3D printer e bay

eBay for Industrial 3D Printers Opened by Pivot AM - 3DPrint.com

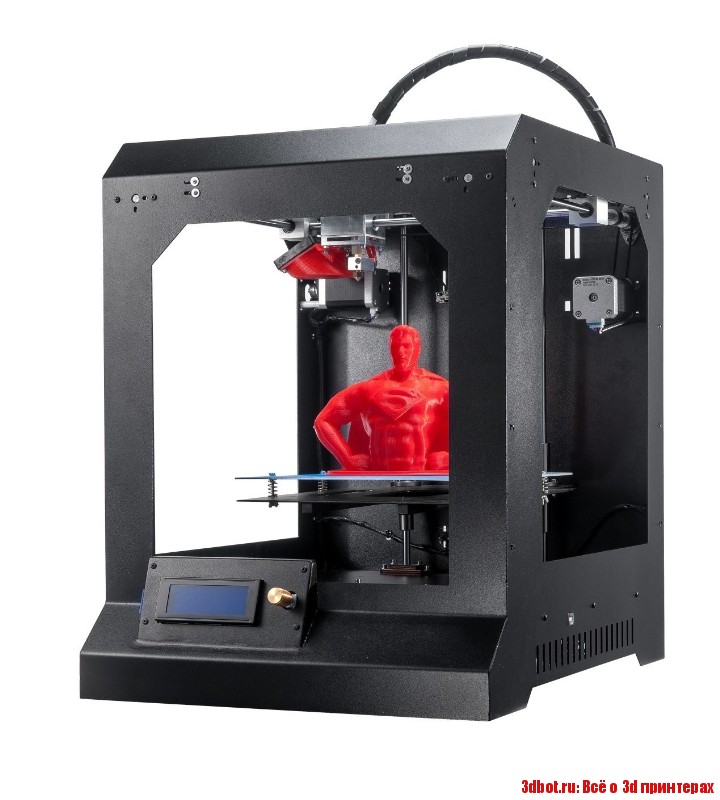

Here’s the thing: industrial 3D printers are pricey. A high-end fused deposition modeling (FDM) 3D printer could run up to over $10,000 just for a smaller or less well-known machine. Given the finicky nature of running a business, we can reasonably assume that a number of 3D printing companies fail. So, there should be a market for used 3D printers. Over the years, we’ve seen businesses attempt to get into selling used equipment, but eBay remains to be the largest source for old 3D printers.

Perhaps, Pivot AM Auctions will change that. A new division of U.S. service and equipment provider Pivot AM Service, the site allows users to bid on refurbished 3D printers in a manner similar to eBay, with “max bid” and “buy it now” options included. Sellers can list their used machines for $250, while buyers pay an eight percent premium above the purchase price.

As of this writing, there are 11 pieces of equipment available, including four Stratasys FDM 3D printers, three 3D Systems stereolithography (SLA) systems, and four pieces of post-processing machines. Most of the starting bids for the FDM units begin around $1,000, while the SLA 3D printers begin at $10,000. There is one 2015 Fortus 400 that is currently bidding at $0, with a buy-now price of $49,000. If that’s not a mistake, you could feasibly purchase it and turn it around for a pretty penny.

The advantage of having a site for auctioning off used 3D printing equipment is that Pivot AM is already integrated into the industry. Its owners know the business and can connect buyers and sellers with de-installers and shippers, as well as financing entities that can enable purchasing loans for the machines.

It is possible to buy used industrial 3D printers from such places as machine resellers and service bureaus, general equipment sites, and eBay. Pivot AM Auctions has the differentiator of acting as an online auction house. However, given the small size of this niche market, it would be difficult to know how much business could really be derived from auctioning or even selling used equipment. This seems particularly difficult as one of the benefits of purchasing directly from the manufacturer or from a reseller would be the technical support, for which this industrial equipment requires a great deal. Therefore, it seems as though the ideal customer would be an existing service bureau or part maker that already knows its way around these machines.

This seems particularly difficult as one of the benefits of purchasing directly from the manufacturer or from a reseller would be the technical support, for which this industrial equipment requires a great deal. Therefore, it seems as though the ideal customer would be an existing service bureau or part maker that already knows its way around these machines.

That said, there definitely has to be a burgeoning market for used industrial 3D printers. What I expect to happen is that a company like Xometry, which has already expanded beyond its role as a network for digital manufacturing services to sell materials and parts, would begin networking sellers and buyers of used equipment as a part of its existing offerings. If Pivot grows large enough, perhaps it could find a welcome home at a company like Xometry.

Image courtesy of Pivot AM.

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

Tagged with: auctions • ebay • industrial 3d printers • Pivot AM • Pivot AM Auctions • Pivot AM Service • refurbished 3D printers • used 3d printers

Please enable JavaScript to view the comments powered by Disqus.

Are printer on aliexpress/ebay good for beginners? - 3D Printers - Talk Manufacturing

aster94

#1

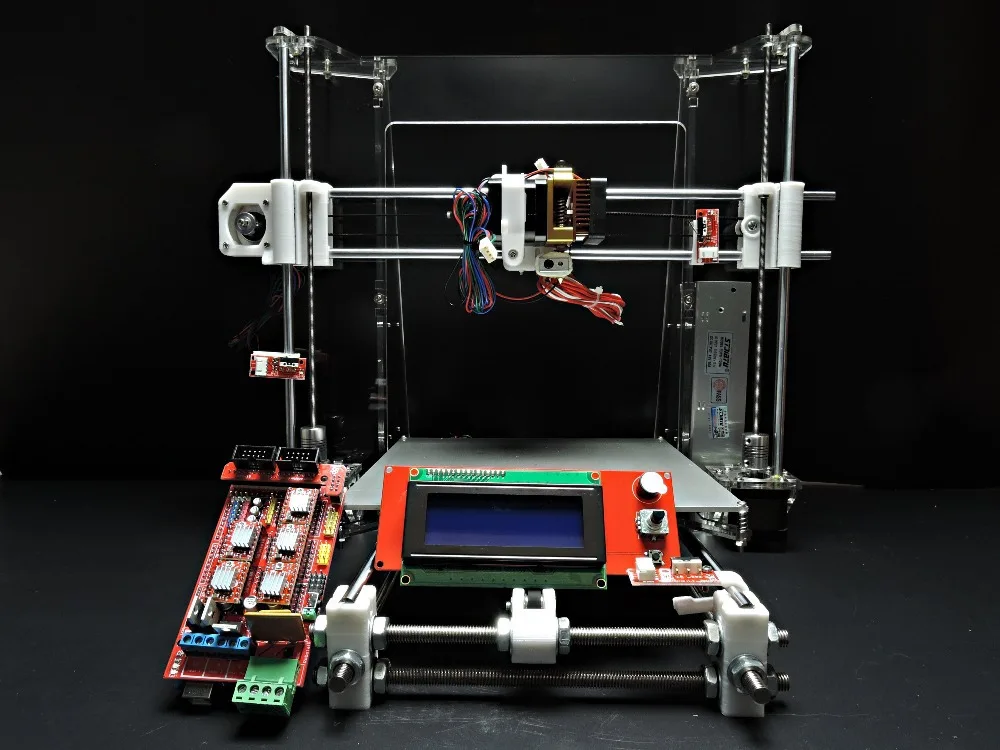

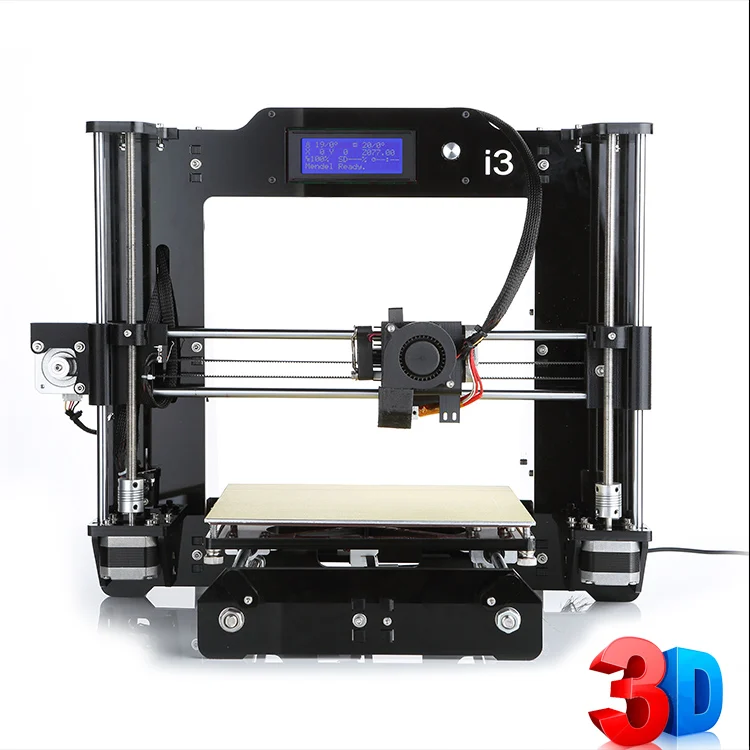

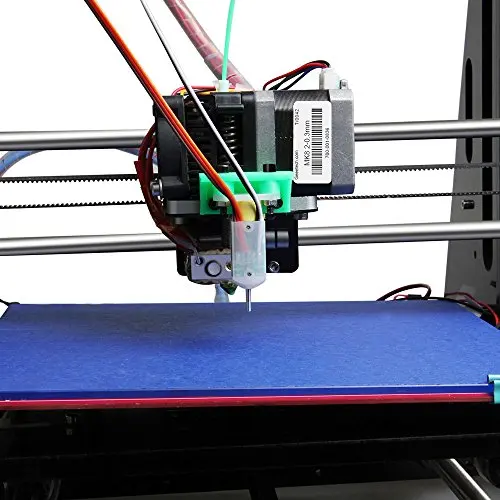

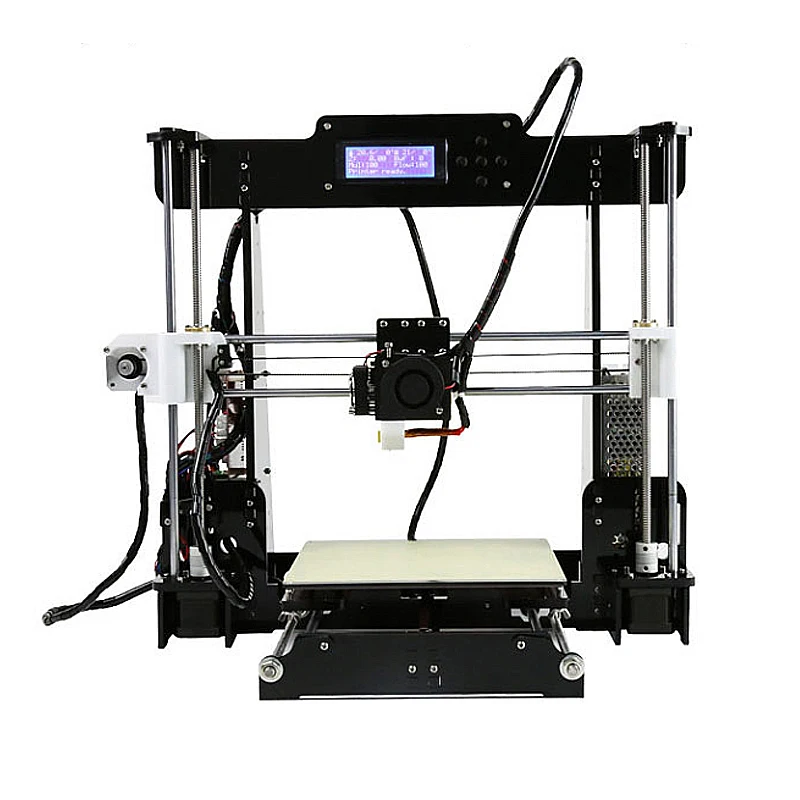

Hello, i would like to buy a first 3d printer, i don t need incredible quality I saw this, what do you think: http://www.ebay.it/itm/282001678547 Or http://www.ebay.it/itm/351857896815

wirlybird

#2

I would google the printers for reviews until your fingers hurt. Search on here also. Look for things in common on issues people may talk about. Some issues are not a big deal while others may be real bad.

Search on here also. Look for things in common on issues people may talk about. Some issues are not a big deal while others may be real bad.

1 Like

learley

#3

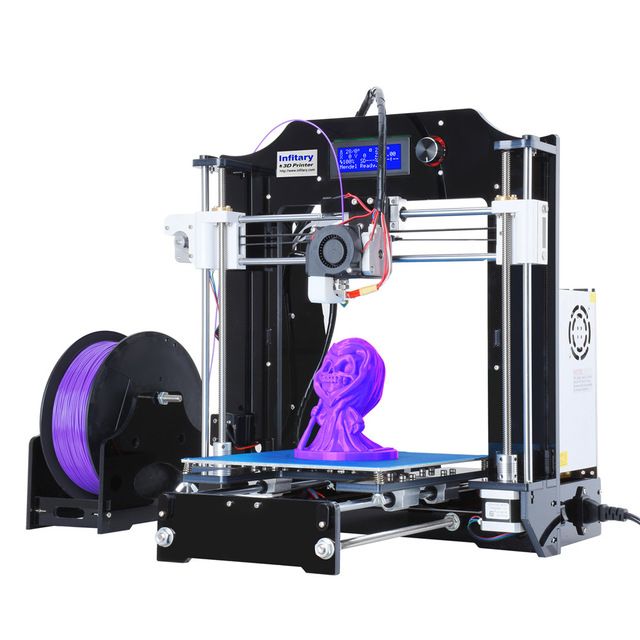

I think it also depends on your personal technical abilities. Are you good with electronics and troubleshooting? In that case a kit may be ok, but you will want to do a lot of reading first on the particular model you end up with because some of them ship with unsafe firmware and/or part design and are a fire hazard out of the box.

If you don’t want to tinker a bunch with the actual printer (at least, no more than a standard printer) and just want something that will work pretty well out of the box with decent quality prints, then I would recommend looking to spend a bit more and getting a more complete package with a reputable manufacturer backing it with support.

I am not saying you can’t make those kits work, but I probably wouldn’t recommend them to someone just getting into 3d printing unless you do a lot of research first.

1 Like

M8ker

#4

I would be careful with cheap printers. There are stories of some cheap printers catching on fire. I have the Monoprice Mini Select and for the price you can’t beat it. And there is a big community on Facebook and Reddit to answer questions when you run into problems

1 Like

aster94

#5

I have a good experience with electronics and diy, i decided to go for the greentech prusa i3 a lot of people made it working out of the box (after the mounting)!!

xxJC3Dxx

#6

For the money you can’t beat a select mini to start. It runs out of the box, parts and upgrades are cheap, the community is large and helpful and you can learn a lot of fixes on a smaller scale.

It runs out of the box, parts and upgrades are cheap, the community is large and helpful and you can learn a lot of fixes on a smaller scale.

aster94

#7

I didn t find it shipped for a reasonable price to italy, i can take the greentech prusa i3 for 160€ shipping included, and i think that i would need more than 12x12cm of printable plate

Bwaslo

#8

Of course one of the most famous for catching fire was Monoprice’s next model up from that one!

http://hackaday.com/2016/12/07/dont-leave-3d-printers-unattended-they-can-catch-fire/

https://www. reddit.com/r/3Dprinting/comments/4rko8m/warning_monoprice_maker_select_v2_fire/

reddit.com/r/3Dprinting/comments/4rko8m/warning_monoprice_maker_select_v2_fire/

2 Likes

eBay without PayPal, oil and a 3D printer are almost for nothing, and pensioners cannot live in Ukraine

October 1, 2014, 19:30 4689

"eBay" is awaiting restructuring. The result will be the separation of "PayPal" from "eBay", these will be two different companies. The board of directors of the corporation made a decision on the independent life of "PayPal" as a separate company. At the same time, throughout the year, any information about the separation of the payment system "PayPal" from the auction corporation "eBay" by all means denied.

They also report that personnel changes are coming. John Donahue (CEO) and Bob Swan (CFO) will now join the directors and leave their positions at eBay. eBay Marketplaces President David Wenig will take over as CEO of the revitalized eBay. In addition, Wenig will serve as the head of two businesses: eBay Marketplaces and eBay Enterprise. Dan Shulman will take over as CEO of the independent PayPal company in 2015. He was in corporate development at American Express.

In addition, Wenig will serve as the head of two businesses: eBay Marketplaces and eBay Enterprise. Dan Shulman will take over as CEO of the independent PayPal company in 2015. He was in corporate development at American Express.

By summer 2015, PayPal and eBay will exist as two separate companies. eBay management believes that such a separation will only positively affect both companies and provide new opportunities.

The Arduino company announced today that they want to get a piece of the 3D printer market. Arduino is known for producing microcontrollers for DIY electronics projects. The new device will be released under the name "Materia 101". The 3D printer will work with PLA plastic and is planned to be developed jointly with Sharebot, an Italian printer manufacturer. The cost of the product was not disclosed in advance, but there are already two options in the plans for release.

The assembled device is expected to cost no more than $1,000, while the DIY kit will cost up to $800.

The manufacturer of the budget 3D printer is ready to name the technical characteristics of the new model. Perhaps soon in every house there will be such a device.

Is cheap oil a dream or a reality? This is real! On the London and New York stock exchanges, following the results of trading on September 30, 2014, oil prices fell quite sharply. Before that, the official oil price fell by 2.6%, having exceeded the lowest mark in the last 27 months (2 years and 3 months). The price was set at $95 per barrel

As for the official cost of WTI oil (Light Sweet), it also decreased by 3.6% and crossed the minimum mark of $91 per barrel, settling slightly higher.

A similar low was observed 19 months ago. Recently there was information that cheap oil for the first time in history influenced the maximum depreciation of the Russian ruble.

Unfortunately, the decline in oil prices is unlikely to improve the lives of Ukrainian pensioners.

In the annual rating from the non-governmental organization "HelpAge International" Ukraine was on the 82nd place. This rating reflects the quality of life of people over 60 in each country.

October 1st is the International Day of Older Persons and the rating has been prepared for this holiday. Interestingly, in our country, pensioners know that there is such a holiday?

Our country took, think about it, 82nd place out of 96 states. Last places: Malawi, Mozambique, Afghanistan. Our country has the worst results among European countries. According to the rating, Ukraine is at the very bottom and among all the countries of the post-Soviet space.

Russia ranks 65th, and Belarus 64th in the ranking. For comparison, in 2013, just a year ago, Ukraine was in 66th place, and the Russian Federation was in 78th place. So, for a year Ukraine has slid down, and Russia has improved its result. Among all the countries of the post-Soviet Union, Estonia turned out to have the best result, it came out on the 20th position.

When creating the rating, HelpAge International took into account 13 components: cf. life expectancy, social activity, pension size, pensioner poverty level, etc.

Norway is ranked as the best country for older people. Close to the leader are: Canada, Switzerland, Sweden, Germany.

I bought a 3D printer as a beginner. Choosing, setting up, problems and solving practical problems / Sudo Null IT News

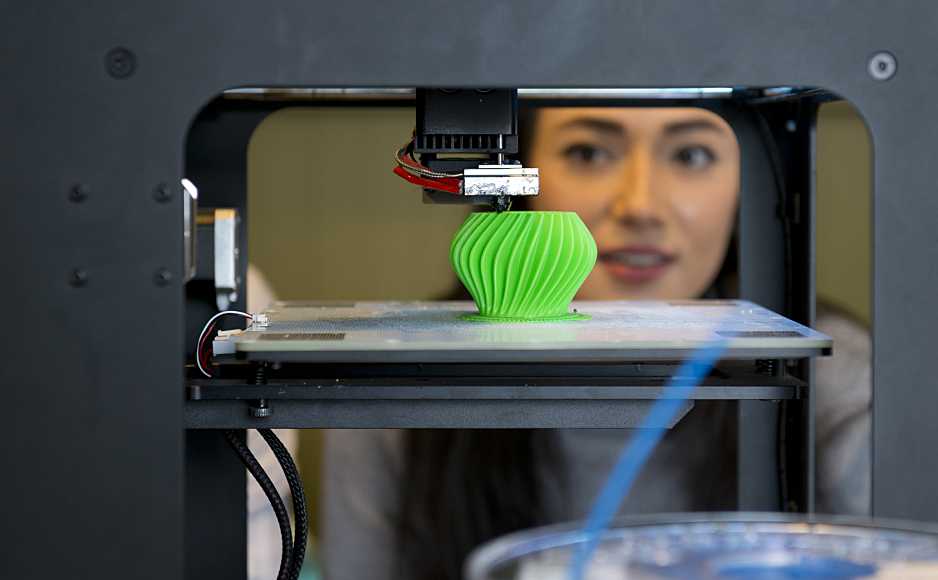

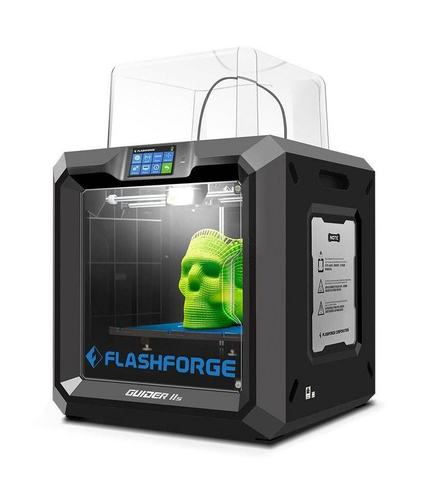

A few months ago, I was thinking about purchasing such a device because I wanted to print a broken part of my robot vacuum cleaner. About a month ago I bought a device I liked on eBay. That's what was important to me when choosing a 3D printer.

Which printer was needed?

Considering that I knew almost nothing about 3D printers (except for a few articles read here on Habré), the important points were:

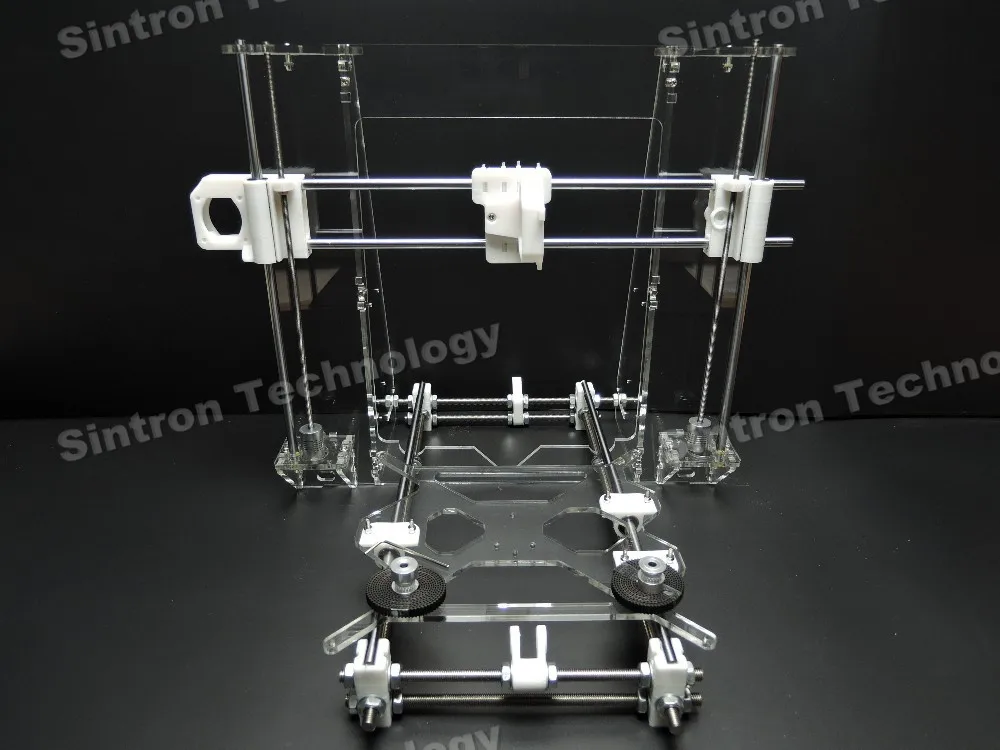

- Printer performance out of the box. I have seen several articles describing how long it takes to set up a "simple Chinese printer".

It needs to be assembled from a large number of parts, and it is not a fact that there will not be defective ones among them. Once assembled, you can mess around with the device for a couple of days, and then it turns out that for some reason it does not work. In short, I needed a printer that didn't need to be assembled and that could work right out of the box.

It needs to be assembled from a large number of parts, and it is not a fact that there will not be defective ones among them. Once assembled, you can mess around with the device for a couple of days, and then it turns out that for some reason it does not work. In short, I needed a printer that didn't need to be assembled and that could work right out of the box. - It shouldn't be too expensive. Seriously, I'm new, I was not sure that after a couple of days I would not abandon the device. And a printer for 500-600 euros would be too expensive a toy. So I was willing to spend a couple of hundred, no more.

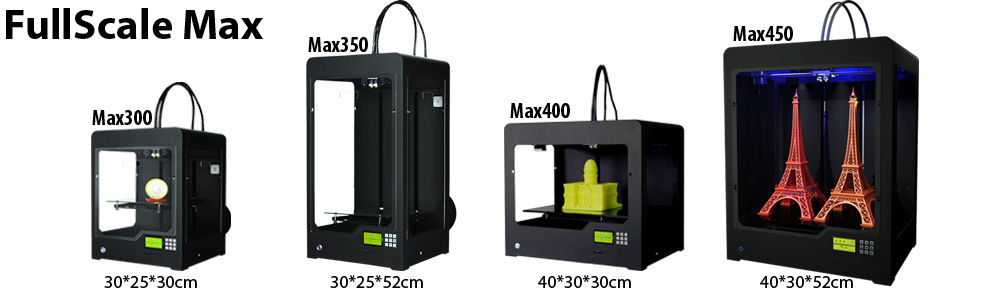

- It should not be too big. Before buying, I allocated a little space for installing the printer, somewhere around 50 * 50 cm. Therefore, the printer had to stand on the allocated area without any problems.

- It shouldn't be too difficult to maintain. This point is closely related to the first. I didn’t want to spend a lot of time on operation and maintenance work - there is sorely not enough time, so constantly eliminating emerging glitches is not an option.

- I wanted to get a printer with WiFi, it was not critical, but important.

What did I end up buying?

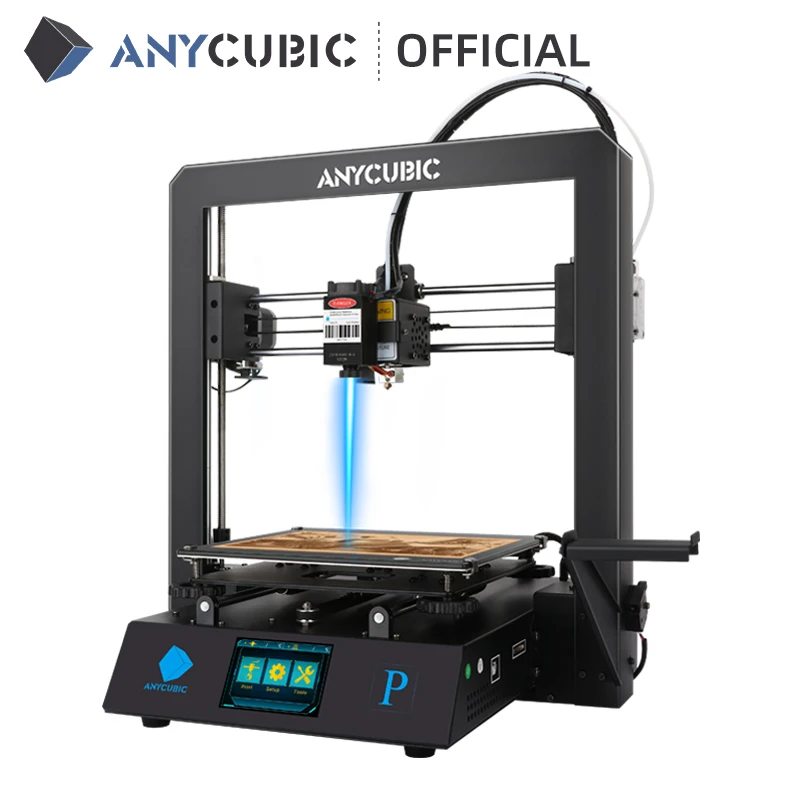

Model Geeetech E180. It was shown by Google after the query “3D printer for beginners”. There were other models in the search results, but this one was liked by the design and the presence of WiFi.

The developers of this printer raised money for it with the help of Kickstarter and a couple of years ago it appeared on the free market. Its price is from 200 to 350 euros, depending on the company that sells it and the store.

Bought on eBay, starting price was 200 euros, but the seller agreed to drop 50 euros, so the total price is 150.

Printer specifications:

- Print technology: FDM

- Working space dimensions: 130 x 130 x 130 mm

- Printing accuracy: 0.05 mm

- Positioning accuracy: X / Y 0.11 mm, Z 0.0025 mm

- Print speed: 80-110 mm/s

- Thread diameter: 1.

75 mm

75 mm - Nozzle diameter: 0.4 mm

- Supported material: manufacturer claims PLA, but may work with other materials

- Operating system: Windows

- Management software: EasyPrint 3D

- File format: .STL, G-code

- Maximum extruder temperature: 230 °C

- Power supply: DC 12V 6A

- Connectivity: WiFi, USB, TF card (offline printing support)

- Display: 3.2" full color touch screen

- Chassis: metal plate + injection molding (portable console 3D printer)

- Work table: aluminum alloy plate

- XYZ Rods: wear-resistant, stainless steel screw and lead (Z axis)

- Stepper motors: 1.8 degree stepped angle with 1/16 micro stepping

Unpacking and setup

Before setting up, I looked at several reviews and tests of the printer. If not for them, I would not have done it myself, the explanation in the instructions is slurred. The setup is simple, but not for a beginner.

The setup is simple, but not for a beginner.

The printer "wound up" as soon as I connected it to power and a laptop. I calibrated the position of the table - it turned out to be simple - inserted a microSD card into the slot, found the contents through the menu on the printer screen, inserted the fiber into the channel and started printing. The printer made a noise and started printing. Or rather, I thought that he started typing, in fact it was not so.

Problems

The printhead moved, the temperature reached 205 degrees Celsius, but there was almost no plastic - in the first few seconds, a few plastic “hairs” came out and that was it. The printer continued to work, but the plastic was not squeezed out of the head.

I wasted several Saturday hours trying to figure out why. I tried to look for an explanation on the net, but solutions to similar problems did not suit me.

The joy of buying disappeared in the first couple of hours of fuss. I wanted a printer that “just works”, but it didn’t work out. As a result, I realized that the fiber was not being fed - the feed mechanism hidden under the plastic cover simply did not work. It did not work because the constituent elements did not rotate. There was no movement at all.

I wanted a printer that “just works”, but it didn’t work out. As a result, I realized that the fiber was not being fed - the feed mechanism hidden under the plastic cover simply did not work. It did not work because the constituent elements did not rotate. There was no movement at all.

I have decided that the printer has a defective electric motor that is responsible for feeding, and I cannot repair it. The next step is to click the Return to Seller button on eBay. After clicking the button and describing the problem, I decided to pack the printer for shipping. Before sealing it in a foam box, just in case, I decided to carefully examine those “insides” that are visible through the holes in the case.

And the reason was immediately found - the assembler at the factory simply forgot to connect the power supply to the engine. Seriously, the cable just dangled inside the case. I connected it to the right connector with tweezers without disassembling the printer. Then I turned on the device again and this time everything was fine, the plastic feed worked as it should.

Then a few more minor problems arose:

- Misaligned table. This caused the table to skew and the print head was pressed against the surface in one place. As a result, the plastic could not be squeezed out of the head, which led to solid print defects;

- Unable to directly print models downloaded from the Internet. Being a beginner, I thought that everything works like with a regular printer - I downloaded a document, sent it to print. It turns out that slicing is also needed. I will not repeat what it is and why it needs to be perfectly described in this article on Habré;

- Slicers are not compatible with the printer model. Slicer needs to set printer desktop size. Some slicers for some reason did not want to work with the dimensions of my printer (13*13*13 cm). Some even crashed (including the printer's native application), some did not "understand" the dimensions. As a result, I settled on ideaMaker;

- No WiFi.

As it turned out, there are two varieties of E180 - one with an integrated WiFi module, the second - without a module, you need to buy it in addition. At the seller, the inscription "need a separate module" was applied to one of the photos of the printer, small and in French (everything else was in English). Not a scam, but close to it. The module decided not to buy more, it is not really needed;

As it turned out, there are two varieties of E180 - one with an integrated WiFi module, the second - without a module, you need to buy it in addition. At the seller, the inscription "need a separate module" was applied to one of the photos of the printer, small and in French (everything else was in English). Not a scam, but close to it. The module decided not to buy more, it is not really needed; - Long printing time. I thought it would take several tens of minutes to print. I was not ready for the fact that large models can be printed for 6-8 hours. This is my own fault - I did not carefully look at the reviews.

Practical use

I didn’t buy a printer for a game, I wanted to get a device that would allow me to create things I need in everyday life, and not run to the store. Before buying, I outlined what I wanted to create:

The lever for separating the water tank in the iRobot Scooba robot vacuum cleaner, the repair review of which I published on Habré. His native pen broke, he did not want to spend money on buying a new one (they are relatively rare, since Scooba is no longer produced and expensive).

His native pen broke, he did not want to spend money on buying a new one (they are relatively rare, since Scooba is no longer produced and expensive).

Finally found a suitable model on Thingiverse and printed it. To my surprise, everything fell into place the first time, the pen still works quite normally (it's been about a month since this part was printed).

Chinese electron microscope stand. I needed it for soldering small parts. I do not want to buy a professional microscope for 400 euros, since I myself do not do repairs very often. A Chinese microscope connected to a laptop is quite an option. But his native tripod is just terrible. Therefore, I wanted to make a new, normal one with my own hands.

Soldering iron stand. You just need a comfortable stand, from which the soldering iron will not fall, like from a Chinese stand that I once bought.

Paste tube squeezer. Yes, the thing is not the most necessary, but practical.

iPhone stand. Convenient, there is a hole for the cable, sound amplification.

Toys for children. Why buy another small doll or dollhouse piece when some things can just be printed out?

Stylus for Nintendo DS Lite. I had a game console bought at a flea market for a long time. The stylus was lost and I (and my daughter) played using the PDA stylus. Recently I found a stylus model for the console, printed it out - it turned out perfectly. It fits into the connector like a factory one.

Extractor for printed parts stuck to the table. Nearly every part sticks to the printer's desktop backing. You can’t do without a special device - an ordinary knife will scratch and cut a special sticker. I found a model that is compatible with the blades of a standard utility knife - works great.

The printer lived up to my expectations. It was possible to print almost everything that is indicated above. All these things fulfill their purpose, and most importantly, I am not afraid that any of them may fail. You can always print a new one.

You can always print a new one.

There are a lot of ready-made models on the net. If you need some detail or thing, in 90% of cases you can find everything you need.

Troublesome little things

Printed parts are far from perfect. In some cases, deformation of some elements occurs and it is necessary to “finish” manually, using a knife and, in fact, a file. It doesn't happen that often, but I wish the printed part didn't need to be reworked (yes, I know you can get it by buying a professional 3D printer).

Sometimes details are printed, but for some reason the real and declared size do not match. So, I tried several times to print different dispensers for AA and AAA batteries, but for some reason the ready-made dispensers did not fit. The diameter of the holes into which the batteries are inserted was always somewhat smaller than the diameter of the batteries themselves. I still do not understand whether the problem is on my part, or the model is problematic. As a solution, you can simply increase the scale of the part in the slicer, by 10 percent. But it’s a pity for the spent plastic - after all, you can find out whether a quality part will turn out or not only after a solid part of it is ready.

As a solution, you can simply increase the scale of the part in the slicer, by 10 percent. But it’s a pity for the spent plastic - after all, you can find out whether a quality part will turn out or not only after a solid part of it is ready.

It takes a long time to print a part. Some printouts take several hours to complete, so it can take up to half a day to create a simple phone holder for a car.

In order to develop something of your own, you need knowledge of CAD , at least at an elementary level. Otherwise, you will have to look for ready-made objects on sites that host models created by someone. In the end, I never found a battery cover for one of the remotes. I am not able to develop it myself - there is almost no time to master CAD.

My printer desktop is small . Not all objects that I would like to print can be implemented. In particular, I wanted to get a different microscope stand model. But it did not work out, because it is larger than the printer table.