3D printer optics

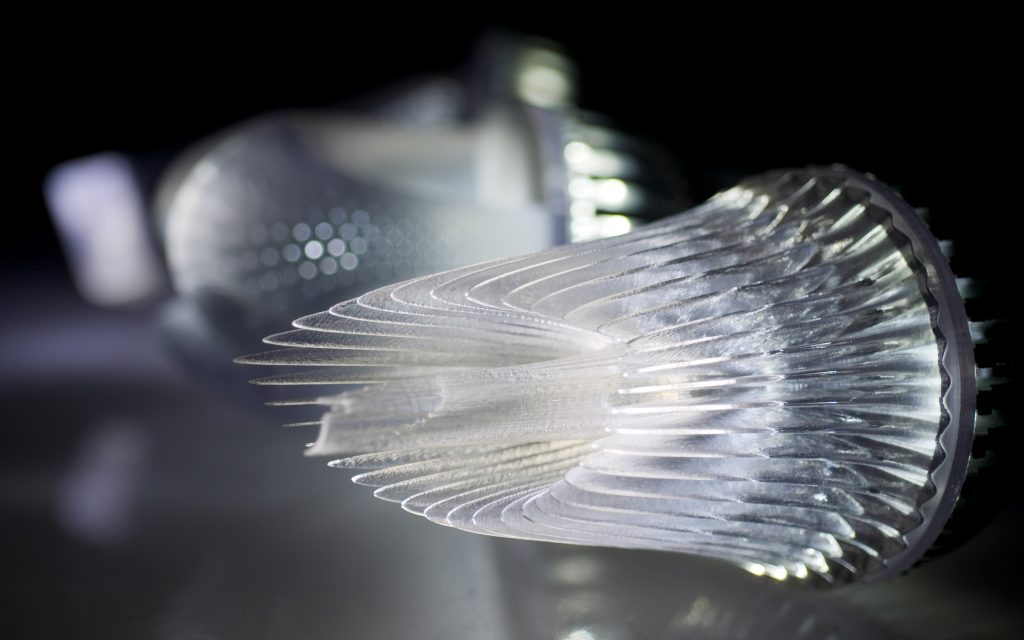

Printed Optics – Luximprint

Skip to contentPrinted Opticsadmin2022-11-23T12:38:40+00:00

3D PRINTED OPTICS

3D printing optically functional plastics is one of the main business areas of Luximprint. We offer optics design and rapid prototyping of illumination optics for lighting design and engineering purposes. With only one step from CAD-to-Optic, prototypes and start-up series of inspirational and functional optical plastics are now available in a short time frame, without the costly commitments to upfront tooling and minimum order quantities!

GET IN TOUCH

3D PRINTED OPTICS: OPTICALLY SMOOTH AND FUNCTIONAL PLASTICS STRAIGT FROM THE PRINTER

Additive optics manufacturing is a totally new way of getting your custom illumination optics prototypes rapidly available: speed, cost-efficiency and flexibility are the key drivers behind our process.No longer, the heavy upfront investments in tooling and inventory (and the MOQ related to that) are the constraints for rapid and iterative product development. With no physical tooling involved, Luximprint additive optics fabrication technology helps you to get inspirational and/or functional optics available in days. New lighting concepts can now rapidly be prepared, presented and iterated if needed before taking the final step to production tooling!

Benefits of 3D Printed Optics

Luximprint offers a fast, flexible and cost-effective way of custom optics prototyping, both for ‘inspirational’ and ‘functional’ purposes. The core advantages of the process include:

• No Upfront Investments: Extraordinary investments in tooling and inventory belong to the past. Optical 3D printing uses a direct CAD-to-Optic fabrication process, with only one step from design to prototype;

• Manufacturing Speed: Compared to traditional optics fabrication technologies and conventional additive fabrication, the Luximprint process comes with the speed of jetting based technologies;

• Easy Design Variations: Get multiple lens designs for easy ‘trial-and-error’ printed in one shot. Cost-efficient and time saving!

Cost-efficient and time saving!

• Easy Design Iterations: Iterative design processing until a satisfactory performance is reached;

• On Demand Ordering: Order functional optics prototypes in exact quantities as needed and when needed. No minimum order quantities (MOQ) apply;

• Ultimate Design Freedom: Experience ultimate freedom on the optical design and fabrication end;

• No need for post-processing: Printed optics are smooth and functional directly from the 3D printer. There is no need for post-processing, such as polishing or grinding.

Printed Micro Lens Structures

In additive manufacturing, complexity is not as critical as it might be for traditional manufacturing technologies. A variety of micro lens features can easily be combined in one design and 3D printed in one single run. Luximprint 3D printing technology is for example ideal for quick ‘trial-and-error’ different lens structure in order to find out the best performing version.

Integrated Lens Features

Functional lens features can seamlessly be integrated in the textured lens surface. Clear textures, branded, animated or natural, it’s finally the designers’ choice!

The on-demand ordering of small quantities custom tilt lenses tailored to our specific project needs, help us to keep stock levels low and our working capital available for operational purposes.

Jonathan Hinton, Managing Director, Binary Lighting Ltd.

The fast and flexible Luximprint prototyping process enabled us to create customized optics for our LpS2015 heat spreader demonstrator with delivery of the parts in a very short timeframe.

Wolfgang Plank, Head of MOEMS Factory, Escatec Switzerland

3D printed optical plastics do offer significant benefits in manufacturing speed, flexibility and affordability.

Mark Jongewaard, LTI Optics /University of Colorado

We selected printed optics by Luximprint because it is a true enabling technology that allowed us to rapidly and inexpensively prototype and test our concepts.

Noel C. Giebink, Pennstate University

Without the speed of Luximprint’s fast printing process for LED optics we would never have managed to get our show presentation ready in time.

Simon Frech, Managing Director, F-sign GmbH

Luximprint’s optical 3D printing technology enabled us to make use of rapid prototyping for optics. With this unique technology we were able to refine our product and iterate until we were satisfied with the product design of the f.lens.

Marco Bozzola, Co-founder, f.lens

3D Printing Color Lenses

Why use lenses AND filters if colors can be easily integrated in one and the same design? Pick and choose the exact color or gradient you need, and combine it with the correct optical structure for a smooth performance!NOTE: All Luximprint products are intended for use in engineering environments or temporary project installations. Unless coated, installation in indoor environments is recommended.

Unless coated, installation in indoor environments is recommended.

Planar Task Light by Smith-Dixon Associatesadmin2023-02-21T13:08:19+00:00

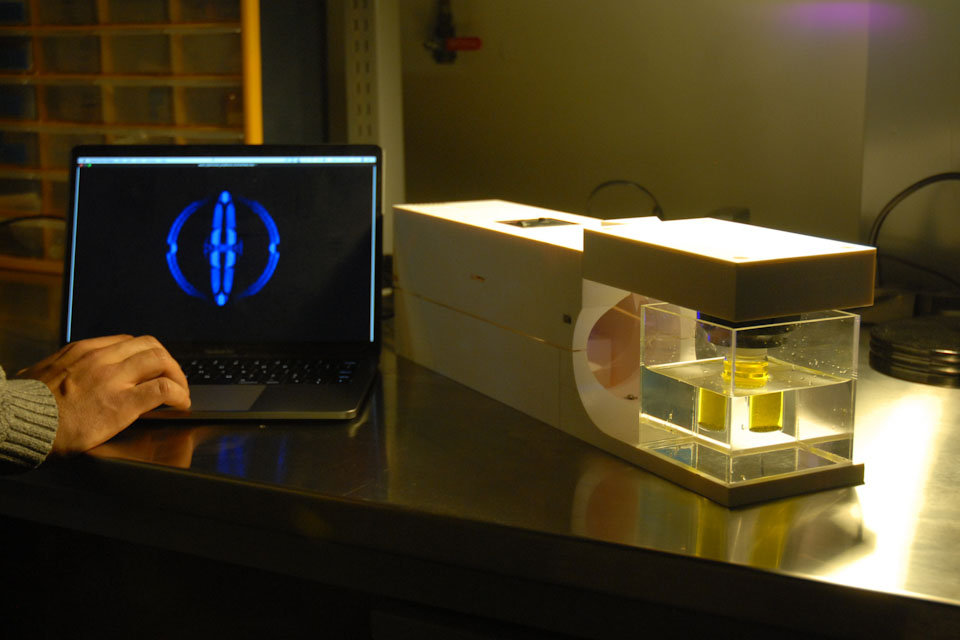

University of Strasbourg: White Light Beam Shapingadmin2018-09-21T08:56:46+00:00

High-Efficiency CPV Fresnel Lenses by Ioffe Instituteadmin2018-12-07T11:04:18+00:00

Barcode Reader Lenses by BARTEC BENKEadmin2018-09-13T11:02:19+00:00

Escatec Trade Show Demonstratoradmin2018-02-16T12:20:00+00:00

CPV Lens Array Pennstate Universityadmin2018-09-13T10:52:01+00:00

Toggle Sliding Bar Area

Recent Works

Samples

Order your Sample Kit now and get 50% refunded on your next order! >>>

Visit our Sample Shop!

Page load link Go to Top3D Printing Creates New Optical Possibilities | Features | Oct 2022

Additive manufacturing technology enables the fabrication of innovative, multifunctional lenses and components that promise to simplify and shrink conventional optical systems.

HANK HOGAN, CONTRIBUTING EDITOR

Emerging 3D printing technology is transforming once-impossible designs of optical components into optimized elements that can improve medical instruments, research tools, communications systems, and consumer devices.

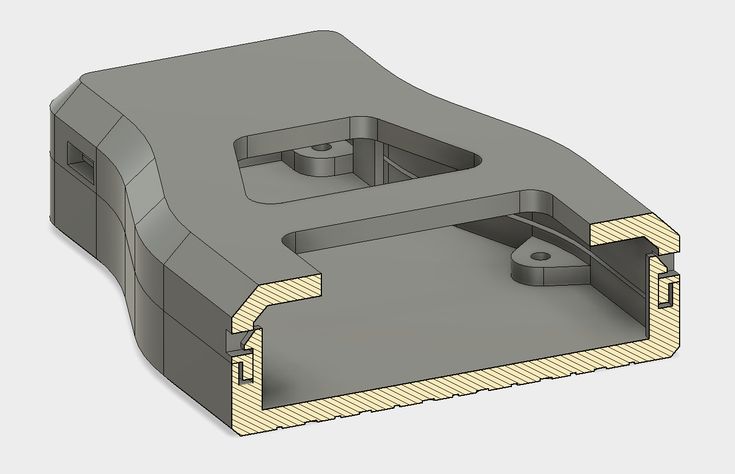

In 3D printing, an additive process prints an entire optical component one tiny particle at a time, enabling designs that combine multiple functions in a single lens or pre-align a system by creating optics, mounts, and baffles together. The new optical designs can reduce a product’s footprint, improve technical performance, and facilitate commercial scale-up.

Australian and German researchers recently 3D-printed a single 330-μmdiameter lens, for example, that simultaneously met high- and low-numerical aperture requirements with a lens-in-lens design1. Impossible to fabricate conventionally, the lens enabled both fluorescence and optical coherence tomography with a 0.52-mm-diameter probe. In their paper, the researchers reported a better than 10× improvement in fluorescence contrast compared to a more traditional fiber-optic design.

“3D printing actually shines in high miniaturization, impossible parts that you cannot do with other methods and also has very nice alignment possibilities,” said Simon Thiele, CTO at 3Dprinting company Printoptix and one of the authors of the paper.

Being able to print an optic along with its mount and other elements saves time and minimizes installation errors. Plus, being able to adjust an optic’s shape and properties on a small scale allows one lens to do the work of several. Medical applications, cellphones, and soldiers in the field could benefit. 3D printing can also reduce the amount of time needed to prototype an optical design from months to days, a significant time savings.

But 3D printing of optical components also faces hurdles, such as limited availability of optically relevant materials, slow manufacturing speed, and high cost, especially for large volumes.

Additive processing options for optics

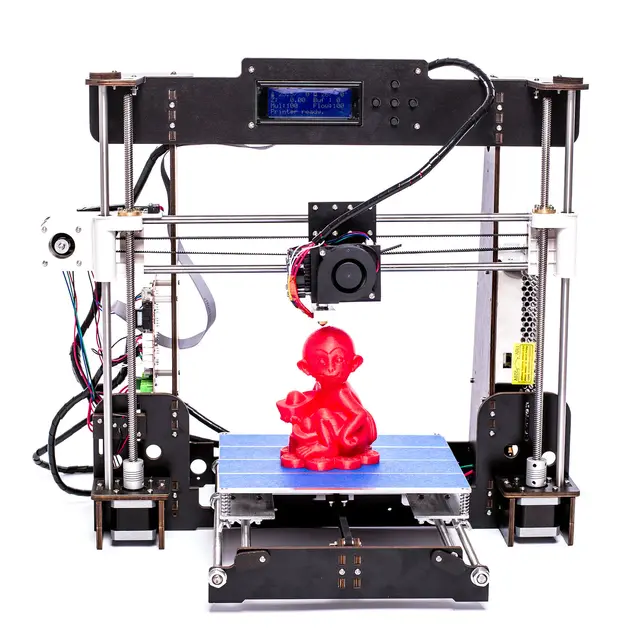

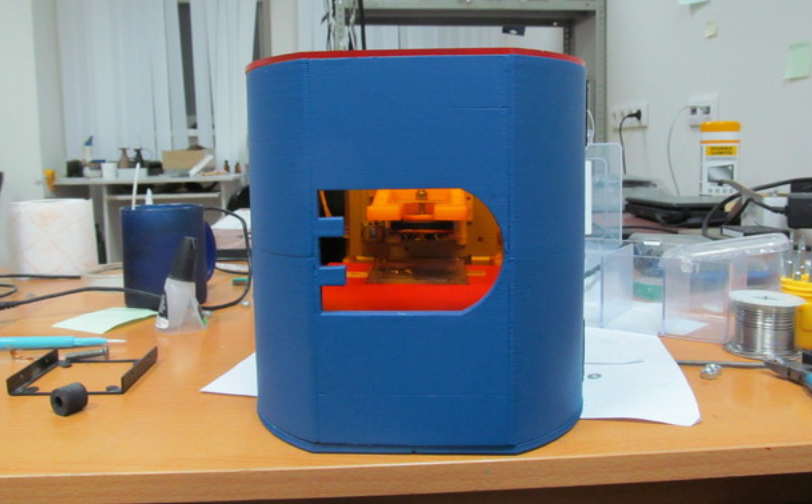

Industry and researchers are addressing these issues with an array of 3D-printing techniques. Professor Tomasz Tkaczyk of Rice University and his colleagues reviewed the capabilities and performance levels of fused deposition modeling, inkjet printing, stereolithography, and two-photon polymerization2.

Professor Tomasz Tkaczyk of Rice University and his colleagues reviewed the capabilities and performance levels of fused deposition modeling, inkjet printing, stereolithography, and two-photon polymerization2.

An integrated 3D-printed 1.1-mm-diameter lens system with a distortion-free 90° field of view for microcamera applications. (Match head used for size comparison.) Made on an optimized Nanoscribe two-photon polymerization (2PP) 3D printer. Courtesy of Printoptix GmbH.

Fused deposition modeling heats a material, extrudes it through a nozzle, and deposits it layer by layer. The researchers reported that the method creates the largest volume structures in the shortest time, but it does so with a feature size of a few hundred nanometers and a surface roughness of about 1000 nm.

In comparison, molded optics have a roughness of about 10 nm. Polished optics are even smoother, with a surface roughness of about 1 nm. Surface roughness and feature size are important because they determine optical performance. They need to be comparable to or below the wavelength of interest for feature size, and well below it for roughness.

They need to be comparable to or below the wavelength of interest for feature size, and well below it for roughness.

Two-photon polymerization (2PP) uses a pulsed laser to induce a multiphoton process that occurs only in a small focal region, and the photons alter the material. Moving the focal point in three dimensions creates structures, layer by layer. 2PP printed the finest features, the researchers said, resulting in feature sizes of <0.1 μm and a surface roughness of 10 nm. However, the technique was the slowest to make a large-volume object. Inkjet printing (which deposits ink drops for 3D printing) and stereolithography (which 3D-prints using photolithography) fell in between the other techniques in terms of speed, feature size, and surface roughness. Inkjet printing allowed for smaller and smoother features.

An image sensor that includes a complex lens system is 3D-printed directly onto an imaging sensor matrix. Courtesy of Andrea Toulouse/Nils Fahrbach.

Various technologies are in commercial production. Luxexcel uses inkjet printing followed by UV curing of a polymer to make 3D-printed lenses, for instance. The company won a 2022 Prism Award for a solution that builds smart eyewear with prescription lenses.

Multi-index elements

Startup NanoVox, which is transitioning its name to Vadient Optics, also uses inkjet 3D printing, but it does so with a twist — offering volumetric index of refraction gradient optics (VIRGO).

“We’re not just printing polymers as they are,” said James Field, the company’s vice president of business development. “We’re using high and low index of refraction monomers that are infused with nanoparticles that sculpt the light in the bulk [material] instead of having to do it with surface curvature.”

NanoVox achieves this optical performance by doping the ink with nanoparticles smaller than 10 nm. The company’s pilot production machine, a third-generation system, can have as many as eight printheads, each loaded with a different ink formulation. The machine adjusts ink dispensing to create optics with changes in index of refraction from one small volume to the next. The technology can fabricate a single flat lens that outperforms a combination of multiple curved ones.

The machine adjusts ink dispensing to create optics with changes in index of refraction from one small volume to the next. The technology can fabricate a single flat lens that outperforms a combination of multiple curved ones.

The potential market for this technique is large, according to Field. Cameras in phones use a stack of eight or nine lenses, for instance, to correct for aberrations and distortions. Using NanoVox’s technology, the lens count could drop to four, which would save phone-makers money and possibly space.

NanoVox is making its own machines while developing the nanoparticle-infused inks. The company will be a service bureau, Field said. Thus, it will make products for others and not sell its own. Another 3D-printing startup is Printoptix, which uses 2PP systems from printmaker Nanoscribe. Printoptix is currently a service bureau that sells printing and prototyping services. It is transitioning to selling its own parts and eventually to licensing its processes, according to managing director Nils Fahrbach. He said the company’s optimizations accelerate optics processing.

He said the company’s optimizations accelerate optics processing.

This increase in throughput could be crucial for some applications. The distance between the eyes varies from person to person, for example, and Fahrbach said matching this spacing is critical for high AR/VR performance in smart glasses or goggles. 3D printing offers a way to achieve personalization quickly and, eventually, perhaps at no extra cost. “You just hit a button and the optics are printed individually to the customer at the same cost as any other optic,” he said of such on-the-spot customized AR/VR display components.

Sofía Rodríguez, product marketing manager for Nanoscribe, said the company’s latest 3D printer and polymers offer alignment accuracies down to 100 nm. This enables the printing of freeform optical elements directly onto optical fiber, fiber arrays, and photonic chips.

Expanding material availability

In June 2021, Nanoscribe announced the release of a photoresin of fused silica glass that the company developed with Glassomer. This material allows 3D printing of glass microstructures, giving users a wider range of materials.

This material allows 3D printing of glass microstructures, giving users a wider range of materials.

Modified inkjet technology is enabling 3D-printed planar lens arrays, such as these 10-mm f/4 gradient index (GRIN) lenses. Current systems can deposit various monomer ink formulations, using up to eight printheads to fabricate flat lenses that meet or exceed the performance of curved optics. Courtesy of NanoVox.

Other researchers are also exploring 3D printing using glass. For example, Rongguang Liang, a professor at the University of Arizona, co-authored an Advanced Science paper this year that introduced a liquid silica resin used in 2PP printing3.

He said some polymers yellow with age, a consequence of being UV light curable. Polymers also absorb water, undergo large expansion and contraction with temperature changes, and are soft compared to glass.

“The optical properties are not as good as glass,” Liang said.

Using a custom-made fused silica resin and a process designed for it, he and his colleagues 3D-printed lenses, a lenslet array, gratings, and freeform optics. They demonstrated the resulting optics’ imaging performance using a standard resolution target, a University of Arizona logo, and biological samples.

They demonstrated the resulting optics’ imaging performance using a standard resolution target, a University of Arizona logo, and biological samples.

Having a wide variety of materials is important for further advancements in 3D printing, Printoptix’s Fahrbach said. One of the strengths of 3D printing is the ability to align the optics, which is easy to achieve when printing optics, baffles, and a mount at the same time. However, if the optic is transmissive, then all of the components — including the baffles — are transparent. As a result, post-processing is necessary, which drives up cost and lowers the overall component throughput. Being able to 3D-print dissimilar materials could overcome this issue and expand the applications.

A lensed fiber array, 3D-printed using Nanoscribe’s 2PP technology, collimates green light into parallel beams. A sample from the research project MiLiQuant. Courtesy of Nanoscribe.

The varying refractive indices that are possible when using NanoVox’s process are one way to achieve this goal of printing different materials.

Currently, the change in refractive index is only 0.15, but Field said work is underway to expand and perhaps double this range. He also said the company is working on a glass 3D-printing material and process, but they are not likely to be available for years.

Currently, the change in refractive index is only 0.15, but Field said work is underway to expand and perhaps double this range. He also said the company is working on a glass 3D-printing material and process, but they are not likely to be available for years.Improving cost and cycle time

To accomplish widespread commercial success, 3D printing must also cost less and/or achieve a faster throughput. Nanoscribe is addressing this challenge, in part, by piloting alternative replication strategies. For example, 3D printing could be used to create an initial component that would then be reproduced in mass quantities using nanoimprint lithography and injection molding, Rodriguez said.

The company Addoptics uses a similar strategy. Marketing manager Meghan Pace said Addoptics 3D-prints a mold that is used to make the optics. Importantly, the components that come out of the mold require little to no postprocessing. This approach reduces the cycle time for a prototype from as much as 18 weeks to six days while also producing a mold suitable for volume production.

Inkjet printing, by its nature, can scale to higher volume production, said Jyrki Saarinen, a professor at the University of Eastern Finland. He and his team have demonstrated and are refining a multimaterial inkjet 3D-printing process for freeform optics.

A dozen planar Alvarez lenses are produced on a NanoVox pilot line with 1-μm drop precision. The line can print lenses measuring in size from 500 μm to 5 in. Scaling volume will require advancements in inkjet equipment, printing materials, and processes. Courtesy of NanoVox.

“The largest printers have tens of printheads attached next to each other,” Saarinen said. “Printing 1 sq cm or 1 sq m, one component versus hundreds of components side by side, takes the same time.”

NanoVox’s third-generation VIRGO pilot production system can churn out 15,000 eyeglass lenses or 300,000 mobile camera lenses per month. This is hundreds of times the throughput of the company’s research system but still small compared to the hundreds of millions of smartphones produced each month.

Further throughput gains require equipment, materials, and process changes. NanoVox’s Field said process throughput and product cost are the most pressing challenges confronting 3D printing of optics.

“They’re just trying to get to the point where they can manufacture it at a cost that makes sense to the buyer,” he said.

References

1. J. Li et al. (2022). 3D-printed micro lensin- lens for in vivo multimodal microendoscopy. Small, Vol. 18, p. 2107032, www.doi.org/10.1002/smll.202107032.

2. G. Berglund et al. (2022). Additive manufacturing for the development of optical/photonic systems and components. Optica, Vol. 9, No. 6, pp. 623-638, www.doi.org/10.1364/optica.451642.

3. Z. Hong et al. (2022). High-precision printing of complex glass imaging optics with precondensed liquid silica resin. Adv Sci, Vol. 9, p. 2105595, www.doi.org/10.1002/advs.202105595.

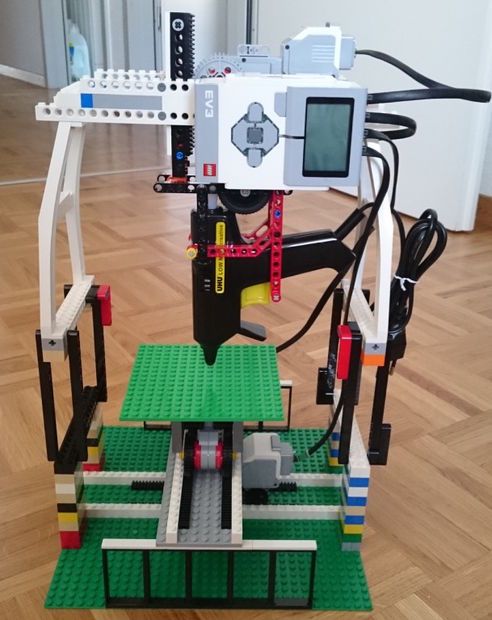

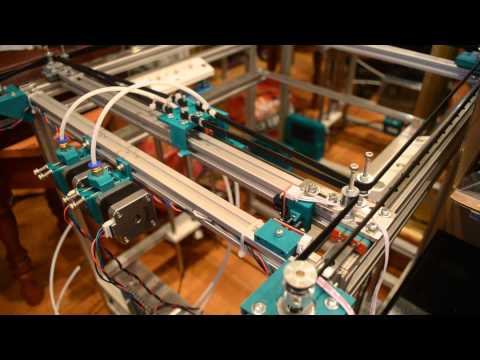

Optics on an FDM 3D printer - how it's done

News

Tomer Gluck of Fennec Labs has published an interesting tutorial on how to make functional optics with a conventional desktop FDM 3D printer.

FDM 3D printing is popular due to the cheapness of equipment and consumables, but as printers proven in battle know, it does not give the best results in terms of resolution. There is one more thing, and that is density. Polymer filament fusing usually results in microvoids between the filaments and layers, which is no good if you're thinking of printing a lens. Tomer's method does not contain anything breakthrough: rather, it is just a detailed description of the printing and post-processing settings for obtaining more or less functional optics, and not just vases of translucent plastic.

Prusa Research's Clear ABS (Clear EasyABS) was used as a consumable. Tomer prepared 3D models in the Cura slicer. The main idea was to increase the fluidity of the plastic and intentionally over-extrusion. In other words, the ABS was heated to the maximum recommended temperature of 255°C and then pressed into the previous layers in order to fill the voids as well as possible and achieve increased density. For this, the material feed rate (Flow) was set at 108%. The plastic was applied with a 0.4 mm diameter nozzle at a head positioning speed of only 24 mm/s. The author selected the layer thickness manually: first, 50 microns, and then Z-adjustment, until the nozzle almost scratched the laid layers.

For this, the material feed rate (Flow) was set at 108%. The plastic was applied with a 0.4 mm diameter nozzle at a head positioning speed of only 24 mm/s. The author selected the layer thickness manually: first, 50 microns, and then Z-adjustment, until the nozzle almost scratched the laid layers.

If everything is printed and nothing is torn off or clogged, post-processing remains. Here Tomer tried using acetone, but the problem with the solvent is that although it smoothes the surfaces, it makes the plastic too cloudy. The best option turned out to be sanding with sandpaper with a grit of 600 to 4000, and then polishing, for which the author suggests using cardboard.

We still failed to obtain high-quality optics, and it is hardly possible at all, so you should not rely on this method for 3D printing of lenses. However, the resulting products still focus the light quite well, as seen in the illustrations above. A detailed description of the project is available at this link.

A detailed description of the project is available at this link.

Do you have interesting news? Share your developments with us, and we will tell the whole world about them! We are waiting for your ideas at [email protected].

Subscribe to the author

Subscribe

Designers from the Cults community have come up with all kinds of glasses. Of course, there are sunglasses and 3D printed glasses, but you will also find fancy glasses for various events or to create cosplay costumes!

Popularity Rating

Sunglasses

Free

VirtualTryOn.fr Eyeglass frame (flat)

Free

Harry Potter Glasses

Free

Nose pad for mask - COVID

Free

Glasses

Free

Universal Glasses Stand

Free

VirtualTryOn.

fr - 3D Printing Glasses - Steve

fr - 3D Printing Glasses - Steve Free

VirtualTryOn.com - 3D Printing Glasses - Steve v2 - VTO

Free

Sunglasses

Free

Glasses / Sunglasses

Free

VirtualTryOn.fr Eyeglass frame

Free

VirtualTryOn.fr - Glasses 3D printing - Low Paulie

Free

Glasses COVID-19

Free

Pencil Case triangle

Free

POP Glasses

Free

Eyeglasses wall mount holder

Free

Bre got glasses?

Free

CUSTOMIZABLE 3D VTO PRINTING GLASSES

Free

Luna Lovegood Glasses

Free

SpecStand (Short) Eyeglasses/Sunglasses Stand

Free

Car Sunglasses Glasses/Card/Ticket Clips Holder

Free

VirtualTryOn.

co.uk - 3D Eyewear - Enio

co.uk - 3D Eyewear - Enio Free

PLASIL 2 Glasses Stand

Free

Thug Life Glasses - Dual Color

Free

3DBK Frames

Free

Nose Glasses Support

Free

Tiki Sunglass Holder

Free

Sunglass holder

1,90 €

Funny Nose Glasses Stand

Free

Melon Shades

Free

Sunglasses

Free

RhinoGlass

Free

3d printable Glasses

Free

Modular Glasses Stand

Free

Face Mask Pozicer-Prevents fogging of glasses

Free

Operating theater glasses 2h Covid 19

Free

Glasses case (rework of Jasoncanning design)

Free

Spectacle holder

1. 98 €

98 €

modular glasses

Free

Jaa's Steampunk Glasses v 1.0

Free

Anti Fog Clip For Surgical Mask

Free

Lashes Glasses

Free

DIY Video Glasses for Raspberry Pi

Free

2020 Silly New Year Glasses with dual extruder option

Free

Sunglasses V2

Free

Eye glasses holder

Free

Sunglasses #2

Free

Spectacle/glass holder (OpenSCAD project)

Free

Modular Glasses Stand

Universal Glasses Stand

Pencil case triangle

CUSTOMIZABLE 3D VTO PRINTING GLASSES

Discover our selection of best 3d files for 3d printers to make glasses or sunglasses .