How do 3d printers make things

3D Printing: What It Is, How It Works and Examples

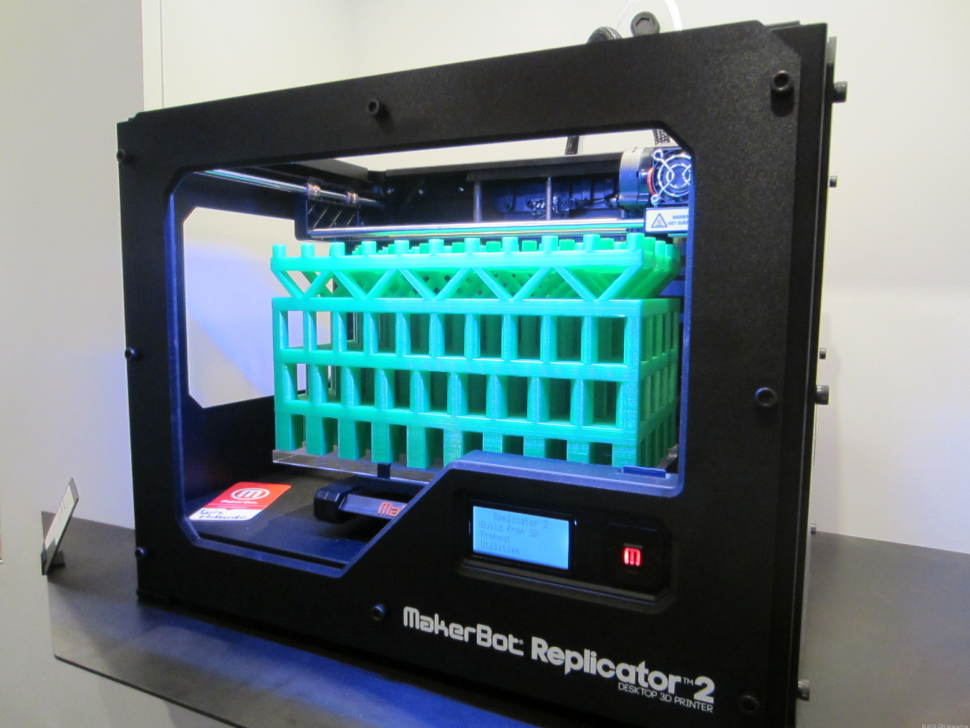

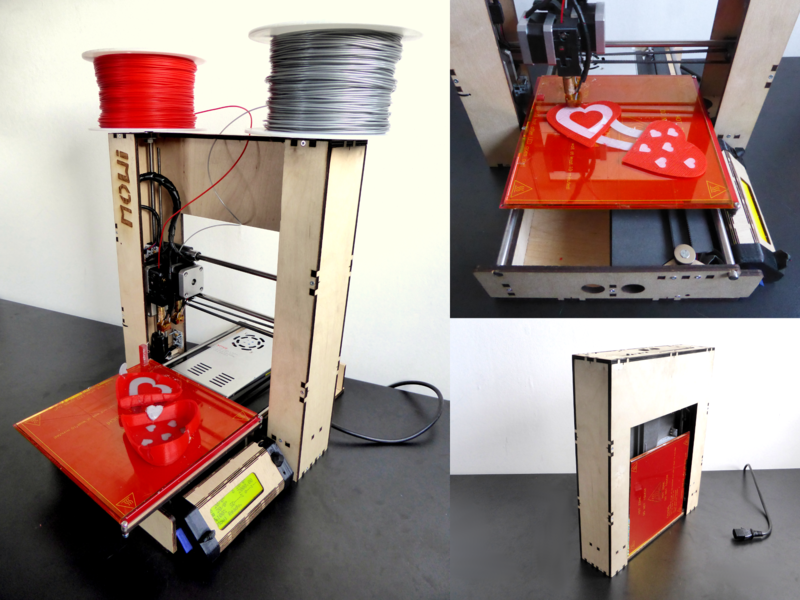

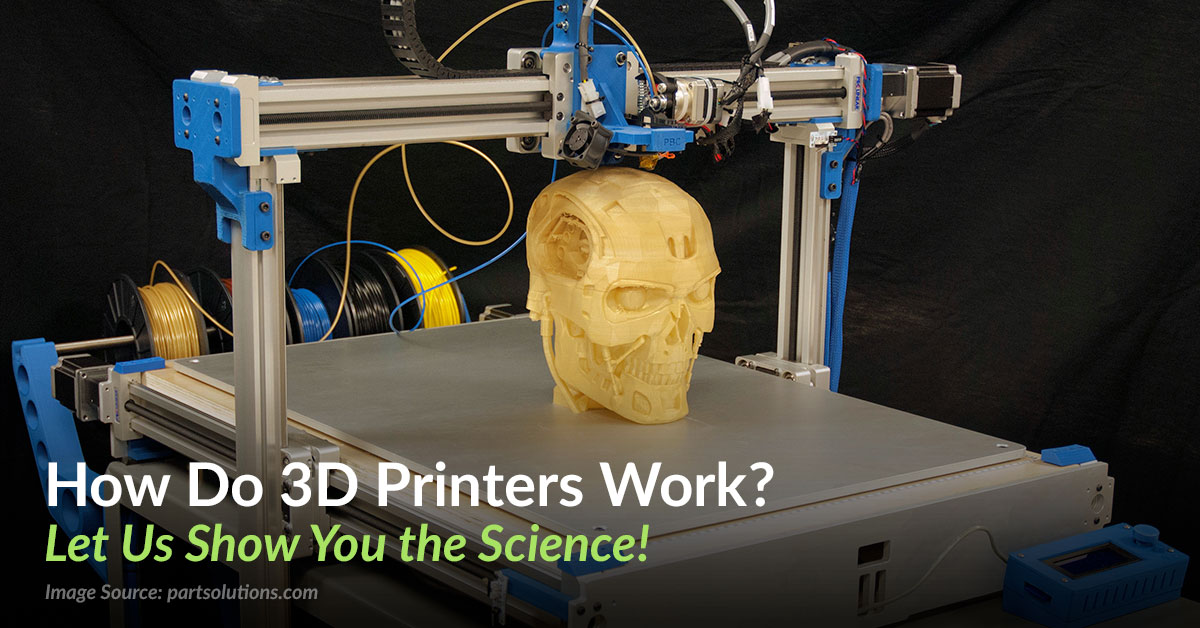

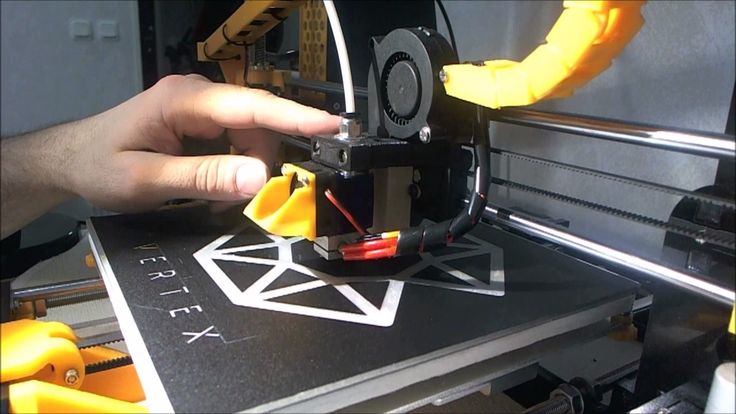

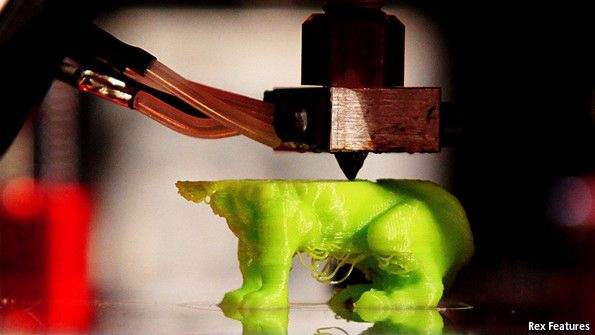

3D printers might seem like they're right out of a science fiction movie, but they're proving to be useful in a variety of industries. | Image: ShutterstockHow Do 3D Printers Work?

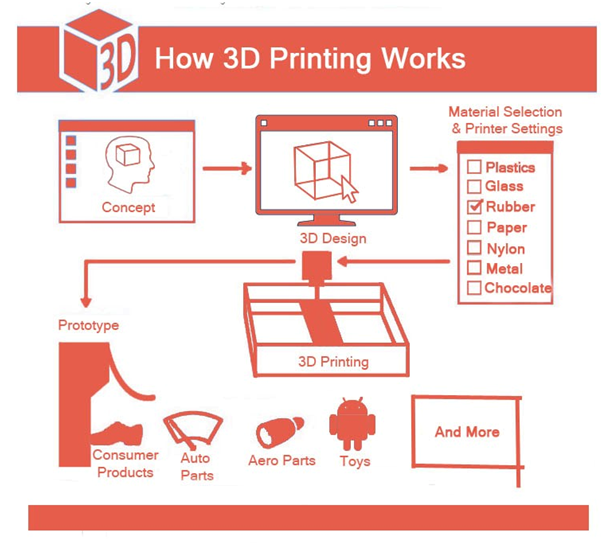

3D printing is part of the additive manufacturing family and uses similar methods to a traditional inkjet printer — albeit in 3D. Additive manufacturing describes the process of creating something in layers, adding material continuously until the final design is complete. This term most often refers to molding and 3D printing.

It takes a combination of top-of-the-line software, powder-like materials and precision tools to create a three-dimensional object from scratch. Below are a few of the main steps 3D printers take to bring ideas to life.

How Does a 3D Printer Work?

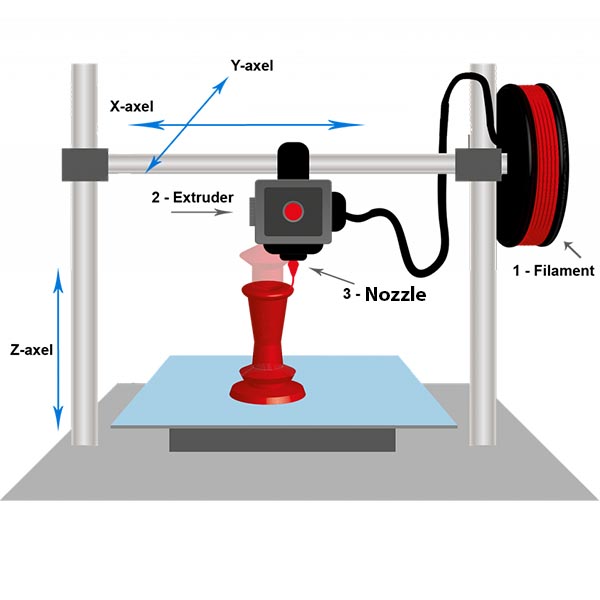

3D printers are related to additive manufacturing. 3D printers use computer-aided design to understand a design. When a design is ready, a material that can be dispensed through a hot nozzle or precision tool is printed layer by layer to create a three-dimensional object from scratch.

3D Modeling Software

The first step of any 3D printing process is 3D modeling. To maximize precision — and because 3D printers can’t magically guess what you want to print — all objects have to be designed in a 3D modeling software. Some designs are too intricate and detailed for traditional manufacturing methods. That’s where CAD software comes in.

Modeling allows printers to customize their product down to the tiniest detail. The 3D modeling software’s ability to allow for precision designs is why 3D printing is being hailed as a true game changer in many industries. This modeling software is especially important to an industry, like dentistry, where labs are using 3D software to design teeth aligners that precisely fit to the individual. It’s also vital to the space industry, where they use the software to design some of the most intricate parts of a rocketship.

3D PRINTERS USE MODELING AND SLICING SOFTWARE TO GUIDE THE PRINTER IN CREATING EACH OBJECT. Video: Digital Trends

Slicing the Model

Once a model is created, it’s time to “slice” it. Since 3D printers cannot conceptualize the concept of three dimensions, like humans, engineers need to slice the model into layers in order for the printer to create the final product.

Slicing software takes scans of each layer of a model and will tell the printer how to move in order to recreate that layer. Slicers also tell 3D printers where to “fill” a model. This fill gives a 3D printed object internal lattices and columns that help shape and strengthen the object. Once the model is sliced, it’s sent off to the 3D printer for the actual printing process.

The 3D Printing Process

When the modeling and slicing of a 3D object is completed, it’s time for the 3D printer to finally take over. The printer acts generally the same as a traditional inkjet printer in the direct 3D printing process, where a nozzle moves back and forth while dispensing a wax or plastic-like polymer layer-by-layer, waiting for that layer to dry, then adding the next level. It essentially adds hundreds or thousands of 2D prints on top of one another to make a three-dimensional object.

It essentially adds hundreds or thousands of 2D prints on top of one another to make a three-dimensional object.

3D Printing Materials

There are a variety of different materials that a printer uses in order to recreate an object to the best of its abilities. Here are some examples:

Acrylonitrile Butadiene Styrene (ABS)

Plastic material that is easy to shape and tough to break. The same material that LEGOs are made out of.

Carbon Fiber Filaments

Carbon fiber is used to create objects that need to be strong, but also extremely lightweight.

Conductive Filaments

These printable materials are still in the experimental stage and can be used for printing electric circuits without the need for wires. This is a useful material for wearable technology.

Flexible Filaments

Flexible filaments produce prints that are bendable, yet tough. These materials can be used to print anything from wristwatches to phone covers.

Metal Filament

Metal filaments are made of finely ground metals and polymer glue. They can come in steel, brass, bronze and copper in order to get the true look and feel of a metal object.

They can come in steel, brass, bronze and copper in order to get the true look and feel of a metal object.

Wood Filament

These filaments contain finely ground wood powder mixed with polymer glue. These are obviously used to print wooden-looking objects and can look like a lighter or darker wood depending on the temperature of the printer.

The 3D printing process takes anywhere from a few hours for really simple prints, like a box or a ball, to days or weeks for much larger detailed projects, like a full-sized home.

How Much Do 3D Printers Cost?

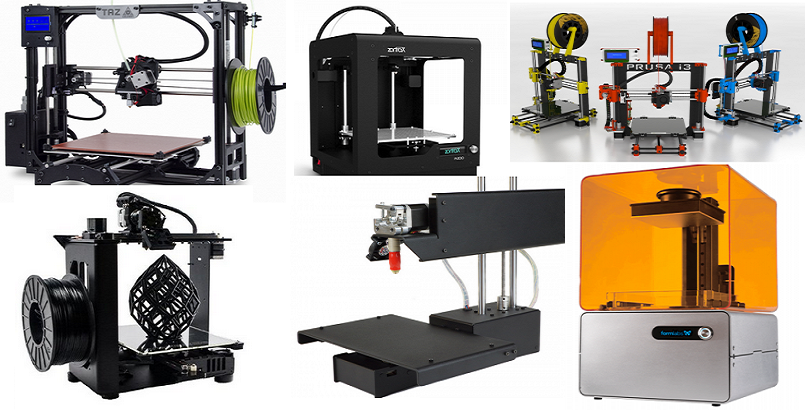

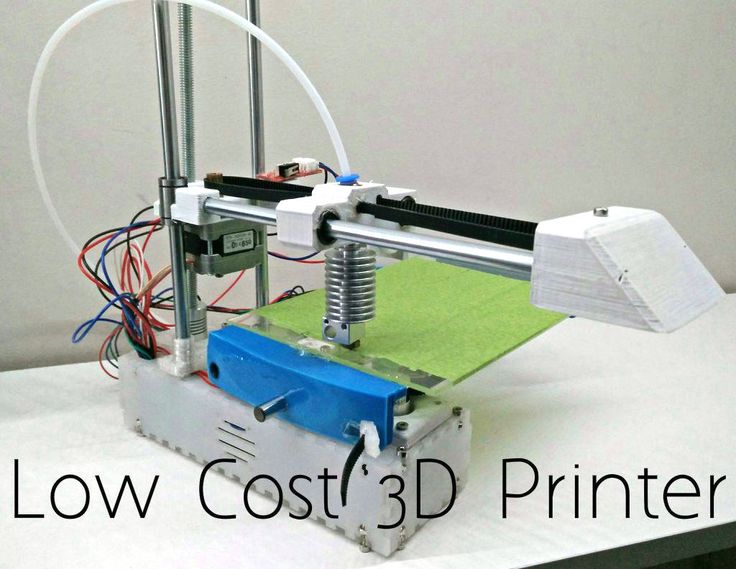

The cost of 3D printers vary based on the size, specialty and use. The cheapest 3D printers, for entry level hobbyists, typically range from $100 to $500. More advanced models can range between $300 and $5,000. Industrial 3D printers can cost up to $100,000.

3D Printing Processes and Techniques

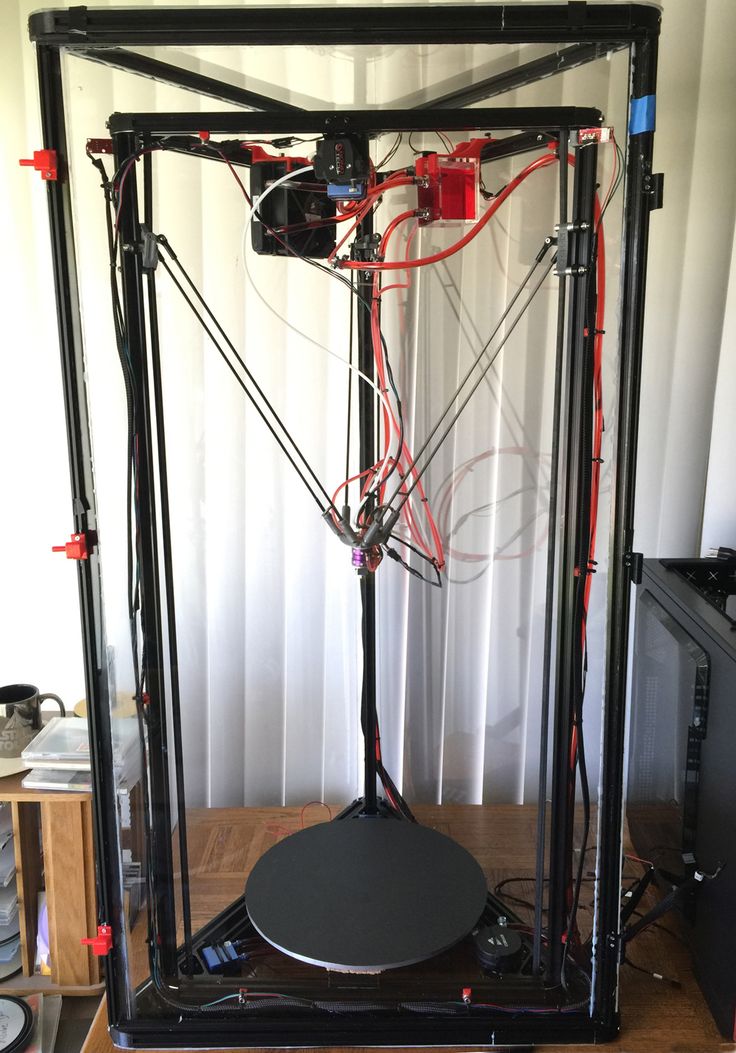

here are also different types of 3D printers depending on the size, detail and scope of a project. Each different type of printer will vary slightly on how an object gets printed.

Each different type of printer will vary slightly on how an object gets printed.

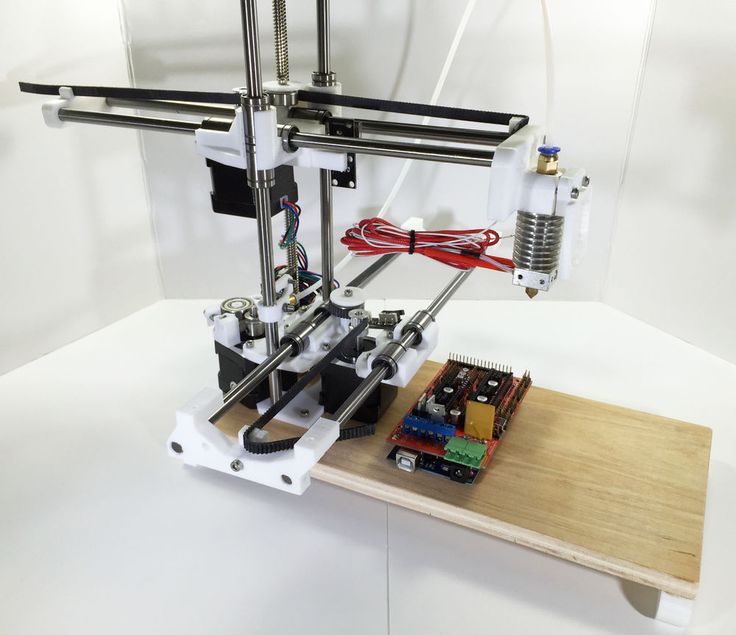

Fused Deposition Modeling (FDM)

FDM is probably the most widely used form of 3D printing. It’s incredibly useful for manufacturing prototypes and models with plastic.

Stereolithography (SLA) Technology

SLA is a fast prototyping printing type that is best suited for printing in intricate detail. The printer uses an ultraviolet laser to craft the objects within hours.

Digital Light Processing (DLP)

DLP is one of the oldest forms of 3D printing. DLP uses lamps to produce prints at higher speeds than SLA printing because the layers dry in seconds.

Continuous Liquid Interface Production (CLIP)

CLIP is amongst the faster processes that use Vat Photopolymerisation. The CLIP process utilizes Digital Light Synthesis technology to project a sequence of UV images across a cross-section of a 3D printed part, resulting in a precisely controlled curing process. The part is then baked in a thermal bath or oven, causing several chemical reactions that allow the part to harden.

Material Jetting

Material Jetting applies droplets of material through a small diameter nozzle layer-by-layer to build a platform, which becomes hardened by UV light.

Binder Jetting

Binder Jetting utilizes a powder base material layered evenly along with a liquid binder, which is applied through jet nozzles to act as an adhesive for the powder particles.

Fused Deposition Modeling (FDM)

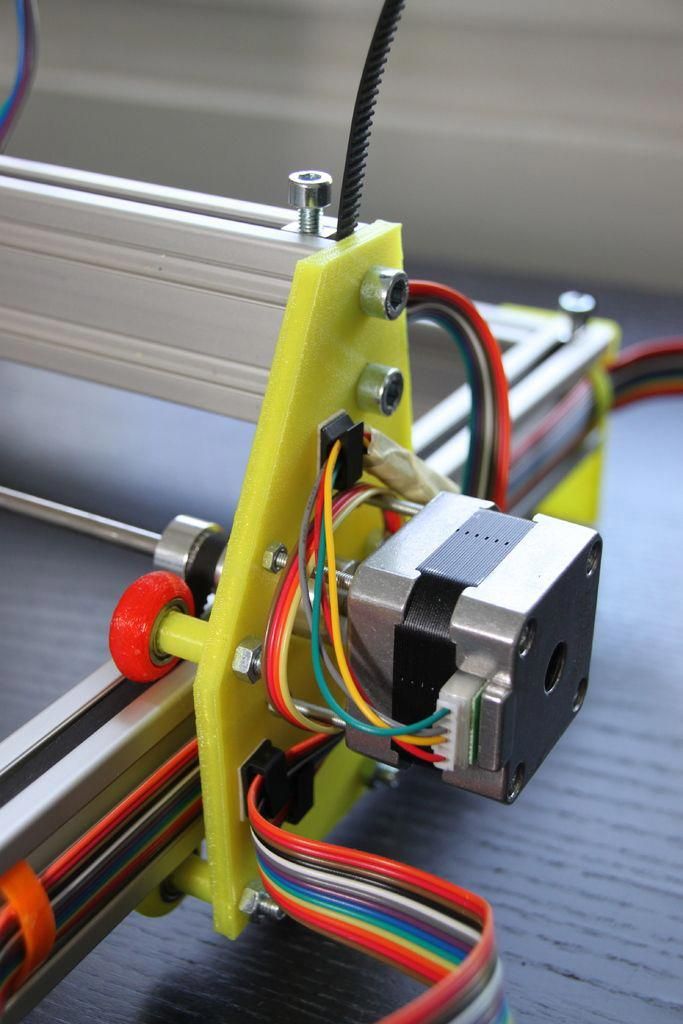

FDM, also known as Fused Filament Fabrication (FFF), works by unwinding a plastic filament from a spool and flowing through a heated nozzle in horizontal and vertical directions, forming the object immediately as the melted material hardens.

Selective Laser Sintering (SLS)

A form of Powder Bed Fusion, SLS fuses small particles of powder together by use of a high-power laser to create a three-dimensional shape. The laser scans each layer on a powder bed and selectively fuses them, then lowering the powder bed by one thickness and repeating the process through completion.

Multi-Jet Fusion (MJF)

Another form of Powder Bed Fusion, MJF uses a sweeping arm to deposit powder and an inkjet-equipped arm to apply binder selectively on top. Next, a detailing agent is applied around the detailing agent for precision. Finally, thermal energy is applied to cause a chemical reaction. Direct Metal Laser Sintering (DMLS) also utilizes this same process but with metal powder specifically.

Sheet Lamination

Sheet Lamination binds material in sheets through external force and welds them together through layered ultrasonic welding. The sheets are then milled in a CNC machine to form the object’s shape.

Directed Energy Deposition

Directed Energy Deposition is common in the metal industry and operates by a 3D printing apparatus attached to a multi-axis robotic arm with a nozzle for applying metal powder. The powder is applied to a surface and energy source, which then melts the material to form a solid object.

How do 3D printers work?

by Chris Woodford. Last updated: April 24, 2021.

Even the best artists struggle to show us what real-world objects look like in all their three-dimensional (3D) glory. Most of the time that doesn't matter—looking at a photo or sketch gives us a good-enough idea. But if you're in the business of developing new products and you need to show them off to clients or customers, nothing beats having a prototype: a model you can touch, hold, and feel. Only trouble is, models take ages to make by hand and machines that can make "rapid prototypes" cost a fortune (up to a half million dollars). Hurrah, then for 3D printers, which work a bit like inkjets and build up 3D models layer by layer at up to 10 times the speed and a fifth the cost. How exactly do they work? Let's take a closer look!

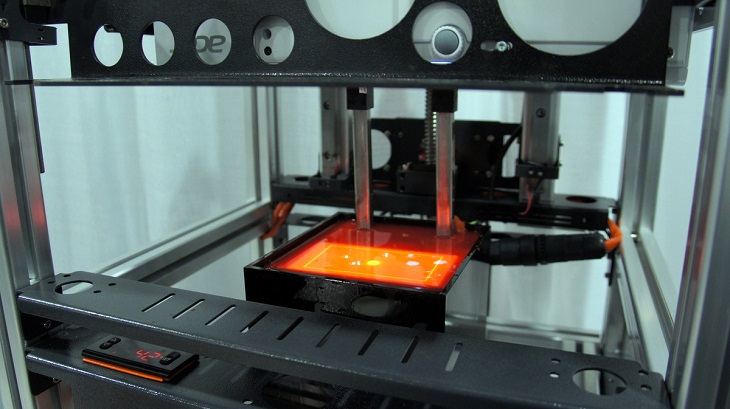

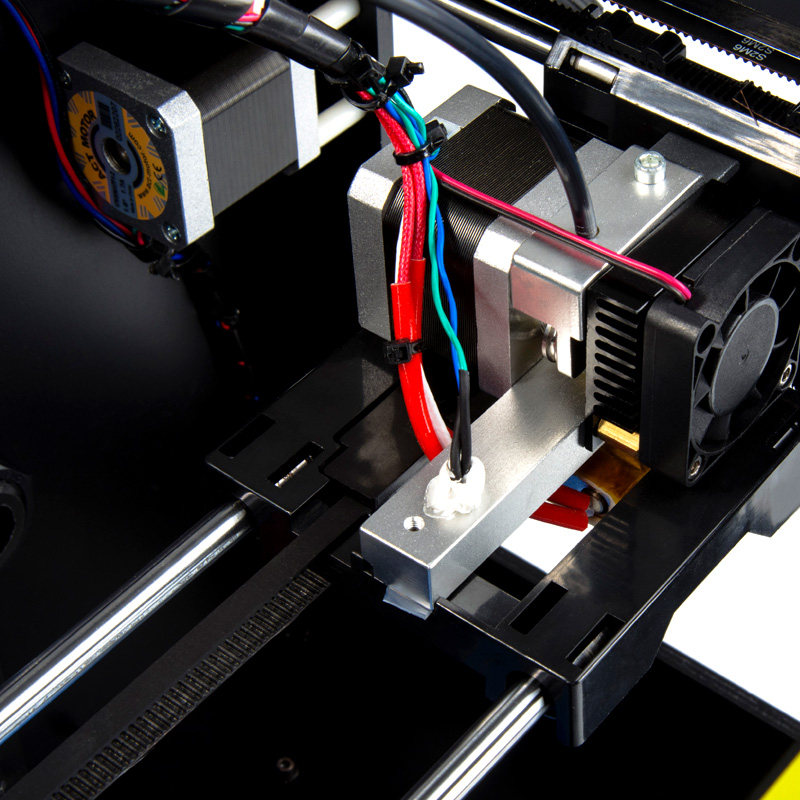

Photo: 3D printing in action: this is the printhead of an Invent3D printer, slowly building up an object, layer by layer, by squirting molten blue plastic out of its precisely moving nozzle. Photo by Cpl. Justin Updegraff courtesy of US Marine Corps.

Photo by Cpl. Justin Updegraff courtesy of US Marine Corps.

Contents

- From hand-made prototypes to rapid prototyping

- How does a 3D printer work?

- Q: What kind of "ink" does a 3D printer use? A: ABS plastic!

- Advantages and disadvantages

- Applications

- Medicine

- Aerospace and defense

- Visualization

- Personalized products

- The future of 3D printing

- Find out more

From hand-made prototypes to rapid prototyping

Photo: A high-quality rapid prototype of a space plane made in wax from a CAD drawing by NASA. Photo courtesy of NASA Langley Research Center (NASA-LaRC).

Before there were such things as computer-aided design (CAD) and lasers, models and prototypes were laboriously carved from wood or stuck together from little pieces of card or plastic. They could take days or even weeks to make and typically cost a fortune. Getting changes or alterations made was difficult and time-consuming, especially if an outside model-making company was being used, and that could discourage designers from making improvements or taking last-minute comments onboard: "It's too late!"

With the arrival of better technology, an idea called rapid prototyping (RP) grew up during the 1980s as a solution to this problem: it means developing models and prototypes by more automated methods, usually in hours or days rather than the weeks that traditional prototyping used to take. 3D printing is a logical extension of this idea in which product designers make their own rapid prototypes, in hours, using sophisticated machines similar to inkjet printers.

3D printing is a logical extension of this idea in which product designers make their own rapid prototypes, in hours, using sophisticated machines similar to inkjet printers.

How does a 3D printer work?

Artwork: One of the world's first three-dimensional FDM printers, developed by S. Scott Crump in the 1980s. In this design, the model (pink, 40) is printed on a baseplate (dark blue, 10) that moves in the horizontal (X–Y) directions, while the print head and nozzle (2 and 4, orange) move in the vertical (Z) direction. The raw material for printing comes from a plastic rod (yellow, 46), melted by the print head. The heating process is carefully regulated by a thermocouple (electrical heat sensor) connected to a temperature controller (purple, 86). The rod is extruded using compressed air from the large tank and compressor on the right (green, 60/62). Things have changed a bit since then, but the basic principle (of building up an object by melting and depositing plastic under three-dimensional control) remains the same. Artwork from US Patent 5,121,329: Apparatus and method for creating three-dimensional objects by S. Scott Crump, Stratasys Ltd, June 9, 1992, courtesy of US Patent and Trademark Office.

Artwork from US Patent 5,121,329: Apparatus and method for creating three-dimensional objects by S. Scott Crump, Stratasys Ltd, June 9, 1992, courtesy of US Patent and Trademark Office.

Imagine building a conventional wooden prototype of a car. You'd start off with a block of solid wood and carve inward, like a sculptor, gradually revealing the object "hidden" inside. Or if you wanted to make an architect's model of a house, you'd construct it like a real, prefabricated house, probably by cutting miniature replicas of the walls out of card and gluing them together. Now a laser could easily carve wood into shape and it's not beyond the realms of possibility to train a robot to stick cardboard together—but 3D printers don't work in either of these ways!

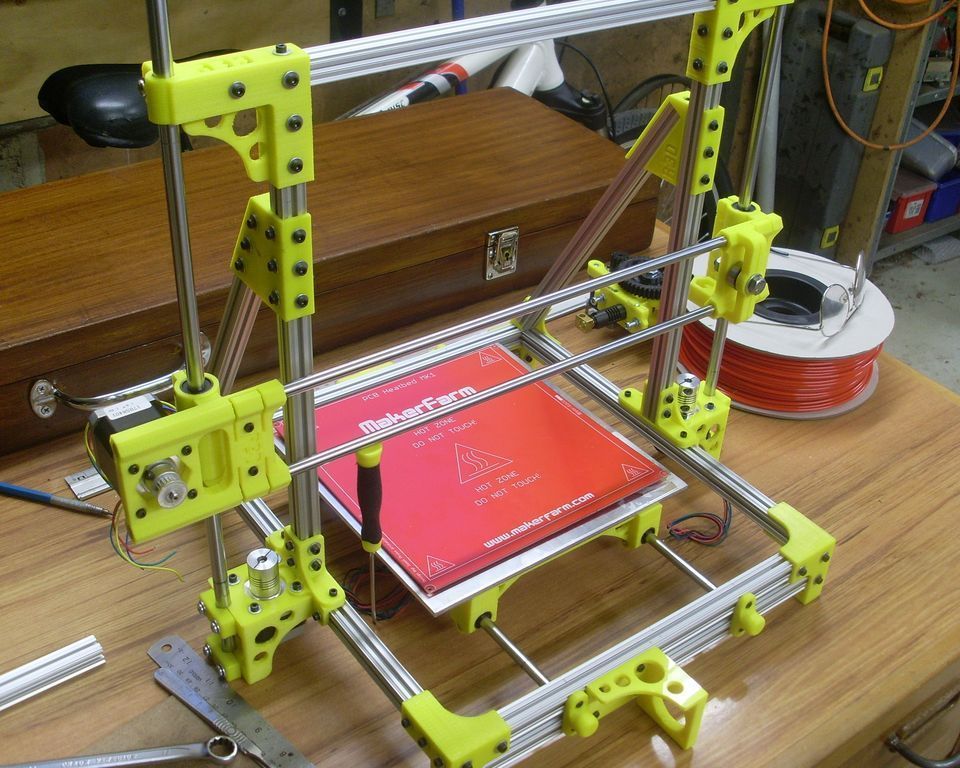

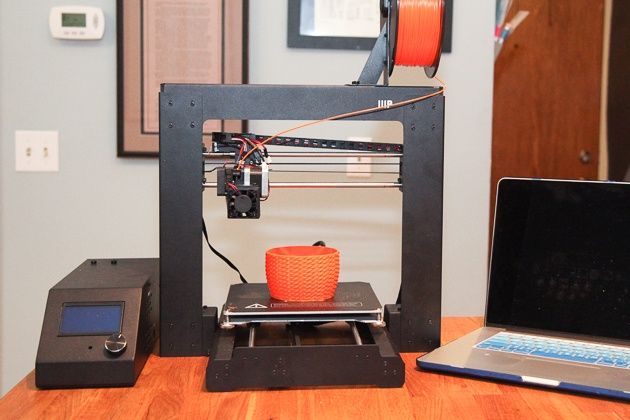

A typical 3D printer is very much like an inkjet printer operated from a computer. It builds up a 3D model one layer at a time, from the bottom upward, by repeatedly printing over the same area in a method known as fused depositional modeling (FDM). Working entirely automatically, the printer creates a model over a period of hours by turning a 3D CAD drawing into lots of two-dimensional, cross-sectional layers—effectively separate 2D prints that sit one on top of another, but without the paper in between. Instead of using ink, which would never build up to much volume, the printer deposits layers of molten plastic or powder and fuses them together (and to the existing structure) with adhesive or ultraviolet light.

Working entirely automatically, the printer creates a model over a period of hours by turning a 3D CAD drawing into lots of two-dimensional, cross-sectional layers—effectively separate 2D prints that sit one on top of another, but without the paper in between. Instead of using ink, which would never build up to much volume, the printer deposits layers of molten plastic or powder and fuses them together (and to the existing structure) with adhesive or ultraviolet light.

Q: What kind of "ink" does a 3D printer use? A: Plastic!

Where an inkjet printer sprays liquid ink and a laser printer uses solid powder, a 3D printer uses neither: you can't build a 3D model by piling up colored water or black dust! What you can model with is plastic. A 3D printer essentially works by extruding molten plastic through a tiny nozzle that it moves around precisely under computer control. It prints one layer, waits for it to dry, and then prints the next layer on top. Depending on the quality of the printer, what you get is either a stunning looking 3D model or a lot of 2D lines of plastic sitting crudely on top of one another—like badly piped cake icing! The plastic from which models are printed is obviously hugely important.

Photo: A Lulzbot 3D printer. You can see the little reel of raw, red plastic (the "filament") that feeds into the print head from the top. Photo by Stephane Belcher courtesy of US Navy.

When we talk about plastic, we generally mean "plastics": if you're a diligent recycler, you'll know there are many types of plastic, all of which are different, both chemically (in their molecular makeup) and physically (in the way they behave toward heat, light, and so on). It's hardly surprising that 3D printers use thermoplastics (plastics that melt when you heat them and turn solid when you cool them back down), and typically either ABS (acrylonitrile butadiene styrene), PLA (polylactic acid), or PETG (polyethylene gerephthalate glycol).

Perhaps most familiar as the material from which LEGO® bricks are made, ABS is also widely used in car interiors (sometimes in outside parts such as hubcaps too), for making the insides of refrigerators, and in plastic computer parts (it's quite likely the mouse and keyboard you're using right now are made from ABS plastic). So why is this material used for 3D printing? It's really a composite of a hard, tough plastic (acrylonitrile) with a synthetic rubber (butadiene styrene). It's perfect for 3D printing because it's a solid at room temperatures and melts at a little over 100°C (220°F), which is cool enough to melt inside the printer without too much heat and hot enough that models printed from it won't melt if they're left in the Sun. Once set, it can be sanded smooth or painted; another useful property of ABS is that it's a whiteish-yellow color in its raw form, but pigments (the color chemicals in paint) can be added to make it virtually any color at all. According to the type of printer you're using, you feed it the plastic either in the form of small pellets or filaments (like plastic strings).

So why is this material used for 3D printing? It's really a composite of a hard, tough plastic (acrylonitrile) with a synthetic rubber (butadiene styrene). It's perfect for 3D printing because it's a solid at room temperatures and melts at a little over 100°C (220°F), which is cool enough to melt inside the printer without too much heat and hot enough that models printed from it won't melt if they're left in the Sun. Once set, it can be sanded smooth or painted; another useful property of ABS is that it's a whiteish-yellow color in its raw form, but pigments (the color chemicals in paint) can be added to make it virtually any color at all. According to the type of printer you're using, you feed it the plastic either in the form of small pellets or filaments (like plastic strings).

PLA is easier to use than ABS and a little more environmentally friendly, though it's softer and less durable. PETG is a halfway house, closer to the strength of ABS, easy to shape, and relatively easy to recycle.

You don't necessarily need to print in 3D with plastic: in theory, you can print objects using any molten material that hardens and sets reasonably quickly. In July 2011, researchers at England's Exeter University unveiled a prototype food printer that could print 3D objects using molten chocolate!

Advantages and disadvantages

Photo: A B9Creator™—a typical low-cost, DIY 3D printer. It was originally available in kit form, priced at $2495; now it comes ready-assembled in three different versions priced from $6000–12000. Photo by courtesy of Windell H. Oskay, www.evilmadscientist.com, published on Flickr in 2012 under a Creative Commons Licence.

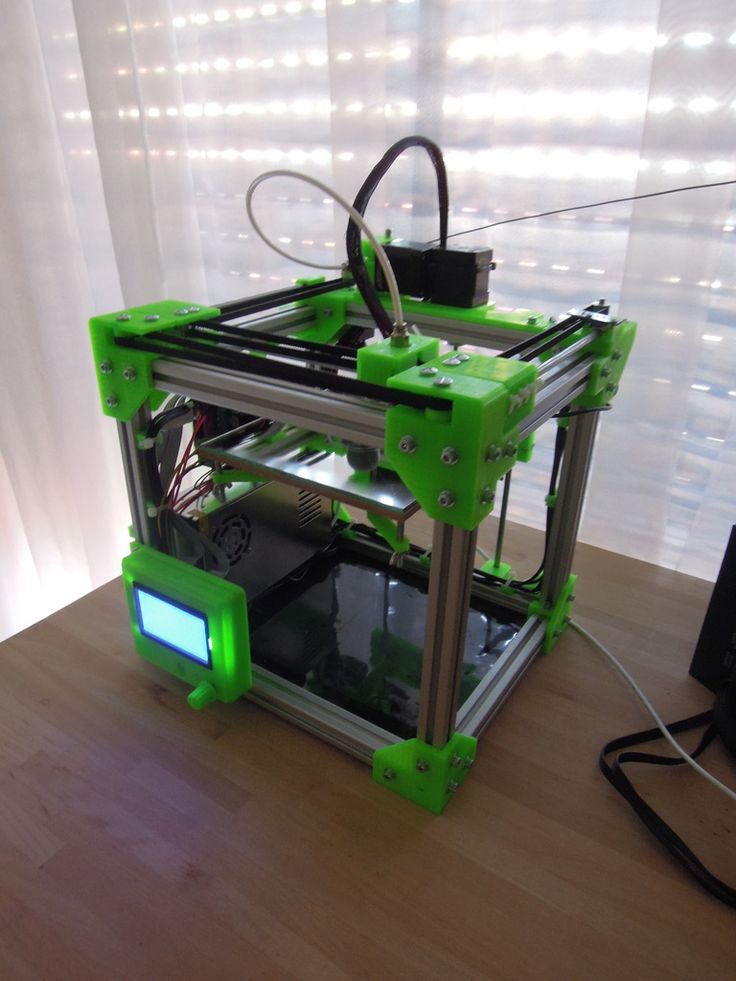

Makers of 3D printers claim they are up to 10 times faster than other methods and 5 times cheaper, so they offer big advantages for people who need rapid prototypes in hours rather than days. Although high-end 3D printers they are still expensive (typically about $25,000–$50,000), they're a fraction the cost of more sophisticated RP machines (which come in at $100,000–$500,000), and vastly cheaper machines are also available (you can buy a Tronxy 3D printer kit for around $100–200). They're also reasonably small, safe, easy-to-use, and reliable (features that have made them increasingly popular in places such as design/engineering schools).

They're also reasonably small, safe, easy-to-use, and reliable (features that have made them increasingly popular in places such as design/engineering schools).

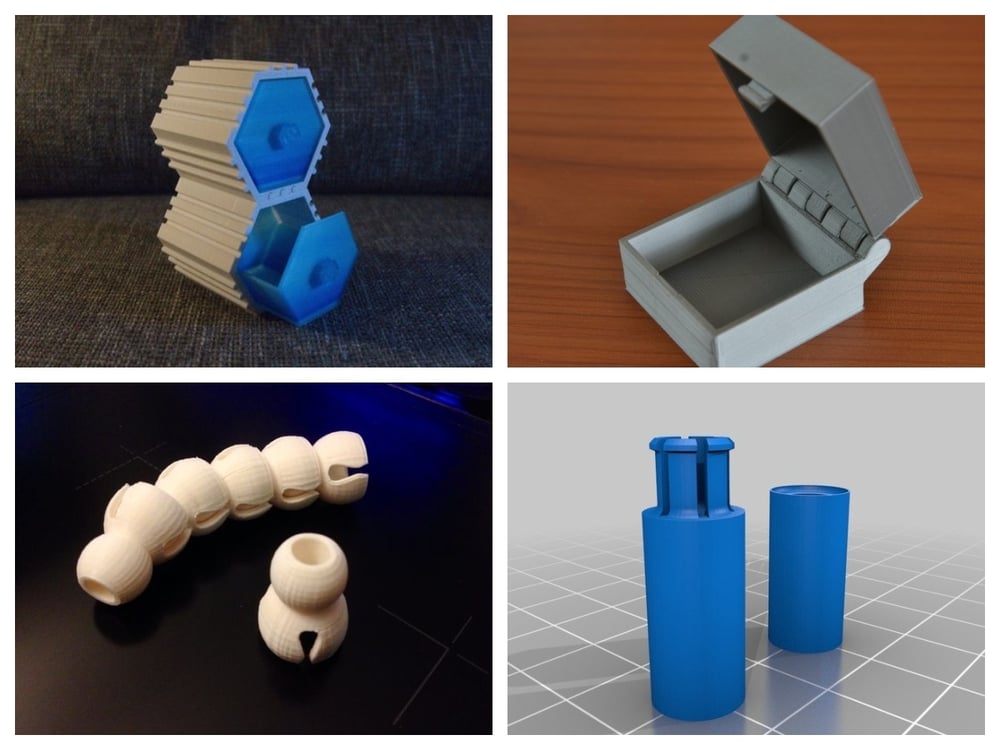

On the downside, the finish of the models they produce is usually inferior to those produced with higher-end RP machines. The choice of materials is often limited to just one or two, the colors may be crude, and the texture may not reflect the intended finish of the product very well. Generally, then, 3D-printed models may be better for rough, early visualizations of new products; more sophisticated RP machines can be used later in the process when designs are closer to finalization and things like accurate surface texture are more important.

Applications

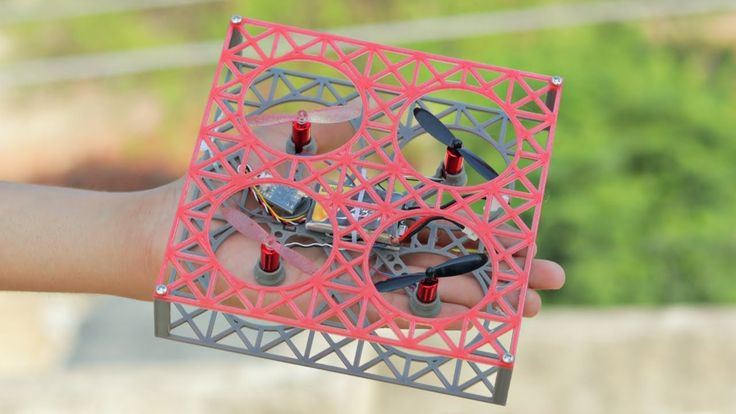

What can you use a 3D printer for? It's a bit like asking "How many ways can you use a photocopier?" In theory, the only limit is your imagination. In practice, the limits are the accuracy of the model from which you print, the precision of your printer, and the materials you print with. Modern 3D printing was invented about 25 years ago, but it's only really started to take off in the last decade. Much of the technology is still relatively new; even so, the range of uses for 3D printing is pretty astonishing.

Modern 3D printing was invented about 25 years ago, but it's only really started to take off in the last decade. Much of the technology is still relatively new; even so, the range of uses for 3D printing is pretty astonishing.

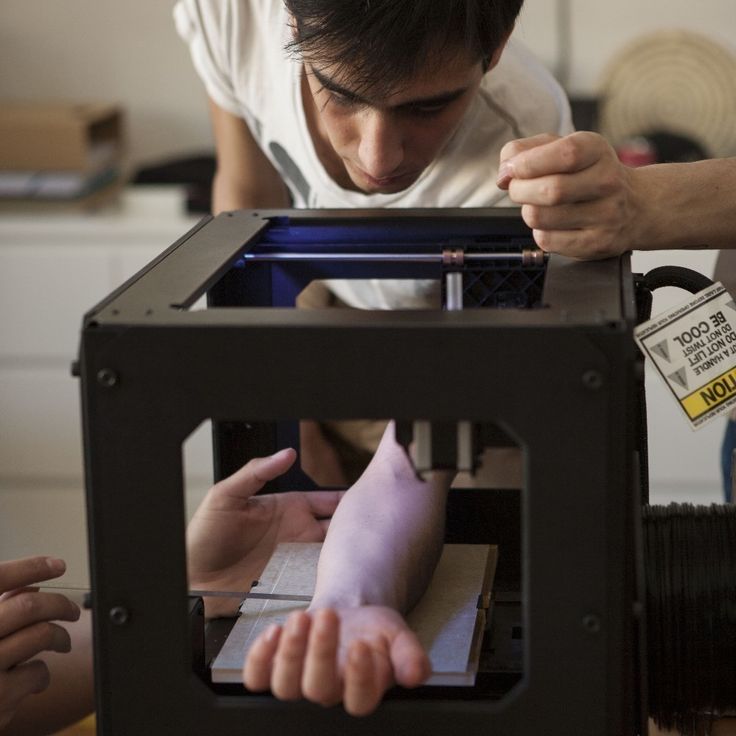

Medicine

Photo: 3D-printed plastic hearts make it possible for surgeons to practise operations with no risk. Model by Dr. Matthew Bramlet. Public domain photo published on Flickr courtesy of US NIH Image Gallery and 3D Print Exchange.

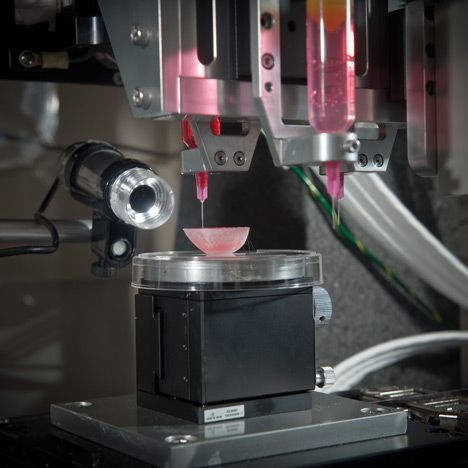

Life's a one-way journey; fallible, aging humans with creasing, crumbling bodies naturally see great promise in a technology that has the potential to create replacement body parts and tissue. That's why doctors were among the earliest people to explore 3D printing. Already, we've seen 3D printed ears (from Indian company Novabeans), arms and legs (from Limbitless Solutions, Biomechanical Robotics Group, and Bespoke), and muscles (from Cornell University). 3D printers have also been used to produce artificial tissue (Organovo), cells (Samsara Sciences), and skin (in a partnership between cosmetics giant L'Oreal and Organovo). Although we're some way away from having complete 3D printed replacement organs (such as hearts and livers), things are rapidly moving in that direction. One project, known as the Body on a Chip, run by the Wake Forest Institute for Regenerative Medicine in North Carolina, prints miniature human hearts, lungs, and blood vessels, places them on a microchip, and tests them out with a kind of artificial blood.

Although we're some way away from having complete 3D printed replacement organs (such as hearts and livers), things are rapidly moving in that direction. One project, known as the Body on a Chip, run by the Wake Forest Institute for Regenerative Medicine in North Carolina, prints miniature human hearts, lungs, and blood vessels, places them on a microchip, and tests them out with a kind of artificial blood.

Apart from replacement body parts, 3D printing is increasingly being used for medical education and training. At Nicklaus Children's Hospital in Miami, Florida, surgeons practise surgery on 3D-printed replicas of children's hearts. Elsewhere, the same technique is used to rehearse brain surgery.

Aerospace and defense

Designing and testing airplanes is a complex and expensive business: a Boeing Dreamliner has about 2.3 million components inside it! Although computer models can be used to test quite a few aspects of how planes behave, accurate prototypes still need to be made for things like wind-tunnel testing. And 3D printing is a simple and effective way to do that. While commercial airplanes are built in quantity, military planes are more likely to be highly customized—and 3D printing makes it possible to design, test, and manufacture low-volume or one-off parts both quickly and cost-effectively.

And 3D printing is a simple and effective way to do that. While commercial airplanes are built in quantity, military planes are more likely to be highly customized—and 3D printing makes it possible to design, test, and manufacture low-volume or one-off parts both quickly and cost-effectively.

Photo: The US Navy has been testing 3D printers on ships since one was installed on USS Essex in 2014. In theory, an onboard printer makes a ship more self-reliant, with less need to carry spare parts and materials, especially during wartime. This is a 3D-printed undersea wireless charger, typical of the objects that might be printed during a mission at sea. Photo by Devin Pisner courtesy of US Navy.

Spacecraft are even more complex than airplanes and have the added drawback that they are "manufactured" in tiny quantities—sometimes only one is ever made. Instead of going to all the expense of making unique tools and manufacturing equipment, it can make much more sense to 3D print one-off components instead. But why even make space parts on Earth? Shipping complex and heavy structures into space is difficult, expensive, and time-consuming; the ability to manufacture things on the Moon, or on other planets, could prove invaluable. It's easy to imagine astronauts (or even robots) using 3D printers to produce whatever objects they need (including spare parts), far from Earth, whenever they need them. But even conventional, Earth-spawned space projects can benefit from the speed, simplicity, and low-cost of 3D printing. The latest, human-supporting NASA Rover uses 3D-printed parts produced with help from Stratasys.

But why even make space parts on Earth? Shipping complex and heavy structures into space is difficult, expensive, and time-consuming; the ability to manufacture things on the Moon, or on other planets, could prove invaluable. It's easy to imagine astronauts (or even robots) using 3D printers to produce whatever objects they need (including spare parts), far from Earth, whenever they need them. But even conventional, Earth-spawned space projects can benefit from the speed, simplicity, and low-cost of 3D printing. The latest, human-supporting NASA Rover uses 3D-printed parts produced with help from Stratasys.

Photo: Spares and repairs are no problem. Closeup view of a Lulzbot Taz 6 3D printer being used to make spare parts onboard a US naval ship. Photo by Christopher A. Veloicaza courtesy of US Navy.

Visualization

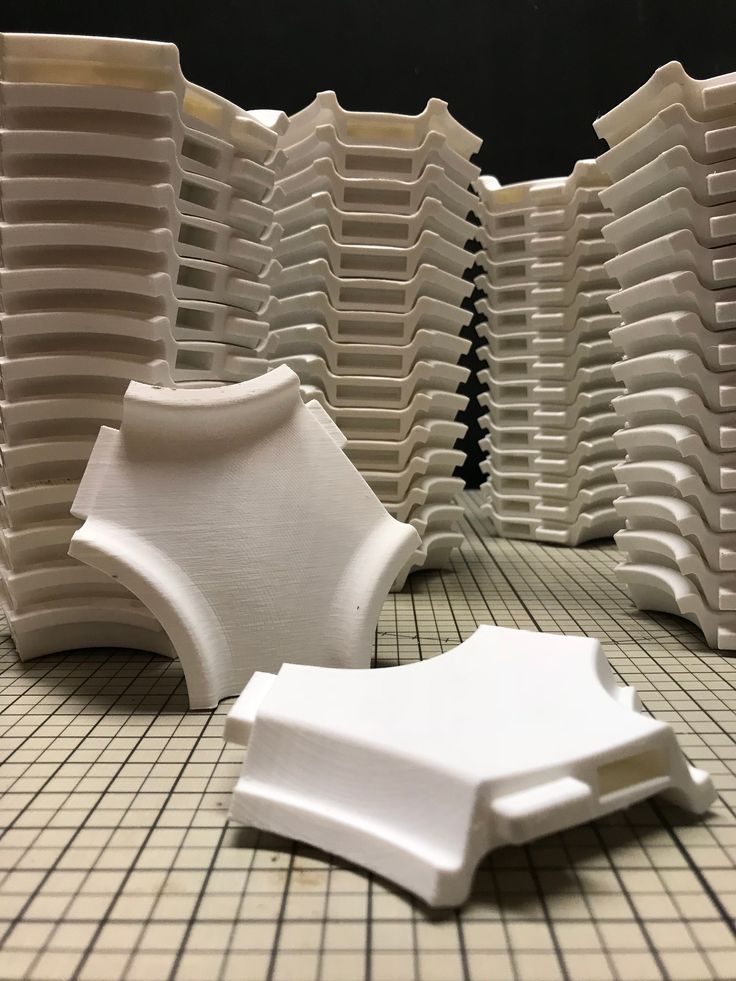

Making prototypes of airplanes or space rockets is an example of a much broader use for 3D printing: visualizing how new designs will look in three dimensions. We can use things like virtual reality for that, of course, but people often prefer things they can see and touch. Increasingly, 3D printers are being used for rapid, accurate architectural modeling. Although we can't (yet) 3D print in materials such as brick and concrete, there's a wide range of plastics available and they can be painted to look like realistic building finishes. In the same way, 3D printing is also now widely used for prototyping and testing industrial and consumer products. Since many everyday things are molded from plastic, a 3D printed model can look very similar to the finished product—perfect for focus-group testing or market research.

We can use things like virtual reality for that, of course, but people often prefer things they can see and touch. Increasingly, 3D printers are being used for rapid, accurate architectural modeling. Although we can't (yet) 3D print in materials such as brick and concrete, there's a wide range of plastics available and they can be painted to look like realistic building finishes. In the same way, 3D printing is also now widely used for prototyping and testing industrial and consumer products. Since many everyday things are molded from plastic, a 3D printed model can look very similar to the finished product—perfect for focus-group testing or market research.

Personalized products

From plastic toothbrushes to candy wrappers, modern life is here-today, gone-tomorrow—convenient, inexpensive, and disposable. Not everyone appreciates off-the-shelf mass production, however, which is why expensive "designer labels" are so popular. In the future, more of us are going to be able to enjoy the benefits of affordable, highly personalized products custom-made to our exact specification. Jewelry and fashion accessories are already being 3D printed. Just as the Etsy website created a worldwide community of artisan crafters , so Zazzy has now replicated that using 3D printing technology. Thanks to simple online services like Shapeways, anyone can make their own 3D printed nick-nacks, either for themselves or to sell to other people without the expense and hassle of using their own 3D printer (even Staples is now offering 3D printing services in some of its stores).

Jewelry and fashion accessories are already being 3D printed. Just as the Etsy website created a worldwide community of artisan crafters , so Zazzy has now replicated that using 3D printing technology. Thanks to simple online services like Shapeways, anyone can make their own 3D printed nick-nacks, either for themselves or to sell to other people without the expense and hassle of using their own 3D printer (even Staples is now offering 3D printing services in some of its stores).

"Customized products" aren't simply things we buy and use: the food we eat can fall into that category too. Cooking takes time, skill, and patience, because preparing a mouthwatering meal goes far beyond mixing ingredients and heating them on a stove. Since most food can be extruded (squeezed through nozzles), it can (theoretically) also be 3D printed. A few years ago, Evil Mad Scientist Laboratories playfully printed some weird objects out of sugar. In 2013, New York Times columnist A.J. Jacobs challenged himself to print an entire meal—including the plate and cutlery. In the process, he chanced upon the work of Cornell University's Hod Lipson, who believes meals may one day be personally, 3D printed to match your body's exact nutritional needs. Which brings us neatly to the future...

In the process, he chanced upon the work of Cornell University's Hod Lipson, who believes meals may one day be personally, 3D printed to match your body's exact nutritional needs. Which brings us neatly to the future...

Photo: In theory, you can make 3D prints from any raw material you can feed into your printer. Here are some fantastic 3D objects printed with granulated sugar by a "CandyFab 4000" (a hacked old HP plotter) by the always entertaining folk at Evil Mad Scientist Laboratories. Photo by courtesy of Windell H. Oskay, www.evilmadscientist.com, published on Flickr in 2007 under a Creative Commons Licence.

The future of 3D printing

Many people believe 3D printing will herald not merely a tidal wave of brash, plastic gimmicks but a revolution in manufacturing industry and the world economy that it drives. Although 3D printing will certainly make it possible for us to make our own things, there's a limit to what you can achieve by yourself with a cheap printer and a tube of plastic. The real economic benefits are likely to arrive when 3D printing is universally adopted by big companies as a central pillar of manufacturing industry. First, that will enable manufacturers to offer much more customization of existing products, so the affordability of off-the-shelf mass-production will be combined with the attractiveness of one-off, bespoke artisan craft. Second, 3D printing is essentially a robotic technology, so it will lower the cost of manufacturing to the point where it will, once again, be cost-effective to manufacture items in North America and Europe that are currently being cheaply assembled (by poorly paid humans) in such places as China and India. Finally, 3D printing will increase productivity (since fewer people will be needed to make the same things), lowering production costs overall, which should lead to lower prices and greater demand—and that's always a good thing, for consumers, for manufacturers, and the economy.

The real economic benefits are likely to arrive when 3D printing is universally adopted by big companies as a central pillar of manufacturing industry. First, that will enable manufacturers to offer much more customization of existing products, so the affordability of off-the-shelf mass-production will be combined with the attractiveness of one-off, bespoke artisan craft. Second, 3D printing is essentially a robotic technology, so it will lower the cost of manufacturing to the point where it will, once again, be cost-effective to manufacture items in North America and Europe that are currently being cheaply assembled (by poorly paid humans) in such places as China and India. Finally, 3D printing will increase productivity (since fewer people will be needed to make the same things), lowering production costs overall, which should lead to lower prices and greater demand—and that's always a good thing, for consumers, for manufacturers, and the economy.

Photo: Two views of the printhead (sometimes called the "tool head") of a 3D printer. Photo by Ashley McLaughlin courtesy of US Marine Corps.

Photo by Ashley McLaughlin courtesy of US Marine Corps.

50 Cool Things to 3D Print / Sudo Null IT News

No ideas for 3D printing? Tired of worthless trinkets? Here is a list of 50 cool really useful things for 3D printing.

Like us, you're excited about the possibilities of 3D printing. But, unfortunately, the horizon is littered with trinkets, trinkets and other unnecessary things. We are in danger of being buried under a heap of useless rubbish.

Throw off the shackles of mediocrity! Let's create really useful things! Here is a list of cool things that you can make on a 3D printer right now. Prove to your family and loved ones that this wonderful technology can be used daily and in practice.

No access to 3D printer? No problem. Just upload your files to our 3D printing price comparison system and choose the best price, ONLINE!

Download from Myminifactory

Cool thing for 3D printing No. 29: Form for Snegles

Download from ThingiVerse

Cool 3D Printable Item #30: Wine Bottle Protector

Download from MyMiniFactory170004

Cool thing for 3D printing No. 31: Pocket ashtray

download from Myminifactory

Cool Press No. 32: Rodist Roll for a glass 9000 9000 9000 9000 download from MYMINIFACTORY

3D Printable Cool Item #33: Apple Remote Stand

Download from MyMiniFactory

3D Printable Cool Item #34: Key Holder

Download with Myminifactory

Cool thing for 3D printing No. 35: Holder of the cutlery for people with disabilities

Download from Myminifactory

Current Passing No. 36: Cover wine bottle

Download from MyMiniFactory

Cool thing for 3D printing #37: Paper cup holder

download from Myminifactory

Cool thing for 3D printing No. 38: Case for blades

38: Case for blades

download from Myminifactory

Cool thing for 3D printing No. 39: Holder for a children from MyMiniFactory

3D Printable Cool Item #40: Towel Rack

Download from MyMiniFactory

3D Printable Cool Item #41: Holder for a glass

Download with Myminifactory

Cool thing for 3D Press No. 42: Holder for a phone in the shower

download from Myminifactory

Twisting thing for 3D printing No. 43: Holder No. 43: Holder No. 43: for beer glasses

Download from MyMiniFactory

Cool thing for 3D printing #44: MacBook Pro stand

download from Myminifactory

Cool thing for 3D printing No. 45: Protection for SD-Cart

download from Myminifactory

Cool thing No. 46: BATERIOUS 9000

Download from MyMiniFactory

3D Printable Cool Item #47: Ice Cream Cone Holder

Download from MyMiniFactory

Printable Cool Item #40016 shower set

download from Myminifactory

Cool Spring No. 49: Evacal separator

49: Evacal separator

download from Myminifactory

Cool Press No. 50 for 3D:

Download from MyMiniFactory

Want more exciting news from the world of 3D technology?

Follow us on social. facebook networks:

20 Amazing 3D Printed Things

If you can print in 2D, can you print in 3D? Well, the technology is already here. You can print 3D objects based on a working template, and they are not only meant to be looked at. They actually work! Manufacturers can provide you with a template from which you can print a broken machine part, say a screw, rather than placing an order and then waiting for a replacement.

Alternatively, you can make a 1:3 scale replica of an expensive car, like a 1960 Aston Martin DB5, for example, and then, for example, shoot it down or burn it down for fun, just like the makers of the James Bond movie Skyfall did.

3D printing is made possible by fusing layer by layer of durable plastics and metals based on a pattern designed with ARPA (Computer Aided Design). Each layer, about 0.1 mm thick, consists of liquid, powder or whole sheets of material.

Each layer, about 0.1 mm thick, consists of liquid, powder or whole sheets of material.

With this technology and a 3D printer, you can design, construct, or 3D print almost everything around you, as long as you have the templates. Just to give you an idea of what you can do with 3D printing, check out these 20 amazing printed masterpieces.

Firearms

In the past, printed firearms broke easily after a few shots. Today, however, the non-profit corporation Defense Distributed is offering users to download the necessary files to print your own firearms if you have a 3D printer at home.

Here is one of the videos of their semi-automatic and semi-automatic weapons:

Acoustic Guitar others know it's possible.

3D printed guitars can be made from plastic complete with a metal sound hole cap and heel. In addition to creating working musical instruments, guitarists can also make exact 3D copies of the guitars of their favorite musicians or idols.

Homemade Camera Lens

A camera lens is not easy to make, but with 3D printing you can make your own lens and even get some creative and unique results with it.

The creator of this lens (http://www.thingiverse.com/thing:37147) used acrylic to replace glass in the lens, as well as some other parts and mechanisms to bring them together. And, most importantly, the lens works! Check out some pictures taken with this lens: http://suzuki11.tumblr.com/

Shakuhachi Flute

This beautiful Japanese flute is 3D printed stainless steel. It comes in a variety of finishes such as gold plated matte or glossy and antique bronze matte (pictured below). The flute is 9.4 inches long and if you look closely you can see a small dragon on it.

You can buy this beautiful musical instrument for $239.95. Just imagine what this technology means for fantasy lovers.

Simple Loom

If you are going to weave a small amount of fabric, you can create this simple loom with a 3D printer and some plastic. All parts were fastened with bolts. To model this loom, the author used a 3D modeling program called openSCAD.

All parts were fastened with bolts. To model this loom, the author used a 3D modeling program called openSCAD.

The lessons of history would be much more interesting if you could see real goods that were sold in a certain period of time.

Machine model: http://www.thingiverse.com/thing:11374

3D kids drawing figures maybe a sculpture? Well, now you can do it for 99 euros. Thanks to 3D printing, your child's colorful drawing can be turned into a work of art.

Approximately 4" long object can be used to decorate your desktop or home, or as a trophy for your child's artistic talents. http://www.crayoncreatures.com/

3 D- embryo

“3D scanning” of your unborn child takes on a whole new meaning. Instead of a picture of your ultrasound, a Japanese company is offering you the so-called Angel Shape, a 3D print of your embryo for $1,275. A 3D model is created based on the processed image data using BioTexture.

Medical models

When it comes to technology, science has to be involved. Thanks to 3D printing, doctors will have a cheaper alternative to study human anatomy, as well as the ability to introduce more realistic models into surgical practice without the use of cadavers.

The printing of these medical models is so accurate that surgeons can use them to plan operations before operating on the real patient.

Illuminated shoes

This sneaker has a lot of intricate details and 1 meter of wires to light it up, so it's not a shoe you could wear. It was 3D printed and used for a commercial advertisement for the Onitsuka Tiger. The link says you can buy it for 5879.83 euros and use as a modern sculpture in your home.

In this video you can see how this amazing shoe was made:

Case for your iPhone with card slot

This Janne Kyttanen creation might look like a good iPhone 5 case design, but it's more functional than a normal case. It can also store any two cards.

It can also store any two cards.

It is called the "Mondriaan" case, after the artist Piet Mondriaan, who liked the design of horizontal and vertical lines. This case costs 34.9$9 and available in 3 colors.

Wire Organizer

If you bring your USB cables or other wires with you and want them to be neatly folded and tangle-free, you can buy this wire holder to help you get rid of from the hassle and save your time.

It can be printed in a wide range of colors and its price ranges from 10 to 20 euros depending on the color and size you choose.

https://www.shapeways.com/product/E6PH6YKMC/gear-wrap

Infinite Sisu iPad Stand

This stand is inspired by the Finnish concept of determination; The little muscular "man" holding your iPad is pretty hard to ignore. This is definitely a work of art that you can purchase for $161.

You may find it expensive compared to the more well-known standard stands for smartphones and tablets, but this is the price you have to pay for any work of art.

Bugdroid custom designed

Fans of the Android operating system and especially its splash logo figurines will also love these 3D figurines created, where the most amazing thing is that you can customize and choose different themes that suit you best.

There are 25 standard themes to choose from, priced at $21.99; If you don't find one that's right for you, then there's the option to customize your own Bugdroid for a starting price of $29$.99

Lamp

Your attention is the so-called palm lamp or lamp (Palm Lamp) from the same designer who made the iPhone case in the 10th item of our list. Janne Kyttanen has designed this rather eye-catching piece of art that comes in a wide variety of sizes. This lamp can be used as part of the decor, as a floor or table lamp or even a chandelier.

Kaleidoscope watch

This is a 3D printed watch that consists of two parts: part "A" and part "B". The first part is the purple dial itself, the second is the design part behind the dial.

The first part is the purple dial itself, the second is the design part behind the dial.

With the instructions, you can quickly and easily assemble and set them up. Two versions of the watch are available for order: the kaleidoscope watch in white design will cost a total of $51, while the black one will cost $61.

Revolution in 3 D anatomical sculpture prints

This piece of art is the creation of one of the most famous 3D designers Joshua Harker. This sculpture is printed in polyamide, obtained by laser sintering nylon and glass. Follow the link to see more photos of this intricate creation: https://www.kickstarter.com/projects/joshharker/anatomica-di-revolutis

Coffee cups

ceramics. The printing process takes almost a full day, and the One Cup a Day project aims to design and create 30 unique cups in 30 days. You can purchase their creations from this site where prices range from $36 to $77: https://www. cunicode.com/works/one-coffee-cup-a-day/

cunicode.com/works/one-coffee-cup-a-day/

High heels

This pair of 3D high heels called "Morphogenesis" was designed by Pauline Van Dongen and made from laser sintered nylon. She collaborated with Freedom Of Creation on the design, which in turn won the Most Creative Collection award at Mittelmoda 2010.

These shoes come in a variety of colors and truly define the future of 3D printed accessories. .

https://www.3dsystems.com/blog/foc/high-heel-shoes-by-pauline-van-dongen

Fabrics printed with 3 D

Designer Jiri Evenhuise together Janne Kyttanen has worked hard to make needle and thread a thing of the past. In their work, they use software that collects data on the physique of a particular person and instantly creates clothes that will fit exactly on the figure.

This type of production is recyclable, less labour-intensive, reduces production time and is ultimately a more sustainable way to produce clothing.

Now you will never lose your socks!

Now you will never lose your socks!  She will appreciate this gesture.

She will appreciate this gesture.  " Do you have such a business card? Find her a pair in the form of this business card holder, printed in its entirety (yes, already with a hinged lid). Instructions for adding a custom logo are included.

" Do you have such a business card? Find her a pair in the form of this business card holder, printed in its entirety (yes, already with a hinged lid). Instructions for adding a custom logo are included.

It is especially suitable for kitchen plants. The next time you buy fresh herbs for cooking, transplant them into this neat device and they'll stay fresh all week long.

It is especially suitable for kitchen plants. The next time you buy fresh herbs for cooking, transplant them into this neat device and they'll stay fresh all week long.  It’s great if you have water limits set in the height of summer.

It’s great if you have water limits set in the height of summer.  28: Protection for disk

28: Protection for disk