3D printer edinburgh

3D Printing Service Edinburgh | Instant Quotes Online

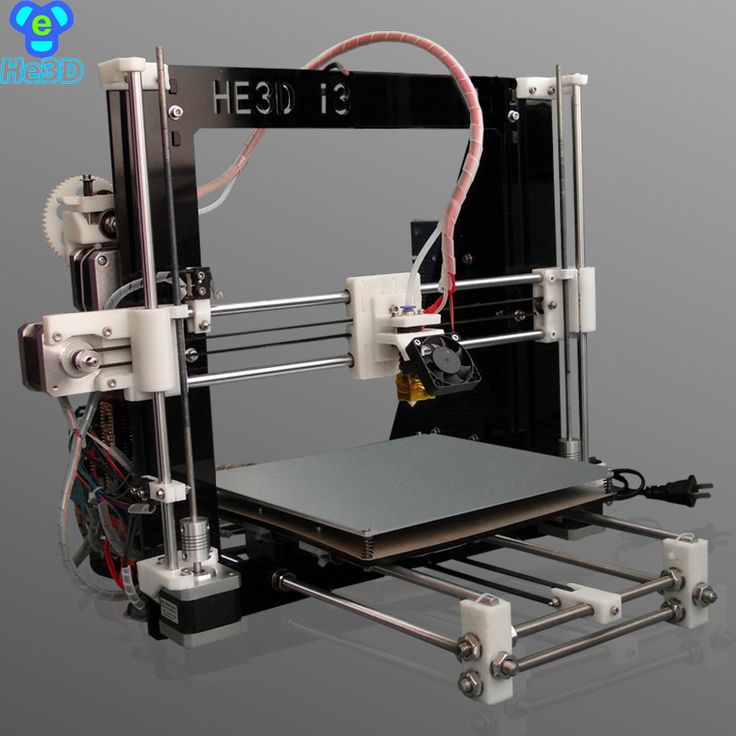

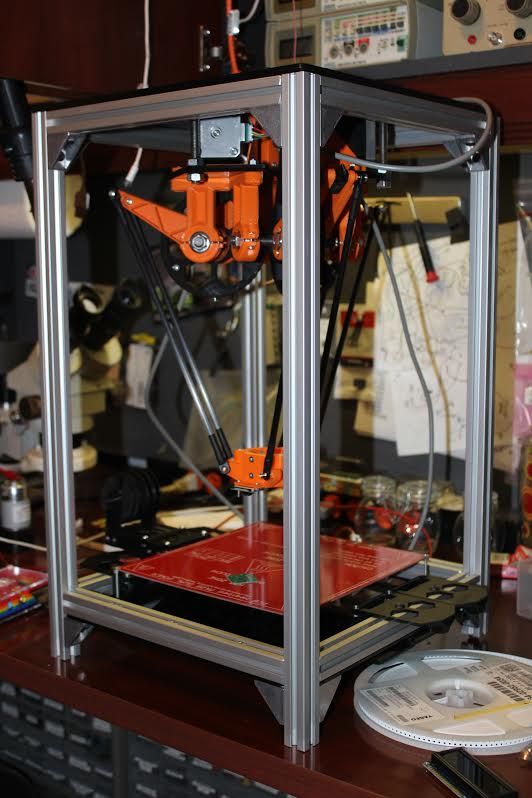

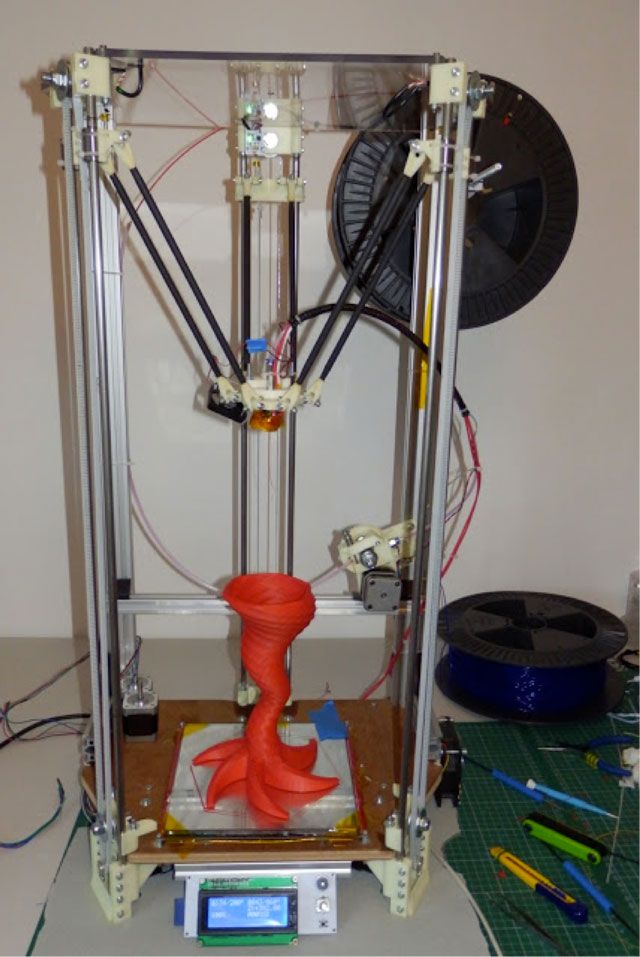

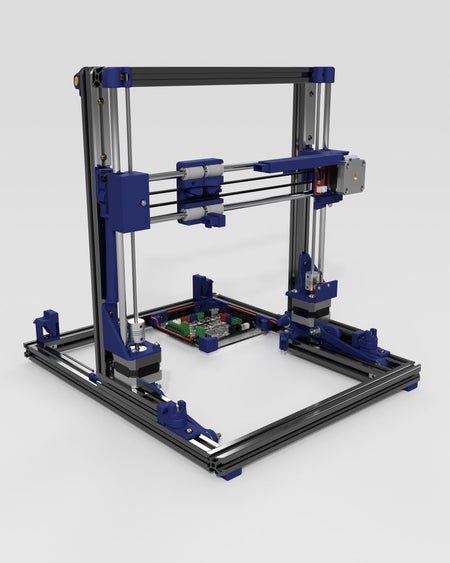

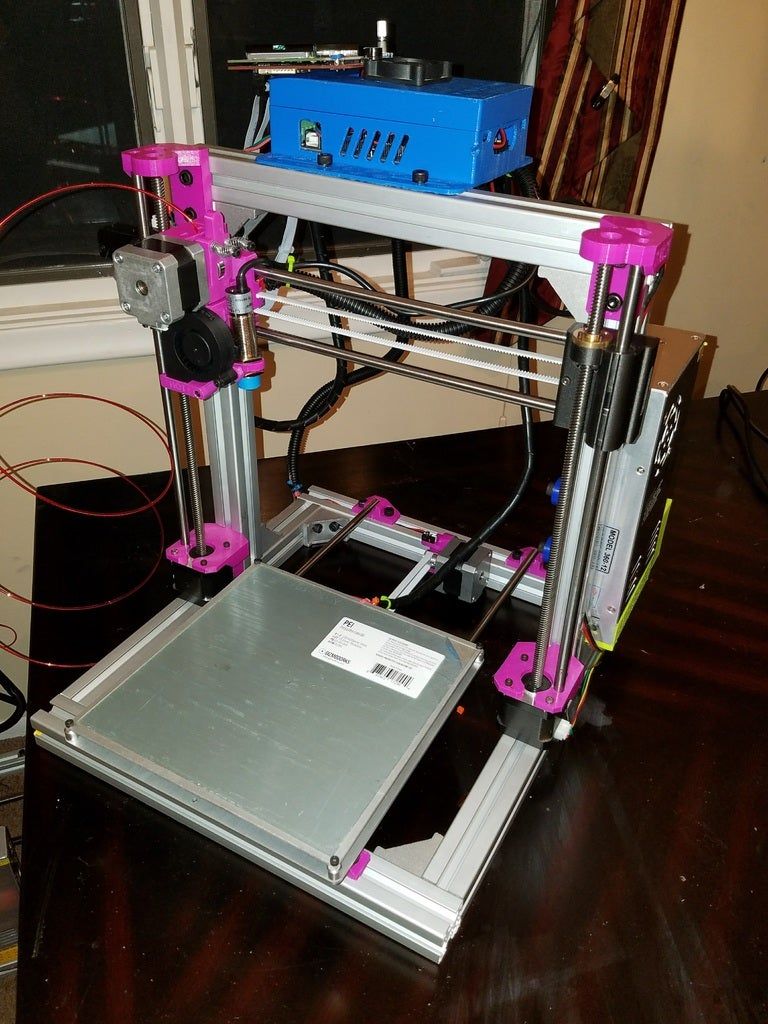

Our 3D printing capabilities

We have over 90 3D printing shops in our network and are well known for manufacturing high-quality parts at competitive prices, from rapid prototyping with Fused Deposition Modeling (FDM) to functional end parts made with Selective Laser Sintering (SLS) or Multi Jet Fusion (MJF).

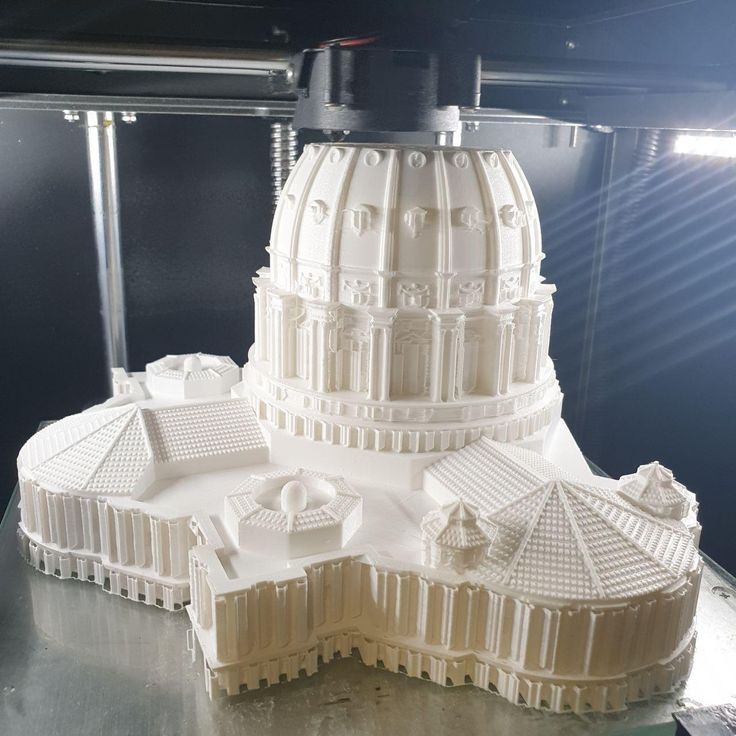

Gallery of 3D printed parts manufactured by Hubs

With over 65,000 customers from every industry, including aerospace, defense, robotics, medical, machinery, automotive and electronics, we have extensive experience meeting a diverse range of 3D printing requirements, from prototyping to production: Visual aids, concept models, injection-molding prototypes, form-fit & function prototypes, tooling and casting patterns, jigs, grips and fixtures, and durable end parts.

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

Instant, online 3D printing quotes

-

Upload a CAD to start (STEP, STP, IGES, IGS, SLDPRT, 3DM, SAT, STL, OBJ or X_T)

-

Price updates in real-time as you change materials, lead time, etc.

.

. -

No hidden costs. Our instant quotes are not just indications, but the actual price, and include shipping and customs up front.

Learn about how our quoting algorithm works

Our ordering process

Receive instant quote

Upload your CAD to our online quoting platform

Confirm specs

Configure your part specifications and select a lead time that suits your schedule

Production

We select the best manufacturer for your order, and production begins immediately

Quality control

We take full responsibility for making sure your parts are manufactured according to our standards

Delivery

Our 3D printing service has been rated 4.9/5

Over 264 customers are satisfied with our 3D printing service.

“Thanks for letting me pick them up in person, I’ll let you know if I need any more help with the project !”

“Fantastic service, communication and advice!”

“Very quick print and turnaround! Great service, will definitely use again!”

“Brilliant service, order completed very quickly and accurately.”

“MRI scan of a human brain - quite a challenging print but turned out great and ready super fast. Many thanks!”

“My first experience with 3D printing. Impressed with all aspects of order and quality of print items. Would certainly use again”

“High quality print with high definition that was very quickly delivered. Would use again.”

“Excellent work, quick and nice to work with”

“Arrived fast, great model and packaged safely. Cheers! ”

“Printed the parts ahead of schedule and kept me up to date every step of the way. Friendly and efficient, would definitely use again.”

“Thank you. Great service, just before Christmas too!”

“Excellent parts and very knowledgeable and helpful guy”

“Were helpful and quick to respond, would definitely recommend to other students and people needing help to 3D print ”

“superb quality, first ever 3d printed part and absolutely blown away by the quality”

“Excellent prints and a pleasure to deal with. ”

”

“Thank you very much for your excellent customer service, the part works perfectly and I very much appreciate your consideration in terms of providing a second part printed in a more suitable material. I will be strongly recommending your service to my colleagues.”

“Very neat top quality flexi prints & super fast service!”

“First time having anything made... Amazing, very happy”

“The best experience I had 3D printing in London!”

“Brilliant delivery - very high standard! Thank you very much!”

“Excellent work. Will certainly use you again for future projects! ”

“Brilliant service as ever. Same day service as well!”

“The prints mark did are super detailed and he went above and beyond what i would expect from an independent printer. Will be using him in future for other prints. ”

“Excellent work, even altered the printer to achieve better results! Will definitely work with this maker again. ”

“First time I've used this sort of service with 3d being new. Fantastic service speedy printing and great communication. Defo use them again!”

Fantastic service speedy printing and great communication. Defo use them again!”

Show more reviews

Show less reviews

Teams build better parts

Create your Hubs team and start collaborating

Read more

The Hubs Standard - consistent quality, every time

Hubs takes the stress out of manufacturing by guaranteeing the quality and consistency of every part. Each order is dimensionally and visually inspected to make sure it meets the Hubs Standard.

3D printing materials

We can generate instant 3D printing quotes for 25+ plastics. For metal 3D-printed parts, you can request a quote from our parent company, Protolabs.

Available materials

SLS

PA 12 Glass filled PA 12

Desktop FDM

Prototyping PETG Prototyping ASA Prototyping TPU Prototyping ABS Prototyping PLA

Desktop SLA

Formlabs Standard Resin Formlabs Clear Resin Formlabs Tough Resin 2000 Formlabs Rigid Resin 4000 Formlabs Grey Pro Resin Formlabs Flexible Resin 80A Formlabs High Temp Resin Formlabs Durable Resin

MJF

HP PA 12 Glass filled HP PA 12

Industrial FDM

Markforged Onyx ABSplus Stratasys ULTEM 9085 Stratasys Stratasys ASA ABS M30 Stratasys ULTEM 1010 Stratasys

Industrial SLA

Accura 25 (PP-like) Accura ClearVue Accura Xtreme White 200 (ABS-like)

3D printing locations near Edinburgh

Edinburgh Dundee Carlisle

Glasgow Aberdeen Ayr

Newcastle Gateshead Greenock

Sunderland

The 3D Printing Handbook

No one understands 3D printing like us - our founders literally wrote the book. Click here to download the sample chapters.

Click here to download the sample chapters.

Buy the book from Amazon

FAQ's

How much does your 3D printing service cost?

The cost of your 3D printed parts depends on factors such as part volume, part complexity, choice of material, which 3D printing technology is used, and if any post processing is required. For more details on these cost factors, see our article on the cost of 3d printing. To check the cost of your 3D printed part, simply upload a CAD (.STL) file and select your material and 3D printing technology to receive a quote within seconds.

How do you guarantee the quality of my prints?

Your parts are made by experienced 3D printing shops within our network. All facilities are regularly audited to ensure they consistently meet the Hubs quality standard. We include a standardized inspection report with every order and offer a First Article Inspection service on orders of 100+ units.

We have partners in our network with the following certifications, available on request: ISO9001, ISO13485 and AS9100.

Follow this link to read more about our quality assurance measures.

How do I select the right 3D printing process for my prints?

You can select the right 3D printing process by examining which materials suit your need and what your use case is.

By material: if you already know which material you would like to use, selecting a 3D printing process is relatively easy, as many materials are technology specific.

By use case: once you know whether you need a functional or visual part, choosing a process is easy.

For more help, read our guide to selecting the right 3D printing process. Find out more about Fused Deposition Modeling (FDM), Selective Laser Sintering (SLS), Multi Jet Fusion (MJF) and Stereolithography (SLA).

How can I reduce the cost of my 3D prints?

In order to reduce the cost of your 3D prints you need to understand the impact certain factors have on cost. The main cost influencing factors are the material type, individual part volume, printing technology and post-processing requirements.

The main cost influencing factors are the material type, individual part volume, printing technology and post-processing requirements.

Once these have been decided, an easy way to further cut costs is to reduce the amount of material used. This can be done by decreasing the size of your model, hollowing it out, and eliminating the need for support structures.

To learn more, read our full guide on how to reduce the cost of 3D printing.

Where can I learn more about 3D printing?

Our knowledge base is full of in-depth design guidelines, explanations on process and surface finishes, and information on how to create and use CAD files. Our 3D printing content has been written by an expert team of engineers and technicians over the years.

See our complete engineering guide to 3D printing for a full breakdown of the different 3D printing technologies and materials. If you want even more 3D printing, then check out our acclaimed 3D printing handbook here.

We have an extensive range of online resources developed to help engineers improve their capabilities.

Introductory guides

Design guides

Material guides

Applications

CAD & file preparation

Post processing & finishing

Our other manufacturing capabilities

CNC machining

CNC machining

Milling (3-, 4- & full 5-axis), turning and post-processing

-

50+ metals and plastics & 10 surface finishes

-

Tolerances down to ±.0008” (0.020 mm)

-

Lead times from 5 business days

See our CNC machining services

Put your 3D printed parts into production today

Get an instant 3D printing quote

3D Printing In Edinburgh | 3D Printed Parts

Supplying Edinburgh with an online 3D printing service. Upload your STL file, get an online price and take advantage of free delivery.

Upload your STL file, get an online price and take advantage of free delivery.

Why use us?

With our experience and technology, we can provide Edinburgh with a cost-effective 3D Printing service.

Instant upload & quote

Upload your 3D file to get an instant price and decide what materials are best for your parts.

Quality 3D prints

We use the latest technology to deliver quality, precise SLS, FDM and SLA 3D prints to Edinburgh.

Free delivery

We offer free delivery on all 3D printed parts to Edinburgh. Start your order now.

Edinburgh 3D Printing service

Ready to order your 3D print?

We’ve got an easy to use cost calculator to give you an online quote. Simply upload your 3D model to see your price.

3D printing materials

Create functional prototypes in PA12 nylon. Great for batch production & strong, end-use parts.

FDM offers great strength, impact resistance and flexibility. Suited to non-visible applications

Suited to non-visible applications

SLA has near injection moulded look with almost no layer lines. Best for detailed & non-functional objects.

Customers who trust us...

A brilliant service from Surface Scan. Thank you. TLDR Robust, accurate 3D Printing and quick delivery. Recommended. This was my very first experience of 3D Printing...Read More »

My first 3D print and it couldn't have been easier. Website is straight forward to use and the part produced has given a fantastic...Read More »

I used Surface Scan to 3D print a small plastic part to my integrated window blinds that broke on several of my blinds. Angela...Read More »

What an amazing company!! They are so patient with a newbie like me when it comes to ordering a 3D print and because of their...Read More »

Need a 3D CAD file?

If you have an idea you want to bring to life, need a design verification, our designers are here to help. Maybe you have STEP file or an unsupported file format, let us convert it for you.

Choosing the best technology

Additive manufacturing offers a range of technologies and materials when manufacturing your files into physical 3D printed parts.

Choosing the best material for your project can depend on a few factors, and it’s end-use.

- How many parts do you need?

- Does the product need to be flexible?

- Does it need to be functional?

- Is the project for outdoor use?

- Is appereance more important?

These are just some of the questions that might need answering before deciding on what might work best for your project.

Material finshes

3D printing services in Edinburgh

Lets Talk

We’re ready for your enquiry. Please fill out the form, and someone will get back to you as soon as possible or give us a call, whichever suits you best.

Name

Phone

Message

Upload

Best 3D printer models Scotland・Cults

Celtic - Celtic Park

14. 65 €

65 €

Cute Highlander

3 €

Scottish court game set

3,75 €

Axial Honcho Tailgate

Free

Rugby Ball Plate (Scotland, England, Wales and Ireland

0.58 €

GENTLEMEN OF SCOTLAND

4 €

File: Pumpkin toon in STL digital format

5 €

Scotland - flag stand

Free

UK - Flag Stand

Free

Scottish Highland Cow

Free

Braveheart Plaque

Free

Alex Ferguson - Soccer STL

9. 76 €

76 €

Coo Coat Hanger for Cubicle, Highland Coo

Free

Horselander (15mm scale)

Free

Scottish Terrier figure

10 €

Alice Cooper bust/wall hanging .

€2.89

Rangers Coaster

Free

Scotland Yard - Custom Mister X Panel

Free

Scotland Saltire Bath Bomb Mold Kit

Free

collie dog figure

10 €

Highland Cattle for Tabletop Wargaming

Free

Edinburgh castle cannon

6.25 €

Brewdog Light-Up Piggy-Bank / Light-Box

Free

Rugby Ball - Collection

6. 25 €

25 €

Rugby Ball - SCO

2 €

Punk IPA Brewdog Beet Mat / Drinks Coaster

Free

Brewdog Beer Mat / Drinks Coaster

Free

Spewdog Beer Mat / Drinks Coaster - Brewdog Parody

Free

2 x Brewdog Keyrings / Keyfobs / Bag Charms

Free

Viking Jewelery Pack

20.50 €

Galloway Hoard Brooch

Free

Shield of Scotland

Free

"spare parts" for a person - World of Knowledge

3D technology has penetrated into various public spheres in the last decade. And it's not just about movies. So-called 3D printers have appeared, on which you can “print” literally anything. This is not only a toy for entertainment, but also a serious helper of mankind. Scientists are planning to create human organs on a 3D printer soon!

This is not only a toy for entertainment, but also a serious helper of mankind. Scientists are planning to create human organs on a 3D printer soon!

EXCLUDES MANUAL WORK

While 3D printing has only been talked about a lot in the last few years, the technology has actually been around for a long time. In 1984, Charles Hull developed 3D printing technology for reproducing objects using digital data, and two years later named and patented the stereolithography technique. At the same time, this company developed and created the first industrial 3D printer.

3D printing is the construction of a real object from a 3D model created on a computer. Then the digital three-dimensional model is saved in a certain format, after which the 3D printer, which outputs the file for printing, forms a real product. The use of 3D printing is a serious alternative to traditional prototyping methods and small-scale production At the moment, equipment of this class can work with photopolymer resins, various types of plastic filament, ceramic powder and metal clay.

The principle of operation of a 3D printer is based on the gradual (layer-by-layer) creation of a solid model, which, as it were, is “grown” from a certain material. The advantages of 3D printing over the usual, manual methods of building models are high speed, simplicity and relatively low cost. 3D technologies, on the other hand, allow you to completely eliminate manual labor and the need to make drawings and calculations on paper - after all, the program allows you to see the model from all angles already on the screen, and eliminate the identified shortcomings not in the process of creation, as is the case with manual production, but directly during development and create a model in a few hours. At the same time, the possibility of errors inherent in manual work is practically excluded. Today, the scope of 3D printing is unusually wide, and medicine is an area where this technology can be especially useful.

BONE PROSTHESES

The first experiments in creating artificial body parts using 3D printing were carried out, as usual, on animals. From what is known from open sources, they were successful. In 2012, information appeared in the media about a bald eagle that had the missing part of its beak printed on a 3D printer, which allowed the bird to lead an almost normal life. And in 2013, scientists helped a lame duck with a paw deformed from birth. The operation was successful, and the duck became the "star" of the Internet.

From what is known from open sources, they were successful. In 2012, information appeared in the media about a bald eagle that had the missing part of its beak printed on a 3D printer, which allowed the bird to lead an almost normal life. And in 2013, scientists helped a lame duck with a paw deformed from birth. The operation was successful, and the duck became the "star" of the Internet.

But such experiments are carried out not only with animals. Already today, 3D printing is successfully used in conventional medicine. Three-dimensional modeling opens up simply revolutionary possibilities. Implants of any shape and size can be printed on a 3D printer, creating an exact copy of the desired body part. And it becomes much faster, more efficient and cheaper to operate than traditional methods allowed.

The price of this technology is very important. The cost of surgical procedures for implantation, according to experts in this field, can be reduced by 80%. This is because what is usually carried out in several stages has become possible to complete in one go. In the United States, kneecaps, menisci, hip joints, bones of the hands, fingers, and skulls are already being made on a 3D printer. This opens up new possibilities in sports traumatology and plastic surgery.

In the United States, kneecaps, menisci, hip joints, bones of the hands, fingers, and skulls are already being made on a 3D printer. This opens up new possibilities in sports traumatology and plastic surgery.

In 2012, the first 3D printed mandibular implant was implanted. The material was titanium. And in 2013, in the United States, specialists managed to “print” 75% of the human skull. This operation was done after two weeks of work with a scanned model of the patient's skull. The result repeats the smallest details of the reform. According to doctors, hundreds of people in the US may be potential clients of clinics specializing in 3D implantation. These include victims of traffic accidents, military personnel and cancer patients with tumors in their skulls.

The production of bone-replacing 3D printed implants has a number of advantages over traditional technologies:

1) Speed. The use of traditional prosthesis casting technologies is a long process.

2) Lightness. Although the weight can be adjusted by changing the porosity of the titanium prosthesis.

Although the weight can be adjusted by changing the porosity of the titanium prosthesis.

3) Porosity. This quality allows the prosthesis to “grow” with living tissues faster, becoming one with the body.

INTERNAL PRINT POSSIBLE

Maximum 3D printing program - creating internal organs. But until that moment, it will still have to wait about ten years, until the technology is perfected and the first experiments on animals are carried out. Here is how the surgeon Emil Bach says about it: “This will make a real revolution. There are so many people on the waiting list for heart transplants. It is a mechanical organ, in other words, a pump. And this is a big plus in the sense that it is easier to make on a printer than organs that secrete hormones, such as the liver, kidneys, intestines. Well, the very pinnacle of skill is to create a 3D projection of the brain.

So far, experiments in this area are being carried out. So, in 2013, for drug research, scientists were able to 3D print liver tissue. The material used was hepatocytes, stellate cells, and cells of the epithelium lining blood vessels. At the moment,

The material used was hepatocytes, stellate cells, and cells of the epithelium lining blood vessels. At the moment,

scientists are facing a number of problems when using 3D printing in prosthetics of internal organs, such as ensuring their blood supply or the reproduction of cellular immunity. So far, scientists have not solved this issue, although the technology is developing very quickly.

So, the British specialists proposed a universal 3D printing technique. Scientists from Heriot-Watt University (Edinburgh, Scotland) have developed a unique 3D printing technique that can help people in need of organ transplants. Doctors use a 3D printer to grow donor organs from stem cells. The printed embryonic cells retain the ability to transform into any other cell type.

With the help of new technology, it became possible to select the necessary organ for a particular patient. The device, by analogy with a 3D printer, was called a 3D bioprinter. This is a biological variation of reprap technology, a device that can create organs and tissues by layering cells on top of each other.

MODELS HELP WITH OPERATIONS

Theoretically, it looks like this. The printer is loaded with cells from a patient in need of an organ transplant, ensuring that the new organ is not rejected by the immune system. First, a sheet of the so-called “biopaper gel” is “printed”, then a circle of cells follows, then again a sheet, again a circle, and so on layer by layer, until a new organ is formed. Subsequently, natural cells begin to reorganize themselves to create new blood vessels. It takes at least an hour to build each vessel, and after a few days the organ can be considered ready for use. Science magazine considers this discovery the scientific breakthrough of the year. According to doctors, stem cells are difficult to manipulate under conditions of growth in a two-dimensional environment. But 3D technology can solve this problem.

Although the creation of full-fledged internal organs is still a matter of the future, even now doctors can create a 3D model of a single organ that needs to be operated on.