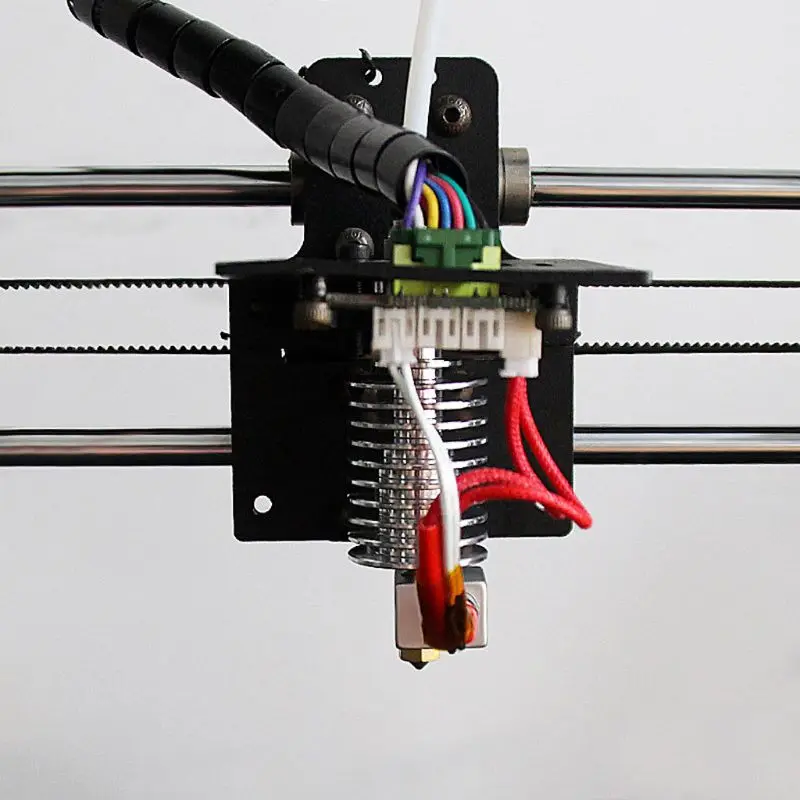

3D printer extruder print head

3D Printer Extruders | MatterHackers

Finding the best extruder upgrade or replacement for your 3D printer can take the quality of your 3D printed parts to the next level. The extruder is responsible for how much and at what speed your 3D printer pushes filament into the hotend. MatterHackers can help you find the perfect extruder for your 3D printer to help you get the best 3D printed parts possible.

Guides & Articles

How to Succeed with Quantum Dichromatic PLA Filament

Follow this guide for tips and tricks on how to get the best results when 3D printing with Quantum Dichromatic PLA filament.

How To Succeed with LayerLock SLA Build Surfaces

Successfully achieve strong bed adhesion for Laser, DLP, and SLA resin prints using LayerLock SLA Resin 3D Printing Build Surfaces.

How To Build A Successful Makerspace

Find out the necessary components to create an effective space for your maker community.

How to Succeed When 3D Printing with Polypropylene

Successfully produce 3D printed parts out of polypropylene filament with these tips on achieving stronger bed adhesion and minimizing shrinkage.

Tech Breakdown and How to Succeed: Ionic Hybrid Support Material

Supporting engineering-grade filament has been difficult without a support material dedicated to higher temperature 3D printing. Ionic aims to solve that.

How To Succeed with OBC 3D Printing Filament

From Dow Chemical, OBC combines flexible and rigid into one unique material with properties of both.

How To Succeed with LayerLock Garolite Build Surfaces

Successfully achieve strong bed adhesion for NylonX, NylonG, and standard filaments using LayerLock Garolite Build Surfaces.

How to Succeed with LayerLock Powder Coated PEI Build Plates

Powder coated PEI steel sheets are a great alternative build surface for strong bed adhesion. Here's how you can succeed using this durable build plate.

Here's how you can succeed using this durable build plate.

How To Succeed When 3D Printing With Nylon

Learn how to 3D print Nylon like a pro. Nylon is a stronger and more durable alternative to PLA or ABS and easy to 3D print with using these Tips and Tricks.

How To Succeed When 3D Printing With ASA Filament

Follow this step-by-step guide to learn how to print with ASA, the perfect material for any outdoor projects.

How to Succeed when 3D Printing with Polycarbonate Filament

Follow these helpful steps to start successfully printing with this extremely tough, professional grade material.

How to Succeed with NylonX

NylonX has quickly become one of our favorite filaments for strong, durable, and ready-to-use parts. Here's an in-depth look at Nylon X, and some printing tips to get the most out of this great new material.

Print head for ceramics - StoneFlower 3D printers for clay / porcelain / concrete.

Add-ons for desktop 3d printers

Add-ons for desktop 3d printersPrint head 6

NETTO PRICE 369 €

Print head from stainless steel 304, for more durability and corrosion-resistance. All-metal inlet adapter (nikel-plated bronze). Facilitated installation of the stator. Includes standard Nema17 stepper motor, cables, nozzle set. Perfect for mortars, clay, corrosive and abrasive pastes and suspensions. Inlet can be oriented in four different ways to fit your equipment.

439,11 €

- 0,85 kg

- Available

- Ships within 1 week1

Features:

- durable chemically resistant two-flute auger screw (SS 316)

- leak-free construction, easily replaceable standard seal and bearing

- stator from stainless steel SS 304

- Durable and strong steel mount.

Stator with seven threaded M5 channels, and standard 1/2 and 1/4 inch holes with NPT thread for inlet and outlet respecively.

Stator with seven threaded M5 channels, and standard 1/2 and 1/4 inch holes with NPT thread for inlet and outlet respecively.

Specifications:

- Dimensions WxDxH = 42x72x124mm (without nozzle)

- Screw length 62mm, diameter 8mm

- Inlet: push-in connector for 16mm pipe (external diameter)

- Outlet: 1/4 NPT threaded hole for up to D=8mm ouput flow

- Comes with metallic nozzles: 2.5mm, 4mm, 7mm, nozzle adapter for standard luer tips, 6 different PE luer tips (0.2mm ... 1.55mm)

- Stepper motor Nema17, 2.5A/phase, 40Ncm, 2-phase, 1.8deg.

This is a spare part! While the print head can be directly connected to the motherboard of a 3D printer, we recommend to use this as a part of 3D Printing KIT and connect to the printer via Control Unit. When used without control unit, this may need to change settings of your stepper motor driver. In case of questions please contact us.

In case of questions please contact us.

Print head 6R

NETTO PRICE 419 €

Reinforced print head from stainless steel 304 with geared stepper motor (5:1). Maximum durability, corrosion-resistance and torque. All-metal inlet adapter (nikel-plated bronze). Facilitated installation of the stator. Includes cable, two-flute auger screw, nozzle set. For very viscous corrosive and abrasive pastes and suspensions. Inlet can be oriented in four different ways to fit your equipment.

498,61 €

- 0,95 kg

- Available

- Ships within 1-3 days1

Features:

- Geared stepper motor Nema 17 (5:1 gear ratio)

- durable chemically resistant two-flute auger screw (SS 316)

- leak-free construction, easily replaceable standard seal and bearing

- stator from stainless steel SS304

- Durable and strong steel mount.

Stator with seven threaded M5 channels, and standard 1/2 and 1/4 inch holes with NPT thread for inlet and outlet respecively.

Stator with seven threaded M5 channels, and standard 1/2 and 1/4 inch holes with NPT thread for inlet and outlet respecively.

Specifications:

- Dimensions WxDxH = 42x72x124mm (without nozzle)

- Screw length 62mm, diameter 8mm

- Inlet: push-in connector for 16mm pipe (external diameter)

- Outlet: 1/4 NPT threaded hole for up to D=8mm ouput flow

- Comes with metallic nozzles: 2.5mm, 4mm, 7mm, nozzle adapter for standard luer tips, 6 different PE luer tips (0.2mm ... 1.55mm)

- Stepper motor Nema17, 2.5A/phase, 40Ncm, 2-phase, 1.8deg.

This is a spare part! While the print head can be directly connected to the motherboard of a 3D printer, we recommend to use this as a part of 3D Printing KIT and connect to the printer via Control Unit. When used without control unit, this may need to change settings of your stepper motor driver. In case of questions please contact us.

In case of questions please contact us.

Nozzle set

NETTO PRICE 40 €

Conical Luer nozzles (PE) of 6 different diameters:

Dark Green - 14 Gauge - 1.55mm

Black - 16 Gauge - 1.19mm

Jade Green - 18 Gauge - 0.84mm

Light pink - 20 Gauge - 0.6mm

Royal blue - 22 Gauge - 0.41mm

Red - 25 Gauge - 0.26mm

- Luer adapter (D about 2mm)

- Bronze nozzles with diameters 2.5, 4 and 7mm.

47,60 €

- 0,01 kg

- Available

- Ships within 1-3 days1

Spare auger screw

NETTO PRICE 70 €

Auger screw, specially designed and optimized for clay extrusion. Includes brass bearing and seal ring. Compatible with StoneFlower print heads 4, 5S, 6. Wear- and corrosion-resistant polished stainless steel 316.

Includes brass bearing and seal ring. Compatible with StoneFlower print heads 4, 5S, 6. Wear- and corrosion-resistant polished stainless steel 316.

83,30 €

- 0,05 kg

- Available

- Ships within 1-3 days1

Mortar print head

NETTO PRICE 1200 €

Large-scale mixing print head from stainless steel 304 with stepper motor Nema23 for mortar/concrete. Maximum durability, and corrosion-resistance. Easy to assemble and clean, thanks to standard tri-clamp connectors. Compatible with 2inch and 1.5inch inlets. Separate inlet for accelerator. Screw diameter 45mm, tube diameter 50mm. Compatible with big ram extruder (2.5L, 5L), and our mortar 3d printer.

1.428,00 €

- 4 kg

- Available

- Ships within 1 week1

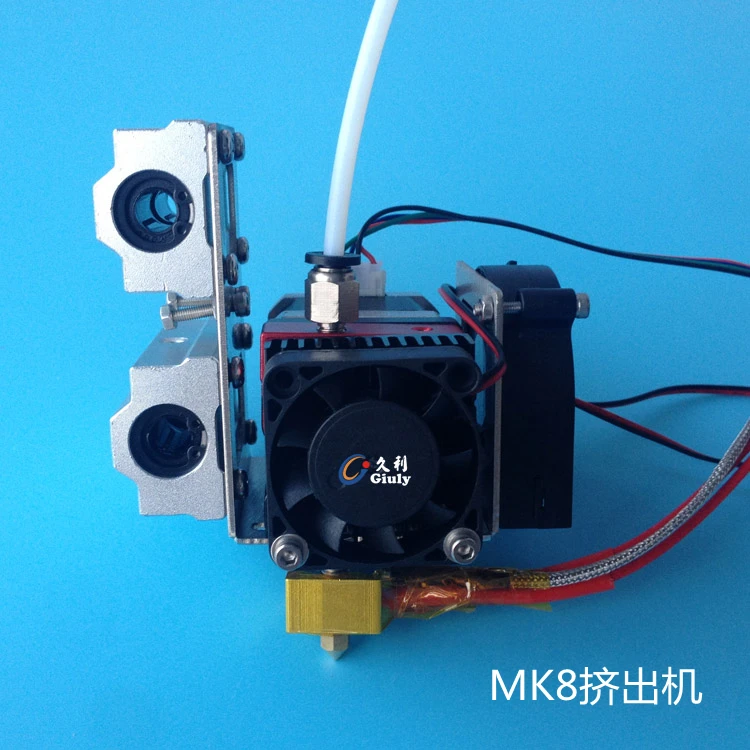

3D printer print head

The 3D printer print head is called an extruder. The name reflects the principle of operation: the print head extrudes the thermoplastic through a special nozzle. Drawing an analogy, glue guns common in everyday life, syringes with sealant, tubes of toothpaste, and finally, operate in the same way.

The name reflects the principle of operation: the print head extrudes the thermoplastic through a special nozzle. Drawing an analogy, glue guns common in everyday life, syringes with sealant, tubes of toothpaste, and finally, operate in the same way.

As a rule, filament (filamentary) thermoplastics such as ABS or PLA are used for 3D printers. What to choose for printing - see the article: Choosing plastic for printing on a 3D printer.

However, sometimes more exotic plastics are used, for example, you can print with nylon on a 3D printer, in fact, cheap trimming line is used.

Despite the variety of 3D printers, their printheads are made on the same principle and do not differ much from each other. For example, a small Myrwell 3D pen is actually a full-fledged extruder enclosed in a body that is comfortable to hold in your hand.

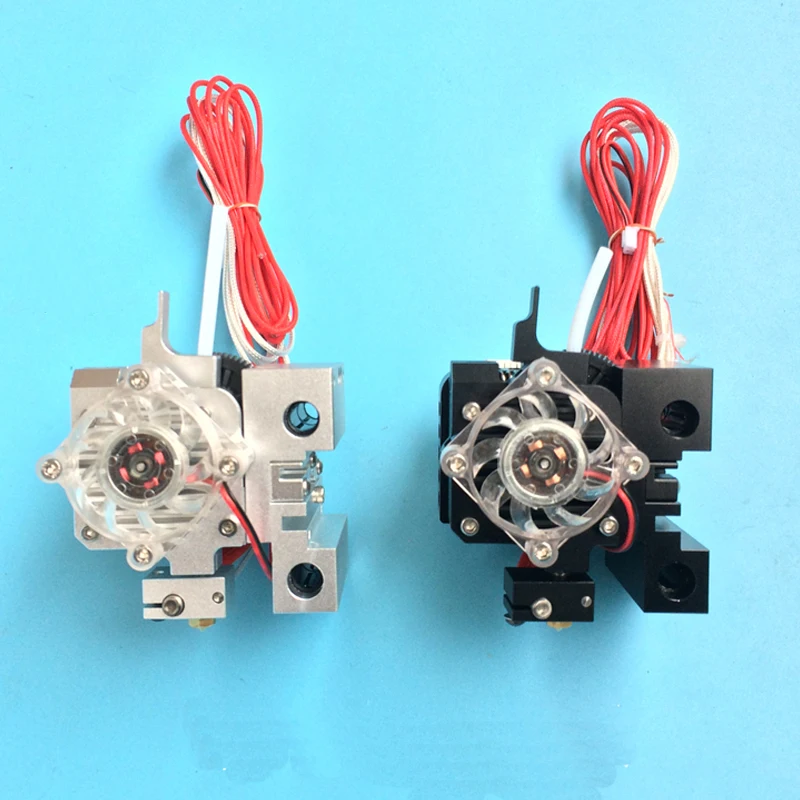

Extruders in general and direct feed extruder in particular can be divided into two main blocks:

- cold-end

- hot-end (literally "hot end") - a nozzle with a heater.

Cold-end , in turn, consists of a gear driven by an electric motor (direct or gear connection) and a clamping mechanism. A rotating gear removes the filament from the spool and passes it into the heater, where the thermoplastic changes its state of aggregation from solid to viscous under the influence of high temperatures, which allows it to be extruded through a nozzle and given the desired shape.

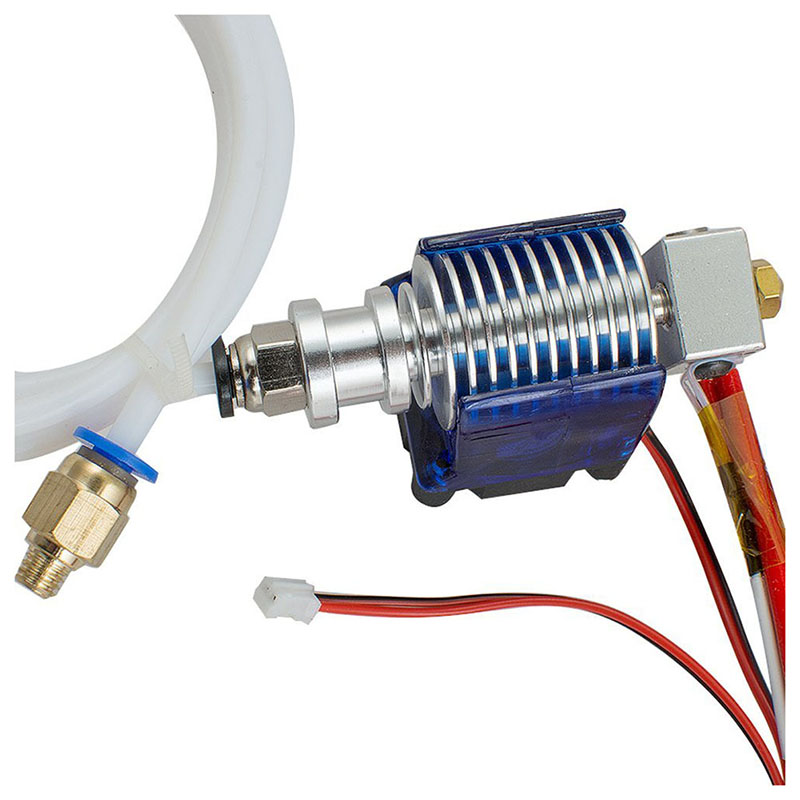

Hot-end is made of aluminum or brass (due to the high thermal conductivity of these metals). The heater consists of a spiral (nichrome wire) and a pair of resistors, as well as a thermocouple for temperature control.

During operation, the hot-end heats up because the melting temperature of the plastic is high enough. At the same time, the rest of the system must remain cold throughout the entire operation cycle. To prevent premature melting of the thermoplastic, there is a heat insulating insert between the "hot" and "cold" ends. Moreover, the extruder is sometimes equipped with an additional heatsink with a fan.

Moreover, the extruder is sometimes equipped with an additional heatsink with a fan.

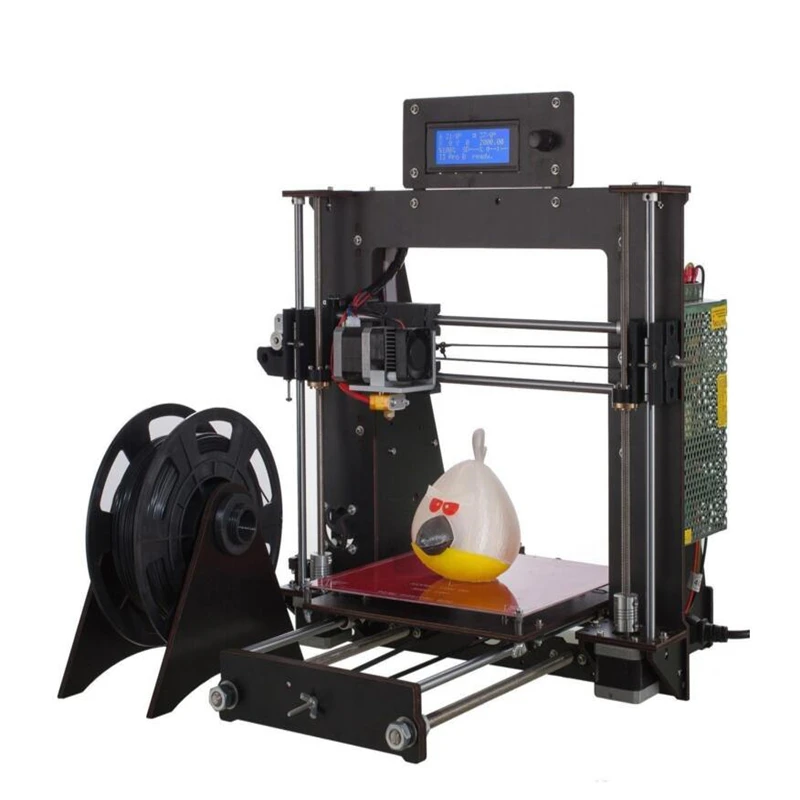

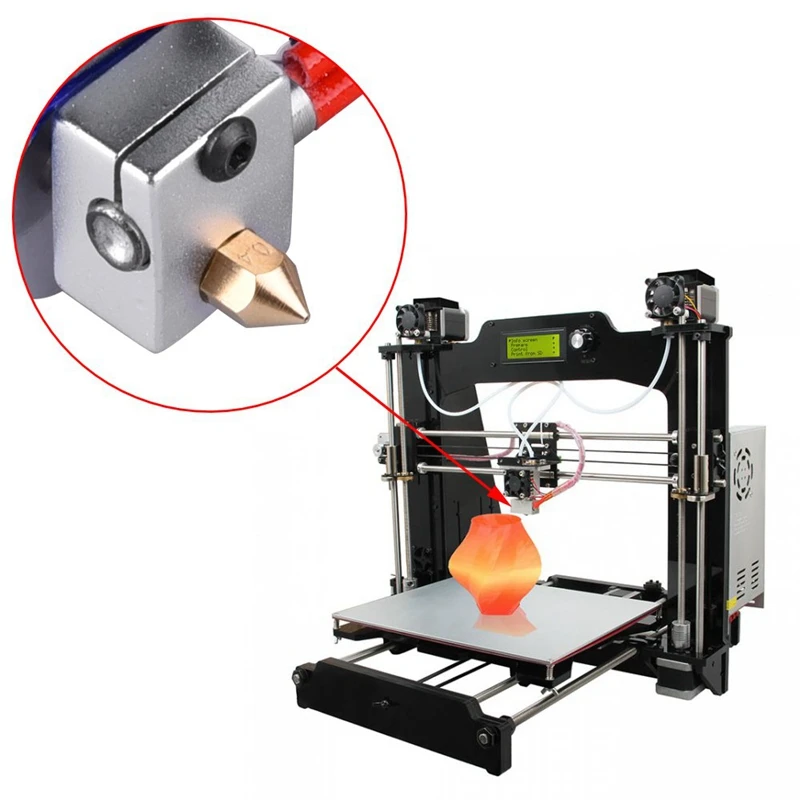

Another type of printhead is bowden extruder extruder (English Bowden extruder ). They differ from direct filament extruders in that the hot-end and cold-end components are spatially separated: the heater and nozzle are located on the print head, and the feeder is located on the frame of the 3D printer.

The filament is fed through a long Teflon tube, however, if there is no Teflon, then an ordinary plastic one is also used, but then a more powerful engine must be installed, as there is frictional resistance in the supply tube.

The tube is needed so that the plastic thread does not bend and is fed into the hot end with decent pressure and speed.

Here is a small video review of the bowden extruder - the video shows a modified version for a delta 3D printer.

The advantage of such a conceptual solution is the reduction in the dimensions and weight of the print head, the minus is that the supply of thermoplastic to the nozzle becomes not as reliable as in direct feed extruders.

Important details to consider when choosing a head for your homemade 3D printer.

Material . Extruders can be equipped with either 3D printed or cast components. It should be borne in mind that the cast parts are stronger, which is especially important if we are not talking about the case, but about those parts of the system that are constantly under stress. Printed components are cheaper, but their strength is an order of magnitude lower than that of cast ones. On the other hand, you can always print spare parts for the 3D printer extruder yourself.

Filament supply . The quality of the feed mechanism determines the continuous supply of filament to the heater, which means it ensures uninterrupted printing. The fact is that the plastic for printing on the way to the nozzle can get confused. If the electric motor has sufficient power, then even the presence of small entanglements will not affect the operation of the entire system.

Feed roll type .

Another problem that may occur is thread slippage due to poor grip on the feed roller. This is true when printing with nylon filament on 3D printers designed to use ABS or PLA thermoplastics, since the feed wheels are made with smooth teeth here. In such cases, it makes sense to use a roller with sharp teeth.

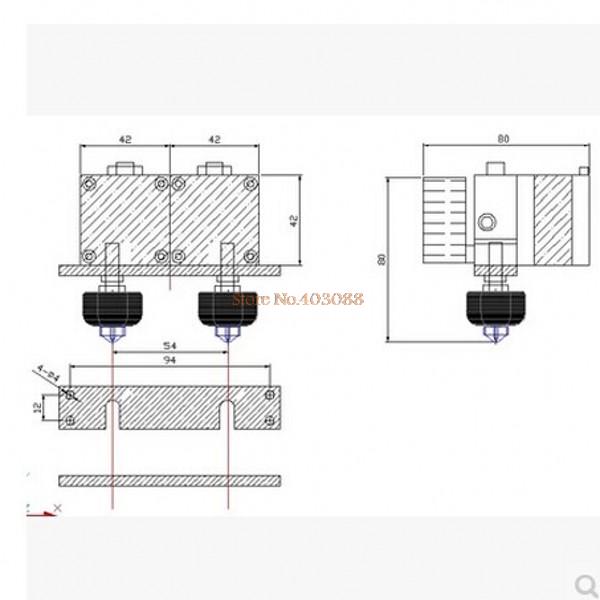

Extruder nozzle size . Printheads are equipped with nozzles with a diameter of 0.4 - 0.5 mm, or 0.2 - 0.3 mm. It all depends on the context in which you plan to use the 3D printer. If the detail of the drawn objects and the increased accuracy of their positioning are important, nozzles of smaller diameters should be chosen. Here it should be borne in mind that the smaller the size of the nozzle, the greater the likelihood of clogging, and the more powerful the electric motor is needed to extrude the thermoplastic. In other cases, extruders with a standard nozzle size of 0.5 mm will be the best option.

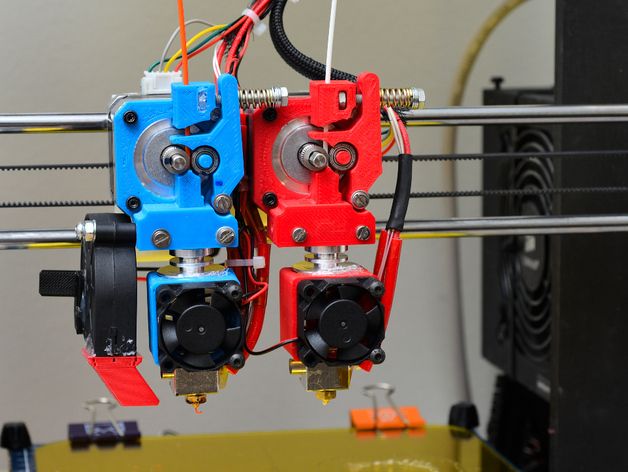

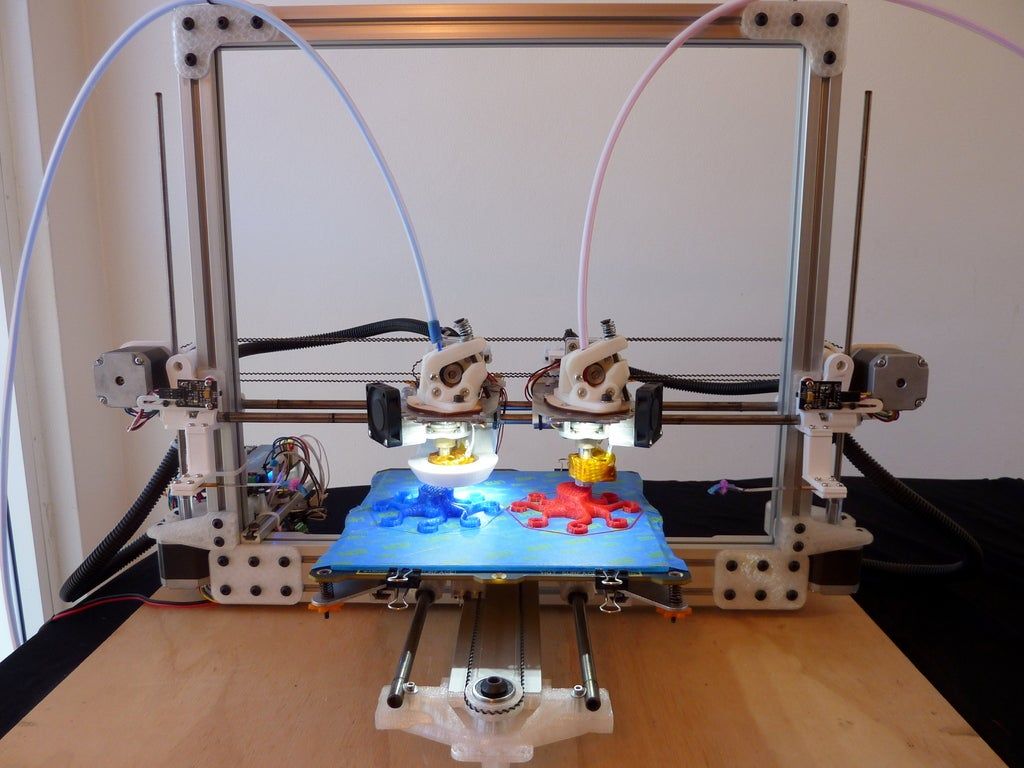

Currently, there are several models of 3D printers with two and three extruders (MakerBot Replicator Dial, 2X).

The dual extruder printers are useful for creating support structures and printing two-color objects because they can use two types of plastic. One of them can be dissolved in ordinary water and used to print support parts, and the second extruder is filled with already working PLA or ABS thread.

The disadvantage of dual extruder printers is that both extruders are attached to the same print head, and therefore simultaneous printing is defective: the printer has to use the extruders separately, as needed.

However, there is also a method of simultaneous printing - "Ditto printing". In this case, the extruders work in parallel and create copies of the same object. There are also some downsides here. The technology has a very limited use, since it produces only small one-color objects, or large two-color objects with a repeating pattern.

In addition to these problems, 3D printers with multiple extruders have two more significant, but standard for new products, disadvantages - price and complexity of setup.

The technology is still "raw", which manifests itself in a decrease in the speed of the device due to an increase in the dimensions and weight of the print head. In addition, during operation, a nozzle that is not involved in printing, at best, leaves traces of the filament on the surface of the drawn object, and at worst, it can deform it.

The versatility of the 3D printer's print material supply system gives free rein to the imagination in choosing the composition of the printing mass. You can use not only thermoplastics, but also clay, plasticine, melted chocolate, silicone and other pasty materials. The only caveat: extruders in this case are equipped with a special syringe, which is filled with the above substances. The syringe rod is driven either by compressed air or by a stepper motor.

Extruder for 3d printer: what does it consist of and how to choose it?

03.10.2017

Any printer for three-dimensional printing has certain features in its design. The main component of each is an extruder for a 3d printer. In simple terms, this is a print head that creates new items. Its principle of operation is simple: a special nozzle squeezes out plastic through it, from which a 3D pattern is formed.

3d printer extruder design

A standard 3D printer uses filamentous plastic. There are many varieties of it, but ABS and PLA are commonly used. Although the materials may differ, the design of the extruder is made according to the same principle.

Any extruder for a 3d printer consists of two parts:

- cool-end block is responsible for feeding the filament. Its design includes a drive from an electric motor, a clamping mechanism, gears.

Due to the rotation of the gear, a thread of plastic comes out of the coil, which passes into the heater. There, the thread becomes viscous under the influence of high temperatures. This helps to squeeze it through the nozzle and turn it into the desired shape.

Due to the rotation of the gear, a thread of plastic comes out of the coil, which passes into the heater. There, the thread becomes viscous under the influence of high temperatures. This helps to squeeze it through the nozzle and turn it into the desired shape. - hot-end block is a nozzle with a heating element. It is usually made of aluminum or brass, as these materials have good thermal conductivity. The heater consists of a nichrome coil, several resistors and a thermocouple. During operation, this block heats up, which contributes to the melting of plastic. The thermal insulating insert between the blocks is responsible for cooling the working surface.

How to choose an extruder?

In order for a 3D printer to work efficiently, you need to choose a print head of the same quality. How to choose an extruder for a 3d printer is a difficult question, but there are a few points that will help you make the right decision when buying: