3D printer enclosure fan

Temperature & Ventilation Guide – 3D Printerly

As we all know, 3D printers place great importance on getting the right temperature conditions in order to create a high-quality 3D print. One of the best ways to achieve that constant temperature is to use an enclosure, but can things get a little too hot?

This article will look into 3D printer enclosures, temperature control, and ventilation.

There are ways to control your 3D printer enclosure’s temperature by using high-quality fans and thermistors. With certain settings, you can keep your 3D printer’s constant temperature in a tight range, giving your 3D prints a better chance to come out successfully.

With 3D printer enclosure temperature control and ventilation, there are more important factors to learn about, so keep on reading.

Does a 3D Printer Need an Enclosure?

If you are printing with PLA which is the most common filament for 3D printing then there is no need to use any enclosure. If you are planning to print with a filament such as ABS, Polycarbonate, or any other filament that may cause problems of warping or curling after being cooled, then an enclosure or a heated 3D printer chamber is a must-have part.

The type of enclosure depends on the work you are doing.

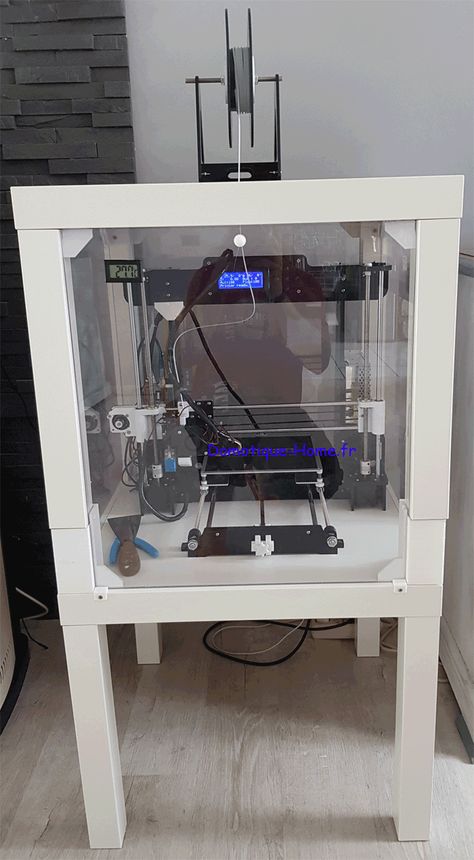

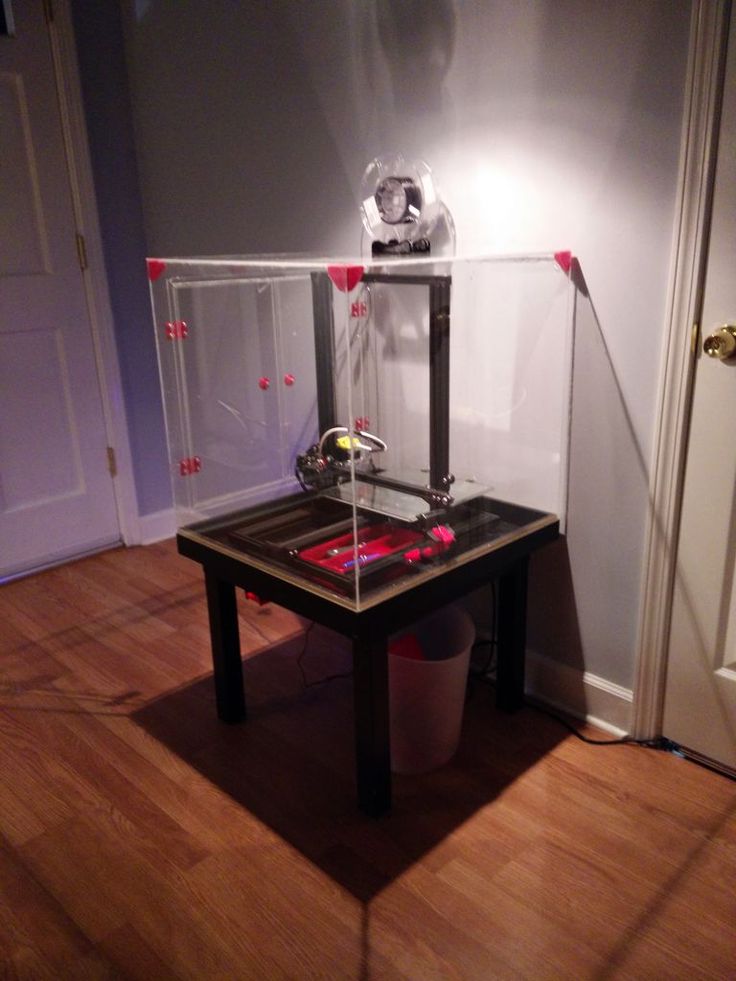

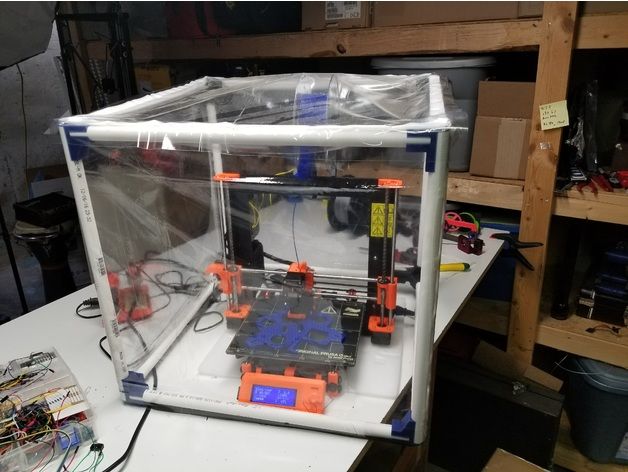

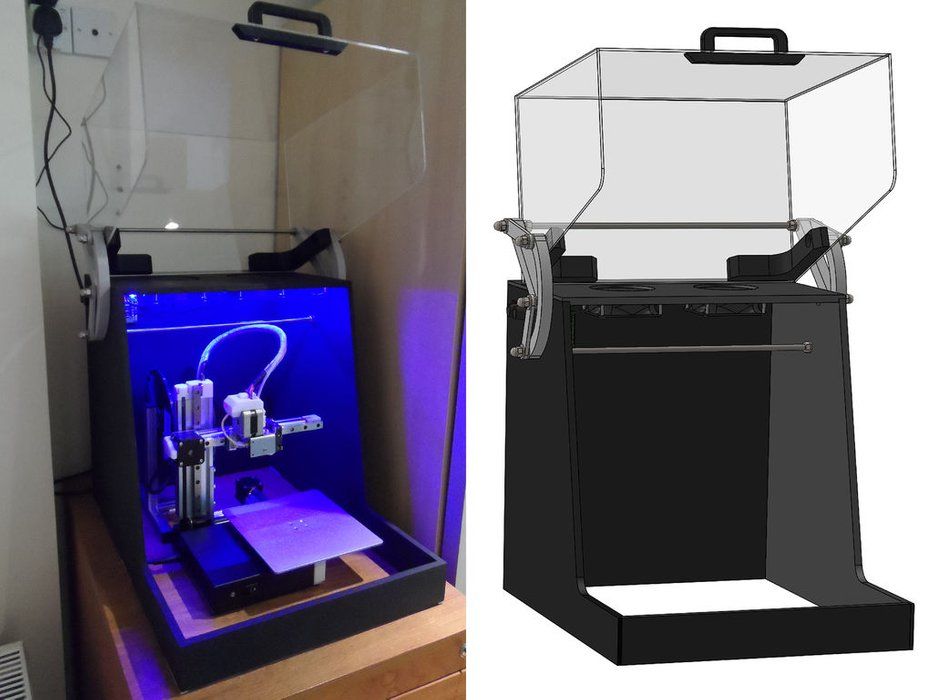

If you just want to hold the heat produced by the print bed and the print nozzle, then covering your 3D printer with any common thing such as cardboard, plastic totes, old table sheet, or something like that will work properly.

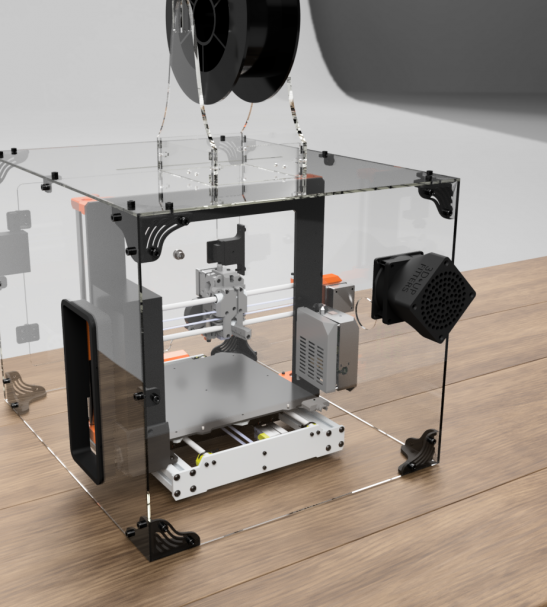

If you want to work like a professional, then build a well-polished and well-designed enclosure that can not only cover your 3D printer while using ABS filament, but also can be opened when you want to print with PLA.

Most people consider an enclosure as an unnecessary part but printing with ABS without an enclosure can damage the quality of the print.

Some prints do benefit from better print quality and fewer imperfections with an enclosure, so figure out which filament you are using, and whether quality improves or declines with an enclosure.

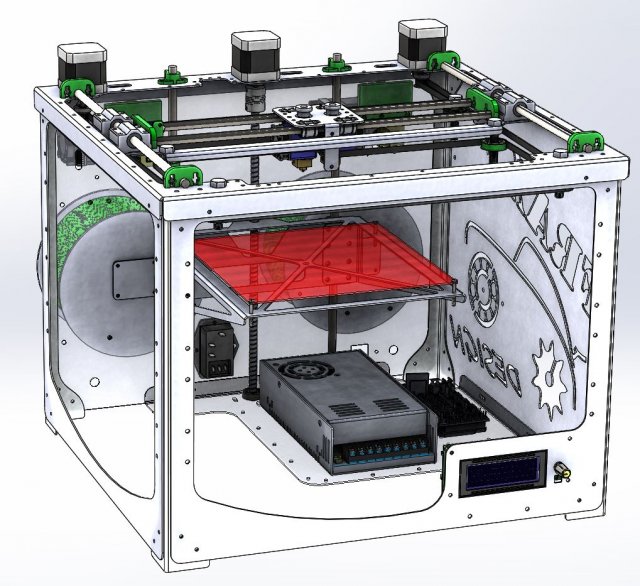

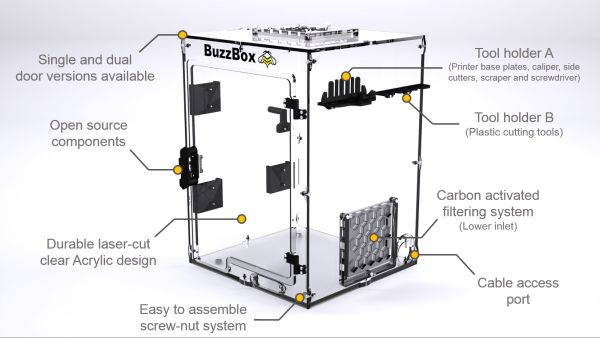

What Should a Good 3D Printer Enclosure Have?

A good 3D printer enclosure should have:

- Enough space

- Good safety features

- Temperature control

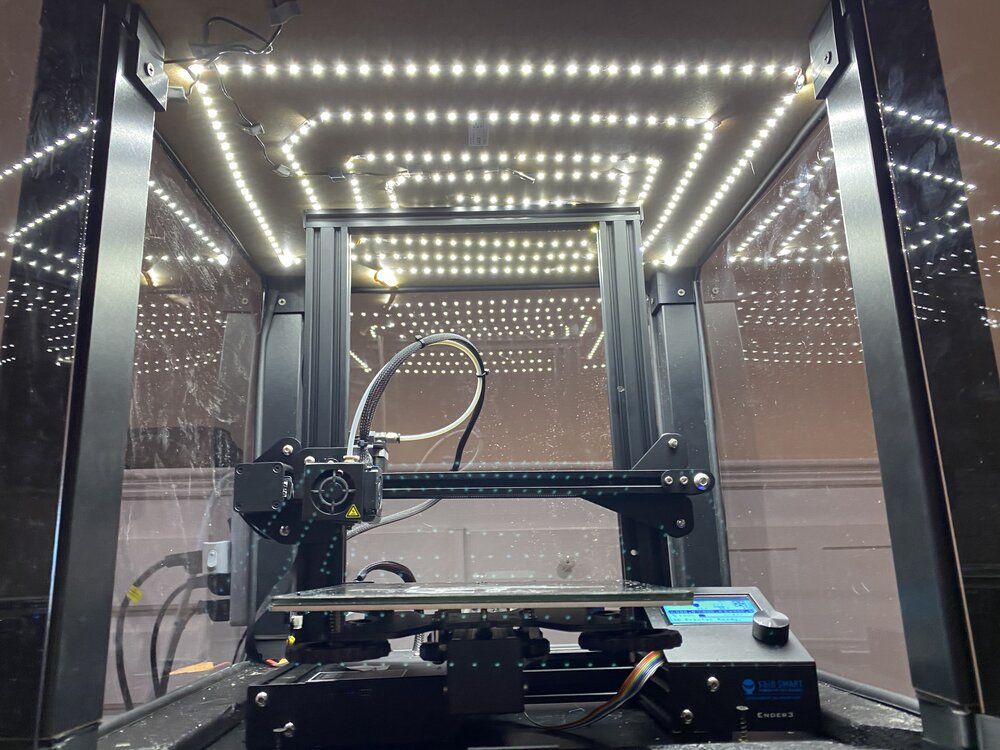

- Lighting

- Air extraction system

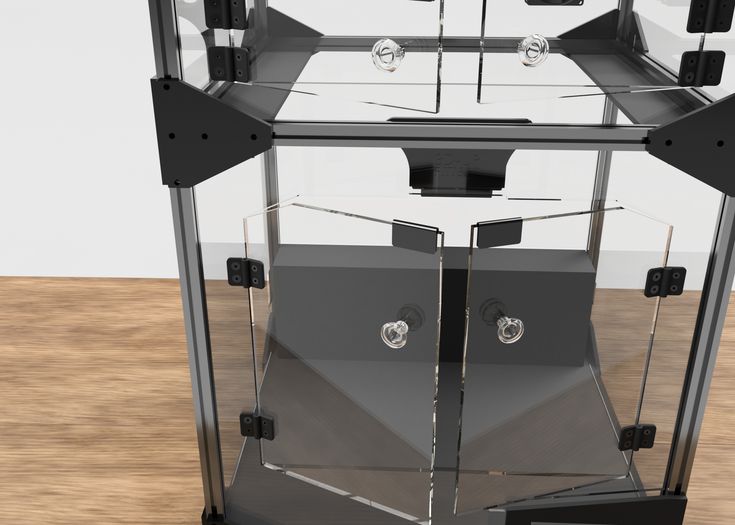

- Operable doors or panels

- Good-looking aesthetics

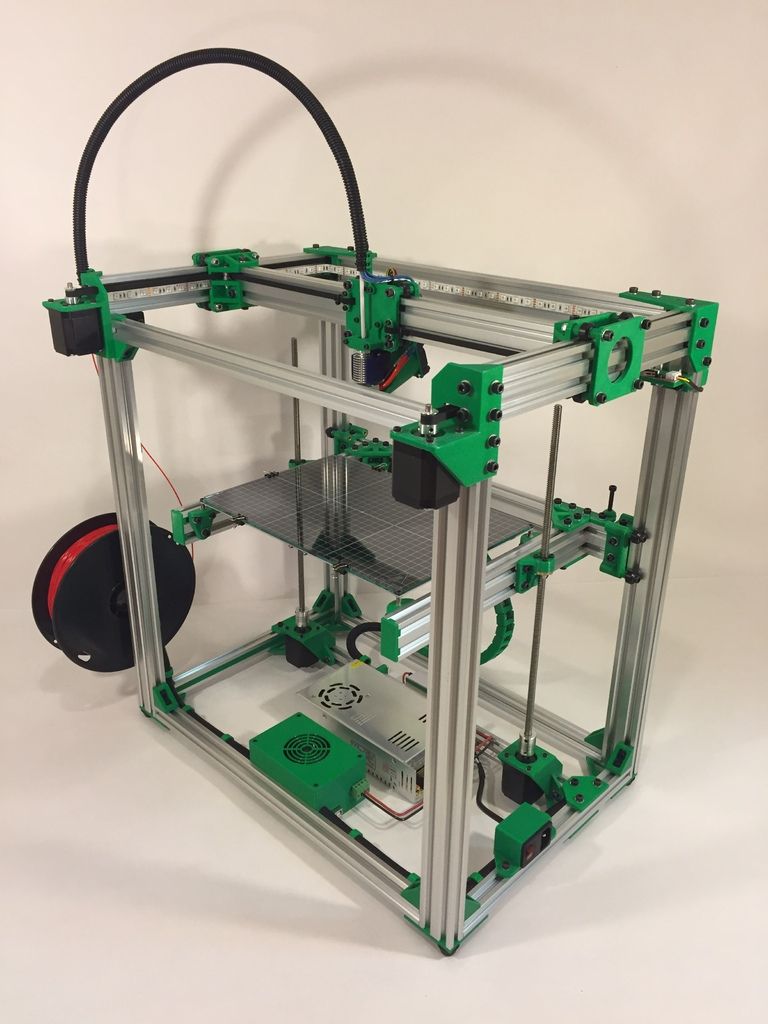

Enough Space

A good 3D printer enclosure should have enough space for all the parts that move in the printing process. While building an enclosure make sure that the moving parts can go up to their maximum range without striking the enclosure.

While building an enclosure make sure that the moving parts can go up to their maximum range without striking the enclosure.

Many 3D printers have wires that move around, as well as the spool itself, so a little extra space for the moving parts is a good idea.

You wouldn’t want a 3D printer enclosure which barely fits your 3D printer because it also makes it difficult to make minor adjustments.

A good example is the Creality Enclosure having two main sizes, a medium for the average 3D printer, then a large for those bigger machines.

Safety Features

One of the main purposes of a 3D printer enclosure is to increase the safety of your working environment. That goes anywhere from physical safety to not touch moving or hot parts, to air filtration, down to fire safety.

There have been reports in the past of a 3D printer catching fire, mainly due to some errors in firmware and heating elements. Even though it is a pretty rare occurrence nowadays, we still want to protect against fires.

Even though it is a pretty rare occurrence nowadays, we still want to protect against fires.

A great fireproof enclosure is a very ideal feature to have, where if a fire did start, it would not catch on fire and add to the problem.

Some people have enclosures made of metal or plexiglass to keep the flames within the enclosure. You can also make sure the enclosure is sealed which effectively cuts off the oxygen supply that a fire requires.

We also should think about kids or pets in this regard. You can have a locking system on your enclosure just to boost the safety aspect of it.

I wrote a post about Whether 3D Printing is Safe for Pets which you can check out for more information.

Temperature Control

I’ve seen some great DIY enclosure which have a built-in temperature control system which measures the temperature inside the enclosure, and increases it with a heater when it gets too low.

You have to make sure your thermistors are in the right place because hot air rises, so placing it at the bottom or top without controlling the air can lead to inaccurate temperature readings for the whole enclosure, rather just one area.

Lights

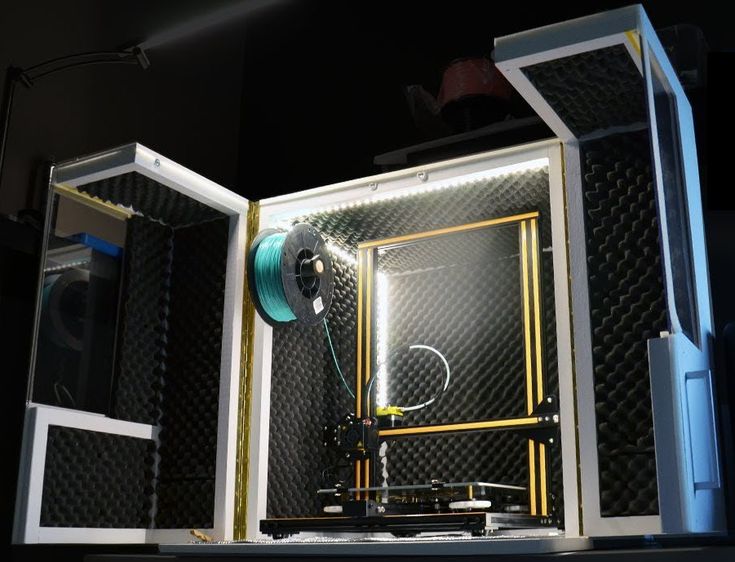

3D prints can be a joy to watch as you see the progress of your objects, so having a nice lighting system for your enclosure is a great feature to have. You can get a bright white light or colorful LED system to illuminate your printing area.

A simple LED light strip connected to your 3D printer’s power supply should be enough to get that going.

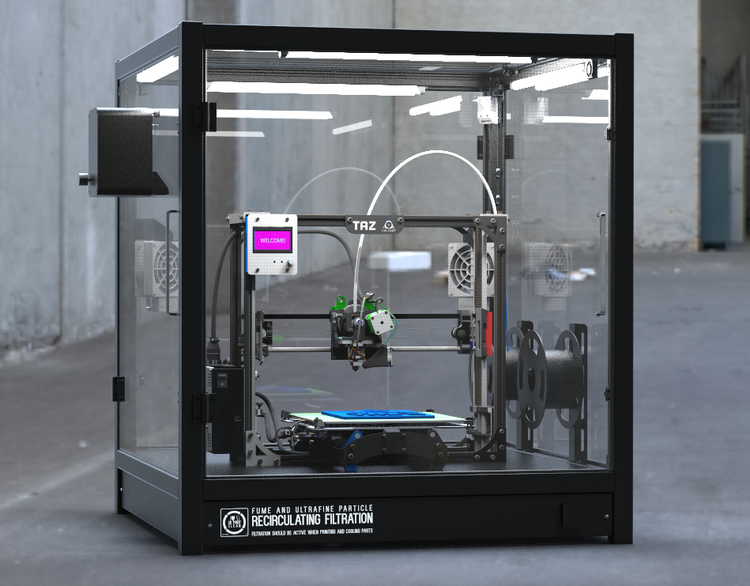

Air Extraction System

The best type of enclosure have some kind of air extraction system built-in, which usually requires an air duct, inline fan and secured tubing which can take the contaminated air and direct it outside.

You can also get a stand-alone filter of some kind, having the air pass through and get cleaned continuously.

It’s a really good idea to have a solid air extraction system in place if you like to 3D print with ABS, or another fairly harsh material. PLA isn’t as harsh as ABS, but I would still recommend having a good ventilation system for it.

Doors or Panels

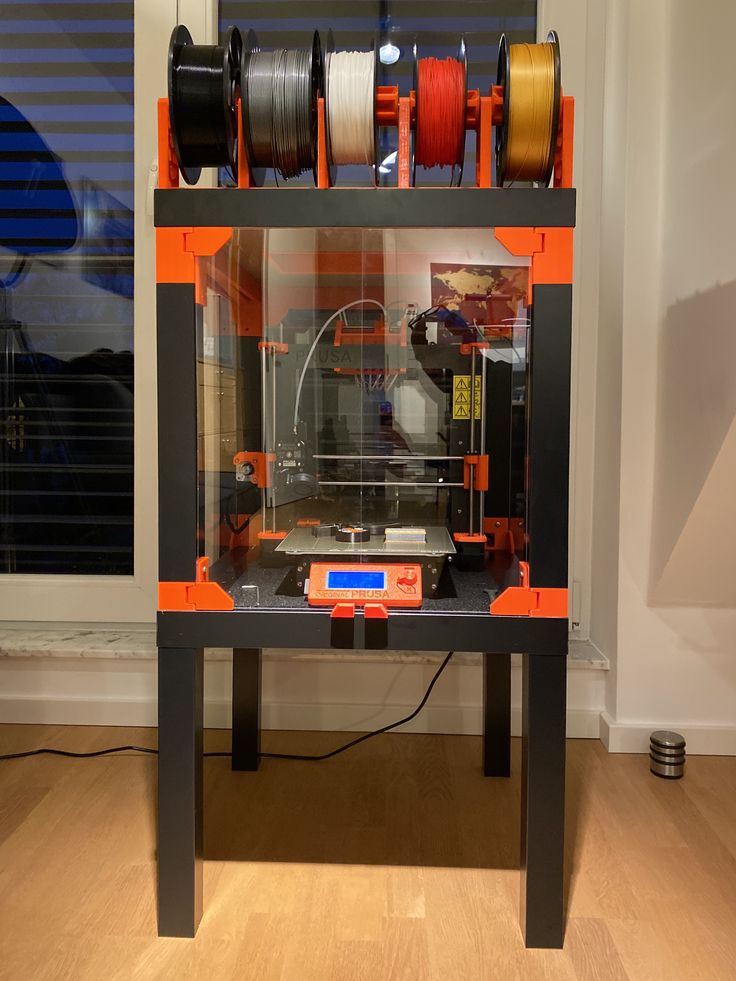

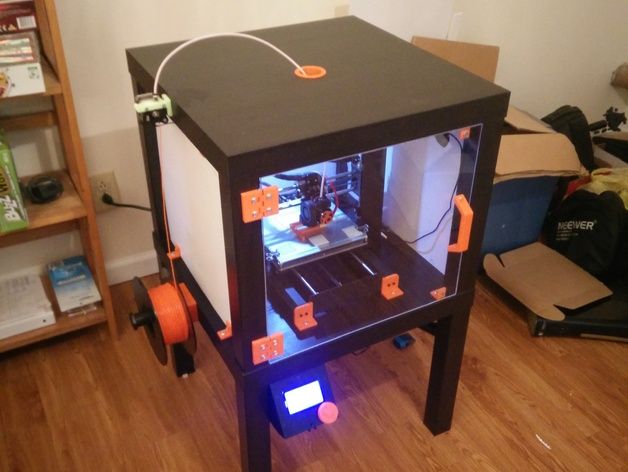

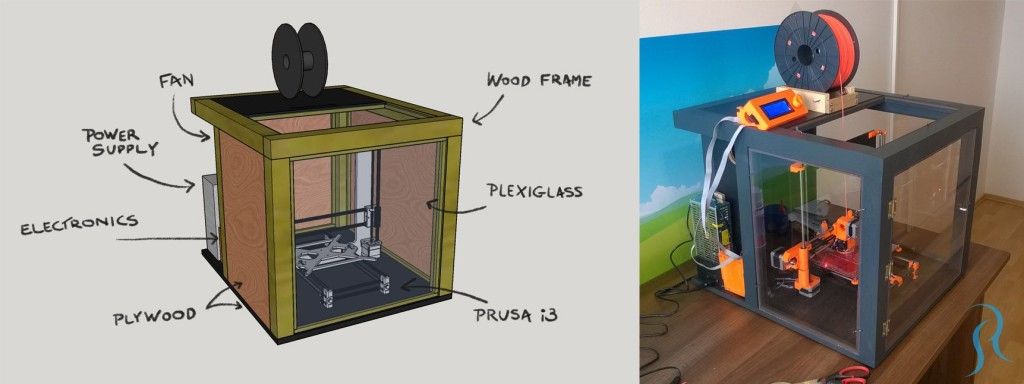

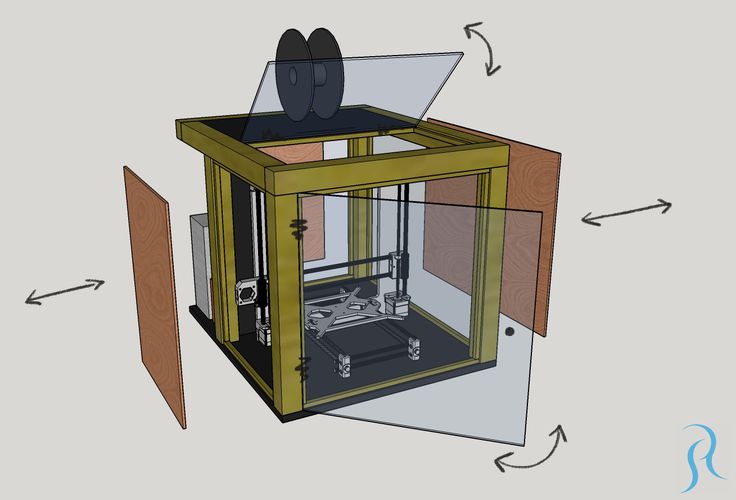

Some simple enclosures are simple a box which lifts directly on top of your 3D printer, but the best kind have cool doors or panels which are removable, and easily opened when needed.

The IKEA lack tables and plexiglass combination is one of the best DIY solutions since you can clearly see around the whole enclosure without opening the door. Other enclosures like the Creality Enclosure don’t give that same visual, but they still work very well.

An open-style enclosure can be beneficial because it still keeps some kind of heat in there, which would be ideal for PLA.

For ABS, you need better temperature control for a higher quality print, which is why the best printers for ABS have an in-built enclosure.

Aesthetics

A good enclosure should be well-designed and well-polished so that it looks good in your room. Nobody wants an ugly looking enclosure to house their 3D printer, so it’s a good idea to take that extra time to make something that looks appealing.

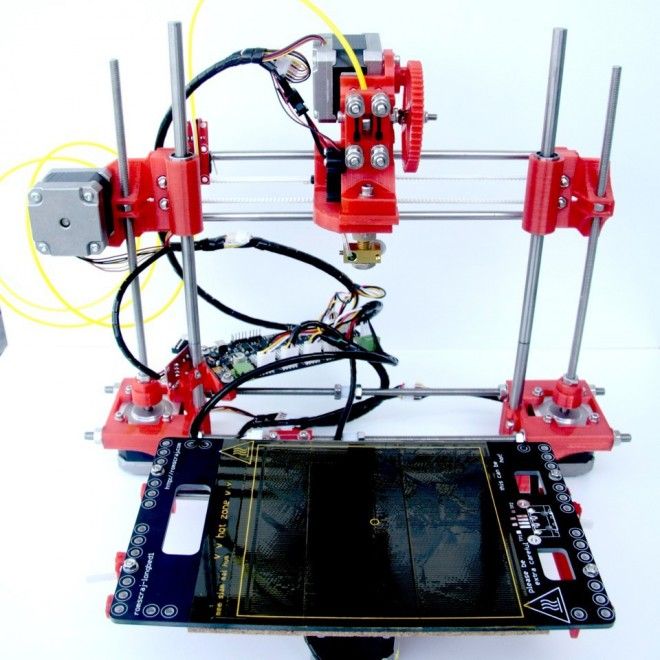

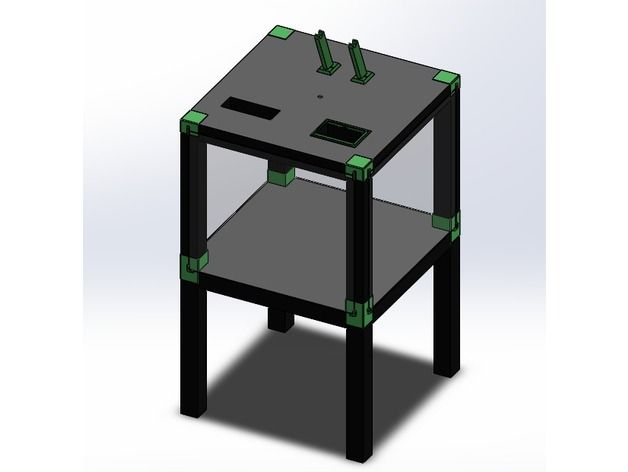

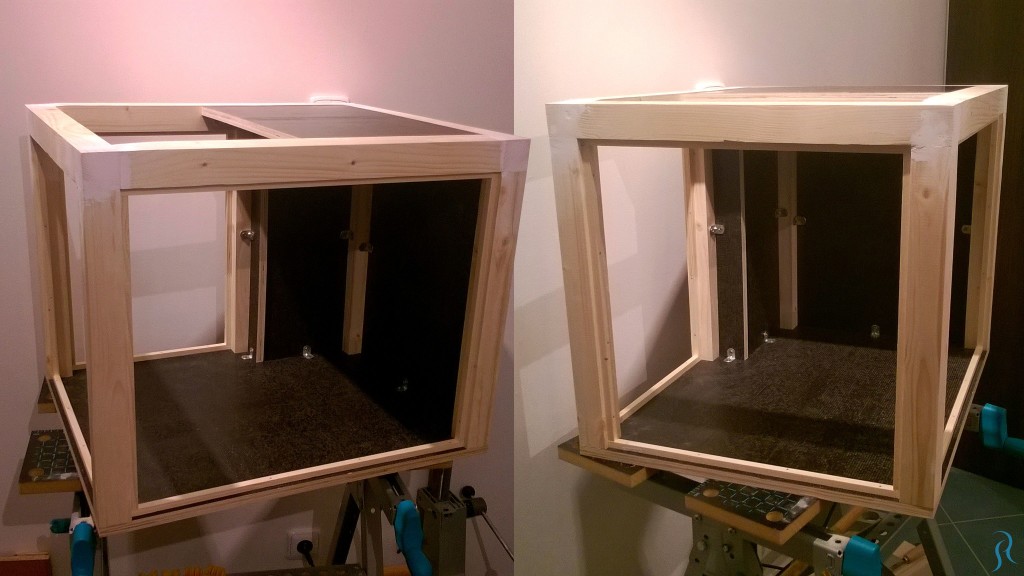

How Do I Build a 3D Printer Enclosure?

There are many different ways to build a 3D printer enclosure, but Josef Prusa does an amazing job guiding you on building a solid enclosure in the video below.

A great enclosure like this can really enhance your 3D printing journey and experience for years to come.

Printing PLA in Heated Enclosure

If you are printing with PLA and have an enclosure, the heat may be a little too high and can prevent your objects from cooling quick enough.

A lot of heat in a sealed enclosure may cause the print layers to collapse which will lead to a poor quality print. When the temperature is too high, PLA has trouble sticking to the previous layer.

Using an enclosure while printing with PLA is considered unnecessary because instead of offering benefits, it can negatively affect your print’s quality and strength.

Without an enclosure, the PLA print will have enough cooling and the layer will solidify quickly. This usually results in a smoother and well-crafted print.

If you have a fixed enclosure on your 3D printer, then it is recommended to open its doors while printing with PLA, this can help the print to come out perfectly.

It is a good idea to have removable panels in your enclosure as removing or opening them will not require too much work.

What Air Filtration Options Are There for 3D Printer Enclosures?

The major existing air filtration options for 3D printer enclosures include:

- Carbon Foam or Filter

- Air Purifier

- HEPA Filter

- PECO Filter

Carbon Foam or Filter

Using carbon foam is a great idea as it can capture chemical fumes and can be a great option when it comes to air filtration for 3D printer enclosures. Carbon filters can help stop VOCs (Volatile Organic Compounds) from the air effectively.

Carbon filters can help stop VOCs (Volatile Organic Compounds) from the air effectively.

Air Purifier

Install an air purifier with the enclosure, it may be quite expensive but it is capable of capturing or preventing fumes, gases, or other toxic particles.

HEPA Filters

HEPA filters can capture the particles of 0.3 microns in size which is the average size of almost 99.97 percent of the air pollutants that pass through a printer enclosure.

PECO Filter

It is considered the best option because of its versatility. It not only captures the VOCs and particles but it destroys them completely. The toxic fumes that come out from the printers are destroyed before they are released back into the air.

All in One Solutions

Guardian Technologies have released the awesome Germ Guardian True HEPA Filter Air Purifier (Amazon) that does a really good job cleaning up the air and reducing odors from smoke, fumes, pets, and plenty more.

It is fairly pricey, but with the number of features and benefits that it brings, it’s a great product to have on your side.

The features and benefits are as follows:

- 5-in-1 Air Purifier for Home: Electrostatic HEPA media air filter reduces up to 99.97% of harmful germs, dust, pollen, pet dander, mold spores, and other allergens as small as .3 microns from the air.

- Pet Pure Filter – An antimicrobial agent is added to the filter to inhibit the growth of mold, mildew and odor-causing bacteria on the filter’s surface.

- Kills Germs – UV-C light helps kill airborne viruses such as influenza, staph, rhinovirus, and works with Titanium Dioxide to reduce volatile organic compounds.

- Traps Allergens – Pre-filter traps dust, pet hair, and other large particles while extending the life of the HEPA filter

- Reduces Odors – Activated charcoal filter helps to reduce unwanted odors from pets, smoke, cooking fumes, and more

- Ultra-Quiet Mode – Ultra-quiet sleep mode with a programmable timer helps you get a good night’s rest with cleaner air

- Choose between 3 speed settings and an optional UV C light

It’s also a #1 Best-Seller in Electrostatic Air Purifiers, so get yourself the Germ Guardian on Amazon for your 3D printing air filtration needs!

For an enclosure specifically, the usual air filtration solution looks like the VIVOSUN CFM Inline Fan & Filter System (Amazon).

You can get the individual parts cheaper, but if you like the whole system picked out of high quality parts and delivered to you for easy assembly, this is a great choice.

This air filtration system has the follow features and benefits:

- Effective Ventilation: Powerful blower with fan speeds of 2,300 RPM, giving an airflow of 190 CFM. Gives optimal ventilation for your target location

- Superior Carbon Filter: 1050+ RC 48 Australian Virgin Charcoal Bed. Dimensions: 4″ x 14″

- Effective Odor Control: The carbon filter eliminates some of the most undesirable odors, pungent smell and particulates from indoor grow tent, hydroponics grow room.

- Sturdy Duct System (with clamps) : Strong, flexible steel wire supports heavy-duty triple layer duct walls. PET core is sandwiched in layers of fire-retardant aluminum that can handle temperatures from -22 to 266 Fahrenheit.

- Easy Assembly: Avoiding the hassle of buying and returning parts that aren’t compatible or safe is easily done with a full-system.

It requires everything you need to get going.

It requires everything you need to get going.

You may need to 3D print a connecting piece to secure to your enclosure so it is airtight. There are many designs on Thingiverse that are related to air purification.

This Minimalist 3D Printed Fume Extractor by rdmmkr was originally created to minimize fumes from soldering, but of course has uses outside of that.

Can You Overheat a 3D Printer with an Enclosure?

Some people wonder whether having an enclosure can actually overheat a 3D printer, which is a fair question to have.

There have been reports of certain parts of a 3D printer overheating such as the stepper motors, resulting in skipped steps and leading to poor quality layer lines on your 3D prints.

It’s also possible to actually overheat your electronics. Cooling is an important aspect of most machines, which is why you have heatsinks, thermal cooling paste, and fans all over the place.

If you don’t take care of the temperature aspect of your actual 3D printer, they can definitely overheat and lead to problems down the line.

Too much heat can definitely shorten the life of your electronics and motors.

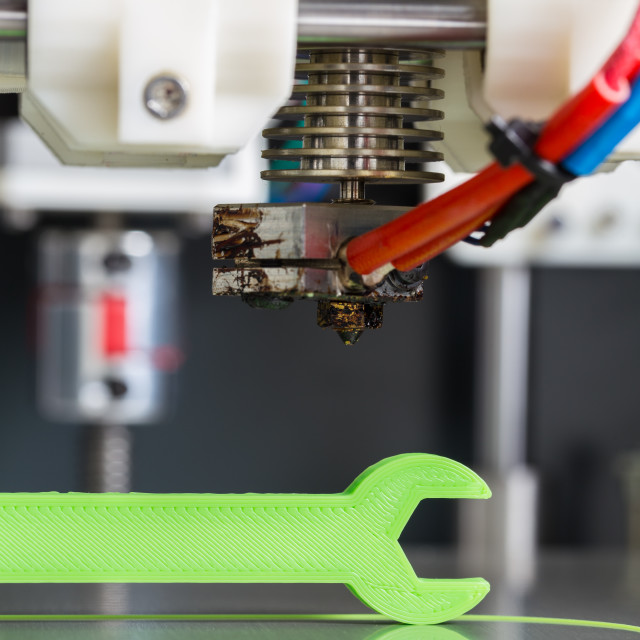

Another thing that can happen is your cold end getting too warm. When this happens, your filament starts to get soft before getting to the heat break and this makes it harder for the filament to be pushed through the nozzle.

It can easily lead to clogs in your extrusion system and nozzle, as well as under extrusion, so make sure you balance this well.

Does Room Temperature Affect the Quality of 3D Prints?

3D printing includes all kinds of temperature fluctuations and specific temperature requirements for the optimal print quality, but does room temperature affect the quality of 3D prints?

Room temperature does indeed affect the quality of your 3D prints. Printing ABS or even resin at low room temperatures can lead to prints failing altogether, or just having poor adhesion and weak layer strength. Room temperature isn’t as big of a problem with PLA since it doesn’t react much to temperature fluctuations.

This is one of the basic reasons that urged the users of 3D printers to build an enclosure to have temperature control.

When you can control the operating temperature of your 3D printer, printing becomes a lot easier to handle. The best kind of enclosure has temperature controls similar to the 3D printing PID system.

You can set and measure your enclosure temperature, and once it gets below a certain point, you can activate a built-in heater to increase the operating temperature back to the set level.

Perfect Bed and Printing Temperatures for Popular Filaments

PLA

- Bed Temperature: 20 to 60°C

- Print Temperature: 200 to 220°C

ABS

- Bed Temperature: 110°C

- Print Temperature: 220 to 265°C

PETG

- Bed Temperature: 50 to 75°C

- Print Temperature: 240 to 270°C

Nylon

- Bed Temperature: 80 to 100°C

- Print Temperature: 250°C

ASA

- Bed Temperature: 80 to 100°C

- Print Temperature: 250°C

Polycarbonate

- Bed Temperature: 100 to 140°C

- Print Temperature: 250 to 300°C

TPU

- Bed Temperature: 30 to 60°C

- Print Temperature: 220°C

HIPS

- Bed Temperature: 100°C

- Print Temperature: 220 to 240°C

PVA

- Bed Temperature: 45 to 60°C

- Print Temperature: 220°C

DIY Ventilation and Filtration for 3D Printing

This 4D Filtration resource is user-supported by donations, affiliate links, and/or ads.

Last Updated: June 6th, 2022

The following simulations are intended to provide a comparison between common ventilation setups for 3D printers. The animations represent the behavior of the particulates and VOCs that are suspended by airflow. The exact concentrations present during printing are not accounted for as these may be touched on in future works.

Grow tents are an affordable and effective option to keep the heat in for both FDM and resin printers. Duct from fume extractors can easily be attached to a grow tent - this is ideal for FDM printers. For resin printers, grow tents can be used to enclose the printer and vent the fumes out a window - this is occurs when you do not have access to a work area outside the residence (ie: garage, shed, etc).

Table of Contents

- Worse Case: Indoors With No Ventilation

- Best Case: Outdoors

- Ideal Case: Garage or Separate Room, No Enclosure

- Ideal Case: Garage or Separate Room, Grow Tent Enclosure

- Using Filtration For Mitigation & Secondary Defense

Assumptions

- The small resin printer is simplified to a 20" cube.

- Air temperature is 90°F (32°C), and there is an external wind speed of 5 mph (2.2 m/s).

- The room size is 12x16' (3.7x4.9 m).

- The airflow is represented by transparent brown arrows; the particles are the spheres, colored by the legend dependent on their velocity.

Worst Case Scenario

Sealed Room With No Ventilation

A completely sealed room allows for the particle concentration to increase.

The mixture remains suspended by free convection that is powered by heat from electronics, sunlight, and artificial light.

Best Case Scenario

Balcony or Patio With 5 mph Wind

While not always practical, placing the printer outside allows for particles to be swiftly carried away by a light wind.

The goal of ventilation is to attempt to reach this behavior while the printer is indoors.

Garage or Indoor Ventilation

Garage or Room With Box Fan

Perhaps the cheapest garage or indoor solution, the good ol' plop a fan in the window method will move a lot of air but will gradually expose the entire room to the external temperature. In a garage, this could work when it is warm outside, but the cool winter air can result in print failures. A small heater will be needed in this case.

In a garage, this could work when it is warm outside, but the cool winter air can result in print failures. A small heater will be needed in this case.

The simulated box fan is rated at 1,800 CFM and ≈0.10 inH2O.

Garage or Room With Box Fan & Cracked Window

Slightly opening a window allows for air to enter the room, ensuring that there are no stale pockets of air.

This case will be common for most rooms due to air leaking in through cracks, ducts, and under doors.

The static pressure experienced by the fan is lowered, thereby increasing the flow rate.

Garage or Room With Box Fan & Open Window

Fully opening a window or door maximizes the circulation and ventilation of the air-particle mixture.

Remember that this showcases the particle behavior and not the concentration.

Garage or Indoor Enclosure and Ventilation

Grow Tent Enclosure With Ventilation

This is an ideal solution for ventilating since the particles are contained and there is minimal impact on the air temperature of the residence.

The simulated enclosure is a grow tent that lets air in through the zipper and small cracks.

The ventilation is provided by a 120mm fan with a meager 40 CFM and 0.11 inH2O. This level of fan prevents excess heated/cooled indoor air from being lost during printing. However, when the enclosure is opened, the small fan is not able to extract the fumes as well as tube-axial (inline) fans.

Recommended Ventilation Equipment

Grow Tent Inspiration

A grow tent could be used:

- outdoors to block wind, sun, rain, and critters on a patio or balcony

- indoors to vent directly outside

- in a garage to help contain heat and optimize venting

- with a fume extractor before being vented

- to fit a printer + a wash & cure station if wide enough

- as a fume hood if using a strong inline fan

See Grow Tents

Sample Size = 178

Install Filtration as a Secondary Defense

Installing ventilation should always be the primary focus, with filtration acting as a secondary defense. In the event that ventilation is not possible then fume extractors can be utilized so long as they are maintained and the filters replaced regularly. For FDM printers, installing filtration is often a necessity since the vast majority of filaments are temperature sensitive.

In the event that ventilation is not possible then fume extractors can be utilized so long as they are maintained and the filters replaced regularly. For FDM printers, installing filtration is often a necessity since the vast majority of filaments are temperature sensitive.

Even if ventilation is installed, you may feel more comfortable with the extra layer of defense provided by an air cleaner. For FDM printers, the focus will be split on removing both particulates and VOCs, whereas SLA will be primarily VOCs.

Particulates can be efficiently removed with MERV 11-16 or HEPA filters. HEPA filters are not always the best option since they often have a lower flow rate compared to a MERV filter, but they perform well for fume extraction.

The efficient removal of VOCs will require a bed of activated carbon granules or pellets. Impregnated foam is not recommended since it is not as efficient nor as long-lasting as granules. The capture efficiency of professional/industrial activated carbon systems can be 92-98%, but smaller units with a carbon thickness of 1-2 inches can have an efficiency of 40-60%. The capture efficiency of carbon will vary depending on the chemicals, impregnation, thickness, temperature, air speed, and etc. The efficiency will decrease when the carbon surpasses a saturation threshold dependent on the thickness of its mass transfer zone.

The capture efficiency of carbon will vary depending on the chemicals, impregnation, thickness, temperature, air speed, and etc. The efficiency will decrease when the carbon surpasses a saturation threshold dependent on the thickness of its mass transfer zone.

Filtration - Fume Mitigation

These small air cleaners are designed to be placed inside the cover of a resin printer. The units only use activated carbon so they be able to capture an estimated 40-60% of fumes until they become saturated. Particulates will not be captured to any meaningful extent. The P Mini air cleaner's files are free to download, it uses a blower fan with a higher static pressure, the extra battery capacity gives hours of additional use, and the thick carbon bed will have a longer life and higher capture efficiency.

4D Filtration - P Mini

DIY

Battery: 5,000 mAh

Carbon: 50 g

Dimensions: 53x53x133 mm

4D FiltrationPrintablesThingiverse

Anycubic - AirPure

$23

Battery: 2,000 mAh

Carbon: 13. 6 g

6 g

Dimensions: 46x46x115 mm

AnycubicAmazonAliExpress

Elegoo - Mini Air Purifier

$25

Battery: 2,000 mAh

Carbon: 13.6 g

Dimensions: 44x44x107 mm

ElegooAmazonAliExpress

Filtration - Fume Extractors

Fume extractors are designed to remove the majority of containments from the air leaving an enclosure. The Promethean air cleaner is offered as an affordable alternative that can be hooked up using duct, be inside an enclosure, or next to the printer - the higher flow rate allows it to act similar to a normal air cleaner. The BOFA air cleaners utilize HEPA media, have a thicker carbon bed, and are a bit more quiet - the downside is the price bump. Fume extractors are ideal for resin and FDM.

4D Filtration - Promethean

DIY or $150

MERV Filter: $15

Activated Carbon: $10+

Airflow: 11-27 cfm

Noise: 41-68 dB

Protection: Particulates & VOCs

via MERV & Activated Carbon Granules

4D Filtration

BOFA - Print Pro 2

$770

Combo Filter: $260

Airflow: 26. 5 cfm

5 cfm

Noise: <44 dB @ "typical"

Protection: Particulates & VOCs

via HEPA & Activated Carbon Granules

BOFAMatterHackers

BOFA - Print Pro 3

$1,200

Combo Filter: $260

Airflow: 88 cfm

Noise: <57 dB @ "typical"

Protection: Particulates & VOCs

via HEPA & Activated Carbon Granules

BOFAMatterHackers

Filtration - DIY

Canisters of carbon are an affordable option for DIY fume extraction for resin printers. The canisters can be used to filter and recirculate the air in an enclosure such as a grow tent, or they can be used to capture the majority of contaminants before venting. These do not capture particulates to any meaningful extent, thus they should not be used for FDM by themselves.

Carbon Canisters

$38+

Amazon - VivosunAmazon - AC Infinity

Activated Carbon

$5+

Make sure to get coconut shell carbon

4D FiltrationAmazon - USAmazon - CAAmazon - UKAmazon - AU

Ultimate Resin Guide - compare resin printers, resin material, and equipment

Preparing for Resin Printing - setting up an enclosure, heating, ventilation, filtration, and cleaning equipment

FDM Printers Guide - comparison table and top picks for filament printers

Resin Properties or Filament Properties - comparison table and top picks for materials

Disclaimer: You assume all responsibility and risk for the use of, but not limited to, the resources, advice, and opinions of 4D Filtration or its employees. 4D Filtration or its employees do not assume any liability or create any warranty for the use of any information. 4D Filtration may receive commissions for referral links. Prices are approximated for simplicity and they may fluctuate due to sales or markdowns. Amazon .com should refer you to your local amazon site if you are not in the United States; there is a chance Amazon's link redirect system will take you to a different product.

4D Filtration or its employees do not assume any liability or create any warranty for the use of any information. 4D Filtration may receive commissions for referral links. Prices are approximated for simplicity and they may fluctuate due to sales or markdowns. Amazon .com should refer you to your local amazon site if you are not in the United States; there is a chance Amazon's link redirect system will take you to a different product.

Did we miss anything or do you have any information worth an update? Let us know!

Like the resources? Consider supporting us via donation, referral links, or purchases!

Extruder cooling fan DC12V 2pin 3D printer

Extruder cooling fan DC12V 2pin 3D printerContacts Request a call Write a letter Wholesalers Articles

11

2617

Description

Extruder cooling fan 2pin for 3D printer. DIY 3D 5015 DC. The size is indicated in the photo.

Specifications

Voltage: 12 VDC

Weight: 87 g

Operating temperature: - 20 + 75 C

Wire length: 30 cm

| For housing | |

| Fan size | 50 mm |

| Country of brand registration | China |

| Country of origin | China |

| Type | Fan units |

Comments

0 No comments yet.

Comment

| Registration is not required to purchase! If you want to place an order, simply add the products you need to the basket, enter your details and click the "Checkout" button. We will contact you shortly. Payment - transfer to the PB account key card - online without commission by card of any bank (LiqPay) - cashless payment without VAT for legal entities - in cash or by card upon delivery (only by Nova Poshta when ordering from 100 UAH) - in cash or through the terminal in our store Found it cheaper? Write to us about it in the chat - the button in the lower left corner of the screen. In the message, provide a link to the active page of the same product in the Ukrainian online store and we will revise the price. nine0092 Delivery - Nova Poshta - Ukrposhta (only with prepayment) - Pickup (you can also call Glovo courier in Ivano-Frankivsk) In most cases, your order will leave on the day of application / payment or the next day.  nine0092 nine0092 Warranty and returns - 14 days return if the product does not fit - 6 months warranty for homemade goods |

Answers to cooling questions

Questions about cooling 3D printers and 3D printed parts.

For questions regarding faults, developments and best practices for cooling 3D printer mechanisms or 3D printed parts.

- Cura: How to prevent my 3D printer from automatically cooling down after printing Is there a setting or G-code to prevent the Ultimaker Cura from setting the nozzle and build plate temperatures to 0? I looked and didn't find anything at the beginning/end of the printer's G-code,...

- Cooling fan noise when moving the head in X direction I have this fan model, it's model number is SUNON MF50151VX-B00U-A99 , and this is the fan type. When the head moves along the x-axis, it makes noise. I think this type…

- Anycubic i3 Mega fanless Can't figure out what's going on with the fans on my Anycubic Mega Pro.

First, the part cooling fan on the Anycubic i3 Mega stopped working, and then soon the extruder fan also…

First, the part cooling fan on the Anycubic i3 Mega stopped working, and then soon the extruder fan also… - Should the 3D printer be enclosed? I have a home package open on all sides.. Would there be any advantage to enclosing the printable area in acrylic?

- Calculating the right pressure for cooling based on compressed air I've heard a little bit about people using air compressors with tubes to the cutting head and outlets there as part of the cooling. One example is Berd Air, but,…

- What makes my PLA prints rise like this? I am printing a Soma cube I found in Thingiverse is a puzzle toy that I remember from the early 1970s and the kind of thing that should be very easy to print. Each of the seven parts…

- How to systematically calibrate all variable speed fan parameters? When the part is thin and the total layer time decreases below a certain threshold, the plastic does not have time to cool enough to harden and properly support the next layer, resulting in…

- Thermoelectric cooler for partial cooling fan? Is there any research on using a thermoelectric cooler together with a partial cooling fan for faster cooling without strong air currents that…

- The fan makes a high noise at full power CR-10S, and it makes a very annoying high-pitched noise at full power.

I have read that PWM can cause this, but not at full power...0152

I have read that PWM can cause this, but not at full power...0152 - Case cooling system SKR E3 mini Ender 5 I was hoping I could find some help as I'm not that familiar with Marlin. I currently have an Ender 5 and am in the process of replacing the stock board. So here's what I...

- Is it possible to replace the hot end cooling fan blade on the creality ender 3? I broke one of the fan blades and it caused the x-box to vibrate. Other than that it works fine and I can still print at very low flow rates and a lot of noise. Will…

- Aluminum block water cooled stepper motor On a budget, I cool my 3D printer with water. I am using a 5V (\$3) aquarium pump. Initially I tried to only use about as much water in a can of chickpeas, but then I found that I needed…

- All metal hot end, cooling fan failures and PTFE on the cold side I will get my favorite bird soon and I know the gas from heating PTFE above 300 °C creates harmful fumes that are bird killers 1 .

To try and prevent even the possibility that I would replace...

To try and prevent even the possibility that I would replace... - How to find the right part of the cooling fans? I have a 2-pin 40mm axial fan as part of a cooling fan. I am not posting the link because I would like a general answer. It runs on 12V and when I run it...

- Is the cooling fan part turned on when printing TPU? I could have sworn I read somewhere that when printing with TPU you need to make sure the part cooling fan is blowing. But I just did a quick google and couldn't find anything similar in Matter...0152

- Correct way to turn off power to FDM printer I just received my first 3D printer today, QIDI X-ONE[2], and so far so good with setup and getting 1 print. I wanted to turn off the 3D printer, but I don't see any instructions on how to…

- Which filament to use for a water circulation application? Let's say I want to build a water block shaped exactly for my hot end Ubis 13s (similar to this instructable), or that I want to circulate water around certain objects,…0152

- Why does the partial cooling fan cause tension? Really weird observation with my MP Select Mini V2 print board.

I printed out a two-fan shroud so I could have a dedicated fan to keep the parts cool. I noticed that...

I printed out a two-fan shroud so I could have a dedicated fan to keep the parts cool. I noticed that... - Marlin on the RUMBA board automatically switches the extruder fan I connected a new extruder with its own cooling fan and tried to change the Marlin firmware so that it automatically turns on at a certain temperature (50 ° C). I didn't notice in…

- Is it worth using an optional external fan(s) for PLA printing? I was wondering if adding (a) extra fan(s) (not connected to the printer but blowing on the printable area) could improve the quality of PLA-based prints (printing at 210°C). In…

- Replacing FAN0 with FAN1 on the TriGorilla printer board I connected a new fan to the PCB fan (TriGorilla v1.4) Fan0 which I found to be broken. I am trying to upgrade the cooling fan parts for a bigger size. K…

- How can I avoid jamming the feeder? We recently bought a Guider II printer from FlashForge at work.

When we try to print high resolution models or models that take too long to print, the feeder becomes clogged. And...

When we try to print high resolution models or models that take too long to print, the feeder becomes clogged. And... - Can't reach hotend temperature with part cooler on I can't use the part cooler I printed. Every time I turn it on the hot end temperature drops too low and for some reason the PID can't seem to recover...0152

- By upgrading to a silicone heat table, will it start a fire? I'm thinking about upgrading my heated table and replacing it with a silicone table. I don't know much about electronics, so I'd like someone more knowledgeable to confirm...

- Understand what CR-10S fans cool I'm designing a fan mount for a CR-10S printer to mount an all-metal v6 HotEnd E3D and sensor BLTuch. The CR-10S printer is equipped with two fans. One on the front…

- Should I autotune the PID with the fan at 100% (Anet A8) I am using Anet A8 with Marlin 1.1.6. I've read countless manuals on automatic PID tuning and never saw that the fan should be on, but when I look at the ANet configuration.

Learn more