3D printer mks

Products – Makerbase

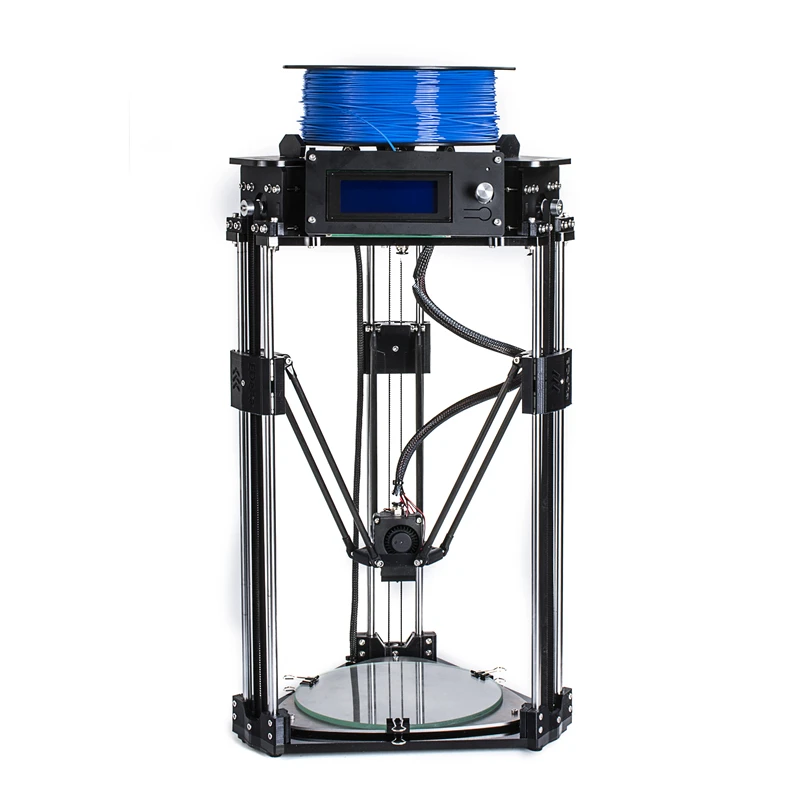

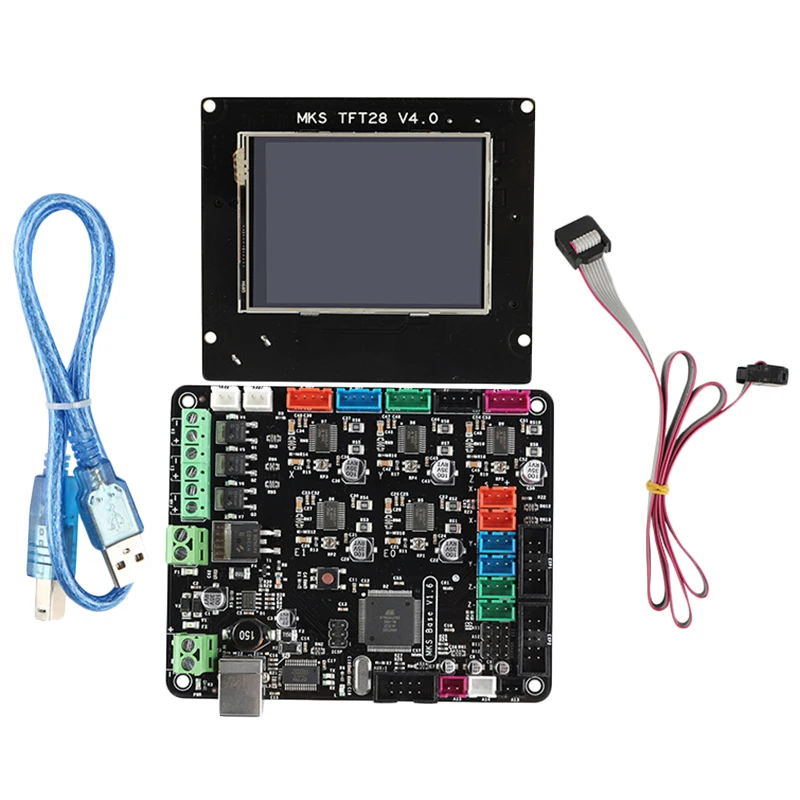

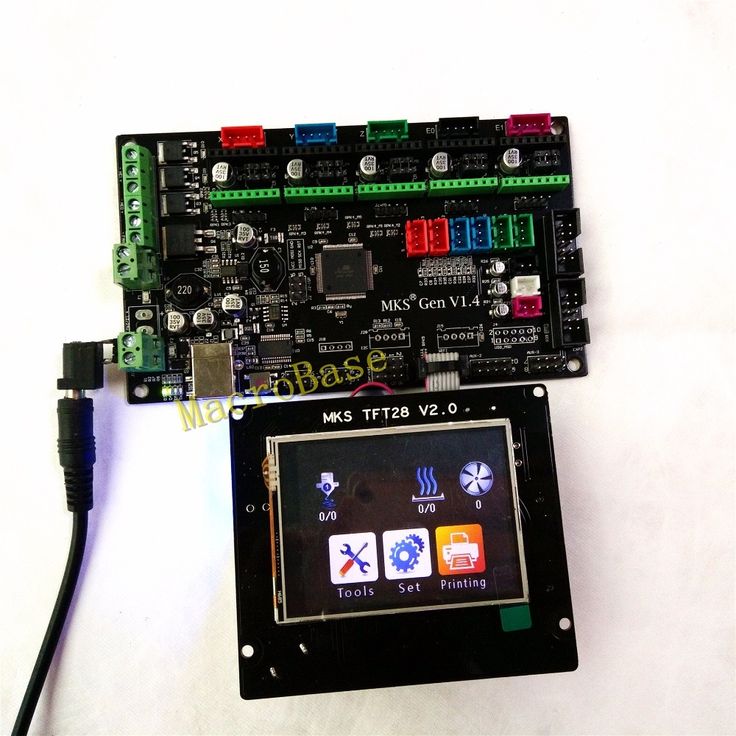

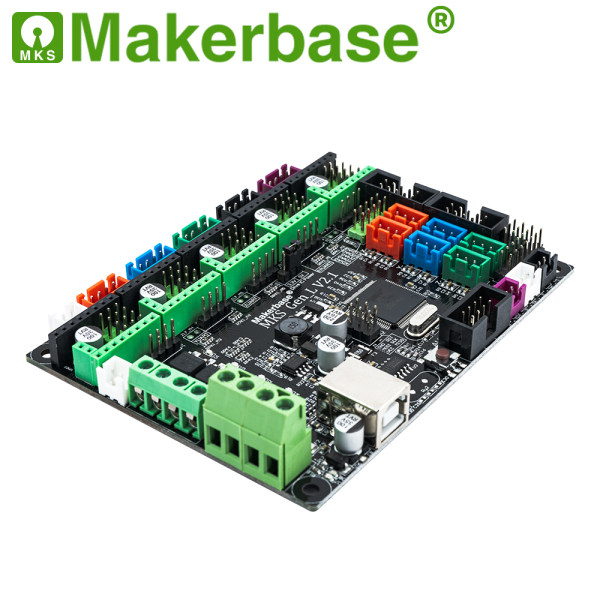

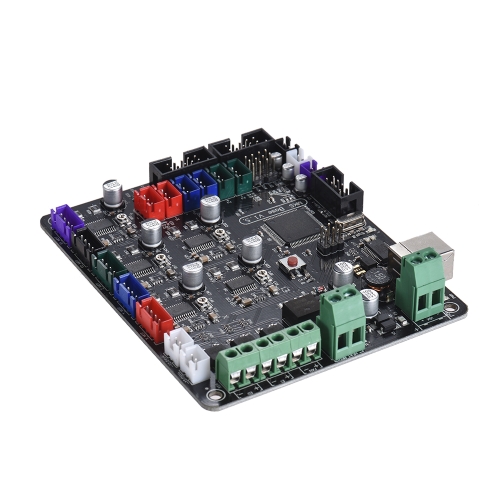

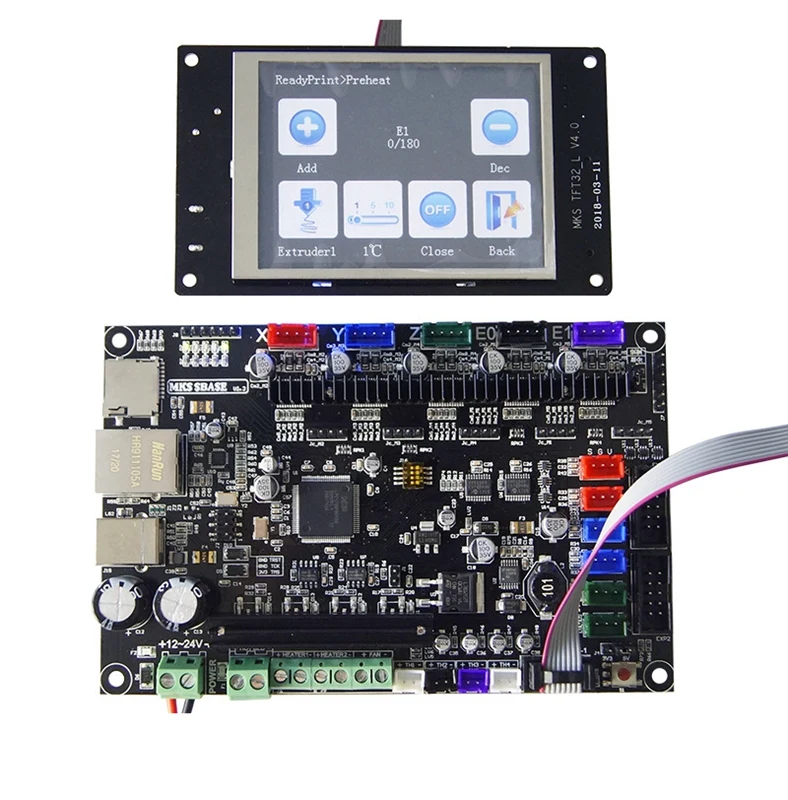

FDM Control Board—Robin Series

Robin series motherboards adopt 32-bit ARM chips, support TFT touch screens of various sizes (2.4 / 2.8 / 3.2 / 3.5 / 4.3).Can achieve a variety of functions, such as breakpoint recovery, filament detection, Auto-off function, wifi transmission and other functions. The hardware has been open sourced, supporting makerbase’s independently developed firmware and marlin 2.0 open source firmware. Based on customer needs. Innovate our products.

Learn More

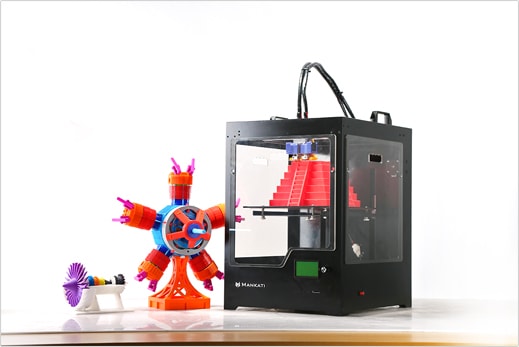

LCD SLA motherboard series

Compared with FDM technology, LCD SLA technology is favored by the market due to an order of magnitude improvement in accuracy, but the market coverage rate is far inferior to FDM technology. Of course, there are various factors such as high cost, few solutions, and consumable limitations. To this end, MKS independently developed the MKS DLP motherboard and its supporting software to advance the development of LCD SLA 3D printing in terms of cost and solution.

Learn More

LCD SLA motherboard series

Compared with FDM technology, LCD SLA technology is favored by the market due to an order of magnitude improvement in accuracy, but the market coverage rate is far inferior to FDM technology. Of course, there are various factors such as high cost, few solutions, and consumable limitations. To this end, MKS independently developed the MKS DLP motherboard and its supporting software to advance the development of LCD SLA 3D printing in terms of cost and solution.

Learn More

Motor drive series

Makerbase has always introduced high-performance products in the field of motors and motor drives. For example, those that focus on heavy currents, focus on ultra-quiet, cost-effectiveness, anti-lost steps. Always innovating and improving to launch more high-quality products.

Learn More

3D Printing Module

| Model | Use |

|---|---|

| 3d touch | Device for auto_leveling 3D printer using Hall effect. |

| Z-probe | External leveling sensor for 3D printer leveling. |

| MKS SLOT/SLOT2 | SD card extension for MKS TFT series touch screen and MKS ROBIN seriesmotherboards. |

| MKS DET | Power detection module. |

| MKS PWC | Auto_shutdown module. |

| MKS FES | Filament detection module. |

| MKS PT100 | PT100 temperature measurement module. |

| MKS TFT WIFI | WIFI module for TFT series touch screen products. |

| MKS Robin WIFI | WIFI module for Robin series products. |

| MKS Smoother | Reduces the vibration of the motor.Recommended to use it after testing the effect. |

| MKS MOS | Used for hot bed control, the maximum current can up to 12A. |

| MKS MOS+ | Used for large hot bed control, the maximum current can up to 30A. |

| AD597 | AD597 Thermocouple Adapt Module |

| MAX31855 | MAX31855 Thermocouple Adapt Module for MKS SBASE / MKS Robin / MKS Robin2 |

3D Printing Software

| MKS Robin series firmware | Firmware for MKS Robin series motherboards |

| MKS TFT series firmware | Firmware for MKS TFT series display |

| MKS PAD system, APP | For Android custom APP on MKS PAD |

| MKS DLP motherboard firmware | Firmware for MKS DLP motherboard |

| MKS WIFI firmware | Firmware for MKS WIFI module |

| MKSCloud | mobile APP, support remote monitoring, printer control and other functions, available in iOS and Android versions |

| MKS HOST | Host computer for FDM printer slice |

| MKS DHOST | Host computer for LCD light curing printer slice. |

Mks best 3D printing files・Cults

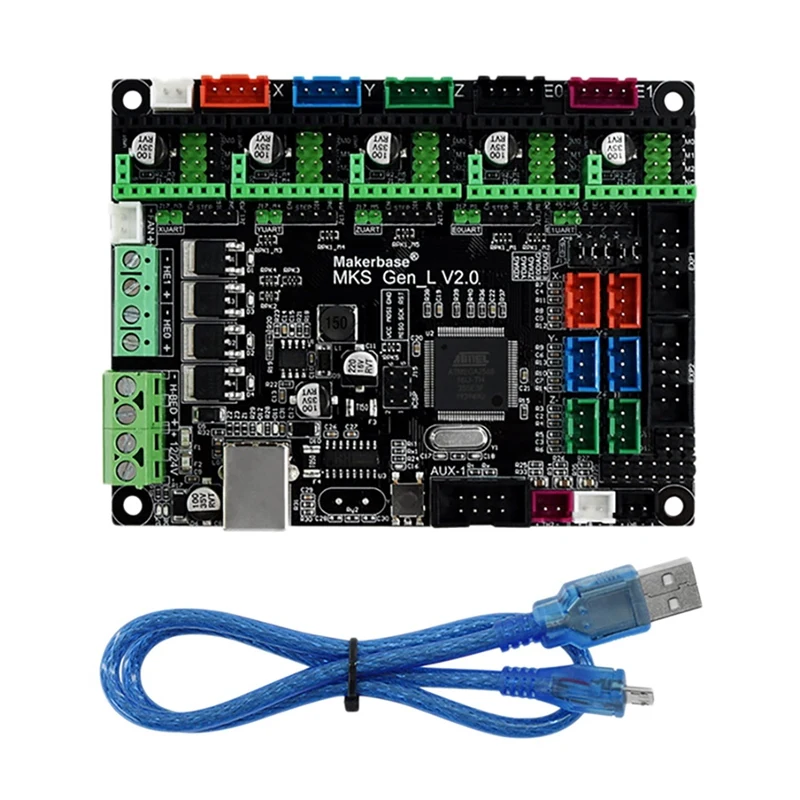

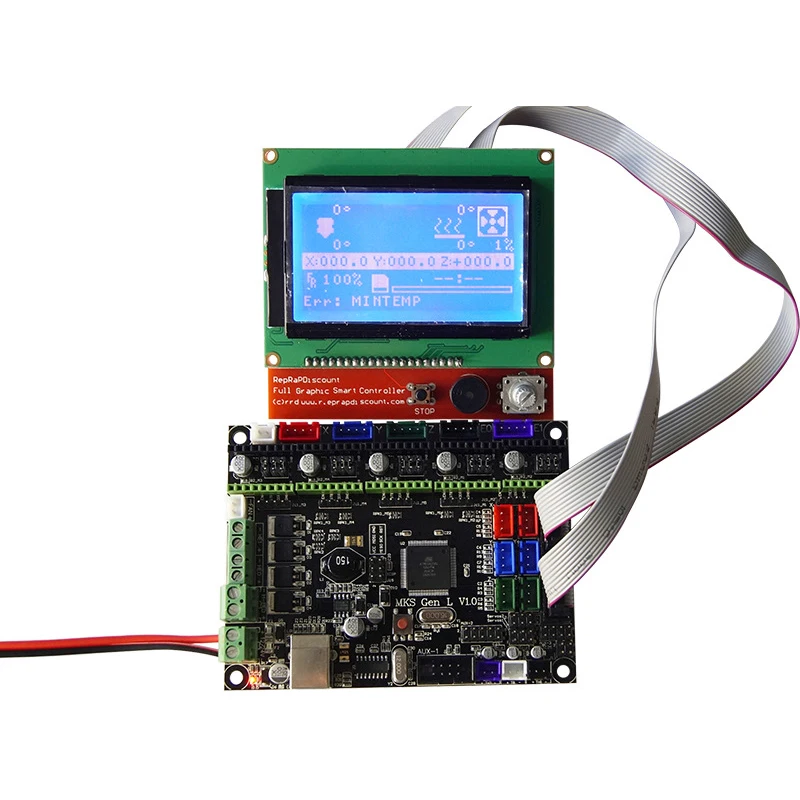

MKS GEN L V1.0 Case

Free

MKS Sbase cover mount for 3030 profile

Free

Holder for MKS TFT32 LCD Casing (fits 3030 profile)

Free

MKS DLC32 TS35 LCD case with 2020 extrusion base for DIY DIODE laser Ortur laser

Free

MKS Gen2Z Holder (for my Hypercube)

Free

Caja para pantalla MKS TFT 3.2

Free

MKS sbase V1.3 cover

Free

SKR 1.3 / SKR 1.4 - P3STEEL OrballoPrinting BOX

Free

Control box for MKS Gen L with Mosfet and TL-Smoother emplacement

Free

Marlin 1.

1.9 and 2.0.0 for MKS Gen L (All my versions)

1.9 and 2.0.0 for MKS Gen L (All my versions)Free

MKS SBase and Smoother Case for 2020 2040 Extrusion

Free

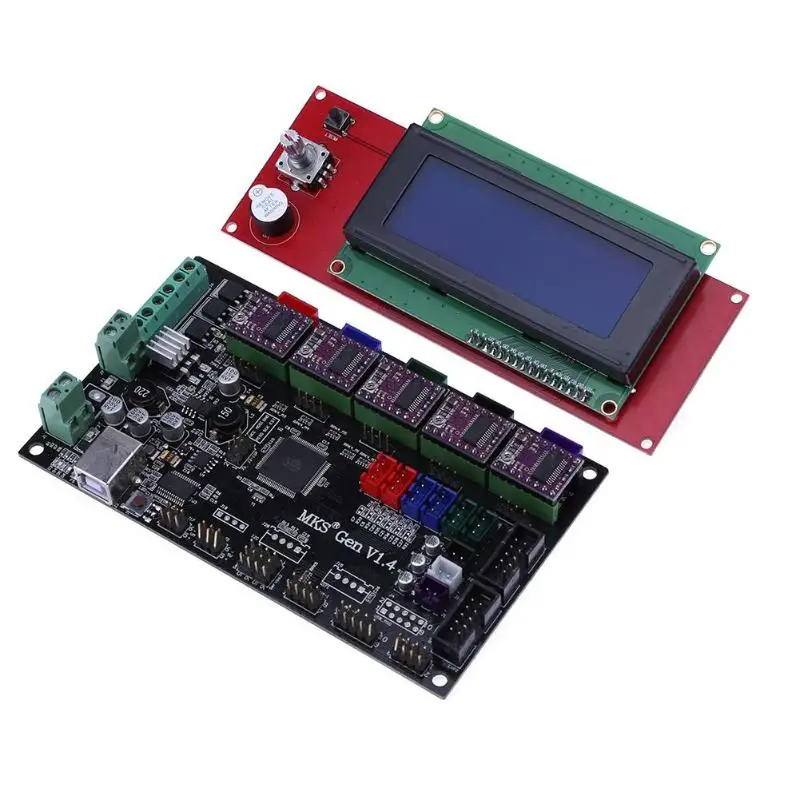

Simple MKS Gen 1.4 Brackets for 2020

Free

Ender 3 Rear MKS Gen L Case with Mosfet and Wemos D1 Mini

Free

MKS Gen L light shassis for 80 or 90mm Fan

Free

Bracket Geeetech I3 Pro B Bigtreetech Skr

Free

Engraver42 Laser with infinite Y axis

Free

MKS TFT32 Enclosure

Free

Port USB for Ender 3 MKS Gen L V1 upgraded

Free

Support MKS TFT 28 with single case

Free

MKS LCD Case bracket for 18mm board

Free

FUEL INJECTION SYSTEMS

€2. 60

60

Box mks dlc32 TS35 v2

€3

Hellbot Magna 2 235 cambio de color M600 Bltouch

Free

MKS Gen L - Case with cable management room and 80x fan

Free

BTT Mini 12864 RGB Enclosure

Free

mks gen l v1.0 cooling box

€1

Robin MKS display fascia for MPSM v2 3D printer with SD card socket

Free

Display cover MKS LCD 12864A

Free

DiY BLTouch Clone | BFPTouch remix

Free

MKS TFT28 and Arduino Mega 2560 (Ch440G) Fix

Free

Casing for 3D-Print-hardware MKS-(S)-GEN L

Free

Makerbase TFT 2.

8 V4.0 Hanging console

8 V4.0 Hanging consoleFree

MKS TS35 V2 for LK4/LK4Pro/U30/U30Pro - 2022 Version

Free

MKS TFT35 Display Support.

Free

CASE MKS TFT35 v1.0

Free

Mks TS35 V2 3030 Case Stand

Free

MKS TS35 V2.0 RMX

Free

Ender3 MKS TFT 35

Free

MKS TS35 new display case

Free

Support for MKS TFT24 in 20x20 profile

Free

MKS GEN L V2.X + V1.0 ,CASE with FAN

Free

Mark Arsenich's Total Electronics Enclosure for Creality Printers

Free

Mks DLC 2.

1 Case with neje 30w-40w control board

1 Case with neje 30w-40w control boardFree

Makerbase MKS Gen L Holder

Free

MKS mini 12864 navigation knob

Free

MKS Gen L Soporte Anet A8 con ventilador 80mm

Free

TFT 32 ALFAWISE U20

Free

Adapter MKS Gen L to U20 Motherboard whith Fans

Free

Astronauts on the ISS have prepared the Russian 3D printer for work and are waiting for print materials / Sudo Null IT News

On August 3, cosmonaut Oleg Artemiev announced the successful activation and testing of a Russian 3D printer on the ISS.

The astronauts also prepared the printer for printing. The Russian crew has not yet begun the main work with the printer. Cosmonauts are waiting for a special material for printing, which should be delivered to the ISS as part of the scientific cargo on the Soyuz MS-22 spacecraft in September.

Already at the end of September, the cosmonauts will try to print simple cubes on a 3D printer, and then they will experimentally print various forms, including details according to the drawings of Russian students. Then the resulting 3D printing samples will be returned to Earth. Roscosmos experts will study their characteristics under various laboratory conditions in order to comprehensively investigate the impact of microgravity on 3D printing.

In case of successful application of the device, the spacecraft may become part of the standard equipment of the ISS Russian Segment.

The Russian 3D printer was delivered for experiments to the ISS on the Progress MS-20 spacecraft in June. The device was specially created for the ISS by RSC Energia in cooperation with Tomsk Polytechnic University and Tomsk State University. Samples and parts that are used in large quantities on board the station will be printed on it from thermoplastic polymers by layer-by-layer imposition of a molten polymer thread (filament).

“This technology will allow astronauts to manufacture, for example, covers for electrical connectors of various nomenclature, research blades, wrenches and other tools, fasteners (nuts, bolts, etc.) necessary for work on the ISS,” said the representative Department of Radiophysics, Tomsk State University.

“The development of additive technologies at the station will open up new opportunities for the domestic astronautics to use 3D printing in the future. For example, in lunar expeditions, cosmonauts will no longer depend on the delivery of the necessary components and structures on transport ships from Earth, but will be able to print them directly in space, which will allow reaching a new level of performing various kinds of tasks, ”the Roscosmos added.

In November 2021, Russian cosmonauts complained that the sockets for hexagons were missing on the ISS and asked to send them, if possible, sockets for tools for 8, 10 and 12. With a printer, they will be able to print them on the station themselves.

Last August, NASA began testing a 3D lunar soil printer on the ISS. The project aims to test the strength and wear resistance of regolith, from which they plan to build colonies on the moon.

In September 2014, the Zero G 3D printer, also developed by Made In Space, was delivered to the ISS. In November, he became the first printer to print a three-dimensional product in space - a plate with the inscription "Made In Space NASA". Two years later, the researchers sent an improved printer model to the station.

3D printers provide astronauts with the necessary tools and parts for various designs. For example, in 2014, astronaut Berry Wilmore 3D printed a socket wrench.

ISS 3D printer | Technologies in the IT Market

- home

- Market

- Technology

05/07/2022Author Petr Chachin

RSC Energia named after S.P. Korolev, together with Tomsk Polytechnic University and Tomsk State University, have developed a 3D printer for use on the International Space Station (ISS).

Using a thermoplastic polymer printer, samples and parts that are used in large quantities on board the station will be printed by layer-by-layer application of a molten polymer thread (filament).

Then the resulting 3D printing samples will be returned to Earth to study the mechanical characteristics of products made using additive technologies (layer-by-layer growth and synthesis of objects). This will allow a comprehensive study of the impact of microgravity on 3D printing.

The first to work with a 3D printer will be the crew of the ISS-67 expedition - Roscosmos cosmonauts Oleg Artemiev, Denis Matveev and Sergey Korsakov. The 3D printer is scheduled to be delivered to the Russian segment of the ISS on the Progress MS-20 spacecraft in June this year. Over time, the device can become part of the station's standard equipment.

Over time, the device can become part of the station's standard equipment.

It is expected that the development of additive technologies at the station will open up new opportunities for the domestic astronautics to use 3D printing in the future. For example, in lunar expeditions, astronauts will no longer depend on the delivery of the necessary components and structures on transport ships from Earth, but will be able to print them directly in space.

IT News magazine

3D printing

Previous

Apple, Google and Microsoft plan to eliminate passwords

Next

French farmers struggle with Russian gas

Want to be the first to know about new materials?

Subscribe to the newsletter

Material Tape

Weekly

By clicking on the button, I accept the terms of the agreement.

Created a device that turns empty plastic bottles into 3D printer filament

The user puts an empty bottle into the Polyformer, the device shreds the plastic, heats it up and draws it into a thread.