3D printer bunnings

Everything you ever wanted to know about 3D Printing in Australia but were too absolutely munted to ask : 3Dprinting

Oi, ya fuckin cunts know we have our own australia-focused subreddit for 3D printing? Problem is that it's about as dead as a tasmanian tiger (probably extinct, maybe not? who knows) and most Q&As put through here are of an American/European bent. So here's basically the masterpost of everything Australia-specific I've ever both seen asked and wanted to know but didn't find here.

Q: I want a printer! What options are available to me?

A: You're fucked on shipping. Most options that get recommended for beginners are simply out of reach for Australians. Monoprice want anything from $200-$400 for shipping alone, you realize? In USD.

Luckily most antipodeans have the advantage of being relatively closer to China-based warehouses so actually feasible options are things like the Creality Ender 3(Pro)/CR-10(S), the gamut of Tevo clones, theoretically the Wanhao lineup but YMMV*, plus any of the poorly made Mk3 copies that infest the Eastern 3D printer market. Places like Aliexpress, Banggood, etc. will have correspondingly shorter shipping times based on where you are on this blighted continent of death. Those are essentially your budget options, where you can depend on a modicum of support from the community without having to pay over $500 (AUD) or so.

*They actually have a Sydney-based reseller but local resellers often pass the cost of shipping down to us pretty much unmodified so all you save is time

Q: What about Amazon?

A: Fuck Amazon. You know how many American/European people I see recommend Amazon and link Amazon shit and go "yes go with Amazon for the customer service and returns policy"? This straw man answer is more for those people who may not be aware that

Amazon don't fucking ship anything down here

Q: But Amazon.com.au exists!

A: Guess what isn't on it and therefore is unavailable to us antipodean fucks, oh look it's literally 95% of everything ever posted

Q: Okay but

A: fuck amazon

2) Q: So I'm limited to kits from China? I don't want to build a kit, though, and my budget is still limited!

A: No one said it was going to be easy.begrudgingly they're a pretty good deal too

Amazon AU also stocks a lot of the China-warehouse complement like the CR-10 and so on, but as far as I can tell you'd get better prices from Aliexpress (since that's where Creality's official store is, for a start). I haven't looked into price comparisons for the Tevo clones, etc. but I feel like you might get better prices off eBay as many of the dealers there offer coupons?

3) Q: What if I want to go bigger than the budget option? What's available to me?

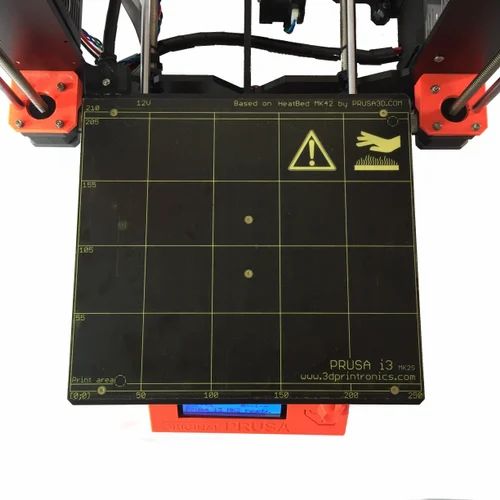

A: Now we enter into the meat of the problem: "Big enough to print nice things but also big enough to warrant a shitton of shipping costs" printers. The higher-end Monoprice Maker Select Pluses/Ultimates, the Prusa i3s y'all hype so much, the Flashforges and the Makerbotsi guess.I mentioned the Flashforges for a reason, so let's start with that: Jaycar. Well, that was easy! Flashforges like the Finder and up are right there in store.

But personally I think they're just a little bit too fiddly and dressed up for the build volume they offer: the Adventurer is 150x150x150, for $900 (AUD), and what you're really paying for is a slightly larger Finder with an enclosure. But it's right there if you want to bypass shipping costs entirely. It really is a pity they stopped selling Creator Pros though; those printers are workhorses (workhorses with incredibly finicky beds).

As previously mentioned Monoprice won't sell to us locally and they charge shipping out the wazoo so if you want a Maker Select (Plus) or a Maker Ultimate be prepared to pay for it. The lowest cost option I've found is still through eBay because as previously mentioned Amazon are evil. There are Amazon AU listings but they're mostly - again - resellers who pass the cost of shipping on to us. You may have more luck with the Wanhao printers, which I'm including in this point for consistency's sake but you're not likely to find, say, a Duplicator 6 for less than its clone, the Maker Ultimate.

Shipping's a bitch.

Prusas, Prusas, Prusas. Why does everyone on this subreddit have such a hard-on for Prusa? (rhetorical question. I know how good the Prusas are). Shipping from the Czech Republic will set you back quite a bit, though, and that cost still gets passed on to you by most of the local resellers that I could find, but I guess when it comes to a Prusa, you're probably willing to pay that extra. [These guys] (http://www.3dprintspecialist.com.au/) are the only ones I have experience with, and no, I'm not affiliated. Melburnians can just drive in and pick one up. The rest of you have to pay for postage, which is included in the pricing. That's pretty much the most no-bullshit option I could find.

Makerbots are stocked by some of the higher end Australian resellers online (whomst you can doeth a google, and trust me, none of them are significantly cheaper than any other) and if you're willing to get in on that mess vis a vis smart extruder then you're gonna have to walk this path alone.

But you won't have to pay exorbitant shipping! Honestly at this price point we should be on the next tier of printers, which we'll get to in a second.

Q: I was at Officeworks and saw some xyzPri-

A: No.4) Q: I am a fantastically rich person who makes more in a day than I will see in a fortnight.

A: This post is probably not for you, just go buy six Ultimakers from Imaginables and stack them like minecraft blocks or something. At that kind of money-expenditure Australia-specific restrictions cease to be relevant, save for time. This actually applies to Makerbots as well, except on top of that you're a bloody idiot.5) Q: Where do I get filament?

A: Funnily enough this is where the resources available at the Australia-specific subreddit do still help, even though half the links are dead.Go look there.

6) Q: I want to finish my prints. I hear good things about XTC blah blah blah

A: Go to Bunnings and pick up some epoxy fillers. Or some auto body fillers. Or some wood fillers. While you're at Bunnings pick up sandpaper and a sausage. Eat the sausage. XTC-3D and other brand-name stuff will, once again, charge us a premium for shipping to the arse end of nowhereland where the prime ministers rain from the sky and disappear into the ocean. Also, go to a hobby shop and pick up some primer if you're looking to paint things.7) Q: I wanna make my own printer!

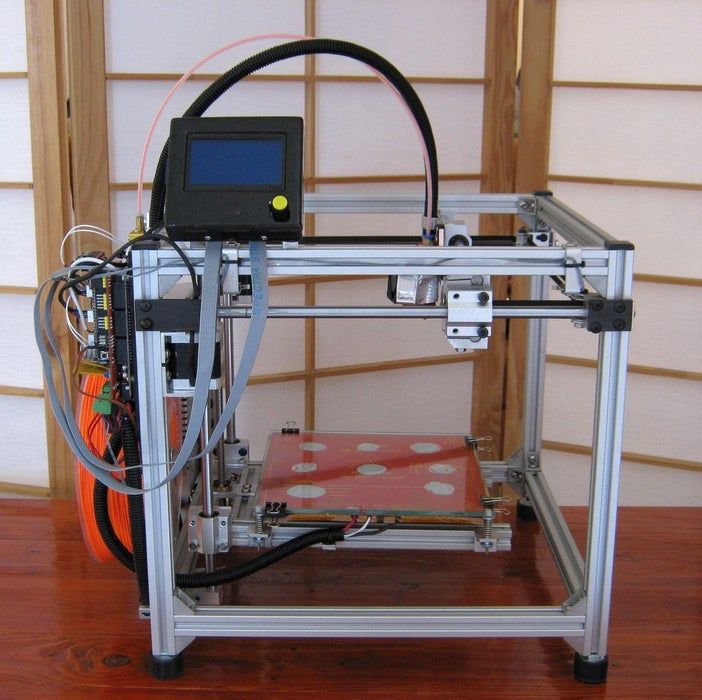

A: Aight. Nice thing about Australia is that there's a lot of hardware that's already here because shipping is a pain. So extrusions, motors, belts and screws are going to be easier to locally source. As for the more specialized shit, you're fucked. It's hard to buy genuine E3D hotends from down under.It's hard to get Duet boards and real stepper drivers at any kind of reasonable price without getting fucked on shipping, and that's not even counting the fact that the Aussie dollar's kind of in the toilet right now. The nice part is that there are companies here that have done the heavy lifting for you. The not so nice part is that they're passing on the cost of shipping to us, because we just absolutely have to get fucked on everything, don't we? Try Aurarum. They do boards. Imaginables do unimaginably high prices on nozzles, and hot ends... I haven't tried new hotends yet so I don't know what the fuck I'm talking about. RS Online have aluminium extrusions and acrylic sheets + decent shipping within Australia. And of course you could just source everything from Aliexpress. Good luck.

8) Q: Can I turn this into a business?

A: Questionable. Market is pretty saturated but the fact is that because we're far away from everyone and printers are a little more relatively scarce here, there is a demand for printed parts.You'd probably have to sign up as a subcontractor with a service that outsources 3d printing to individuals. Even then you'd probably have to have a pretty flexible setup that's prepared to print many things of many types if you want a chance at being able to fulfill these orders to satisfaction, is my experience.

9) Q: Who's the prime minister? A: fuck if I know

tl;dr - australia is very far away from everywhere and everything needs to be marked up for shipping in your cost estimates

edit - formatting as usual

3D Printing | Jaycar Electronics

- Home

- >

- 3D Printing

Shape the future with our huge range of 3D printers, filament and resin available in-store & online.

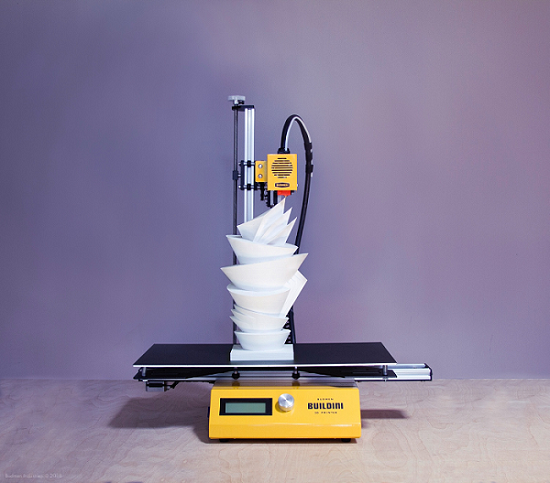

3D printing really isn't brand new technology now. We've sold 3D printers for a number of years, after all.

Perhaps the biggest thing that has changed however, is the quality, and reliability of their output.

Jaycar's range of 3D printers, scanners & pens represent fantastic value for money with amazing features and reliability. Now you can find a suitable printer that fits your own unique prototyping requirements, as well as your budget.

New 3D Printing Products

Filaments

Snapmaker 3-in-1

3D Printers & Scanners

Resin 3D Printers and Wash & Cure Machines

3D Printer Accessories

3D Printer Spare Parts

WARNING: Don't buy a 3D printer until you read this!

OK - so maybe it's not a warning, but we do want to make sure you understand a few basic principles of 3D printing before you dive in. You may end up purchasing a unit that either does too little, or too much for your intended purpose.

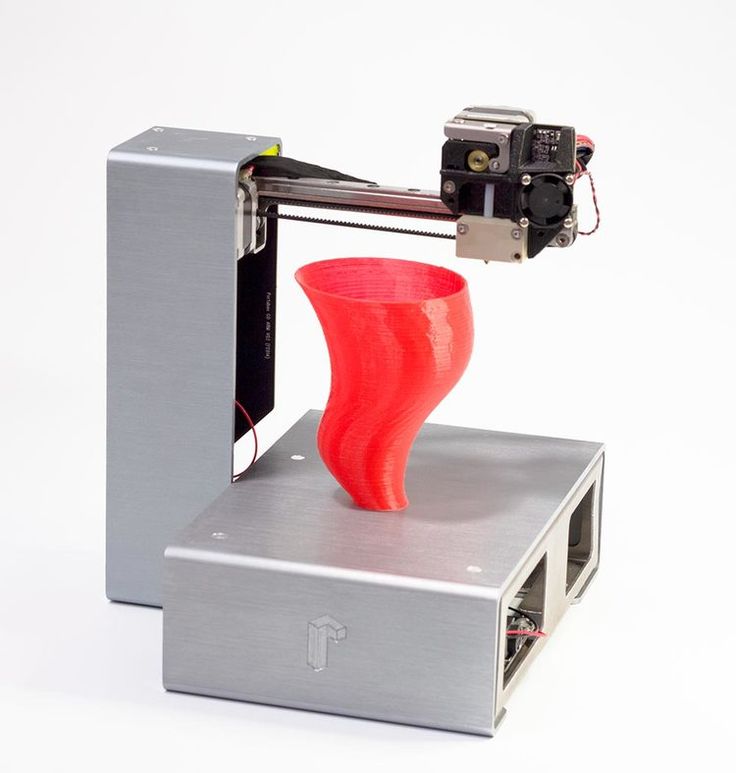

3D printing is changing the way we produce things. Instead of buying a physical item from a store or having a professional manufacturer make a protoype of your idea, you can now print it in your home, office, workshop, etc.

There's no tooling necessary which opens up a world of opportunity to the designer - or everyday joe just wanting to make cool stuff. There's also an element of self-sufficiency and novelty: the notion that you not only sourced an item locally, but made it yourself! If you're not a designer, there's a number of 3D printing libraries online where you can download free CAD drawings which you can print, and at the same time interact with other fans on tips and processes. 3D printing is a fun, exciting and quickly evolving world.

But how exactly does 3D printing work, and what do you need to know to get started 3D printing your own projects?

3D printing is an "additive production process". That means that it prints a 3D item in hundreds (or even thousands) of super-thin horizontal layers from the bottom up to form a solid object. Due to this layering process, the printer can create hollow objects, intricate internal components, and moving parts like hinges and wheels inside a solid case - which you cannot achieve with traditional manufacturing.

The objects you're planning on 3D printing will determine what quality and capabilities you need your 3D printer to have.

What is "Z Resolution"?

In 2D printing, we talk about "DPI" (dots per inch) with the general rule being - the finer the dots, the higher the resolution and the sharper the printed image. In 3D printing, this is the layer thickness or "z resolution" - the finer the layer, the smoother and more detailed the printed object will be. For example, if you have a 100mm height print, which is made up of 0.5mm layers, your printer will use 200 layers to create the object. If you print the same object with a printer capable of just 0.1mm layers, the printer will require 1000 layers to produce the same object - but the detail will be finer and the result generally smoother. Of course most printers have an adjustable z resolution so you can fine-tune the output to find a balance between speed and quality, within certain parameters. These decisions are also based on the diameter of the extrusion nozzle, and as filament comes in two basic sizes - it does affect the quality of the printed object.

What is "Infill"?

Infill is a repeating structure used to fill the empty space of your 3D prints. As well as improving the visuals on some prints, it can also improve strength or load bearing characteristics. Often, too high an infill setting may be overkill.

This helpful image will give you an idea of what kind of settings you need for your prints. Click the image to view a high resolution version.

Filament vs Resin What Printer do I Need?

Filament (FDM) Printers and Resin Printers are the two most common 3D printer you will find on the market at the moment, each with their own pros and cons.

Filament (FDM) Printers will generally be larger build area, up to 300 x 300 x 400mm with our CR-X Dual filament Printer from Creality. FDM printers also allow for easy change of material mid print or multiple material types at the same time. They are easy to set up and customise to fit your workflow or hobbies. Making them the go to printers for props, rapid prototyping in different materials, and your everyday models.

But, they have the down side of having to lay down each bit of material one by one which means they are slower than their Resin counterpart.

Resin printers will typically be smaller in build size while also limited to a single resin during print. Resin printing also offers a significantly higher quality model with precision that can't be replicated on their FDM counterparts. These printers will be used to make very small highly details models and parts that FDM printer can't make. The main examples being DnD models, Warhammer models, small high detailed prototypes. Resin printers have the ability to print much faster at higher detail due to the fact that resin printers can print an entire layer of the model in one go. A Resin printer down sides are cleaning up resin, washing and curing the prints as well as small print size and weaker prints when compared to PLA filament prints.

Filament What Type do I Need?

Filament comes in a vast array of types and special colours especially in the last few years.

With everything from standard PLA and PLA + plastic, the most common among 3D printers, to Carbon Fibre allowing the rapid prototyping of high strength parts on standard printers, and TPU allowing the printing of flexible parts like shoes and rubber wheels. See the table below to find what is best for you.

Filament type Description Use Requirements PLA Standard PLA plastic Standard models and 3D parts Nozzle – 210c

Bed – 65c*ABS Standard ABS plastic Stronger models and 3D parts Nozzle – 215c

Bed – 105c

Enclosed PrinterPETG High strength / chemical resistance High strength parts and engineering parts Nozzle – 240c

Bed - ~80cTPU/TPE Flexible rubber like material Flexible and bending parts Nozzle - ~230c

Bed - 50c*

Direct Drive recommendedWood PLA plastic with up to 70% wood infused Realistic wood parts Nozzle – 200c

Bed – 50c*Carbon Fibre Combination of Carbon fibre with PETG High strength engineering and mechanical parts Nozzle – 215c

Bed – 50c

Hardened NozzlePVA Water soluble material Supports that can be dissolved Nozzle – 190c

Bed – 50c*Silks Very shiny finish / metal like finish Standard models and 3D parts Nozzle – 205c

Bed 60c**Heated bed optional but recommended

As for special colours, eSilk or Silk filament has taken the show.

Silk filament has all the printing properties of PLA filament but with a silky and naturally shiny finish to it, so there is no need for post processing work to be done. Allowing you to print our parts with a more realistic metal finish for props, or a beautiful shine to models.

Single Vs. Dual Filament Extrusion

Single and dual extrusion comes in three main types. Single filament single head, dual filament single head, and dual filament and dual head.

Single filament and a single head is perfect for when you are using a single type or colour of filament for a 3D print and generally are you standard 3D printer.

Dual filament single head is the go to printer configuration for doing a print in two colours or materials. A perfect example is doing a complex PLA based print with a lot of support, PVA can be loaded into the second filament feed and be used as a water soluble support, making the support removal process incredibly fast and easy. No more hours lost to snipping them away one by one.

Finally dual filament dual head. These printers are generally your most expensive printers but have the features to back them up. A dual filament dual head printer not only will be able to print a model in two colours or two materials like the dual filament single head, but can also be set up to print two models at the same time**. Cutting down on print times for multiple parts.

**Both models have to be the same to do simultaneous printing.

How Big Can You Print?

Your design's largest single piece, will always be limited to the "maximum print size" of your printer which is dictated by the size of the Build plate, and the printer's z-height capability. If your printer's max print area is too small for your design, you can print an object in separate vertical parts and then glue the pieces together. Unless the design deliberately considers interlocking parts however, the finished quality is sometimes dubious (especially if the layers don't align exactly). Therefore, we suggest you select a 3D printer with a maximum print size suited to the size of prints you intend to make or design.

The only printers that don't follow these rules are Infinite Z belt printers, for those printers you are limited to the X and Y limits with no Z limit (Filament printers only).

How Long Will it Take?

This is dependent on a number of variables, such as; the complexity of the object to be printed, the filament size and type, the extruder head type and z resolution. It also depends on the quality of the printer you are using. You can always speed things up but you will generally sacrifice the quality of the output. It is important to remember that speed isn't everything. When it comes to 3D printing, slow and steady usually wins the race. Most 3D printing programs will advise you of the expected printing time once the drawings and settings have been uploaded.

The general standard is the higher the quality the long it will take, as well as the bigger the item the longer it will take. Most of our printers have the option to speed up a print while printing without quality loss (running at 150% speed or higher) but as you turn up the speed the printer model is more likely to fail completely.

This is only recommended for printers that are very well tuned. As an example, the CR-X can go up to 300% but might not extrude fast enough in some areas, causing very small holes on the print.

With Resin printing, the only factors are the resolution you are printing in and Z height, X and Y don't add any print time.

3D printing is loads of fun. Whether you just want to have a go at creating something from (virtually) nothing, or genuinely have a need to create unique objects, we are confident you will find a quality printer option amongst our range of 3D printers. We also have dozens of suitable filaments, including some very interesting options like glow in the dark, flexibles, eSilks, and much more.

Printer Troubleshooting

3D Printers have come a long way over the years and they are now easier to service and maintain. Each printer should come with a little tool kit for you to disassemble and repair when needed. We will maintain a series of guides for you to browse whenever you have an issue, so that you can easily get in and service your printer without the costly or slow repairs through a 3rd party.

If you find an issue that we do not have here, get in touch with your local store; we can work on a solution and provide the information to others on this webpage.

Some of this information is for specific models, or others might be general in nature, but the process will generally be similar for all types of 3D printers.

Some of the common issues that printers can occur are:

- Nozzle Clogs – Can be caused by a blocked extruder during print, improper loading and unloading, overheating of filament, incorrect settings for a filament type, and general wear and tear on the nozzle.

- Warping of Print – Incorrect heat settings for bed and extruder, incorrect cooling, poor bed adhesion, over extruding, incorrect bed levelling. Resin – incorrect exposure time, incorrect levelling.

- Bed out of Level – wear and tear beds do get knock out of level from time to time, incorrect z-limit switch, incorrect distance between bed and nozzle.

Resin – Incorrect distance between build plate and vat, material in the way, bumped during print or print removal.

- Model has Bumps – Filament isn't dry enough and has taken on water, nozzle is too hot for the material, printing too fast.

- Z Layer Shift – Part of the model maybe lose from the bed, bed isn't mounted to the baseplate correctly, printing too fast, model or bed knocked during print. Resin – Bumped during print, model to thin or resin too thick for speed being used.

- Extruder Clicking or Grinding Filament – Clogged or about to be clogged nozzle, incorrect bed levelling, jam in filament feed, incorrect nozzle temp for material, printing too fast.

- First Layer Won't Stick – Bed levelling issues, bed could be damaged, bed isn't clean.

Getting Started with Resin 3D Printing

Check out this fantastic video by Creator Academy on how to get started with resin 3D Printing using the Anycubic Photon Mono.

The ISL 3D food printer made it possible to print a ready-made bun

Imagine a digital bun - can you eat it? ISL experts unequivocally say yes! We were the first in the world to print a real bun on an ISL 3D printer. And very tasty.

What is so surprising about this, you ask? Chocolate printing is no longer nonsense. It is possible to create human organs and tissues, complex mechanisms and much more. What is special about a bun?

Not everything is so simple…

Whatever one may say, modern 3D food printing is still at a primitive level: it works with sugar and paste-like raw materials - chocolate, mashed potatoes from various products, batter for pancakes. So far, this is a business - selling souvenir beautiful sweets, applying foam to coffee, unusual desserts and decorating dishes.

But the bun is a symbol of home cooking, everyday life and family. Imagine a full three-course dinner without a stove and microwave, slow cooker and pots. We installed the cartridges in a 3D food printer, set the program and voila - appetizing meat, a side dish appear on the plate, and the serving is no worse than in the most status restaurant from a world-class chef.

How a modern 3D food printer works

Devices have already appeared on the market and are quite in demand, especially among confectioners. But their possibilities are limited by this - the creation of decorative elements and souvenir sweets.

Modern food 3D printers work on the principle of "squeezing out of a syringe":

- a 3D model is created in a computer program;

- the file is being loaded into the printer;

- food ingredients are loaded, which are fed into the extruder during operation.

The technology for making pancakes is a little more complicated, because they need to be fried. This is done on a heated platform. But pizza or pie after printing previously had to be baked additionally - in the oven. And aesthetically, the product looks far from perfect. In addition, every housewife knows that when heated, complex pastries can be deformed. So practical application has not yet been found, food printing of this level is at an experimental level.

Developed by ISL

We succeeded in creating a food printer that printed out a finished 3D flour product. The bun consisted of 20+ layers. Baking was done immediately, as each layer was created. When we removed the pastries from the working chamber, they could be eaten immediately. The warm fragrant bun was perfectly baked and kept the shape given by the program.

This is a big breakthrough in 3D food printing. The new technology will make it possible to create baked goods and confectionery products without human intervention. The need to stand in the kitchen for hours and worry about the result will disappear. An ideal cake, mouth-watering pizza, unusual bread will become available not only to professional confectioners and bakers, but to every housewife.

Fill the printer with products - meat, cheese, sauce and dough, enter the program and get the selected recipe. Sweet stuffed pies that don't take hours to make - isn't that a dream?

Scientists from ISL are not going to stop there.

Indeed, in our case, academic interest and the desire to create something truly innovative are combined with personal interest - it is a pleasure to try experimental samples! In the future, we are considering the option of automating filling, flushing and cleaning. There are ideas - it just takes time to experiment.

A remarkable extruder

At the heart of our development is a revolutionary extruder with a remote feed system, which has no analogues in the world.

Development features

One of the main differences is the ability to work with heterogeneous ingredients containing up to 60% solids in the composition. This is a real breakthrough, as modern technologies allow printing only with pasty materials.

It is also important to note the principle of operation.

- The product is baked directly during printing.

- Retract system for precise work. The extruder allows not only to feed the ingredients, but also to "suck" them into itself.

Due to this, streaks and drops are not formed when the printing device is moved to different positions along the X and Y axes and the raw material is changed.

- Designed for ultra-precise material flow - not a single extra milligram.

- Active cooling technology has been designed and already tested in operation. This gives us the opportunity not only to bake (as required in cases of using dough or meat, for example), but also to cool the product immediately during printing. Such a system allows you to print chocolate at a much higher speed than well-known imported chocolate 3D printers.

No volume limit!

Separately, I would like to dwell on one more feature - the remote supply of ingredients for dressing. Commercially available analogues, for example, XXX, work on the principle of a "syringe", squeezing the material onto the platform. The material flask has a limited volume (from 30 to 100 ml), which limits the size of the product and increases the weight of the device.

This effect leads to a decrease in the accuracy and speed of food printing due to the strong inertia during the movement of the extruder and, as a result, the need to reduce the speed of its acceleration and deceleration. We have implemented a remote filling system: components are fed through silicone tubes from tanks located outside the working chamber. Containers with products can have absolutely any volume, if necessary, individually heated or cooled before printing.

This removes restrictions on the quantity of each ingredient - in the future, our printer will allow you to print even multi-kilogram products without having to stop the process for refueling. At the same time, compressed air is not required and there is no need to use a bulky and noisy compressor, which is used on prototypes of 3D printers with a remote supply system from foreign developers.

An additional advantage of our development in the design of component transfer pumps: they are designed so that when moving from tanks to the extruder, food does not come into contact with any elements of the device, but moves only through tubes that are made of safe silicone.

What lies ahead?

Huge painstaking work. But this first pastry, which we enjoyed trying with the whole ISL team, is a symbol of victory. Yes, we as scientists were inspired by an ordinary bun! However, we see opportunities that it opens up in the future. And we are pleased to know that it was ISL scientists who took this first step. Imagine such a printer in space, on a remote drilling rig, in a submarine where rations are severely restricted. Appetizing delicious food will not become a luxury, but everyday life for everyone. And the incredible help for women who spend hours in the kitchen? When a person is free from routine, he is capable of much. Perhaps thanks to our development, the time spent on the stove and pans will be used to make the discovery of the millennium, who knows?

The most unexpected things created on a 3D printer

Airplane, ear, rocket engine, food, blood vessels, weapons, building, artificial limbs. And this is not the whole list of things that were created on a 3D printer.

\n\n

Here are the masterpieces of 3D printing technology.

\n\n

Sweets and fast food (Food 3D printers)

\n\n

Cornell University specialists have developed a new technology "Solid Freeform Fabrication", thanks to this technology, Loading the hydrogels, widely used in the food industry, into the 3D printer, can print chocolate, whipped cream, apple, banana, bread, cheese, biscuits, marshmallows and more.

\n\n

In turn, Los Angeles-based company Sugar Lab, has demonstrated the ability to print on a 3D printer geometric shapes completely created from sugar, more like works of art than sweets.

\n\n

3D food printers printers work on the same principle as a conventional inkjet printer, only food ingredients are used to "refuel" the printer. A huge list of recipes can be stored in the memory of a food printer and it is possible to add your own.

The technology is so promising that NASA awarded a grant to build a printer capable of printing food for astronauts - this will be a real alternative to food from tubes.

\n\n

\n\n

3D Printing Musical Instruments

\n\n

The 3D printer made it possible to create a real violin with amazing sound. South West Music School student Laura gave a showcase performance on CNN using this unique musical instrument.

\n\n

In addition, 3D printing technology allows you to create a unique design of any musical instrument , while maintaining all its functions.

\n\n

\n\n

3D printed weapon

\n\n

University of Texas student Cody Wilson created the first 3D weapon . The Liberator Pistol is made entirely of plastic except for the metal trigger mechanism. The weapon was tested with 380mm bullets.

\n\n

\n\n

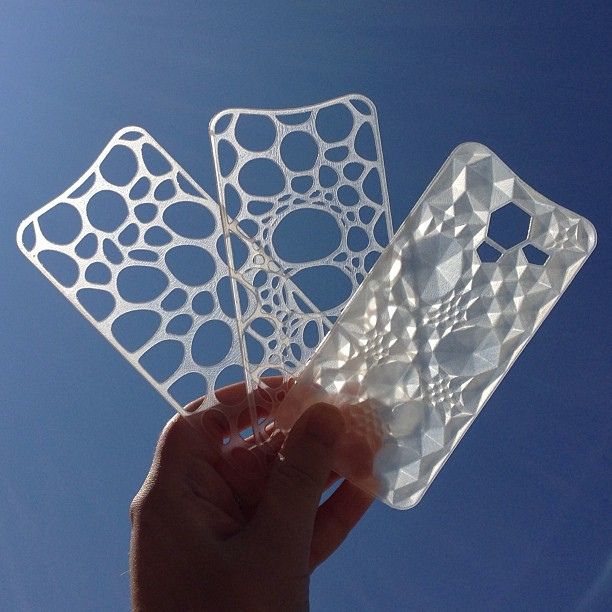

Clothes and shoes are now 3D printed

\n\n

Iris Van Herpen (famous Dutch fashion designer) presented her "Tension" collection at Paris Fashion Week, all models of this collection were created using 3D printing technologies.

\n\n

Multiple materials can be used to create a single piece of clothing on a 3D printer, so these items are more durable and elastic.

\n\n

\n\n

Jenna Feasel and Mary Hong (designers at Continuum Studio) created the world's first 3D printed bikini. Bikinis are round nylon plates connected by thin springs.

\n\n

In 2011, also appeared the first pair of shoes printed on a 3D printer through the efforts of Swedish students. Today, such three-dimensional shoes are present on the world's leading catwalks. Three-dimensional shoes take into account all the individual characteristics of the future owner, even the shape of the foot.

Materials for creating "3D shoes" are rubber, plastic and polyurethane.

\n\n

\n\n

Medicine

\n\n

Bionic ear Calf cells, silver nanoparticles and a polymer gel were used to create a bio-ear. The bio-ear is able to perceive radio waves that are outside the range of human hearing. It is planned that such an ear will be directly connected to the neurons of the brain.

\n\n

\n\n

Own embryo

\n\n

The Japanese company Fasotec can print a 3D model of the fetus based on images from a magnetic resonance imaging scanner - t .

\n\n

\n\n

Stem cells.

\n\n

\n\n

Human organs and tissues

\n\n

By loading organic substances and cell compounds into a 3D printer, it is possible to form tissues of a human organ. In 2011, an experiment was carried out to print a kidney , in 2013, scientists at Oxford University created an analogue of the nervous tissue .

In addition, artificial tissues created by 3D technologies do not have a genome, which excludes the process of their rejection by the human body.

\n\n

European clinics use heart model for training to improve the practical skills of surgeons.

\n\n

\n\n

Wheelchairs. Each seat has been created with the individual parameters of the players in mind.

\n\n

\n\n

Reproductions and robots (3D printing of museum exhibits)

\n\n

Using a high-tech scanner and 3D printer , a reproduction of Thomas Jefferson was created at the Smithsonian Research Institute .

\n\n

For the first time in over 150 years, paleontology has taken a significant step forward, scientists have printed the dinosaur robot, which can test hypotheses about the dinosaurs' propulsion system and the interaction of prehistoric creatures with the environment.