3D printer using copper

Introducing 3D Printed Copper

Learn Blog

Our team is extremely excited to introduce our newest material for the Metal X — Copper. For the first time ever, it’s now incredibly simple to 3D print pure copper. With the Markforged Metal X system, you can now easily manufacture complex parts with high electrical and thermal conductivity that were previously expensive, time-consuming, or impossible to make. Copper joins the already available Metal X materials — 17-4PH Stainless Steel, Inconel 625, h23 Tool Steel, D2 Tool Steel, and A2 Tool Steel.

What is Markforged Copper?

Markforged Copper is greater than 99.8% pure copper with excellent thermal and electrical conductivity and high ductility. Markforged Copper can be used where thermal or electrical conductivity is required — and traditional manufacturing processes are too expensive or fall short. Alternatively, customers who work with aluminum over copper because of its processing challenges can now take advantage of easily 3D printing a copper part, and benefit from the material’s higher thermal and electrical conductivity.

Source: https://www.upmet.com/

Copper is our first metal material that is valued for thermal and electrical properties, marking an exciting time at Markforged. Check out our data sheet to get a more in-depth look at the electrical, thermal, and mechanical properties.

Check out our data sheet to get a more in-depth look at the electrical, thermal, and mechanical properties.

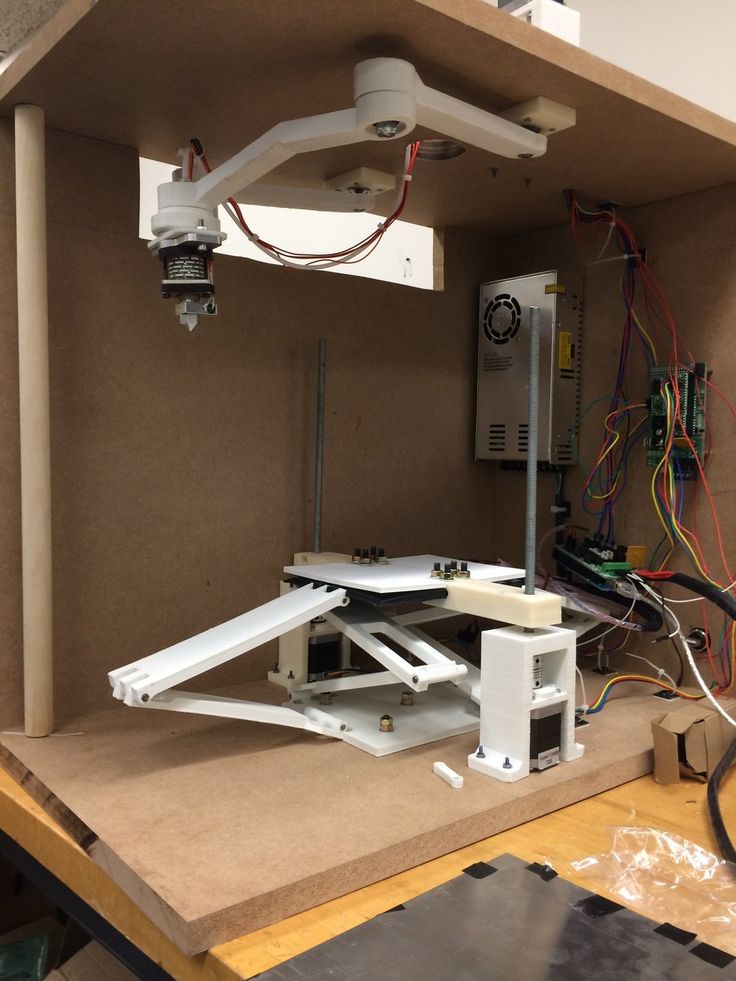

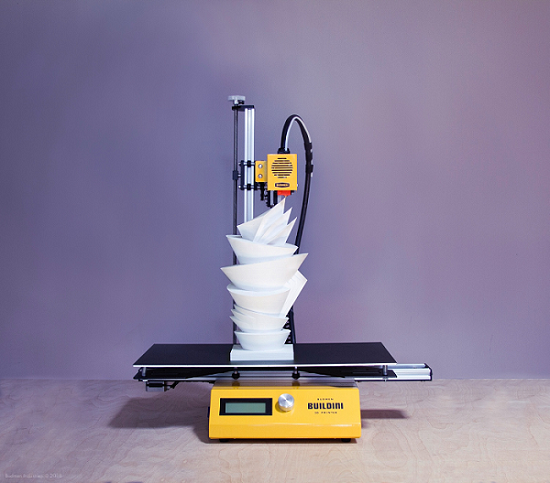

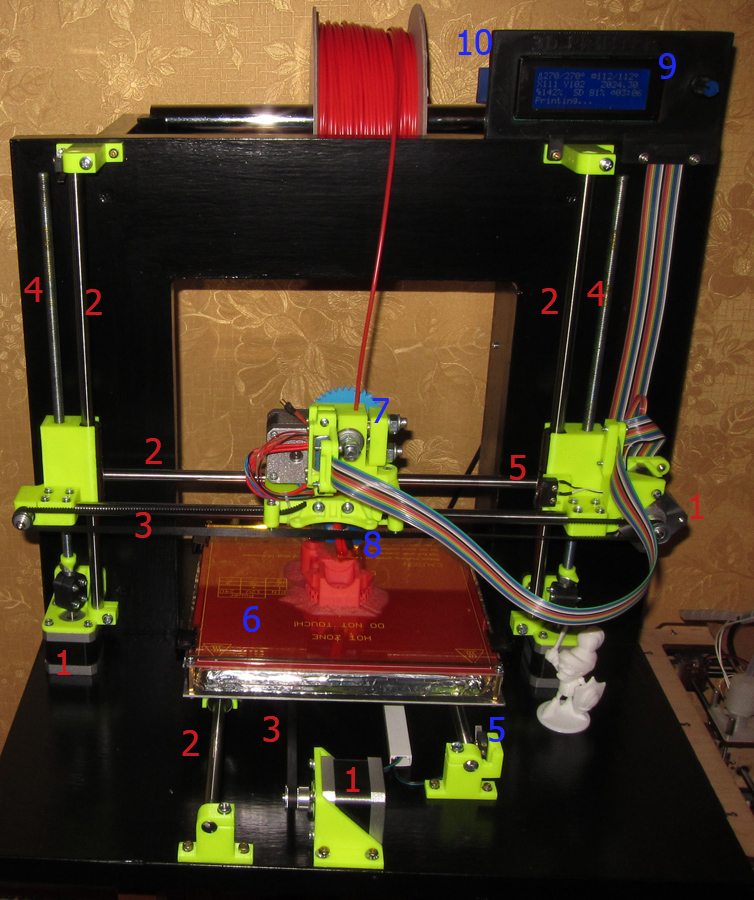

Copper on the Metal X System

Copper parts coming out of the Markforged Sinter-2

There are several reasons why we’re excited about the addition of Markforged Copper:

- One platform.

Printing with Markforged Copper involves the same simple process Markforged customers are used to with our existing metal materials on the Metal X System. No hardware changes are needed to start printing copper. Markforged customers order a spool, choose ‘Copper’ in the material drop-down menu in our cloud-based slicing software Eiger, and begin printing right away. Switching materials on the Metal X takes about 10 minutes. With the addition of Markforged Copper, we are excited that customers can now make electrical and heat transfer components on the same printer as our stainless steel, nickel super alloy, and tool steels. In our labs, we are working on additional materials to further expand the line up.

In our labs, we are working on additional materials to further expand the line up.

- Easy to print.

The Metal X leverages a Fused Filament Fabrication (FFF) processing method that makes printing copper simple for the first time. The process starts with metal powder, captured in a plastic binder (which makes it safe to handle filament on a spool), and then forms it into the part shape one layer at a time. After printing, users wash the part to debind the wax, and then load the part in a furnace which thermally removes the remaining binder and then sinters the powder into the final fully metal part. This process overcomes the traditional challenges of 3D printing copper with directed energy systems (such as DMLS) due to copper’s high thermal conductivity.

- Expanded applications.

Markforged Copper offers Metal X customers the ability to print parts that require thermal and electrical conductivity. This breaks open a new set of applications for manufacturers across industries.

This breaks open a new set of applications for manufacturers across industries.

A 3D printed Copper weld shank

Applications

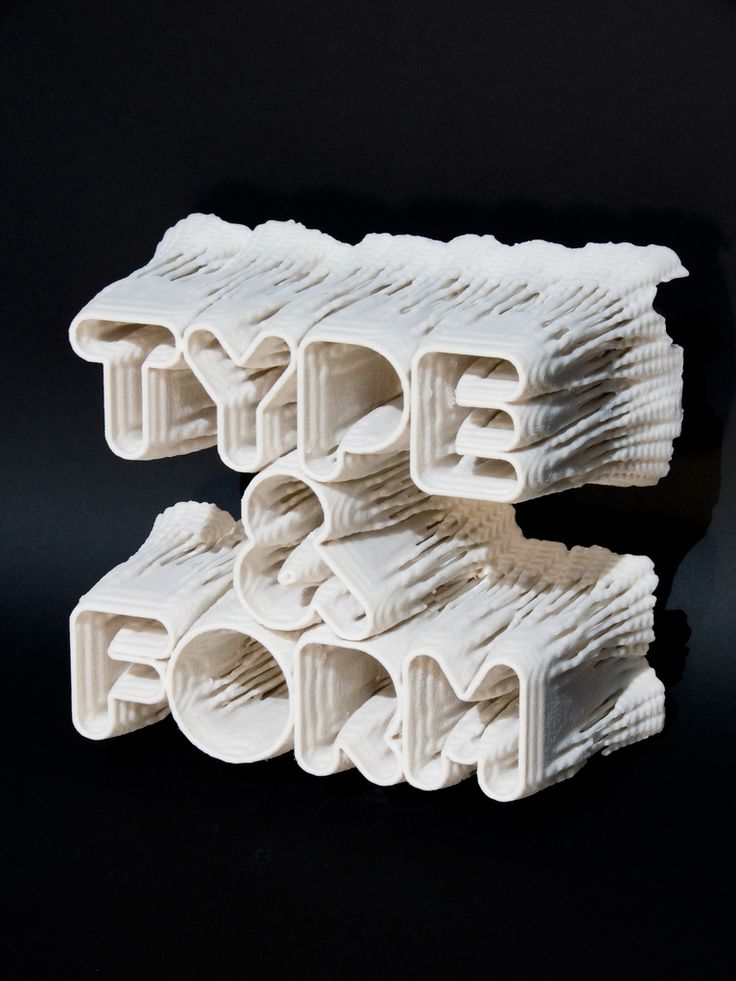

From heat sinks and bus bars, to custom welding shanks, Markforged customers are now able to reinvent the way they manufacture copper components. Customers are even experimenting with printing parts with complex internal cooling channels. Eliminate brazed or welded assemblies to reduce cost, increase consistency, and get rid of weak points. Here are some of the other ways you can use Markforged Copper:

- Low-volume Production Parts. Print in copper for low-volume production parts when the cost of tooling would be too high and the geometries are complex. Examples include bus bars and heat sinks.

- Tooling. Users have already started seeing great results in printing tooling in copper. A great example would be spot welding arms, which require high electrical conductivity.

- Functional Prototypes.

Users can test out ideas in Markforged Copper before investing in production tooling.

Users can test out ideas in Markforged Copper before investing in production tooling.

Conclusion

Copper is now available for Markforged customers around the world. We’re really looking forward to seeing what our customers print with Markforged Copper. Markforged 3D printing platform is transforming manufacturing today— so what are you waiting for?

Request a demo

All of the blogs and the information contained within those blogs are copyright by Markforged, Inc. and may not be copied, modified, or adopted in any way without our written permission. Our blogs may contain our service marks or trademarks, as well as of those our affiliates. Your use of our blogs does not constitute any right or license for you to use our service marks or trademarks without our prior permission. Markforged Information provided in our blogs should not be considered professional advice. We are under no obligation to update or revise blogs based on new information, subsequent events, or otherwise.

Never miss an article

Subscribe to get new Markforged content in your inbox

required required requiredSubmit

5 ways you can 3D print with copper

Home > Latest Articles > 5 ways you can 3D print with copper

By Leslie Langnau Leave a Comment

According to a recent analyst forecast, the market for using copper material in 3D printing applications will grow 51% thanks to key technical developments in copper additive processes and materials.

While copper materials are being explored within each of the three primary metal AM print technology families, their chemistry presents challenges to processing using established or ‘conventional’ metal AM system configurations in most available technologies. These challenges include:

These challenges include:

• Alterations to or adaptations of hardware architecture of existing printing systems

• Tailoring of material properties and powder characteristics of copper materials used

• Development of alternative metal additive printing technologies suited to copper printing

Several additive vendors, however, have developed unique ways of solving these challenges.

GE Additive Arcam uses Electron Beam Melting (EBM) to produce electrically pure copper in geometries not possible with traditional manufacturing. The novel geometries can help remove other process steps such as; soldering, joining or bending, especially where these steps might compromise conductivity and possibly the lifetime of the component.

Copper’s ability to absorb energy varies with the wavelength of the energy source. Pure copper absorbs 80% of the energy from an electron beam, compared to only 2% of the energy from a red laser beam. This gives EBM an advantage in terms of the ability to melt.

The vacuum environment in which EBM operates minimizes the oxygen pick-up in copper, allowing a high conductivity copper to be produced. Oxygen reduces the conductivity of copper while also embrittling the component.

The ability to produce complex geometries in pure copper without compromising the high electrical or thermal conductivity is suited to a range of sectors, including the automotive industry, or customers looking at applications for electrical connectors, induction coils, and heat exchangers.

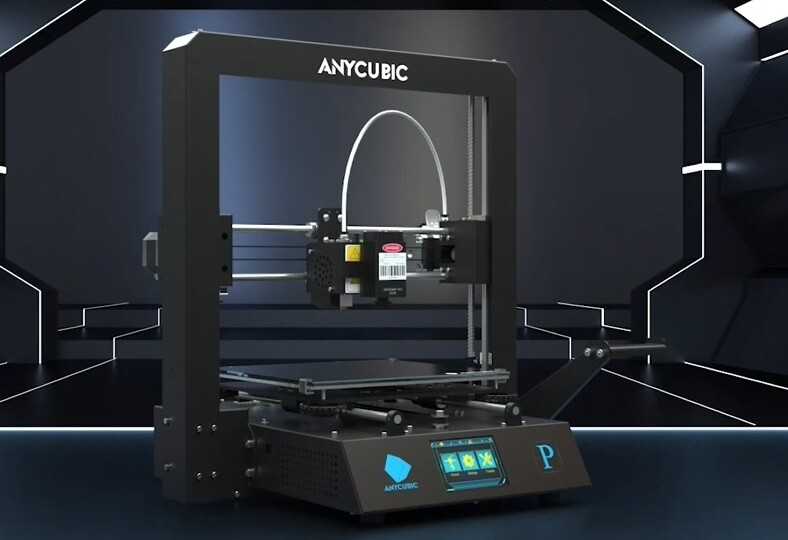

The Markforged Metal X 3D printer can be used to manufacture complex copper parts with high electrical and thermal conductivity. Markforged uses a copper that is more than 99.8% pure. (The Metal X System also works with Markforged stainless steel, nickel superalloy, and tool steels and aluminum over copper options.)

The copper powder is combined with a plastic binder and extruded in a Fused Filament Fabrication (FFF) process like other materials offered by Markforged. Once a part is built, users wash the part to debind the wax, and then load the part in a furnace which thermally removes the remaining binder and then sinters the powder into the final fully metal part.

Once a part is built, users wash the part to debind the wax, and then load the part in a furnace which thermally removes the remaining binder and then sinters the powder into the final fully metal part.

Applications include heat sinks, bus bars, custom welded shanks, and parts with complex internal cooling channels. One benefit of 3D printing this way is it can eliminate brazed or welded assemblies.

Optomec offers a pure copper additive manufacturing process using its LENS directed energy deposition (DED) systems. Pure copper is a challenge for DED systems because of its high reflectance. The infrared wavelengths on most standard, laser-based AM systems are not readily absorbed by copper, making it difficult to establish a melt pool as the laser energy is reflected back into the source, causing havoc. Optomec’s laser-based solution is virtually immune to any back reflection, so the laser can operate at full power on reflective surfaces without difficulty. Optomec engineers have developed process parameters to account for thermal conductivity differences, as well as big changes in absorption and have demonstrated efficient DED builds with pure copper.

Establishing a DED process for pure copper is particularly important for designers of heat exchangers in a variety of industrial applications in aerospace and chemical processing. The Optomec copper process is also applicable to alloys of copper such as bronze, brass and cupronickel.

Spee3D introduced its copper 3D printing system a couple of years ago. This additive manufacturing technology uses supersonic deposition. Material is shot through a jet engine nozzle at speeds to Mach 3, and deposited in geometric patterns layer by layer. Known as Supersonic 3D Deposition (SP3D), no heat is used to melt the metal powders. And parts can safely be handled immediately after the build. The sheer kinetic energy of the moving particles causes the powders to bind together to form a high-density part with normal metallurgical properties.

The technology suits the production of parts you would otherwise build using sand or die casting. Applications include automotive, mining, commercial, HVAC and industrial parts. The machine does not need to use inert gases as the process works with normal compressed air. Post processing consists of finish machining. The deposition rate is up to 100 g/min. The deposition spot size is 4 to 7 mm.

The machine does not need to use inert gases as the process works with normal compressed air. Post processing consists of finish machining. The deposition rate is up to 100 g/min. The deposition spot size is 4 to 7 mm.

Stratasys offers Copper (C18150), a chromium zirconium copper (CuCr1Zr) alloy, which offers excellent thermal and electrical conductivity. The company implemented controlled heat treat processes to optimize mechanical and material properties.

Stratasys uses its direct metal laser sintering (DMLS) technology with copper. Designers developing parts to be made of copper should keep an eye on wall thicknesses and feature details. Conformal cooling and complex internal passages may require the use of support structures. With heat exchangers, thinner walls are better, but there are limits on wall thinness–roughly 1000 micrometers of 0.040 in. In some cases, parts will need post-processing, including machining to improve the finish. Heat treatments may be needed for densification.

You will also find a number of service providers able to offer 3D printing with copper materials.

Filed Under: FAQs, Materials

Copper 3D Printing - Complete Guide

Copper is one of the newest and most promising areas of metal 3D printing for everything from electric motors to heat sinks.

Previously, copper 3D printing was a challenge due to the metal's reflectivity and high thermal conductivity, but advances in printers and materials have largely resolved these early problems. Today, 3D printed copper propulsion systems send rockets into space, 3D printed copper heatsinks cool processors, and 3D printed copper coils boost the performance of electric motors.

3D printed copper parts (Source: Trumpf)

Why 3D print copper?

Copper has always been a very useful metal due to its ability to conduct heat and electricity, resist corrosion and even kill bacteria and viruses. Demand for complex copper parts is on the rise as 3D printing opens up even more uses and possibilities for this metal.

3D printing (also known as additive manufacturing) enables the creation of exceptionally complex shapes, fine details, internal structures and lattice inserts that are not possible with any other form of metal fabrication. These capabilities reduce weight, increase efficiency, and reduce fabrication and assembly times, as multi-component assemblies can be 3D printed as a single unit.

Additive Metallurgy

3D printing also makes it possible to produce this relatively expensive metal more efficiently, reducing waste because only the amount of material needed is used to make each part. For companies interested in copper 3D printing, reducing raw material costs is critical.

If you already produce custom copper parts, 3D printing can significantly reduce your production costs while optimizing part performance.

Markforged 3D printed copper heatsink (Source: Markforged)

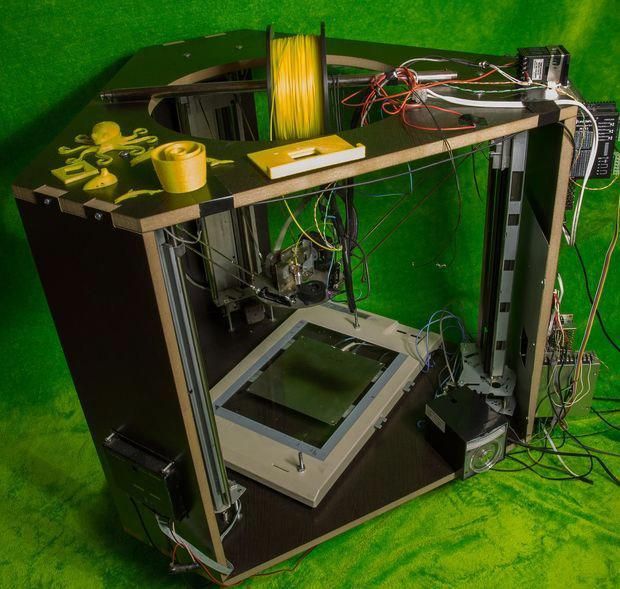

Although there aren't many 3D printers that can print copper, there is still a wide variety of printing technologies and prices.

FDM printers using copper-filled plastic filament can produce copper jewelry, decorative items, and other parts that are almost 100% copper. While for more advanced production, 3D printers using copper powder, rods or copper polymer slurry produce industrial parts with excellent mechanical and conductive properties, which can meet international standards such as IACS (International Annealed Copper Standard).

Let's look at what types of printers can work with copper today.

Trumpf's TruPrint 1000 Green Edition 3D printer

several equipment manufacturers have recently included copper in their material list. Since copper is highly reflective, laser processing of the powder has been a hurdle for manufacturers. However, this technology and materials have evolved to solve this problem.

3D printer manufacturer Trumpf, for example, has developed an industrial green laser that can 3D print materials such as copper, copper alloys, and precious metals that are difficult to process with infrared waves.

Two powder layer technologies for metal 3D printing, DMLS (Direct Metal Laser Sintering) and EBM (Electron Beam Melting), work by depositing a thin layer of copper powder onto a platform inside the printer. The powder heats up while lasers or electron beams draw the first layer of the part. When the particles in the layer fuse, the platform is lowered slightly into the assembly chamber, and fresh powder is poured on top, and the process is repeated. Some of the copper powder left over from the process can be recycled for use in the next print.

Copper additive manufacturing powder from GNK Powder Metallurgy (Source: GNK)

Copper-bonded 3D inkjet printers

Copper powder bonded with a liquid binder and sintered in a furnace is a 3D printing technique known as binder inkjet printing that produces parts without the use of an auxiliary material. Binder jetting is a no-heat process in which a bonding layer is sprayed between each layer of metal; the binder is then removed during the sintering process.

Binder blasting is a popular additive manufacturing method for high volume metal parts.

Featured image of

Metal-on-Copper FDM Blasting Bet

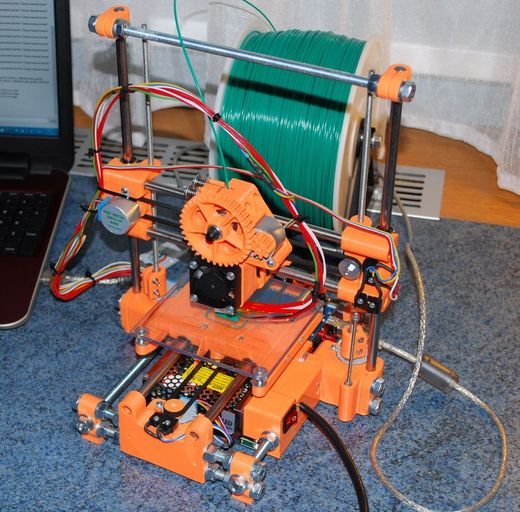

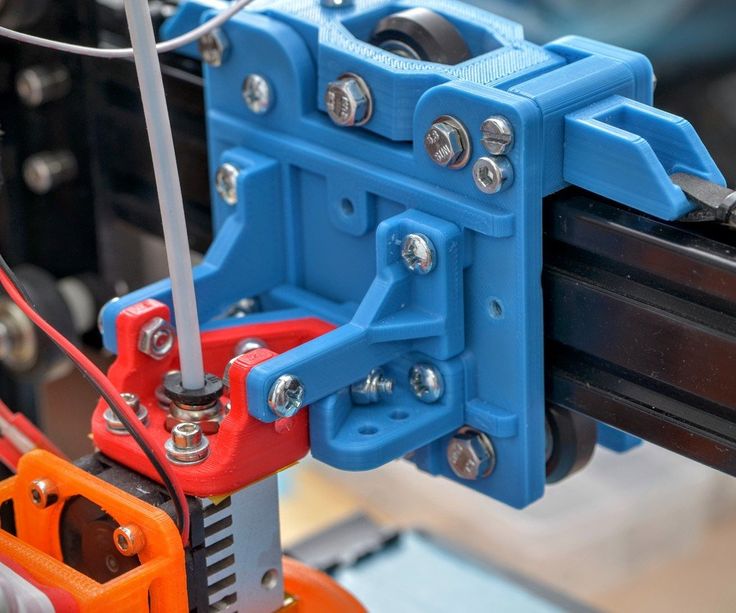

Metal-on-Copper Printed Copper Parts The most economical approach to 3D printing copper parts is to use machines that extrude the filament. Metal filament for printing metal parts consists of a plastic base with metal particles evenly interspersed in it. Copper interspersed filament for copper parts is a unique type of composite filament that, when used correctly, produces strong, chemically resistant, and near-solid metal parts. Virtually any Fused Deposition Modeling (FDM) printer can print near-solid metal parts using a polymer filament filled with copper powder. Currently, there is only one option on the market - from the manufacturer of threads The Virtual Foundry. The company claims that its copper filament is suitable for printing on any filament 3D printer with a hardened nozzle and a hot end that can reach temperatures of up to 225ºC. Other types of copper thread contain enough real copper particles to be polished and given a metal-like weight, but are for decorative purposes. A company in Chile called Copper3D produces a copper-filled filament that produces parts that do not have metal parts, but parts that have the antibacterial and antimicrobial properties of copper. NASA is even testing the filament for use in "interplanetary microbial contamination," according to the company. In addition to the mainstream FDM printers, two other filament-extruding printers also offer copper, but they use their own proprietary materials. Desktop Metal uses a bonded metal filament, while Markforged uses a similar metal powder bonded into a plastic matrix. The printers from these manufacturers produce all-metal parts designed for industrial use, such as machine tools, induction coils, heat sinks, and functional prototypes. Cold spray and DED copper 3D printers WarpSpee3D cold spray 3D printer (Source: Spee3D) Although these two methods of metal 3D printing are not usually combined together, we are combining them here due to their general application for coating metal parts with another metal and for layering metal parts with metal powder. Directed Energy Deposition (DED) is a system developed by Optomec of New Mexico to create, improve and repair metal parts. Like SLS, in DED, high-power lasers build up 3D structures in layers, creating parts with high density and strength, ideal for mechanical applications. In 2019Optomec developed a new copper DED process to produce heat exchangers for use in the aerospace, chemical and other industries. Spee3D's WarpSpee3D process is unique in its use of supersonic 3D deposition to produce parts from a range of metal powder materials, including copper and aluminum. Cold spray is an additive manufacturing technique in which metal powder is injected into a supersonic pressurized gas stream. Cold spray is also the fastest metal 3D printing method. Spee3D printed a 17.9kg (17.9kg) pure copper aerospace rocket nozzle lining (pictured below) on WarpSpee3D in about three hours at a cost of just $716, according to the company. Parts like this are usually made from solid forged copper, which takes weeks and costs tens of thousands of dollars. One of the disadvantages of DED and cold spray is that they are limited in the production of complex geometries. Rocket nozzle copper plating, engineer spark-free copper hammer and copper cable clamp, 3D printed by Spee3D (Source: Spee3D) Photopolymerization Holo) Metal DLP 3D printing is similar to resin 3D printing in that it uses UV light projected onto a photosensitive slurry to cure layer by layer. California startup Holo recently completed a facility where it plans to 3D print pure copper parts on its proprietary 3D printers that are not for sale. Holo will specialize in 3D printed copper cooling solutions for high performance computers, electric vehicles, RF antennas and heat exchangers. Admatec, a Dutch manufacturer of 3D printers, offers printers that also use copper slurry to produce highly detailed copper parts. Copper slurry material for 3D printing (Source: Admatec) Share article:  However, parts do not become metal immediately after printing and require additional post-printing steps to melt the resin binder and leave only the metal.

However, parts do not become metal immediately after printing and require additional post-printing steps to melt the resin binder and leave only the metal.

Instead of melting the metal, cold spraying holds it together in a process called plastic deformation. Companies such as Spee3D are using cold spray technology to apply an antimicrobial copper coating to doors, handrails and touch panels intended for use in hospitals, schools and other public places.

Instead of melting the metal, cold spraying holds it together in a process called plastic deformation. Companies such as Spee3D are using cold spray technology to apply an antimicrobial copper coating to doors, handrails and touch panels intended for use in hospitals, schools and other public places.  Instead of resin, metal DLP printers use a liquid polymer filled with metal powder and a small amount of binder. After the parts are printed, they have to go through several more stages before they become the final metal parts. Metallic DLP printing is valued for fine detail.

Instead of resin, metal DLP printers use a liquid polymer filled with metal powder and a small amount of binder. After the parts are printed, they have to go through several more stages before they become the final metal parts. Metallic DLP printing is valued for fine detail.

3D Printing copper products

14 But did you know that you can 3D print it? Check out this article to find out more.

What is this?

Even coins can be 3D printed (but they are not legal tender). (Source: i.materialise.com)

(Source: i.materialise.com)

Although metal printing in general is still quite difficult at home. However, there have been significant advances in professional metal printing over the past few years. This is now commonplace in some industries, such as the automotive industry.

Method 1: FDM Printing

This Filamet copper engine block was printed on a standard FDM printer. (Source: hackaday.com)

In terms of FDM printing, the only real option is to use copper filament. Many try to produce it, but only one company, The Virtual Foundry, achieves 90% metal in their PLA hybrid filaments. The idea behind the filament is that once an object has been printed, it can be fired in a sintering oven to achieve a 100% copper composition.

Of course, one of the big drawbacks of this method is that the loss of the PLA binder causes the part to shrink by 15-20%. However, most details can be adjusted before printing.

After firing the material in a furnace, it retains all the properties of copper, incl. high electrical conductivity.

Of course, this thread does not come cheap. One kilo costs $121, and because of the much higher density of copper, you end up with a lot less filament than you'd expect than if it were 100% PLA.

Unlike conventional PLA, Filamet must be preheated and hung on a low friction spool holder to prevent filament breakage during printing. Also, Virtual Foundry recommends printing slowly (less than 30mm/s) at first.

In terms of performance, the filament can print layers up to 100 microns thick.

Method 2: Direct Metal Laser Sintering (DMLS)

Parts manufactured using DMLS. (Source: proto3000.com)

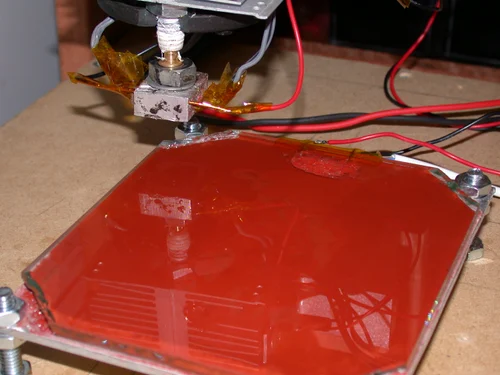

DMLS is a laser-assisted process that fuses metal powder into a fully functional 3D part. The powder is deposited and the product is built up layer by layer. After building the part, excess powder must be removed using compressed air in a closed chamber.

This process is quite messy and requires tools similar to those that will be used for a sandblasting system. Health issues should also be taken into account, as it is dangerous to breathe small metal particles.

Buying your own DMLS machine is not an option for most people as these machines typically cost over $100,000. However, various 3D printing companies can print your parts on demand. Despite this low availability, DMLS has many uses, depending on the type of metal used. For example, NASA is investigating DMLS to produce printed rocket parts.

Price: Depends on the complexity of the part and the amount of metal used, but generally over $1,000 per kilo.

Availability. The availability of DMLS technology is essentially zero for a person who wants to purchase their own machine, but it is possible that a 3D printing service will print your part for you.

Performance: The layer thickness is about 38 microns, and the finished metal part has the same properties (conductivity, density, etc. ) as the cast metal part.

) as the cast metal part.

Method 3: Investment casting

Cast metal part. (Source: 3D systems)

Wax casting

Lost wax casting is the process by which an original object created in wax can be turned into a mold to create a part from another material (usually metal). The steps to achieve this goal are as follows:

1. Create an object in wax.

2. Pour plaster around the wax part to create a plaster mold.

3. Place the plaster mold in the oven to burn the wax out of the inside of the mold.

4. Pour molten metal into a plaster mold to create a cast object.

5. Clean the part from the plaster mold.

It should be noted that this investment casting process results in the loss of small parts and results in a finished part smaller than the original wax cast. Therefore, exact dimensions compared to the original part should not be expected without careful consideration of material shrinkage.

PLA Casting

Lost wax casting is done in the same vein with 3D printing, but it is a faster process. You need to follow a few simple steps.

1. 3D printed object in PLA. During the design process, access channels can be designed in detail to make it easier to pour the copper into the mold after it has been created.

2. Create a plaster mold around the 3D printed object.

3. Burn the PLA from the inside of the mold.

4. Pour molten metal into an empty plaster mold to create a cast object.

5. Clean the finished part.

In terms of cost, printing an object will cost no more than a few dollars (depending on the size of your print). The price of melting PLA depends on whether you are using an existing oven or decide to build your own. Furnaces can cost anywhere from $500 to several thousand dollars, depending on the size and thermal performance desired. Gypsum and sand can be purchased for less than $50, depending on the quantity needed.