3D printer filament length

How Long Does 1Kg of 3D Printer Filament Last? – Printing It 3D

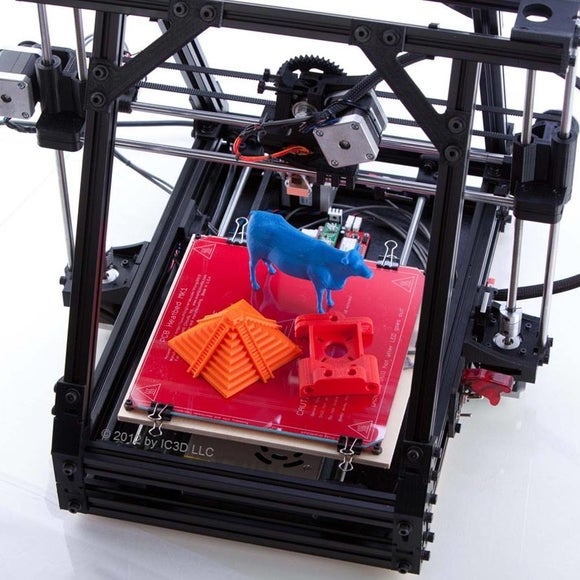

Filament materials for fused deposition modeling (FDM) 3D printers usually come in two standard diameter sizes: 1.75 millimeters (0.07 inches) and 2.85 millimeters (0.11 inches). They are also generally sold in 500-gram (17.64-ounce) and 1-kilogram (2.20-pound) spools. But how long does 1kg (2.20lbs) of 3D printer filament last?

A 1kg (2.20lbs) 3D printer filament generally lasts a month or two if you print a bunch of small objects. But it really depends on a few factors, like the size, material, quantity of prints, and infill. The slicer software helps take the guesswork out by saying how much filament to use for each project.

In this article, I will talk about everything you need to consider to determine how long your filament material will last. I will also give you examples of how users gauge their filament consumption based on their 3D projects.

Exactly How Long Is the Filament in a 1Kg Spool?

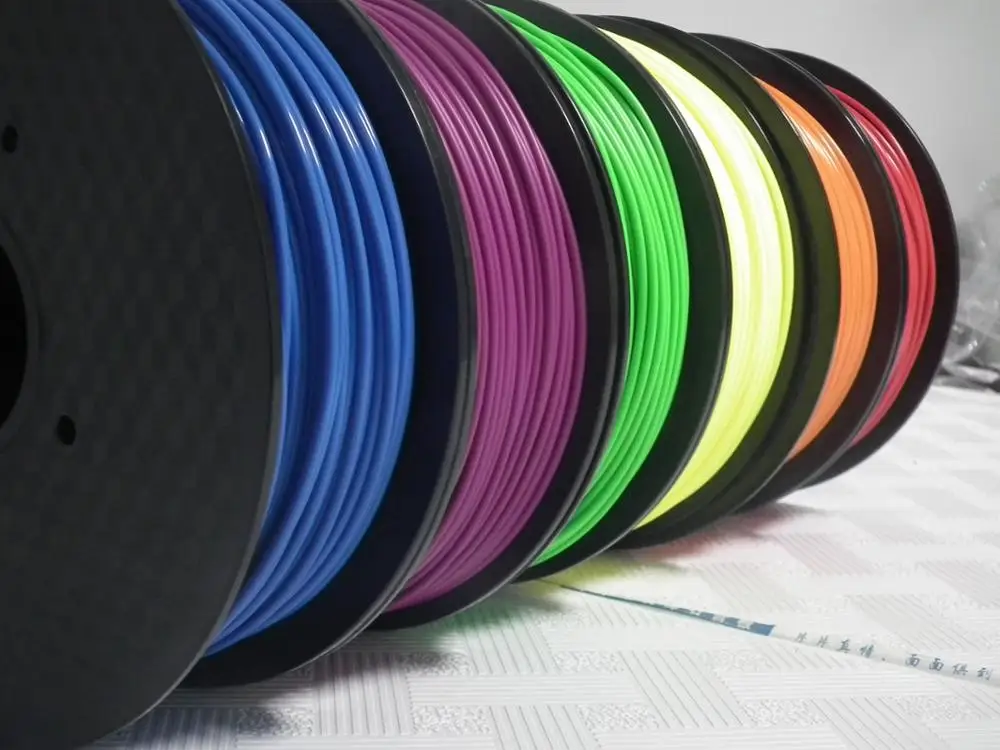

There are different types of filament materials and thermoplastics used in 3D printing. And different kinds of filaments have different densities. As such, a 1kg (2.20lbs) roll of filament means varying lengths, depending on what specific material it is.

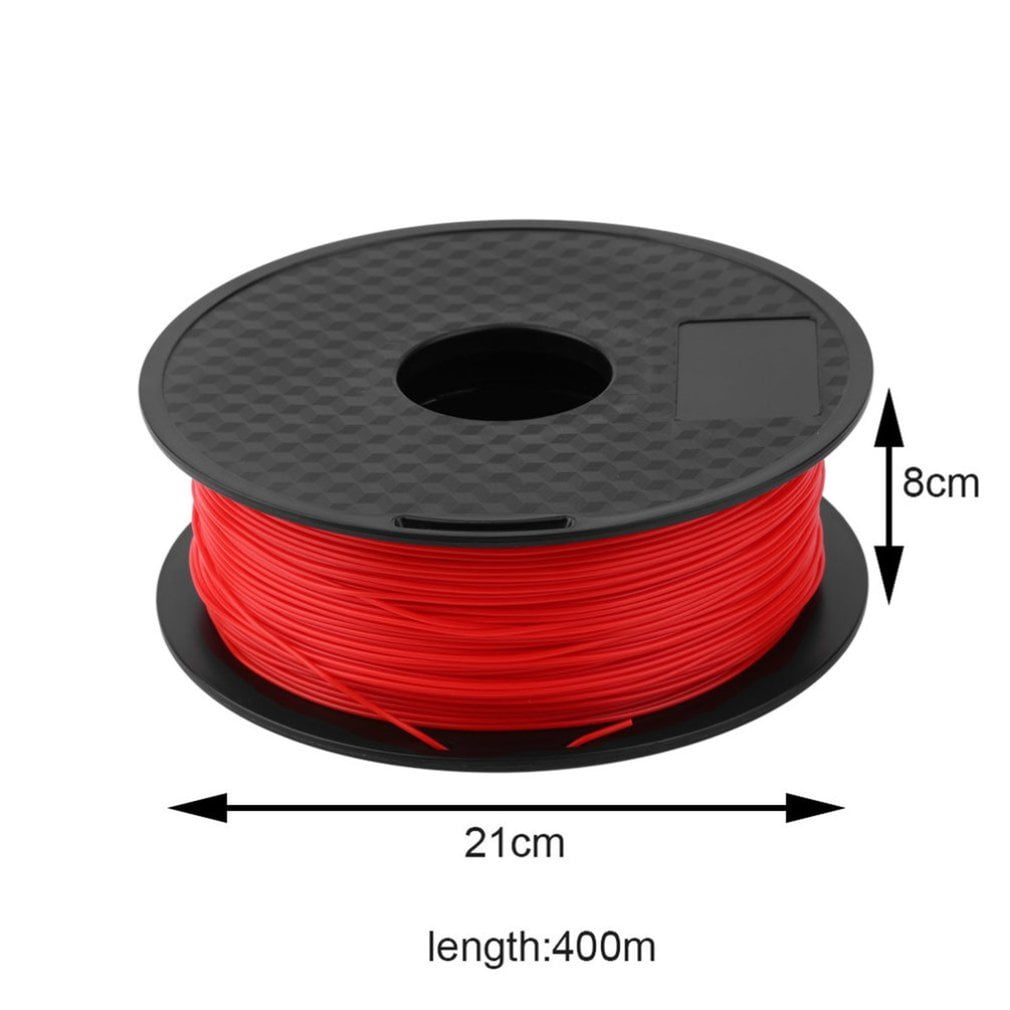

Generally, a 1kg (2.20lbs) spool of filament with a 1.75mm (0.07in) diameter can be 327.4 to almost 400 meters (12,890 to 15,740 inches) long, while a 2.85mm (0.11in) filament can be anywhere from 123.4 to 150.7 meters (4,858 to 5,933 inches) long.

It is also important to know the different properties of various filament materials because these things could affect the flow rate of your printer.

ABS

Acrylonitrile butadiene styrene or ABS filament is a very durable thermoplastic commonly used in additive manufacturing and rapid prototyping environments. It has higher temperature resistance, machinability, flexibility, and strength, all of which make it an ideal material for engineering and mechanical applications.

- Density of ABS: 1.04 g/cm3

- Length per kg of a 1.

75mm (0.07in) ABS: 399.8 meters (15,740 inches)

75mm (0.07in) ABS: 399.8 meters (15,740 inches) - Length per kg of a 2.85mm (0.11in) ABS spool: 150.7 meters (5,933 inches)

PLA

Polylactic acid or PLA is a thermoplastic that is made from ecological and renewable resources like tapioca roots, sugarcane, or cornstarch. Because of its more environment-friendly origins and because it is easy to work with, PLA has become a popular choice and gained wide acceptance in the 3D printing industry. This material is a semi-crystalline polymer with a lower melting temperature than ABS.

- Density of PLA: 1.24 g/cm3

- Length per kg of a 1.75mm (0.07in) PLA: 335.3 meters (13,201 inches)

- Length per kg of a 2.85mm (0.11in) PLA: 126.4 meters (4,976 inches)

ASA

Acrylonitrile styrene acrylate or ASA filament is an all-purpose 3D printing thermoplastic suitable for various applications. Its chemical makeup is similar to ABS plastic, but it has better mechanical properties, it is UV-resistant, and it has better aesthetics. This material also comes in more colors than the other filament materials.

This material also comes in more colors than the other filament materials.

- Density of ASA: 1.07 g/cm3

- Length per kg of a 1.75mm (0.07in) ASA: 388.6 meters (15,299 inches)

- Length per kg of a 2.85mm (0.11in) ASA: 146.5 meters (5,768 inches)

Nylon

Nylon is a versatile yet extremely durable 3D printing material. It makes an excellent 3D printing material because it has superior layer adhesion, which is essential in making strong prints for working prototypes and end-use applications. Higher-grade nylon materials are chemically and thermally stable, allowing 3D prints to keep their shape throughout a wider temperature range.

- Density of nylon: 1.08 g/cm3

- Length per kg of a 1.75mm (0.07in) nylon: 385 meters (15,157.5 inches)

- Length per kg of a 2.85mm (0.11in) nylon: 145.1 meters (5712.6 inches)

Polycarbonate

Polycarbonate or PC filament is a strong, impact-resistant, and heat-resistant thermoplastic material with various applications, including medical ones. It has good electrical insulation properties and boasts high optical clarity. It also absorbs moisture in the air and can become unprintable within 24 hours if exposed to humidity.

It has good electrical insulation properties and boasts high optical clarity. It also absorbs moisture in the air and can become unprintable within 24 hours if exposed to humidity.

- Density of PC: 1.20 g/cm3

- Length per kg of a 1.75mm (0.07in) PC: 346.5 meters (13,641.7 inches)

- Length per kg of a 2.85mm (0.11in) PC: 130.6 meters (5,141.7 inches)

PMMA

Polymethyl methacrylate or PMMA is a strong, transparent, and lightweight thermoplastic. This material is also called acrylic, and it is used as a stronger, impact-resistant, and less fragile alternative to glass. Its density is half that of glass, but it has comparable UV absorption properties and transparency. When printed correctly, this filament provides great light diffusion.

- Density of PMMA: 1.18 g/cm3

- Length per kg of a 1.75mm (0.07in) PMMA: 352.3 meters (13,870 inches)

- Length per kg of a 2.

85mm (0.11in) PMMA: 132.8 meters (5,228 inches)

85mm (0.11in) PMMA: 132.8 meters (5,228 inches)

HIPS

High Impact Polystyrene or HIPS filament is a dissolvable thermoplastic that is frequently used as support material because it can be removed easily and cleanly with a limonene solution. HIPS does not require cutting, scraping, sanding away, or any other removal method.

This filament is quite similar to ABS. You can experience the real magic of using this type of filament if your 3D printer has a dual extruder and you use it as an easy-to-remove and easy-to-dissolve support material.

- Density of HIPS: 1.07 g/cm3

- Length per kg of a 1.75mm (0.07in) HIPS: 388.6 meters (15,299 inches)

- Length per kg of a 2.85mm (0.11in) HIPS: 146.5 meters (5,767.7 inches)

PVA

Polyvinyl alcohol or PVA filament is a water-soluble, non-toxic, and 100% biodegradable support material ideal for dual- or multi-extrusion printing. This material will give you the convenience and freedom to design complex geometrical models that require supports.

The supports can then be safely dissolved in ordinary tap water. This filament reliably adheres to PLA and nylon. It has good thermal stability and therefore gives your print better degradation resistance.

- Density of PVA: 1.19 g/cm3

- Length per kg of a 1.75mm (0.07in) PVA: 349.4 meters (13,756 inches)

- Length per kg of a 2.85mm (0.11in) PVA: 131.7 meters (5,185 inches)

TPU

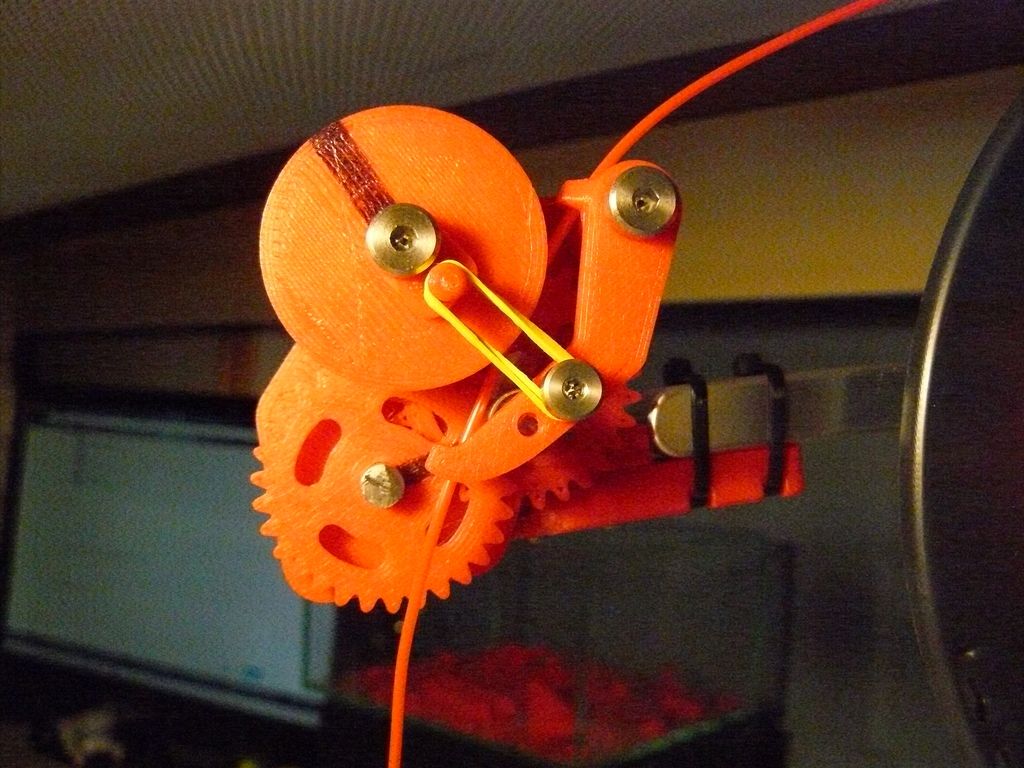

Thermoplastic polyurethane or TPU is a highly flexible, durable, and easy-to-use filament. However, the relative softness of TPU could mean that it is difficult for an average extruder to handle. Instead of smoothly feeding into the hot end of the extruder, TPU’s flexibility causes it to knot up and bend in the print head’s excess spaces.

- Density of TPU: 1.20 g/cm3

- Length per kg of a 1.75mm (0.07in) TPU: 346.5 meters (13,641.7 inches)

- Length per kg of a 2.

85mm (0.11in) TPU: 130.6 meters (5,141.7 inches)

85mm (0.11in) TPU: 130.6 meters (5,141.7 inches)

PETG

PETG is a co-polymer that is a combination of polyethylene terephthalate and glycol. It’s an extremely durable and tough yet flexible and easy-to-use 3D printing material. It combines the relative ease of use of PLA and the rigidity and strength of ABS, making it a common choice for food packaging and medical applications.

PETG also boasts high break resistance and can stand up to cutting, sanding, grinding, and other post-processing techniques, making it ideal for prototyping.

Density of PETG: 1.27g/cm3

Length per kg of a 1.75mm (0.07in) PETG: 327.4 meters (12,889.8 inches)

Length per kg of a 2.85mm (0.11in) PETG: 123.4 meters (4,858 inches)

Here’s how long a 1-kg spool of filament is in table format:

| Filament Type | Density | Length Per 1kg(Diameter Size: 1. 75mm) 75mm) | Length Per 1kg(Diameter Size: 2.85mm) |

| ABS | 1.04 g/cm3 | 399.8 meters | 150.7 meters |

| PLA | 1.24 g/cm3 | 335.3 meters | 126.4 meters |

| ASA | 1.07 g/cm3 | 388.6 meters | 146.5 meters |

| Nylon | 1.08 g/cm3 | 385.0 meters | 145.1 meters |

| Polycarbonate | 1.20 g/cm3 | 346.5 meters | 130.6 meters |

| PMMA | 1.18 g/cm3 | 352.3 meters | 132.8 meters |

| HIPS | 1.07 g/cm3 | 388.6 meters | 146.5 meters |

| PVA | 1.19 g/cm3 | 349.4 meters | 131.7 meters |

| TPU | 1.20 g/cm3 | 346.5 meters | 130.6 meters |

| PETG | 1.27 g/cm3 | 327.4 meters | 123.4 meters |

If you have already used up some of the filament in a 1kg (2. 20lbs) spool and would like to know how long your remaining filament is, you can use this filament calculator.

20lbs) spool and would like to know how long your remaining filament is, you can use this filament calculator.

Factors That Affect How Long Your 1Kg Filament Will Last

Some people will say that a 1kg (2.20lbs) roll of filament lasts them a few weeks, while others will say that it lasts them a few months. And that’s because the amount of time it takes for your roll of filament to run out depends on a few things.

Other than the type of filament material you are using, these factors include the kind of objects you are printing, how small or big these objects are, how often you will be printing, and the infill or internal mass of these objects.

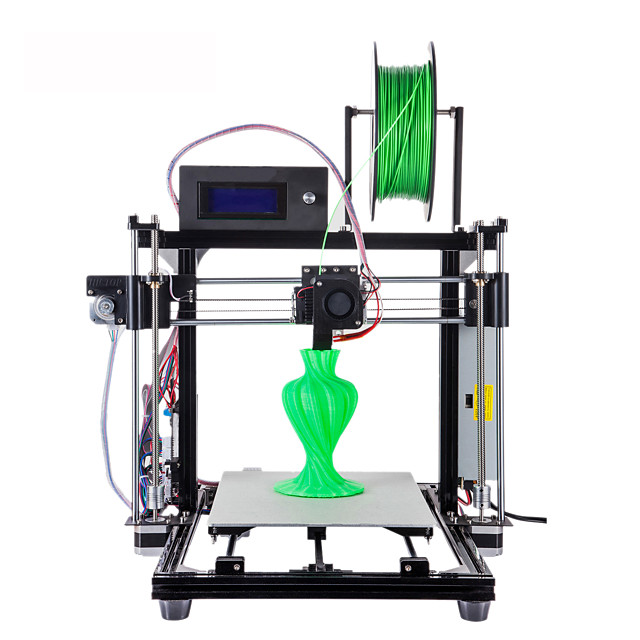

If we are talking about big projects like cosplay props and costumes, you can easily use up several 1kg (2.20lbs) spools of filament. Of course, how quickly each 1kg (2.20lbs) roll runs out would also depend on the size of your 3D printer and its nozzle or extruder.

If your 3D printer, build area, and extruder are small, you can only print big objects one part at a time, and these parts will be assembled later. So, it may take a few days to use up 1kg (2.20 lbs) of filament.

So, it may take a few days to use up 1kg (2.20 lbs) of filament.

However, if you are printing large objects using a large printer with a much larger extruder, 1kg (2.20lbs) of filament could quickly run out in one day.

For example, a certain piece or part that needs almost 500 grams (17.64 ounces) of filament takes 45 hours or almost two days to print using a 0.4mm (0.02in) nozzle. That means two similar pieces take 1kg (2.20lbs) of filament in 90 hours.

But if you change the nozzle size to 1mm (0.04in), the number of hours it takes to print this same piece is reduced to less than 17 hours. Yet along with the 60% decrease in total printing hours in this example, filament consumption increases to 627 grams (22.12 ounces).

Changing to a bigger nozzle may make the printing process faster, but it can also be expected to use up more filament. This is because while the finished product would look the same, its inner structure or design changes. Your print may need more support, or its infill pattern may change.

Meanwhile, if you like printing miniatures and tiny objects, like Dungeons & Dragons figures, and if you print in low volumes, a 1kg (2.20lbs) roll of filament could last you one or two months. For example, a D&D item can use up around one to 3% of a 1kg (2.20lbs) filament spool.

How Many 3D Objects Can I Print With 1Kg of Filament?

To give you a picture of what you can print with 1kg (2.20lbs) of filament, it’s somewhere between 335 calibration cubes with only 5% infill and 90 calibration cubes with solid or 100 percent infill.

Calibration cubes are simple geometric cubes that are common test prints to help fine-tune the settings of a 3D printer.

You can also print around 400 chess pieces of average size with 1kg (2.20lbs) of filament. Or, you can print 125 pieces of 8-gram (0.28-ounce) chess pawns, which takes one hour and 26 minutes of print time each.

The good thing is that if you don’t want to do all these computations and all the guesswork, your slicer software always gives you an estimate of how much filament each project will use.

This way, you can just subtract how many grams of filament are consumed by your current print from the kilogram of filament roll. And knowing this will allow you to estimate how many more projects you can print and how many printing hours you have left until your spool needs to be replaced.

How Can You Make Your Filament Last Longer?

There are different ways to make your 3D printer filament last longer. One is to reduce the size of your 3D prints if that is possible. You can also reduce your use of supports, skirts, rafts, and brims to cut down on your plastic consumption. Reducing your infill is another trick, too.

You can play around with your printer’s settings or with your slicer software so you can lower your use of filament. This could be trial and error at first, but the more you learn about 3D printing, the easier it will be for you to do these things. You can pick patterns for your infill to ensure that while your print is not solid inside, it is also not weak and hollow.

Conclusion

How long your 1kg (2.20lbs) roll of 3D printer filament will last depends on several things, so there is never an absolute number of hours or days. Instead, you can estimate how many similar objects you can print by taking note of how much filament they need.

Based on the number of hours it took to finish printing the first object, you’ll get an idea of the total number of printing hours for a 1kg (2.20lbs) spool.

Computations are trickier when printing objects of various sizes, though even more so if you need different-size nozzles for each print.

How Many Meters of Filament on a Spool? [Filament Calculator]

Categories Rigid Ink, Guides

Last updated:

Use the calculator below to work out how much filament you have left on a spool. Simply weight your remaining spool, and select the material.

Our calculator will tell you how much filament is left in grams and length. The table below also shows popular spool sizes and lengths for filament over a variety of different materials.

The table below also shows popular spool sizes and lengths for filament over a variety of different materials.

Choose type of filament:PLA (1,24 g/cm³)ABS (1,04 g/cm³)ASA (1,07 g/cm³)PETG (1,27 g/cm³)Nylon (1,08 g/cm³)Polycarbonate (1,20 g/cm³)HIPS (1,07 g/cm³)PVA (1,19 g/cm³)TPU/TPE (1,20 g/cm³)PMMA (1,18 g/cm³)CopperFill (3,90 g/cm³)

Choose filament diameter used:1.75 mm2.85 mm3.00 mm

Enter weight of reel & filament in grams:Basic Spool Weight Assumed to be 248g

Calculate

If you find this calculator useful, please bookmark it and share.

This is a comprehensive list of filament materials and their lengths on 500g, 750g, 1KG and 3KG spools for both popular 1.75mm and 2.85mm sizes, based on each material’s density.

This should allow you to correctly budget remaining filament for prints based on the remaining weight of your spool. So you can work out exactly how many meters of filament in a 1KG (or whatever size) spool you’re using. 3.

3.

Here we explain the relationship between filament volume, density and length. Before we can ask how much filament is on a 1kg spool, we first need to know the weight of the empty spool.

Q: How much does an empty filament spool weigh?

A: For reference, our empty spools weigh 248g. And this is approximately an industry average.

Using this knowledge you can easily weigh your spool, to see how much filament in weight is left – and knowing the weight, diameter and density of the material, you can work out how much is left on your spool in meters.

Wondering how many meters are in a KG of filament? We make it easy for you in the table below.

Our filament calculator has been made to 6 decimal places, which should be accurate enough given that manufacturers’ resin densities are always rounded to just 2 decimal places.

These lengths are meant as an accurate guide only, not a guarantee of what you will have received on your spool from other suppliers. 3.

3.

This means we know how many meters in a kilogram of PLA 1.75mm to be 335.3 meters. Or if you’re wondering how many grams in a meter is 1,000 Grams / 335 Meters = 2.98 grams per meter.

To see how many meters is 1KG of filament, look under the 1KG spool column. Move left and right to see lengths for other spool weights.

How Long is a Spool of Filament:

Filament Material / Density | 500g Spool | 750g Spool | 1KG = How Many Meters | 3KG Spool |

| PLA: 1.24g/cm3 | 1.75mm = 167.6m 2.85mm = 67.0m | 1.75mm = 251.5m 2.85mm = 94.8m | 1.75mm = 335.3m 2.85mm = 126.4m | 1.75mm = 1005.9m 2.85mm = 379.3m |

ABS: 1. 04g/cm3 04g/cm3 | 1.75mm = 199.9m 2.85mm = 75.4m | 1.75mm = 299.8m 2.85mm = 113.0m | 1.75mm = 399.8m 2.85mm = 150.7m | 1.75mm = 1,199.3m 2.85mm = 452.1m |

| ASA: 1.07g/cm3 | 1.75mm = 194.3m 2.85mm = 73.3m | 1.75mm = 291.5m 2.85mm = 109.9m | 1.75mm = 388.6m 2.85mm = 146.5m | 1.75mm = 1,165.8m 2.85mm = 439.5m |

| PETG: 1.27g/cm3 | 1.75mm = 163.7m 2.85mm = 61.7m | 1.75mm = 245.6m 2.85mm = 92.6m | 1.75mm = 327.4m 2.85mm = 123. | 1.75mm = 982.2m 2.85mm = 370.2m |

| Nylon: 1.08g/cm3 | 1.75mm = 192.5m 2.85mm = 72.6m | 1.75mm = 288.8m 2.85mm = 108.9m | 1.75mm = 385m 2.85mm = 145.1m | 1.75mm = 1,155m 2.85mm = 435.4m |

| Polycarbonate: 1.20g/cm3 | 1.75mm = 173.2m 2.85mm = 65.3m | 1.75mm = 260m 2.85mm = 98m | 1.75mm = 346.5m 2.85mm = 130.6m | 1.75mm = 1039.4m 2.85mm = 391.9m |

| HIPS: 1.07g/cm3 | 1.75mm = 194.3m 2.85mm = 73. | 1.75mm = 291.5m 2.85mm = 109.9m | 1.75mm = 388.6m 2.85mm = 146.5m | 1.75mm = 1,165.8m 2.85mm = 439.5m |

PVA: 1.19g/cm3 | 1.75mm = 174.7m 2.85mm = 65.9m | 1.75mm = 262m 2.85mm = 98.8m | 1.75mm = 349.4m 2.85mm = 131.7m | 1.75mm = 1,048.1m 2.85mm = 395.2m |

TPU/TPE: 1.20g/cm3 | 1.75mm = 173.2m 2.85mm = 65.3m | 1.75mm = 260m 2.85mm = 98m | 1.75mm = 346.5m 2.85mm = 130.6m | 1.75mm = 1039.4m 2.85mm = 391.9m |

PMMA: 1. 18g/cm3 18g/cm3 | 1.75mm = 176.2m 2.85mm = 66.4m | 1.75mm = 264.2m 2.85mm = 99.6m | 1.75mm = 352.3m 2.85mm = 132.8m | 1.75mm = 1,057m 2.85mm = 398.5m |

| CopperFill: 3.90g/cm3 | 1.75mm = 53.3m 2.85mm = 20.1m | 1.75mm = 80m 2.85mm = 30.1m | 1.75mm = 106.6m 2.85mm = 40.2m | 1.75mm = 319.8m 2.85mm = 120.6m |

We hope this list of lengths based on weight and density is useful to you. Now you know how many meters of ABS in a 1KG spool. Or you’ll know the answer to how much can you print with 1KG of filament.

Please comment below if you have any questions, and feel free to provide any constructive feedback if you feel we’ve missed anything. We hope this tool allows you to easily calculate how much filament is on a 1KG spool.

We hope this tool allows you to easily calculate how much filament is on a 1KG spool.

Alternatively there might be a material we’ve missed, so you cannot work out the length of filament in a 1KG spool – if yours isn’t mentioned, please let us know.

Related articles:

- Pillowing and stringing during 3D printing – how to fix

- What to do with empty filament spools

- Best 3D printers

3dsourced

We've covered the 3D printing industry since 2017, tested over a dozen of the world's most popular 3D printers, and we're dedicated to being the most informative 3D printing site in the world to help democratize the technology.

How many meters of thread are in the spool?

Author Kirill Sokolov Reading 6 min. 81 views Posted by

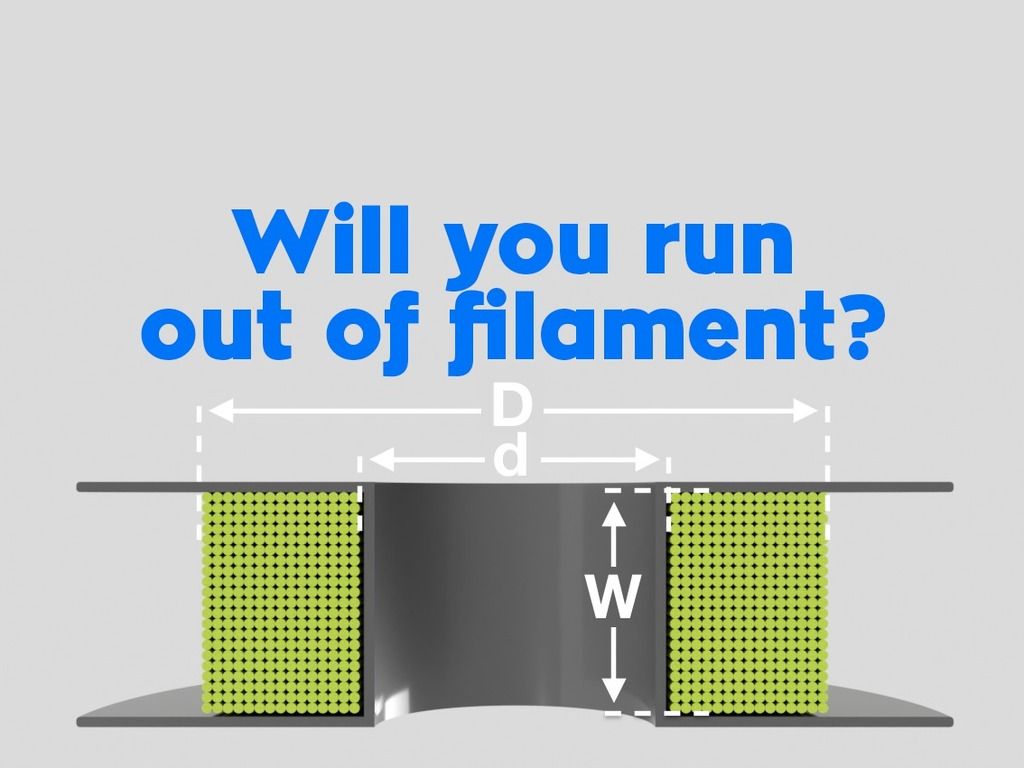

Have you ever been in the middle of a 3D printing project only to notice that the amount of filament left in your spool can reduce it to what your model needs? This can cause concern for anyone, as running out of filament in the middle of the print may require a fresh start.

It can be difficult to pinpoint exactly how much thread is left in the spool. , but it is quite possible to give a reasonable estimate. If you've always wanted to document the length of thread in each of your partially used spools, then here's a quick guide.

Contents

- Why worry about it?

- While you are cutting the 3D model

- When you are setting up the spool to start 3D printing

- What information do you need?

- Empty spool weight

- Filament density

- Filament diameter

- How to calculate the length of the filament in the spool

- Final thoughts

Why bother with this?

While it doesn't take a lot of work to estimate how much filament you have left for each spool, many of them claim it's not necessary. Not knowing is bliss and one can just order another reel online if they are close to running out. However, there are two crucial moments in a 3D printing project when this information can come in handy:

While you're cutting the 3D model

One of the last steps When translating a 3D model into a language the 3D printer can understand, it needs to be processed in the cutting software. Here you can make changes to the mode to optimize it for 3D printing. You can adjust the wall thickness, change infill patterns, and add support structures as needed.

Here you can make changes to the mode to optimize it for 3D printing. You can adjust the wall thickness, change infill patterns, and add support structures as needed.

Changing any of these parameters means that the software will adjust the amount of filament needed to print the design. . Once you are satisfied with your settings, the program will give you a final number, usually in terms of the length of thread you will need.

Now check this number against the length of thread you want. gone. If you don't have enough filament then this is your last chance to change your slicer settings so you can get the last print off your spool.

When you set up a spool to start a 3D print

If you don't keep a detailed record of how much filament you have in each spool, then installing any of them on your 3D printer to start a project is an exercise in guesswork at best . Do you have enough filament or will you run out before the project is completed?

It's better to be sure, because watching a 3D printer for hours is just a step up in entertainment. spectrum to watch the paint dry.

spectrum to watch the paint dry.

Fortunately, there is only one tool you need to reasonably estimate the length of thread left on the spool, and that is a digital scale. If you don't have one yet, then it's time to think about buying one. A digital scale should be an integral part of your 3D printing workshop. They don't have to be expensive. This digital kitchen scale from 1 BY ONE holds 5kg, comes with a stainless steel platform, and costs less than $15.0005

After the digital balance is balanced and calibrated, weigh the coil with the remaining filament. Write down this number. In this example, we will designate this variable as Spool weight + thread and designate the value 725 grams .

We are not quite out of the woods yet. There are three other very important values that you need to look for.

Empty spool weight

There was a time when spools of 3D printing filament looked the same and an estimate of 250 to 260 grams seemed reasonable. There are too many brands today, some of which use clear plastic or cardboard spools. For this reason, the use of an estimate without a basis is no longer acceptable.

There are too many brands today, some of which use clear plastic or cardboard spools. For this reason, the use of an estimate without a basis is no longer acceptable.

There are two ways to do this: weigh the empty spool yourself if you have one, or ask the manufacturer to provide the weight of their empty spools. Please note that there will inevitably be differences in the weight of these empty reels, even if they come from the same production line.

In our example, this variable would be Empty spool weight with a value of 235 grams .

Thread density

You also need the density of the filament, or its weight per unit volume. Ideally, you can use the book value for the density of each material. For example, PLA has a standard density of 1.25 grams per cubic centimeter, while ABS has a density of 1.53 grams per cubic centimeter.

However, the use of the book value may not be accurate enough. 3D printing filaments are rarely made exclusively from a base material. Dyes are added to give them color, while some fibers may contain additives that improve their fluidity or increase their heat resistance.

Dyes are added to give them color, while some fibers may contain additives that improve their fluidity or increase their heat resistance.

To resolve this uncertainty, it is best to contact the manufacturer directly. For some threads, the density value is indicated on the package itself. If not, then most manufacturers will be kind enough to give you an estimate.

In this example, will be assigned a thread weight of . a value close to PLA - 1.32 grams per cubic centimeter .

Filament diameter

Finally, you will need a value for your filament diameter. This should be easy because there are only two options: 1.75 or 3.00 millimeters. This should be clearly marked on the reel. In our example, let's say we have a thread 3.00 millimeters ..

How to calculate the length of the thread in the spool

Let's group all our values into a nice little table so we don't get confused:

| Meaning | |

|---|---|

| Spool weight + thread | 725 grams |

| Empty spool weight | 235 grams |

| Thread weight | 1. 32 grams per cubic centimeter 32 grams per cubic centimeter |

| Thread diameter | 3.00 mm OR 0.3 cm |

With all these values at hand, just follow the instructions for calculating the thread length.

1. Determine the weight of the thread by subtracting the weight of the empty spool from the total weight of the spool of thread.

Weight of thread = (Weight of spool + thread) - (Weight of empty spool)

= 725 grams - 235 grams

= 490 grams

2. Calculate the amount of thread remaining in the spool 92

= 0.07065 square centimeters

4. Calculate the length of the remaining thread

Thread length = volume of thread / cross-sectional area

= 371.21 cubic centimeters / 0.07065 square centimeters

= 5254 centimeters OR 52, 54 meters

For our example, we came up with an estimated remaining filament length of 5254 centimeters. Note that the keyword here is VALUE. We have made many simplifications (among other things, empty spool weight and thread density), which means that this value can vary by several centimeters. Just in case, make sure you have at least 10% allowance of the thread length needed for your model.

We have made many simplifications (among other things, empty spool weight and thread density), which means that this value can vary by several centimeters. Just in case, make sure you have at least 10% allowance of the thread length needed for your model.

Closing Thoughts

Experienced 3D printing pros know how hard it is to keep so many half-used spools of filament in their workshops. There's also the worry of not knowing if the spool you've loaded - which feels uncomfortably light - has enough filament to complete the 3D print of the model.

The good news is that it won't take long. with a reasonable estimate. Simply take out this digital scale every time you need to print with a spool that is on the verge of running out.

Attention! 3D printers must not be left unattended. They can pose a fire safety hazard.

3D printer printed multi-colored filament from different materials

3D printing materials

Complexity 1.7

Haruki Takahashi et al./ ACM Digital Library

Engineers have presented a new technique for printing colored plastic objects on a simple 3D printer with a single nozzle without the use of additional tools. To do this, it is necessary to print a thread consisting of colored segments in the right places in several steps, and then you can use this filament for conventional printing by layer-by-layer deposition. In addition to color, the method also allows you to create a thread from different materials. Article published at ACM Digital Library .

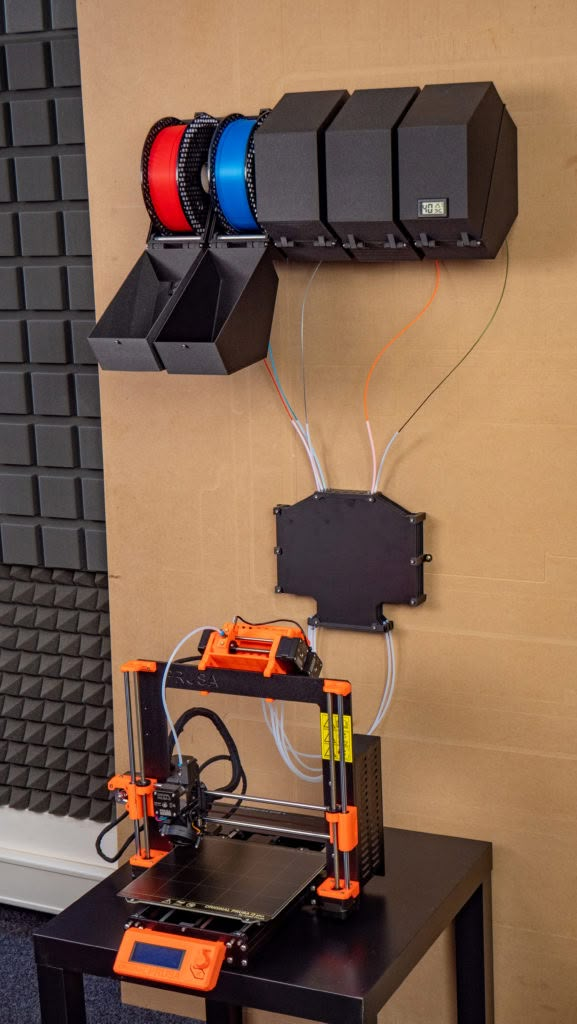

The most common and affordable 3D printing method is Fused Deposition Modeling (FDM). FDM printers have one (sometimes more) extruder that supplies filament to the substrate, and to print multi-colored objects, you either need to change the filament spool manually, stopping the printing process, or print on a printer with several extruders, or use additional devices to thread several threads at once.-black-kupit-v-soin-store.ru-3.jpg) Printing with two extruders increases the chance of shearing, welding and other defects, and these defects are also difficult to avoid when manually changing the filament. In addition, manual replacement may be required several times during the printing process, which can greatly increase the time spent and increase the likelihood of printing defects. Accessories, on the other hand, need to be bought separately, and they often require certain skills and training, complicate and increase the cost of printing. There are also multi-color threads and materials that can change their color and properties, but these are not universal solutions that are usually not available to the average user.

Printing with two extruders increases the chance of shearing, welding and other defects, and these defects are also difficult to avoid when manually changing the filament. In addition, manual replacement may be required several times during the printing process, which can greatly increase the time spent and increase the likelihood of printing defects. Accessories, on the other hand, need to be bought separately, and they often require certain skills and training, complicate and increase the cost of printing. There are also multi-color threads and materials that can change their color and properties, but these are not universal solutions that are usually not available to the average user.

Haruki Takahashi of Meiji University and colleagues have come up with a low-cost method for printing different colors and even materials on a printer with only one extruder. The method involves the creation of a programmable thread for each individual project using a 3D printer, which is then fed into the 3D printer as a regular filament. The length and number of required segments is generated in G-code format from a 3D model or 2D image using printer software.

The length and number of required segments is generated in G-code format from a 3D model or 2D image using printer software.

A program developed by scientists uses this G-code to design a future filament and offers optimal printing options. The printer sequentially prints the filament in the form of a spiral, starting from the edge towards the center. First, all segments of one color are printed, and only then another, which significantly reduces the number of manual filament changes. The ends of the segments are cut diagonally during the printing process to increase the contact area between the segments, and are additionally fused with stitches - additional layers of filament. Fusing the stitch and simultaneously passing a hot nozzle at the point of contact increases the strength of the connection.

Illustration of the process of creating a multi-component thread

Haruki Takahashi et al./ ACM Digital Library

Share

The scientists tested their technique on four different printers using filaments of different colors and different materials: polylactide, thermoplastic polyurethane, acrylonitrile butadiene styrene, polyvinyl acetate, nylon.

4m

4m 3m

3m