3D printed clocks

⌚ Best STL files 3D printed for clocks and watches・Cults

⌚ Best STL files 3D printed for clocks and watches

Download free clocks and watches 3D files

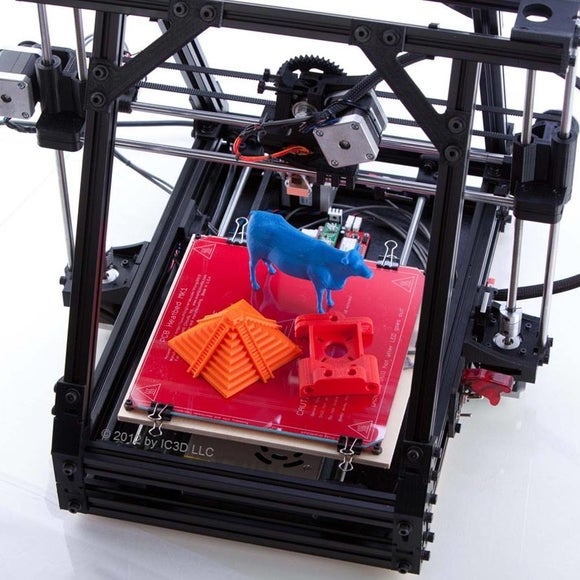

Discover our selection of 3D files of beautiful watches and clocks perfectly 3D printable to add a touch of 3D printing to your interior or on your wrist. You will find in this collection all the 3D models you need to always be on time, no more excuses!

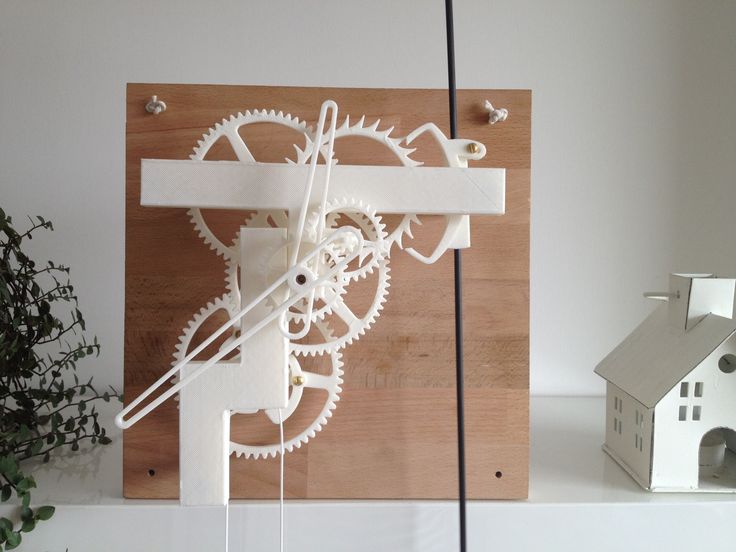

Clock One

Free

Gyro Winder / Watch Winder

€2.50

Gyrotourbillon

Free

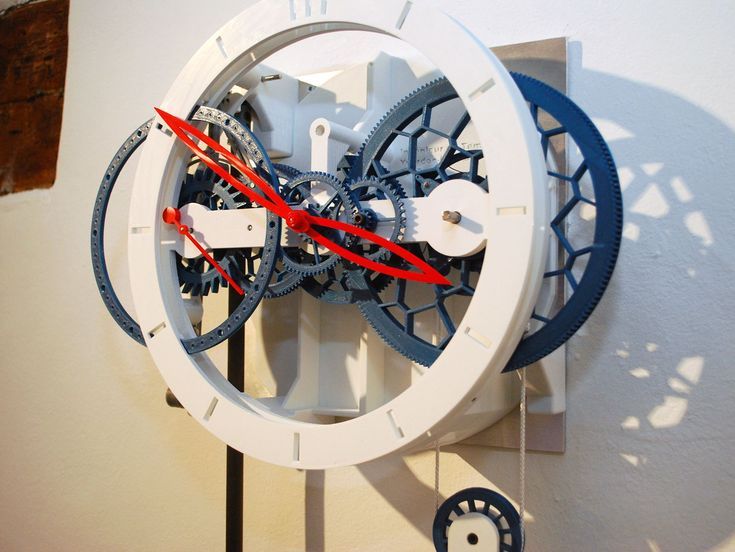

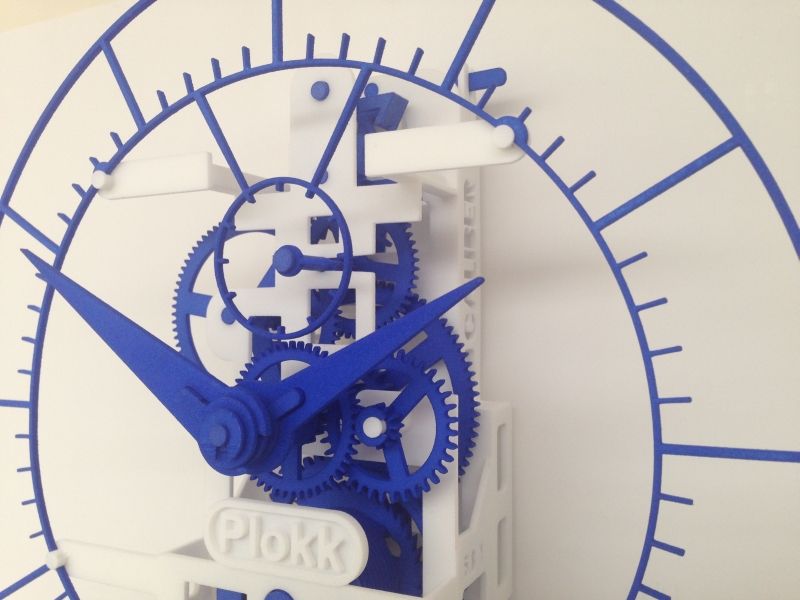

Christian Huygens 3D printed clock

Free

Reloj Simpsons

Free

Reloj Spiderman

Free

Reloj gato v3

Free

Structure Clock

Free

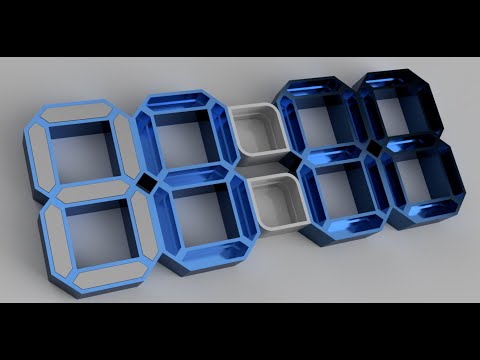

7-Segments

€7.96

Reloj The Beatles

Free

Reloj Dragon Ball Z

Free

Clock Games

Free

Reloj Beatles

Free

Clock Game of Thrones

Free

Reloj vinilo The Lord of the Rings

Free

Kitchen clock "Coffee time"

Free

Triaxial Motorized

Free

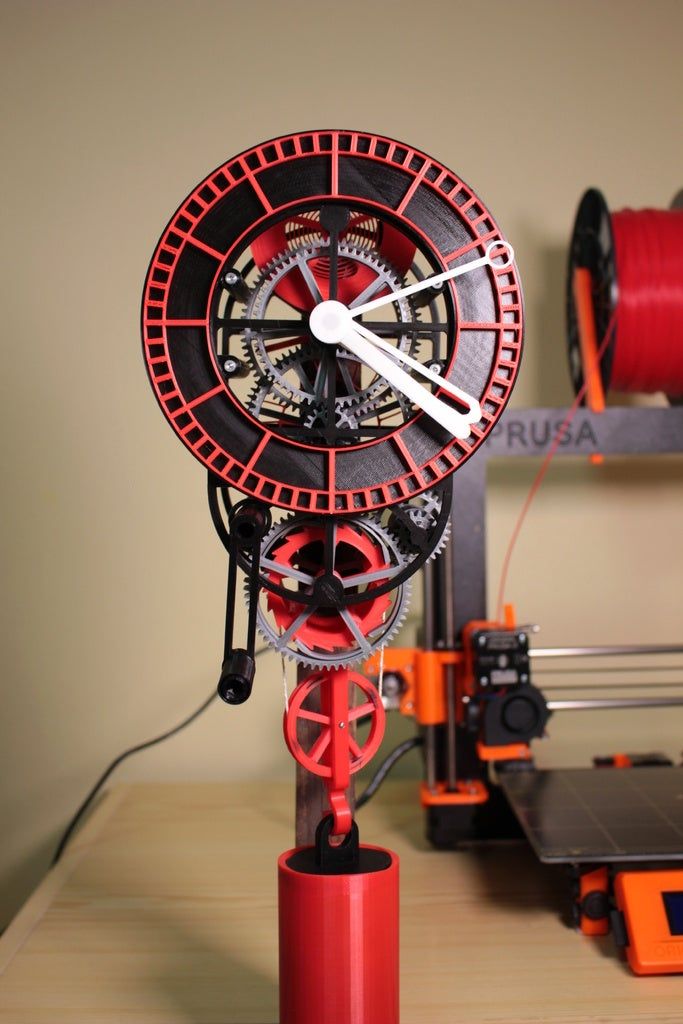

Mechanical clock to go up

Free

Reloj Rick y Morty

Free

Reloj spiderman V2

Free

Triaxial Quartz Movement Upgrade

Free

Clock with decorative mechanism.

Free

Galileo Escapement Design

Free

Spiral exhaust movement

Free

Round Clock

Free

Reloj Star Wars

Free

Drip Clock

Free

Reloj Astérix

Free

Reloj Jasmine (X3 VERSIONES)

Free

Reloj Queen Freddie Mercury

Free

3D Printed Galileo Escapement Clock with Hands

Free

The First Clock

Free

Extra large roman wall clock

Free

Batman logo Wall Clock Ikea STOMMA

Free

Alien Clock 3D

Free

Modular Wristwatch - 3D Printing Build

Free

Reloj cubo RUBIK

Free

Game of Thrones Clock

Free

Reloj de pared

Free

STAR WARS LOGO STENCIL

Free

MICHAEL JACKSON WATCH

Free

pink floyd clock 350 mm diameter

Free

Mario 3D Clock

Free

Darth Vader Clock

Free

Table Clock

Free

M&O Paris Clock

Free

Reloj Walking Dead

Free

Reloj Chewbacca

Free

Galileo Escapement clock spring driven and hands

Galileo Escapement Design

Gyro Watch Winder | Gimbal Watch Winder | Watch Winder with ESP32 and Wifi

Gyro Winder / Watch Winder

Here is our selection of the best 3D files of clock and watch for 3D printers, all these creations are from the STL file library Cults and are perfectly 3D printable.

This collection includes free or paid STL files of superb clocks created by the designers of our community. 3D printing allows you to create an extreme variety of shapes to enhance your interior decoration in the best way. All you need to do is add a classic clock mechanism to transform your print into a beautiful clock. In this selection you will also find 3D models allowing you to print your watch in 3D. In the same way as for els clocks, it will obviously be necessary to complete with a classical mechanism such as a Casio or Swatch for example.

The 3D designers who propose their creations on the 3D file download platform Cults have really competed in ingenuity to make all these objects, if you download them, don't forget to post pictures of the result! It's also a great gift idea for your friends who are always late!

3d Printed Clocks - Etsy.

de

deEtsy is no longer supporting older versions of your web browser in order to ensure that user data remains secure. Please update to the latest version.

Take full advantage of our site features by enabling JavaScript.

Find something memorable, join a community doing good.

( 426 relevant results, with Ads Sellers looking to grow their business and reach more interested buyers can use Etsy’s advertising platform to promote their items. You’ll see ad results based on factors like relevancy, and the amount sellers pay per click. Learn more. )

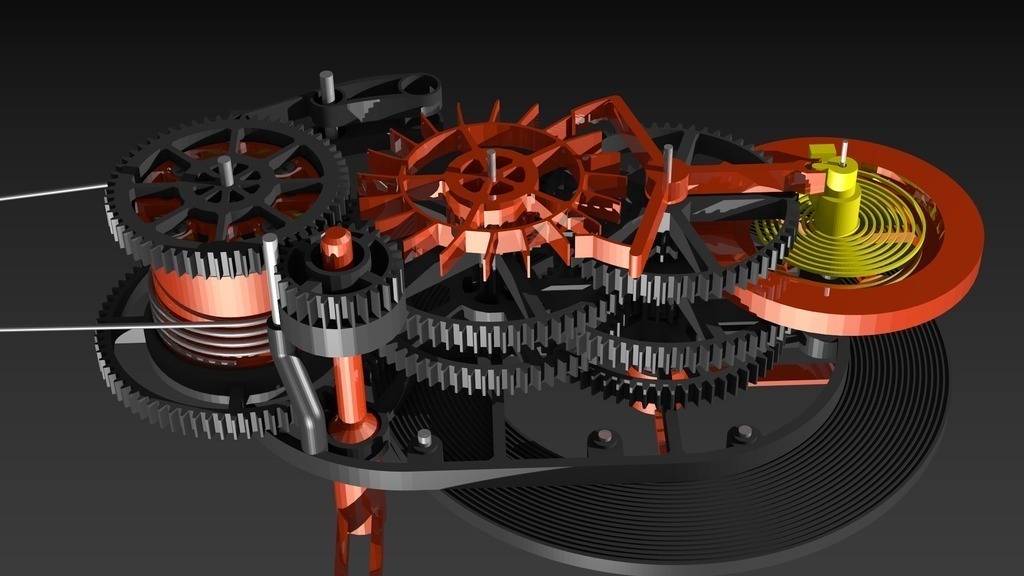

3D printed tourbillon watch - how it's made

Creativity

Dear friends! While gathering the best content for you, we couldn't get past popular YouTube videos like '3D Printed Tourbillon Watch - How It's Made'.

Therefore, now we will translate the most interesting of them so that you can enjoy them to the fullest :)

3D printed tourbillon watch - how it's made

This project presents a 3D printed mechanical tourbillon watch. The main driving force of the clock is the spring installed inside. The approximate operating time of the watch on a single charge is 30 minutes. Accuracy is approximately one second deviation within one minute (depending on printing settings).

Clock designed in Autodesk Fusion 360 and printed on Ultimaker 2.

Model available for download on Thingiverse

Build time TimeLapse

Animated assembly process

Autodesk Fusion 360 design:

Assembled parts

Non-printed parts:

.5 mm, 12 mm long (armature axis)

1 Pin, 1. 5 mm diameter, 8.5 mm long (planetary gear axis)

5 mm diameter, 8.5 mm long (planetary gear axis)

and hour wheel)

6 pins, diameter 2 mm, length 22 mm (axle for base gear)

1 Pin, diameter 2 mm, length 15 mm (mainspring attachment)

1 Pin, diameter 3mm, length 22.5mm (axle for mainspring)

1 Pin, diameter 3mm, length 31mm ( axle for main gear)

3 Washers, 3 mm dia. (mainspring, cogwheel)

6 Washers, 2 mm dia. (gear)

5 Washers, 1.5 mm dia. , diameter 1.8 mm, length 6.5 mm ( ratchet )

5 Screws, diameter 1.5 mm, length 5 mm (walking drum)

4 Screws, diameter 1.5 mm, length 10 mm (base plate)

4 Screws, diameter 1.8 mm, length 12 mm ( dial)

3 Screws, diameter 1.5 mm, length 10 mm (tourbillon)

Source of information. Translated by iGo3D.

Our groups in social networks:

VKontakte

Your iGo3D team

Follow author

Subscribe

Don't want

16

More interesting articles

spc

Loading

04. 10.2022

10.2022

1083

twenty

Subscribe to the author

Subscribe

Don't want to

It seems that when you start making tanks, there is no going back. You can talk for a long time, but the fact...

Read more

Hagen

Loading

09/20/2022

687

19

Subscribe to the author

Subscribe

Don't want

Greetings to all!

Saying "Long time no see" is almost nothing to say. 1.5 year...

Read more

NotJes

Loading

14.02.2017

38535

211

Subscribe to the author

Subscribe

Don't want

Greetings to all readers of the portal! After my article, many people asked what paints I used. ..

..

Read more

8 unusual things printed on a 3D printer

Many people think that a 3D printer creates products that are beyond our daily life, however 3D printed products are already being used by many consumers who are appreciating the benefits of the new technology.

In recent years, the global trend towards personalization is changing the picture of the entire consumer market. The opportunity to purchase a special product, made to measure, is increasingly becoming a determining factor in the purchase. In addition to attracting the consumer, 3D printing also gives companies a competitive advantage in production, significantly reducing the time for the implementation of each individual project. Now, instead of lengthy logistics, complex supply chains, stockpiling, the entire production process can be packed into a few days, and 3D printing of most objects will take hours. Thus, it turns out to optimize resources and reduce the cost of the final product.

Already today with HP Inc. Multi Jet Fusion 3D printers. companies all over the world from different sectors of the economy print unexpectedly interesting and useful things:

1. Orthopedic insoles

Startup Invent Medical operates under the motto "Help through innovation." This is the case when medicine combined 25 years of human biomechanics research with 3D printing, scanning and design algorithms.

The company prints unique orthopedic insoles according to the individual parameters of the client in order to match the physiological characteristics and lifestyle of each consumer.

2. Glasses

Horizons Optical is not your typical optical manufacturer. The brand does not just create glasses, but develops innovative products and services.

One of the company's most innovative projects is the Made4U concept, which uses imaging and 3D printing technologies to create fully personalized glasses that perfectly fit any face type. To create them, a special system for scanning the structure of the face has been developed, which allows printing frames taking into account all the individual characteristics of the client.

To create them, a special system for scanning the structure of the face has been developed, which allows printing frames taking into account all the individual characteristics of the client.

3. Shoes

Designer Annie Fu has created a collection of futuristic women's shoes.

Don't let the bright and unusual shape of these shoes scare you: in fact, all models are comfortable and absolutely comfortable to wear, because each pair is created according to the measurements and shape of the foot of a particular client.

4. An alternative to braces

The Swiss company Nivellmedical has developed an aesthetic alternative for those who are embarrassed by iron shackles and dream of a beautiful smile. Instead of installing classic braces, the company offers transparent caps, using 3D printing and thermoforming to make them. Virtually invisible plastic elements gently yet effectively align teeth

To create molds, the doctor first scans the patient's jaw and then creates a virtual object that is quickly 3D printed.

5. Helmet of the Guards

The military unit of the Swiss Guards of the Vatican, existing since 1506, is responsible for the protection of the Pope. Their 3D-printed helmets are exactly the same as the original 16th-century models, but weigh just over 500 grams. The helmets are made in just fourteen hours, when the previous ones took about seven times longer to create.

6. Dolls

The Spanish toy manufacturer Look Real has implemented a project to create personalized dolls that are like two drops of water similar to their owners. Psychologically, this could set the trend for the entire gaming industry.

It has been scientifically proven that the proportions of a doll affect the mental and physical health of a child and form his idea of his body. Since the doll acts as a prototype of a person in a children's game, it is important that her appearance is as close to real as possible. In the first seven years, the child's psyche is characterized by special mobility and the ability to project: the most striking features of the toy remain in the mind. The goal of the startup was to take into account these features and, using innovative technologies, create a special doll for each child, helping to form a healthy perception of their appearance.

The goal of the startup was to take into account these features and, using innovative technologies, create a special doll for each child, helping to form a healthy perception of their appearance.

7. Personal protective equipment

During the coronavirus pandemic, the speed of developing and producing new products has become a key advantage of 3D technology. If in traditional production it takes weeks to reconfigure devices, then the new method allows you to send a file with a product layout for printing in one click, just like we start printing any document on a regular printer.

Literally within twenty-four hours, the technology allows hundreds of elements to be simultaneously produced from scratch. In the first months of the pandemic alone, more than 3.3 million parts for hospitals around the world were quickly printed on HP 3D printers. These include face shields, mask holders, face shields, nose swabs, touchless door openers and respirator components. In addition, in order to provide the largest number of patients and medical institutions with scarce protective equipment, HP Inc. created a page where 3D model files are published in the public domain, which can be downloaded and sent for 3D printing anywhere in the world.

In addition, in order to provide the largest number of patients and medical institutions with scarce protective equipment, HP Inc. created a page where 3D model files are published in the public domain, which can be downloaded and sent for 3D printing anywhere in the world.

8. Car Parts

Racing car brand Cupra uses 3D printing to produce side windows and air vents. Thanks to these developments, the company has the ability to print several elements in a short period of time and change their configuration in the car during the production process.

The German automotive concern Volkswagen has produced more than ten thousand models of the ID.3 mid-range electric car, also using 3D printing to produce gear levers and mirror attachments.

Recently, the Nissan brand has also joined these companies: spare parts for rare cars are created on 3D printers. Long out of production retro model parts like these are no longer available in warehouses and used to take many months to find, but now they can be 3D printed in just a few hours.

Finally, to help make 3D printing waste sustainable, Ford and HP are collaborating on waste-free 3D printing of automotive parts. So, from recycled materials, Ford creates clips for fuel hoses for Super Duty F-250 pickups. According to engineers, such parts have better moisture resistance, they are 7% lighter and 10% cheaper. It is planned that this model of production of parts from recycled materials will be applied to the manufacture of parts for other cars of the company. The more manufacturers adopting these zero-waste processes, the sooner we can achieve a circular economy with minimal environmental impact.

“3D printing is one of the breakthrough technologies of Industry 4.0. Already today, we are seeing the use of our 3D printers in the automotive, healthcare, consumer goods and other industries. In the near future, we will see an increasing penetration of additive technologies in a wide variety of industries. 3D printing will continue to grow in popularity through faster end-to-end product lead times, simplified supply chains, and lower unit costs,” said HP Inc.