3D printer mirror image

Mirror Image Print - 3D Printers - Talk Manufacturing

User_2639

#1

Very weird one…I have just assembled my ANET A8. And so far it’s been Fantastic, it has helped in having some engineering and electronics background I think.

I have now after a few test prints figured out my optimal print settings for temp, infill, etc.

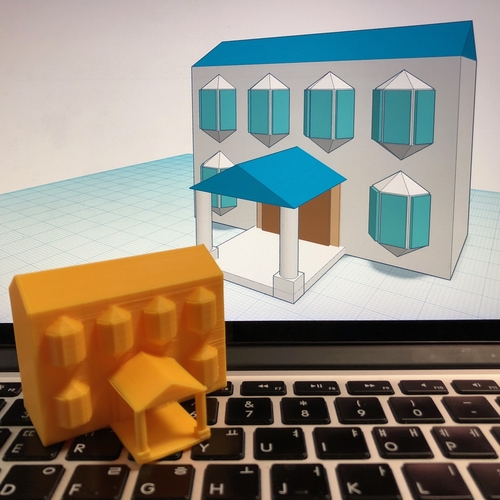

However - when I tried to print the Semi-circular Fan duct it printed mirror image. Per the attached image.

So I immediately created a small model with a Key notch out of the bottom left (Closest Home position to compare.) and it Printed that notch in exactly that position…

I thought perhaps when I exported from Sktechup that the import into Repetier the position was rotated…However that is irrelevant as it is just the positional axis and wouldn’t obviously Flip the image.

When I looked at the Slic3r copy it was fine - but somehow the A8 has flipped the image. For anything symmetrical of course this is irrelevant, but for this part it doesn’t fit on the squirrel blower… circular.gcode

I have attached both gcodes of the Blower and Mirror test I did.

Any thoughts would be appreciated before I go into trying bigger prints and wasting filament.

It is Not an Axis issue with steppers either When I HOME the Printer it places the Bed to the back of the printer which hits the cutoff switch, and Print head to the Far Left (again cutoff switch) and then Z axis the head comes level with bed (within .2mm according to having levelled it of course.)

mirrortest.gcode (53.4 KB)

travisW

#2

Did you try just printing it again and making sure that it wasn’t mirrored before hitting print? You should be able to tell on the first layer if it is mirrored.

It is easy to mirror items in most slicing software, you could have misclicked somewhere.

I printed some mirrored things in my first days printing, too.

Also, try other slicing software if your current workflow is magically flipping things somehow.

gikam

#3

how does it look printing in another slicer? check printers setting about x/y axis

mozCORP

#4

had this exact same problem when first setting up my printer.

the machine should home the x axis before the y axis before printing. I think you have it in reverse, switch the x and y motors where they are are plugged in to their respective sockets. you may have just switched the cables around

you may have just switched the cables around

1 Like

User_2639

#5

OK mozCORP - sorry for delay, have been printing since and not having too many problems - mainly trying to get best Extruder Temp, Speed, etc. settings without worrying about Axis…etc.

Found the issue - like you said X and Y. But it was due to the Cables themselves being swapped. SO I must have plugged the Y cable into the X motor and vice versa, so when I looked at Motherboard end it shows as in correct ports! The giveaway should have been that when I first turned it on weeks ago it tried to Home and the Stepper was just Grinding and grinding, I figured I had the Limit switches the wrong way around so I quickly swapped them over.

Now the way I figured it out tonight was I got Repetier talking to the Printer with USB (had port problems before…) and when clicking on X and Y axis to move the bed, etc. I noticed the wrong axis moving…AHAH!!! So when I looked at the Motors I had the right cables plugged in, but they were in the Wrong Motors, so swapped it around and did a HOME, and GRRRRIIIINNNNNDDDD…Oh crap…Panic - Depower, check the Switches and noticed they were actually in reverse>?!>?! So if I was paying attention when I built it I would have realised. But I suppose what made me overlook it was I didn’t know at that point which Axis was Y and X, since the instructions were lacking and had to rely on an Audioless Youtube video…

I noticed the wrong axis moving…AHAH!!! So when I looked at the Motors I had the right cables plugged in, but they were in the Wrong Motors, so swapped it around and did a HOME, and GRRRRIIIINNNNNDDDD…Oh crap…Panic - Depower, check the Switches and noticed they were actually in reverse>?!>?! So if I was paying attention when I built it I would have realised. But I suppose what made me overlook it was I didn’t know at that point which Axis was Y and X, since the instructions were lacking and had to rely on an Audioless Youtube video…

Anyway - All fixed now…Looking forward to printing off some Orientation specific Models now, without having to Slice them in reverse!

Many thanks

Guide for Mirror Parameters in CHITUBOX

Under the slicing TAB of CHITUBOX, there is a drop-down option in machine parameter named mirror including LCD_mirror, DLP_normal and Normal. Many users are confused about these three options. And many times they choose one at random, resulting in the parts being mirrored directly. Here, let's take a look at the three mirror parameters in CHITUBOX.

Here, let's take a look at the three mirror parameters in CHITUBOX.

Mirroring

Before we get to the three mirror parameters in CHITUBOX, we need to figure out what mirroring is. In geometry, a mirror image, as the name implies, is the image of an object with respect to a mirror. In two dimensions, the mirror image of an object (or figure) is the virtual image of the object reflected in a plane mirror. The mirror image is the same size as the original, but not the same, unless the original would have been symmetrically reflective.

The concept of mirror images can also be extended to objects in three dimensions, including their interiors, although these objects are not necessarily transparent.

Mirror Settings in CHITUBOX

Among the three mirror parameters of CHITUBOX, DLP_normal and Normal can be understood as the same one which do not do any image processing, while LCD_mirror will mirror the image.

Since the light source of the bottom-up uv-curable 3D printer is placed below, the image projected by the projector itself is already processed. In the bottom-up printing process, the image is processed again. The mirrored mirror image will be a normal one which can be understood as "minus minus equals plus". Therefore, DLP does not need to be mirrored.

While the LCD image is a normal one, it will be mirrored during the bottom-up printing process. Therefore, LCD needs to do another mirror processing.

On a same printer, when selecting LCD_mirror and DLP_normal/ Normal respectively, you will notice that the two parts are mirrored in the YZ plane, that is, the plane between the Y axis and the Z axis.

As shown below, the left (LCD_mirror when using LCD 3D printer) and the right (DLP_normal/Normal when using LCD 3D printer) are mirrored on the plane between the Y-axis and z-axis. It looks like that there is a a mirror between the two sets of models.

For non-axisymmetric parts, miror processing is different from rotation. Rotation can change the direction to make the two sets of parts exactly the same. But after mirror processing, no matter how to rotate, the two sets of parts cannot be exactly the same. As shown below, although both control groups can present the word BEER after rotation, it can be seen that the pointing direction is completely different and there is a significant difference at the letter R.

How to Choose Mirror Parameters in CHITUBOX

In general, LCD 3D printers correspond to the LCD_mirror option, while DLP 3D printers correspond to the DLP_normal/Normal option. However, due to the influence of machine assembly, control board firmware setting and other factors, sometimes this is not always right.

Currently, CHITUBOX's built-in printers already default to the best way for mirror settings. Users do not have to worry about this problem either if your 3D printer is not in the list. As the AB option, it is either A or B. Generally speaking, if the part is mirrored by LCD_mirror, then select DLP_normal/Normal, and vice versa.

As the AB option, it is either A or B. Generally speaking, if the part is mirrored by LCD_mirror, then select DLP_normal/Normal, and vice versa.

Model Source:

https://www.thingiverse.com/thing:4029706

https://www.thingiverse.com/thing:2761937

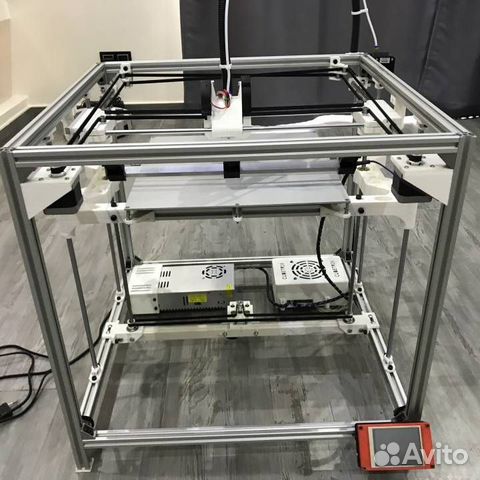

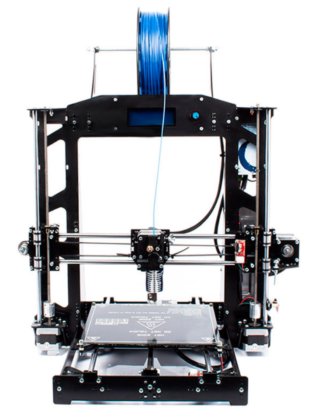

3d printer defects: errors, main problems

Causes of Defects in 3D Printing and How to Fix Them

Buying a 3D printer is only half the battle. A beginner printer has a lot to go through. First, he will learn how to set up the device, calibrate the print head, set the necessary parameters, and test different types of filaments. But that's not all. The most unpleasant thing that can appear during operation is printing defects. And they need to be eliminated.

- What are 3D printing defects?

- Classification of defects

What are 3D printing defects?

After the printing process is completed, various defects can be found on the finished model. Most often they are associated with improper distribution of plastic. Defects appear for various reasons. But the main result is always the same - the model is damaged, you need to do the project on a new one. Printing defects cause downtime. Lost time and meters of filament.

Most often they are associated with improper distribution of plastic. Defects appear for various reasons. But the main result is always the same - the model is damaged, you need to do the project on a new one. Printing defects cause downtime. Lost time and meters of filament.

Important! Within the framework of this article, defects that occur on FDM printers will be described. These are models of printing devices operating on the technology of hot deposition of plastic.

Sometimes mistakes can be seen right from the start. For example, when printing the first layer of a model. In these and other cases, it is necessary to prevent the defect in time. However, the press all the same should be stopped. But this way you can save material and time. This article will discuss the most common defects, as well as ways to eliminate them. At the end of the article, a comparative classification of faults will be given.

Layer displacement

The second name of this defect is skew. There are several options for the development of events at once. The skew can be slightly noticeable, with a slight deviation along the Z axis. The second option is a strong offset, the model is printed in pieces. In all these cases, the reason lies in the mechanical part of the printer.

There are several options for the development of events at once. The skew can be slightly noticeable, with a slight deviation along the Z axis. The second option is a strong offset, the model is printed in pieces. In all these cases, the reason lies in the mechanical part of the printer.

Solutions:

- Check tension belts. They should be clearly in the grooves. It is not allowed to fray or stretch the belt. Sometimes it is easier to replace the entire set of belts with a new one.

- Sometimes small misalignments are caused by an incorrectly set pulley. Make a mark with a black marker before printing, after the end of the process, check the result. Calculate the difference. Tighten the problem area if necessary.

- The printer's Y and X axes are not properly aligned. They are not perpendicular to each other. They need to be set at 90°.

Attention! In rare cases, the problem is electrical. This option must be disassembled separately, armed with a multimeter.

The first layer does not stick

The initial layer acts as a foundation. If it "floats", then the whole model will get the wrong geometry. The second and subsequent layers may slightly shift the entire workpiece. The most unpleasant thing is that this defect can be found at the very end of the print.

Solution methods:

- Platform calibration. If the print bed is skewed, there is a good chance that the first layer will not stick. It is best to check platform calibration before starting printing. Many 3D printing programs help to go through this setting in a semi-automatic mode.

- Wrong print nozzle height. Another point worth considering. Most often, the extruder height setting is set through the printer parameters: Edit Process Settings → G-Code. They are located in the main menu of the device.

- The first layer was printed too quickly.

The plastic just didn't cure. This setting must be found in the menu of the printing device. Approximate location: Settings → First Layer Speed. It is worth setting the print speed of the first layer 50% lower than the rest.

The plastic just didn't cure. This setting must be found in the menu of the printing device. Approximate location: Settings → First Layer Speed. It is worth setting the print speed of the first layer 50% lower than the rest. - Plastic cooling temperature. This option can be found on printers with a cold platform. The filament hits a cold surface, quickly hardens and rebounds. Here you need to experiment with the settings for the melting temperature of the filament or initially take a printer with a heated surface.

Important! Poor adhesion can be caused by covering material placed over the platform. Different glue, tape, adhesive tape - all this can repel plastic.

Pimples on the model

This also includes such defects as “snot”, swelling, sagging. All these faults are of approximately the same nature. They are related to the operation of the extruder. As it moves, it should stop, then start working again. Not all devices can lay even layers without defects. This is how the irregularities described above appear.

They are related to the operation of the extruder. As it moves, it should stop, then start working again. Not all devices can lay even layers without defects. This is how the irregularities described above appear.

Solving methods:

- Retract and coast setting. The first parameter is responsible for starting the extruder. In this case, you need to configure the retraction through the device menu: Edit Process Settings → Extruders. Here you need to find the parameter Extra Restart Distance. Try reducing the fill length. When unevenness occurs when the nozzle stops, you need to tighten the roll-on stroke (roll-up movement). This setting is referred to as Coasting. It is in the same section where the retraction is set.

- It is better to avoid retraction and coasting altogether. That is, the filament must be flush with the edge of the nozzle. This parameter is especially critical for Bowden printheads. Another option is to set up retraction. You need to find the Advanced tab.

It contains the Ooze Control Behavior setting. This option controls filament leakage and retraction start time.

It contains the Ooze Control Behavior setting. This option controls filament leakage and retraction start time.

If minor defects are still present, it is worth pointing out the entry points to the printer. This setting is found in the Edit Process Settings menu on the Layer tab. For example, you can leave small flaws inside the shape, starting printing from the inner layers.

3D printer won't print

This is one of the scariest things for a beginner 3D maker. The device appears to be broken. However, in most cases this is not the case. The printer turned on, but did not start to push through the plastic? There are four reasons for this.

Solutions:

- Plastic does not come out of the extruder due to leakage. This can often be seen in some cheap Chinese models. The filament is preheated in the extruder, it can seep through the hot end. The same effect can be observed after the end of the work.

In this case, printing starts 3–4 seconds after the start. Automatic broken geometry of the first layer. To avoid this defect, experienced printers make the so-called skirt. This is a thin circle of filament around the future model. It is printed to bring the printer to life and fill the nozzle with plastic.

In this case, printing starts 3–4 seconds after the start. Automatic broken geometry of the first layer. To avoid this defect, experienced printers make the so-called skirt. This is a thin circle of filament around the future model. It is printed to bring the printer to life and fill the nozzle with plastic. - The extruder is too close to the platform. The plastic just gets stuck inside the nozzle. The situation continues on the second layer. Only by the 3rd or 4th layer does the plastic begin to come out. The solution is to adjust the Z-axis height through the G-Code command.

- Sometimes the filament is simply chewed off by the drive gear. This is the part that pushes the thread forward. If a small amount of filament shavings is visible near the printer, it is likely that the gear has worn off the filament. You need to calibrate this node.

- Clogged extruder. There may be several reasons: ordinary dirt or rubbish, plastic coked inside the extruder, poor cooling of the filament.

Mechanical cleaning of the nozzle with special needles or drills will help. They are sold in specialized stores.

Mechanical cleaning of the nozzle with special needles or drills will help. They are sold in specialized stores.

Important! Just do not need to clean the nozzle with a screwdriver or other improvised tools. You can completely ruin the extruder.

Prints in the air

Various users are experiencing the same problem. The reasons for printing by air are related to setting new plastic settings in the slicer. Sometimes a defect appears due to incorrect setting of the Z axis.

All solutions come down to the fact that the user needs to carefully study the G-code of the printer. Sometimes the reason lies in the lowered Z-axis height settings. You can also see the print step here, perhaps it exceeds the required parameter. In the slicer, you need to check the plastic installation parameters. View the heating temperature of the nozzle and platform. All settings must be checked manually. When importing a profile, the left parameters can be picked up.

Prints in reverse: how to fix

A rare defect that is not always visible at the start of printing. That is, the model comes out normal, but mirrored. Such malfunctions are often found in Chinese kits or noname devices. There are two solutions. One is simple, the other is more difficult.

Methods of solution:

- It is necessary to invert one of the axes: X or Y - it does not matter. But only one. This can be done by flipping the contacts on the power board or on the motor itself.

- Invert axis via device firmware. This method is suitable for advanced users who are familiar with programming skills.

In any case, it's better to first check all the settings in the slicer again, only then go into the electronics of the device.

Layers skipped

The finished model shows that one or more layers have been skipped. This is eloquently evidenced by the gaps in the finished model. In rare cases, this defect is associated with insufficient extrusion. Perhaps there are problems with the capture and supply of the filament. Sometimes the reason lies in the wedging of the Z axis.

Perhaps there are problems with the capture and supply of the filament. Sometimes the reason lies in the wedging of the Z axis.

Solution methods:

- Check the mechanical part of the printer. If gaps began to appear frequently, you need to arrange an unscheduled maintenance of the device. Examine all shafts. Check that they are level and not misaligned. Power off the printer, try moving the head with your fingers. If resistance is felt, then one of the shafts is not installed correctly.

- Bearing wear. This element may simply wear out. You can see that the printer vibrates slightly. There is an unusual sound when printing. Diagnose a breakdown in the same way as the shaft. Turn off the power and move the extruder with your hands to find the problem part.

Attention! Remember to maintain your printer regularly. Lubricate the shafts with special oil. For example, for sewing machines. Before lubricating, clean the moving parts from dirt and plastic residues.

Just don't overdo the oil. A large amount of lubricant can lead to the opposite effect.

Doesn't print in the center of the bed

Some users are having trouble printing on one side of the bed instead of the center. At the same time, in the slicer, the model is clearly in the center. There may be several solutions here.

Methods of solution:

- Slicer settings are down or incorrectly set. It is necessary to change the characteristics of the kinematics. Set the Delta robot parameter instead of the Cartesian robot. You also need to set the size of the table, equal to the square inscribed in the specified print area. In this case, set the Origin Offset parameter to half the side of the square.

- Try to adjust the position of the X-axis limit switch. In some cases, it is moved a little to the right.

What are the problems with the 3D printer test cube?

This figure is used to check the print quality. Naturally, during the test, she can clearly demonstrate where there are problems. It can be completely different defects. Most often, the test shows bulges and dents on the model.

It can be completely different defects. Most often, the test shows bulges and dents on the model.

Such defects result from overheating and shrinkage. To find out for sure the cause and eliminate these factors, you need to print four cubes in different angles. For some ABS plastics, you need to reduce the temperature, as well as turn on the blower by 5-10%.

3D printing echo

This problem can be described as thin stripes that form when printing layer by layer. That is, the final model does not have a formed and even surface. There is waviness (echo) on the edges. This defect is also called ringing on the walls. Typically, two factors are the cause: print speed and vibration.

Solutions:

- Reduce vibration. Make sure the printer is on a level and stable surface. Assess the condition of the bearings. Replace them if necessary.

- Inspect the shafts. Clean them of dirt and dust, lubricate with oil.

- Reduce the print speed through the printer settings.

Try changing the typing speed first, then check the mechanics.

Interesting! Even a single loose bolt can cause strong vibrations. Check all fasteners. Pull the bolts.

Salmon leather

This defect is somewhat similar to the previous one. Only there are no obvious waves or ripples. The defect manifests itself in the form of a pattern. It is similar to the representation of heights on topographic maps or the structure of salmon skin that is drawn on the walls of the model. In English resources it is called salmon skin. The defect appears due to two reasons: vibrations and incorrect characteristics of the current coming to the motors.

Solutions:

- Remove any vibrations that may occur in the device. Tighten the bolts and check the frame geometry. You can also slightly reduce the print speed.

- Installation of a special impulse reducer (TL-Smoother) in the circuit between the driver and the axle motor.

This solution balances the current indicators. The edges are more even.

This solution balances the current indicators. The edges are more even.

Salmon skin defect is common on DRV8825 stepper motor drivers.

Ripple

In this case, we are talking about the partial impact of waves on some parts of the model. The ripples are often of the same nature as the echo. It is also tied to vibrations and the speed of the extruder. However, unlike waves, ripples are especially pronounced at sharp corners, when the nozzle abruptly changes direction.

Methods of solution:

- Reduce the print speed. You need to find the Edit Process Settings menu in the printer settings, and then open the Other tab. Change two settings: Default Printing Speed and X/Y Axis Movement Speed. The first is responsible for the speed of all movements of the nozzle, the second - the speed in the absence of plastic supply. Sometimes the reason lies in the factory firmware. It initially indicates increased extruder acceleration.

- We remove vibrations.

Check the geometry of the device, stretch all the bolts, assess the condition of the shafts and bearings. Lubricate the device if necessary.

Check the geometry of the device, stretch all the bolts, assess the condition of the shafts and bearings. Lubricate the device if necessary.

We recommend checking the print speed settings first.

Poor filling

If the figure is not filled enough, this means that it will not receive sufficient strength. The model may simply break or crack. Usually the causes of poor coverage lie in the slicer settings or print speed settings.

Solutions:

- Try changing the fill pattern. It is indicated by the Internal Fill Pattern parameter. There are presets in the settings with complicated filling options that give more strength to the finished model: Grid, Triangular and Solid Honeycomb. The printing time will increase, but the strength will also increase.

- Reduce print speed. The fast movement of the print head results in less infill.

You need to tweak this parameter through the settings of the device itself or through the slicer parameters.

You need to tweak this parameter through the settings of the device itself or through the slicer parameters. - Change extrusion width parameter. Some 3D printing programs allow you to set different infill values for individual elements. For example, for the outer layers, set the size to 0.4 mm, for the inner layers - 0.8 mm. These settings can be viewed in the menu Edit Process Settings → Infill. In it you need to find the parameter Infill Extrusion Width. It is shown as a percentage. The higher the number, the thicker the layer.

Attention! When setting the Infill Extrusion Width parameter, make sure that the set value (in percent) is supported by the printing program (slicer).

Plastic is leaking from the extruder threads

This fault can be attributed to local printer failures, although they can create a number of defects in the form of “snot” on the model. Plastic oozes through various slots, flows down the extruder thread, exits the opening of the heating element. There may be several options for solving the problem.

There may be several options for solving the problem.

Solutions:

- Check all screw connections. Sometimes a caked piece of plastic gets stuck between them. It creates a gap, the filament flows out.

- Clean and polish the surfaces of the thermal barrier tube and nozzle. Installing a fluoroplastic washer or winding a fum tape can also help.

- Reinforced cold drawing of threaded connections.

Attention! Sometimes the reason lies in a manufacturing defect. Nothing can be done here. Just completely change the extruder.

Plastic does not come out of the nozzle

For some reason, the printer stopped feeding filament. The device continues to make noise with the engines, but the plastic does not come out of the nozzle. There may be several reasons and solutions for this.

Solving methods:

- The plastic is out. For some printers, the filament spool is covered with a casing.

Therefore, it is impossible to immediately understand that the thread is over. Check for material in the spool.

Therefore, it is impossible to immediately understand that the thread is over. Check for material in the spool. - The thread has broken. There was a gap between the hot end and the extruder. A common cause is with Bowden printheads. Perhaps the problem is with the filament itself. You need to try other material.

- Low plastic melting point set. The thick filament cannot pass through the narrow nozzle opening. Recommended temperature parameters for different types of plastic: PLA - heating t 180 °C, table heating t 60–80 °C; ABS - heating t 240 °C, table heating t 110 °C.

Interesting! Sometimes a clogged nozzle is causing the print to stop. This can happen even during work.

Model delamination

Visually, this defect looks like an accordion. In some places, the layers move away from each other. At the same time, it is clear that this is not a pass, but the absence of sticking of plastic. Layer separation occurs due to incorrect setting of the filament thickness or its melting temperature.

Solving methods:

- Reduce layer thickness (height). Here you need to follow the rule: the maximum layer thickness should be no more than 80% of the nozzle diameter. Otherwise, the layers will not stick to each other.

- Raise the melting point of plastic. If the height parameter is in order, then you need to look at the temperature settings. For example, the optimum melting temperature of ABS plastic is 220–240 °C, but some users set it to only 190 °C. You can increase the melting temperature in the slicer settings: Edit Process Settings → Temperature.

If standard temperatures are not suitable, try raising the setting by 10 °C. See if the adhesion of the layers improves or not.

3D printer extruder does not heat up

At the same time, the device shows 100% heating power, the set temperature is on the display, but the extruder is cold. In most cases, the cause lies in a break in the wires or in the heating element itself. Ring all circuit elements after the controller. To cut off problems on the heating element, apply 12 V to it. It should start to heat up.

To cut off problems on the heating element, apply 12 V to it. It should start to heat up.

Attention! Newer printers may encounter factory extruder defects. This element needs to be changed. There is no point in repairing the item.

Plastic falls in waves

Another name for this defect is “elephant foot”. In this case, the upper layers of the model are pushing against the lower parts, causing a wave effect. It sort of descends from top to bottom, forming a thick layer at the base of the model. This problem is especially common on models of printers with a heated bed.

Methods of solution:

- Find the optimal temperature regime between heating the table and blowing the model. Lower the heating temperature in steps of 5 °C. It is important to find a balance here, when the lower layers have already gained strength, but still retain adhesive properties for the following layers.

- Calibrate the table.

Try applying the default settings. If the problem persists, slightly change the Z-axis height settings. Calibrate the new settings on the test cube. This is the base shape that clearly shows how the layers are laid down.

Try applying the default settings. If the problem persists, slightly change the Z-axis height settings. Calibrate the new settings on the test cube. This is the base shape that clearly shows how the layers are laid down. - Chamfer the base. The option is suitable for homemade devices. You need to start with a bevel of 5 mm and 45 °, after which you can make small adjustments.

Wall gaps

Such defects can be found when printing rather thin walls in the model. For example, when the extruder nozzle prints strips up to 0.4 mm thick, and the user needs to make a 1 mm edge. In such places, cracks may appear at the joints of the two layers. Typically, the defect is eliminated through the adjustment of the slicer.

Solution methods:

- We need to find the setting that is responsible for the wall thickness. Usually they are in the menu: Edit Process Settings → Advanced. Here you need to find the Gap Fil parameter. He is just responsible for overlapping areas and filling the gaps between thin walls.

Check the box next to Allow gap fill when necessary. There is also an alternative. Go to the Infill tab and tweak the Outline Overlap parameter.

Check the box next to Allow gap fill when necessary. There is also an alternative. Go to the Infill tab and tweak the Outline Overlap parameter. - Simply adjust the extrusion width. Increase the parameter value if possible. The strip width can be set on the Extruders tab via the Edit Process Settings menu.

Try and experiment to get the best fit.

Web

A special case of filament leakage, when sloppy plastic threads remain between the parts. This happens for the same reasons as influxes. The solution methods are exactly the same:

- Changing the speed and distance of thread retraction. Full instructions are listed above.

- Lower print temperature. Try tweaking this setting to reduce the fluidity of the plastic. Here you need to be careful. Excessive decrease in temperature can lead to a delamination defect.

- A separate solution is to set a parameter in the slicer that launches the print head in a long and winding path over empty space.

The web falls near the model without sticking to its walls. No bridge is formed between the layers. To enable this option, go to the advanced settings of the slicer (Advanced). Check the box next to the Avoid crossing outline for travel movement option.

The web falls near the model without sticking to its walls. No bridge is formed between the layers. To enable this option, go to the advanced settings of the slicer (Advanced). Check the box next to the Avoid crossing outline for travel movement option.

Interesting! Some 3D makers do not consider a web defect as something serious. They simply cut off the excess filament with a knife after the print is finished.

Extruder does not feed plastic

This problem is in the filament feed mechanism. Or the nozzle is too close to the table.

Solution methods:

- Check the plastic filament. It may have burrs on it. The feed gear has slipped. Check the condition of the thread, you may need to tweak the gear settings a little. Or change the plastic.

- Calibrate the table position. Raise the Z-axis slightly.

Sometimes the extruder will not feed plastic due to a clogged nozzle. It needs to be cleaned up.

It needs to be cleaned up.

Classification of defects

Almost all defects are one way or another related to two reasons: a malfunction of the mechanical part of the printer or incorrect software settings. Based on these parameters, it is possible to make a classification based on the most common problems in printing:

- Deterioration of nodes and the absence of a normal fastener feed. This parameter affects vibrations, nozzle movement trajectories.

- Poor extruder maintenance. The print head needs to be cleaned from time to time, to remove the sintered filament.

- Inaccurate (wrong) calibration of the platen and nozzle height. Another common mistake that causes a lot of print defects.

- Problems with printer settings. Most often solved through manual setting of parameters or adjustment of the G-code.

- Lost settings in the slicer. This includes: changed parameters, errors or inaccuracies in the firmware.

- Poor quality filament.

The problem may lie in the quality of the plastic. It is necessary to monitor its condition, quantity. If necessary, try to replace the manufacturer, or even switch to another type of filament.

The problem may lie in the quality of the plastic. It is necessary to monitor its condition, quantity. If necessary, try to replace the manufacturer, or even switch to another type of filament. - Electrical problems. To find such a malfunction, you need to arm yourself with a multimeter and ring all the circuits after the controller.

- Factory defect. The problem is solved by replacing a low-quality part.

These are the main printer malfunctions that in one way or another affect its operation, which leads to printing defects. The printer may have several problems at once. They will lead to the appearance of a group of defects. You need to be able to recognize the first signs of breakdown in time and eliminate them.

Important! At least once every two weeks, pay attention to the mechanics of the printer, carry out maintenance on the device. Clean the nodes, lubricate the shafts with oil. Check the platen and extruder calibration.

Defects during printing are annoying. An experienced 3D maker should be able to recognize and classify a malfunction in time. Knowing the causes will help to quickly eliminate the breakdown. The user will not spend a lot of time and effort to eliminate the defect, and will not lose money on a damaged filament.

- 07 March 2021

- 14310

Get a specialist consultation

Printer prints mirrored how to fix

Miscellaneous »RIGHTS» Printer prints mirrored how to fix

Mirror printing

SNECKY

LOOK

03/03/2016 9000 9000 9000 9000

Questions and Answers Guys, tell me forever to figure out what the problem is, and so I decided to print a stand for an iPhone for a friend, found the model they liked, put it on print and left. the model was printed in a mirror image (((what is the problem ?? it should have been so printed out Answers to questions

the model was printed in a mirror image (((what is the problem ?? it should have been so printed out Answers to questions

FAQ

sanqapone

Loading

09/16/2020

614

Hello everyone. I know it's a belt tension issue. Tried tightening and vice versa - relaxing, the problem does not go away. Any ideas ?

Read more DJ_DiX35

Loading

08/30/2020

364

Good evening everyone.

There is a printer with ultra-kinematics. Mirrors the X axis when printing.

Is it possible in the printer firmware somehow...

Read more mlizart

Loading

12/07/2016

18159

Colleagues, help!

In a modeling class, a student asked - What is the difference between a 3D printer and a 3D plotter and what is better for a new...

Read more but you need to dig into the registry with Regedit. But first I wanted to recap the problem and a couple of easier solutions.

But first I wanted to recap the problem and a couple of easier solutions.

Problem:

All HP printing shortcuts available in the Printing Preferences window are broken, possibly after updating Windows XP to SP3. The effect is that whenever you select one of these presets, it prints in a mirror image unless you manually, after selecting a shortcut, go to the Advanced tab and set Mirror Image to Off. .". This works fine until you select one of the shortcuts next time.

Default print workaround:

As others have noted, go to Start/Printers, select your printer, and choose Printing Preferences. On the Advanced tab, set Mirroring to Off. Click OK. This works fine, but only for default settings.

Workaround for custom shortcuts:

You can create your own "Print Shortcuts" in the Print Options window, and if you manually set "Mirror Image" to "Off", they should work fine . But you cannot change or remove pre-existing shortcuts except by editing the registry as shown below.

But you cannot change or remove pre-existing shortcuts except by editing the registry as shown below.

Hotfix for HP Preinstalled Print Shortcuts:

This includes changing registry keys and applying the usual caveats. Execute Start / Run / regedit then navigate to:

HKEY_LOCAL_MACHINE \ SOFTWARE \ Microsoft \ Windows NT \ CurrentVersion \ Print \ Printers \ [HP Officejet Pro K5400 Series] \ DMCDriverData \ Printing \ HPPresetRoot \ Preset PoolData

ly the printer name may differ. Select one of the PresetPool entries (for example, PresetPool: 0, PresetPool: 1, etc.) and double-click to change. Scroll down to about 0DA8 or shortly thereafter, where you will see the word "H.P.M.i.r.r.o.r.P.r.i.n.t.i.n.g" on the right (each letter is separated by a dot representing zero). After that, you will see several zero values and then the word "T.r.u.e".

Change the letters T.r.u.e to read F.a.l.s.e, being careful not to change the number of bytes (eg. ).

).

Do this for each preset and for each HP printer on your system that has this set of PresetPoolData keys.

The fix works immediately.

.

Resolved: Mirror Image - Reverse Print? - HP Support Community

Hi @ art4lynn,

Welcome to the HP Support Forums. Good day. :) I understand you need help printing a mirror image. I will be happy to help you with this.

Excellent description and excellent diagnosis of the issue before publication. Kudos to you in this regard. 🙂 You are a valued HP customer and I am honored to share this platform with you. 🙂

- What operating system is used with the printer? Is it Windows or MAC OS?

Try the following steps on these links first:

Link 1 : https://h50434.www3.hp.com/t5/Inkjet-Printing/Setting-The-Printer-For-Reverse-Or -mirror-image/td-p/7 ...

Link 2 is a workaround in MS Word: http://h50434. www3.hp.com/t5/Inkjet-Printing/Mirror-Image-Reverse-Printing/td-p/365777/page/3

www3.hp.com/t5/Inkjet-Printing/Mirror-Image-Reverse-Printing/td-p/365777/page/3

.

Please keep me posted. I will follow your reply.

Hope this helps. Let me know how it goes. I sincerely hope that the problem will be solved without problems and the device will work perfectly. 🙂 Any questions please contact me and I will be there to help you. 🙂

Just to say thank you, , press the thumbs up button to give me Kudos to appreciate my efforts in helping.

If it helps, please mark as "Accepted Solution" as it will help several other people with the same problem solve it without problems. 🙂

Be careful and you will have a wonderful week ahead. 🙂

DavidSMP

I am an HP employee

.

How do I print a mirror image? - HP Support Community

Using PowerPoint to print a reverse image:

1. Use the printer to scan the image to your computer as a .jpg file

Use the printer to scan the image to your computer as a .jpg file

2. Open PowerPoint (PowerPoint comes with Microsoft Office)

3. Select Insert from the top menu bar

4. Go to your image and press Paste

5. The image will appear in your PowerPoint file

6. On the FORMAT tab, select Rotate Option

7. From the drop-down menu, select Flip Horizontally

8. Print this image on plain paper to make sure that this is exactly what you want before using transparent paper

I'm sure there are other software packages out there that can flip the image for you. This is exactly what I have on my home computer and I really liked it.

Good luck!

Regards

BethenyF

Click the thumbs up to say thank you. Mark as the accepted solution if the solution solves your problem.

.

Resolved: Mirror Printing - HP Support Community

Welcome to the HP Support Forums! 🙂 I see that you are interested in mirror printing on your HP LaserJet P1102. After reviewing the Technical User Guide, this feature is not listed in the list of supported features.

You will see this option under the Paper/Quality tab, see below:

You can use this workaround: open the Paint program, rotate the image 180 degrees and flip it horizontally. This will flip the image.

Hope this helps, let me know the result. I shall wait for your answer.

Thank you for being part of the HP community. Let me know if this helps resolve the issue by marking this post as "Accept as Solution" . If you need further assistance, please let me know and I will gladly do my best to help. If you want to thank me for my help, click Like to get Kudos .

HevnLgh

I'm working on behalf of HPPress "Kudos Thumbs Up" to the left of the answer button to say "Thank you!"

.