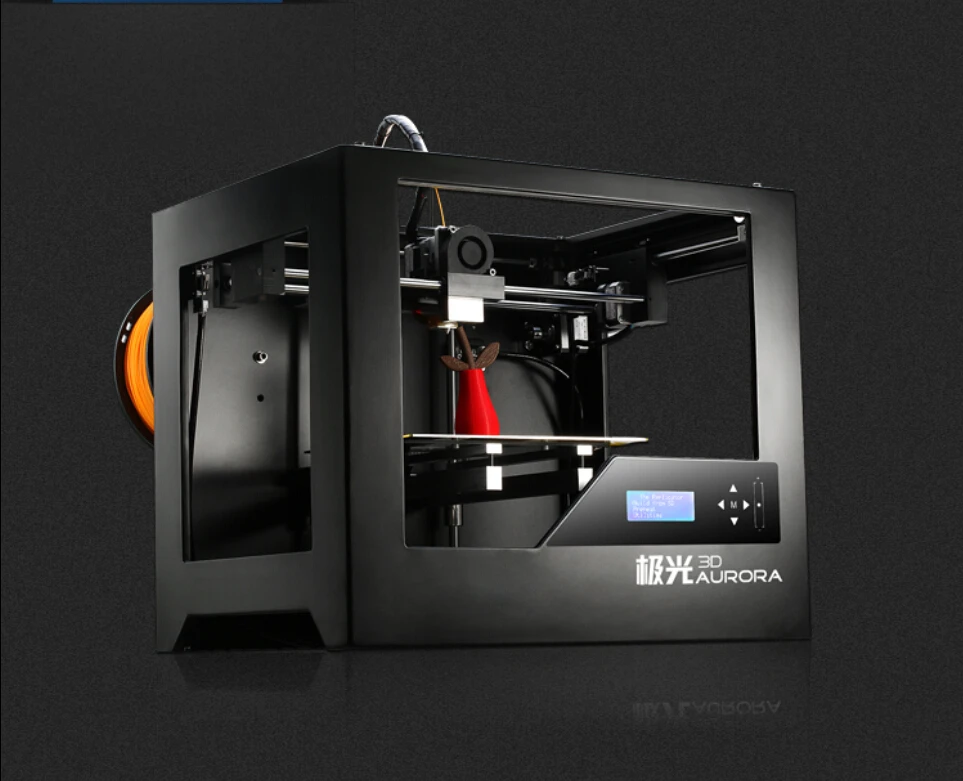

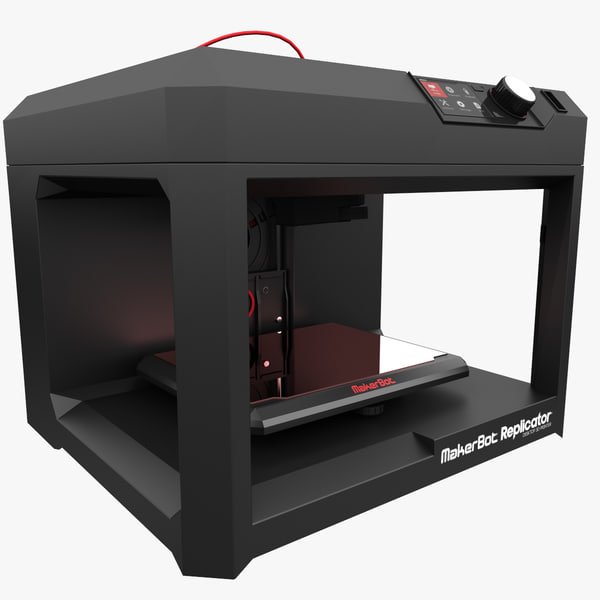

Used makerbot 3d printer for sale

MakerBot Replicator 3D Printer Materials

Rigorously Tested and Tuned

MakerBot 3D Printing Materials are optimized to give you the best results and highest quality with MakerBot 3D Printers.

Rigorously Tested and Tuned

MAKERBOT MATERIALS FOR

REPLICATOR+ & REPLICATOR Z18

MakerBot 3D Printing Materials are optimized to give you the best results and highest quality with MakerBot 3D Printers.

With up to 2X the impact-strength of ABS and similar tensile and flexural strength properties, Tough gives you durability you need for functional part testing.

Colors Available:

Safe for the classroom, office, or home, this material is non-toxic and easy to print with minimal warping or curling. It’s also the best, most consistent material to use with previous MakerBot Replicator 3D printer models.

Colors Available:

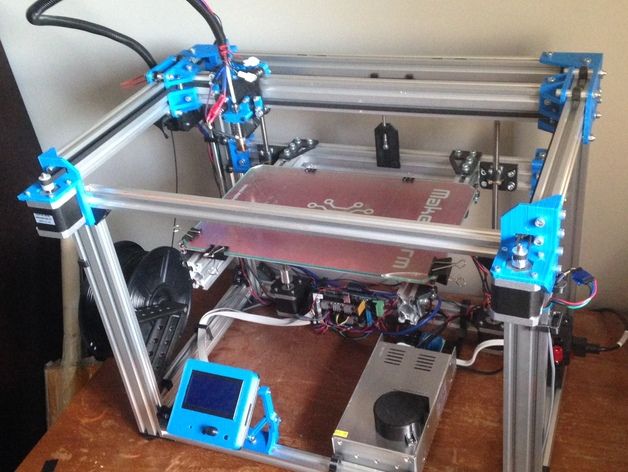

Experiment with Your Own Materials

MAKERBOT LABS

An experimental platform for engineers and developers to create, build, customize, and collaborate on MakerBot 3D printing solutions. Discover a wide range of 3D printing materials including bronzefill, copperfill, and woodfill with the MakerBot Labs Experimental Extruder.

Learn More

MakerBot Materials for Replicator+ and Replicator Z18

| TOUGH | PLA | ||

| APPLICATIONS | Durable, usable prototypes; manufacturing aids | Clean concept models | |

| PRINT SURFACE REQUIREMENTS | Grip Surface (standard) | ||

| COLORS | Slate Gray Onyx Black Stone White Safety Orange | True Colors True Black True White Cool Gray Warm Gray True Orange True Red True Yellow True Blue True Purple True Green Natural | Limited Colors Glow-in-the-Dark Translucent Red Translucent Orange Translucent Yellow Translucent Blue Translucent Purple Neon Green Neon Orange Ocean Blue Army Green Khaki |

| EXTRUDER | Tough Smart Extruder+ | Smart Extruder+ | |

| EXTRUDER WARRANTY | 6 Months | ||

MakerBot Materials for Replicator+ and Replicator Z18

METHOD

INDUSTRIAL 3D PRINTING FOR EVERY ENGINEERNext-Generation desktop 3D printing platform that delivers manufacturing-grade parts with advanced engineering materials.

SKETCH CLASSROOM

THE IDEAL CLASSROOM SETUP

The most reliable classroom 3D printing setup, giving your students the access they need and setting you up for classroom success.

A manufacturing workstation

METHOD

Print real, production-grade ABS with a 100°C chamber—powered by Stratasys®.

SKETCH CLASSROOM

THE IDEAL CLASSROOM SETUP

The most reliable classroom 3D printing setup, giving your students the access they need and setting you up for classroom success.

MakerBot for Professionals

Fast and Reliable Rapid Prototyping

Get prototypes and production parts out the door quickly and efficiently with MakerBot 3D printers.

MakerBot for Educators

3D Printing in the Classroom

MakerBot offers the easiest setup experience with no tinkering required.

Get started right away with hundreds of 3D printing lesson plans.

MakerBot for Professionals

FAST AND RELIABLE RAPID PROTOTYPING

Get prototypes and production parts out the door quickly and efficiently with MakerBot 3D printers.

MakerBot for Educators

3D Printing in the Classroom

MakerBot offers the easiest setup experience with no tinkering required.

Get started right away with hundreds of 3D printing lesson plans.

Ready to get started?

Shop now, or talk to a representative

ORDER ONLINE

Order from our online store to get started 3D printing, fast.

TALK TO AN EXPERT

Get started today with a sample part, a demo, or a quote from the MakerBot sales team.

Call Now

Mon - Fri 9am - 6pm ET

+1 347 676 3456

3D Printers

MakerBot Replicator+ and MakerBot Mini Replicator+

Basics

- A 3D printer is a tool used to create three-dimensional items that have been designed on a computer.

.jpg) 3D printers lay down material layer by layer to build an item.

3D printers lay down material layer by layer to build an item. - Build volume for each printer (the largest object they are able to make)

- Replicator+ 11.6” x 7.6” x 6.5”

- Mini Replicator+ 4”L x 5”W x 5” H

What you will need

- Your object file –

- you can download pre-made object files from websites such as Thingiverse

- design your own objects using free online websites like TinkerCAD or Sketchup

- small objects may be scanned with a 3D scanner available in the Lab

- Knowledge of 3D printing basics. Patrons wanting to use the 3D printers should attend a 3D demonstration or visit the following site to learn more about 3D printing https://www.makerbot.com/learn

- Knowledge of the program MakerBot Print. This is software that allows you to view, arrange, adjust, and preview a sliced version of your 3D object. All print jobs must be opened in this software prior to printing.

A tutorial on using MakerBot Print is available at the following website. https://support.makerbot.com/learn/makerbot-print-software/using-makerbot-print/using-makerbot-print_13586

A tutorial on using MakerBot Print is available at the following website. https://support.makerbot.com/learn/makerbot-print-software/using-makerbot-print/using-makerbot-print_13586

Cost

15₵ per gram (final weight includes raft)

3D Printing Pen (now available for check out)

3D Printing Pen improves creativity and imagination allowing you to literally draw in 3 Dimensions.

Cost

15₵ per gram

EinScan-SP Desktop 3D Scanner

Basics

- Scan and convert items to 3D files

- Objects must be smaller than 12”

What you will need

- Flash drive to save your scan.

Cost

- There is no charge for using this equipment

- If you choose to print your item, it is 15₵ per gram

FAQ

3D Printers

Is filament available?

You must use the filament we have available in the Lab. The filament used is MakerBot PLA filament and is available in a few different colors.

The filament used is MakerBot PLA filament and is available in a few different colors.

Where can I get files to print?

You can create your own designs with free websites like Tinkercad.com or Sketch.com. If you want a file that is ready to print, you can visit sites like Thingiverse.com.

Can I scan an exisiting item to 3D print?

We do have a 3D scanner that can scan smaller items. Items that do not scan well are:

-

Black or very dark items

-

Flat items

-

Items that have hidden or hard to see spaces – these will be shadowed and may not scan well

-

Textured items

-

Clear/Transparent items

- You may need to export the scanned file into a program like TinkerCad to clean up the model prior to printing.

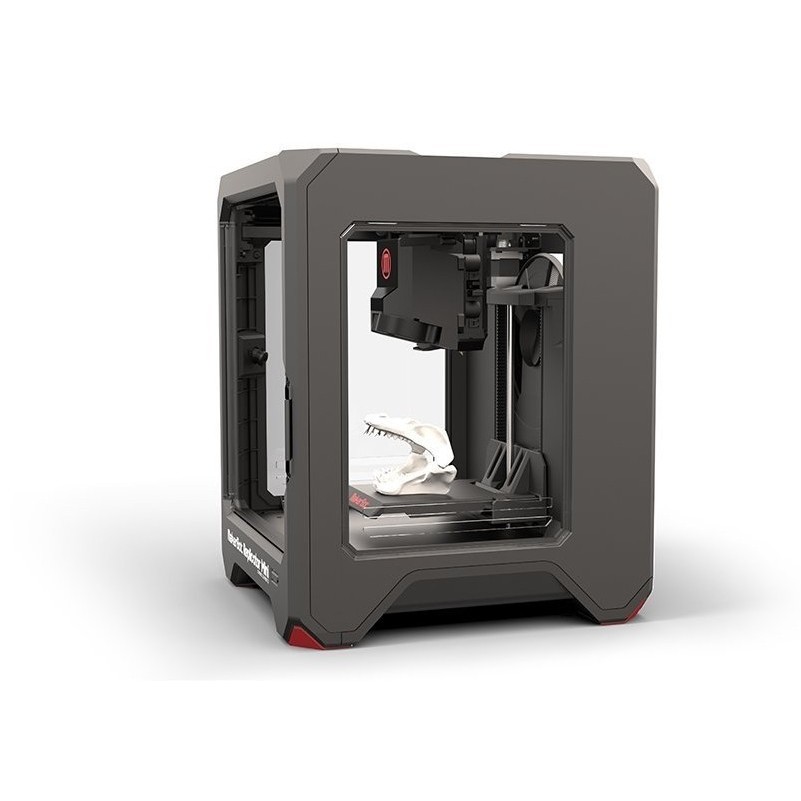

Detailed review of the MakerBot Replicator Plus

3D printer3DPrintStory Reviews Detailed review of the 3D printer MakerBot Replicator Plus

TheMakerBot Replicator Plus has received improvements in terms of design, speed and many other features compared to previous models. This time around, MakerBot tried to attract a professional audience to 3D printing, and it succeeded. This 3D printer is quieter and has many other advanced features that make it one of the strongest 3D printers in its price range.

MakerBot Replicator Plus 3D Printer Specifications

Let's take a look at the MakerBot Replicator Plus features that make this 3D printer a real gem. It has a few limitations and is expensive. But the implementation of the rest of the nodes of this 3D printer makes it easy to neglect these shortcomings. Overall, this 3D printer has been and remains very popular among 3D printers.

It has a few limitations and is expensive. But the implementation of the rest of the nodes of this 3D printer makes it easy to neglect these shortcomings. Overall, this 3D printer has been and remains very popular among 3D printers.

The MakerBot Replicator Plus is all black and looks great thanks to its rugged design. The company has increased the dimensions of this 3D printer compared to its predecessor, which is 410 x 440 x 525 mm. The weight is about 18 kg. Nozzle diameter 0.4 mm.

The build volume of the 3D printer is 165 x 290 x 190 mm. Open frame design. It is open at the top, front and sides, providing a great view for those who like to follow the 3D printing process.

MakerBot boasts many updates that have been implemented in this 6th generation released by the company. All new features are worthy of attention. This model would be a great option for teaching the basics of 3D printing or for those who want to start a small 3D printing business. With 25% more workspace and 30% faster 3D printing than the previous version, the MakerBot Replicator Plus is a clear improvement over its predecessor.

Price MakerBot Replicator Plus 3D Printer

MakerBot succeeded in many ways in terms of quality, but not in terms of price... The MakerBot Replicator Plus is expensive. $2,499 is a hefty amount of money for most people, especially if someone is just getting started with 3D printers.

Although the company intended to target the professional and educational sector, the price was even by that measure. There are many professional 3D printers with comparable features at a lower price.

The price of the MakerBot Replicator Plus certainly limits its availability to most users. But as the 3D printing community grows, the number of those who can pay that price has also increased. This way, MakerBot will have no problem selling its item, given that its features are worthy for this price. Let's now dig deeper to see what exactly this 3D printer delivers at such an indiscreet price.

MakerBot Replicator Plus 9 First Impressions0009

The first impression of the MakerBot Replicator Plus is the same 3D printer as its predecessor, with a slightly expanded 3D print workspace. In fact, it has the same metal case with plastic containers. Like most older versions, the model is sleek and durable. The open design makes this model suitable for any lab or garage. This same openness makes the MakerBot Replicator Plus a great option for training centers.

In fact, it has the same metal case with plastic containers. Like most older versions, the model is sleek and durable. The open design makes this model suitable for any lab or garage. This same openness makes the MakerBot Replicator Plus a great option for training centers.

However, when you start setting up this 3D printer and start 3D printing, you will realize that many changes have been made to the functionality of the previous version.

Size is the first thing people pay attention to. Once you start plugging this model into an outlet, you will realize that it is nothing like the fifth generation version. If not for the biting price, then the MakerBot Replicator Plus is a great choice for a desktop 3D printer.

Setting Up the MakerBot Replicator Plus 3D Printer

Setting up the MakerBot Replicator Plus is simple, but the instructions could be better illustrated. To set up, you need to connect to WIFI and download the mobile phone app. There is no mention of which OS version is compatible with the mobile phone app. Doesn't work with old version.

Doesn't work with old version.

If your phone's OS is not updated to the latest version, problems may occur. However, this is not a big problem and it can be fixed. But at some point, the instructions will continue to be confusing. Setup can be done via the USB connector on the back of the 3D printer. There is no mention of this in the instructions. You can also use an Ethernet cable for the necessary settings.

You also need to create an account with MakerBot before starting setup. This gives you the added benefit of remote viewing and 3D printing.

In addition, the mobile phone application is quite easy to use and even beginners will find it useful when setting up a 3D printer.

MakerBot Replicator Plus 3D Printing Price

This 3D printer is based on the FDM process. The material is heated and extruded to be deposited layer by layer on the worktable. After each layer cools and solidifies, another layer of molten material is applied to the previous layer. This way the whole part will be printed.

This way the whole part will be printed.

Controls and User Interface : Controls are placed at eye level in front of the 3D printer body. Thanks to a clear interface, you can choose between different setting options. The display can be navigated using one button wheel and two more buttons. You can also preview the model before 3D printing. This is a great feature as you can use this 3D printer without a desktop computer via the USB port to preview your model before starting 3D printing.

Material storage : MakerBot has made major changes to the material storage system. Unlike many other options available on the market where the spool storage is located outside, the MakerBot's plastic spool storage is hidden in the back of the 3D printer. This allows you to control the remaining material. Loading material is also simple and convenient. MakerBot didn't mention it directly, but you are forced to use only MakerBot stuff. This is noted in the 3D Printing Materials Warning from other manufacturers, which states that the warranty may be voided if other materials are used. The material offered by MakerBot is as expensive as their 3D printer itself. Coil of PLA plastic weighing 0.9kg will cost from 48 to 65 dollars. Available in about 30 different shades and types of materials.

The material offered by MakerBot is as expensive as their 3D printer itself. Coil of PLA plastic weighing 0.9kg will cost from 48 to 65 dollars. Available in about 30 different shades and types of materials.

3D Printing Process : Although printing with this 3D printer is effortless, you may have to work a little to remove parts from the desktop when printing is complete. Before printing details, you need to adjust the layer height. After that, a file for 3D printing is generated and sent to the printer for direct printing. After starting 3D printing, you can turn off your computer or control the printing process by turning it on.

3D print speed : The company claims that this version prints 30% faster than the previous model. And this 3D printer is really faster.

Extruder : MakerBot offers a "smart" extruder, available at an additional cost, that is designed to use 1.75mm PLA. It can detect when material is running low and immediately pause 3D printing. It also notifies the user to submit material in order to start 3D printing again.

It also notifies the user to submit material in order to start 3D printing again.

MakerBot Replicator Plus 3D Print Quality

MakerBot Plus 3D print quality is better than most professional 3D printers. However, at $2,499 you can expect better results. Perhaps the company could work a little more on print quality in the context of the overpriced.

With this 3D printer, you can print fine details in decent quality. However, there are a few problems, such as the tendency of this 3D printer to leave filaments between voids. Although they are removable, they still leave traces and in fact the print is not perfect.

Smooth and beautiful curves can be printed. This 3D printer allows you to create curves with fine details. However, the print speed will have to be reduced to improve detail and accuracy.

Geometric prints are also great, although not as dramatic. The MakerBot Replicator Plus can create bevelled edges with fine detail. This 3D printer does an excellent job of making sculptures and geometric shapes. However, don't expect perfectly sharp corners. Remains of material between the voids will also show up in similar 3D models.

However, don't expect perfectly sharp corners. Remains of material between the voids will also show up in similar 3D models.

You can also try printing assembled gears. However, when 3D printing sets of gears, the amount of post-processing work increases.

The biggest flaw that calls into question the quality of this 3D printer is no heat desktop ...

MakerBot Replicator Plus 3D printer software

The MakerBot Print application compatible with this model can be considered almost flawless. With simple commands, you can start the 3D printing process in seconds. Just open the printable file and send it for 3D printing. You can even export files to USB or other external drives. The application can be used with a mobile phone or tablet. Thus, you can send a 3D print command over Wi-Fi or even remotely.

MakerBot Support

The company offers good customer support. Your inquiries will only be welcome, and you can get feedback from the manufacturer pretty quickly.

MakerBot Replicator Plus performance rating

Before buying a 3D printer, the user looks at various parameters. Based on these parameters, there are a few things you can consider before making your final decision.

MakerBot Replicator Plus 9 Cost0056 : 3D printer is expensive. Since professional 3D printers start at a lower range, there are many options available at a lower price point. The price also looks higher compared to the quality that this 3D printer provides. What's more, FDM 3D printers are available for as little as $200... However, they won't give you the power that the MakerBot Replicator Plus provides.

3D Print Quality MakerBot Replicator Plus : Expect decent 3D print quality with few to no imperfections.

3D print speed MakerBot Replicator Plus : 3D print speed is excellent. However, there are some issues with creating finer details at high settings.

The possibilities of the 3D printer MakerBot Replicator Plus: The possibilities of the 3D printer are enormous. You can use this printer for both complex geometric shapes and regular models. However, you are limited to using PLA.

Practical 3D printer MakerBot Replicator Plus : This 3D printer is not designed for high end 3D printing. It is designed for professionals who use 3D printers for general purpose printing and especially for educational purposes.

What 3D Printer Users Expect MakerBot Replicator Plus : At this price, you should expect an impressive design. However, if you're willing to compromise a bit on 3D print quality, it's worth considering less expensive models.

Conclusions

As MakerBot struggles to provide you with a one-size-fits-all solution, you're in for a huge opportunity. If you're new and want to make 3D printing a profession in the future, the MakerBot Replicator Plus is a great starter option. All in all, this is a good option for professional use and a great model for teaching 3D printing.

All in all, this is a good option for professional use and a great model for teaching 3D printing.

what a 3D printer can do

3D printing possibilities

Unfortunately, the current level of awareness in 3D technologies leaves much to be desired. It happens that even with a basic knowledge of 3D printers, the actual application of 3D printing remains incomprehensible to a number of users. To avoid such situations, we have prepared this article and will consider in detail all the possibilities of 3D printing.

Application of 3D printing

When it comes to the application of 3D printing, it is worth considering not only the existing possibilities, but also the prospects. Already today, the application of 3D printing technology is extremely extensive and does not stop expanding. Of course, in the future we expect a large-scale distribution of additive techniques, but the practical application of 3D printing is available to everyone today. We will not delve into narrowly specific aspects of technology, such as 3D food printing, or bioprinting. Instead, let's talk about how 3D printing technology can be used by ordinary users with desktop 3D printers.

We will not delve into narrowly specific aspects of technology, such as 3D food printing, or bioprinting. Instead, let's talk about how 3D printing technology can be used by ordinary users with desktop 3D printers.

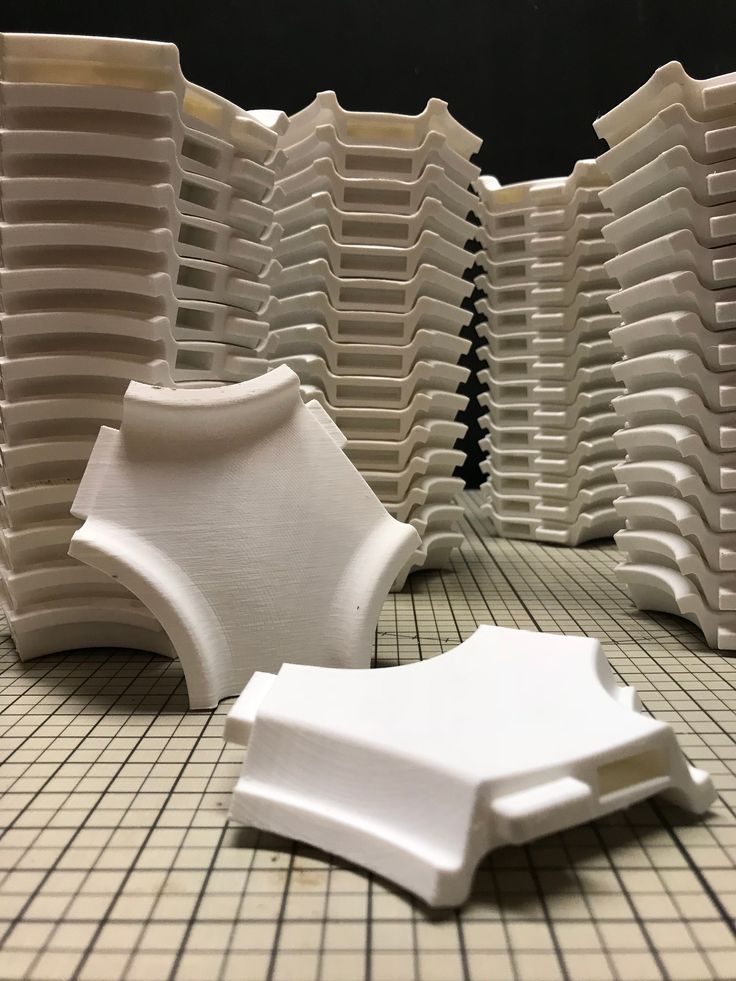

1. Prototyping

The best way to use 3D printing is for its intended purpose. Rapid prototyping is not only the second name of the technique, but also the original goal of its development. Creating prototypes using 3D printing significantly reduces production time and costs. And thanks to the possibilities of 3D modeling, the range of designed parts is practically unlimited. Prototyping allows you to visually assess the possible shortcomings of the product at the design stage and make significant changes to the design of the part even before its final approval.

2. Small-scale production

For small-scale production, 3D printing is a godsend. The properties of many materials allow the production of finished components at minimal cost. Compared to traditional production methods, small-scale production using 3D printing is very profitable from a financial point of view. The manufacture of molds, for example, is a lengthy and costly process. At the same time, injection molding itself takes a lot of time. On a 3D printer, you can print a batch of the necessary products in a matter of hours. This application of 3D printing is extremely relevant for frequent orders for small batches of parts.

The manufacture of molds, for example, is a lengthy and costly process. At the same time, injection molding itself takes a lot of time. On a 3D printer, you can print a batch of the necessary products in a matter of hours. This application of 3D printing is extremely relevant for frequent orders for small batches of parts.

3. Repair and restoration

Another application of 3D printing is the repair and restoration of damaged parts. For these purposes, 3D printing is ideal. You can carry out such a procedure both independently, with the appropriate skills and equipment, and in specialized 3D printing services, such as 3DDevice. First, a correct 3D model is built on the basis of the damaged product. 3D scanning can also be used to simplify design. Next, the finished model is sent to print and reproduced on a 3D printer in the required number of copies. Repair and restoration of damaged parts using 3D printing is fast, and the presence of a digital model of the component allows you to reprint it at any time.

4. Production of functional models and finished components

One of the industrial applications of 3D printing is the production of functional models and finished components. Making products on a 3D printer from a transparent material allows you to see the work of a functional part “from the inside”, which is very useful when developing various engineering samples. In addition, a wide range of different materials for 3D printing turns it into a full-fledged production tool. Industrial 3D printers are gradually becoming a part of every industry, allowing the production of durable metal components.

Other questions and answers about 3D printers and 3D printing:

- Opportunities What is the future of 3D printing?

- Finance How to choose the right 3D printer?

5. Household items

Need an office organizer? Or a knife holder? Any household items can be printed on a 3D printer. The advantage of this application of 3D printing is that there are no restrictions when developing 3D models. That is, if you want to show imagination and create something original - all the cards are in your hands. Thanks to 3D printing, your home can be decorated and made more functional easily and inexpensively.

That is, if you want to show imagination and create something original - all the cards are in your hands. Thanks to 3D printing, your home can be decorated and made more functional easily and inexpensively.

6. Toys and souvenirs

Having a 3D printer makes it very easy to make a child happy – just make cute 3D toys. There are already some pretty interesting projects of collective 3D printed games, and in the future this list will only expand. This application of 3D printing will please not only children, but also enthusiastic collectors, because on a 3D printer you can print figures of any characters and attributes of computer games and films. And color 3D printing will make it possible to produce exclusive full-color souvenirs - miniature figurines of real people. To do this, a digital model of a person is formed on the basis of 3D scanning data. In this case, all textures and color data are preserved. Everyone will definitely like such a gift, because getting a tiny copy of yourself is so unusual.

7. Design products

For creative people, there is another use for 3D printing. 3D technology in general is a unique opportunity to show your talent in the most unusual way. Artists, sculptors, fashion designers and designers from all over the world use 3D printing to create exclusive pieces of art that would be impossible to produce with standard methods. Such designer pieces impress with their beauty and originality, often fusing digital and traditional art. In addition, 3D printing techniques for clothing and footwear are being actively developed. Some models have even gone on sale, but it's too early to talk about mass production.

8. Capabilities of a 3D printer

We have listed the main capabilities of a 3D printer, but they do not end there. 3D printing finds application in a wide variety of industries. With its help, electronics, various components, food and even living tissues are printed. Of course, this list will be replenished in the future, but already now it impresses with its scale.