3D print bowing

What Causes 3D Print Warping and How to Prevent It

3D print warping is a common problem in fused deposition modeling (FDM) that causes parts to deform on the print bed. If you’ve ever noticed that the base of your 3D print is curling up and the corners are unsticking from the build plate, that’s warping. The good news is that there are several tips and tricks to prevent warping and improve your chances of a successful, warp-free 3D print.

What causes 3D print warping?

3D print warping happens when extruded filament layers on the 3D printer build plate cool too quickly and shrink. This causes the plastic material to contract and pull away from the build plate, resulting in warping (or curling, as it is sometimes known).

We can understand the problem of warping better if we zoom out a bit and look at the FDM process on the whole. In FDM 3D printing, a heated extruder deposits melted filament onto a print bed. This filament is made from a thermoplastic, a type of material characterized by its ability to melt into liquid form and resolidify when cooled. This means that in the printing process, as each layer is deposited, the filament hardens as it cools, but it also shrinks.

Thermoplastic filament shrinks as it cools; if it shrinks too quickly it can lead to warping

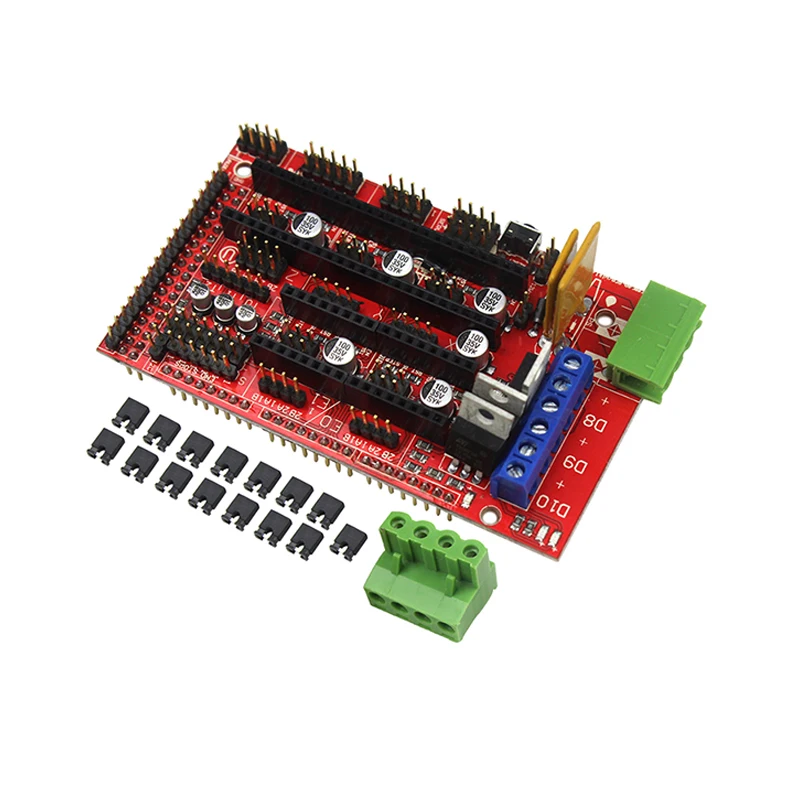

Warping occurs when the cooling process happens too quickly or unevenly and 3D printed layers shrink and pull on less solidified layers, ultimately lifting the first layer off the build platform and causing deformation. Though it is possible to experience warping with any type of 3D printed part, it is more common when 3D printing larger parts or parts with a large surface area. Certain 3D printing filaments are also more prone to warping than others. Typically, materials with a higher printing temperature, like ABS, suffer more from shrinkage because the temperature difference as they cool is more extreme.

How to fix 3D printer warping?

Fortunately, the chances of 3D print warping can be mitigated and 3D print outcomes can be improved using a few key techniques.

Bed Adhesion

One effective way to minimize the risk of 3D print warping is to improve your 3D printer’s build plate adhesion. Good bed adhesion will keep your 3D printed part stuck to the build surface and prevent the first layers of the print from curling up as they cool.

Bed adhesion can be achieved in a few ways. For example, there are dedicated 3D printer adhesives that can be applied to the build plate before printing. Many also opt for more DIY adhesives, like glue sticks and hairspray. A third option is tape, which is placed on the build plate surface. Painter’s tape is a popular option because it can be removed easily and the porous texture of the non-stick side keeps filament stuck down.[1] Kapton tape is also commonly used to encourage bed adhesion.

If you are using adhesives on your 3D printer, be sure that the print surface is clean before and after printing. Glue residue can cause an uneven print surface, potentially impacting calibration and the quality of future prints. It is also a good idea to try a test print if you are using a new adhesive to ensure it keeps the bottom layer of the print down but can also be easily unstuck when the print is done.[2]

It is also a good idea to try a test print if you are using a new adhesive to ensure it keeps the bottom layer of the print down but can also be easily unstuck when the print is done.[2]

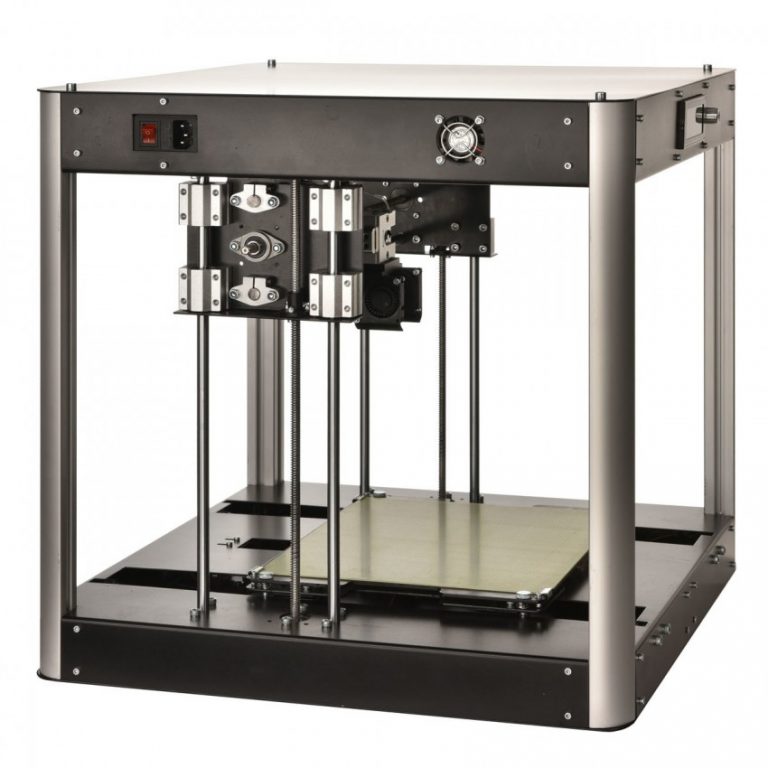

An enclosed build chamber can reduce the risk of warping by maintaining a stable print temperature.

Temperature

Because cooling filament too quickly is what causes shrinkage and warping, it is key to control the temperature of your build as much as possible. 3D printer temperatures can be regulated using different methods or a combination of approaches. One of the most effective tricks for improving bed adhesion is to use a heated build plate. Each type of filament will have its own recommended bed temperature for good adhesion—for example, PLA works best with a heated bed at a temperature of between 60 and 70°C, while ABS requires a hotter print bed of between 100 and 120°C.[3]

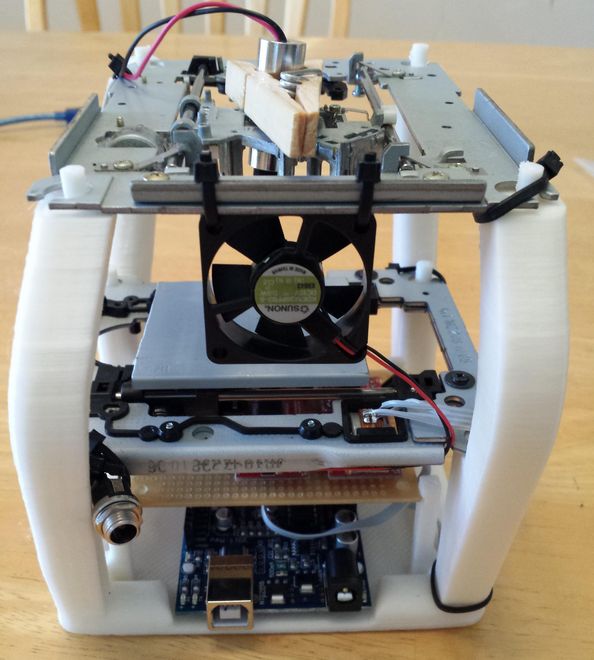

Using an enclosed print chamber can also help to maintain an ambient temperature throughout the printing process and stop 3D printed layers from cooling too quickly. Many 3D printer models have a built-in enclosed chamber, but those that don’t can still benefit from a DIY enclosure. Other ways to improve temperature consistency in your 3D printer are to adjust cooling fan speed settings (especially for the first layers of a print) and keeping your room temperature as ambient as possible (i.e. keeping cold air out by closing windows).

Many 3D printer models have a built-in enclosed chamber, but those that don’t can still benefit from a DIY enclosure. Other ways to improve temperature consistency in your 3D printer are to adjust cooling fan speed settings (especially for the first layers of a print) and keeping your room temperature as ambient as possible (i.e. keeping cold air out by closing windows).

Brim or Raft

Brims and rafts are tried and true techniques for boosting bed adhesion, especially for ABS and other high-temperature filaments. These 3D print features are added in slicer software right before printing and have several functions.

Specifically, a brim is a 3D printed border that connects to and goes around the edges of a 3D printed part. Brims are typically a few millimeters wide and consist only of 1-2 layers. They increase the footprint of the 3D printed part and anchor its edges to the build platform. A raft is similar, only it is also printed under the 3D printed part, acting as a base for it.

Brims and rafts are especially beneficial for 3D printed parts with unbalanced geometries or small footprints, as they can stabilize the print and secure it to the build surface. Both brims and rafts must be removed after printing, either by hand (by peeling them off) or using a tool. Printed parts with brims or rafts may require additional post-processing to achieve a smooth first layer.

3D printed brims can help to anchor the printed part down to the build platform.

Slicer settings

The risk of warping can also be reduced substantially by implementing the right print settings for the first layers of the printed object. Most slicer software programs allow you to adjust the print speed and layer height specifically for the first layer. A slower print speed for the first printed layer of a build will help to ensure that the filament sticks to where it has been deposited and is not pulled by the nozzle as it moves. Choosing a slightly thicker layer height for the first layer can also improve bed adhesion and help reduce any leveling inconsistencies.

Another print setting that can influence warping is fan speed. Fans are built into some FDM 3D printers and ensure the build space does not get too hot. By tweaking fan speeds you can maintain closer control over print cooling. For example, fans can be programmed to turn on only after the first few layers of a print have been deposited. This helps the first layers cool slowly and evenly on the print bed.

Conclusion

3D print warping is a frustrating problem most makers will encounter at some point or another. By following the tips and methods laid out in this article, however, you can ensure good bed adhesion, consistent printing temperatures, and ultimately reduce warping and improve print quality overall.

References

[1] TapeManBlue, 2022. “The Complete Guide to Blue Tape for 3D Printing”. [Internet]

https://tapemanblue.com/blogs/tips-tricks/blue-tape-for-3d-printing [Accessed March 31, 2022].

[2] Ultimaker, November 10, 2020. “Build plate adhesion: How to get your print to stick to the build plate”. [Internet] https://support.ultimaker.com/hc/en-us/articles/360012015680 [Accessed March 30, 2022].

[3] Simplify3D, 2022. “Warping”. [Internet] https://www.simplify3d.com/support/print-quality-troubleshooting/not-sticking-to-the-bed/ [Accessed March 30, 2022].

Prevent Warping - You Can Do It

In particular, if you frequently print with materials like ABS and HIPS, over time you will get annoyed by what is known as “warping”. This is an unsightly misprint in which part of the model bulges or warps. In the worst case, the print is completely detached from the bed.

Especially with functional parts, the accuracy of which is of great importance, warping can quickly mess up the entire print. Mostly, models with a large contact surface on the print bed are affected. In this article, you will find out what causes warping and how you can avoid the “warp effect”.

Warping occurs due to uneven temperature distribution and the resulting tension in the substrate. Since ABS or HIPS filaments warp more at uneven temperatures than PLA, for example, and tend to shrink during cooling, the warp effect can be observed more frequently with these materials.

If an ABS print is cooled down at room temperature, it can shrink by almost 1.5%. The larger the print model, the more unevenly it cools, the layers shrink unevenly and parts of the print bulge.

So the reasons for warping mostly have to do with temperature:

- Unevenly heated print bed

- Too fast printing process

- Incorrect location of the 3D printer (for example at the window)

- Incorrect slicer settings

- Contaminated print bed

1. Use a heated bed

Use a heated bed

A heated print bed keeps the model evenly warm during the printing process by equalising the temperature in the print object. At the same time, it also ensures better bed adhesion. If possible, the bed temperature should be just below the filament softening point, because: The higher the temperature of the bed, the lower the temperature difference in the individual filament layers and the resulting warping. However, be careful not to set the heating bed temperature too high, otherwise you risk plastic deformation of the model and intensification of the warp effect.

In addition, always preheat your heating bed and do not print immediately without waiting for a suitable temperature so that the heat can stabilise to some extent. The print bed can even be insulated for optimal heat distribution; temperature-resistant insulation from the automotive sector is very suitable for this.

2. Print in an enclosed print chamber

A closed housing keeps the temperature inside the model constant during the entire printing process. When printing with a heated chamber, you should always make sure to keep the doors closed during the printing process so that the heat inside cannot escape. You can find a suitable 3D printer cover in our shop.

When printing with a heated chamber, you should always make sure to keep the doors closed during the printing process so that the heat inside cannot escape. You can find a suitable 3D printer cover in our shop.

3. Choose the right location for your 3D printer

A 3D printer should ideally be set up in a place where there are no drafts. A window seat, in the hallway or next to a door is therefore less ideal, as drafts of air unintentionally cool the print. Basically, you should regulate the room temperature by keeping windows and doors closed as much as possible.

4. Turn off the material fan for the first few layers

To prevent the bottom layers from becoming detached from the build bed, you can turn off or slow down the fan while the first layers are printing. Keep in mind, however, that the melted filament still needs to solidify quickly enough to allow a precise build-up of the layers.

5. Improve bed adhesion with adhesives or a suitable bed surface

As already mentioned, the lack of adhesion of the print to the bed can also lead to warping. To avoid warping your prints, use a build plate with good adhesion or improve your adhesion with adhesives, glue, blue tape, or a print bed coating.

To avoid warping your prints, use a build plate with good adhesion or improve your adhesion with adhesives, glue, blue tape, or a print bed coating.

Since most FDM printers are equipped with a glass or aluminium surface and the surfaces are often too smooth for printing thermoplastics, it can be worthwhile to use a flexible plate as a print bed upgrade.

6. Adjust your slicer settings

Not only can the temperature and print bed adhesion affect the bulging of your 3D print, but the wrong slicer settings also have an impact on your print quality.

- Reduce your printing speed

Especially if you have frequent problems with warping, you should try to reduce your printing speed. At the same time, the nozzle temperature should also be reduced accordingly as the extra heat is not heated with this lower flow.

- Use rafts and brims

A raft can help with larger and a brim with smaller components to avoid warping by building up a base layer, the edges of your model are “held” and these warp less. The raft can easily be detached from the model after printing.

The raft can easily be detached from the model after printing.

7. Thoroughly clean your print bed

If you often have problems with warping or your prints do not adhere to the bed, clean it thoroughly with the cleaning agents provided. Stubborn residues such as glue can be removed with chemical solvents.

If your build platform is uneven or damaged, you should definitely replace it.

8. Use good quality filament

Last but not least, it should be said that you should always use high-quality filaments for successful 3D printing - and always adhere to the material-dependent application instructions. Only a high-quality filament that has been used correctly can achieve a beautiful print result.

Shirts Summer Men Bow T Shirt Tuxedo Retro Tie 3D Print T Shirt Casual Short Sleeve Streetwear Funny Fake Suits

9000 9000 9000 9000 9000 9000 9000 9000 9000 9000)0003

T-shirts, sweatshirts and sweatshirts, sweaters, jackets and coats, jeans, trousers, shorts, overalls and overalls, sportswear and two-piece suits (for men and women). We also sell shoes, fashion accessories and bags.

We also sell shoes, fashion accessories and bags.

Company Profile

We are a cross-border e-commerce company that integrates several overseas online and offline sales channels.

About Shipping

* Generally, all orders will be processed within 3-5 business days after DHGATE confirmation.

* When placing an order, the item will be shipped via your chosen EPACKET, SFEXPRENT, YANWEN, CHINA POST AIGHAIL, EMS, DHL, FEDEX, USPS. After sending the package, the delivery time depends on the carrier, plus international transportation, delivery may be delayed, I hope you can understand and endure patiently. Thanks in advance.

* You can track your package on 17Track. If you can't find tracking information about it, please contact us.

customer service:

1. If you need help online chat (instant message) or email, please contact us as soon as possible, we will reply immediately after reading.

2. All photos are taken in kind. The material of the products meet different standards, the latest technology, new styles, sophisticated products, reliable performance, easy to use, reasonable prices, directly controlled by foreign trade factories, convenient, stylish and easy to use. Wear, suitable for different occasions, display angle and color and shooting may differ from the actual product. Take the actual product as the standard and bring the fashion trend.

Wear, suitable for different occasions, display angle and color and shooting may differ from the actual product. Take the actual product as the standard and bring the fashion trend.

3. If you have any questions before or after submitting the order or receiving the package, please contact us first, instead of opening a dispute, we will do our best to solve it for you.

Give it back

* Upon receipt of the goods, your early confirmation will be highly appreciated

*Your feedback is very important to us. If you are satisfied with our products and services, we sincerely hope that you can maintain a positive review of all 5-star feedback. We will be very grateful for our efforts to improve the quality of our services. You can also get more attention to our products and stores. We will continue to provide you with quality and satisfactory service.

* If you have any questions about our projects or services, please feel free to contact us before leaving a negative feedback, we will do our best to solve any problems and provide you with the best customer service.

QA.

Q: When will my order arrive?

Answer: Delivery depends on the destination and the carrier you choose, and it is international transportation, it takes time, please understand and wait patiently.

Q: What if I want to change my address?

A: The address cannot be changed after the package has been shipped, so please check if your address is correct before submitting the order.

Q: What should I do if I receive an incorrect/damaged product or an empty package?

Answer: We will check and check carefully, but if this happens, please contact us first, instead of causing a dispute, we will do our best to solve it for you.

Q: What should I do if I ordered the wrong item?

Answer: Please contact us ASAP and let us know what you really need, we can change it for you before delivery.

Q: I can't track the package, what's wrong?

Answer: Usually the tracking information will be updated 2-5 days after shipment. If it still cannot be tracked, please contact us and we will check for you as soon as possible.

If it still cannot be tracked, please contact us and we will check for you as soon as possible.

Q: When can you ship my order?

Answer: If your order has been paid for and confirmed by DHGATE, we will ship it within 3-5 business days.

American designer for the first time printed completely 3D-printed sneakers - Moscow 24, 03/23/2022

Shoe manufacturers are increasingly turning to 3D printing technologies. What is the future of the industry, as well as how 3D printers will change the patterns of production and consumption, argues scientific observer Nikolai Grinko.

Photo: yankodesign.com

Virginia Tech graduate Calan Kerner unveiled the world's first fully 3D printed sneaker. They are made from a special material that can be completely recycled. Shoes are a monolithic product, a bit reminiscent of clogs. But, unlike traditional Dutch shoes, it is made at a modern technological level and in a futuristic design.

In general, shoe companies have been experimenting with 3D printing for a long time, but most often only soles and decorative elements are made using this method. This is completely logical: at the current stage of development, 3D printers cannot work with either textiles or leather. Their main working material is plastic, but this will not always be the case.

This is completely logical: at the current stage of development, 3D printers cannot work with either textiles or leather. Their main working material is plastic, but this will not always be the case.

Printing technologies are constantly improving, and if you think about what such machines can work with today, you can find liquid concrete (for building construction), dough (for baking) and even living cells (for printing artificial organs) on this list. Printers, of course, are unlikely to learn how to weave a fabric from threads, but some time will pass and they are guaranteed to be able to "print" something very similar to textiles. That's when amazing things start to happen.

It took half a century for computers to become personal, and today there is no industry left that does not use them. One can try to imagine what will happen when a personal 3D printer appears in every home and learns how to stamp objects from any materials. Perhaps the very first thing that people will print for themselves is clothes and shoes.

The usual dimensional grids will disappear, since each item will be made exactly for a specific user. All mass producers will have to urgently and deeply rebuild: they will need to produce not shirts and sneakers, but files that are accepted by 3D printers.

The buyer will go to the store's website, choose the style and color, pay for the purchase and immediately send it to print. The phrase "downloaded new jeans" will become commonplace and completely familiar. Not only that, there will immediately be a market for illegal files, just as there is now a huge industry of fake Nike or Dolce & Gabbana. Manufacturers will actively fight against piracy, but they will not be able to win - fakes have always existed and are unlikely to disappear in the near future.

Photo: yankodesign.com

The good news is the coming flowering of creativity and self-expression. In fact, if you can make clothes and shoes right at home, why make it the same as everyone else? Experiment as much as you like. In the same way that today anyone can make a website from ready-made blocks with their own design and content in half an hour, in the future it will be possible to get a coat or skirt of a personal style and color.

In the same way that today anyone can make a website from ready-made blocks with their own design and content in half an hour, in the future it will be possible to get a coat or skirt of a personal style and color.

There will most likely be smartphone apps (if smartphones themselves don't disappear by then) in which users will invent their own garments, share files, edit finished products, and so on. In the end, a new fashionable "bow" can be printed daily, handing it over for processing in the evening. Most of the "self-printed" models will, of course, be strange, defiant or simply terrible, but successful and even brilliant ones will appear among them. Fashion designers will have to make room under the onslaught of self-taught.

Retail clothing and footwear stores will disappear - there will be no point in them. The textile industry, if it does not disappear altogether, will be seriously restructured. Logistics, storage, construction and rental of warehouses - all this will become completely unnecessary.