Eco resin 3d printing

Plant-based, non-toxic and eco resins for 3D-printing

Since the invention of resin 3D-printing back in 1986, 3D-printing resin materials were mainly based on epoxy and acrylate chemistry from non-biobased sources. Recently the industry is focused on sustainable material feedstock and development of alternative eco- and bio-based 3D-printing resins. On this topic, 3D ADEPT Mag interviewed Liqcreate’s Sales & Marketing Executive, Ruben Bosch. They discussed non-toxic materials and the different forms of toxicity and solutions explored to reduce toxicity in resin 3D-Printing.

Development of biobased and plant based eco uv resin for 3D-printing

In the field of material and resin development, additive manufacturing (AM) / 3D-pinting offers the possibility of producing a versatile range of customized materials and resins. From the work field, there is an increasing need for sustainable building blocks to develop biobased resin. Although thermosetting photopolymer resins are sustainable because of no environmental pollution, volatile organic solvents are used in the resin formulations, most of the raw materials are still from non-biobased sources. Therefor the thermosetting photopolymer resin formulations available on the market could be even more sustainable.

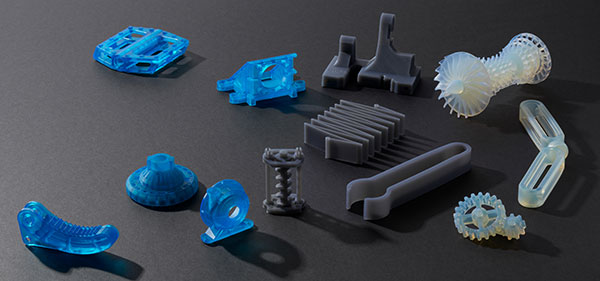

Image from eco plant-based resin developed by Liqcreate and NHL Stenden, published in ACS applied polymer materials.

The raw resin materials are mostly still of fossil origin and once cured, the 3D-printing objects are not recyclable or reprocessable into other objects. In this project, NHL Stenden and Liqcreate will work on developing bio-based photopolymer resins based on building blocks derived plants. Based on these building blocks, photopolymer resin formulations will be made and cured, after which the mechanical properties will be mapped. The best photopolymer resin formulations will be used for 3D-printing objects, the recyclability of which will be studied. The R&D team at Liqcreate is working closely together with the labs and researchers of the NHL Stenden University to develop a prototype resin formulation for 3D-printing. Next to our current product offering, new bio-based photopolymer resins are developed for commercial use. In the next phase of the project the best biobased resin technology and raw materials are scaled and properties of the resins are validated and optimized.

Next to our current product offering, new bio-based photopolymer resins are developed for commercial use. In the next phase of the project the best biobased resin technology and raw materials are scaled and properties of the resins are validated and optimized.

Mechanical properties of plant-based 3D-printing resin

The first phase of the study focused on the development of a plant-based, bio-based and eco 3D-printing resin. The main goal was to get a high biobased content (the actual percentage of material that has a bio source) in combination with interesting properties and good printing behavior. Multiple resin mixtures were made with biobased content from 70% up to 84%. The best resins are listed in table 1. The results of this study were published in the Journal of ACS applied polymer materials. Compared to the bio-based resins, the materials are softer and bendable. Future development will focus in increasing the rigidity and toughness of this plant-based resin while maintaining the biobased content.

| Table 1. Characteristics of 3D printed products from biobased resins. | |||||

| Resin | Tg °C | Tensile modulus MPa | Elongation at break % | Tensile Strength MPa | Biobased content |

| Sample-06 | 80.2 | 870 ± 44 | 18 ± 3 | 36.4 ± 0.4 | 76.0 % |

| Sample-09 | 96.9 | 1007 ± 30 | 10 ± 2 | 43.7 ± 0.3 | 77.5 % |

| Sample-10 | 78.1 | 727 ± 12 | 24 ± 3 | 28.3 ± 0.3 | 79.7 % |

Difference between eco, bio-based and recyclable resins

Often mixed-up, bio-based and recyclable resins are two different classes of materials. Biobased means that the raw materials are sourced from a non-fossil origin. In almost all cases, a part of the raw material chemicals are sourced from plants. Often a percentage of biobased content is given. Recycling means that the material can be used again. With cross-linked resins it is often difficult to up-cycle or recycle. To give the polymer resin a second life and not use as energy in a power plant or use it in a low-end application.

In almost all cases, a part of the raw material chemicals are sourced from plants. Often a percentage of biobased content is given. Recycling means that the material can be used again. With cross-linked resins it is often difficult to up-cycle or recycle. To give the polymer resin a second life and not use as energy in a power plant or use it in a low-end application.

Toxicity of eco, plant-based and bio-based 3D-printing resins

Some brands have launched a plant-based, bio-based or eco 3D-printing resin lately. Think about the eSUN eResin-PLA, the Anycubic Plant-based UV resin, the Elegoo Plant-based rapid resin and many more. Most resins are based on soybean oil which are chemically turned into acrylates to be used in 3D-printing resins. Unfortunately none of the plant-based resins available show any bio-based content so it is unknown how much these materials really help creating a world without reliability on fossil sources. Additionally these resins are often seen as low odor alternatives. The smell of a resin has not much to do with the bio-based nature of the product, but more with the choice of raw materials from the other resins. For instance most of our Liqcreate resins are also very low in odor.

The smell of a resin has not much to do with the bio-based nature of the product, but more with the choice of raw materials from the other resins. For instance most of our Liqcreate resins are also very low in odor.

Future developments in non-toxic, eco and plant-based 3D-printing resins.

As listed above, the current options in plant-based, eco and non-toxic SLA resins are confusing and limited to non-industrial use, there are quite some steps to improve. Liqcreate is working together with leading universities to develop plant-based eco resin with high biobased content which can be used for functional parts. With the current technology it is possible to create a material with very high bio-based content, however, the properties need to improve for industrial use. Liqcreate started several new studies together with the University of Groningen, Maastricht University and NHL Stenden University to develop 3D-printed resins that can be re-moulded and recycled after printing. Follow us on Instagram, Facebook or Linkedin to get the latest news about our plant-based eco resin development.

Follow us on Instagram, Facebook or Linkedin to get the latest news about our plant-based eco resin development.

Support

Do you need any help with 3D printing our SLA, DLP or LCD resins? We can help you! Just look for the question you have below. If you can’t find it, let us know by contacting us!

Printer Settings →Plant-Based Resins: Best Brands & Printing Guide

Being environmentally conscious is at the forefront of many people’s priorities these days, and it’s the little changes that can really add up – such as using plant-baed resins rather than standard ones.

3D printing companies and enthusiasts alike are opening themselves up more and more to these changes, and so there’s recently been a huge focus on eco-friendly resins.

In FDM, recyclable or biodegradable filaments have come about – and so we’ll look at some of the best plant-based resins available today, and how you can be more environmentally friendly with resin 3D printing, and how they work.

Table Of Contents

- What is Plant-Based/Eco-Friendly Resin?

- Plant-Based vs Standard Resins: The Differences

- Are Eco-Resins 100% Environmentally Friendly?

- How to 3D Print with Eco-Resin

- Are Plant-Based Resins Toxic?

- Best Plant-Based Resins

- Anycubic Eco-Resin

- Elegoo Plant-Based Resin

- Siraya Tech Plant-Based Eco-Friendly Resin

Plant-based resins are 3D printer resins that are made primarily from oils. These oils come from soybeans and corn in most cases, but can also come from sunflowers, whey, potatoes, beets, and even algae.

By creating 3D printer resin with plants, we end up with eco-friendly materials that are recyclable, biodegradable, and ready to make the high-resolution print projects you know and love.

Plant-Based vs Standard Resins: The DifferencesStandard 3D printer resins are made with a variety of chemical compounds to achieve the look, color, and properties ideal for printing with resin. Like many plastics, these polymers are often toxic made using non-eco-friendly methods that leave them unrecyclable and hazardous to both the environment and your health.

Like many plastics, these polymers are often toxic made using non-eco-friendly methods that leave them unrecyclable and hazardous to both the environment and your health.

Typical SLA resins pose the same danger to the environment as plastic. Through irresponsible disposal and misuse, they are a real threat to the planet and are generally considered to be toxic waste in the worst of cases.

This is why environmentally friendly ‘bio-resins’ are becoming more and more popular and widely available as they’re now much easier to find on online marketplaces and have costs comparable with standard UV resins. Not only are the plants from which they’re made found in abundance, but they’re also fairly cheap to produce.

It wasn’t that long ago that eco-friendly resins were a niche market, hard to find and often expensive. Now, these resins are found in most marketplaces by well-known brands, and often for a price similar to that of more traditional materials.

In essence, plant-based resins are an excellent substitute for standard resins with basically no downsides aside from occasionally being slightly more expensive. Aside from that, you’ll find the same top-quality as many other resins on the market, meaning nothing has been sacrificed for greener, more eco-conscious printing.

Aside from that, you’ll find the same top-quality as many other resins on the market, meaning nothing has been sacrificed for greener, more eco-conscious printing.

As of writing, these bio-resins are only really available in standard resin form, meaning you’re not likely to find ABS-like or particularly tough ‘treated’ resins on the market just yet. But we’ve got high hopes for the ever-greener-looking future!

Are Eco-Resins 100% Environmentally Friendly?Despite eco-friendly resins being a great step forward, the sad answer to this question is no. The ‘plant-based’ nature of eco resins is only the tip of the iceberg, as currently the plant oils they’re made from only make up around half of the total composition.

While still a viable, safer, and far more eco-friendly alternative to standard resins, eco-resins still have a long way to go before they can be considered 100% environmentally sound.

Don’t be discouraged, though, the lowest quantity of these oils I could find in any given resin was 45% soybean oil in Anycubic’s plant-based eco-resin. This is still a heck of an improvement over the typical compounds we’ve all been using for years.

This is still a heck of an improvement over the typical compounds we’ve all been using for years.

You can treat eco-resins as standard resins in terms of printer settings. The two are functionally identical, and thus carry some of the same risks.

In the same way that you can use plant-based resins with your 3D printer just like normal resins, you should also keep up the same safety precautions you’ve hopefully been using thus far.

These precautions include using a well-ventilated space for your printing, as well as wearing protective gloves, masks, and even eyewear if you’re particularly worried.

Are Plant-Based Resins Toxic?Make no mistake, all resins are toxic when uncured. The toxicity and general hazards vary from brand to brand, and plant-based resins are not without their dangers.

Depending on what they’re made from, even plant-based resins can irritate the skin and eyes, and even cause respiratory damage if not handled with care before and during printing.

Just like how you still wouldn’t ingest plant-based resins, you should still be careful when using them. Resins, even plant-based ones, should never come into direct contact with the skin until fully cured, and even then you should still avoid contact with your eyes and mouth.

Research into potential medical applications of plant-based resins has been conducted, but even that hasn’t proven to be fully safe or even consistent when using the purest of currently available compounds.

Now that you know all the basics (and warnings) of using plant-based resins, the main problem now is which brand to choose. Here we’ll look at some of the best and most reliable bio-resins on the market today, and which you should go for.

Because readily available plant-based resins are still a fairly new concept, there isn’t quite as much choice out there as there are for other types like water-washable and ABS-like resins, so be sure to choose wisely!

Best Plant-Based Resins

3DSourced is reader-supported. When you buy through links on our site, we may earn an affiliate commission. Learn more

When you buy through links on our site, we may earn an affiliate commission. Learn more

- Price: Check price on Amazon here / Also available at Anycubic here

- Available Colors: White, Black, Translucent Green, Gray, Pink, Yellow, Clear

Anycubic offers one of the most extensive ranges of 3D printer resins, one of which is, naturally, their soybean oil-based Eco-Resin.

With its low shrinkage, high compatibility, impressive quality, and natural biodegradability, it’s easy to see why Anycubic’s affordably priced eco-resin is at the top of many people’s lists.

While the range of colors available isn’t quite as exciting as their standard resin or Resin+ lines, they do offer quite a bit of variety, including the ever-popular (and frankly my favorite) translucent green.

While Anycubic’s resins are known for their low odor, their plant-based resin goes a step further, taking advantage of their own formula to further remove the unpleasant smells from their plant-based resin, which is already naturally low on the stink scale.

Anycubic also doesn’t sacrifice print quality and resolution for environmental friendliness, and is a great resin to go for if you want top-quality prints while maintaining a clearer conscience.

Anycubic is also a model of affordability. While originally around $70 per kilogram (0.9L), it will now only set you back around half that at $36. Compare this to their standard resin price of $32/kg, and you can see it’s one heck of a deal.

Elegoo Plant-Based Resin

- Price: Check price on Amazon here

- Available Colors: White, Black, Gray, Clear Green, Translucent

Like Anycubic, Elegoo resins are known for their high resolution, print quality, color variation, and affordability.

Elegoo’s plant-based resin is fast-curing and has very low emission rates, making it one of the safest bio-resins on this list without you having to take any extra steps. Don’t be fooled, though, remember that there’s no such thing as a fully non-toxic resin (yet).

With similarly low shrinkage, color variation, and print quality to Anycubic’s eco-resin, the main reason to go for Elegoo here is its price.

Sold in bottles as small as 500g, it’s a great under-$20 option if you either don’t want to buy much at once, or are just looking to test out plant-based resin for yourself before committing to it as a regular-use material.

As for color options, there aren’t quite as many to choose from as their standard resins, which are known to be numerous at around 10 colors for each standard resin. If you’re looking for vibrant projects, I recommend the clear green. It’s vibrant, brilliant, and quite eye-catching.

Of course, you could also opt for their translucent resins for some cool unique projects too. Though these recommendations are coming from a writer who’s getting a little sick of white and gray, so you don’t have to take these recommendations as gospel.

Be advised that while Elegoo does advertise their eco-friendly resin as being low-irritant and virtually odor-free, I still absolutely recommend taking the usual precautions we mentioned above like good ventilation, protective gloves, and generally careful handling

Siraya Tech Plant-Based Eco-Friendly Resin

- Price: Check price on Amazon here

- Available Colors: Gray, Obsidian Black

While the most expensive (even if only marginally) and more boringly colored plant-based resin on this list, the lesser-known Siraya Tech’s eco-friendly resin is still very much worth a look.

As well as being low-odor and fast-curing like its competitors, Siraya is very easy to clean, needing very little post-processing for some insanely high-quality results.

Of course, due to its extremely limited color options, you will need to properly treat and paint your projects if you want them to stand out.

The key to Siraya’s plant-based resin is how insanely easy it is to use. Advertised as being perfect for students, educators, or just straight-up beginners, it’s a pretty great option if you’re still new to 3D printing or are looking to start out with plant-based resins on the right foot.

Overall, Siraya Tech is a good, hassle-free, environmentally-friendly resin that won’t disappoint and offers a great toe-dipping experience for those of you unsure of where to begin.

It’s also highly compatible and should work just fine with any resin printer, eliminating the guesswork for those of you who’ve had trouble finding compatible materials in the past.

This beginner-friendliness is further proven by Siraya Tech’s excellent support network, which is keen to hear from users and answer their questions as clearly as possible. All in all, this is the plant-based resin for you if you happen to need a helping hand in learning or teaching about eco-friendly resins as well as just resins in general.

All in all, this is the plant-based resin for you if you happen to need a helping hand in learning or teaching about eco-friendly resins as well as just resins in general.

Related posts:

- Recycling 3D Printer Filaments

- Best Anycubic Resins

- Best Elegoo 3D Printers

- Strongest 3D printer resins

- Best flexible resins

- Coolest resin prints and resin 3D printer files

Choosing a liquid photopolymer for a 3D printer. Classification of materials for SLA/DLP 3D printing.

Contents:

- Introduction

- SLA Overview

- SLA Standard Resins

- Standard photopolymer resin - Standard

- Clear Photopolymer Resin - Clear

- Engineering photopolymer resins

- Rigid photopolymer resin - Tough (like ABS)

- Durable photopolymer resin - Durable (PP-like)

- Heat resistant photopolymer resin - Heat resistant

- Rubber-like photopolymer resin - Rubber-like (Elastic)

- Ceramic photopolymer resin - Ceramic filled (Hard)

- How to choose the right resin for your application

- Dental and medical SLA resins

- Medical Device Photopolymer Resin - Custom Medical Appliances (Class I Biocompatibility)

- Dental Long Term Biocompatible Resin (Class IIa Biocompatible)

- Biocompatibility class I vs biocompatibility class IIa

- Cast SLA resins

- Cast resin for jewelry making

- Generalized rules

Hello everyone, Friends! With you 3DTool!

This article compares photopolymer resins using Formlabs SLA 3D printing products –

Catalog of photopolymer 3D printers

Photopolymers from FormLabs

Detailed review of the Formlabs Form 3 3D printer

Introduction

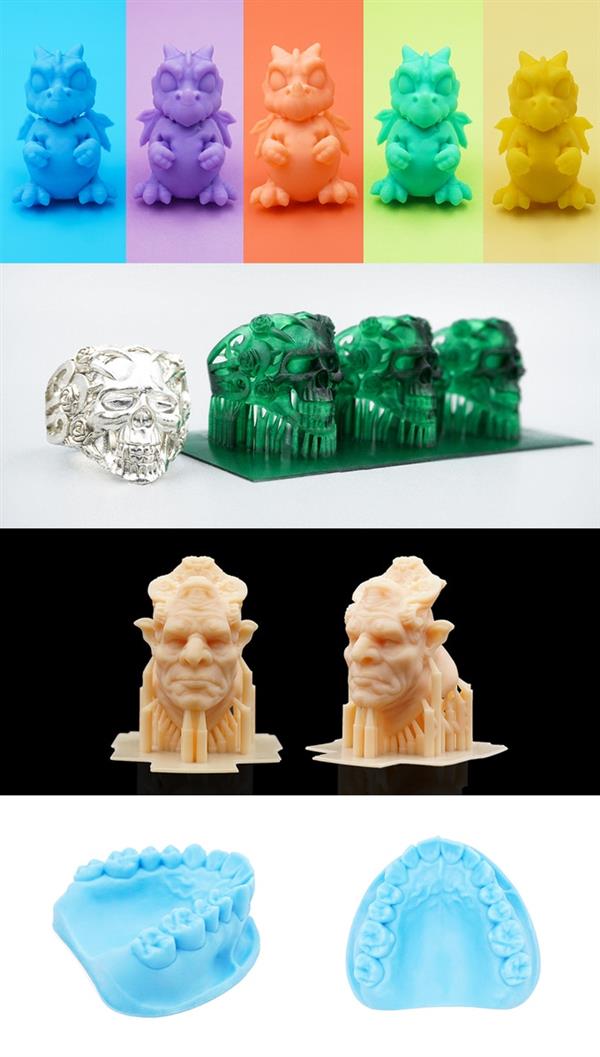

The stereolithography prints plastic parts with high resolution, good fine detail and smooth surface. Due to the variety of photopolymer resins available for SLA, this technology is used in many different industries:

-

"Standard" photopolymers are used for prototyping

-

Engineering photopolymers have certain mechanical and thermal properties

-

Dental and medical photopolymers have biocompatibility certificates.

-

Cast photopolymers have a zero ash content after burning.

SLA 3D Printing Resin Overview

SLA uses a laser to cure a liquid photopolymer resin. This process is called photopolymerization. Various combinations of polymers and other additives that are part of the resin allow you to get different material properties.

The main advantages and limitations that are common to all resins in SLA 3D printing are:

Benefits:

Weaknesses:

Base Resins for SLA

Post-Processing SLA/DLP 3D Printing Article

Standard photopolymer resin - Standard

Standard resins produce parts with high stiffness, detail and a smooth surface. The low cost of resins, from $250 per liter, makes them ideal for prototypes.

The color of the resin also affects its properties. For example, in FormLabs products, gray resin is suitable for models with fine details, and white resin for parts that require the smoothest possible surface.

Benefits of using Standard grade resins:

Cons Standard:

Also included in the class of "Standard" photopolymer resins from FormLabs is the Color KIT - a set of special dyes and "Color Base" photopolymer resin for mixing and obtaining a variety of color solutions. This eliminates the need for painting parts after 3D printing.

This eliminates the need for painting parts after 3D printing.

FormLabs Engineering Photopolymer Resins

Engineering resins have a range of properties for injection molded plastics.

All engineering resins require additional UV curing, such as using the Form Cure, to achieve their maximum properties.

Tough photopolymer resin - Tough (ABS equivalent)

Tough resin was developed for models that need to withstand high loads and be durable.

This material produces strong, shatter-resistant parts and functional prototypes such as snap-on housings.

Pros:

Cons:

Ideal for: functional prototypes, mechanical parts

Durable photopolymer resin - Durable

Durable resin is a wear-resistant and flexible material with mechanical properties similar to polypropylene.

Durable photopolymer produces models with a smooth glossy surface and high resistance to deformation.

Durable Resin is ideal for:

- Bushings and bearings;

- Various functional compounds

Pros:

Cons:

-

Not suitable for thin wall parts (recommended minimum wall thickness 1mm)

-

Low heat distortion temperature

-

Low flexural strength (lower than hard resin)

Ideal for: functional prototypes.

Refractory Photopolymer Resin - Formlabs High Temp Resin

The heat resistant resin is ideal for parts that require high temperature resistance and operate at high temperatures.

Formlabs High Temp Resin provides the highest melting point (HDT): 238°C at 0.45 MPa.

The resin should be used to print detailed, accurate prototypes with high heat resistance.

Pros:

Cons:

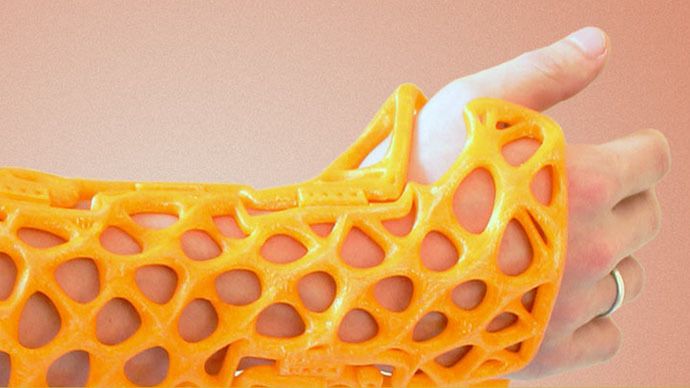

Flexible Resin

Rubber-like resin allows flexible parts to be made. This material has a low tensile strength and high elongation at break and is well suited for parts that will be bent or compressed.

It can also be used to add ergonomic features to multi-material assemblies such as: dies, wearable prototypes, handles, pads and grips.

Pros:

-

High flexibility (high elongation at break)

-

Low hardness (simulates 80A durometer rubber)

-

High impact resistance

Cons:

-

Doesn't have all the properties of real rubber

-

Requires extensive support structures

-

Material properties deteriorate over time as the part is exposed to ultraviolet radiation (sunlight)

-

Not suitable for thin wall parts (recommended minimum wall thickness 1mm)

Ideal for flexible prototyping.

Ceramic photopolymer resin - Rigid Resin

This resin is reinforced with glass, which provides very high rigidity and a polished surface. The polymer is very resistant to deformation and is excellent for 3D printing thin elements.

Ideal for: molds and tooling, jigs, manifolds, retainers, electrical and automotive fixture housings

Thermal management components printed with SLA ceramic (hard) resin. Image credit: Formlabs

How to choose the right resin for your application

The table below shows the main mechanical properties of photopolymers for SLA:

Source: Formlabs

Standard resin ( standart ) has high tensile strength but is very brittle (very low elongation at break) so it is not suitable for functional parts. The ability to create a good part surface makes it ideal for visual prototypes and art models.

Durable ( durable ) resin has the highest impact strength and elongation at break of any other SLA material. Best suited for prototyping parts with moving parts and latches. It lacks, however, the strength of thermoplastic 3D printing materials such as SLA nylon.

tough tough resin is a compromise between the material properties of tough and standard resin. It has a high tensile strength, so it is best suited for rigid parts that require high hardness.

heat resistant resin ( heat resistant ) can withstand temperatures above 200 o C, but has poor impact strength and is even more brittle than standard resin.

ceramic ( ceramic reinforce ) resin has the highest tensile strength and flexural modulus, but is brittle (poor elongation at break and toughness). This resin is preferred for thin wall parts that require increased rigidity.

The graphs below compare the mechanical properties of the most common SLA materials visually:

Comparison chart for elongation at break and toughness for common SLA printing specifications and standard media. Image courtesy of Formlabs.

Stress-strain curves for conventional SLA technologies and standard materials. Image credit: Formlabs

Pros:

Cons:

- Moderate wear and tear resistance

Ideal for: Surgical aids and appliances

Dental Long Term Biocompatible Resin - Dental Long Term (Class 2A biocompatible)

0114

These resins are specially formulated for long term dental fixtures. Class 2A biocompatible resins can come into contact with the human body for up to a year.

High resistance to breakage and wear make this resin ideal for making rigid cotter pins or retainers.

Pros:

Cons:

-

High price

Ideal for: durable dental instruments, fracture and wear resistant medical parts, rigid cotter pins, retainers

What is the difference between class 1 and class 2a biocompatibility?

Class 1 biocompatibility rules apply to materials that are allowed to be used for:

-

non-invasive devices that come into contact with intact skin

-

devices for temporary use or short-term use in the mouth or ear canal or in the nasal cavity

-

reusable surgical instruments

Class 2a biocompatibility rules apply to materials that are allowed to be used for:

-

devices that come into contact with bodily fluids or open wounds

-

devices used to introduce substances into or remove substances from the human body

-

invasive short-term devices such as invasive surgical items

-

long-term implantable devices placed in the teeth

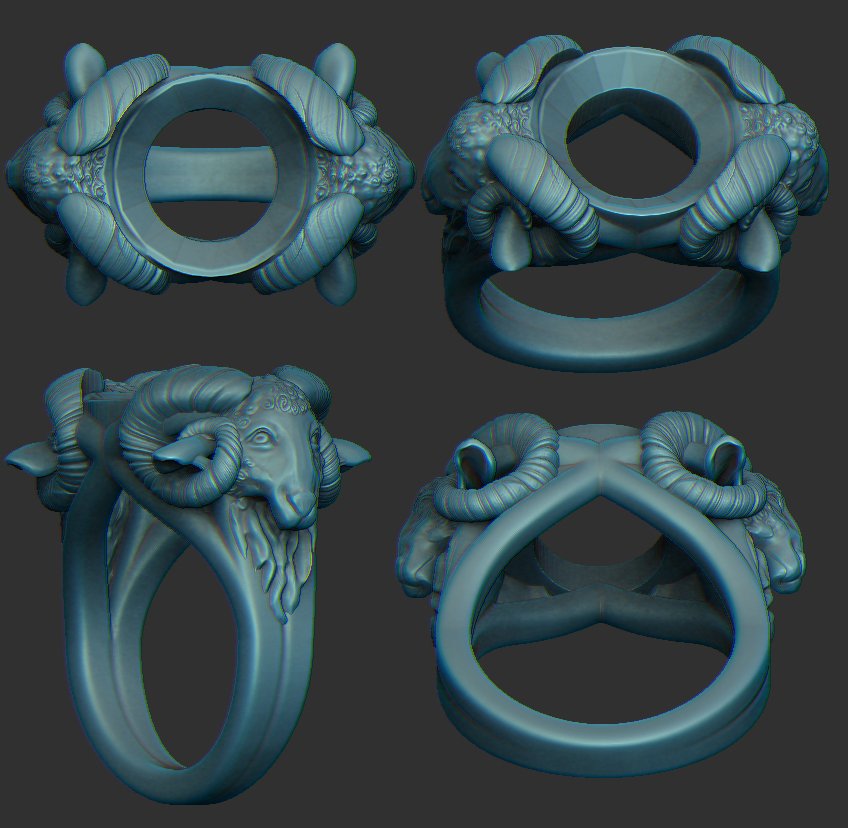

Photopolymer resins in SLA 3D printing for jewelers

Jewelry resins

This material allows you to print models with fine details and a smooth surface without leaving ash or residue after burning.

Cast resin allows you to get the finished product directly from design to precision casting with just one 3D printed part. It is suitable for making jewelry and other small and complex components.

Pros:

Cons:

Ideal for: investment casting, jewelry making

SLA/DLP 3D printer catalog

Photopolymers from FormLabs

Post-Processing SLA/DLP 3D Printing Article

Well, that's all we have! We hope this article was useful for you!

You can order Formlabs SLA 3D printers or ask your questions and find out the status of your order, you can

- Email: [email protected]

- By phone: 8(800)775-86-69

- Or on our website: http://3dtool.ru

-

Don't forget to subscribe to our YouTube channel:

Subscribe to our groups in social networks:

In contact with

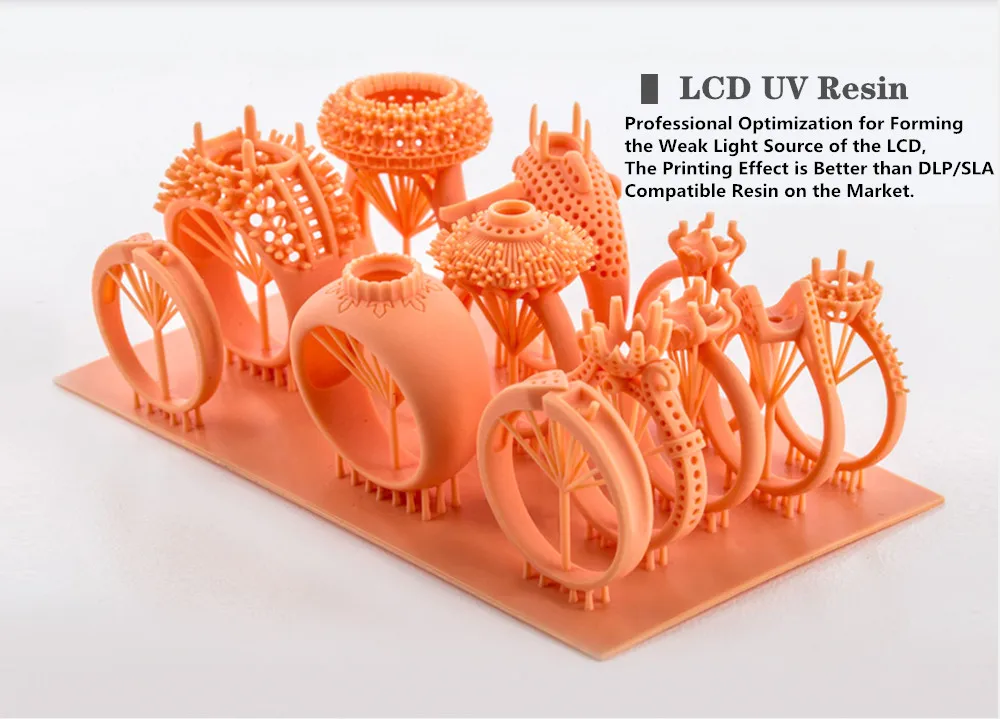

Eco-friendly Photopolymer resin Anycubic ECO RESIN for 3D printing on LCD/DLP printers 0.

5 l Black in Syzran

5 l Black in Syzran 1,790 ₽

1 offer

- 1. Click, “I want to buy”.

- 2. Get offers from sellers.

- 3. Choose the most favorable purchase condition.

Payment and delivery

Payment

Cash on delivery

Payment by card online

Credit or installment plan

Calculation Calculation

Delivery

from the seller’s warehouse

Aptory

Guarantee

Accurate terms of goods

9005 daysVideo

🌑 ANYCUBIC PHOTON X The newest photopolymer 3D printer The largest print field Igor Beletsky

🌑 ANYCUBIC PHOTON X The newest photopolymer 3D printer The largest print field Igor Beletsky

PT6M58Strue

Resin RESIONE from Aliexpress. Great review! Which Resin to Choose?... Print Order

Overview of 3D Printing Resins: Main Types of Photopolymer Resins

Overview of 3D Printing Resins: Main Types of Photopolymer Resins

PT6M58Strue

Overview of 3D Printing Resins: Main Types of Photopolymers resins

Review and test of photopolymer resins abc like, resione K, M68 #3d_model #3d #tutpinkod

Review and test of photopolymer resins abc like, resione K, M68 #3d_model #3d #tutpinkod

PT6M58Strue

Review and test of photopolymer resins abc like, resione K, M68 #3d_model #3d #tutpinkod

Anycubic ECO UV resin - review of vegetable resin

Anycubic ECO UV resin - review of vegetable resin 63

Anycubic ECO UV resin - review of vegetable resin

Anycubic Foton Mono photopolymer printer. 2 part.

2 part.

Anycubic Foton Mono photopolymer printer. How long does 1kg of resin last. 2 part.

PT6M58Strue

Anycubic Foton Mono photopolymer printer. How long does 1kg of resin last. 2 part.

Photopolymer 3D Printing Technology Review & Comparison - SLA, LCD, DLP, LFS, ILS, MJP

Photopolymer 3D Printer Technology Review & Comparison - SLA, LCD, DLP, LFS, ILS, MJP

PT6M58Strue

Review & Comparison photopolymer 3D printing technologies - SLA, LCD, DLP, LFS, ILS, MJP

CHINESE, WHAT ARE YOU DOING?? BEST PHOTOPOLYMER 3D PRINTER 2022! TOP 3D PRINTER

CHINESE WHAT ARE YOU DOING?? BEST PHOTOPOLYMER 3D PRINTER 2022! TOP 3D PRINTER

PT6M58Strue

CHINESE, WHAT ARE YOU DOING?? BEST PHOTOPOLYMER 3D PRINTER 2022! TOP 3D PRINTER

Display Protection/ How to clean FEP film/ Resin for beginners

Display Protection/ How to clean FEP film/ Resin for beginners

PT6M58Strue

Display Protection/ How to clean FEP film/ Resin for beginners

3D printer Photon S. Fairy tale! We print with resin. All about photopolymer 3D printer / Arstyle /

Fairy tale! We print with resin. All about photopolymer 3D printer / Arstyle /

3D printer Photon S. Fairy tale! We print with resin. All about photopolymer 3D printer / Arstyle /

PT6M58Strue

3D printer Photon S. Fairy tale! We print with resin. All About Resin 3D Printer / Arstyle /

Quick Review | Anycubic Photon Mono X 6K

Quick Review | Anycubic Photon Mono X 6K

PT6M58Strue

Quick Review | Anycubic Photon Mono X 6K

Review Elegoo Saturn 2 8k Best Polymer 3D Printer in 2022

Overview Elegoo Saturn 2 8K Best Polymer 3D Printer in 2022

PT6M58STRUE

ELEGOO SATURN 24Durn 2 8K Best Photopolymer 3D in 2053D in 2053D in 2000. 3D in 2022 Consumables for photopolymer printing. FEP for Anycubic Photon Mono 4k

3D in 2022 Consumables for photopolymer printing. FEP for Anycubic Photon Mono 4k

There is a choice! Consumables for photopolymer printing. FEP for Anycubic Photon Mono 4k

PT6M58Strue

There is a choice! Consumables for photopolymer printing. FEP for Anycubic Photon Mono 4k

Anycubic Photon 3D printer review: Inexpensive and cool - budget photopolymer 3D printer

Anycubic Photon 3D printer review: inexpensive and cool - budget photopolymer 3D printer cool — budget photopolymer 3D printer

MIRACLE PHOTOPOLYMER 3D PRINTER CREALITY HALOT-SKY

MIRACLE PHOTOPOLYMER 3D PRINTER CREALITY HALOT-SKY

PT6M58Strue

MIRACLE PHOTOPOLYMER 3D PRINTER CREALITY HALOT-SKY

A dangerous purchase for a modeller! Review of ELEGOO MARS 3 PRO 4K LCD MSLA 3D PRINTER (+RESIN TEST).

A dangerous purchase for a modeller! Review of ELEGOO MARS 3 PRO 4K LCD MSLA 3D PRINTER (+RESIN TEST).

PT6M58Strue

A dangerous purchase for a modeler! Review of ELEGOO MARS 3 PRO 4K LCD MSLA 3D PRINTER (+RESIN TEST).

Slicer Review, R_E_R_F, First Print AnyCubic Foton Mono X

Slicer Review, R_E_R_F, First Print AnyCubic Foton Mono X

PT6M58Strue

Slicer review, R_E_R_F, first print AnyCubic Foton Mono X

Drain resin conveniently!!! DIY 3D Resin VAT wall holder. Anycubic Photon Mono 4k.

Drain resin conveniently!!! DIY 3D Resin VAT wall holder. Anycubic Photon Mono 4k.

PT6M58Strue

Drain resin conveniently!!! DIY 3D Resin VAT wall holder. Anycubic Photon Mono 4k.

Anycubic Photon Mono 4k.

1 790 ₽

1 offer

- 1. Click “I want to buy”.

- 2. Get offers from sellers.

Video

🌑 Anycubic Photon X The newest photopolymer 3D printing Press Igor Beletsky

🌑 Anycubic Photon 3 The largest photopolymer 3D printing field Igor Beletsky

🌑 ANYCUBIC printer The largest print field Igor Beletsky

WHAT THE ANYCUBIC PHOTON

PHOTOPOLYMER PRINTER CAN DO WHAT THE ANYCUBIC PHOTON 9 PHOTOPOLYMER PRINTER CAN DO0053PT6M58Strue

WHAT ANYCUBIC PHOTON CAN DO

RESIONE Resin from Aliexpress. Great review! Which photopolymer to choose?... Print order

RESIONE resin from Aliexpress. Great review! Which photopolymer to choose?.

.. Print order

.. Print order PT6M58Strue

RESIONE resin from Aliexpress. Great review! Which Resin to Choose?... Print Order

Overview of 3D Printing Resins: Main Types of Photopolymer Resins

Overview of 3D printing resins: main types of photopolymer resins

PT6M58Strue

Overview of 3D printing resins: main types of photopolymer resins

Overview and test of photopolymer resins abc like, resione K, M68 #3d_model #3d #tut5pinko3d

Review and test of photopolymer resins abc like, resione K, M68 #3d_model #3d #tutpinkod

PT6M58Strue

Review and test of photopolymer resins abc like, resione K, M68 #3d_model #3d #tutpinkod

Anycubic ECO UV resin - vegetable resin review

Anycubic ECO UV resin - vegetable resin review

PT6M58Strue

Anycubic ECO UV resin - vegetable resin review

1 kg resin.

2 part.

2 part. Anycubic Foton Mono photopolymer printer. How long does 1kg of resin last. 2 part.

PT6M58Strue

Anycubic Foton Mono photopolymer printer. How long does 1kg of resin last. 2 part.

Photopolymer 3D Printing Technology Review & Comparison - SLA, LCD, DLP, LFS, ILS, MJP

Photopolymer 3D Printer Technology Review & Comparison - SLA, LCD, DLP, LFS, ILS, MJP

PT6M58Strue

Review & Comparison photopolymer 3D printing technologies - SLA, LCD, DLP, LFS, ILS, MJP

CHINESE, WHAT ARE YOU DOING?? BEST PHOTOPOLYMER 3D PRINTER 2022! TOP 3D PRINTER

CHINESE, WHAT ARE YOU DOING?? BEST PHOTOPOLYMER 3D PRINTER 2022! TOP 3D PRINTER

PT6M58Strue

CHINESE WHAT ARE YOU DOING?? BEST PHOTOPOLYMER 3D PRINTER 2022! TOP 3D PRINTER

Display Protection / How to clean FEP film / Resin for beginners

Display Protection / How to clean FEP film / Resin for beginners

PT6M58Strue

Display Protection / How to clean FEP film / Resin for beginners 9064 9062 3D printer Photon S.

Fairy tale! We print with resin. All about photopolymer 3D printer / Arstyle /

Fairy tale! We print with resin. All about photopolymer 3D printer / Arstyle / 3D printer Photon S. Fairy tale! We print with resin. All about photopolymer 3D printer / Arstyle /

PT6M58Strue

3D printer Photon S. Fairy tale! We print with resin. All About Resin 3D Printer / Arstyle /

Quick Review | Anycubic Photon Mono X 6K

Quick Review | Anycubic Photon Mono X 6K

PT6M58Strue

Quick Review | Anycubic Photon Mono X 6K

Elegoo SATURN 2 8K review best resin 3D printer in 2022

Review Elegoo SATURN 2 8K best resin 3D printer in 2022

PT6M58Strue

Review Elegoo SATURN 2 8K best resin 3D printer in 2022

There is a choice! Consumables for photopolymer printing.

FEP for Anycubic Photon Mono 4k

FEP for Anycubic Photon Mono 4k There is a choice! Consumables for photopolymer printing. FEP for Anycubic Photon Mono 4k

PT6M58Strue

There is a choice! Consumables for photopolymer printing. FEP for Anycubic Photon Mono 4k

Anycubic Photon 3D printer review: Inexpensive and cool - budget photopolymer 3D printer

Anycubic Photon 3D printer review: inexpensive and cool - budget photopolymer 3D printer cool — budget photopolymer 3D printer

MIRACLE PHOTOPOLYMER 3D PRINTER CREALITY HALOT-SKY

MIRACLE PHOTOPOLYMER 3D PRINTER CREALITY HALOT-SKY

PT6M58Strue

MIRACLE PHOTOPOLYMER 3D PRINTER CREALITY HALOT-SKY

A dangerous purchase for a modeller! Review of ELEGOO MARS 3 PRO 4K LCD MSLA 3D PRINTER (+RESIN TEST).

Learn more