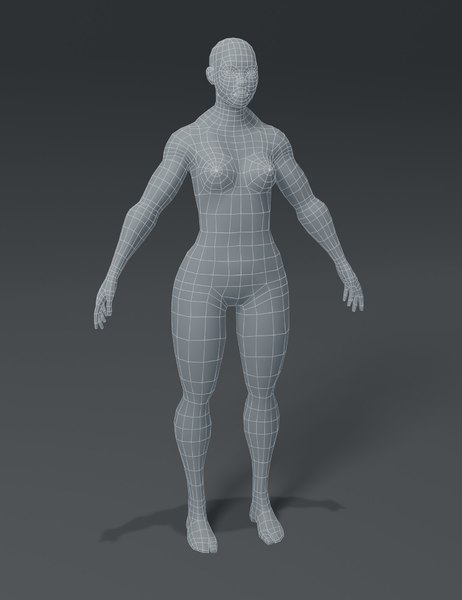

3D printer human body

3D-printed organs: The future of transplantation

Sign up for CNN’s Wonder Theory science newsletter. Explore the universe with news on fascinating discoveries, scientific advancements and more.

CNN —

What if doctors could just print a kidney, using cells from the patient, instead of having to find a donor match and hope the patient’s body doesn’t reject the transplanted kidney?

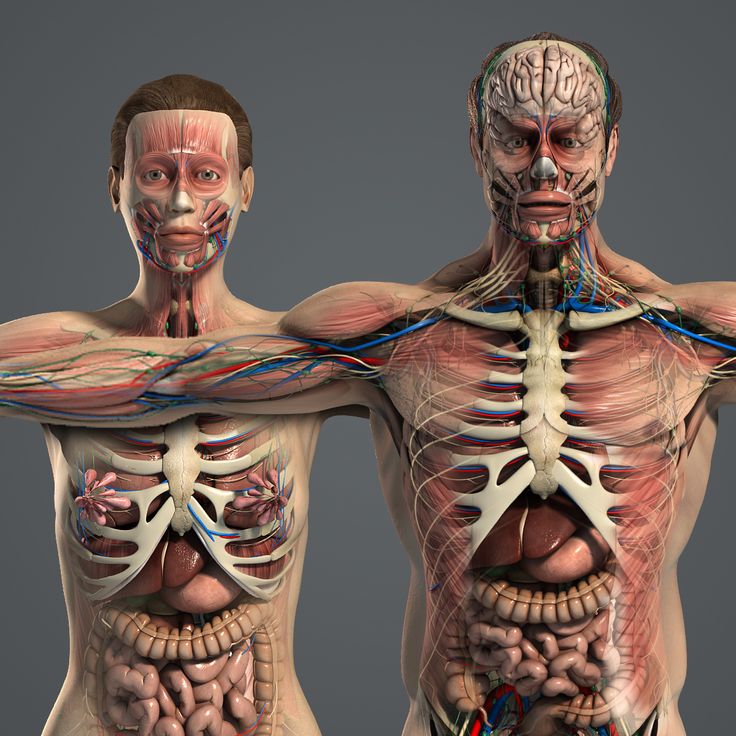

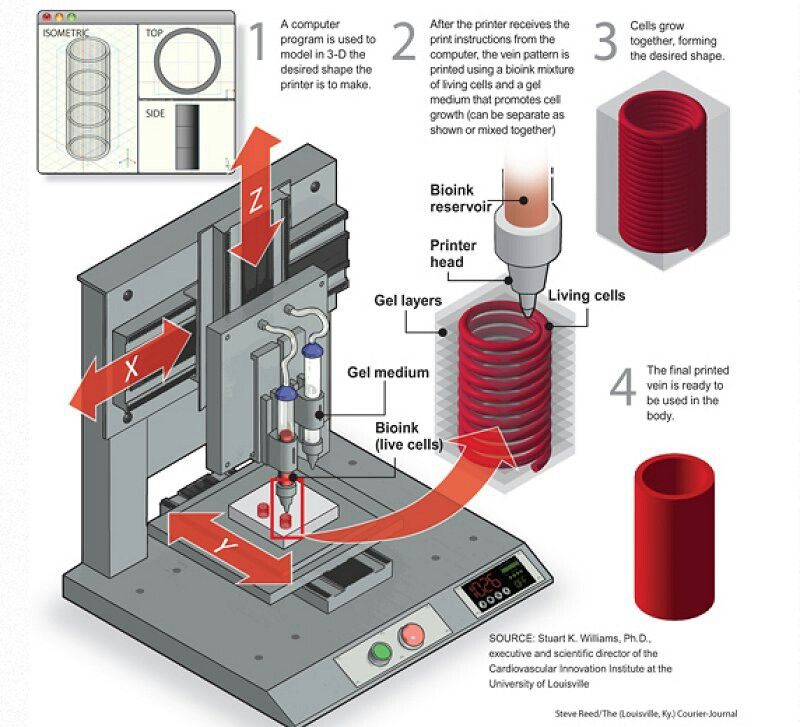

The soonest that could happen is in a decade, thanks to 3D organ bioprinting, said Jennifer Lewis, a professor at Harvard University’s Wyss Institute for Biologically Inspired Engineering. Organ bioprinting is the use of 3D-printing technologies to assemble multiple cell types, growth factors and biomaterials in a layer-by-layer fashion to produce bioartificial organs that ideally imitate their natural counterparts, according to a 2019 study.

This type of regenerative medicine is in the development stage, and the driving force behind this innovation is “real human need,” Lewis said.

In the United States, there are 106,800 men, women and children on the national organ transplant waiting list as of March 8, 2023, according to the Health Resources & Services Administration. However, living donors provide only around 6,000 organs per year on average, and there are about 8,000 deceased donors annually who each provide 3. 5 organs on average.

5 organs on average.

47-year-old Steve Verze is to become the first man in the world to be fitted with a 3D printed eye, according to Moorfields Eye Hospital. He tried the eye for size earlier this month, as photographed here.

Moorfields Biomedical Research CentreBritish man given 3D printed eye in world first, hospital says

The cause of this discrepancy is “a combination of people who undergo catastrophic health events, but their organs aren’t high enough quality to donate, or they’re not on the organ donor list to begin with, and the fact that it’s actually very difficult to find a good match” so the patient’s body doesn’t reject the transplanted organ, Lewis said.

And even though living donors are an option, “to do surgery on someone who doesn’t need it” is a big risk, said Dr. Anthony Atala, director of the Wake Forest Institute for Regenerative Medicine. “So, living related donors are usually not the preferred way to go because then you’re taking an organ away from somebody else who may need it, especially now as we age longer.”

Anthony Atala, director of the Wake Forest Institute for Regenerative Medicine. “So, living related donors are usually not the preferred way to go because then you’re taking an organ away from somebody else who may need it, especially now as we age longer.”

Atala and his colleagues were responsible for growing human bladders in a lab by hand in 2006, and implanting a complicated internal organ into people for the first time — saving the lives of three children in whom they implanted the bladders.

A bladder scaffold is seeded with cells at the Wake Forest Institute for Regenerative Medicine.

Courtesy Wake Forest Institute for Regenerative Medicine Every day, 17 people die waiting for an organ transplant, according to the Health Resources & Services Administration. And every 10 minutes, another person is added to the waitlist, the agency says. More than 90% of the people on the transplant list in 2021 needed a kidney.

And every 10 minutes, another person is added to the waitlist, the agency says. More than 90% of the people on the transplant list in 2021 needed a kidney.

“About a million people worldwide are in need of a kidney. So they have end-stage renal failure, and they have to go on dialysis,” Lewis said. “Once you go on dialysis, you have essentially five years to live, and every year, your mortality rate increases by 15%. Dialysis is very hard on your body. So this is really motivating to take on this grand challenge of printing organs.”

“Anti-hypertensive pills are not scarce. Everybody who needs them can get them,” Martine Rothblatt, CEO and chairman of United Therapeutics, said in June 2022 at the Life Itself conference, a health and wellness event presented in partnership with CNN. United Therapeutics was one of the conference sponsors.

United Therapeutics was one of the conference sponsors.

“There is no practical reason why anybody who needs a kidney — or a lung, a heart, a liver — should not be able to get one,” she added. “We’re using technology to solve this problem.”

To begin the process of bioprinting an organ, doctors typically start with a patient’s own cells. They take a small needle biopsy of an organ or do a minimally invasive surgical procedure that removes a small piece of tissue, “less than half the size of a postage stamp,” Atala said. “By taking this small piece of tissue, we are able to tease cells apart (and) we grow and expand the cells outside the body. ”

”

This growth happens inside a sterile incubator or bioreactor, a pressurized stainless steel vessel that helps the cells stay fed with nutrients — called “media” — the doctors feed them every 24 hours, since cells have their own metabolism, Lewis said. Each cell type has a different media, and the incubator or bioreactor acts as an oven-like device mimicking the internal temperature and oxygenation of the human body, Atala said.

“Then we mix it with this gel, which is like a glue,” Atala said. “Every organ in your body has the cells and the glue that holds it together. Basically, that’s also called ‘extracellular matrix. ’”

’”

Richard Roth with Samira Jafari

Courtesy Samira JafariLiving organ donations save lives. This is how you become a donor

This glue is Atala’s nickname for bioink, a printable mixture of living cells, water-rich molecules called hydrogels, and the media and growth factors that help the cells continue to proliferate and differentiate, Lewis said. The hydrogels mimic the human body’s extracellular matrix, which contains substances including proteins, collagen and hyaluronic acid.

The non-cell sample portion of the glue can be made in a lab, and “is going to have the same properties of the tissue you’re trying to replace,” Atala said.

The biomaterials used typically have to be nontoxic, biodegradable and biocompatible to avoid a negative immune response, Lewis said. Collagen and gelatin are two of the most common biomaterials used for bioprinting tissues or organs.

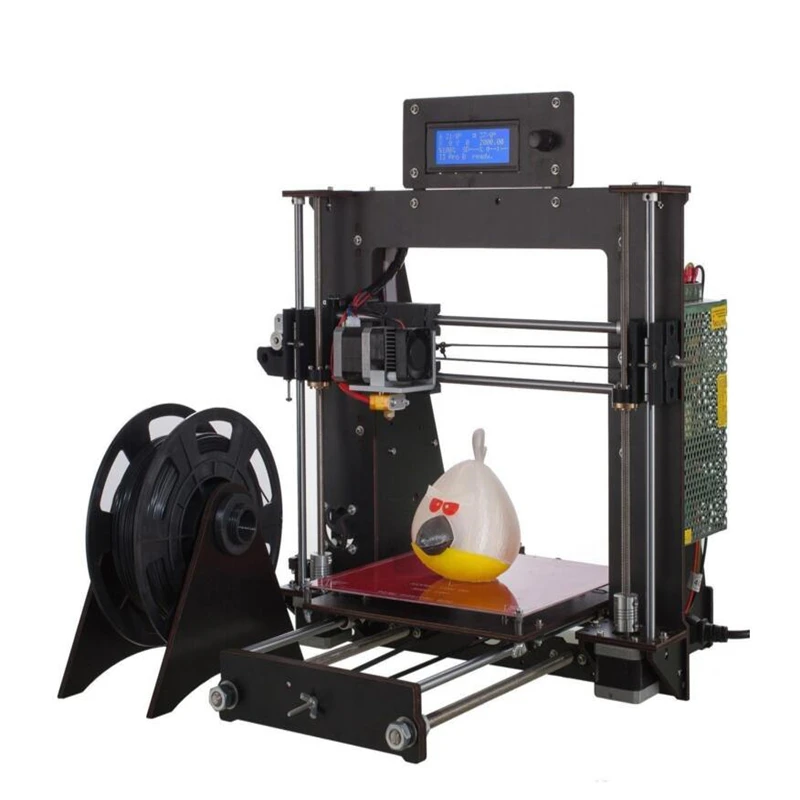

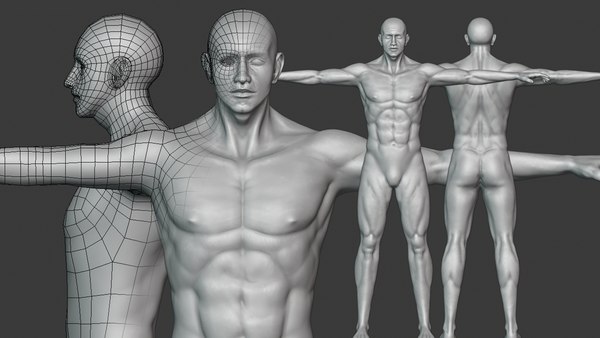

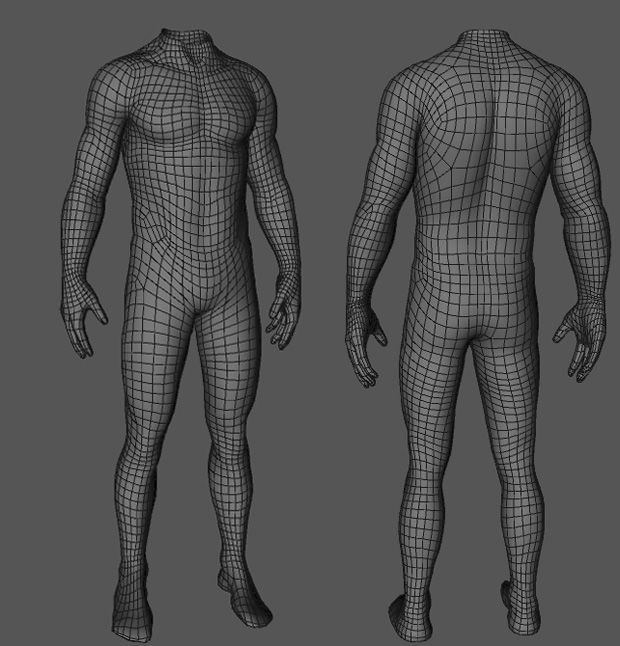

From there, doctors load each bioink — depending on how many cell types they’re wanting to print — into a printing chamber, “using a printhead and nozzle to extrude an ink and build the material up layer by layer,” Lewis said. Creating tissue with personalized properties is enabled by printers being programmed with a patient’s imaging data from X-rays or scans, Atala said.

“With a color printer you have several different cartridges, and each cartridge is printing a different color, and you come up with your (final) color,” Atala added. Bioprinting is the same; you’re just using cells instead of traditional inks.

How long the printing process takes depends on several factors, including the organ or tissue being printed, the fineness of the resolution and the number of printheads needed, Lewis said. But it typically lasts a few to several hours. The time from the biopsy to the implantation is about four to six weeks, Atala said.

A 3D printer seeds different types of cells onto a kidney scaffold at the Wake Forest Institute for Regenerative Medicine.

The ultimate challenge is “getting the organs to actually function as they should,” so accomplishing that “is the holy grail,” Lewis said.

“Just like if you were to harvest an organ from a donor, you have to immediately get that organ into a bioreactor and start perfusing it or the cells die,” she added. To perfuse an organ is to supply it with fluid, usually blood or a blood substitute, by circulating it through blood vessels or other channels.

Depending on the organ’s complexity, there is sometimes a need to mature the tissue further in a bioreactor or further drive connections, Lewis said. “There’s just a number of plumbing issues and challenges that have to be done in order to make that printed organ actually function like a human organ would in vivo (meaning in the body). And honestly, this has not been fully solved yet.”

“There’s just a number of plumbing issues and challenges that have to be done in order to make that printed organ actually function like a human organ would in vivo (meaning in the body). And honestly, this has not been fully solved yet.”

Once a bioprinted organ is implanted into a patient, it will naturally degrade over time — which is OK since that’s how it’s designed to work.

“You’re probably wondering, ‘Well, then what happens to the tissue? Will it fall apart?’ Actually, no,” Atala said. “These glues dissolve, and the cells sense that the bridge is giving way; they sense that they don’t have a firm footing anymore. So cells do what they do in your very own body, which is to create their own bridge and create their own glue.”

So cells do what they do in your very own body, which is to create their own bridge and create their own glue.”

Atala and Lewis are conservative in their estimates about the number of years remaining before fully functioning bioprinted organs can be implanted into humans.

“The field’s moving fast, but I mean, I think we’re talking about a decade plus, even with all of the tremendous progress that’s been made,” Lewis said.

“I learned so many years ago never to predict because you’ll always be wrong,” Atala said. “There’s so many factors in terms of manufacturing and the (US Food and Drug Administration regulation). At the end of the day, our interest, of course, is to make sure the technologies are safe for the patient above all.”

“There’s so many factors in terms of manufacturing and the (US Food and Drug Administration regulation). At the end of the day, our interest, of course, is to make sure the technologies are safe for the patient above all.”

Whenever bioprinting organs becomes an available option, affordability for patients and their caregivers shouldn’t be an issue.

Patients who need regular dialysis treatments have high rates of staph infections in their blood compared with people who don't need these treatments, according to a new CDC report.

Mailson Pignata/Adobe StockBlack, Hispanic dialysis patients are at greater risk of dangerous bloodstream infections

They’ll be “accessible for sure,” Atala said. “The costs associated with organ failures are very high. Just to keep a patient on dialysis is over a quarter of a million dollars per year, just to keep one patient on dialysis. So, it’s a lot cheaper to create an organ that you can implant into the patient.”

“The costs associated with organ failures are very high. Just to keep a patient on dialysis is over a quarter of a million dollars per year, just to keep one patient on dialysis. So, it’s a lot cheaper to create an organ that you can implant into the patient.”

The average kidney transplant cost was $442,500 in 2020, according to research published by the American Society of Nephrology — while 3D printers retail for around a few thousand dollars to upward of $100,000, depending on their complexity. But even though low-cost printers are available, pricey parts of bioprinting can include maintaining cell banks for patients, culturing cells and safely handling biological materials, Lewis said.

Some of the major costs of current organ transplantation are “harvesting the organ from the donor, the transport costs and then, of course, the surgery that the recipient goes through, and then all the care and monitoring,” Lewis said. “Some of that cost would still be in play, even if it was bioprinted.”

“Some of that cost would still be in play, even if it was bioprinted.”

3D Printers Can Already Create Human Body Parts

In recent years, updates in 3D printing technologies have allowed medical researchers to print things that were not possible to make using the previous version of this technology, including food, medicine, and even body parts.

In 2018, doctors from the Ontario Veterinary College 3D printed a custom titanium plate for a dog that had lost part of its skull after cancer surgery.

Source: University of Guelph“By performing these procedures in our animal patients, we can provide valuable information that can be used to show the value and safety of these implants for humans”, said veterinary surgical oncologist Michelle Oblak at the time. “These implants are the next big leap in personalized medicine that allows for every element of an individual’s medical care to be specifically tailored to their particular needs.”

And not just for animal patients.

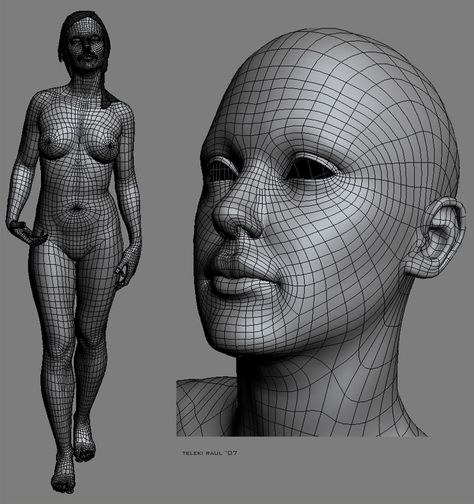

What is 3D bioprinting?

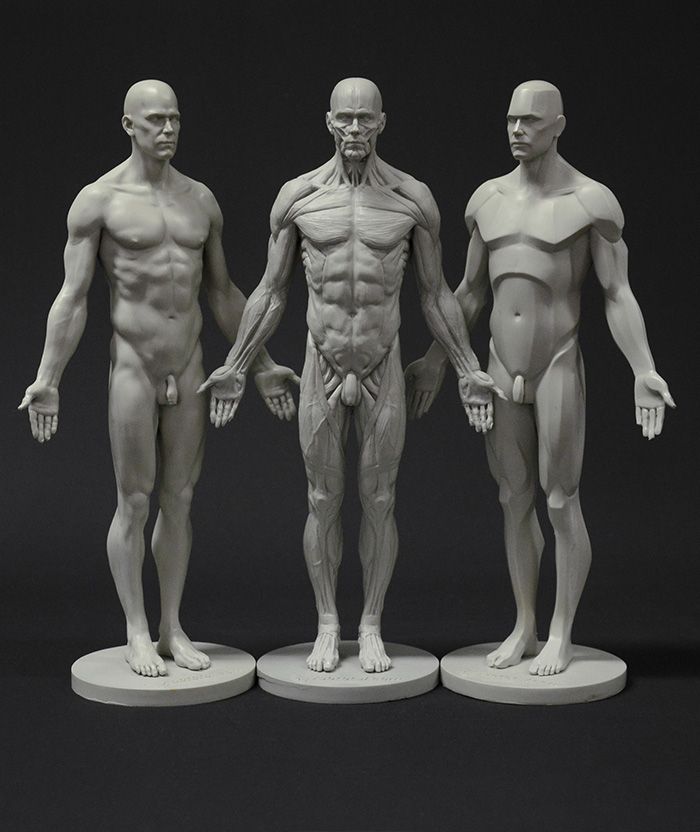

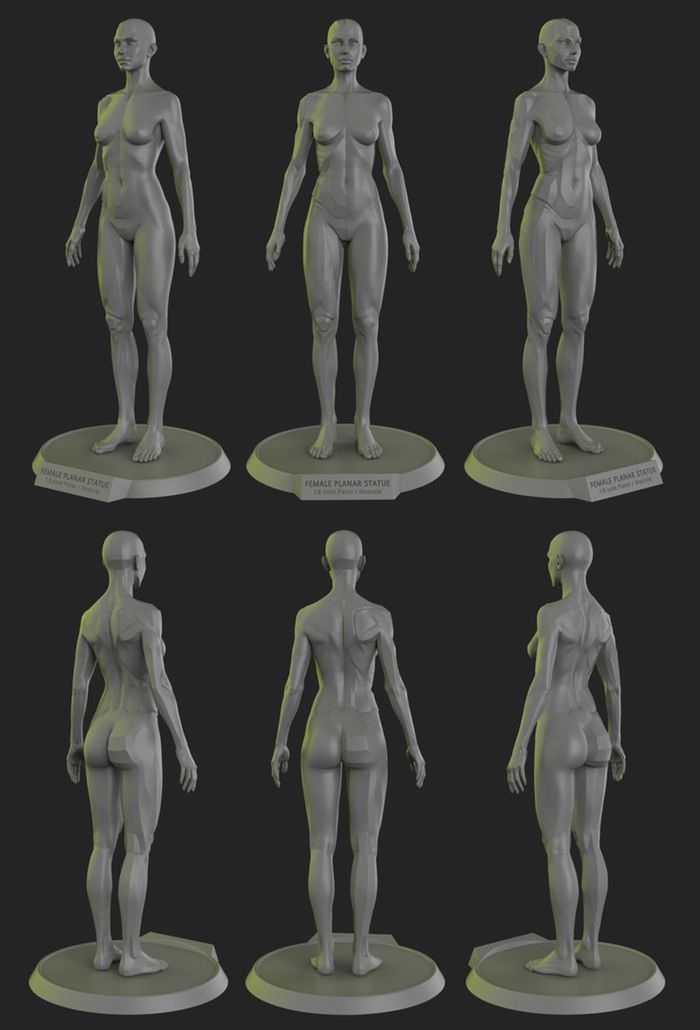

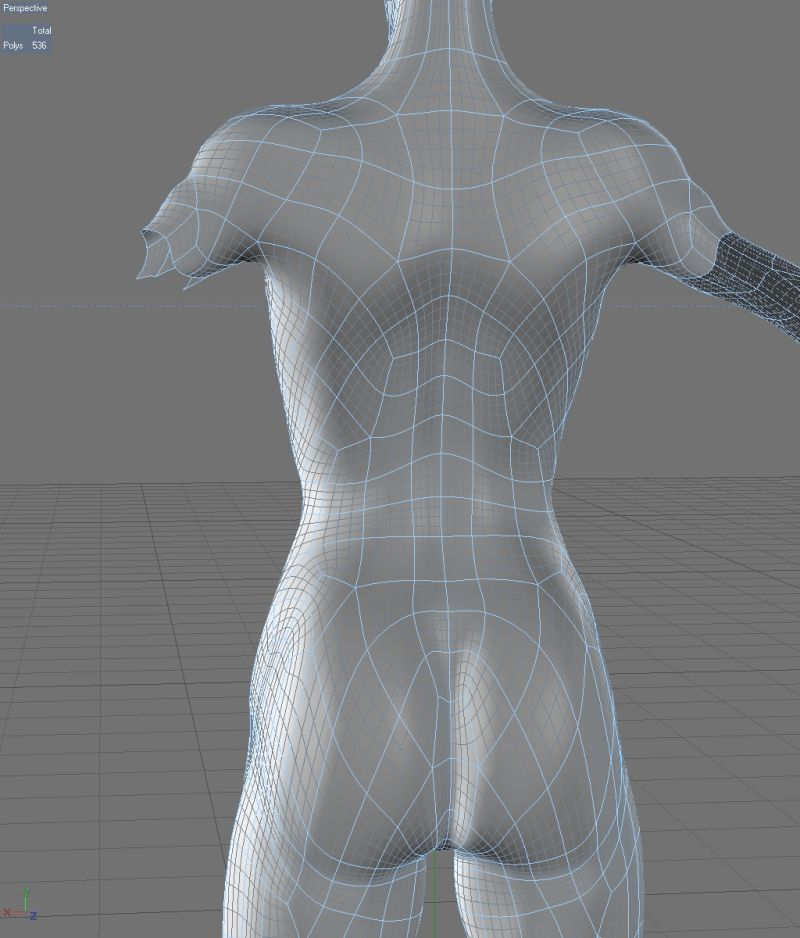

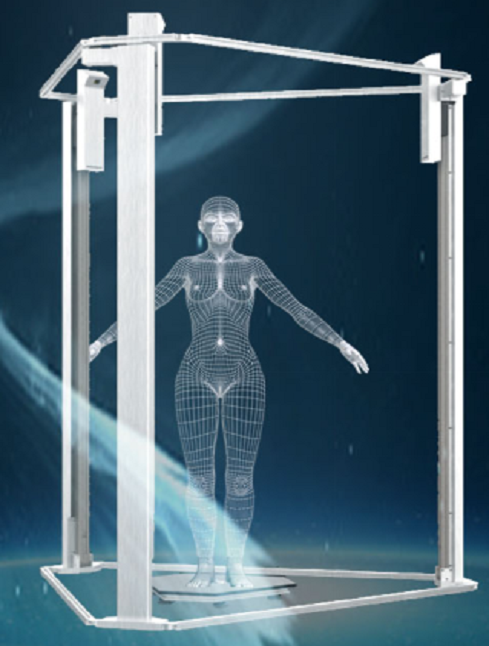

3D bioprinting is the utilization of 3D printing technologies to fabricate body parts. Bioprinters work in a similar way to 3D printers. However, instead of depositing materials such as plastic or ceramic, they deposit layers of biomaterial, including living cells, to build complex structures like blood vessels or skin tissue.

The required cells are taken from a patient and then cultivated. These cells are usually combined with a carrier material or scaffold. This carrier is usually a type of biopolymer gel, which acts as a 3D molecular scaffold and provides protection for the cells during the printing process. Cells attach to the gel, which is sturdy enough to allow printing and flexible enough to allow the flow and diffusion of nutrients and the movement of cells. This combination of encapsulated cells and biopolymer gels is the bio-ink used by biomedical engineers to create 3D-printed, tissue-like structures.

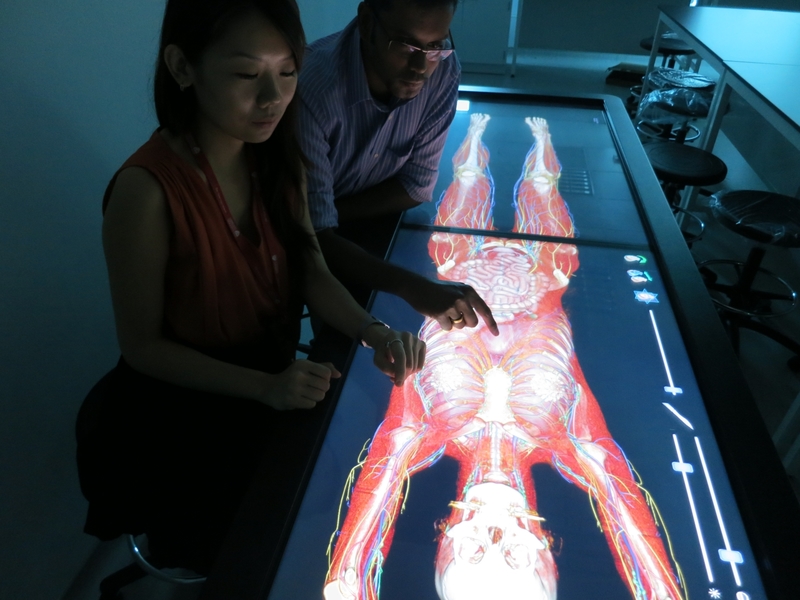

Detailed computer designs and models are first made, often based on scans such as magnetic resonance imaging or computerized tomography taken directly from a patient. Precision printer heads then deposit cells and bio-inks exactly where they are needed and, over the course of several hours, an organic object is built up using a large number of very thin layers.

Precision printer heads then deposit cells and bio-inks exactly where they are needed and, over the course of several hours, an organic object is built up using a large number of very thin layers.

The cells are kept alive using liquefied nutrients and oxygen during the whole process.

In the post-printing stage, the structures may be crosslinked with UV light or ionic solutions to make them more stable. Cells are chemically and mechanically stimulated to control the remodeling and growth of tissues. Then, the 3D printed product is put into an incubator to allow the cells to grow.

When it’s ready, the structure must be used as soon as possible, unless the 3D bioprinting is combined with cryopreservative techniques — something that researchers from Brigham and Women's Hospital and Harvard Medical School achieved last year.

Most Popular

The work, published on December 21st, showed how the team was able to 3D print tissues onto a cold plate at -4°F (-20ºC), after which they were preserved in a freezer at -320.8°F (-196ºC). The tissues, researchers said, can then be thawed within minutes for immediate use.

Tendons and ligaments

In 2018, biomedical engineers from the University of Utah developed a method for 3D printing ligaments and tendons. The method involves first taking stem cells from the patient and printing them on a layer of hydrogel to form a tendon or ligament. This is allowed to grow in vitro in a culture before being implanted. However, the process was very complex, because connective tissue is made up of different cells in complex patterns. The team first needed to develop a special printer head that could lay down human cells in the highly controlled manner they require.

To do this, the team partnered with Utah-based company Carterra, Inc., to develop a specialized printhead that would let them lay down cells in complex patterns. The printhead was then attached to a 3D printer normally used to print antibodies for cancer treatment.

The printhead was then attached to a 3D printer normally used to print antibodies for cancer treatment.

With this technique, the scientists managed to 3D print stem cells taken from a patient’s body fat onto a layer of hydrogel. This hydrogel facilitates cell growth in vitro in a culture, forming either a ligament or tendon in the process.

The new tissue is then implanted in the damaged area of the patient’s body, eliminating the need for additional tissue replacement procedures.

Replacement tissues for those needing it are often harvested from elsewhere on a patient's body or from a cadaver. However, tissue from cadavers runs a high risk of being rejected by the surrounding tissues or of being of poor quality and ineffective.

Instead, tissues created from the patient’s own cells can reduce the complications involved with a transplant and speed up the healing process.

Skin bioprinting and wound healing

3D bioprinting could also help us say goodbye to skin grafts in the near future, as doctors could be able to 3D print new skin for each patient.

Skin grafting is the transplantation of healthy skin from an animal, a human donor, or the patient’s own body to another part of his or her body where the skin is badly damaged. The procedure is commonly used to treat severe wounds, burns, ulcers, and infections, or after the removal of skin cancers.

Source: Scientific Animations/Wikimedia CommonsBut the technique involves several risks, from hemorrhages and loss of sensitivity to infections, scarring, and rejection.

This is why scientists from Wake Forest Institute for Regenerative Medicine (WFIRM) are working on a mobile bedside skin bioprinting system that could let doctors print bi-layered skin directly on the patient’s wound.

“The unique aspect of this technology is the mobility of the system and the ability to provide on-site management of extensive wounds by scanning and measuring them in order to deposit the cells directly where they are needed to create skin,” said Sean Murphy, Ph. D., a WFIRM assistant professor who was the lead author of the paper.

D., a WFIRM assistant professor who was the lead author of the paper.

To do this, the scientists isolated certain skin cells from a biopsy of healthy tissue and grew them in culture. After that, they combined the cells with a hydrogel and put them into the bioprinter. The device printed the cells onto the damaged area following the data extracted from the wound’s scan through a software.

Again, because the cells are taken from the patient’s own body, there is a much lower risk of rejection.

Meanwhile, in Dublin, scientists from the RCSI University of Medicine and Health Sciences developed a hydrogel scaffold with natural platelet-rich plasma (PRP) that has promising regenerative properties. The compound can be used as a bio-ink to accelerate the wound healing process in 3D printed tissues.

“Existing literature suggests that while the PRP already present in our blood helps to heal wounds, scarring can still occur,” said RCSI Professor Fergal O’Brien. “By 3D printing PRP into a biomaterial scaffold, we can increase the formation of blood vessels while also avoiding the formation of scars, leading to more successful wound healing.”

“By 3D printing PRP into a biomaterial scaffold, we can increase the formation of blood vessels while also avoiding the formation of scars, leading to more successful wound healing.”

Blood vessels

Perhaps the ultimate goal of 3D bioprinting is to assemble functional organs and solve the problem of organ transplantation.

Currently, there are more than 100,000 people waiting for an organ on the U.S. national transplant waiting list. Roughly 17 of them die each day because they don’t receive the organ they need. This is largely due to the lack of donors. Although around 60% of Americans are signed up as donors, organ donation is only possible in 3 out of every 1,000 deaths.

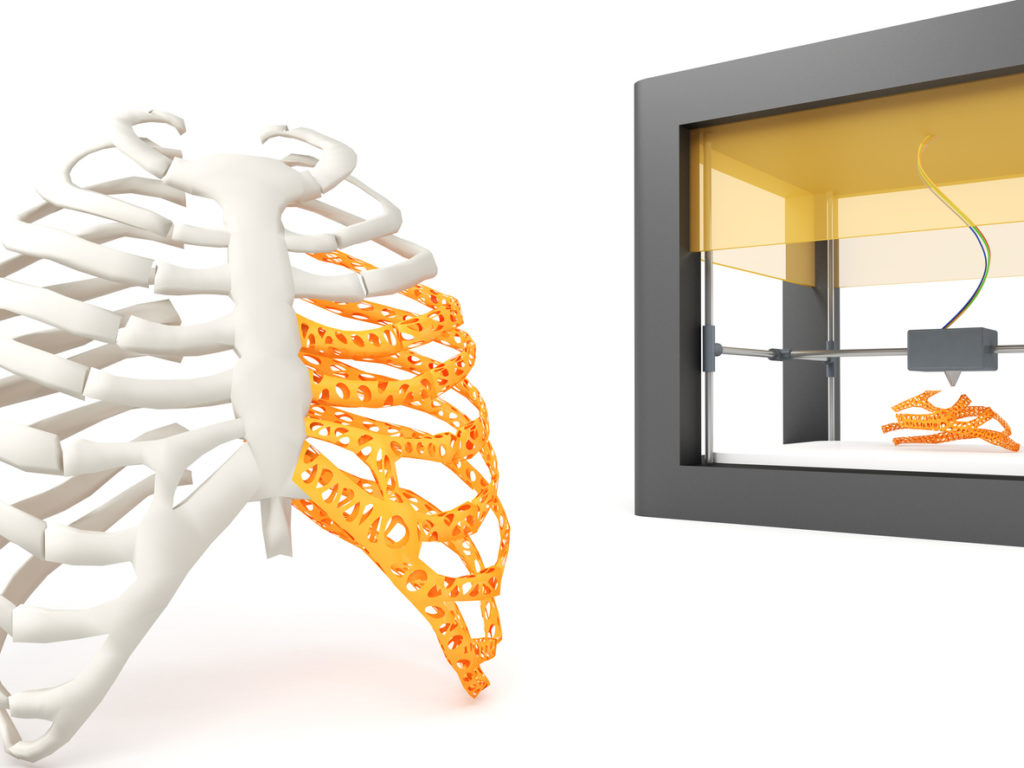

3D bioprinting of organs could save a lot of lives, but scientists struggle to create the vascular structures needed to create viable printed organs. All organs, including 3D-printed ones, need an effective, continuous blood supply to prevent the death of the cells and the tissues.

In October 2021, a team of researchers at Israel's Technion Institute of Technology managed to 3D print blood vessel structures to add a blood supply to tissue implants.

These structures grew spontaneously after the team implanted endothelial cells from the inner layer of blood vessels in the body in a polymeric collagen scaffold.

However, these are only microvessels that can be used to improve in vitro tissue development — they wouldn’t be able to, “feed” a whole organ, and so far, they don’t allow the integration of lab-grown tissues into the patient’s vascular system.

This study shows that there’s still a long way to go until we can actually 3D print organs on demand. But who knows which techniques can scientists develop to solve this issue in the future?

For You

innovation

Researchers at the University of Tokyo fitted robotic eyes on a golf cart - to reduce accidents by self-driving vehicles. Did it work?

Deena Theresa | 9/24/2022

innovationPersonalized nutrition via 3D printing can be a revolution in food technology

Deena Theresa| 8/29/2022

innovationSpace cannon could fire payloads to orbit in 10 minutes at Mach 20

Chris Young| 2/2/2023

More Stories

health

'Tranq' is a dangerous flesh 'rotting' narcotic taking the US by storm

Christopher McFadden| 3/22/2023

health

Tardigrade protein can keep medicines stabilized without refrigeration

Mrigakshi Dixit| 3/21/2023

health

Deadly fungal infection spreading rapidly through US, warns CDC

Mrigakshi Dixit| 3/21/2023

STL file Human body・3D printer design download・Cults

Mudkip bobblehead fanart

5. 64 €

64 €

Alcancia Gudetama / Piggy bank Gudetama

2.79 €

Ornament Gudetama

1.32 €

Raichu Alola Surfing (lamp) FanArt

3,20 €

Car Low Poly

0,76 €

Calcifer with lamp adapter and extra mini figure upgraded.

€4.06

kamehameha power beam

0,76 €

Human Body V2 modular

1,93 €

Steelix articulated

2.54 €

mobile girl

1.52 €

mega-steelix

2.54 €

Shuttle Lamp

1. 02 €

02 €

Best 3D printer files in Game category

Titan BT 7274

Free

Deactivated

Ava - Animal Crossing

Free

HELMET WITH A MEDIEVAL CROSS FOR LIFE-SIZE PLAYMOBIL FIGURES

2,50 €

Fit 2007 (shell model)

Free

Head of an enchantress - table miniature

2.82 €

Army tank 1

3 €

BABYFOOT HOMER SIMPSON

4 €

Bestsellers in the Game category

Good flexi dragon

1. 77 €

77 €

Nintendo Switch Crystal Dock - Classic & OLED Version

3.05 €

Beautiful blue dog

1.07 €

Bob the Bear, the first of Octahaunted's sadists

8.88 €

Octopus 2.0

3.75 €

DESTROYABLE KATANA - ICHIGO - BLEACH - EASY TO PRINT - NO SUPPORTS

2,50 €

Lazy Cat

3.75 €

Japan Cloud Dock for Nintendo Switch - Classic & OLED Version

3.05 €

Furion - prince of demons - WARNED

5.99 €

Vurgalis

11.27 €

Articulated dragon

3. 75 €

75 €

Alpha Chads helmets for new Heresy

3 €

BODIES, TORSO, LEGS IN 3rd GENERATION POWER ARMOR

8,50 €

Flying unicorn

1.77 €

GIANT CROCODILE HINGED

4.24 €

Space Police Adaptus...

4 €

💖 Do you want to support Cults?

Do you like Cults and want to help us continue our journey on our own ? Please note that we are a small team of 3 people, so it is very easy to support us in maintaining activities and creating future developments. Here are 4 solutions available to everyone:

-

AD: Disable your AdBlock banner blocker and click on our banner ads.

-

AFFILIATION: Shop online with our affiliate links here Amazon.

-

DONATIONS: If you want, you can donate via Ko-Fi here 💜.

-

INVITE YOUR FRIENDS: Invite your friends, discover the platform and the great 3D files shared by the community!

Body parts that can already be printed on a 3D printer – Blog Imena.UA

Today, 3D printers are expected to revolutionize all areas of human activity. Including in medicine. Presumably, with the help of this equipment, the problem of donation will be finally solved. After all, almost any part of the body or organ can simply be printed. And no matter how fantastic it may sound, scientists have already achieved amazing results in this direction.

Pinna

At least 1 in 12,500 newborns is born with microtia, a condition that can lead to hearing problems due to abnormal or missing pinna. In this case, surgical intervention is attempted, or a complete replacement of the shell may be required. Up to this point, artificial implants were used, which were often rejected by the body.

In this case, surgical intervention is attempted, or a complete replacement of the shell may be required. Up to this point, artificial implants were used, which were often rejected by the body.

But using a 3D printer, it is already possible to create an auricle from living cells. The organ is first modeled in SolidWorks CAD software (and it is not difficult to create an exact copy of the other ear using 3D scanning), and then printed using a special high-density gel consisting of cells taken from bovine cartilage - they require about 25 million. Collagen (protein, providing strength and elasticity of the fabric) is “extracted” from rat tails. After the "printing" procedure, about 3 months of incubation period is required.

Being completely natural, this auricle is more readily accepted by the body. The chance of rejection is much lower. The technique was developed by scientists from Cornell University.

By the way, ears can be printed not only for the treatment of diseases or injuries. So, scientists from Princeton University are creating special ears that can pick up radio signals. It is assumed that such additions will be very useful for various electronics for the time being, and in the future they will be able to expand human capabilities.

So, scientists from Princeton University are creating special ears that can pick up radio signals. It is assumed that such additions will be very useful for various electronics for the time being, and in the future they will be able to expand human capabilities.

Kidneys

As you know, with a sick heart or stomach, a person can live more or less normally for many years. Sick kidneys usually mean a significant reduction in life expectancy. However, it is sometimes extremely difficult or simply impossible to make a “replacement” due to the lack of a suitable donor. And the possibility of "conveyor" production of kidneys would save the lives of tens of thousands of people around the world.

Scientists from the Wake Forest Institute for Regenerative Medicine are currently working on 3D printing of kidneys. To create a new organ, cells are taken directly from the organs of the patient. That is, the chance that his body will more readily accept an implant that will not differ much from the replaced one increases significantly.

Unfortunately, this is only a project so far, but with very bright prospects. It is likely that in the very near future, scientists will learn how to create kidneys for "any requests."

Blood vessels

Teams of scientists from the University of Pennsylvania and the Massachusetts Institute of Technology are currently working on making printed blood vessels. For work, a printer developed by the RepRap project and software specially created for such purposes is used.

Future vessels are based on sugar, mold fungi and special polymers obtained from corn. Moreover, sugar is needed only for shaping, then it is washed out with water.

However, the obtained vessels cannot yet be used in the human body. But we are talking only about the development of the principles themselves. But the ability to create blood vessels that are indistinguishable from real ones is an important step towards creating any human organs using 3D printers.

Leather

Scientists from the Wake Forest Institute of Regenerative Medicine, already mentioned above, are also developing a technique when the skin will not be transplanted from other parts of the victim's body or from a donor, but printed directly on the affected area.

"Print" is preceded by a preliminary scan and mapping of the patient's wound. When creating the skin, various proteins and enzymes will be used, such as fibrinogen, collagen, thrombin, etc., each of which is then involved in the process of creating cells.

The ultimate goal is to create a compact 3D printer that can be used in disaster areas or in war.

Bones

Every year, thousands of people suffer complex bone fractures that are very difficult to repair using traditional methods. The technique, on which scientists from the University of Washington are currently working, is good because it will allow you to create replacements for any bones in the human body.