3D printer multi material

The 9 Best Dual Extruder 3D Printers for Multi Material Printing – Clever Creations

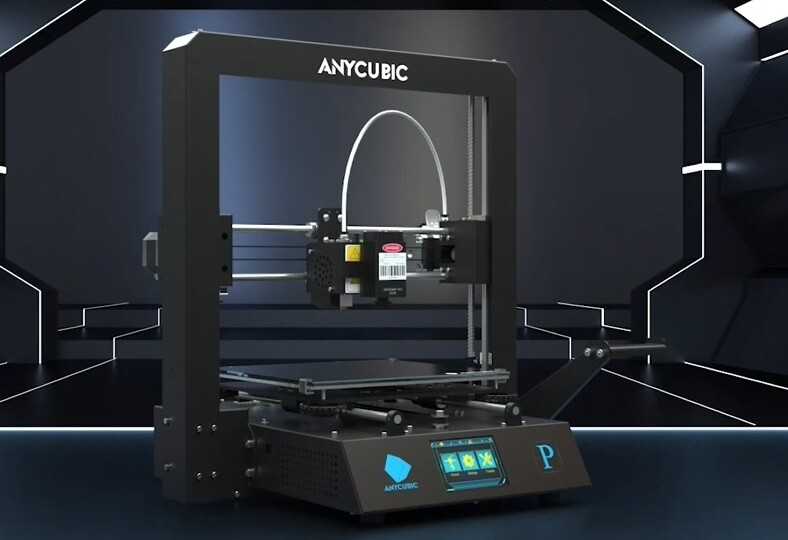

Dual-extruder 3D printers are an excellent solution for multi-color and multi-material 3D printing. You don’t need to swap out filaments for a color change or limit yourself to printing with only a single material at a time. In a dual extrusion printing process, you get two entirely separate extruders for printing with multiple filaments.

If you decide to buy a dual extruder 3D printer, you’ll encounter terms like IDEX system, dual print-head system, and more. It can get quickly confusing to select the right printer for your needs, and you might end up getting one that is not the best fit for you.

In this article, we’ve created a list of the best dual extruder 3D printers that are available for you to buy right now and sorted them into different categories to make your buying decision a little bit easier.

Read on to understand more about these machines and how to choose the best dual extruder 3D printer for your needs.

| Dual Extruder 3D Printer | Category | Type | Price (~) | Best Offer |

|---|---|---|---|---|

| Sovol SV02 | Best under $500 | Single hot end | $359 | Sovol3D |

| Flashforge Dreamer | Best under $500 | Dual hot end | $449 | Flashforge |

| TENLOG TL-D3 Pro | Best under $1000 | IDEX | $699 | Amazon |

| Flashforge Creator Pro 2 | Best under $1000 | IDEX | $649 | Flashforge |

| QIDI Tech i-Fast | Best prosumer | Dual hot end | $2299 | Amazon |

| Ultimaker S3 | Best prosumer | Dual hot end | $4725 | MatterHackers |

| BCN3D Sigma D25 | Best professional | IDEX | $3995 | MatterHackers |

| Raise3D Pro 3 | Best professional | Dual hot end | $5249 | MatterHackers |

| Ultimaker S5 | Best professional | Dual hot end | $6355 | MatterHackers |

What is a Dual Extruder 3D Printer?

A dual extruder 3D printer is a machine that has two extruders, as the name suggests. These extruders can be used to print with different colors or different materials simultaneously. This way, you don’t have to swap out filaments every time you want to change the color of your print.

These extruders can be used to print with different colors or different materials simultaneously. This way, you don’t have to swap out filaments every time you want to change the color of your print.

You can also use dual extruders to print with multiple materials at the same time, for example, printing with both ABS and TPU filaments in a single 3D print. This opens up a lot of possibilities for interesting prints that wouldn’t be possible with a single extruder printer.

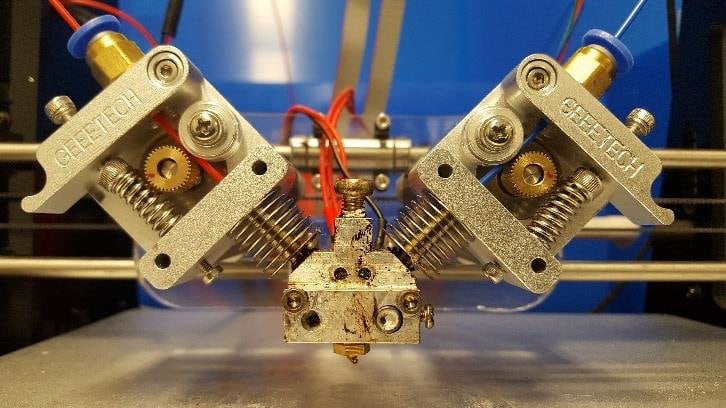

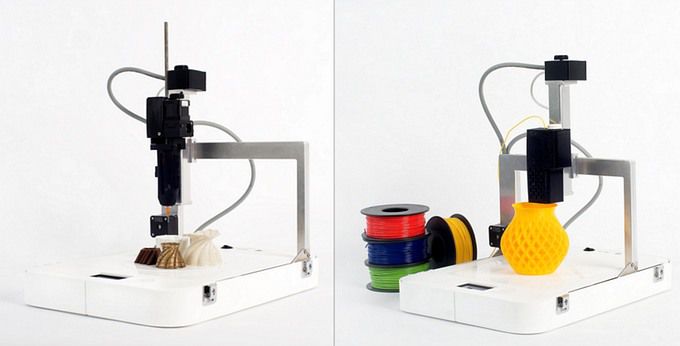

In this article, we’ve covered three types of different dual extrusion 3D printers: Single hot end setup, Dual hot end extrusion, and Independent Dual Extruder system (IDEX).

The single hot end setup is the least complex. It gives you the benefits of dual extrusion 3D printers without actually having a second print head or a complex motion system.

The dual hot end setup incorporates a second print head next to your primary hot end, and both hot ends move together. You can assign different materials for each hot end, effectively giving you the capabilities of printing with two 3D printers, albeit on a single print bed.

You can assign different materials for each hot end, effectively giving you the capabilities of printing with two 3D printers, albeit on a single print bed.

One of the best and the most practical applications of dual extruders is the IDEX style of 3D printer. These printers have two independent print heads that can be controlled and moved separately. This gives you a lot of control over the printing process and opens up a lot of possibilities for complex prints.

What is the Benefit of a Dual Extruder 3D Printer?

A dual extruder 3D printer triumphs over the regular single extruder 3D printer in many ways. You do not need to swap out any filaments mid-print for any color changes, leading to a faster print speed.

You can print with multiple materials simultaneously with a dual extruder printer. You can use one print head to print the outer shell of the model, while the secondary hot end will print the infill with a more robust material. Similarly, you can use filaments with different colors to print a colorful model.

IDEX printers give you the added benefits of printing modes. You can print multiple objects simultaneously with the duplication mode and print a mirrored version of your design with the mirror print mode. It leads to increased productivity and is useful for 3D printing larger batches of objects.

The last and probably one of the most popular benefits of dual extruder 3D printers is their ability to print soluble supports. You can use PVA or HIPS filament in your secondary extruder to print water dissolvable supports. It gives you the freedom to print complex objects and significantly saves post-processing time, as it takes away the need to remove supports manually.

The Best Dual Extruder 3D Printers

Sovol SV02

Best under $500

Check Price

AmazonSovol3D

The Sovol SV02 is an excellent budget dual extruder 3D printer. It features a Y-shaped, two-in, one-out single print head. It is a clever way to carry out multi-filament printing without adding too many extra 3D printer costs.

The SV02 has a decent printing volume and a dual Z-axis design for better printing accuracy. Its textured glass bed helps with first-layer adhesion and makes the removal of prints easier.

Its mainboard features TMC 2208 stepper drivers for a silent 3D printing process. You also have the option to install a BLTouch auto-leveling sensor as an upgrade, taking away the need for manual bed leveling.

Additionally, you can buy a mixing hot end that lets you mix two different colors simultaneously. This feature gives a lot of room for fun experimentation and creative 3D prints.

The SV02 is an excellent fit for schools to print colorful educational models and for beginners and amateurs users who want to experiment with dual extruder 3D printing without breaking the bank.

Standout Features

- 2-in-1-out hot end

- Optional color mixing

- Dual Z-axis

Technical Details | |

|---|---|

| Build volume | 280 x 240 x 300 mm |

| Dual extrusion setup | Single hot end |

| Max hot end temperature | 260°C |

| Bed leveling | Manual |

| Connectivity | SD Card or Data Cable |

| Compatible materials | PLA, TPU, HIPS, ABS, PETG, WOOD |

What We Like

- Lightweight hot end

- Silent 3D printing

- Can mix two colors

Could Be Better

- Inconsistent print quality

- Occasional filament jams

Find Sovol SV02 at

AmazonSovol3D

Flashforge Dreamer

Best under $500

Check Price

AmazonFlashforgeMatterHackers

The Flashforge Dreamer is one of the most popular dual extruder 3D printers in the market that comes with some elegant features for easy multi-material 3D printing. It comes fully assembled, and you can get started with 3D printing on it within 30 minutes of unboxing the printer.

It comes fully assembled, and you can get started with 3D printing on it within 30 minutes of unboxing the printer.

With the Dreamer, you get two print heads with a direct-drive setup that can help you print a wide variety of materials with ease. The fully enclosed design prevents any harmful 3D printer fumes from leaving the printer and aids considerably with printing ABS. It includes an aluminum heated print bed for a more even heat distribution on the print surface.

The dual extruder design does result in a slight reduction in the build volume of the 3D printer, however, and you get a relatively small print area for the price. Some users also find the bundled FlashPrint slicing software limiting in terms of features.

Nonetheless, considering that the Dreamer is primarily aimed towards beginners, it does an excellent job in the user convenience and accessibility department. It is a good choice for educational institutes and amateur 3D printer users who want a plug-n-play solution for their multi-color and multi-material printing needs.

Standout Features

- Fully enclosed print chamber

- Aluminum build plate

- Wi-Fi connectivity

Technical Details | |

|---|---|

| Build volume | 230 x 150 x 140 mm |

| Dual extrusion setup | Dual hot end |

| Max hot end temperature | 240°C |

| Bed leveling | Assisted Manual |

| Connectivity | USB cable, SD card, Wi-Fi |

| Compatible materials | PLA, TPU 95A, ABS, PETG |

What We Like

- Stable printing area

- Beginner-friendly

- Plug-n-play functionality

Could Be Better

- Small build volume

Find Flashforge Dreamer at

AmazonFlashforgeMatterHackers

TENLOG TL-D3 Pro

Best under $1000

Check Price

Amazon

The Tenlog TL-D3 Pro is a rare dual extruder 3D printer to feature an IDEX system under $1000. It has two independent extrusion systems that move independently and let you print in mirroring print modes and duplicating modes.

It has two independent extrusion systems that move independently and let you print in mirroring print modes and duplicating modes.

You get a linear rail precision guide on the X-axis to support the IDEX system and a sturdy metal frame to deliver accurate printing quality. The tempered glass heated print bed gives excellent bed adhesion, and the silent motherboard with TMC 2208 and TMC 2225 stepper drivers delivers a quiet 3D printing experience.

The Tenlog TL-D3 Pro is a great dual extruder 3D printer that provides a unique mix of features at an affordable price. If you’re someone who has the need for batch 3D printing in a semi-professional setup, or you want an IDEX 3D printer on a budget, the TL-D3 Pro is a solid option.

Standout Features

- Multiple printing modes

- X-axis linear rail

- IDEX system

Technical Details | |

|---|---|

| Build volume | 300 x 300 x 350 mm |

| Dual extrusion setup | IDEX |

| Max hot end temperature | 300°C |

| Bed leveling | Manual |

| Connectivity | SD card, USB 2. 0 0 |

| Compatible materials | TPU, PVA, PLA, ABS, HIPS, WOOD, PETG, FLEXIBLE |

What We Like

- Easy to assemble

- Silent 3D printing

- Wide material compatibility

Could Be Better

- Open-frame design

Find TENLOG TL-D3 Pro at

Amazon

Flashforge Creator Pro 2

Best under $1000

Check Price

AmazonFlashforgeGeekbuyingAliExpress

While the aforementioned Flashforge Dreamer is suited for beginners and amateur users, the Flashforge Creator Pro 2 is aimed more towards the professional user base. The Creator Pro 2 is a fully enclosed 3D printer with a similar level of user convenience, but now with an upgraded independent dual extruder (IDEX) system.

The Flashforge Creator Pro 2 has multiple printing modes that let you print mirrored designs, duplicate your models for faster 3D printing, and even print with soluble support materials for complex and intricate 3D designs. The heated print bed and the enclosed design further expand the material compatibility of the printer, letting you print with PLA, ABS, HIPS, and PVA.

The heated print bed and the enclosed design further expand the material compatibility of the printer, letting you print with PLA, ABS, HIPS, and PVA.

The Flashforge Creator Pro 2 is a superb dual extruder 3D printer for industry professionals and hobbyists alike. You get a robust build quality, an IDEX system, ease of use, and excellent printing, all for a relatively low cost. In our book, it’s the best dual extruder 3D printer under $1000

Standout Features

- Fully enclosed design

- Residue scraping

- Easy to use touchscreen

Technical Details | |

|---|---|

| Build volume | 200 x 148 x 150 mm |

| Dual extrusion setup | IDEX |

| Max hot end temperature | 240°C |

| Bed leveling | Manual |

| Connectivity | SD Card |

| Compatible materials | PLA, ABS, PVA, PETG |

What We Like

- Affordable IDEX printer

- Excellent print quality

- Great support team

Could Be Better

- Small printing volume

- Lacks air filters

Find Flashforge Creator Pro 2 at

AmazonFlashforgeGeekbuyingAliExpress

QIDI Tech i-Fast

Best prosumer

Check Price

AmazonGeekbuying3DPrintersBay

The QIDI Tech i-Fast is not for the masses and is instead more positioned as a premium 3D printer for prosumers. For almost $2300, you get a printer that comes with many high-end features and a large build volume (uncommon in dual-extruder 3d printers) to accommodate a wide variety of 3D designs.

For almost $2300, you get a printer that comes with many high-end features and a large build volume (uncommon in dual-extruder 3d printers) to accommodate a wide variety of 3D designs.

Its heated print chamber measures 330 x 250 x 320 mm and is fully enclosed. For better printing with high-end materials like Nylon, Polycarbonate, and PolyPropylene, it can be heated up to 60°C. The motion system is fully supported with high-quality precision linear rails, and it has a dual Z-axis setup for increased accuracy.

The QIDI Tech i-Fast is a feature-packed dual extruder 3D printer for professional use case scenarios and printing high-end prototypes. Despite its high price, it still offers excellent value compared to similar printers in this price range. If you’re planning on adding an industrial machine to your workflow, the i-Fast is likely to be a perfect choice for your prototyping needs.

Standout Features

- Heated build chamber

- Extra all metal print-heads

- Large build volume

Technical Details | |

|---|---|

| Build volume | 330 x 250 x 320 mm |

| Dual extrusion setup | Dual hot end |

| Max hot end temperature | 300 °C |

| Bed leveling | Manual |

| Connectivity | Wi-Fi, USB and SD Card |

| Compatible materials | PLA, Nylon, TPU, PETG, ABS, PC, Wood, CF |

What We Like

- Quiet 3D printing

- Prints ABS very well

- Retractable hot ends

Could Be Better

- Manual bed leveling

- Limited firmware support

Find QIDI Tech i-Fast at

AmazonGeekbuying3DPrintersBay

Ultimaker S3

Best prosumer

Check Price

MatterHackers

The Ultimaker S3 is feature-packed and one of the best dual extruder 3D printers by Ultimaker. It is for professional users who want a high-quality, compact printer that consistently delivers excellent print quality.

It is for professional users who want a high-quality, compact printer that consistently delivers excellent print quality.

With the Ultimaker S3, you get a modest build volume of 230 x 190 x 200 mm. This is enough for most typical 3D prints but can be a limitation if your needs involve creating larger multi-color or multi-material objects.

The dual extruders on the Ultimaker S3 have swappable print cores that let you print with advanced materials if you need to. Over 200 materials are tried and tested on the S3, making it one of the most compatible dual extruder printers in terms of filaments.

Additional features include a 4.3-inch touchscreen with an easy-to-use UI, an onboard camera for remote monitoring, and an automatic bed leveling system to give you perfect bed adhesion and first layers every time.

The Ultimaker S3 is a premium 3D printer, and at a price point of over $4000, it is undoubtedly not for primary hobby purposes. The features it provides and the materials it supports are more geared towards industrial prototyping and end-component solutions for industries. If you’re someone who fits in that bracket, the S3 is a good choice for your 3D printing needs.

If you’re someone who fits in that bracket, the S3 is a good choice for your 3D printing needs.

Standout Features

- Swappable print cores

- Onboard camera

- Automatic bed leveling

Technical Details | |

|---|---|

| Build volume | 230 x 190 x 200 mm |

| Dual extrusion setup | Dual hot end |

| Max hot end temperature | 280 °C |

| Bed leveling | Automatic |

| Connectivity | Wi-Fi, Ethernet, USB |

| Compatible materials | PLA, ABS, PETG, NylonX, TPU, PVA, PP, PC |

What We Like

- Excellent print quality

- Professional software support

- Wide material compatibility

Could Be Better

- Limited build volume

- Expensive replacement parts

Find Ultimaker S3 at

MatterHackers

BCN3D Sigma D25

Best professional

Check Price

MatterHackers

Improving on the R17 and R19 Sigma’s series of independent dual extruder (IDEX) 3D printers, BCN3D’s new Sigma D25 is a professional-grade 3D printer that comes in a new light gray color and with a desktop-sized footprint. It features an independent extruder system, letting you print with multiple print modes and enhance your productivity.

It features an independent extruder system, letting you print with multiple print modes and enhance your productivity.

The Sigma D25 includes stainless steel, precision linear rails on the X-axis, and a robust Z-axis designed for durability and maximum print accuracy. For better bed adhesion, its new aluminum heated build plate comes with a silicon thermal pad to evenly heat its area.

It also includes a new set of custom-made E3D hot ends coupled with Bondtech extruders that support a wide variety of materials and deliver a consistent 3D printing performance. The filament spools are neatly tucked within the printer frame itself, protecting them from any external debris and giving the printer a clean look.

BCN3D Sigma D25 aims to deliver the highest dual extrusion 3D printing in a clean-looking, easy-to-use package. The large build volume, IDEX system, and interface make it suitable for batch printing, print farms, and educational purposes.

Standout Features

- IDEX setup

- Built-in filament holders

- Large build volume

Technical Details | |

|---|---|

| Build volume | 420 x 300 x 200 mm |

| Dual extrusion setup | IDEX |

| Max hot end temperature | 300°C |

| Bed leveling | Manual |

| Connectivity | SD card, Wifi, Ethernet |

| Compatible materials | PLA, PVA, PET-G, TPU, PP, PA |

What We Like

- Easy to use interface

- Great build quality

Could Be Better

- Manual bed leveling

- Limited Z-height

Find BCN3D Sigma D25 at

MatterHackers

Raise3D Pro 3

Best professional

Check Price

MatterHackers

The Raise3D Pro 3 is one of the flagship 3D printers by the Raise3D team. It builds upon the previous generation of the Pro 2 series of industrial 3D printers. Its improvements lie with its new dual extruder setup, interchangeable hot end, and airflow system to give you great 3D printing results every time.

It builds upon the previous generation of the Pro 2 series of industrial 3D printers. Its improvements lie with its new dual extruder setup, interchangeable hot end, and airflow system to give you great 3D printing results every time.

The Pro 3 comes with a large build volume of 300 x 300 x 300mm. That volume is fully enclosed to isolate the print area from the external environment. Additionally, it includes a HEPA filtration system to keep away potantially unhealthy 3D printer fumes.

Its automatic bed leveling minimizes the calibration time required, resulting in improved productivity. The built-in ‘EVE intelligent assistant’, too, is a unique feature with the Pro 3 designed to locate and resolve any issues and give helpful feedback to the user.

The Raise 3D Pro 3 is for professional users who need a robust, large-sized 3D printer that lets you execute multi-material 3D printing on an industrial scale. You can use it to carry out batch 3D printing with advanced materials and end-use components without hassles.

Standout Features

- Airflow manager

- Interchangeable hot ends

- EVE Smart assistant

Technical Details | |

|---|---|

| Build volume | 300 x 300 x 300 mm |

| Dual extrusion setup | Dual hot end |

| Max hot end temperature | 300°C |

| Bed leveling | Automatic |

| Connectivity | Wi-Fi, LAN, USB port |

| Compatible materials | PLA, ABS, HIPS, PC, TPU, TPE, PETG, ASA, PP, PVA, Nylon |

What We Like

- Professional build quality

- High repeatability

- Auto bed leveling

- Large filament compatibility

Could Be Better

- Large investment

Find Raise3D Pro 3 at

MatterHackers

Ultimaker S5

Best professional

Check Price

AmazonMatterHackers

The Ultimaker S5 is the bigger brother of the Ultimaker S3, but with a larger build volume to utilize the benefits of dual extrusion 3D printing fully. It is similar to the S3 in many aspects, but the additional upgrades and add-ons make it an automated industrial-level 3D printer.

It is similar to the S3 in many aspects, but the additional upgrades and add-ons make it an automated industrial-level 3D printer.

The S5’s large build volume of 330 x 240 x 300 mm is suitable for big-sized objects, and it can be fully enclosed with an optional air management system to maintain a stable temperature in the printing area. This makes it more suitable as a Nylon 3D printer or to work with other high-temperature filaments.

To expand this 3D printer further, you can add a material station that takes up to six materials and automatically choose the required material for the current print without any user intervention.

The swappable print cores, retracting nozzles, and automatic bed leveling are the same as the S3, delivering a predictable and high-quality 3D printing experience each time.

The Ultimaker S5 is an excellent printer for industrial environments and can be upgraded to fulfill even more complex needs. It is our top pick for the best dual extruder 3D printer for professionals.

Standout Features

- Large build volume

- Additional upgrades

- Swappable print cores

Technical Details | |

|---|---|

| Build volume | 330 x 240 x 300 mm |

| Dual extrusion setup | Dual hot end |

| Max hot end temperature | 280°C |

| Bed leveling | Automatic |

| Connectivity | Wi-Fi, Ethernet, USB |

| Compatible materials | PLA, ABS, PETG, NylonX, TPU, PVA, PP, PC |

What We Like

- Wide material compatibility

- Premium components

- Reliable

Could Be Better

- Pricy upgrades

Find Ultimaker S5 at

AmazonMatterHackers

What to Look For When Buying a Dual Extruder 3D Printer

Dual extruder type

When you consider buying a dual extruder 3D printer, you’ll come across technologies such as the IDEX system, double hot ends, and a single Y-shaped hot end.

The IDEX system lets you simultaneously 3D print with two independently driven extruders and a hot end setup.The advantages of an IDEX system are the multiple printing modes that you get with it. You get to duplicate and mirror your models, effectively resulting in increased productivity.

If you look at the single hot end setup, you’ll notice that the hot end is much lighter, and you do not lose any printing area to a second print head. The downside, though, is that this setup is more likely to run into issues, as a single print head is used for multiple materials at a single time.

The most common and relatively more accessible dual extrusion system is double hot ends. You get two individual hot-ends and extruders, and each hot end can be configured to print a single material with maximum efficiency. However, two hot ends next to each other occupy extra space, cost more, and do not increase productivity like the IDEX system.

If you want a printer for maximum productivity and are looking to run it into print farms or to run multiple batches of prints, the best dual extruder 3D printer for you is an IDEX one. In contrast, the dual hot end setup is more suitable for conventional dual extrusion 3D printing, where you do not need to print many parts.

In contrast, the dual hot end setup is more suitable for conventional dual extrusion 3D printing, where you do not need to print many parts.

Printing modes

While the single nozzle and the dual hot ends styles let you print with multiple materials and soluble supports, printing modes are truly available only on the IDEX style of dual extruder 3D printers.

There are four printing modes that come with dual extruder 3D printers – Mirror, duplication, soluble supports, and multi-material mode. The mirror mode lets you print symmetrical mirrored objects, and you can print the part and its inverse simultaneously. For example, shoes, gloves, and other things come in a couple but are symmetrically opposite.

Another helpful model is the duplication mode, which helps carry out batch prints. In duplication mode, both the hot ends repeat the same movements and produce identical copies of the original design. It drastically improves your productivity rates and is suitable for print farms.

The soluble supports and the multi-material modes are similar and not just available in the best dual extruder 3D printers; any dual extruder printer can do them. While the primary nozzle is used for the main filament, you can use the secondary nozzle with either soluble supports or a differently colored material.

Print Volume

The dual extruder design reduces the printing volume of any 3D printer due to the extra space the secondary extruder takes up. This results in a smaller printing volume on the Y-axis in dual extruder printers compared to a single extruder setup.

When you use print modes, too, you’ll realize that the print area is reduced considerably due to the second extruder’s size in mirror mode. Hence, in the case of dual extruder printing, it becomes more crucial to look at the actual printing volume that you’ll get.

If you need a bigger print size, you should look at the Raise3D Pro 3, Ultimaker S5, and the BCN3D Sigma D25. These printers come with a large print volume that gives you more freedom to take full advantage of their dual extrusion capabilities.

Print Speed

Even with the addition of a second hot end on the motion system, the printing speeds of dual extruder 3D printers are relatively unaffected. Powerful stepper motors and a rigid frame can compensate for the added weight of the hot end.

Almost all of the 3D printers in this list can comfortably print at around 60-100 mm/s of printing speeds, while travel speeds go up to 200 mm/s. These speeds give you a good balance between print quality and lead times.

If you consider the other benefits of dual extruder 3D printers, you’ll realize that the printing modes lead to a considerable increase in overall productivity. The ability to print with two print heads simultaneously easily triumphs the faster printing speeds of any other 3D printer.

Filament Compatibility

Ensuring that your 3D printer is compatible with many filaments is one of the primary things you need to consider while buying any 3D printer. More so with dual extruder 3D printers due to their second print head.

The second print head is helpful for printing soluble supports. If you’re getting a dual extruder printer specifically for printing with soluble filaments such as PVA and HIPS, you should check whether or not it is compatible with these materials.

Every printer in this list is equipped to print with these materials. And some of the dual extruder 3D printers like the Ultimaker S3, S5, Raise3D Pro 3 go beyond and let you swap your print heads for printing with specific materials, thus increasing their material compatibility.

Enclosure

A 3D printer enclosure plays a crucial role with dual extruder 3D printers. The isolated printing area on enclosed 3D printers lets you print with tricky materials such as ABS filament and keeps 3D printing fumes within the printer body itself.

Aside from the Sovol SV02 and the Tenlog TL-D3, all other dual extruder 3D printers come with at least a partially enclosed design. And with the Creator Pro 2, you get the benefits of both; you can choose to keep the printer open on the top while printing with PLA and fully enclose it when you want to print with ABS.

The Ultimaker S5 goes a step beyond its airflow management system, however, the QIDI Tech i-Fast is the only dual extruder 3D printer on the list with an actively heated build chamber. This ensures that you get the best print quality and that the printer is compatible with a wide variety of materials.

Warranty

Warranty is often an overlooked factor when buying dual extruder 3D printers. You need to carefully evaluate the warranty conditions and everything that is covered within it. Some manufacturers offer a warranty on specific components for a short while, while the best dual extruder 3D printers tend to get comprehensive coverage of any manufacturing defect in the printer.

In this list, all the dual extruder 3D printers have at least a 12 months warranty period that covers any manufacturing defect from the company’s end.

FAQ

Are dual extruder printers faster?

Even the best dual extruder 3D printers are not necessarily faster than any other 3D printer. However, the dual extrusion process leads to an overall increase in productivity due to the ability to print multiple copies at the same time.

However, the dual extrusion process leads to an overall increase in productivity due to the ability to print multiple copies at the same time.

Can dual extruder printers print with soluble filaments?

Yes, all of the dual extruder 3D printers in this list are capable of printing with soluble filaments.

How many extruders can a 3D printer have?

Most 3D printers have a limit of two extruders. However, depending on the electronics capabilities and general hardware setup, some 3D printers can have up to four or five extruders.

What is the advantage of a dual extruder printer?

The dual extruder setup allows for printing with multiple materials, which leads to an increase in productivity. Additionally, dual extruder printers are compatible with a wider range of filaments.

Do dual extruder printers have an enclosed build area?

No, dual extruder printers do not necessarily have an enclosed build area as it is not necessary for their operation. However, some dual extruder printers do come with a partially or fully enclosed design.

However, some dual extruder printers do come with a partially or fully enclosed design.

Can you 3D print multiple objects at once?

Yes, dual extruder 3D printers can print multiple objects at once provided that they have the necessary build volume. However, the print quality may not be as good as if you were to print them one at a time.

What is the average price of a dual extruder 3D printer?

Dual extruder 3D printers generally cost more than single extruder 3D printers. However, the price difference is not as significant as it used to be and there are a number of excellent dual extruder 3D printers in the market at a wide range of prices.

You can find a good one, like the Flashforge Creator Pro 2, for around $650. The best dual extruder 3D printers, however, cost multiple thousands of dollars.

How do you print multiple filaments?

To print multiple filaments, you need to have a dual extruder 3D printer with two extruders. The filaments are then loaded into the extruders and the printer will print with both filaments simultaneously.

Conclusion

Dual extruder 3D printers let you print with multiple materials simultaneously, and that too with ease. Especially with the IDEX style of printers and the multi-material capabilities, you get the added benefits of various printing modes that increase your overall productivity and are great for the batch style of prints.

From the list, the best dual extruder 3D printer that stands out on the top is the Flashforge Creator Pro 2. It gives you the benefits of the IDEX system, is fully enclosed, and has broad material compatibility while still being affordable and accessible for professionals and hobbyists alike. Its only downside is a relatively small print volume.

If print area is your main criteria, you should consider the QIDI Tech i-Fast and the BCN3D Sigma D25 for their large print chambers in decent footprint size. These are professional dual extruder 3D printers with advanced features, excellent print quality, and great for industrial prototyping needs.

Let us know your thoughts on the list, and if you have anything else to add, feel free to comment below.

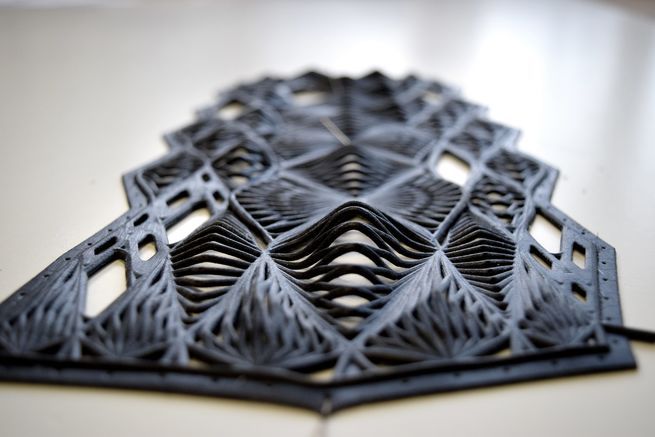

MM3D: Multimaterial Multinozzle 3D Printing

MM3D printing can seamlessly print objects out of inks with varying degrees of stiffness, such as this collapsible origami-inspired sheet. The “joints” are printed from a softer, more flexible material than the “panels,” so the whole structure can be repeatedly folded and unfolded. Credit: Lori K. Sanders3D printers are revolutionizing manufacturing by allowing users to create any physical shape they can imagine on-demand. However, most extrusion-based printers available commercially are only able to build objects from a single nozzle at a time. Those that can deposit multiple inks are even slower due to the additional time required to switch between materials.

Multimaterial multinozzle 3D printing (MM3D), a new technique created by researchers at the Wyss Institute and Harvard’s John A. Paulson School of Engineering and Applied Sciences (SEAS), has finally brought extrusion-based 3D printing-at-scale into the realm of possibility thanks to its unique system of high-speed pressure valves that enable rapid, continuous, and seamless switching between up to eight different printing materials up to 50 times per second, about as fast as a hummingbird beats its wings.

Play

Multimaterial multinozzle 3D (MM3D) printing can switch between up to eight different inks 50 times per second, allowing the creation of complex, high-quality 3D objects in a fraction of the time currently required by other extrusion-based printing methods. Credit: Wyss Institute at Harvard UniversityThe key to MM3D printing’s speedy ink-switching is a series of Y-shaped junctions inside the printhead where multiple ink channels come together at a single output nozzle. The shape of the nozzle, printing pressure, and ink viscosity are all precisely calculated and tuned to prevent backflow and ink mixing during the printing process, thus enabling the precise printing of a 3D multimaterial part. The lengths of the ink channels can also be adjusted to account for materials that have different viscosities and yield stresses, and thus flow more quickly or slowly than other inks.

The lengths of the ink channels can also be adjusted to account for materials that have different viscosities and yield stresses, and thus flow more quickly or slowly than other inks.

Jennifer A. LewisMM3D printing has potential applications in many settings, including:Using our broad palette of functional, structural, and biological inks, disparate materials can now be seamlessly integrated into 3D-printed objects on-demand.

- Rapid prototyping and iteration

- Scalable and massively parallelized 3D printing

- Large-scale and rapid biofabrication

- 3D printed soft robotics and lightweight composite materials

- 3D printed electronics and sensors

The Wyss Institute is seeking industrial and research partners to assist with commercialization efforts of this technology.

Cerafab Multi 2m30: multimeterial stereolithography from Lithoz

News

Subscribe to

Subscribe

I do not want

9000 5 Austrian company Lithoz or the dion-mosquito 3D, the permissible 3rd composite materials based on photopolymer.

Lithoz additive systems are designed with the minimum amount of work material in mind: 3D printing is carried out according to the "inverted" scheme, that is, with the projector under the transparent bottom of the rotating tank, the consumable is added in minimal portions, and then mixed and leveled before the platform is immersed and illumination. This approach reduces the risk of contamination of fresh photopolymers and makes it easier to work with highly viscous and composite materials, such as resins with metal or ceramic fillers.

The CeraFab Multi 2M30 3D printer is interesting in that it has the ability to 3D print with two photopolymer materials simultaneously. This is achieved through the use of two containers on a movable platform. When changing the material, automatic cleaning of residues is provided to avoid mixing. As a result, stereolithographic printing of products with areas of different density or transparency, the combination of electrically conductive and insulating materials, ceramics and metals, as well as the integration of materials with magnetic properties becomes possible. Combination is possible both from layer to layer and within one layer.

Combination is possible both from layer to layer and within one layer.

The resolution of the mask with LED illumination is 1920x1080 with a pixel size of 40 microns, the thickness of the layers varies within 10-100 microns. The size of the construction area reaches 76x43x170 mm.

One example of the application of the new system is the 3D printing of a mandibular implant demonstrator with a zirconia ceramic shell filled with a bioresorbable material ( in the illustration above ). Such a design should contribute to the restoration of bone tissues with the gradual replacement of the implant filling and the final complete osseointegration of the hard shell.

Additional information is available on the manufacturer's website at this link.

stereolithography Lithoz CeraFab Multi 2M30

Follow author

Follow

Don't want

5

Article comments

More interesting articles

13

Subscribe to the author

Subscribe to the author

Don't want

The author of the best feature article will receive a new system for 3D printing with photopolymer resins from. ..

..

Read more

5

Subscribe to the author

Subscribe

Don’t want

Rostec State Corporation presented at the Weldex-2022 exhibition a vacuum cathode-beam...

Read more

82

Subscribe to the author

Subscribe

Don't want

Collaboration 3D

We are pleased to present you our joint development with Speci...

Read More

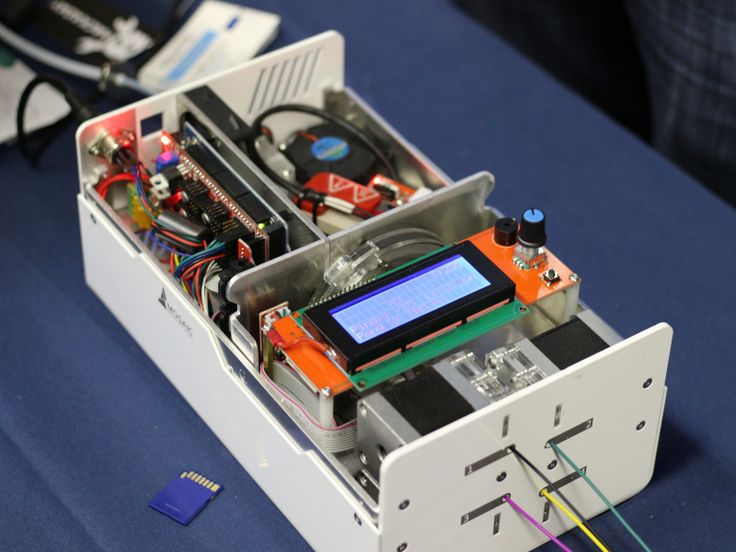

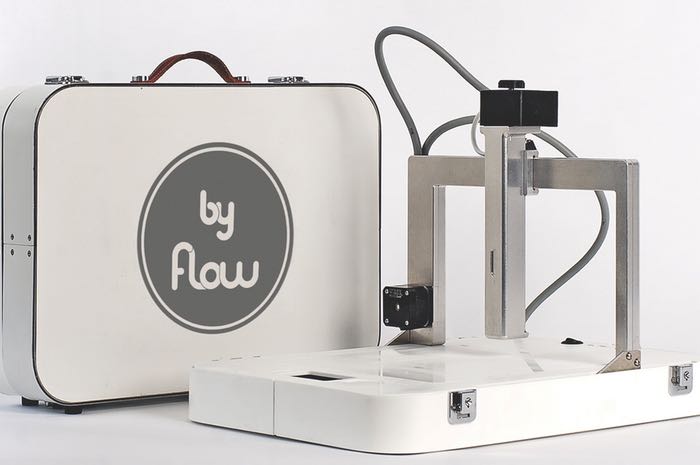

Palette 2S Pro 3D Printing Mixing Gadget Overview

Table of Contents

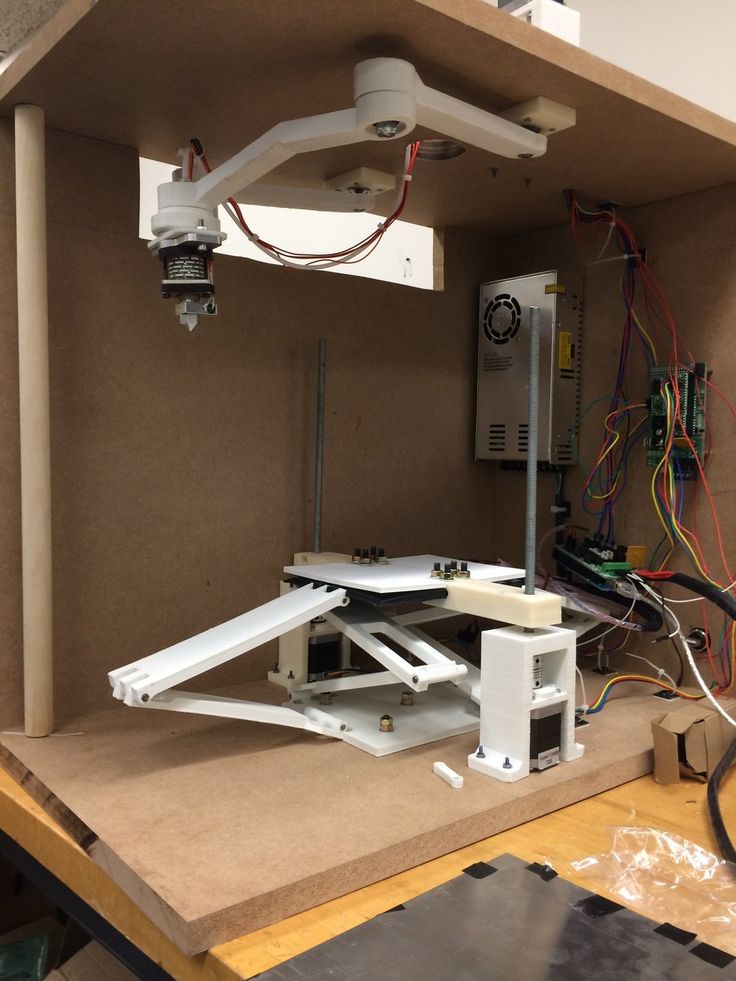

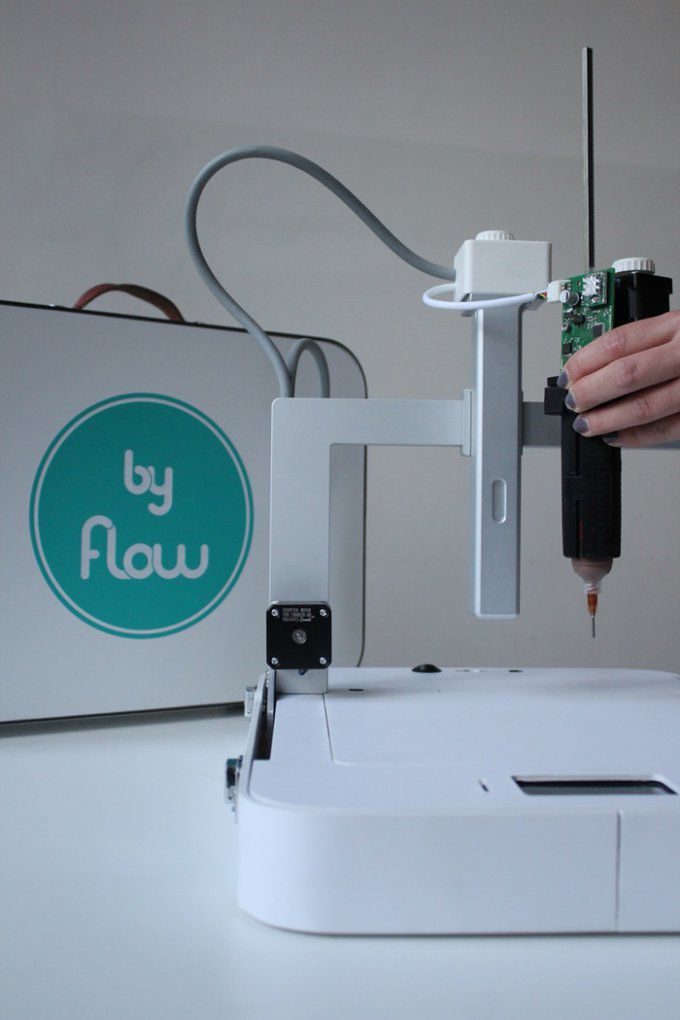

Today we are going to talk about an updated professional 3D printing gadget that can mix materials right in the process of 3D printing.

Specification

| Specification | Meaning |

|---|---|

| Technology | FFF |

| Splicing technology | Splice Core S Pro, Solid State Splicer |

| Media | PLA, TPU, PETG, Scaffold |

| Thread diameter, mm | 1. 75 (0.069 IN), recommended tolerance max. 0.03 mm 75 (0.069 IN), recommended tolerance max. 0.03 mm |

| Print speed mm/min | 182-280 |

| Operating temperature | 15-30°C (60-86°F) |

| Motor | 6 x Nema 17 Stepper Motors |

| Housing material | Aluminum |

| Control | 32-bit ARM 9 processor0112 |

| Display | 3.2” color touch screen 240x320 pixels |

| Connection interface | Canvas Hub (USB) or SD card |

| Software | Windows, Mac, Linux (Tested on Ubuntu 16.04) |

| Power supply | 100-240V (50/60Hz) 1.5A |

| Power supply | 12 V DC, 3 A Max |

| Weight (without packaging), kg | 3.6 |

| Weight (with packaging), kg | 7.1 |

| Dimensions (without packaging), mm | 230x204x840 |

| Dimensions (with packaging), mm | 470x210x230 |

| Certificates | cTUVus, CE (Conformité Européene), TUV-Inspected Manufacturing Facility, CAN/CSA C22. 2, NO 62368-1-14 2, NO 62368-1-14 |

| Country of manufacture | Canada |

Description Palette 2S Pro

Canadian company Mosaic Manufacturing has introduced the Palette 2S Pro, an improved version of the device for mixing plastic filament directly in the printing process. It is designed for soldering four strands of plastic for multi-color and multi-material printing in real time. The device cuts bars, heats, connects and cools them. For best results, the manufacturer recommends choosing a plastic with the same melting point.

The gadget is suitable for printing on 3D printers that have a single extruder and use a standard filament diameter of 1.75 mm for their work. Since the longest action is cooling, that is, the filament must have time to cool before being fed into the print head, the glass transition time of materials should be taken into account. This will affect the print speed. For example, ABS and nylon heat up and cool down faster than PLA. Accordingly, their processing speed will be higher. Processing can also be affected by factors such as layer height, nozzle diameter, extrusion multiplier, print acceleration settings in the slicer and in the printer, and high-volume printing of thin-walled objects.

This will affect the print speed. For example, ABS and nylon heat up and cool down faster than PLA. Accordingly, their processing speed will be higher. Processing can also be affected by factors such as layer height, nozzle diameter, extrusion multiplier, print acceleration settings in the slicer and in the printer, and high-volume printing of thin-walled objects.

Recommended print speeds for various materials

| Material combination examples | Print speed in [mm/s] with Palette 2S Pro |

|---|---|

| PLA-PLA | 80 - 135 |

| ABS-ABS | 122 - 221 |

| PETG-PETG | 101 - 176 |

| TPU-TPU | 66 - 109 |

| PLA-PVA or PVOH | 65 - 108 |

| PLA-TPU | 47 - 75 |

| Nylon-Nylon | 179 - 280 |

The following settings were used for the recommendations above:

-

Layer height 0.

2 mm, nozzle diameter 0.4 mm, extrusion multiplier 1.0;

2 mm, nozzle diameter 0.4 mm, extrusion multiplier 1.0; -

4-color multi-color printing in standard Palette 2 printing mode;

-

recommended fusion settings for each material.

When in doubt, we recommend using the minimum print speed set in the slicer.

If you want to increase the print speed, use the "Speed Control" function included in the CANVAS Hub S. With it, the printer will only print slower when the filaments are connected. This method is especially good for standard four-color models and for printing with a gradient or in another special mode.

Exterior

Palette 2S Pro has a solid aluminum body and a transparent inner panel except for the areas where the heating elements are located. The lid is attached to magnetic holders, it can be easily removed at any time and inspect the insides. On the front there is a touch screen, which is easy to use.

Delivery kit

Palette 2S Pro comes with manual and consumables:

-

blades and straws

-

power supplies for 3A and 12V

-

adapters for different types of sockets

-

screwdriver

-

2 Teflon tubes

-

cable and tube clip

-

stand

-

wall mount.

Software

The unit comes with a Canvas Platform Slicer. It supports all the necessary settings for mixing colors, materials and speed control. For compatibility with third-party software, the free Chroma app is used.

Also, for the correct collaboration of the printer, PC and Palette 2S Pro, you can separately purchase a specialized communication node - CANVAS Hub S. It allows you to control printing and transfer files via the Internet and local network. It has a simple intuitive interface that greatly speeds up the work with plastics, the function of the transition with filling to save time and materials, and also helps to easily track, organize and save models and parameters in the cloud storage.

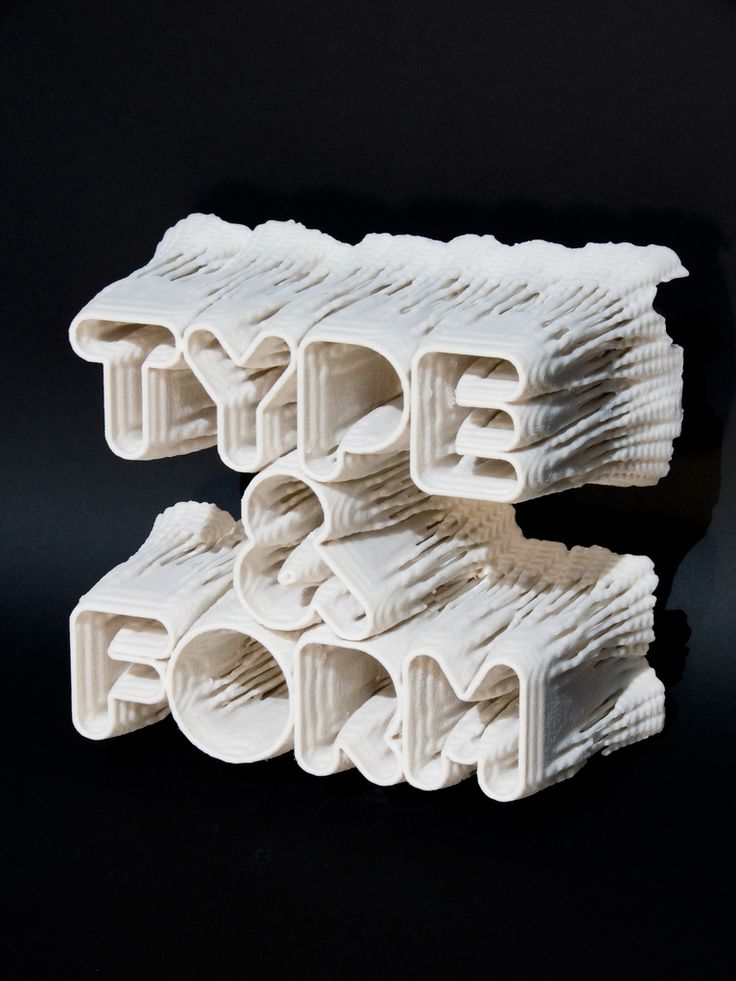

Examples of printing using Palette 2S Pro

A wide range of applications of this splicer allows you to create a bright unusual design of familiar things: dishes, toys, jewelry, architectural models, souvenirs.

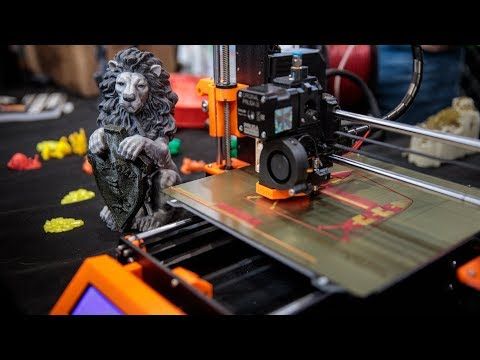

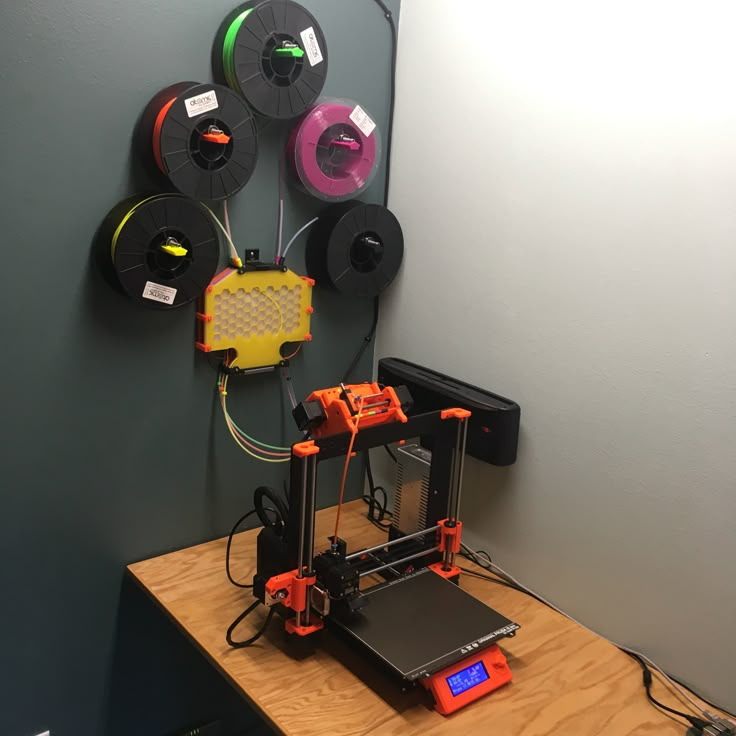

For example, Facebook user Cristian Castiglioni used his Prusa I3 Mk3 3D printer to print Leonardo's figurine from Teenage Mutant Ninja Turtles using a Palette 2S Pro.

German Instagram user Jens posted a Christmas present on his account - custom-made key rings.

For St. Patrick's Day, Tiffy's Lemonade Stand printed four-color plastic leaf earrings. And also not without the help of Palette 2S Pro.

3Dprintman posted on their account a layout of the Florence Cathedral, printed using Palette 2S Pro and Canvas Hub-S on a Prusa I3 MK3S.

But such an original tray was presented in the official Mosaic Manufacturing Facebook group.

Pros and Cons of Palette 2S Pro

Benefits of using Palette 2S Pro:

-

Increased soldering speed compared to previous models,

-

Ready factory firmware,

-

Printing in different colors and plastics,

-

Less waiting time with frequent material combinations,

-

Cancel printing from machine panel directly,

-

Updated drives for reliable operation with soft plastics,

-

Compatibility with other software via Chroma app,

-

Possibility of updates and additions,

-

2 year extended warranty.

Not without some cons:

-

Unable to change the temperature during printing. It is necessary to select materials with the same melting point.

-

It is not possible to use plastics with abrasive particles - ceramic, carbon fiber, etc.

-

Expensive cleaning. Color change costs on average an additional 150-230 mm of thread.

However, the issue of plastic waste when changing colors has been resolved with a firmware update to the Pallete 2S Pro software. The standard mechanism for changing the filament color when printing with one nozzle is as follows: the slicer sets the thread consumption with a certain margin, and when the time for color change comes, the printer stops printing the specified object and proceeds to print some draft object, conditionally "tower", to be used to the end the remainder of the thread of the same color and eliminate the color transition on the final printed object. After completely removing the plastic of the first color from the nozzle and starting printing with the second color, the printer returns to printing the main, finishing object.

After completely removing the plastic of the first color from the nozzle and starting printing with the second color, the printer returns to printing the main, finishing object.

Updating the Pallete firmware solves this problem: the transition from one color/plastic type to another is done inside the printed object, i.e. internal filling of the object to give it strength and stability is combined with cleaning the nozzle when changing threads. Such a feint allows you to save plastic, unlike the standard method with a draft "tower". The manufacturer also recommends printing on the platform the maximum number of products at a time to reduce costs.

It is important to note that although the palette of colors printed with Palette 2S Pro is limited, it is resistant to fading, rough handling and does not require expensive ink cartridges for color printing.

Conclusion

This device is the best solution for professionals in the field of toys, souvenirs, mock-ups, prototypes, promotional products, and for amateur makers.