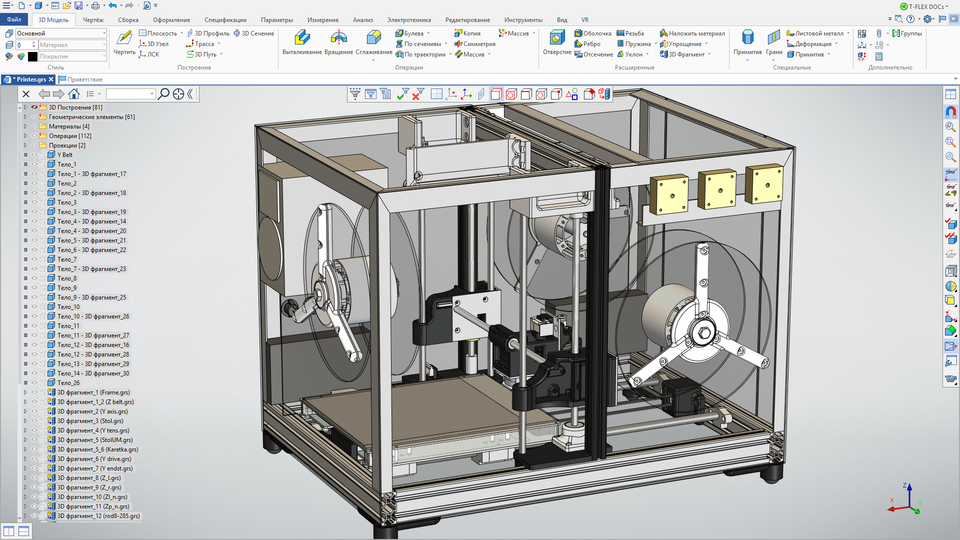

3D printer flex

FLEX Filament | 3D Printing Materials

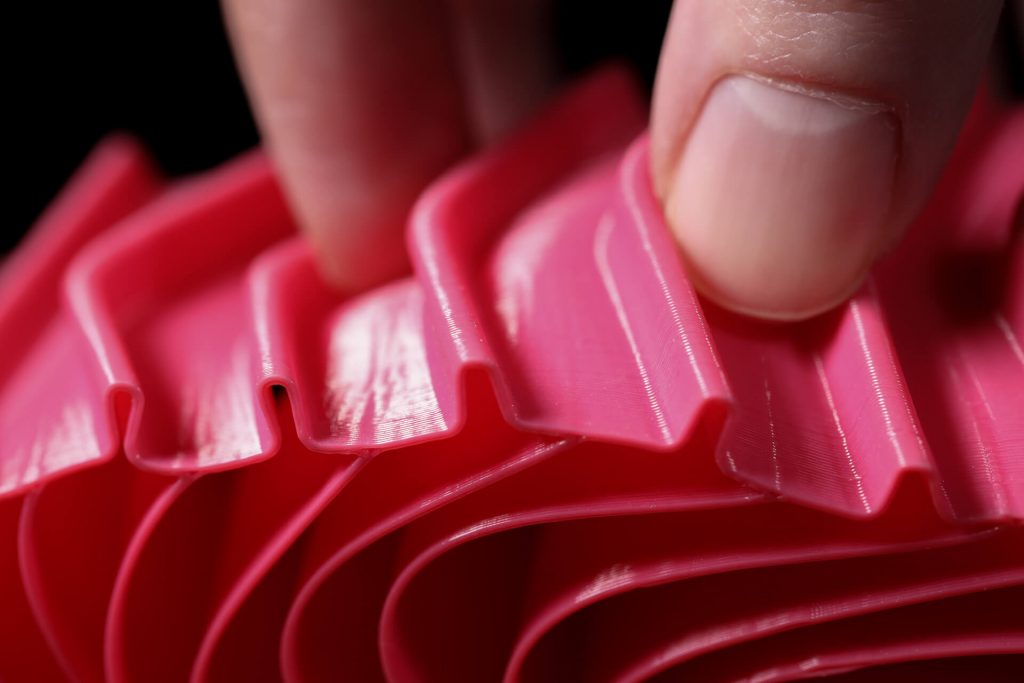

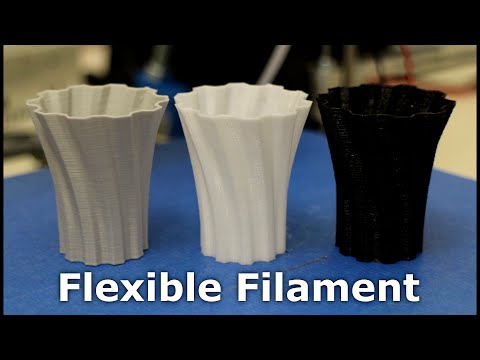

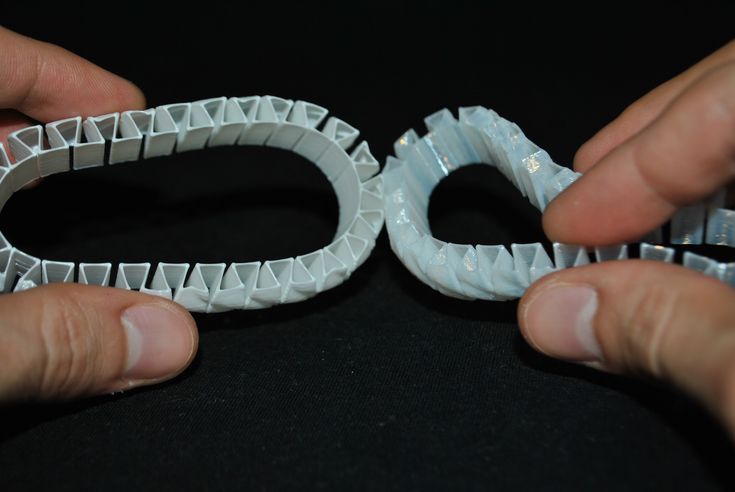

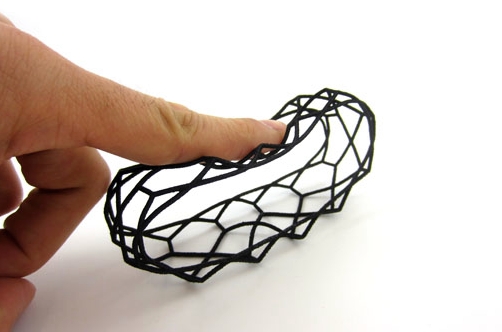

Flex is a filament that uses a combination of plastic and rubber. The main benefit of Flex filament is the creation of flexible prints with elastic properties. When printing with Flex, the amount of infill can control the stiffness of your print. Flex printed with 100% infill will be quite rigid, whereas a 0% infill would create a rubber tube or even balloon-like print.

Flex can be used for rubber wheels, mechanical grips or tough durable parts with superb shock absorption using 100% infill.

Print Speed: Use consistent flow rates and also smaller layer heights to ensure better interlayer adhesion.

Storage: Keep flexible filament dry and away from moisture.

Flexible

Impact Resistant

FLEX PRINTING GUIDLINES

Extrusion temeprature

±230 ºC

Bed temperature

± 70 ºC

Weight (kg)

0.

Warping

None

Layer bonding

High

Suitable for

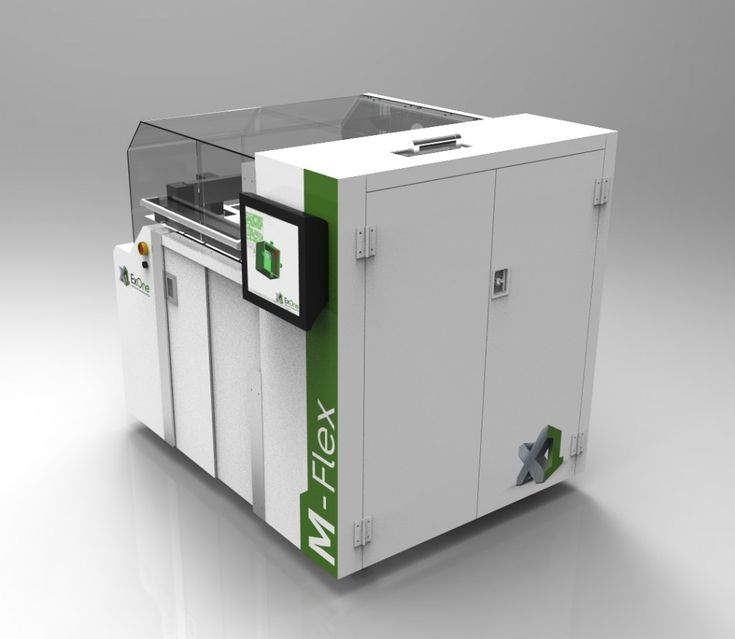

Bolt Pro

Filament diameter (mm)

1.75

Applications

Visual Prototypes

Due to its rubber content, Flex is a great material to showcase rubber based visual prototypes because, with the correct settings, the achievable quality is high due it its strong interlayer adhesion features.

Functional prototypes

Flex is also used to create high-quality functional parts. The strength of the mix between plastic and rubber gives printed objects great durability features while being flexible. Specifications

ABS

Carbon

E-PLA

Flex

HIPS

Hybrid

Nylon

PETG

PP

Scaffold

ABS

ABS (Acrylonitrile Butadiene Styrene) is a strong popular filament that is used widely for 3D printing parts. It has strong material properties which produce parts with high impact, high-temperature resistance. Having these qualities however does make it a little harder to print with than some other filaments, but our printers come with a heated bed that ensures the filament is constantly heated to ensure prints adhere to the bed and print to specifications.

It has strong material properties which produce parts with high impact, high-temperature resistance. Having these qualities however does make it a little harder to print with than some other filaments, but our printers come with a heated bed that ensures the filament is constantly heated to ensure prints adhere to the bed and print to specifications.

Temperature: ABS is very sensitive to temperature fluctuations during the printing process. It often cracks or warps as different layers cool differently. To ensure this issue is mitigated, our printers come with an enclosure system and heated bed to produce better results.

Sunlight: Direct sunlight over long periods can degrade the quality of the printed object so store ABS parts away from UV sources.

Carbon

Carbon filament is great for printing strong and durable parts. It is the perfect choice for mechanical parts, housing, shells or other protective casings. Carbon filament usually contains additional printing materials within its composition (ABS, PETG, NYLON etc.) depending on the product needed.

Carbon filament usually contains additional printing materials within its composition (ABS, PETG, NYLON etc.) depending on the product needed.

Steel Nozzles: Carbon filament is very abrasive and it is better to print with steel nozzles to reduce clogging.

Print Speed: To ensure better results, print carbon parts with a lower printing speed. This will ensure better results.

E-PLA

Leapfrog Engineering PLA (Polylactic Acid)is a biodegradable plastic that was formulated to provide greater durability than standard PLA without compromising on its eases of use when printing. PLA is the most popular filament used globally, offering great print quality with good dimensional accuracy and is used in many applications.

E-PLA is used in various settings mainly due to its ease of use compared to other filaments. It is the best filament to begin with for novice 3D printing users.

Sunlight: Direct sunlight over long periods can degrade the quality of the printed object so store E-PLA parts inside.

Storage: Store the filament in dry areas since it absorbs moisture.

Flex

Flex is a filament that uses a combination of plastic and rubber. The main benefit of Flex filament is the creation of flexible prints with elastic properties. When printing with Flex, the amount of infill can control the stiffness of your print. Flex printed with 100% infill will be quite rigid, whereas a 0% infill would create a rubber tube or even balloon-like print.

Flex can be used for rubber wheels, mechanical grips or tough durable parts with superb shock absorption using 100% infill.

Print Speed: Use consistent flow rates and also smaller layer heights to ensure better interlayer adhesion.

Storage: Keep flexible filament dry and away from moisture.

HIPS

HIPS is a filament that is used to both print objects and acts as support material during the construction of complex geometric objects with angles greater than 45 degrees. Acting as a support material, HIPS is easily removed when the completed object is submerged in D’Limonene where HIPS is soluble. The best material to pair HIPS with as support is ABS since they both have very similar mechanical properties. If used as a standard material, HIPS objects are very stiff and have good heat resistance.

Printing tips

Heated Bed: Temperature affects HIPS when printing and you need to ensure better management for better printing results.

Hybrid

Leapfrog Hybrid (CPE) is a strong material that is easy to print with and has various properties that make it an ideal material for large objects or objects that are used for mechanical prototypes. In terms of durability, it is between ABS and PLA and produces objects that can withstand high temperatures.

Temperature: Printing with Hybrid requires correct print bed temperature settings and managment.

Nylon

Nylon is a well known and very tough filament that has a wide array of applications. It’ is slightly flexible giving it the ability to bend without breaking and has durability properties such as heat resistance and impact resistance. Compared to other materials, it is the most versatile due.

Printing tipsStorage: Nylon filament like some other filaments can absorb moisture from the air and can lead to printing issues.

PETG

Polyethylene Terephthalate is the most widely used plastic globally and is used to create various products like standard water bottles. PETG on the other hand is specifically designed for 3D printing applications and is considered the bridge in terms of mechanical properties between PLA and ABS. It offers strength, impact resistance and chemical resistance without having issues like warping.

Having similar properties to PLA and ABS, PETG is a great filament for a number of applications that require more durability than PLA can offer, while being easier to print with than ABS.

Printing tipsPrint Speed: We recommend printing with lower than average print speed if the desire is to achieve better strength properties due to better layer adhesion.

Storage: Store the filament in dry areas since it absorbs moisture.

PP

PP (Polypropylene) is a light flexible material that offers a number of highly desired properties. It has high impact strength and bending abilities making it great for parts that require heavy use. In the consumer market, it is used for applications, such as packaging, stationary and more.

Printing tipsTemperature: Printing with Polypropylene requires planning and careful temperature management to ensure successful prints. It is a material that is not as forgiving as E-PLA during the printing process.

It is a material that is not as forgiving as E-PLA during the printing process.

Storage: Store the filament in dry areas since it absorbs moisture.

Scaffold

Scaffold Soluble Support Filament is used to print complex geometric parts. Objects that have angles greater than 45 degrees or overhangs require another material to keep the shape uniform, especially during the printing and cooling process.

Printing tips

Storage: Scaffold being soluble in water means it is highly hygroscopic and should be stored in a dry environment.

Flex 3D Printing Guide | Top 3D Shop

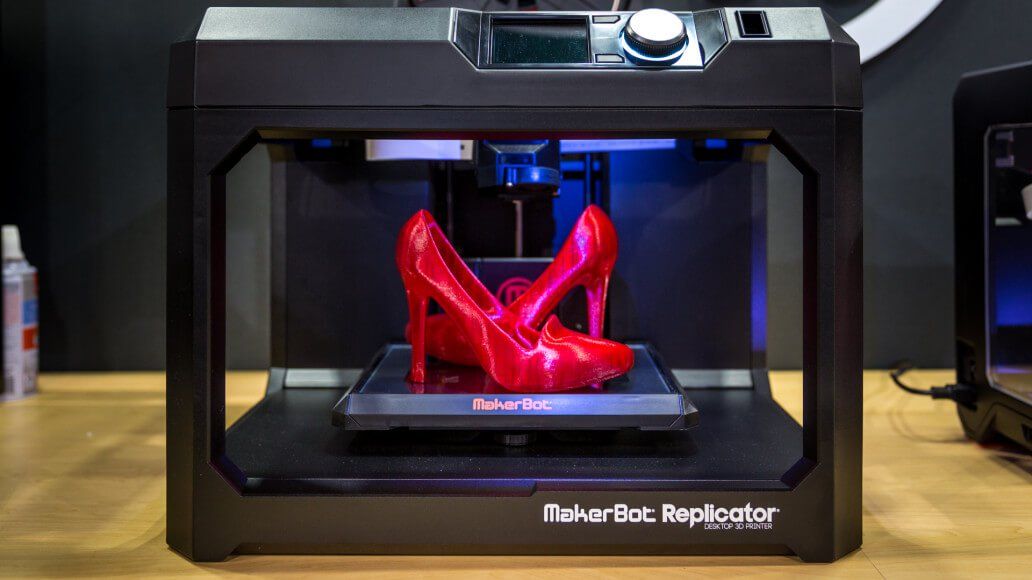

Flexible plastics are among the most popular 3D printing materials that boast a wide array of applications. As a rule, these flexible polymers are employed to create elastic shock-absorbing parts like gadget cases and sports shoe soles.

Due to their physical properties, however, there are several important storage and printing rules that must be followed to uncover their full potential. Read the article to find out how to reliably print with flexible filaments and organize your workflow in a streamlined fashion.

Read the article to find out how to reliably print with flexible filaments and organize your workflow in a streamlined fashion.

About Flexible Plastics

Source: aerospace.basf.com

Flexible plastics come from a common category of elastic filaments and are called thermoplastic polyurethane (TPU). Since TPU belongs to the category of thermoplastic elastomers (TPE), there may be some confusion involving these terms. As for this particular article, we will be using "printing with flexible materials" as an equivalent of "printing with TPU".

Source: felfil.com

Brief History

Source: en.wikipedia.org

Thermoplastic polyurethane was first created in 1959 by Lubrizol Engineered Polymers, a Berkshire Hathaway company. The thing that determined the physical properties of TPU was the decision to unite the features of copolymers with rigid and elastic structures in one. To be more precise, the rigid blocks of copolymers included in the formula consisted of isocyanate, while the elastic ones consisted of polyol. By mixing the polymers in various proportions, the company has been able to create different kinds of TPU. Some of the created materials were elastic like rubber, and are now widely used in 3D printing, while the other ones were incredibly tough and hard to break.

By mixing the polymers in various proportions, the company has been able to create different kinds of TPU. Some of the created materials were elastic like rubber, and are now widely used in 3D printing, while the other ones were incredibly tough and hard to break.

Specifications

Flexible plastics are light-colored elastic materials that, compared with their ABS-based counterparts, can withstand higher torsional and tensile stress. The main features of such polymers are:

- Density: 1.18-1.25 g/cm³;

- Strength and flexibility;

- Resistant to dilute acids and alkali solutions at room temperature;

- Melting temperature: 200—225 °C;

- Glass transition temperature: -10 — -50 °C;

- Heat resistance: up to 125 °C (up to 140 °C for some filament brands).

Source: beeverycreative. com

com

Touching upon post-processing capabilities, TPU-based models can be easily sterilized, welded, machined, dyed, printed, and cut. The material offers outstanding temperature resistance and good corrosion resistance at room temperature. TPU-based products are resistant to engine oils and lubricants, even at high temperatures. Moreover, TPU is soluble in aromatic hydrocarbons such as benzene and toluene at room temperature. Besides, TPU-based products dissolve in acetone, methyl ethyl ketone, cyclohexanone, methyl pyrrolidine, and tetrahydrofuran.

To test out the capabilities of TPU, six identical models printed with different filaments were partially immersed in a particularly strong Nitro-P solvent. The TPU-based part absorbed the liquid, resulting in a 50% increase in volume. However, after the evaporation of the solvent, the model assumed its original volume without losing any of its physical properties.

Pros and Cons

Source: 3dprintingmedia. network

network

Pros:

- Astonishing temperature resistance;

- High tensile, torsional, and compressive strength;

- Easy to paint;

- Budget-friendly;

- Recyclable.

Cons:

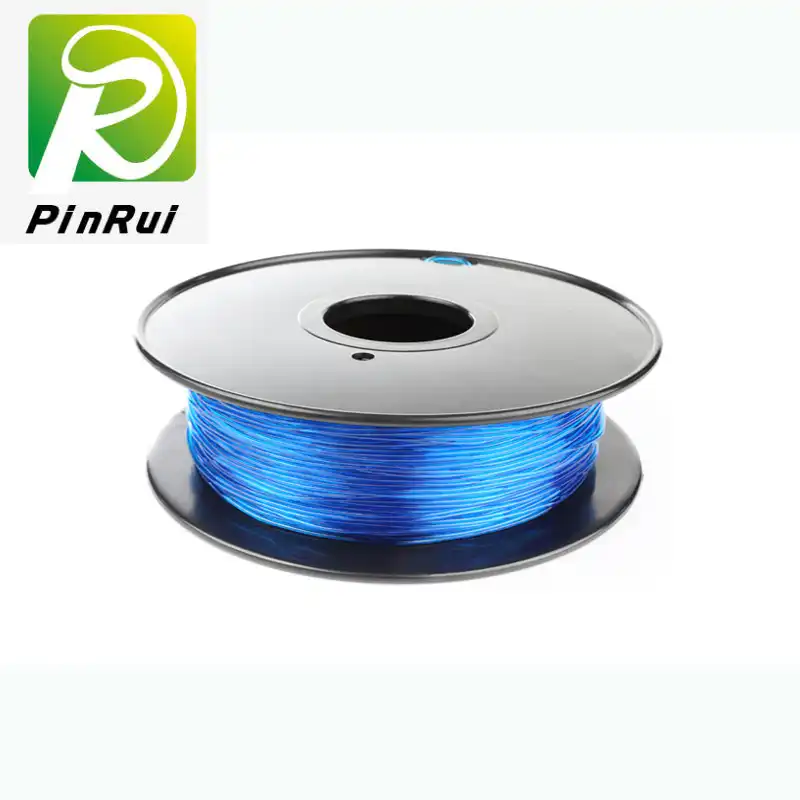

- Hygroscopic material;

- Challenging to print;

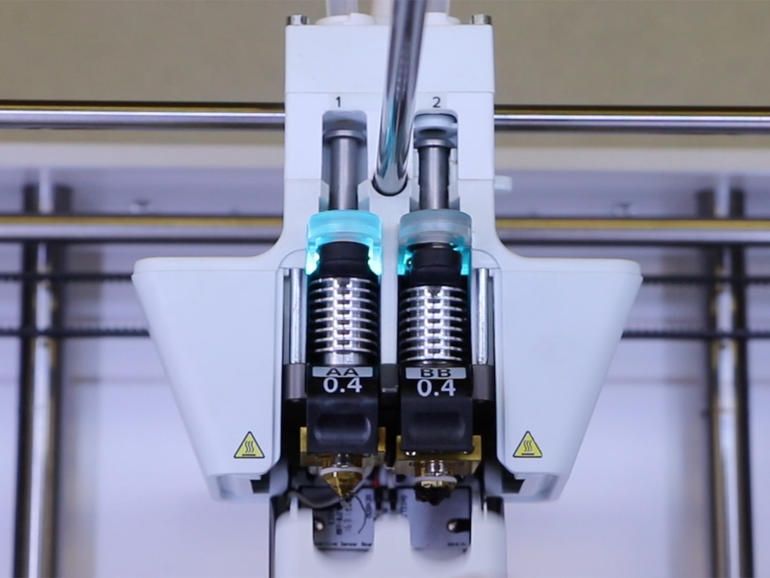

- Not recommended to be used with Bowden extruders;

- Not suitable for food storage.

Safety Rules

Source: extrudr.com

Just like the case with other filaments, there is a set of safety rules that must be followed when printing with flexible materials to ensure a secure and hassle-free workflow. Make sure to wear gloves to protect yourself from thermal burns. Use respirators and print in well-ventilated premises. If possible, print on a fully enclosed device that features a reliable and effective ventilation system. In case the molten polymer comes into contact with human skin, pour some cold water over the place and follow the standard thermal burn treatment rules. After hardening, the polymer will fall off on its own.

After hardening, the polymer will fall off on its own.

Moreover, make sure to organize the disposal of flexible plastics correctly. Burning them would not be a good idea since the polymer releases toxic fumes of carbon monoxide, nitric oxide, hydrogen cyanide, and isocyanate when burned.

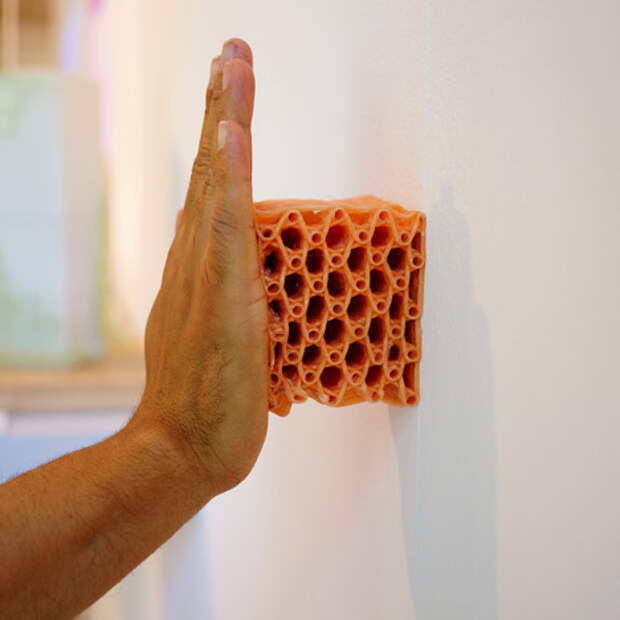

3D Printing with Flexible Filaments: A Closer Look

Flexible plastics are used to create durable yet resilient parts like dampers, shock absorbers, and flexible connection elements. Along with the creation of such supporting elements, flexibles are employed in unique large-scale projects. For instance, XEV Limited, a Chinese startup, developed an electrical car prototype with body parts 3D printed with Nylon, PA, and TPU. The price for a two-seater city car the size of a Smart City Coupe was supposed to be $10,000. Sadly enough, the inventors could not find investors to start mass production.

Source: amfg.ai

On the other hand, New Balance, a well-known US-based manufacturer of athletic shoes, created a series of running shoes with elastic soles 3D printed with flexible materials. According to the company’s statement, the solution united the benefits of 3D printing and advances in materials science to achieve the optimal balance of flexibility, strength, weight, and durability. The sole has been designed in a particularly efficient way to ensure even distribution of heel-caused pressure over the whole sole, making for a comfortable and convenient solution.

Filament Storage

Since flexible filaments are hygroscopic, they are prone to absorbing moisture when left open in rooms with high humidity. To ensure reliable long-term storage, the filaments should be vacuum-sealed together with a desiccant. If you are unsure whether the filament was properly stored before the printing session, make sure to process it in a filament dryer (e. g. Wanhao Box 2) before proceeding to the actual production.

g. Wanhao Box 2) before proceeding to the actual production.

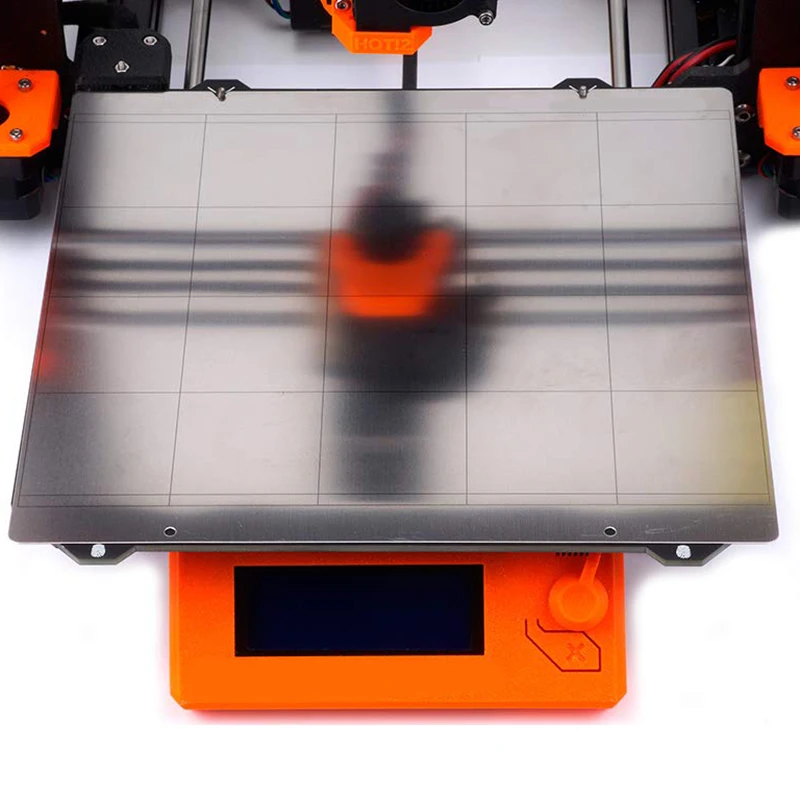

Heated Bed Temperature

Source: reddit.com

To achieve optimal first layer adhesion when printing with TPU, keep the heated bed temperature at around 45—60 °C. Besides, covering the print bed with masking tape or using a sheet of polyetherimide (PEI) as a base would also be a good idea.

Printing Speed and Other Settings

3D printing with flexible filaments may become challenging due to the material properties. The polymer becomes extremely viscous when heated, which may lead to clogging when printing too fast. However, there’s always a recommended printing speed proposed by manufacturers that depends on the filament brand. The recommended value usually lies within the range of 10 to 30 mm/s, meaning that the correct printing speed can be found after making a couple of test prints and seeing what suits your particular filament better.

Filament Cooling

To reliably print with flexible plastics, make sure to turn on all the ventilation systems offered by your machine during printing.

Post-Processing

Heat Treatment

After a TPU-based part has been printed, you can provide it with an even smoother and glossier appearance. Place it in a special oven (front side up), set the temperature to 200°C, and wait from two to three minutes. The top layer will melt just enough to improve the model’s outlook without deforming it.

Machining and Smoothing

Due to the physical properties of flexible filaments, it is particularly challenging to polish TPU-based parts manually. This can be very time-consuming, therefore, we recommend using a CNC machine to polish such prints. The supports of TPU-made parts, however, are incredibly easy to remove and can be detached even with a box cutter.

The supports of TPU-made parts, however, are incredibly easy to remove and can be detached even with a box cutter.

Spackling your Prints

Another way to post-process a print made from flexible materials would be to cover it with a flexible filler. This approach is especially useful in case you are working with large models and don’t require millimeter-precise dimensional accuracy.

Gluing

TPU-based parts can be glued together just like all other plastic-made parts. To do this, you can use special rubber-to-rubber adhesives. Moreover, you can employ aprotic solvents like tetrahydrofuran, dimethyl sulfoxide, and dimethylformamide.

Just like the case with parts made from ordinary FDM 3D printing materials that are similar to the conventional thermoplastics, models printed with TPU must be cleaned and dried. After adding a small layer of adhesive, firmly press the two parts that need to be glued together against each other and allow the adhesive to dry.

After adding a small layer of adhesive, firmly press the two parts that need to be glued together against each other and allow the adhesive to dry.

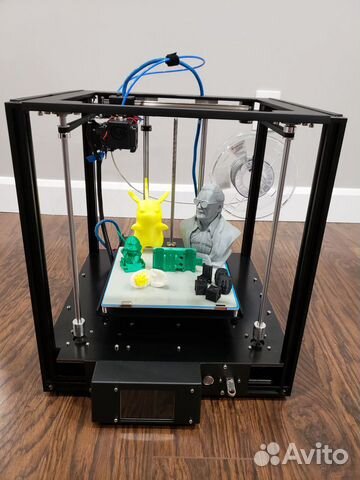

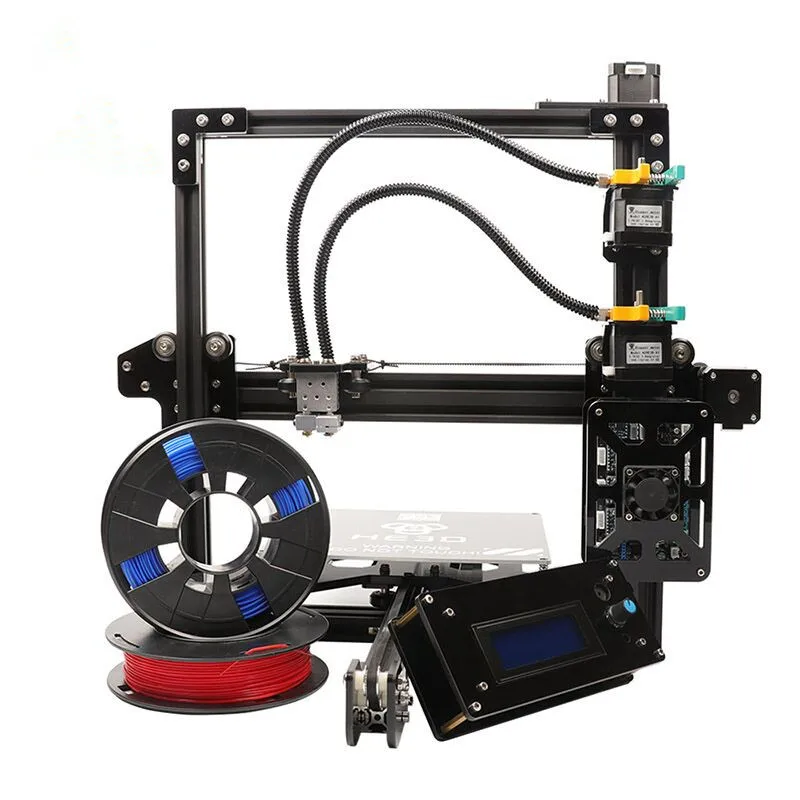

Affordable 3D Printers that Print with TPU

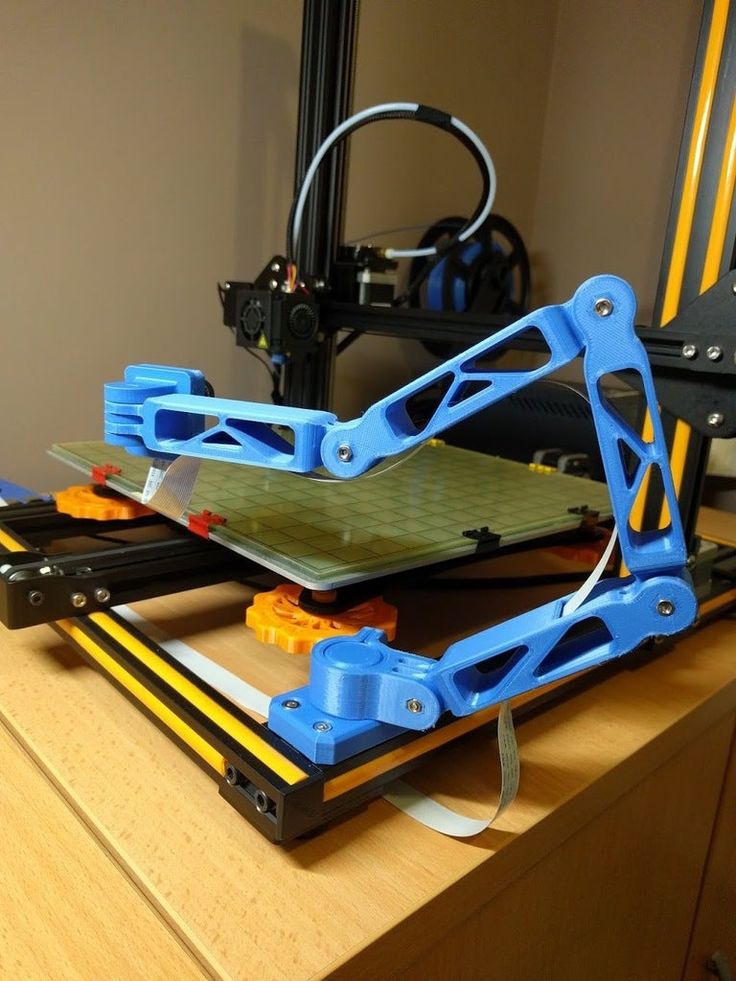

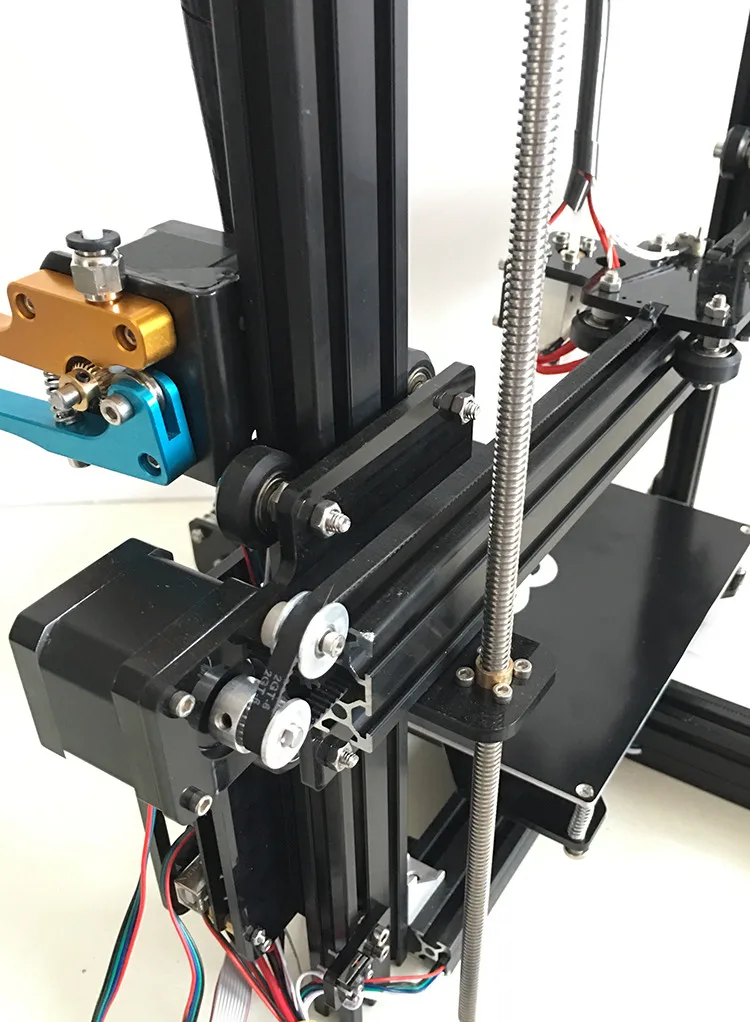

Anet A8

Recommended settings:

- Heated bed temperature: 60 °C

- Extruder temperature: 225 °C

- Layer height: 0.1 mm

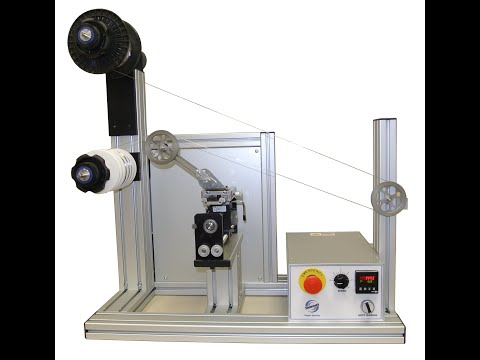

It is extremely important to minimize nozzle clogging when printing with flexible materials by providing vertical filament-to-nozzle feeding. Luckily, the Anet A8 3D printer’s extruder can be installed with a guide that should be placed between two gears for a streamlined printing experience. Please check the video above for a detailed installation process.

Creality Ender 3

Recommended settings:

- Heated bed temperature: 60 °C

- Extruder temperature: 225 °C

- Layer height: 0.1 mm

Just like the deal with the Anet A8, it is important to ensure optimal filament feeding before printing with flexible materials on the Creality Ender 3 too. There’s a special nozzle cap that can be installed onto the extruder to prevent clogging and other related issues like gears-induced filament chewing.

Troubleshooting

One of the most common issues that goes hand in hand with TPU 3D printing is stringing. The problem manifests itself by creating thin threads between the walls of a printed model. Some users resolve the issue by burning string with a gas burner. This may sound effective, but there is a high risk of damaging the printed model during the process. Obviously, the best way to fix stringing is to prevent it from happening by turning on the retraction and adjusting the nozzle temperature along with printing speed.

Obviously, the best way to fix stringing is to prevent it from happening by turning on the retraction and adjusting the nozzle temperature along with printing speed.

Wall delamination is yet another common problem that occurs due to improper filament storage. The issue can be solved by drying the filament before printing. As you can see, unlike stringing, delamination is much easier to fix.

Source: print.theporto.com

To get rid of stringing once and for all, consider doing the following:

- Turn on the ‘retraction’ feature in your slicer.

- Decrease the printing speed. In most cases, going as low as 20 mm/s will be more than enough.

- Make sure that you use dry filament that was stored properly. If you don’t have enough information about the matter, use a filament dryer before printing.

- Check whether the nozzle is clear from filament leftovers that could be left there during the previous printing session.

The easiest way to do this is to create a small test print that will be finished in several minutes. You can determine the presence of leftover filament by checking the color of the test print. The leftover filament will be of a different color.

The easiest way to do this is to create a small test print that will be finished in several minutes. You can determine the presence of leftover filament by checking the color of the test print. The leftover filament will be of a different color.

Use Cases

Source: reprap.me

Source: simplify3d.com

Source: gizmodo.com

Source: blog.prusaprinters.org

Bottom Line

Elastic flexible plastics are used to create resilient yet durable parts on FDM 3D printers. Parts printed with TPU will feature astonishing temperature resistance, high tensile, torsional, and compressive strength. That’s why this material can be used to create anything: a smartphone case, a cosplay costume, or even car body parts. Due to the physical properties of the material, however, TPU may be challenging to print with for entry-level makers. Nevertheless, the challenges are incredibly easy to overcome if one adjusts the print setting before printing as well as stores the filament properly. Consider following the guidelines presented in this article to ensure yourself with a hassle-free and streamlined printing experience.

Consider following the guidelines presented in this article to ensure yourself with a hassle-free and streamlined printing experience.

Flexible plastic for 3D printing: tricks and features of work

Mar152017

Flexible plastic for 3D printing: varieties

Of course, flexible materials for 3D printing significantly expand the list of possibilities and allow you to create a huge number of useful products. Choosing a flexible plastic for 3D printing is necessary according to the requirements for the final product. In our video review, the following types of plastic will be indirectly affected:

- Elastan. A flexible 3D plastic that deforms and returns to its original position after being subjected to an external load. Resistant to oils and fats, non-toxic when printing;

- Elastan D. Offers the same properties as regular Elastan but with greater strength. They are a little easier to type on;

- Plastan. Shock-resistant and heat-resistant 3D plastic, resistant to weak alkalis, acid and salt solutions, water and alcohol.

Able to plastically deform;

Able to plastically deform; - Flexible PolyEster (Flex). The most flexible of all the materials presented, more like rubber. Durable, flexible and heat resistant.

The last flexible plastic, Flex, is the best for our purposes. We will print them today.

Working with flexible 3D plastic

Flexible plastic has its own characteristics of work, which are important to remember before starting 3D printing. Following these guidelines will help you avoid playback problems and possible printer problems (some types of flexible plastic can clog the 3D printer's nozzle).

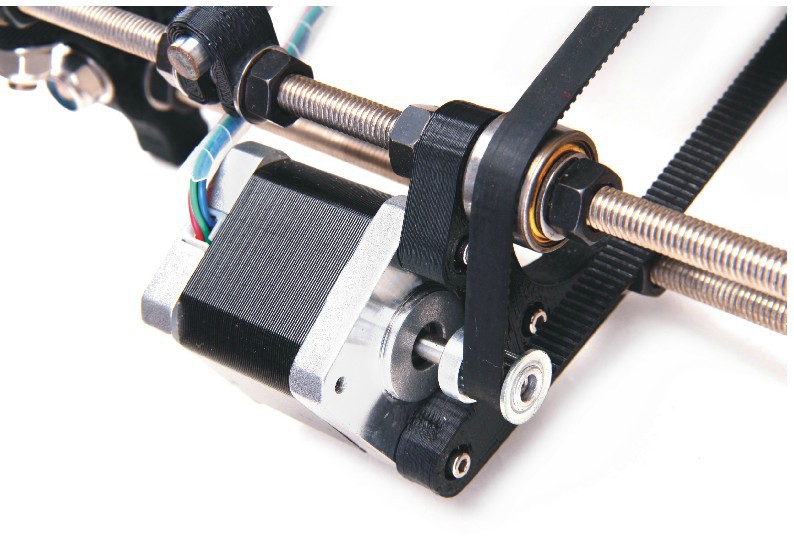

- First, the flexible plastic must be loaded into the 3D printer manually. Automatic loading is possible at a low material feed rate, but it is still desirable to stop at manual loading.

- Please note that a number of problems with flexible plastic are due to the fault of the clamping mechanism: work with the material is greatly simplified with a new generation clamping mechanism (with a spring or notches).

- In addition, when loading filament into the feeder, make sure that there is a minimum gap between the feed wheel and the filament hole, otherwise the thread may become tangled and caught.

- Print settings for Flex are the same as for PLA, with a few differences. The temperature of the platform is set to 80 ° C, and in order to avoid undermining the parts, increase the “Border” parameter and use blue tape or special glue as the table substrate).

- Also, do not set the print speed to high. Optimal - from 20 to 40 mm / s.

Flexible plastic Flex (Flexible PolyEster, FPE)

Separately, it is worth noting that flexible plastic Flex is the most difficult to print of all elastic materials due to its high flexibility. For example, Elastan plastic is much easier to work with, but it tends to clog in the printer nozzle. FPE, on the other hand, due to its high elasticity, can be difficult to load into the printer. In addition, when printing parts from it, it often undermines from the 3D printer platform. For 3D printing, it is better to use a nozzle with a diameter of 0.4 mm. If necessary, a 0.2 nozzle can also be used, but this is undesirable, because plastic can crumple and clog it. It is also important to remember that flexible plastic Flex shrinks a lot (almost at the level of ABS plastic). To clearly demonstrate the features of working with the material, we suggest watching a short video on this topic:

For 3D printing, it is better to use a nozzle with a diameter of 0.4 mm. If necessary, a 0.2 nozzle can also be used, but this is undesirable, because plastic can crumple and clog it. It is also important to remember that flexible plastic Flex shrinks a lot (almost at the level of ABS plastic). To clearly demonstrate the features of working with the material, we suggest watching a short video on this topic:

https://www.youtube.com/watch?v=s8tccOBHoQc&t=5s

Flexible plastic: buy

We would like to remind you that our store offers the most diverse flexible plastic, which is very easy to buy using the online order form . It is also possible to order the necessary materials by phone or e-mail, indicated in the "Our contacts" section. In addition, we have a wide range of 3D pens, 3D printers, 3D scanners, spare parts and accessories for 3D printing. Contact us, we will be glad to cooperate!

Back to main page

Best flexible materials for 3D printing: FLEX, TPU, eLastik and more

There are many applications that require parts printed from flexible, elastic, and soft materials.

Flexible materials can have a wide variety of properties: elasticity, durability, strength, fire resistance, chemical resistance (oil, gasoline, alkali), biocompatibility, which also makes them ideal for industrial applications. Today, flexible filaments approved for long-term skin contact are becoming increasingly common, making them ideal for prosthetics and wearable electronics. There are also flexible plastics made from 100% recycled material.

There are many manufacturers of flexible filaments for 3D printing on the market today. In this article, we will look at material options for high-quality printing of flexible wide-profile parts: from auto parts to smartphone cases.

Esun eTPU-95A

Esun eTPU-95A is the most widely used flexible 3D printing filament and is highly resistant to various types of loading. The high coefficient of elasticity provides a stable shape and long-term resistance of products to physical deformations. The material is resistant to industrial oils and chemicals, and also has moisture resistance, so that the resulting products can constantly come into contact with water. Esun eTPU-95A is perfect for printing sanitary napkins and seals, industrial dampers, and orthopedic insoles. Shore hardness is 95A, so thick-walled parts resemble hard rubber.

The material is resistant to industrial oils and chemicals, and also has moisture resistance, so that the resulting products can constantly come into contact with water. Esun eTPU-95A is perfect for printing sanitary napkins and seals, industrial dampers, and orthopedic insoles. Shore hardness is 95A, so thick-walled parts resemble hard rubber.

Esun eLastic

Esun eLastic is another common flexible material from Esun that is much softer than Esun eTPU-95A. Esun eLastic belongs to the category of TPE filaments, and its hardness is only 85A Shore. Given its high wear resistance, resistance to mechanical damage and low temperatures, this material is also suitable for use in industry, printing dampers and gaskets, especially in cases where the softness of thick-walled parts is important. Products made from Esun eLastic have a pleasant tactile properties, which is great for printing covers for portable electronics, shoes, medical devices, vehicle steering pads. Esun eLastic is considered a difficult material to print due to the high elongation of the rod, so a direct feed extruder must be used for printing.

Esun eLastic is considered a difficult material to print due to the high elongation of the rod, so a direct feed extruder must be used for printing.

Raise3D TPU-95A Premium

Raise3D TPU-95A Premium is a flexible filament from professional FDM printer manufacturer Raise3D. This material is designed specifically for industrial use and has the appropriate quality certificates. Raise3D TPU-95A Premium has a 95A Shore hardness, ideal for printing seals, bushings, gaskets, tubes, protective covers, shoes and insoles, etc.

BFlex Bestfilament

BFlex Bestfilament is an analogue of TPU-95A from a domestic manufacturer, so a printer with an extruder of the Bowden system can easily handle printing with this material. Claimed hardness is 40 Shore D, which is equivalent to 95A on the more common hardness scale for flexible materials.

BFlex Bestfilament is designed for industrial applications, as it is highly resistant to physical stress and mechanical damage, as well as to chemically aggressive media: oils, gasoline, alcohol and solvents. However, this filament is not resistant to UV rays, so it is not recommended to print parts that are intended to be exposed to sunlight for a long time.

However, this filament is not resistant to UV rays, so it is not recommended to print parts that are intended to be exposed to sunlight for a long time.

TPU Soft Bestfilament

TPU Soft Bestfilament is much softer than BFlex Bestfilament and is closer in properties to Esun eLastic, so a direct extruder is recommended for printing with this material. Despite being noticeably soft, the material has excellent compressive strength, abrasion strength, and greater tensile strength than the harder BFlex Bestfilament. TPU Soft Bestfilament is resistant to oils and gasoline, and is suitable for printing dampers, gaskets and rubber rollers.

BFGummy Bestfilament

BFGummy Bestfilament is a filament that is comparable in softness to TPU Soft Bestfilament, which also makes it necessary to use a direct extruder for printing. BFGummy Bestfilament, unlike most flexible materials, is not resistant to oils, gasoline and other solvents.