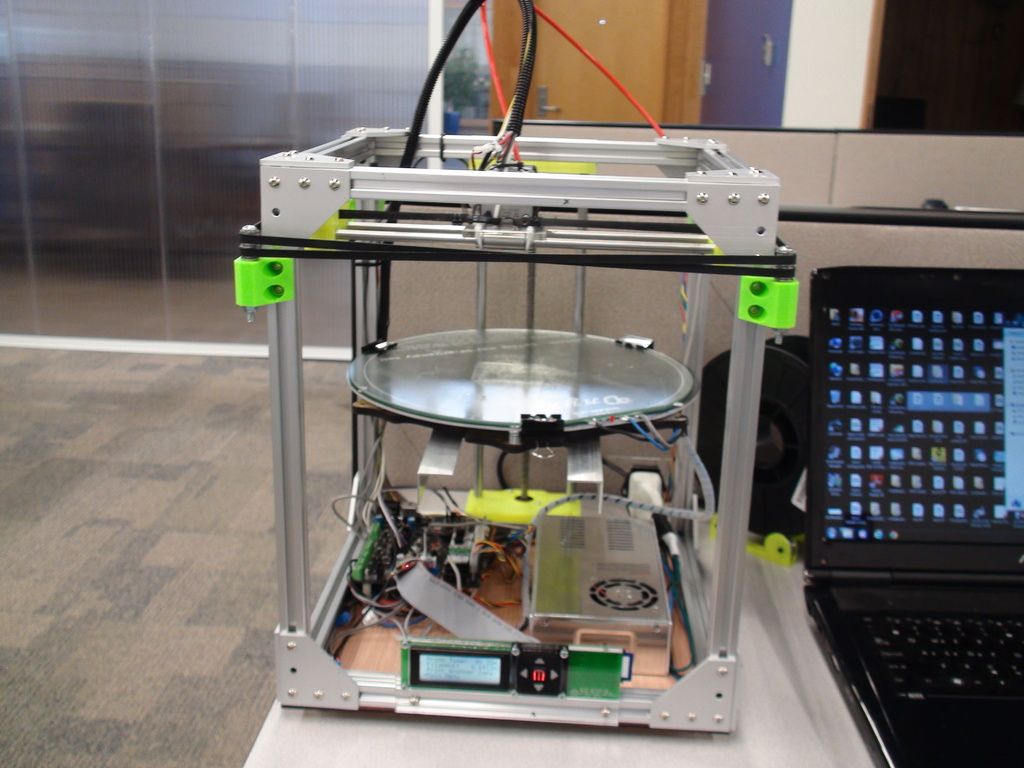

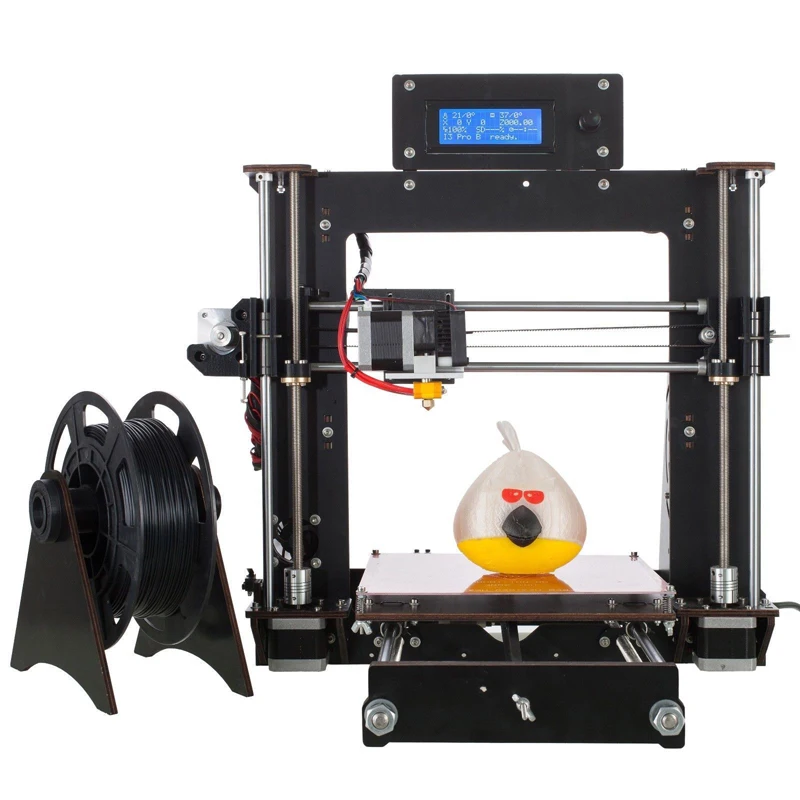

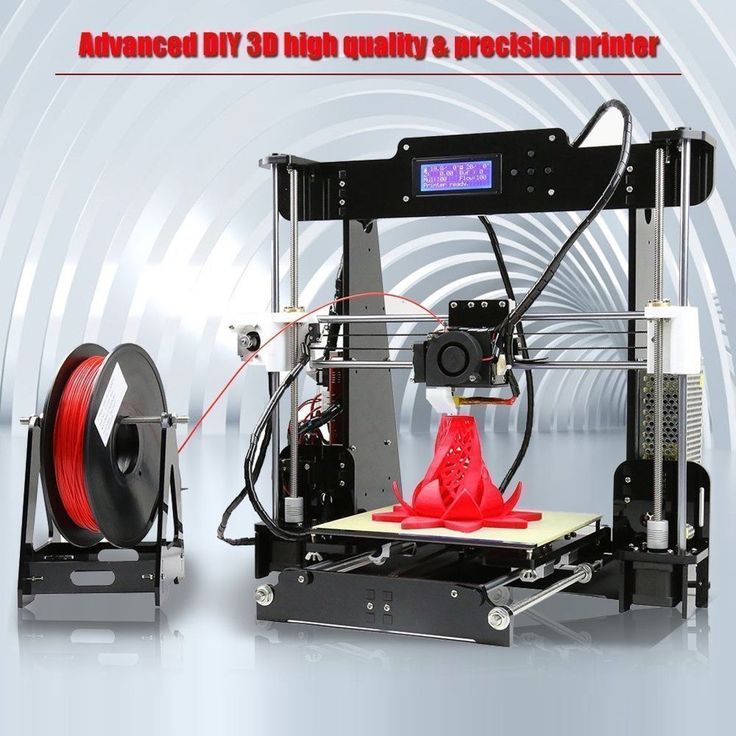

Mk8 3d printer

MK6 Vs MK8 Vs MK10 Vs E3D V6 – Differences & Compatibility – 3D Printerly

Being in the 3D printing field I’m sure you would have seen these MK6, MK8, MK10 and E3D V6 terms thrown around without knowing the actual differences. I’ve made this post for that exact reason, to set out and explain, compare and answer what makes each nozzle different.

Depending on what 3D printer you have, there will be a certain extruder that is compatible for you.

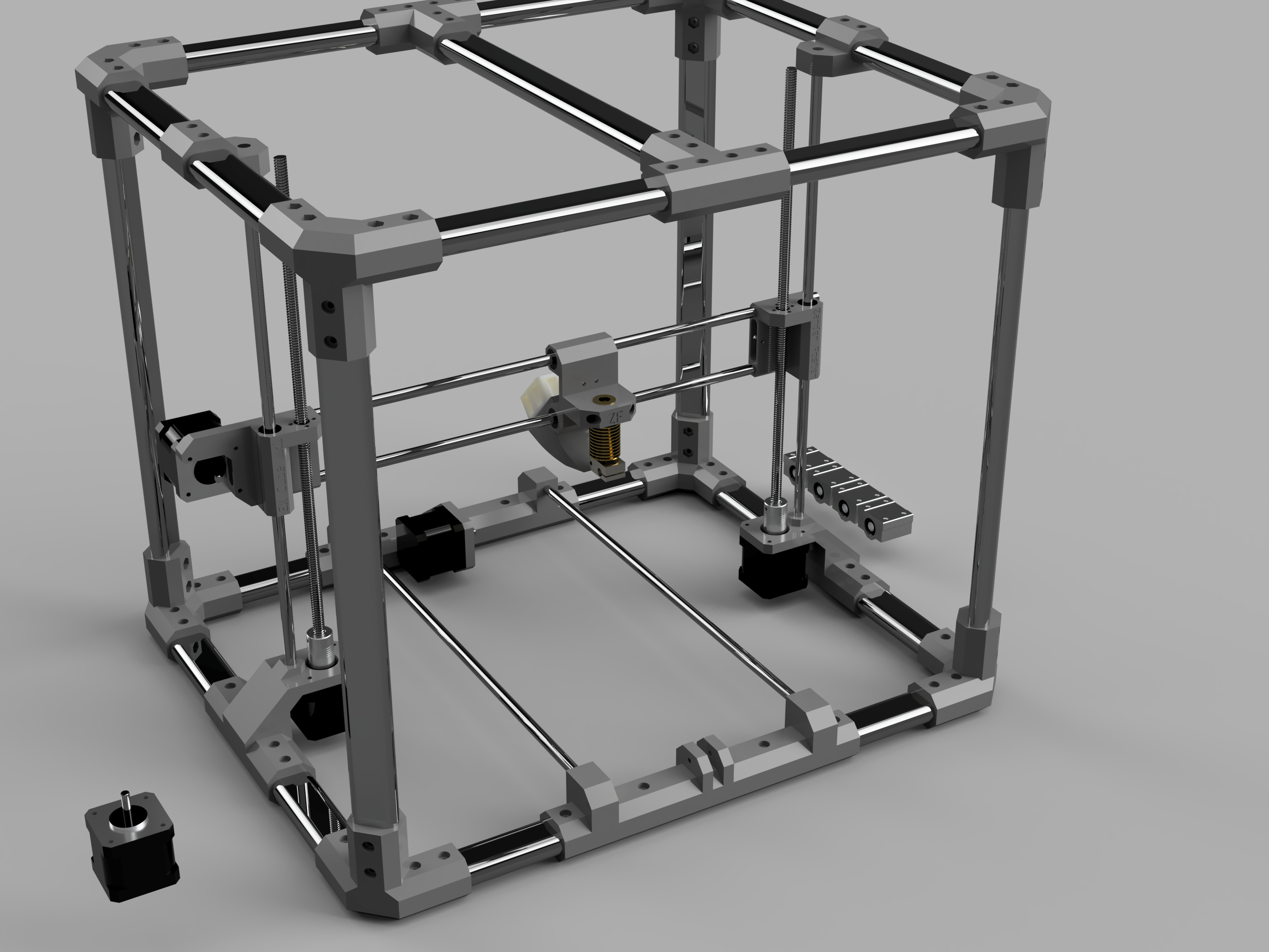

The MK6, MK8, MK10 & E3D V6 are a series of hotends, extruders and nozzle combinations which come together to make a system which allow filament to pass through the 3D printer down to the nozzle, known as an extrusion system. There is compatibility between the MK6, MK8 & V6 range.

The name ‘MK’ came about by the common practice of distinguishing versions in a series of products (shortened from Mark).

It’s similar to how militaries give number designations to their arsenal (Mk 6 assault boat) or even the British Railway production series (Mark 1, 2, 3 British Rail coaches).

It began with the Makerbot brand starting their own series of hotends using MK as their foundation.

It started from MK1 and to my knowledge has gone all the way up to MK11 so far but it isn’t very common in the mainstream 3D printing market. The mains ones you would have come across are the MK8, MK10 & E3D V6 range.

I’m going to get into the details of what makes each nozzle different, while also comparing compatibility and other bits of information so read on to find out.

- Make sure if you are getting an extruder, it is compatible with your 3D printer

- The differences between the nozzle types are quite small, but can make a difference

- If you use the wrong nozzle on a hotend, it might just not work or could actually lead to some damage.

If you are interested in seeing some of the best tools and accessories for your 3D printers, you can find them easily by clicking here (Amazon).

MK6

These terms MK6 and so refers to the version in a long series of different parts. It refers to the extruder, hotend and nozzle and these usually come as a kit so they can all be put together, but can be bought individually.

The MK6 catered more towards 3mm filament since it was before the 1.75mm was as popular as it is today. It also was mainly made for printing ABS rather than PLA.

Check out my article explaining the Differences Between 1.75mm vs 3mm Filament, and giving some useful information behind the two sizes.

The MK6 range, to my knowledge was the first commercially available hotend sold as a whole kit rather than individually. It has a stainless steel heater block whereas the MK6+ upgrade kit has an aluminum block which a different design, making it smaller and lighter.

The MK6 nozzle has an M6 threading size meaning the diameter of the thread measures up to 6mm.

When you want to upgrade a certain part you just have to make sure it follows the same type of threading (screwing in part) and is compatible with your current parts. Once you purchase a 3D printer you’ll know which range is compatible.

Once you purchase a 3D printer you’ll know which range is compatible.

Extruders from MK6 and below really don’t have much of a bearing in today’s 3D printing world because they just didn’t keep up to performance and quality standards and had a tendency to wear out and slip/grind up filament.

Comparison

We don’t really compare MK6 to other ranges since it wasn’t up to high standards and was still a working progress at the time. Now we have extruder systems which beat the MK6 and below series with ease.

The MK7 was the first extruder which made the move to dedicated 1.75mm filament extrusion. The MK6+ had parts which could be adapted to fit a 1.75mm filament but it didn’t work quite as well as they thought.

The MK7 incorporated the all-metal thermal barrier and allowed users to print PLA or ABS.

However, the MK7 feeder used a preload with a plunger and fixed distance washers which was a huge drawback as the plungers wore out and damaged the filament. Unfortunately, they didn’t have V groove bearings either.

Unfortunately, they didn’t have V groove bearings either.

3D Printer Compatibility

MK6 – Makerbot, Creality CR10, Ender 3 Pro, Tevo Tornado, Anet A8, Prusa I3 and so on.

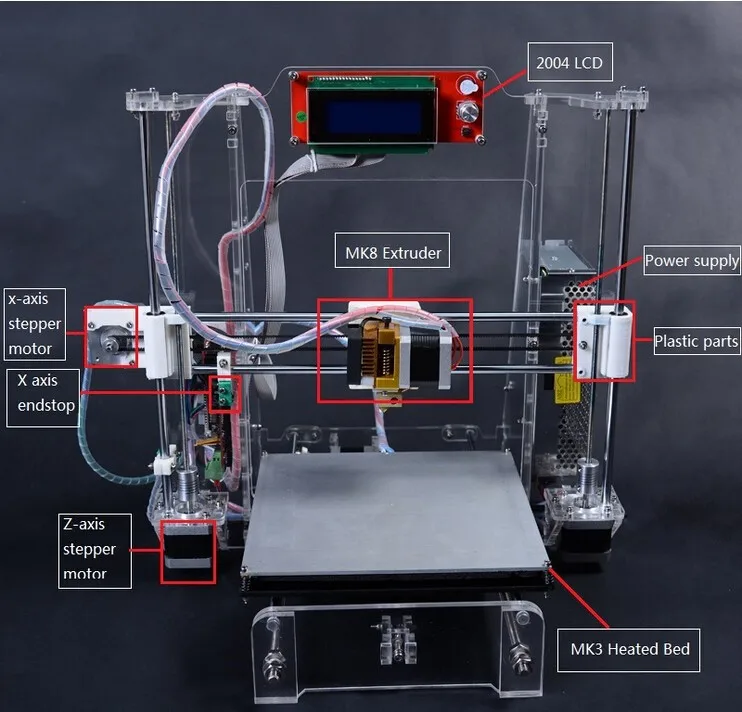

MK8

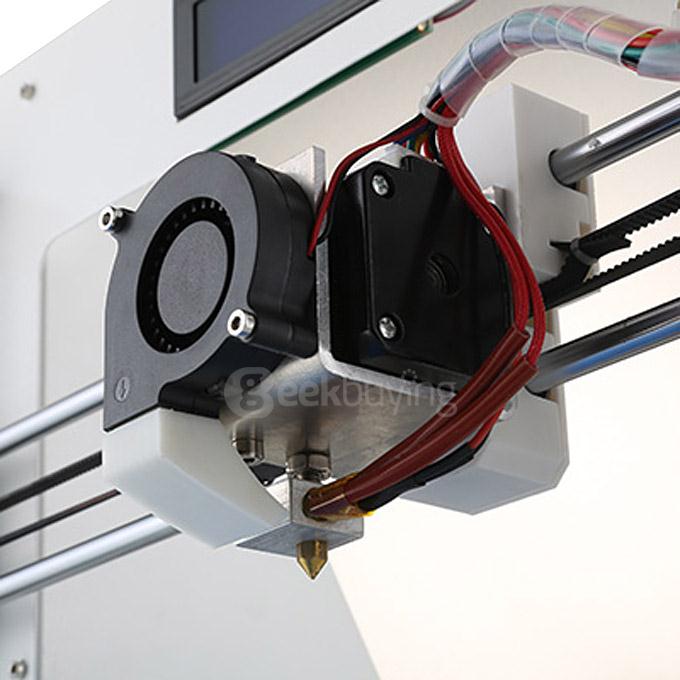

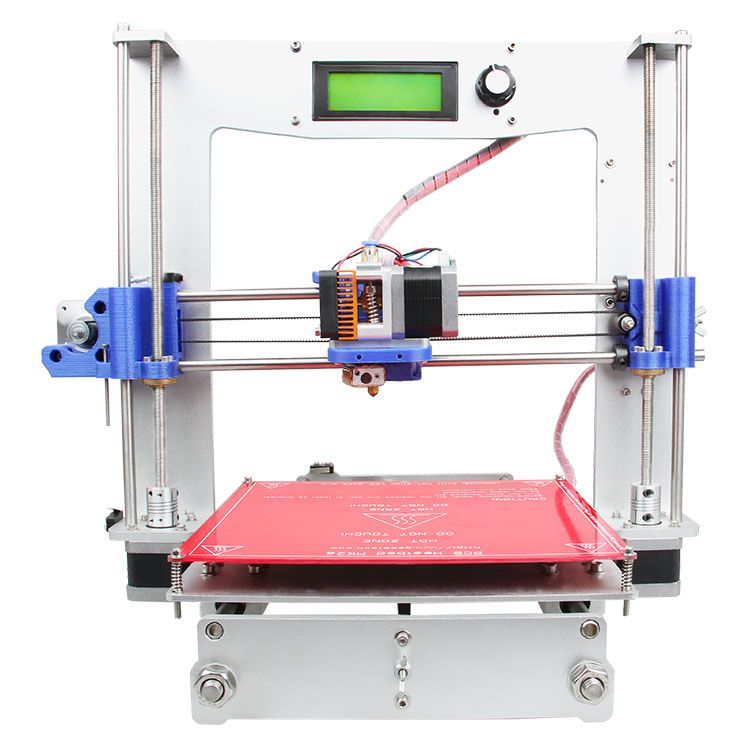

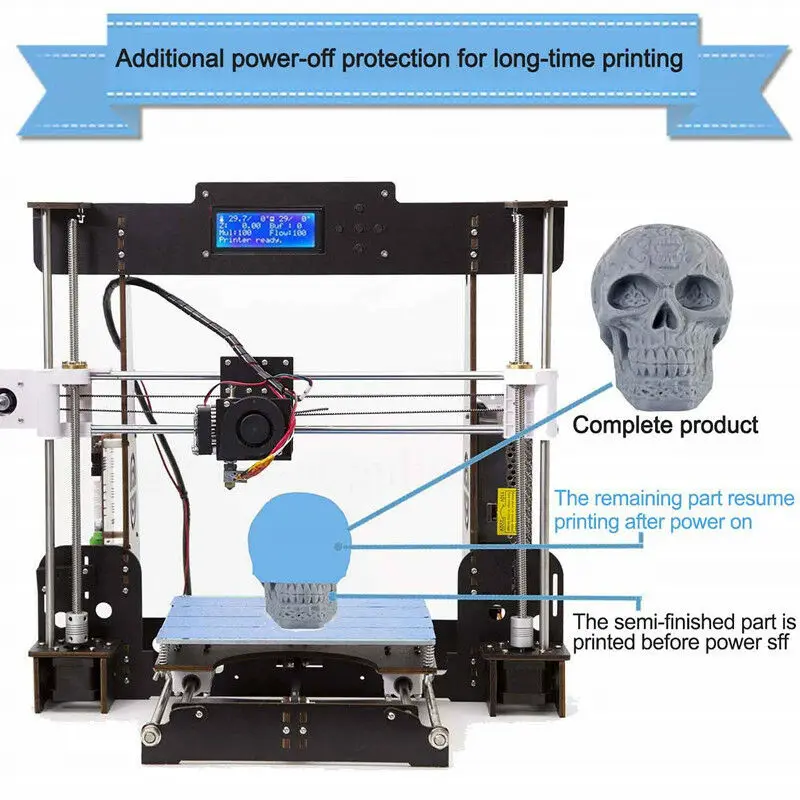

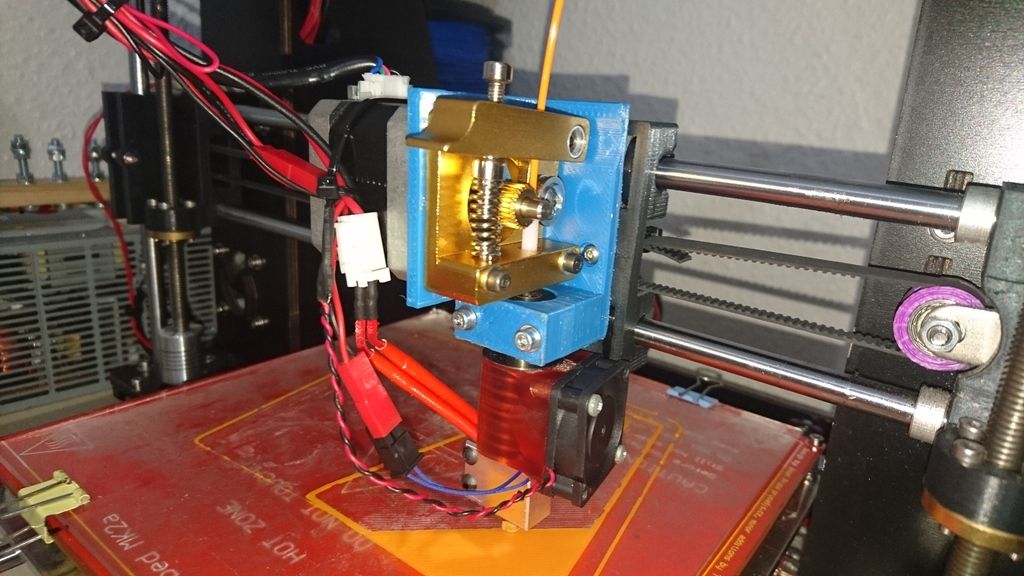

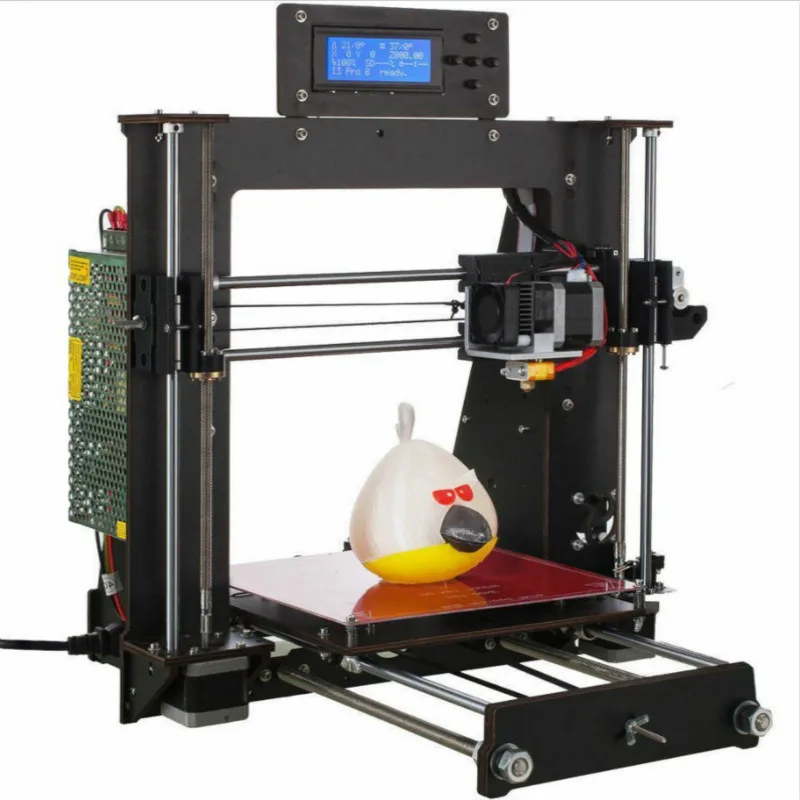

The Makerbot Replicator was responsible for the all new dual extruder hotend setup called the MK8. It had a cooling bar which was thicker than the MK7 range but it shared the same all-metal thermal barrier.

The MK8 had small differences in the nozzle geometry from within and externally which supposedly had a positive impact on printing performance.

An MK8 nozzle as you can see from the video above has sharper, more angled sides coming off the tip of the nozzle, meaning it’s not as flat as other nozzles. It has a very pointy look to it from the sides all the way through to the tip.

The MK8 nozzle also uses the M6 threading size. This means an MK8 nozzle can be used with an MK6 extruder and vice versa.

You can check the size of the threads of your nozzles by using some simple calipers which is a necessary part of the 3D printing tool kit.

If you don’t have calipers I would recommend the Rexbeti Digital Calipers. It’s a stainless steel, water-resistant measuring tool that allows you to measure precisely with smooth operation. It’s highly reliable and should last you years to come.

The large LCD screen, easy reset button and large battery are only some of the key features.

One of the best MK8 nozzle sets I could find on Amazon is the Disacayson 0.4mm Nozzle with Free Storage Box (30 pcs).

It has the highest ratings out there for MK8 nozzles, it’s very easy to install and they have a 1-month unconditional refund policy, so satisfaction guaranteed!

Comparison

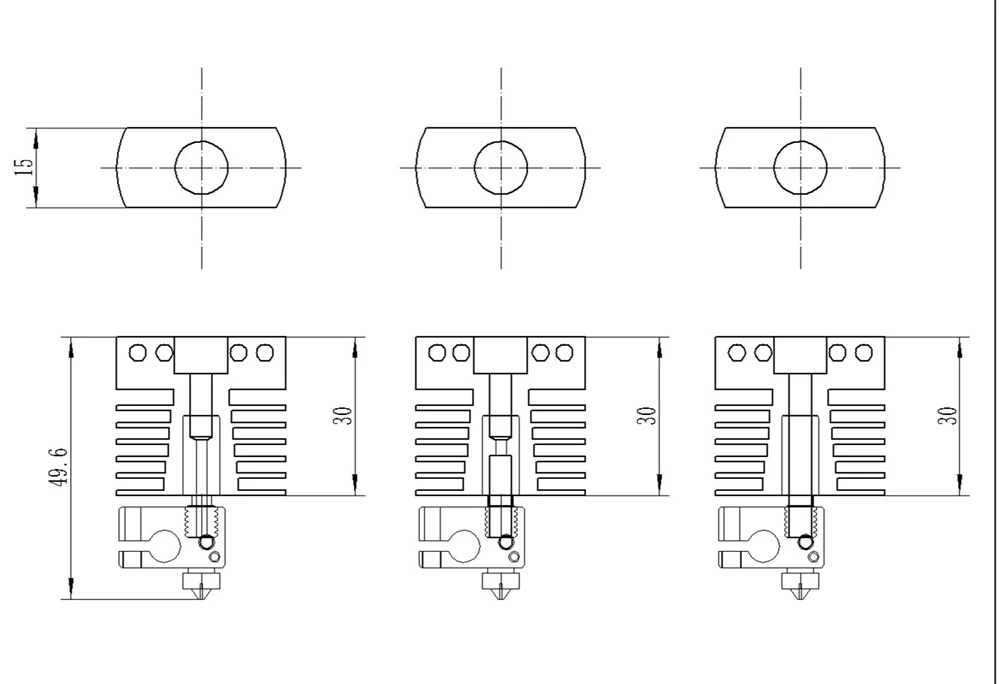

One of the differences between an MK8 hotend and a V6 hot end is the length. The overall length of the V6 is shorter than the MK8 but it has a longer thread.

If you are changing from a MK8 to a V6 nozzle you might have to move your Z-End-stop switch up a little bit so you can still level out your bed.

The E3D V6 nozzles in hardened steel are usually easier to find rather than hardened steel MK8 nozzles.

The threading hole of an MK8 nozzle has a smaller hole compared to an MK10 nozzle.

The stock MK10 design uses a PTFE tube as the thermal barrier within the filament guide tube, resulting in a reduced melt rate of filament compared to the MK8 design with the stainless thermal barrier tube.

You can see this during filament loading, where the same filament at the same temperature will flow a little bit better on the MK8 design.=

In terms of stringing, there should be little difference between the two once retraction and temperature are properly adjusted.

The MK10 hotends do run a little hotter than MK8 hotends for their indicated temperatures – so the MK10 may be prone to stringing if you don’t lower the temperature.

In terms of parts costs, there are far more MK8-compatible replacement nozzles out there (due to its M6 thread which is a very popular thread size for a lot of printer builds.

We sell our high lubricity wear-resistant MK8 and MK10 nozzles for the same price though.

3D Printer Compatibility

MK8 – Same as MK6 because it has the same M6 threading.

MK10

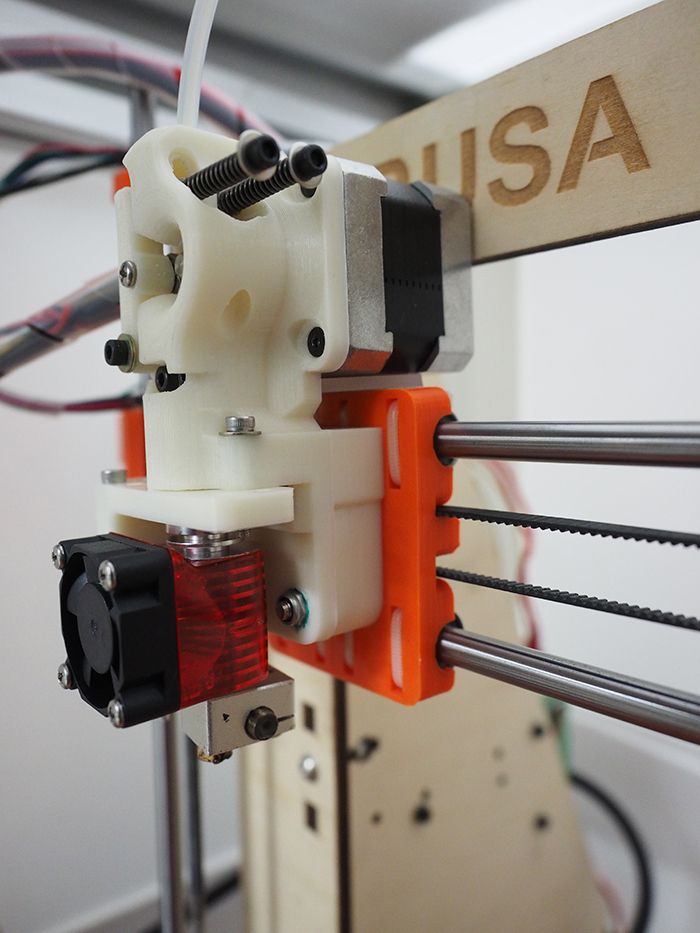

MK10 was a complete change of the hotend, using the MK9 as a base model (uses MK9 feeder parts). With this range of hotends you have smooth OD thermal barriers along with a 4mm OD 2mm ID PTFE liner.

One of the main differences is the MK10 uses M7 threads rather than the M6 threads which all the previous models use.

The main reason for this is because a 4mm PTFE liner doesn’t have enough metal to make the outer tube with M6 threads. You won’t be able to use the MK10 range with any other previous hotend models since they have different sized threads.

So make sure you don’t purchase an MK10 nozzle if you have an MK8 extruder and vice versa.

MK10 is completely incompatible with all previous hotend parts. Every part is different.

For a solid MK10 nozzle set, the Umlife MK10 Brass Nozzle Set is a great choice. It comes with:

- 4x 0.

4mm nozzles

4mm nozzles - 1x 0.2mm nozzle

- 1x 0.3mm nozzle

- 1x 0.5mm nozzle

- 1x 0.6mm nozzle

- 1x 0.8mm nozzle

- 1x 1mm nozzle

- 5x cleaning needles

Comparison

You can identify an MK10 nozzle by looking at the angle of the metal sides that come off the tip of the nozzle. They are at a roughly 45 degree angle and is relatively flat compared to the other nozzles out there.

So you’ll have the tip of the nozzle, then a 45-degree angle then the vertical angle leading to the thread of the nozzle.

The threading hole of an MK10 nozzle will have a bigger hole compared to the other nozzles because its purpose is to fit the plastic PTFE tube which feeds filament straight through to the nozzle.

The threading is called an M7 thread because it measures up at 7mm diameter

3D Printer Compatibility

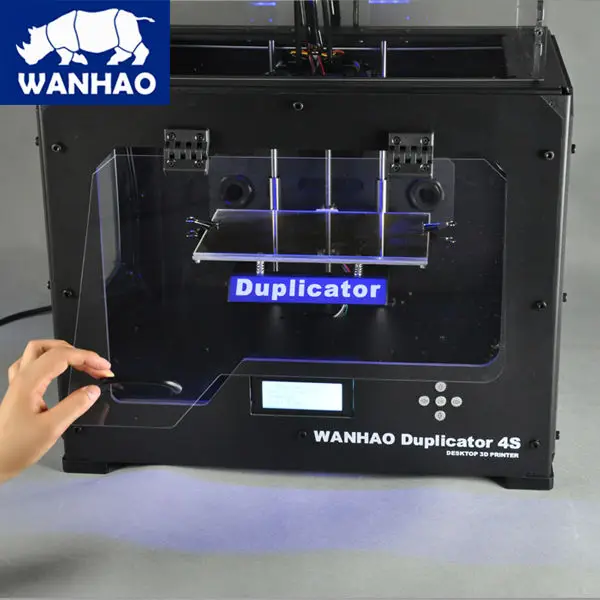

MK10 – Monoprice Maker Select, Wanhao Duplicator i3 (D4, D6), Qidi Tech, Cocoon Create, Flashforge Creator (Dreamer, Finder)

E3D V6

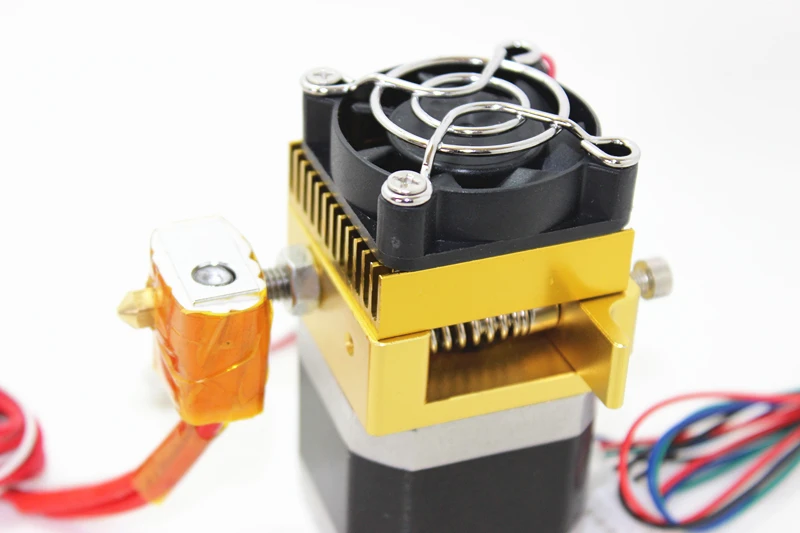

The E3D V6 range is one that has it’s own ecosystem (M6 thread) of parts that all work together seamlessly. It’s very well-known for having high quality, reliable branded parts that get the job done.

It’s very well-known for having high quality, reliable branded parts that get the job done.

The Hardened Steel nozzle that E3D sell is one that you can rely on when printing abrasive filaments that would rip through standard brass nozzles.

Rather than have to constantly change your nozzle over when wanting to print with abrasive filament, you can just have this nozzle installed, slightly increase the temperature and get great results.

Top reviews, amazing performance and long-lasting durability are just some of the reasons why you would go with the E3D V6 nozzle.

Compatible with any 3D printers that use the E3D V6 ecosystem (M6 thread), including Prusa i3 and i3 MK2 3D printers.

The internal geometry of V6 Nozzles is optimized to reduce back-pressure, ensuring a smooth, easy flow of filament while improving the effectiveness of retraction.

The flat surface tip of the nozzle which flattens down the layer is custom machined to each nozzle size. A small nozzle tip gives you high precision, and a wide nozzle tip assists in the smooth printing of larger layers.

A small nozzle tip gives you high precision, and a wide nozzle tip assists in the smooth printing of larger layers.

3D Printer Compatibility

E3D V6 – Same as MK6 & MK8 with M6 6mm threading.

Comparison

When you look at the extruders you definitely see differences between them such as some having the block fuse horizontal or vertical with a longer nozzle.

Nozzle Thread Type & Length

There are two main important things you want to take into account when looking at nozzle thread.

That’s the thread type and the thread length. If you don’t have the correct thread type you just won’t be able to the nozzle in so it would be of no use.

If the thread length is incorrect you’ll end up in a situation where, if it’s too long, you have a lot of the nozzle sticking out of the heat-block so it won’t heat up efficiently.

If it’s too short, you’ll have a big gap between your heat-break and the nozzle, which will result in filament not being able to extrude properly and cause blockages.

The good thing here is there is quite a large difference between the thread length so if you know what you’re looking for, you can get the right one.

A standard E3D V6 nozzle will have a 5.5mm length thread and is the M6 x 1mm pitch (the most common thread type).

A Volcano nozzle which also uses the M6 x 1mm pitch has a length of 14mm. The Supervolcano nozzle is even longer.

Your extruder design will have a clear nozzle that it is compatible with.

I would say there isn’t necessarily a thread type which is better than another performance-wise. There are specific design reasons why an extruder will use a thread type.

The main thing you should worry about is the thread length. The longer the nozzle, the longer your heat-block is likely to be. If you have a nozzle which isn’t the correct, your printing performance will be negatively affected.

So, Which Extruder Should I Buy?

There are several extrusion systems that are tried, tested and work very well. Some charge a real premium, while you can still get a high-performance extrusion system for a reasonable price, it really depends on what level of 3D printing you are trying to get to.

Some charge a real premium, while you can still get a high-performance extrusion system for a reasonable price, it really depends on what level of 3D printing you are trying to get to.

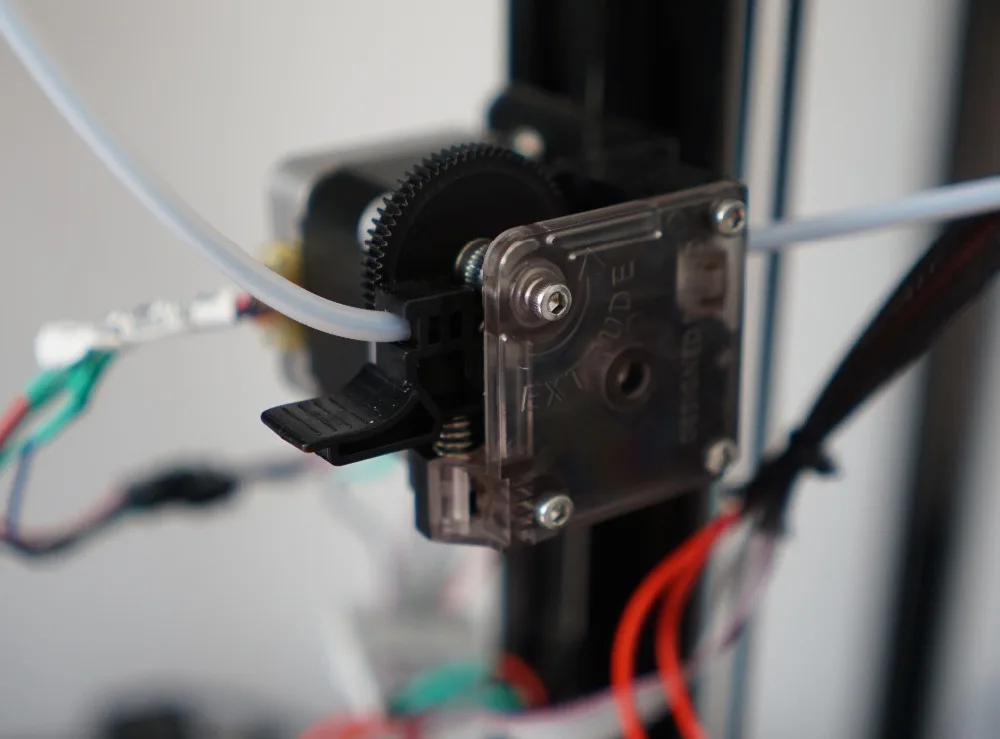

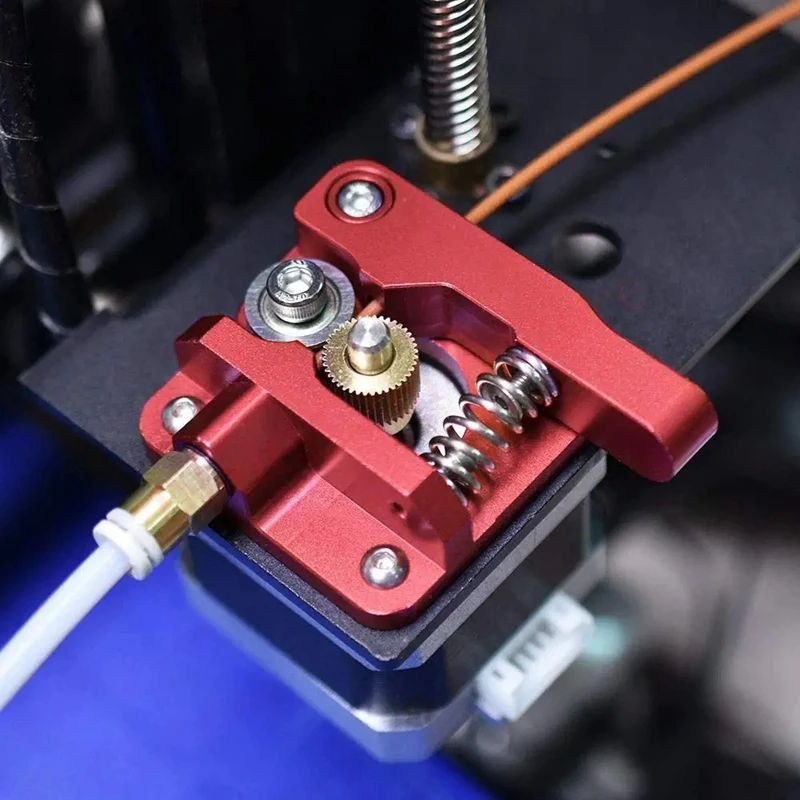

If you are happy with a simple, gets the job done, lower range type of extrusion system I would recommend the Redrex Upgraded Aluminum Extruder.

- It’s a durable MK8 Bowden extruder with direct extrusion support and fits perfectly on the CR-10 Ender 3 series, TEVO Tarantula, Anycubic Kossel i3 Mega and much more.

- The ratings on this extruder are very promising and it sports an 18 month warranty

- You can print with all sorts of material including flexible TPU filament.

- Expect long-lasting performance with the 18 months warranty.

- It’s simple, easy to use and comes at a very convenient price!

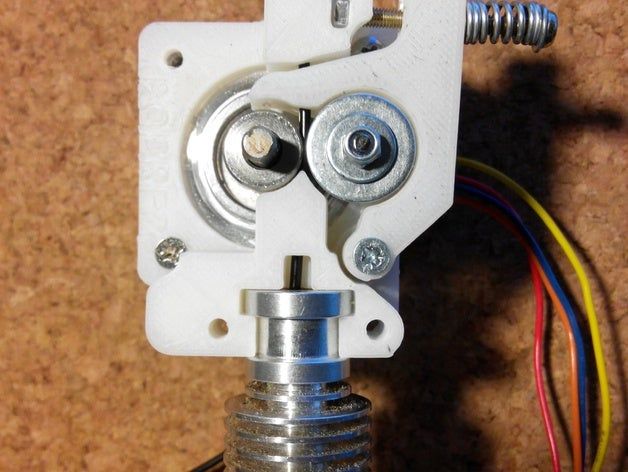

Some people want an advantage over having the lower range extrusion systems which I can understand. If you’re one of these people who want something mid-tier and are willing to spend a little extra, I’d go for the BMG Bowden Dual Drive Extruder.

- High performance extruder for your 3D printer

- It’s a TriangleLab BMG Clone which is a very high-end extruder for a fraction of the price

- Solves filament grinding issues

- The downside here is it takes a few extra steps to manually advance filament through it

For the 3D printer enthusiasts who take a lot of pride in their 3D printing quality and strive for the top range, I would recommend the E3D Hemera Extruder System. There are many reasons why this is the choice I would go for, you can get more in-depth information by reading my Hemera Extruder review.

It not only comes with one of the highest quality extruders in the 3D printing game, but also a state-of-the-art hotend system with patented cooling designs that go above and beyond normal expectations.

- Dual drive extrusion system

- Convenient mounting system with compact design

- Designed to support the user, easy to assemble and disassemble

- Heatsink design that reduces risk of warping and uneven stresses

- Can push filament with up to 10KG of force

If you love great quality 3D prints, you’ll love the AMX3d Pro Grade 3D Printer Tool Kit from Amazon. It is a staple set of 3D printing tools that gives you everything you need to remove, clean & finish your 3D prints.

It is a staple set of 3D printing tools that gives you everything you need to remove, clean & finish your 3D prints.

It gives you the ability to:

- Easily clean your 3D prints – 25-piece kit with 13 knife blades and 3 handles, long tweezers, needle nose pliers, and glue stick.

- Simply remove 3D prints – stop damaging your 3D prints by using one of the 3 specialized removal tools

- Perfectly finish your 3D prints – the 3-piece, 6-tool precision scraper/pick/knife blade combo can get into small crevices to get a great finish

- Become a 3D printing pro!

Which Nozzle Should You Be Using?

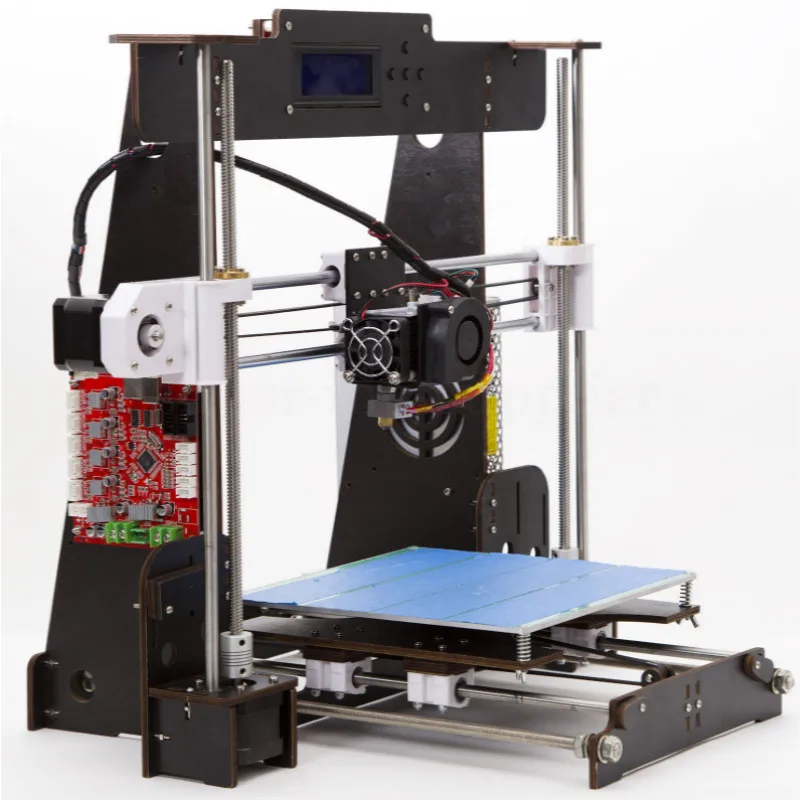

3D printing has completely changed how we create and produce products; it allows us to become more sustainable as advancements occur in this industry. There are now so many types of 3D printers and different nozzles you can use for those printers. Every nozzle will provide different features and designs, so you must understand which type can provide a specific outcome.

If you are looking to do smaller designs, an MK8 will work perfectly due to the smaller hole the product forms out of. The MK10 has a wider hole at the bottom, it will not be as accurate due to this, but it will provide bigger objects.

When you buy your 3D laser printer, you will want to learn as much as you can about the accessories you can invest in. This will help you create intricate objects at a faster speed. When you know which nozzle is best suited for your needs, it will change the way you create. You can learn more about the features and what each nozzle can provide for you. This is the ultimate guide to learn more about Mk8 and Mk10 nozzles.

What Nozzle Should You be Using?

If you are looking for something to create small fine details, you should always go for a smaller filament and thread. This will help you get the small details that would usually be incredibly hard for a larger thread.

If you are creating more massive objects, the Mk10 will be sufficient for you, but you will want to make sure it is compatible with your 3D printer.

Pros and Cons of an Mk8

There are a few pros and cons of using an Mk8 extruder or nozzle.

Pros:- It is more precise than the Mk10

- It is a higher quality

- This nozzle is compatible with more printers

- It is easy to clean while offline

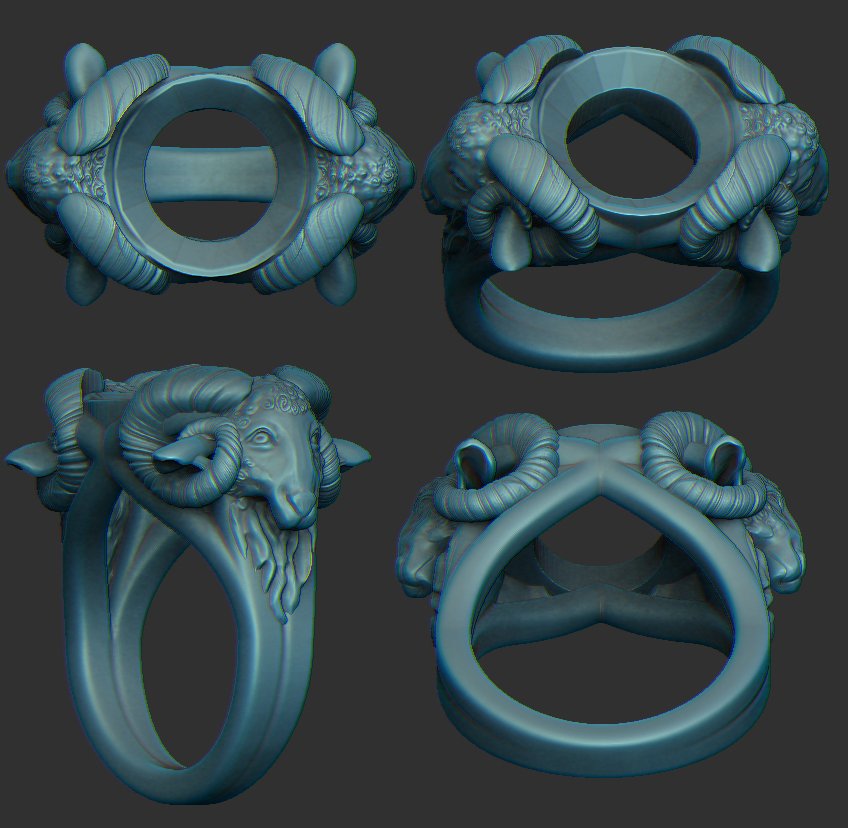

- It can create the most detailed jewelry

- It is slower than the Mk10

- There are fewer materials you can use with this nozzle

- You may have to replace it more depending on the material you print with

- There is a height limit

The Mk10 has some pretty amazing qualities that come in useful for printing; here is a list of pros and cons for them.

Pros:- This nozzle can print heavier and thicker materials

- It can print larger items

- This nozzle can help speed up the process

- It can use more materials to print, including the ones an Mk8 can

- The filament will not get stuck in the nozzle

- This nozzle cannot produce high quality, intricate designs

- It is not compatible with many printers

There are pros and cons to both nozzles, but neither of them is a terrible choice.

When You Should Choose the Mk8

- Fine Details. If you have an object printed that needs smaller and precise details, a small nozzle should always be printed.

- This is perfect if you have a lot of time. Your object will turn out a little bit better and more accurate, but you will have to print for much longer than usual because of the small feed you will have. So, this is only good if you have patience and time.

- If you are making art or jewelry, you should always opt for a small printer nozzle.

- Height must not go over 80% of the nozzle. This means it needs to be a shorter object.

- Suppose you are printing with something other than wood, glass, or metal. These have large particles that will clog the nozzle. So, if you are using some plastic, that is much better for a small nozzle.

Smaller nozzles are great for extreme detail in small objects of applications like textiles, jewelry, miniatures, or something that needs extra strength.

When to Choose the Mk10

Large nozzles may seem less superior than a small nozzle, but that is not true. They can handle much more materials and have some great benefits that you may want to utilize.

- You can print much taller objects with a bigger nozzle, which is excellent if you make something over a certain height. This is great for tall figures and can be painted in or add detail after the initial printing.

- Fast printing time because of the larger hole at the bottom. This allows more to come out at once but not in a precise manner. If you are in a rush to get something printed, this is a perfect choice.

- Things built with a bigger nozzle are more challenging. They may not be as sturdy in structure, but they will not break easily. This can be a great benefit if you’re looking for something that will hold up over time.

- If you plan on using glass, wood, or metal filament, this is a great option. You will still need to clean your nozzle after a print, but it will not get clogged in the process, which means you can watch it less.

- This is perfect for anyone who doesn’t mind low print quality resolution.

If you are printing bigger objects that don’t need many fine details or trying to use metal, this is a perfect option for you.

What to Expect with the Mk8

Both of these nozzles have unique features that maybe suited for your project. They are both well-made and can be of use to you. Here are the specific features of an Mk8 nozzle, and who should use it.

- Nozzle Shape- Makerbot created a totally new nozzle shape on the inside and outside of the printer. This can give you a unique look when compared to the other nozzles. It is also a tad bit smaller than the Mk10, which can be great for intricate designs and a specific look of objects. This nozzle also looks too pointed, unlike flatter versions.

- Cooling Bar- This is a thicker cooling bar than previous versions, which is unnecessary for all people but could be useful when printing objects.

- Dual Extruder- A great feature if you’re looking to use multiple materials and multiple colors at once. This isn’t on the top of everyone’s priority list when printing, but it will help you create objects that are uniquely yours.

- M6 Thread- This uses a smaller thread than the Mk10. Perfect for small details.

The best thing about Mk8 nozzles is they can work for many different 3D printers; they are very versatile. Especially if you are looking to use multiple colors or need sharper-looking objects that need something other than a flat nozzle.

What Printers Work with Mk8 Nozzles?

The best thing about these nozzles is that they are a great conductor of heat for various 3D printers, much more than the Mk10 nozzle.

- Creality Ender 5

- Creality CR-10 Mini

- Makerbot Replicator 1

- Numerous Rep 1 clones

- Makerbot Replicator mini

- BQ Witbox

- Craftbot

The list is extensively long. The second-best thing about this nozzle is that it can be used for most desktop 3D printers too! This is the perfect versatile nozzle. Chances are if you buy this online, you will be able to use it, and you will not be disappointed.

The second-best thing about this nozzle is that it can be used for most desktop 3D printers too! This is the perfect versatile nozzle. Chances are if you buy this online, you will be able to use it, and you will not be disappointed.

What to Expect with the Mk10

The Mk10 is a new version of the previous versions and is a lot harder to buy online because they are not common. If you buy online, be sure to go to a reputable website, because you can accidentally order the wrong pieces quickly.

- Hotend- This nozzle is not compatible with any previous models for hotends because the threads are a different size. So, you will need to buy the hotend and the nozzle to get the best outcome.

- Mk9 Feeder- Pretty much everything about this nozzle is different, including that it uses Mk9 feeder parts.

- M7- This nozzle uses M7 thread, unlike previous versions.

Though nozzles seem similar, there are differences in the size thread they use, creating different objects.

Now all nozzles will do what you need, but certain types may not work with your printer. The Mk10 is excellent but only for a select few printers that use 4mm PTFE tubes.

What Printers Work with Mk10 Nozzles?

A few types of 3D printers have 4mm PTFE tubes that will work for Mk10 nozzles. They are different printers from the printers that can work with Mk8 nozzles.

- Cocoon Create 3D Printer

- Wanhao Duplicator 4S

- Qidi Tech

- Monoprice Maker Select 3D Printer v2

- FlashForge Dreamer

There are a few more versions of these brands that you could easily use. However, you will want to be very careful; this nozzle will not work for many other types of 3D printers.

What Else You Need to Know About Nozzles

No matter which nozzle you choose, the Mk8 or Mk10, there are a few essential pieces of information to keep in your back pocket. These will help you maintain your printer and keep it running smoothly.

When to Change Your Nozzle

The nozzle is the one piece that is a good heat conductor and controls the thread. It takes a lot of wear and tears, the more you print things.

You will want to change it for three months if you use your printer frequently. If you use it less, you can wait up to six months before changing the nozzle.

You know you need to change your nozzle frequently, but what does a nozzle do? Is it necessary to use a nozzle? Yes! This is one of the most significant pieces to create the object you desire. It is the final piece that creates the part you need. The item shoots out of the nozzle and is controlled by the arms of the 3D printer.

Replacing a Broken Nozzle

If your nozzle breaks, you can easily replace it, and there are a few simple steps you can take to make sure it is fitted correctly.

- Heat the end; this will create a loose nozzle

- Remove the nozzle with your tools because it will be too hot to touch

- Add on the new nozzle with your tools

- Then print

Suppose you have a nozzle that is not working correctly, even if it is new. You can easily clean it by heating it up the nozzle and taking a cleaning tool to get rid of any gunk that may be stuck in it.

You can easily clean it by heating it up the nozzle and taking a cleaning tool to get rid of any gunk that may be stuck in it.

Other Nozzle Options

Though we focus on two types, there are a few other industry favorites that can help you do an excellent job on the printing. They are identified as how wide they are and the materials they are made from.

- Brass Nozzles- This has an exceptionally high heating rate, and it is used for many of the nozzles you will find on the market. They are perfect for creating things for a printer that uses high heat because it is a great thermal conductor, one of a nozzle’s sole purposes. The problem with this is that it is usually too abrasive for sensitive materials. This means a brass nozzle will wear out incredibly fast, and not all materials will work for this piece.

- Hardened Steel Nozzles- Though brass nozzles are cheap and some of the go-to choices, researchers found a less abrasive, budget-friendly material for nozzles.

This led them to hardened steel nozzles. This is a long-lasting nozzle that is a great heat conductor but cannot get as hot as brass, is easy to make, and not ungodly expensive. However, if you are making something like jewelry and will be next to your skin, this piece contains lead. You will not want anything like plates that touch your food or jewelry to be made with this nozzle.

This led them to hardened steel nozzles. This is a long-lasting nozzle that is a great heat conductor but cannot get as hot as brass, is easy to make, and not ungodly expensive. However, if you are making something like jewelry and will be next to your skin, this piece contains lead. You will not want anything like plates that touch your food or jewelry to be made with this nozzle. - Stainless Steel Nozzles- Unlike the hardened steel, this does not contain lead. The best thing is using stainless steel nozzles for food ware, and the FDA has approved jewelry. It has a hardness that makes it last, but will not be too rough on the filament. This is a perfect choice for anyone who is creating products, but brass is always cheaper.

- Nozzles Ruby- This is a brass nozzle but at the very tip is a bright red ruby. The appearance is somewhat striking and will add some flare to your 3D printer. This ruby provides the nozzle to stabilize in temperature, it is way more precise than any other nozzle, and it is more durable than any other option.

The downside of this nozzle is that it is not always the cheapest.

The downside of this nozzle is that it is not always the cheapest.

No matter which you choose, they are all excellent choices. They have some advantages and drawbacks like everything else, and you will want to make sure the nozzle you pick is right for the project you’re doing. If you can afford a ruby tipped nozzle, that may be one of the best choices for a detailed outcome.

Best Material to Print With

There are so many excellent materials you can print with now! When 3D printing originated, you could print with only a few materials. It was inaccurate, not precise, and looked like blocky shapes.

Now with the crazy advancements in our technology, you have some fantastic options to choose from.

- Plastics- Though this is not the most sustainable material to print with, it is the most user friendly. Most 3D printers can take certain plastics types, and they can create remarkable things out of the plastics.

- Powders- A few 3D printers can take powders, mix it, and turn it into some incredible objects.

They can use nylon and aluminide. There are also powdered steel and copper forms that are way easier to transport in this form and easy to manipulate in the 3D printer.

They can use nylon and aluminide. There are also powdered steel and copper forms that are way easier to transport in this form and easy to manipulate in the 3D printer. - Resin- There are now many kinds of resins to choose from, allowing you to create unique objects in 3D printers. There are three main kinds you can choose from. The high-detailed resin is used for tiny objects that need immense detail, printable resins, which is great for something with a smooth surface, a transparent resin which is the strongest out of all three.

- Metal- This has been used for several years and can create unbreakable and unbendable objects if you are looking to do so. You can do materials like bronze, gold, aluminum, stainless steel, titanium, and nickel.

There are so many more materials you can now print from your nozzles and a 3D printer, but not all nozzles are created equally. You will have to make sure you choose the appropriate one for the job.

Final Thought

There are tons of nozzles to choose from, but there is no wrong answer between the Mk10 and the Mk8. The Mk8 is better for jewelry making and creating small figurines with details on every application inch. However, if you are on a time restraint and don’t need anything too high-quality, the Mk10 is a perfect choice. This can also be one of the best nozzles for beginners because it will not be easily clogged. No matter which you choose, you will have to maintain your nozzles for the best outcome.

(There is a solution) What is the difference between MK6 and MK8 and even MK10?

All credits for the following actions belong to user "vermon" who posted in this thread.

Below is a heavily modified version of his longer answer.

Makerbot has really started its hotend series, using MK as iterations (for Label). The first commercially available version was [Makerbot] MK4 on cupcake around 2009year. The MK4 was handcrafted with nichrome wire heaters and is prone to all sorts of glitches. They only worked with ABS and 3mm filament.

They only worked with ABS and 3mm filament.

Following here, Makerbot has been overlooked as a manufacturer, which is what we're talking about. The correct nomenclature would be Makerbot Hotend MK#

The MK5 has been completely redesigned with huge nozzles and a thick PTFE gasket. It used 2 high power resistors in parallel for heating and was also prone to failure.

MK6 was the first hotend sold as a kit that I know of (however Repraps also started using them, probably earlier).

TheMk6+ was the first hotend cartridge heater sold as a kit. The MK5/MK6 heater block was made from stainless steel, while the MK6+ upgrade kit was an aluminum block that was slightly smaller, much lighter and now had a standard 1/4" heating cartridge.

The MK7 was the first hot end you guys would recognize. This was the first transition to 1.75 mm filament extruders. While the MK6+ kit had parts to adapt to 1.75mm filament, it never worked well at all and was really a failure.

Again, this is the era of Mathika and cupcakes. Other than a few clones, there really wasn't a third-party market in the US at the time. You either had a MakerBot or some other Reprap-based kit. Wanhao, Flashforge - they didn't even exist, and if they existed, they wouldn't be talked about like they are now.

TheMK8 was a brand new hotend dual extruder setup on a MakerBot Replicator. The cooling rod was thicker than the MK7, but the same all-metal thermal barrier, and presumably the MK8 has slightly different nozzle geometry inside and out.

MK9 was the MK8 heater, cooling rod, thermal barrier and nozzle, but we know the new spring arm feeder on all modern models. That's why it's confusing, MK9 was a feeder update, not a hotend change.

MK10 was a complete hotline change. The MK10 uses smooth outer thermal barriers with a larger PTFE liner of 4mm diameter and 2mm diameter. The MK10 also uses M7 threads compared to the M6 of all previous models. This is because the 4mm thick PTFE liner is barely enough to make an outer tube with an M6 thread. MK10 is completely incompatible with all previous hotend parts. Each part is different. MK10 still uses MK9 feeder parts. The

MK10 is completely incompatible with all previous hotend parts. Each part is different. MK10 still uses MK9 feeder parts. The

MK11 on the D6 is just the MK10 nozzle and thermal barrier, but the other heater block and cooling rod are part of the D6's center cross. Again, the only real difference is that the MK11 is a different heating block and this is for adapting a different and longer heating cartridge and inserting a thermocouple. The MK11 still uses the MK9's plastic feed parts.

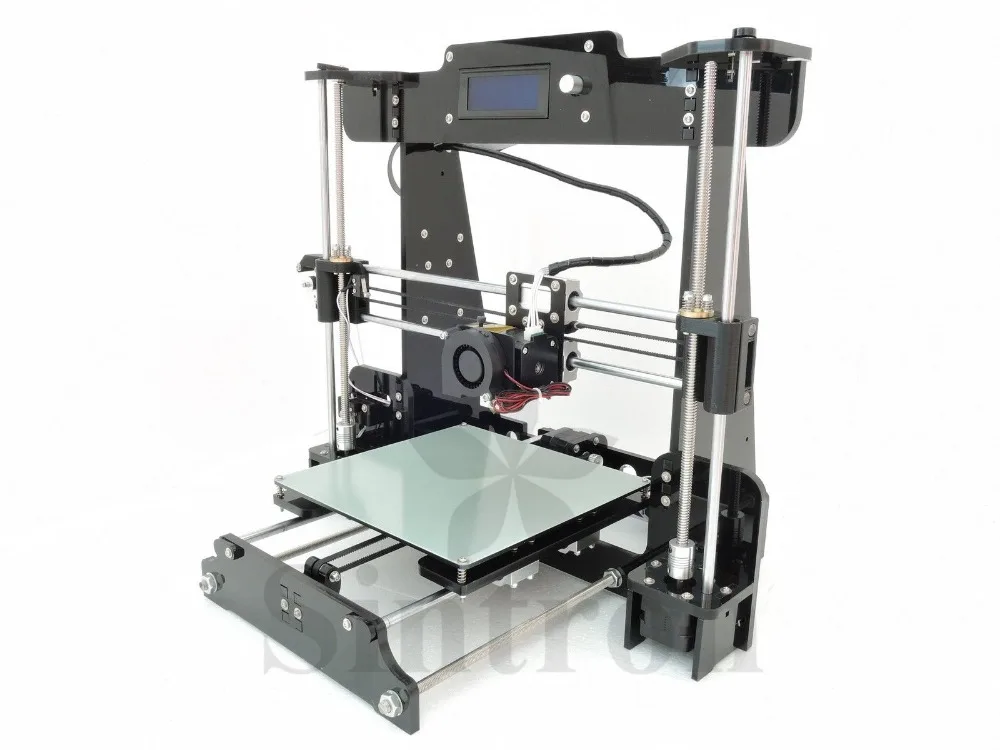

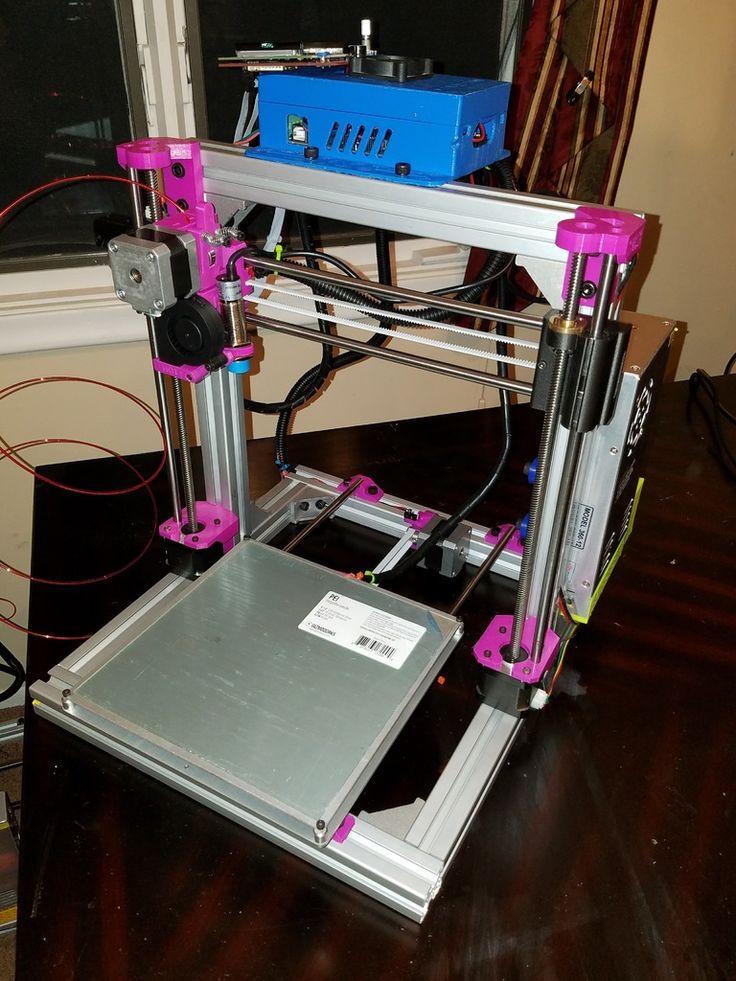

I wanted to know which group my printer belongs to since the base is a direct extruded Prusa clone.

This question seems to be hard to answer specifically as the batch number appears to be assigned based on a combination of heater block technology and format, feed geometry, nozzle shape and threads that were adopted on MakerBot printers. Your actual combination of the three may not exist in the MakerBot universe.

However, I suggest you read the full, abridged version of the post linked above, as it may reveal more information relevant to your request.

Page not found - Plastic for 3D printing in Yekaterinburg

Nothing found at this address. Use the search or see the links below.

Search:

Discounts

-

ABS plastic SEM 1.75mm White 900g

1190 RUB Add to cart1 pc. in stock

ABS plastic SEM 1.75mm White 900gr

ABS plastic for 3D printers with a diameter of 1.75 mm from the domestic manufacturer SEM. Designed for the manufacture of parts for housings, various designs, kitchen products, as well as medical supplies. Printed products can be used in water, for example in the manufacture of parts for sanitary ware or aquariums. The material is suitable for various FDM 3D printers.

1190 RUB

-

Sale!

ABS plastic SEM 1.75mm Yellow 900g

1190 RUB Add to cart1 pc.

in stock

in stock ABS plastic SEM 1.75mm Yellow 900gr

ABS plastic for 3D printers with a diameter of 1.75 mm from the domestic manufacturer SEM. Designed for the manufacture of parts for housings, various designs, kitchen products, as well as medical supplies. Printed products can be used in water, for example in the manufacture of parts for sanitary ware or aquariums. The material is suitable for various FDM 3D printers.

1190 RUB

Popular Items

-

3D printer adhesive 250 ml The 3D “Click” New

550 RUB Add to cart8 pcs. in stock

3D printer adhesive 250 ml The 3D “Click” New

Adhesive for FDM printing. Perfectly solves the problems of poor adhesion of plastic to the table. How to use: before printing, apply the glue solution to the fabric and wipe the surface of the table of the heated platform with it.

For easy removal of the product from the table, after printing, wait for the work surface to cool down to 30°C. Ingredients: isopropyl alcohol, P-complex, water, fragrance. Ingredients: isopropyl alcohol, P-complex, water, fragrance.

For easy removal of the product from the table, after printing, wait for the work surface to cool down to 30°C. Ingredients: isopropyl alcohol, P-complex, water, fragrance. Ingredients: isopropyl alcohol, P-complex, water, fragrance. 550 RUB

-

Nozzle brass 0.4mm MK8 for plastic 1.75mm 5APlus

40 ₽ Add to cart17 pcs. in stock

Nozzle brass 0.4mm MK8 for plastic 1.75mm 5APlus

Brass, size: 13 mm x 6 mm. Thread diameter: 1.75 mm. Thread diameter: 6 mm. Nozzle outlet diameter: 0.4mm

Suitable for 3D printers with MK8 type hotend: Anet A6, Anet A8, Creality CR-10, Ender-3, Ender 5, Ender 5 plus, etc.

40 ₽

-

Nozzle brass 0.4mm V6 for plastic 1.75mm 5APlus

40 ₽ Add to cart10 pcs. in stock

Nozzle brass 0.4mm V6 for plastic 1.75mm 5APlus

Brass, size: 12.

Learn more