or phone case.

3D printing has these qualities:

- Objects are created by adding or depositing layers of material, not subtracting or cutting out pieces from a block of material.

- Because objects are created by adding layers, the computer file with details about your model must be converted into slices the printer will create layer by layer.

- Printing a three-dimensional object can take hours or days to complete, depending on the complexity and size of the object.

- Cost is based on materials used, among other factors. In contrast, if you buy a piece of wood then cut out pieces to create your object you pay for the original piece of wood.

How 3D Printing is Used

Today 3D printing is mostly done by business, students, and designers. Home or consumer use of 3D printing is mostly limited to people trying out the technology. However, there’s a lot of value in printing three-dimensional objects for students, designers, and anyone who needs a small object to demonstrate their ideas or create usable objects. Students as young as 10 years old also might use a 3D printer in shop class.

It’s the future uses of this technology which have people excited. For example, replacing the plastic back of your TV remote might involve going to a website, finding the part, then clicking a button to have the part printed locally where you can pick it up. Today you either replace the complete remote control or figure out where to get the replacement part which has been created elsewhere, likely overseas.

Today you either replace the complete remote control or figure out where to get the replacement part which has been created elsewhere, likely overseas.

More interesting, 3D printing makes it possible to experiment with fashion and other parts of our lives we take for granted. It might be possible to create medical implants, for example, using tissue from the patient.

Perhaps the most talked about, and misunderstood, use of 3D printing involves making guns. While it is possible, there are many factors that make printing a gun dangerous and uncommon. It’s easier and safer to create a light saber.

It’s also possible 3D printing will be used as part of a larger manufacturing process, for example, to create cars. In addition to a new set of cars offered every year by automakers, 3D printing might make it easy to buy a 1967 Mustang with the latest engine, safety, and other technologies from your local car dealer.

The same dynamic applies to shoes and frames for glasses, for example, where older designs unavailable today might be available for 3D printing at home or nearby at a print shop.

In addition, there is at least one group that provides students a way to use their school 3D printers to create prosthetic parts for medical use. Students get hands on experience creating something other than a phone case while helping others.

How 3D Printing Works

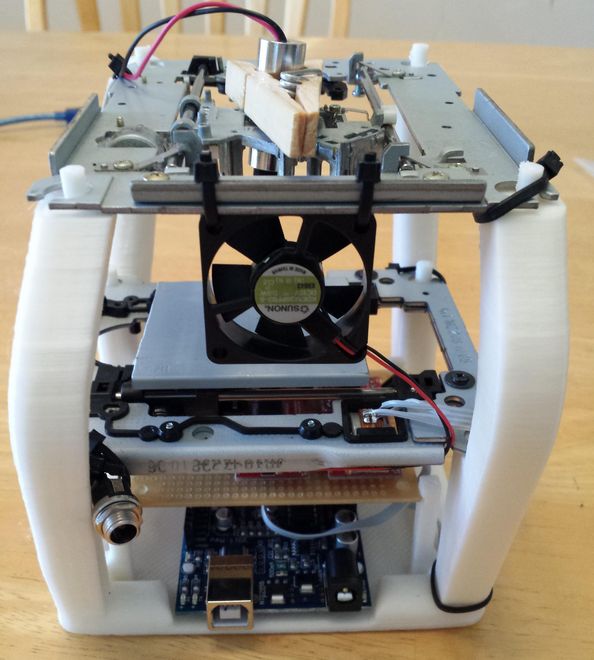

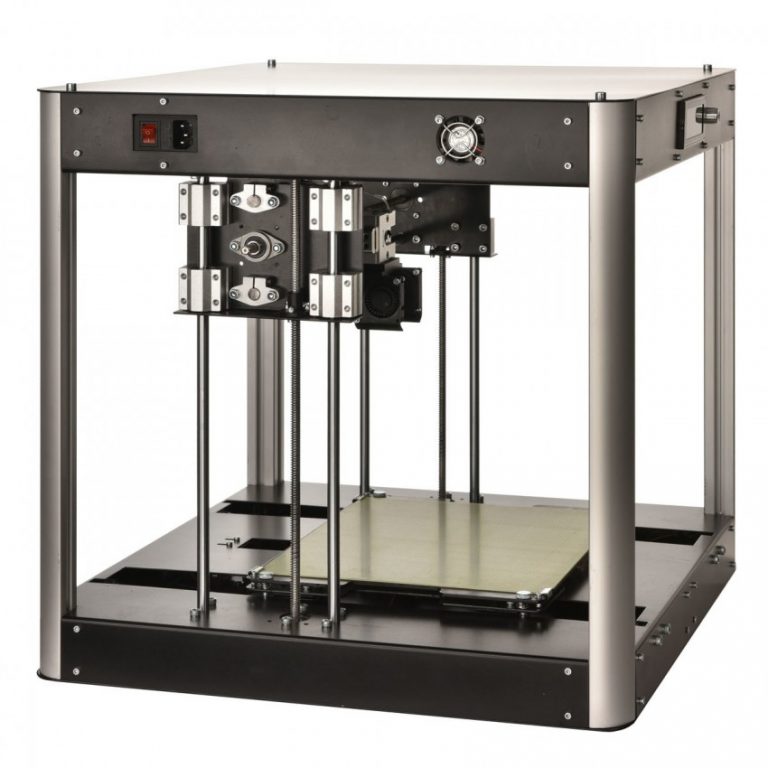

At a high level, a 3D printer takes material, usually plastic wrapped on a spool, heats the material, and then fuses the material layer by layer to build a three-dimensional object. The material is extruded, or pushed out and deposited.

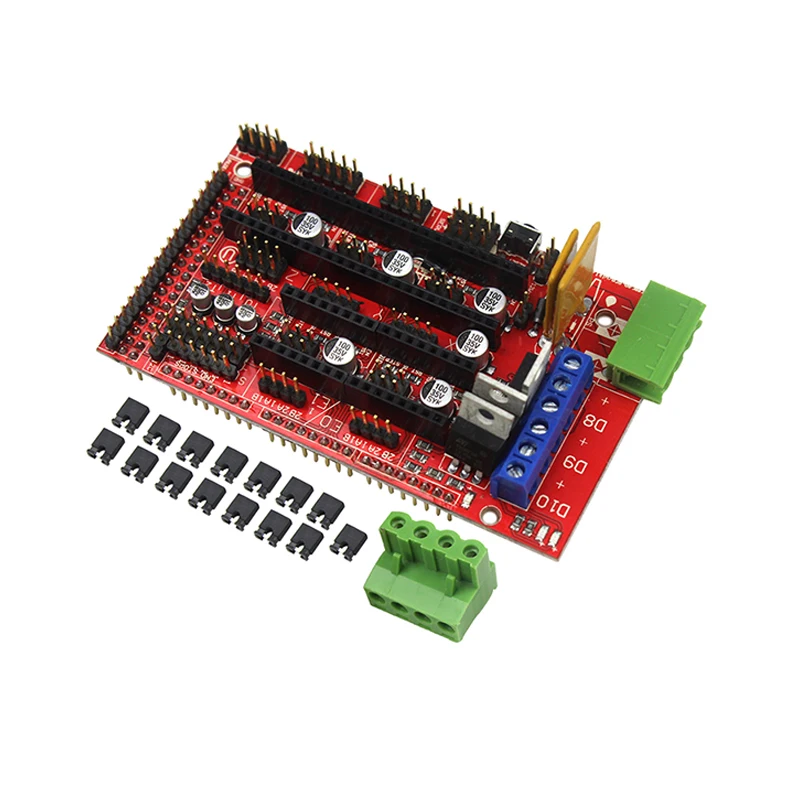

Precision is critical for 3D printers. The print head, pulleys, and extruder hardware must be aligned, as well as software dimensions translated to the correct real world dimensions used by the printer hardware.

The Printrbot printer is a low end printer you can build yourself to understand how all the pieces of a 3D printer fit together and work. Most people, however, use a pre-built printer where they adjust the location of the print head and build platform, as well as test the extruder heads emit the material used to print.

There are at least two kinds of additive 3D printing, resin and non-resin. Printing objects with resin uses laser technology to solidify layer by layer to create objects. It often is extremely costly and uses light and chemicals to cure the object. However, the results are more precise than non-resin printing.

When people talk about 3D printing, they’re mostly talking about non-resin printing. Instead of resin, lasers, and chemicals, non-resin printing uses plastic, food, ceramics, or other material and adds layer upon layer to create an object.

The 3D Printing Process

Printing a three-dimensional model is more complicated than opening up Microsoft Word and printing to your 2D printer. At a high level, to create a 3D model you follow these steps:

- Find a model or create a model with Blendr, SketchUp, or OpenSCAD software.

- Prepare your model for printing, for example, ensuring the model is watertight with no gaps.

- Create an STL file which converts your model into code the 3D printer understands, using Netfabb, Meshlab, or similar software.

- Print your 3D model, adjusting the printer as needed.

You might do some or all of these steps, depending on whether or not you have a 3D printer or use a printing service. There’s also lots of help if you use a printing service or find help online or use a local hacker collective.

Materials Used in 3D Printing

Non-resin 3D printers use mostly ABS and/or PLA plastic which becomes pliable when heated then solid. There are other possible thermoplastics used. Some printers use metal wire. And newer printers can print ceramics or with food materials. Materials are fed into the printer with a spool that has plastic or other material wound around the spool.

Resin 3D printers use custom formulated plastic resin poured into a tank. The resin is light sensitive and hardens when laser light heats a spot within the resin.

A Simple 3d Printing Glossary

These are key terms you will encounter with 3D printing:

3D — having three dimensions: length (width), depth, and height.

ABS — Acrylonitrile butadiene styrene (ABS) is one type of thermoplastic used in 3D printing. It becomes soft and pliable when heated. See PLA.

Additive — In 3D printing, the process of building an object by adding layer upon layer.

Build Platform — In non-resin 3D printing, the flat level surface used as a base to create a three-dimensional object. Resin 3D printing uses a tank filled with resin instead of a build platform.

Build Volume — The maximum length, depth, and height a 3D printer can use to build an object. Also called Print Volume.

CAD — Computer-Aided Design (CAD) software is used to create complete models, usually buildings, structures, and mechanical parts. CAD models are more precise than other types of models. CAD models also use NURBs to define curved edges. Polygon modeling and sculpture modeling software also are used to create 3D models for printing.

Extruder — A nozzle that takes thermoplastic wire or other material and deposits the material at a precise location with the print head.

FDM — Fused deposition modeling (FDM) is a process to use a fused material to deposit layer upon layer and create a three-dimensional object. FDM is trademarked. An alternative un-trademarked term is Fused Filament Fabrication (FFF).

FFF — Fused filament fabrication. An alternative term for FDM which is trademarked. See FDM.

Gantry — Larger non-desktop 3D printers use a steel frame made of connected beams to suspend the print head and other parts of the printer as objects are created.

Gcode — a programming language used by machine tools, including 3D printers. A 3D model must be saved as an STL file format before it can be converted to Gcode for printing.

NURB — Non-Rational Uniform Splines (NURBs) are a type of shape where the edges of the shape are splines (curves) controlled and adjusted by handles visible onscreen. You drag a handle to change the length and position of the curved spline edge.

You drag a handle to change the length and position of the curved spline edge.

OBJ — The OBJ file format is a common 3D model format used by modeling software. For 3D printing, OBJ files must be converted to STL file format then Gcode for printing.

PLA — Polylactic acid (PLA) is a thermoplastic used in 3D printing as an alternative to ABS. Because it is made from sugars, PLA when heated can give off a sweet smell. See ABS.

Polygon Modeling Software — Polygon modeling software creates models by connecting and combining polygon shapes at their edges. Polygon models rarely, if ever, use NURBs for curved edges. Instead, polygons are subdivided into new polygons to create the appearance of smooth round edges. Computer-aided design (CAD) and sculpture modeling software also are used to create 3D models for printing.

Print Volume — See Build Volume.

Quad Geometry — Quad geometry is used to describe 3D models as four-sided polygons, for example, in polygon modeling and sculpting software. Printing a 3D model requires converting quad geometry to the triangle geometry used by the STL (stereolithography) file format.

Printing a 3D model requires converting quad geometry to the triangle geometry used by the STL (stereolithography) file format.

Sculpting Software — Sculpting programs can be used to create 3D models. They are polygon modeling software optimized to handle large numbers of polygons, for example, to create human shapes and round edges. Computer-aided design (CAD) and polygon modeling software also are used to create 3D models for printing.

Slicing — The process of converting (slicing) a 3D model computer file into layers and then translate each layer into machine code used by the 3D printer to build the three-dimensional object.

Stereolithography — An additive 3D printing process building layer upon layer by curing a resin with a laser.

STL — The STL (stereolithography) file format describes a 3D model as a set of triangles. STL files are converted to GCode which 3D printers use to print objects. Most 3D modeling software lets you save or export files in STL format. Otherwise, files are saved in OBJ (object) format and netfabb software is used to create the STL file from the OBJ format.

Most 3D modeling software lets you save or export files in STL format. Otherwise, files are saved in OBJ (object) format and netfabb software is used to create the STL file from the OBJ format.

subD — A subdivision (subD) surface is used in polygon modeling software to provide rounded edges to otherwise square surfaces, for example, a cube with rounded edges. The subD surface allows a specified set of edges to be subdivided into additional polygons to provide the rounded edge.

Subtractive — Creating an object by removing (subtracting) parts of a single block of material.

Thermoplastic — Plastic that becomes pliable upon heating then solid when cooled.

Triangle Geometry — The STL (stereolithography) file format describes 3D models as a set of triangles. Models also can be describe with polygons or quad geometry.

Watertight — A 3D object model is watertight when the printer can tell the inside from the outside of the model. If you filled up the model with water, no water would drain out.

If you filled up the model with water, no water would drain out.

Also check out the 3D Printing Resources page for links to 3D printers, buyer guides, software, and more.

Learn More

3D Printing

http://en.wikipedia.org/wiki/3D_printing

https://www.youtube.com/watch?v=UwPWLCVekGc

Bits to Atoms: Your 3D Printing Software Options

http://www.tested.com/tech/3d-printing/460165-bits-atoms-your-3d-printing-software-options/

Gartner Says Consumer 3D Printing Is More Than Five Years Away

http://www.gartner.com/newsroom/id/2825417

3D Printing Doesn’t Live Up To The Hype Yet

http://www.forbes.com/sites/mitchfree/2013/03/12/3d-printing-hype-doesnt-equal-reality-ye/

The Sweet, Creamy Goodness of 3D Chocolate Printing From Hershey and 3D Systems

http://www.3dprinterworld.com/article/sweet-creamy-goodness-3d-chocolate-printing-from-hershey-and-3d-systems

Fused Deposition Modeling (FDM)

http://en. wikipedia.org/wiki/Fused_deposition_modeling

wikipedia.org/wiki/Fused_deposition_modeling

ABS/PLA Plastic

http://en.wikipedia.org/wiki/Acrylonitrile_butadiene_styrene

http://en.wikipedia.org/wiki/Polylactic_acid

http://www.protoparadigm.com/news-updates/the-difference-between-abs-and-pla-for-3d-printing/

http://en.wikipedia.org/wiki/Thermoplastic

Slicers and 3D Software

http://edutechwiki.unige.ch/en/Slicers_and_user_interfaces_for_3D_printers

http://slic3r.org/

8 Tips for 3D Printing with Sketchup

Includes a definition of “watertight” and solutions. Applies to any 3D software used to create models.

http://www.mastersketchup.com/8-tips-for-3d-printing-with-sketchup/

Sterolithography

http://en.wikipedia.org/wiki/Stereolithography

Author

Also In The February 2015 Issue

Concepts

What is 3D Printing?

A basic introduction to 3D printing with concepts, examples, and a glossary of 3D terminology.

Read Article

History

Gnomes, Gnomedozers, Spoonriders, and Zen Gnomes

Why are there so many gnomes available for 3D printing?

Read Article

Projects and Puzzles

3D Projects

From simple to complex, nine three-dimensional models you can download then print to explore 3D printing.

Read Article

People

Jill Hodges Talks about Fire Tech Camp

An American living in the United Kingdom, Jill Hodges talks about how she started a summer technology camp for kids.

Read Article

Best Practices

What 3D Models Print Best?

When you create a three-dimensional model for printing, it's important to know what prints well and what does not.

Read Article

Notebook

Two Books Teach Coding and Computer Science

One book teaches JavaScript in a fun way, the other computer science as fable.

Read Article

Projects and Puzzles

Lateral Thinking Puzzles

Practice problem solving skills programmers use every day.

Read Article

History

Dead Programming Languages

Of 8500 plus programming languages, many are forgotten or lightly used enough to be called dead programming languages.

Read Article

Best Practices

Where Can I Find Local 3D Printing Services?

It's possible to print your 3D project the same way you print a flyer at the UPS store. Here are several options.

Here are several options.

Read Article

Whatever good things we build end up building us.

— Jim Rohn

Language of the Month

VRML

The VRML language, or Virtual Reality Modeling Language, is ancient but still lets you create simple three-dimensional objects.

Read Article

Notebook

3D Printers

3D printers may be new technology but there are several printers individuals, schools, and businesses might buy.

Read Article

Learn More Links

February 2015 Learn More Links

Links from the bottom of all the February 2015 articles, collected in one place for you to print, share, or bookmark.

Read Article

News Wire

February 2015 News Wire

Interesting stories about computer science, software programming, and technology for December 2014 and January 2015.

Read Article

Concepts

Floating Point Numbers

While many people are familiar with floating point numbers in school math problems, they're very useful in computing.

Read Article

how it works and how it will change our lives

The world of 3D printing is very exciting. With the advent of affordable machines, creative entrepreneurs and start-ups, and new materials, this sector of the market is growing rapidly. Since the invention of the 3D printer by Chuck Hull in 1983, a wide variety of machines and technologies have been born and constantly improved. Here are 10 reasons that may convince you that this business is worthy of your attention, and that one day this technique may appear in your home.

1. 3D printing is a key technology in 2014

Expectations for this technology are high as the 3D market develops in both the consumer and enterprise sectors. According to research by Gartner, the sub-$100,000 printer market grew 50 percent in 2013, and another 75 percent so far. Currently, most companies use 3D printing to create prototypes of future products, but the number of those who use it in industrial design is growing.

2. 3D printers empower creators

Chris Anderson, Editor-in-Chief of Wired, wrote in his book Makers that the new industrial revolution is being driven by the use of open source and 3D printing. Many entrepreneurs use small-scale production to create limited batches of products. And thanks to donation sites, they can no longer wait for financial support from venture capitalists.

3. Focusing on individual needs as the next step in the development of 3D technology

Soon the question will no longer be how to print things, but what exactly we need to print. Focusing on individual needs (customization) will be the next milestone in the development of this industry, according to Pete Basilier, chief analyst at Gartner. Spare parts, toys, various designer items and any designs found on the Internet can be customized to the requirements of a particular user. Since the machine can only print one product at a time, this will be fairly easy to do. For example, on the Shapeways website, customers can directly contact designers and order anything from jewelry to home decor.

For example, on the Shapeways website, customers can directly contact designers and order anything from jewelry to home decor.

4. There are several 3D printing technologies

Fused Deposition Modeling (FDM). MakerBot is one excellent example of this technology. In this printer, a plastic filament is melted, followed by layer-by-layer application of the melt until the required part is obtained. The plastic from which the thread is made can be of two types - ABS, obtained from petroleum products, or PLA biopolymer, which is produced on the basis of vegetable organic matter.

Stereolithography. These printers use a laser to cure a special resin, and objects are also made in layers. This technology has a high prototyping speed, it does not need supports to support the part, but in general the support part must be removed manually.

Selective Laser Sintering (SLS). Here, a laser is used to sinter a metal powder, resulting in a solid structure. Each new layer is sintered on top of the already finished one.

Each new layer is sintered on top of the already finished one.

5. People 3D Print Anything

Visit the Makerbot Thingiverse website and you'll see all the creative ways to 3D print things. This is a society of "creators" who upload digital files or photos of objects made using 3D printers. There are about 100,000 models on the site and the number is growing every day. From sci-fi movie helmets to flower pots or pendants, the variety of these objects is endless.

6. The ethical issues of 3D printing will be widely discussed

Be prepared for the fact that in the near future there will be a big discussion on the political, ethical and religious issues related to 3D printing. This is especially true for "bio-printing", which is developing rapidly. Scientists at Cornell University successfully printed a human ear last year, and Scottish scientists are developing a way to print embryonic stem cells.

Another problem is weapons. In 2012, a person shared online 3D drawings for making a handgun, which were downloaded over 100,000 times before the US State Department closed the giveaway. The gun was capable of firing, and the author was on the Wired list of the most dangerous people on the planet.

In 2012, a person shared online 3D drawings for making a handgun, which were downloaded over 100,000 times before the US State Department closed the giveaway. The gun was capable of firing, and the author was on the Wired list of the most dangerous people on the planet.

7. Low prices will stimulate consumer demand

Small companies have begun to produce their own 3D printers, and prices for these machines are constantly falling. The Makerbot Compact Printer is already available for $1,375. Of course, for many of us, this price seems a bit high, but for this technology, this is more than a reasonable cost.

"Of course, there will always be people who are willing to invest in new technology and who are willing to buy their own printer," Basilière said. “But as the prices for this technique will decrease, the number of such buyers will grow.” He added that industrial printers are unlikely to become cheaper quickly, but their parameters (speed and quality of work) will be constantly improved.

8. HP enters the game on the side of 3D technology

Typically, 3D printer manufacturers are small specialized companies, but there is also a giant: HP, which plans to launch these products for the mass market. The company has already built a 1.5-meter-tall prototype 3D printer in its Palo Alto lab, and plans to put it into production later this year.

“3D printing is still in its infancy,” Meg Whitman, HP's CEO, said at a conference in Bangkok last year. “This direction promises great opportunities, and we are working on it. We'll have it by the middle of next year."

9. 3D printing will completely change manufacturing as we know it

Open source electronics allow companies to experiment with both the design and the design of future products. Ultimately, there will be no need to design each element in-house, and send all the details of the future design to the customer, since they can be produced right on site. Accordingly, the logistics will be greatly simplified.

Accordingly, the logistics will be greatly simplified.

Most companies are not yet adopting this technology because it will revolutionize the industry. According to Basilier, the key to long-term growth here is the range of materials that can be used in 3D printing. It is still narrow, but constantly growing.

10. 3D printing has the potential to disrupt many industries

So 3D printing will be the new word in mass production, but what else will this technology affect?

Almost everything. Teachers will be able to print any manuals in schools. Artists will receive a fundamentally new tool for work. Doctors will be able to do everything necessary for treatment in clinics. And parents - in a matter of hours, print new toys for children to replace broken ones, or make home decor elements.

Interesting facts about 3D printing and 3D printers - 3DDevice

The most interesting facts about 3D printing and 3D printers

3D printing technology is very versatile and often used for quite unusual purposes. Of course, this leads to interesting results that attract a lot of attention. But all events cannot be covered, and some achievements remain behind the scenes. We believe that this is wrong and in this section we want to list interesting facts about 3D printing that you may not have known. We will tell you about something that goes beyond the usual applications of 3D printing, but, nevertheless, is of great practical value.

Of course, this leads to interesting results that attract a lot of attention. But all events cannot be covered, and some achievements remain behind the scenes. We believe that this is wrong and in this section we want to list interesting facts about 3D printing that you may not have known. We will tell you about something that goes beyond the usual applications of 3D printing, but, nevertheless, is of great practical value.

Interesting facts about 3D printing

Let's start with some interesting facts about 3D printing. Of course, many more points can be attributed here. It all depends on the awareness of people. Indeed, today everyone already knows that with the help of a 3D bioprinter it is possible to create artificial organs and living tissues, as well as a lot of other similar information. Therefore, we have chosen revolutionary techniques that are only gaining popularity and are of particular interest and value in certain circles.

1. 3D printed all-in-one pills

In the US, 3D printed pills for epilepsy can already be found in pharmacies. And scientists do not intend to stop at the production of only one drug. Currently, new methods for 3D printing of medicines are being developed, and researchers pay special attention to SLA technology. The main advantage of using 3D printing for this purpose is the possibility of gradual release of active substances. That is, such a tablet can be programmed for sequential dissolution over a certain time. If you need to take several different medications a day, this can be a real breakthrough in treatment.

And scientists do not intend to stop at the production of only one drug. Currently, new methods for 3D printing of medicines are being developed, and researchers pay special attention to SLA technology. The main advantage of using 3D printing for this purpose is the possibility of gradual release of active substances. That is, such a tablet can be programmed for sequential dissolution over a certain time. If you need to take several different medications a day, this can be a real breakthrough in treatment.

2. 3D food printing

You probably already know about this, but this fact is worth talking about in more detail. To date, this branch of 3D technology is not too developed, but progress is moving forward rapidly. There are already several 3D printed food restaurants operating around the world, and some culinary specialists are using 3D printing to bring their creative ideas to life. On top of that, 3D printed products represent a real possibility for astronauts. Indeed, with the help of 3D printing, it is possible to endow food with the maximum amount of useful substances and serve it in the most convenient way.

3. 3D printing of living tissues

Interesting facts about 3D printing are simply unthinkable without this item. 3D bioprinting is a real panacea in the world of medicine. With its help, scientists intend to create full-fledged living tissues suitable for implantation into the human body. Experiments are now being actively conducted on the manufacture of artificial organs, bones, blood vessels and even hair using living cells. And such initiatives are extremely successful! Of course, mass 3D printing of full-fledged organs is still a long way off, but we are definitely moving in the right direction.

4. Space

3D printing promises to be a major technology in space. With its help, people will not only conquer the expanses of the universe, but also explore new territories. 3D printing is used to produce parts for rockets, satellites and other spacecraft, and the ISS even has its own 3D printer that works in zero gravity. Moreover, 3D printing is being considered as a potential technology for creating human settlements on the Moon and Mars. Who knows how far 3D technology will take us.

Who knows how far 3D technology will take us.

Don't miss also:

Interesting facts about 3D printers

This is not the end of the facts about 3D printing, but we decided to highlight some of them in a separate paragraph. Here we will write interesting facts about 3D printers that you might not know.

1. Industrial robots-manipulators

The following approach is increasingly used in factories: industrial robots-manipulators adapted for 3D printing are used as 3D printers. This is interesting primarily because the construction area in such cases is practically not limited by either the dimensions or the X, Y, Z axes. Some companies are even touting the approach as "5D printing" while the work platform is also in motion. And recently, a presentation of the concept of a 3D printer with six axes took place, which allows printing products without supports.

2. 3D printer tattoo machine

Tattoo artists immediately noticed the possibilities of 3D printing and decided to use it for their own purposes. Today, there are several projects for the use of 3D printers as tattoo machines at once, and their results are quite successful. Needless to say, such an application is extremely specific and is unlikely to be widely used. But the idea is interesting.

Today, there are several projects for the use of 3D printers as tattoo machines at once, and their results are quite successful. Needless to say, such an application is extremely specific and is unlikely to be widely used. But the idea is interesting.

3. Huge 3D printers and smartphone printers

3D printing technology is more extreme than ever. This is due to the huge functionality of the technique, which allows it to be applied in a variety of directions. 3D printers print houses, huge metal structures and other large-scale structures. But in parallel with this, the developers also take care of the production of smaller parts. So, the whole world is waiting for a 3D printer for smartphones, the concept of which rocked Kickstarter some time ago. And scientists print microscopic structures and full-fledged electronics, giving odds to professional manufacturers.

4. 3D printer with artificial intelligence

For such an unusual development, the already mentioned robotic arm was used, for which not only the control code was written, but also the artificial intelligence algorithm.