Flash print 3d software

download center 3d printer software

download center 3d printer software- Home

- Download Center

- Software

- FlashPrint

FlashPrint

FlashPrint_5.5.1

- Upload date:2022-10-28

- File Size:11.48 MB

- Version:5.5.1

- Support System:Linux

FlashPrint_5.5.1

- Upload date:2022-10-28

- File Size:24.08 MB

- Version:5.5.1

- Support System:MacOS

FlashPrint_5.5.1

- Upload date:2022-10-28

- File Size:28.

88 MB

- Version:5.5.1

- Support System:Win64

FlashPrint_5.5.1

- Upload date:2022-10-28

- File Size:27.62 MB

- Version:5.5.1

- Support System:Win32

FlashPrint_5.5.0

- Upload date:2022-09-19

- File Size:11.47 MB

- Version:5.5.0

- Support System:Linux

FlashPrint_5.5.0

- Upload date:2022-09-19

- File Size:24.08 MB

- Version:5.

5.0

5.0 - Support System:MacOS

FlashPrint_5.5.0

- Upload date:2022-09-19

- File Size:27.51 MB

- Version:5.5.0

- Support System:Win32

Flashprint_5.5.0

- Upload date:2022-09-19

- File Size:28.92 MB

- Version:5.5.0

- Support System:Win64

FlashPrint 5.4.1

- Upload date:2022-08-09

- File Size:24.94 MB

- Version:5.4.1

- Support System:MacOS

FlashPrint 5. 4.1

4.1

- Upload date:2022-08-08

- File Size:10.55 MB

- Version:5.4.1

- Support System:Linux

FlashPrint 5.4.1

- Upload date:2022-08-08

- File Size:27.93 MB

- Version:5.4.1

- Support System:Win32

FlashPrint 5.4.1

- Upload date:2022-08-08

- File Size:29.38 MB

- Version:5.4.1

- Support System:Win64

FlashPrint_5.3.4

- Upload date:2022-06-02

- File Size:10.

46 MB

46 MB - Version:5.3.4

- Support System:Linux

FlashPrint_5.3.4

- Upload date:2022-06-02

- File Size:22.97 MB

- Version:5.3.4

- Support System:MacOS

FlashPrint_5.3.4

- Upload date:2022-06-02

- File Size:27.45 MB

- Version:5.3.4

- Support System:Win64

FlashPrint_5.3.4

- Upload date:2022-06-02

- File Size:26.23 MB

- Version:5.

3.4

3.4 - Support System:Win32

FlashPrint_5.3.3

- Upload date:2022-04-27

- File Size:26.21 MB

- Version:5.3.3

- Support System:Win 32

FlashPrint_5.3.3

- Upload date:2022-04-27

- File Size:27.44 MB

- Version:5.3.3

- Support System:Win 64

FlashPrint_5.3.3

- Upload date:2022-04-27

- File Size:22.95 MB

- Version:5.3.3

- Support System:Mac

FlashPrint_5. 3.3

3.3

- Upload date:2022-04-27

- File Size:10.21 MB

- Version:5.3.3

- Support System:Linux

FlashPrint_5.3.2

- Upload date:2022-04-24

- File Size:10.44 MB

- Version:5.3.2

- Support System:Linux

FlashPrint_5.3.2

- Upload date:2022-04-18

- File Size:22.95 MB

- Version:5.3.2

- Support System:MacOS

FlashPrint_5.3.2

- Upload date:2022-04-18

- File Size:27.

44 MB

44 MB - Version:5.3.2

- Support System:Win64

FlashPrint_5.3.2

- Upload date:2022-04-18

- File Size:26.21 MB

- Version:5.3.2

- Support System:Win32

FlashPrint_5.3.1

- Upload date:2022-04-16

- File Size:22.91 MB

- Version:5.3.1

- Support System:MacOS

FlashPrint_5.3.1

- Upload date:2022-04-16

- File Size:27.38 MB

- Version:V5.

3.1

3.1 - Support System:Win64

FlashPrint_5.3.1

- Upload date:2022-04-16

- File Size:26.09 MB

- Version:V5.3.1

- Support System:Win32

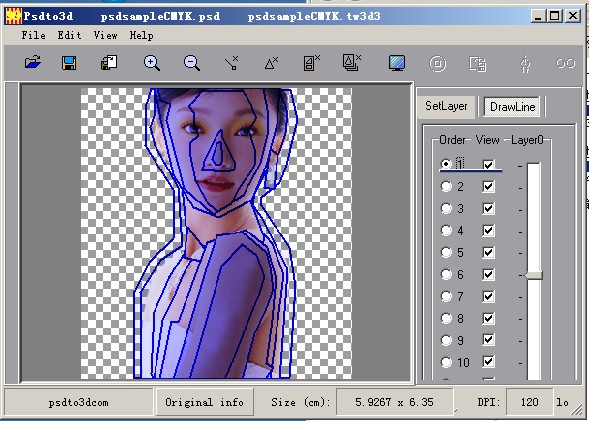

FlashAD Slicer for Flashforge AD1 3D Printer

The special slicing & designing software, FlashAD, makes it easier to make complex designs, therefore, even our user may create an amazing shadow effect with returned slant at some angles as he wishes, eliminating trouble of calculating the curving angle in CNC machining. Strong help to get complicated logo easily.

Download

Automatically generate the required print file through the input text and select the font in the software.

You can also use CorelDRAW and other software to design 2D vector graphics, import them into FlashAD and automatically generate print files.

You can select a range of different types that best fit for your vision and image.

Top

- Top step effect

- Top closure effect

- Top chamfering effect

Bottom

- Bottom closure effect

- Extended bottom effect

- Bottom step effect

Side :

There's a convex platform to support acrylic panel, and the acrylic panel can be embedded into the side.

Closed top with letter.

Side:

There's a convex platform to support acrylic panel, and the acrylic panel can be embedded into the side.

It could be as a refer to this height of steps line when dropping the liquid acrylic.

It is better for adhering to platform when the bottom is wider.

A channel with the bottom enclosed.

-

The thickness of the printed shell. The default is 1mm. The higher the value, the thicker the shell is.

The higher the value, the thicker the shell is. -

The overall height of the printed shell. The default is 20mm. The higher the value, the higher the shell is. The maximum height supported is 70mm. -

The height difference between internal and external shell on the bottom. Generally, the height of the external shell is higher.

Represent

- Monochrome printing

- Two-color printing

- Two-color interlacing

- Two-color cycle interlacing

- Two-color free cycle interlacing

3D bevel edge channel letter: Support setting of tilt angle and direction of shell. The tilt angle should be changed by following the size of channel letter, or the improper tilt angle will cause printing failure.

3D side arc edge channel letter: Support the setting of outward side arc degree of shell and the distances between the two sides and the arc edge.

3D side closed angle edge channel letter: The side of the shell has a closed corner shape effect. Support setting of closed angle and the distance between the two sides and the closed angle edge.

Support setting of closed angle and the distance between the two sides and the closed angle edge.

3D top arc channel letter: Achieve the shell side and the panel printing together and the panel appears an arc roof effect. Support the top arc edge degree setting.

3D top closed angle channel letter: Achieve the shell side and the panel printing together and the panel appears a pointy roof effect. Support the top closed angle setting.

3D inclined structure channel letter: It has inclined body effect. To change the tilt degree of inclined body by adjusting the height of the shorter line. The smaller number setting, the bigger tilt degree.

3D top stairs channel letter: It is suitable for panel installation to guarantee a smooth surface. Support stair height setting.

The files output by the software include 3D printing files and cutting files of the carving machine, and there is no need to design separate files for the carving machine.

Four printing mode

Automatic generation of hidden joint marks in slicing files according to different patterns to ensure smooth surface of print production.

No need to copy the file after it is generated, and able to print directly via cloud platform.

No trouble of copying files many times to the printer, which improves working efficiency a lot and saves time when operating multiple devices.

Platform Grid

Large Format Raise3D RMF500 for 3D Printing with Carbon Fiber Reinforced Materials

Last autumn, the well-known Chinese manufacturer of 3D printers, Raise3D, announced the creation of a new 3D printer for small-scale production in the industrial sector - RMF500 . The unique feature of the novelty is the combination of the ability to print with carbon fiber reinforced material (colloquially carbon fiber), wide format and affordability .

We all know that high technology is becoming more accessible every day, and the RMF500 is a prime example of this. There have been systems on the 3D printing market for several years that print carbon fiber composites of similar quality, but, unfortunately, they are not available to all companies due to the very high cost and supply problems. For example, such professional 3D printers are produced by the American company Stratasys - Fortus 450mc, but they are equipped with less technological features and are much more expensive.

There have been systems on the 3D printing market for several years that print carbon fiber composites of similar quality, but, unfortunately, they are not available to all companies due to the very high cost and supply problems. For example, such professional 3D printers are produced by the American company Stratasys - Fortus 450mc, but they are equipped with less technological features and are much more expensive.

Let's take a closer look at what the RMF500 is and how it differs from other 3D printers.

The RMF500 is specifically designed for printing complex parts with high durability. It will enable 3D printing companies to expand their product portfolio with carbon fiber and fiberglass end parts. Both materials specially developed by Raise3D, such as PA12 CF, and materials from other manufacturers approved by Raise3D under the Open Filament Program (OFP) will work. Parts made of carbon and fiberglass are more rigid, durable, resistant to heat and shock than parts made of other plastics. For carbon and fiberglass printing, the RMF500 uses silicon carbide nozzles with a hardness of more than 60 HRC.

For carbon and fiberglass printing, the RMF500 uses silicon carbide nozzles with a hardness of more than 60 HRC.

PA12 CF filament is the result of long-term development by Raise3D engineers. This is a carbon fiber reinforced filament with increased stiffness and reduced shrinkage and does not require a thermostatic print chamber. The parts obtained from it are light and extremely durable, sometimes they can even be used instead of metal. In addition, the company has developed the PPA GF glass-filled filament specifically for the RMF500 and plans to release PET-CF, ASA-GF, PPSU-GF and PP plastics for medical use. Raise3D promises that all fiber reinforced plastics will be competitively priced.

The RMF500 has a huge building area 500x500x500 mm. The size of the build area matters in the production of large parts and small-scale production. For comparison, the print area of the Fortus 450mc is 406x355x406mm.

In the photo: printing a large model with carbon fiber in the RMF500 3D printer from Raise3D.

Repeatability and print speed are very important for low volume production. The maximum print speed of the RMF500, according to the manufacturer, can reach 300 mm/s. Positioning accuracy along the XY axis - 1 micron, along the Z axis - 0.09765 microns.

Synchronous feedback control with 1 µm accuracy reduces speed fluctuations as motor load changes, further improving accuracy. Stability and repeatability of printing has long been a hallmark of Raise3D printers. The FFF technology on which this 3D printer is based allows the production of parts with a high degree of repeatability, high positioning accuracy and uniform extrusion. The RMF500 can quickly print large batches of identical parts.

Pictured: production of lots from a large number of parts on the RMF500.

The printer has a printing system with two independent IDEX extruders. It allows you to print with one or two extruders at once. The RMF500 can run two jobs at the same time, further increasing productivity and task speed. The extruders are manufactured using high temperature alloys and industrial ceramic composite materials. These characteristics provide stable and high extrusion speed up to 500 g/h.

The extruders are manufactured using high temperature alloys and industrial ceramic composite materials. These characteristics provide stable and high extrusion speed up to 500 g/h.

The RMF500 has a strong design . The one-piece frame is made of hardened steel. Stainless steel linear guides have a design load of approx. 100 kg. The bearing of the linear guides has minimal backlash and does not require frequent maintenance.

An important detail - Raise3D has developed special support material for printing with reinforced plastic PA12 CF, which can be easily detached.

Pictured: Parts printed on the RMF500 with PA12 CF filament with special proprietary support.

The RMF500 is equipped with four large compartments for plastic spools. Switching between the main and auxiliary compartments occurs automatically. This feature reduces the amount of time spent threading the filament. The humidity control system keeps the relative humidity in the chamber below 5%, preventing humid air from entering from outside.

What else is there in the RMF500 from nice additional options. The front of the printer has a large 13.3-inch touch screen. Supports connection, management and printing via Wi-Fi and LAN. There is a reliable auto-calibration system from Raise3D.

Carbon fiber printed parts are strong enough to be used in the automotive and aerospace industries. Of course, they will not replace functional parts that have a special load, but their scope can be very wide. Raise3D has already presented the results of the first RMF500 printing and its application.

Pictured: Functional parts, accessory tools and fixtures, car décor printed on the RMF500.

Pictured: Functional parts, accessories and aerospace prototype printed on the RMF500.

In the photo: on the left is a prototype of the hinged window mechanism (details are printed with metal filament and carbon), on the right is a carbon fixture. Carbon parts printed on RMF500, metal parts printed on Metalfuse. Printing with fiber-filled plastics does not require a heated chamber, peak power consumption is less than 3 kW. The average power consumption per unit of print area of the RMF500 is 60% lower than the competition.

Printing with fiber-filled plastics does not require a heated chamber, peak power consumption is less than 3 kW. The average power consumption per unit of print area of the RMF500 is 60% lower than the competition.

| Operating temperature of the extruder | to 330 ℃ | to 300 mm/s 900 mm/s 900 mm/s 900 mm/s 900 mm/s 900 mm/s 900 mm/s 900 mm/s 900 mm/s 900 mm/s 900 mm/s 900 mm/s -filter | yes |

| Build Tak pad surface | yes |

| Positioner | Rockchip ARM Cortex-M4 |

| Operating systems | Linux, Windows, iOS |

| Maintained file formats | STL/ Obj/ OLTP |

ETERARNETS, WIRELESS 802. 1 1 | |

| Ports | USB 2.0 × 1 |

| Electrician | 30 A @ 380 volts AC |

| Energy consumement | 24 V, 350 WATT; 12V, 75W |

| Memory | 1 GB, built-in flash memory 8 GB |

| Sizes (without packaging) | 1340 × 2370 mm |

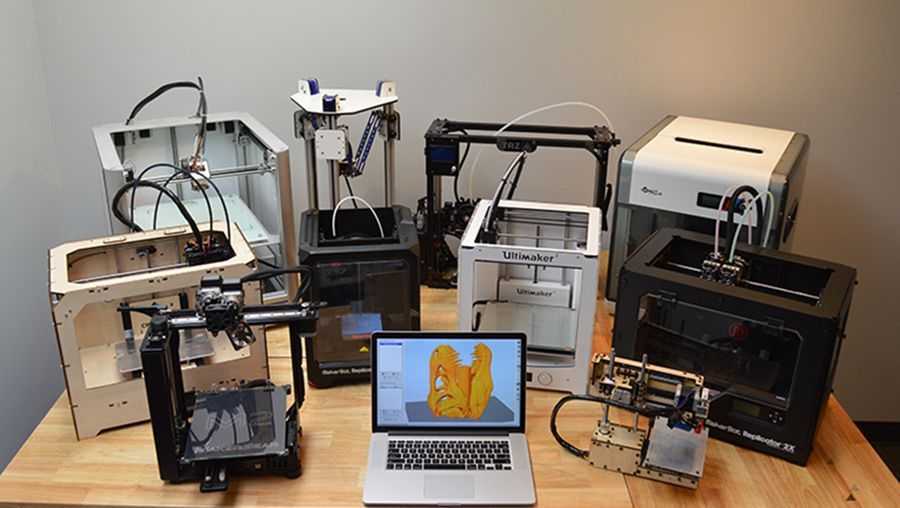

Top 20 Free 3D Printing and 3D Printing Software

Looking for 3D printing software? We've rounded up the top 20 software tools for beginners and professionals alike. Most slicers are free.

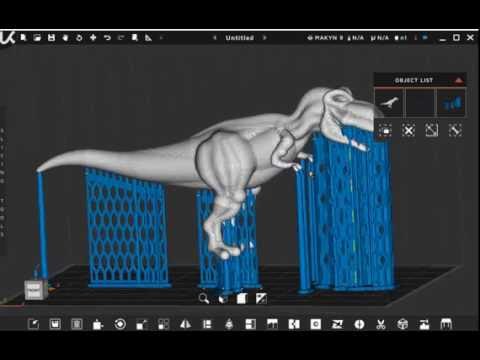

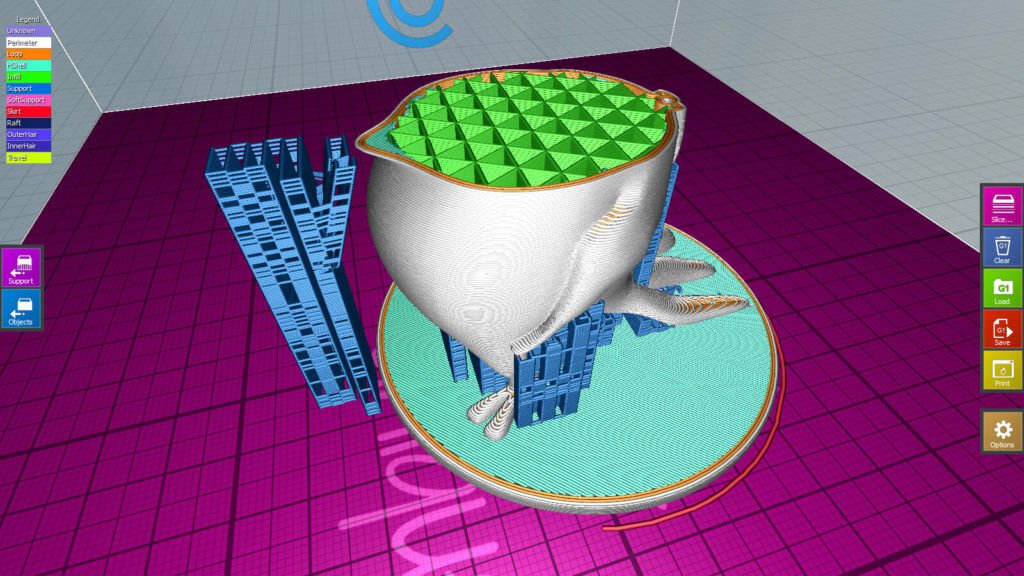

What is a slicer? This is a program for preparing a digital model for printing. Models for 3D printing are usually distributed in STL files. To turn an STL file into G-code (a language that a 3D printer understands), a slicer program is required. It is called a slicer because it cuts (to slice - English) a 3D model into many flat two-dimensional layers, from which a 3D printer will add a physical object.

It is called a slicer because it cuts (to slice - English) a 3D model into many flat two-dimensional layers, from which a 3D printer will add a physical object.

Which slicer should I choose? In this article, we will tell you which slicer is best for 3D printing for each stage of your work. Which one is better for preparing a 3D model for printing? But what if you need to create a 3D model from scratch? And if you are only taking the first steps in 3D?

Don't be afraid: we've answered all of these questions, including the required skill level for each program and where you can download it. The great thing is that most of these programs are completely free and open source.

- Cura

- CraftWare

- 123D Catch

- 3D Slash

- TinkerCAD

- 3DTin

- Sculptris

- ViewSTL

- Netfabb Basic

- Repetier

- FreeCAD

- SketchUp

- 3D Tool

- Meshfix

- Simplify3D

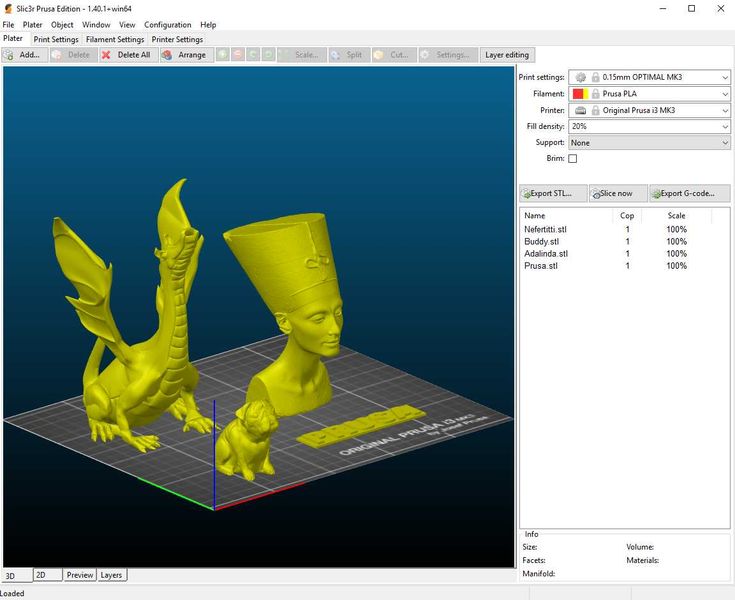

- Slic3r

- Blender

- MeshLab

- Meshmixer

- OctoPrint

#1: Cura

For beginners who need a slicer to prepare STL files for 3D printing

Cura is the default slicer software for all Ultimaker 3D printers, but can be used with most others , including RepRap, Makerbot, Printrbot, Lulzbot and Witbox. The program is completely open source, its capabilities can be extended using plugins.

The program is completely open source, its capabilities can be extended using plugins.

This program is very easy to use and allows you to manage the most important 3D printing settings through a clear interface. Start in Basic mode to quickly get up to speed and change print quality settings. If finer control is required, switch to Expert mode.

Cura can also be used to directly control the printer, but then the printer and computer must be connected to each other.

Download: Cura

Price: Free

Systems: PC, Mac, Linux

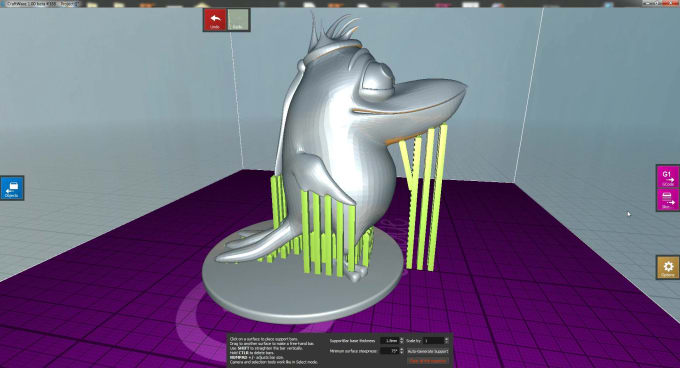

#2: CraftWare

For beginners to prepare STL files for 3D printing 3D printers by the Hungarian startup CraftUnique to support their CraftBot crowdfunding machine. However, the program works with other printers.

Like Cura, CraftWare allows you to switch from "Easy" to "Expert" mode, depending on how confident you feel. It's a colorful app that features a visual G-code visualization with each function represented by a different color. But the most outstanding feature is the individual support service. As far as we know, only the paid program Simplify3D has this.

But the most outstanding feature is the individual support service. As far as we know, only the paid program Simplify3D has this.

Please note, however, that this program is still in beta, so bugs may occur.

Download: CraftWare

Price: Free

Systems: PC, Mac

#3: 123D Catch

-systems, smartphones and tablets, which allows you to convert images of objects into a 3D model. Pictures can be taken with a smartphone/tablet or digital camera.

You need many photos of the object from different angles - the more the better - after which they will be compiled into a 3D model.

123D Catch is more of a fun app than a professional 3D printing tool, but after some tambourine dancing, you can get good results, especially when paired with an STL editor like MeshLab or Meshmixer.

Price: Free

Systems: PC, Android, iOS, Windows Phone

#4: 3D Slash

and surprisingly simple, and refreshingly new. With 3D Slash, you can design 3D models using your dice skills.

With 3D Slash, you can design 3D models using your dice skills.

You can start with a large block and, like a virtual sculptor, remove small cups from it with tools such as a hammer or drill, or start from empty space and build a model from cubes and other shapes. You can paint with flowers or use template pictures.

Other features worth mentioning are tools for creating logos and 3D text. The Logo Wizard imports an image and creates a 3D model, while the Text Wizard allows you to enter and format text, and then turn it into 3D.

Recommended!

Download: 3dslash.net

Price: Free

Systems: PC, Mac, Linux, browser

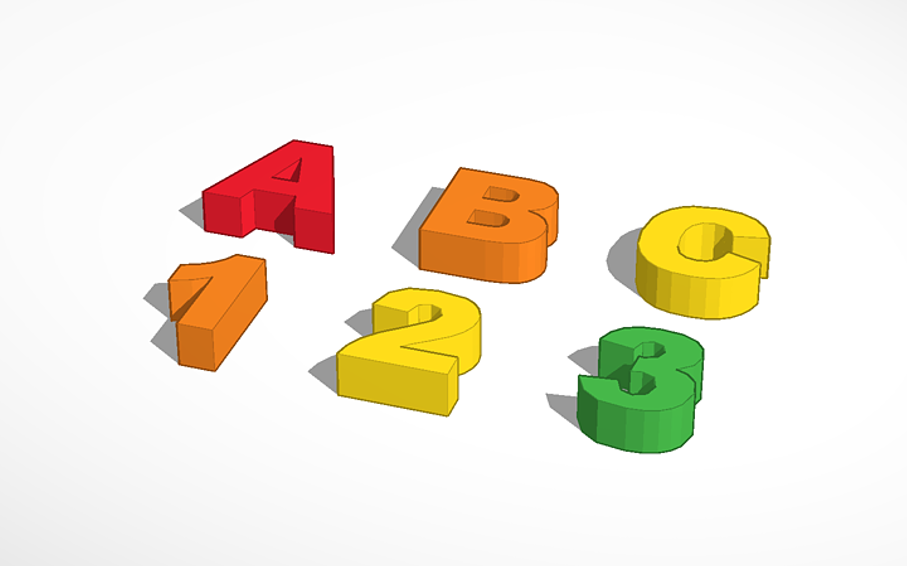

#5: TinkerCAD

- A computer-aided design (CAD) system for 3D printing, which is a good starting point for beginners. Since its capabilities are limited compared to Blender, FreeCAD and SketchUp, many users switch to more powerful tools after some time.

As in 3D Slash, here you can build models from basic shapes. At the same time, unlike 3D Slash, TinkerCAD allows you to create vector shapes in 2D and convert them into three-dimensional models.

At the same time, unlike 3D Slash, TinkerCAD allows you to create vector shapes in 2D and convert them into three-dimensional models.

Come in: Autodesk TinkerCAD

Price: Free

Systems: Browser

#6: 3DTin

For beginners who want to create 3D printable models

another easy and intuitive online tool choice for beginners in 3D modeling. All you need is a Chrome or Firefox browser with WebGL enabled.

Choose from a huge library of 3D shapes and add them to your sketch. All sketches are stored in the cloud, access to them is free if you honor the Creative Commons license. Everything can be exported to STL or OBJ formats.

Enter: 3DTin

Price: Free

Systems: Browser

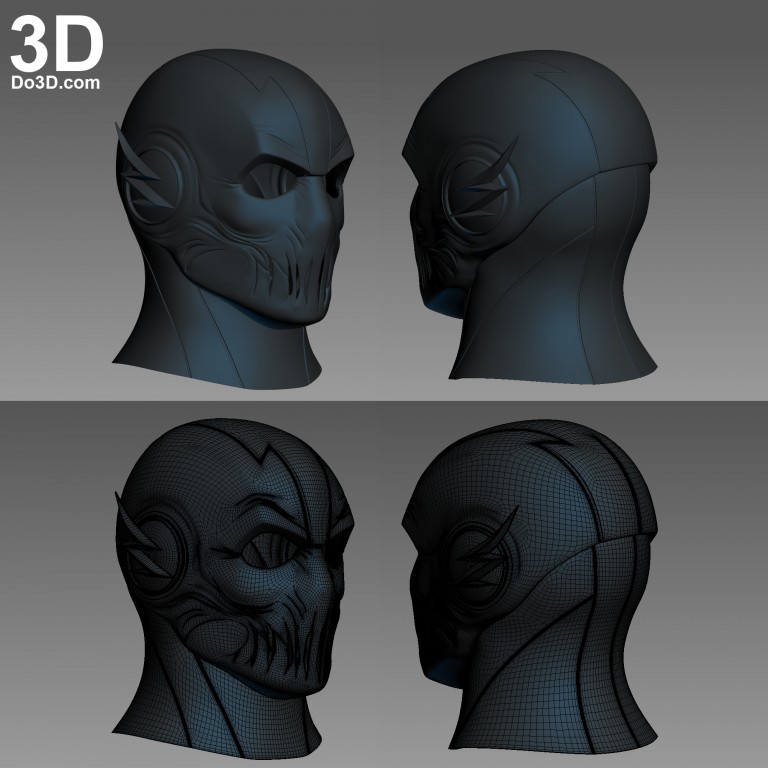

#7: Sculptris

For beginners who want to create 3D printable models

clay. This is a fantastic 3D modeling program if figurines are your main task. For example, you can make a bust of your favorite video game or comic book character. Sculptris is completely free and bills itself as a stepping stone to the more complex (and expensive) ZBrush tool.

Sculptris is completely free and bills itself as a stepping stone to the more complex (and expensive) ZBrush tool.

Download: Pixologic Sculptris

Price: Free

Systems: PC, Mac

#8: ViewSTL

For beginners who want to view STL files

Using ViewSTL is the easiest way to view STL files . Simply open a web page and drag the STL onto the dotted box.

The STL online viewer allows you to display the model in one of three views: flat shading (for a quick view), smooth shading (for a high-quality image), and wireframe.

Enter: ViewSTL

Price: Free

Systems: Browser

#9: Netfabb Basic

some nice features that allow you to analyze, "repair" and edit STL files before moving on to the model cutting stage.

A good choice if you need more than just a slicer and want to be able to quickly fix STL files without having to learn programs like MeshLab or Meshmixer.

Don't let the 'Basic' in the name fool you, Netfabb Basic is actually a very powerful 3D printing tool. It's "basic" only in the sense that it doesn't cost €1,500 like Netfabb Professional!

It's "basic" only in the sense that it doesn't cost €1,500 like Netfabb Professional!

Download: netfabb.de

Price: Free

Systems: PC, Mac, Linux

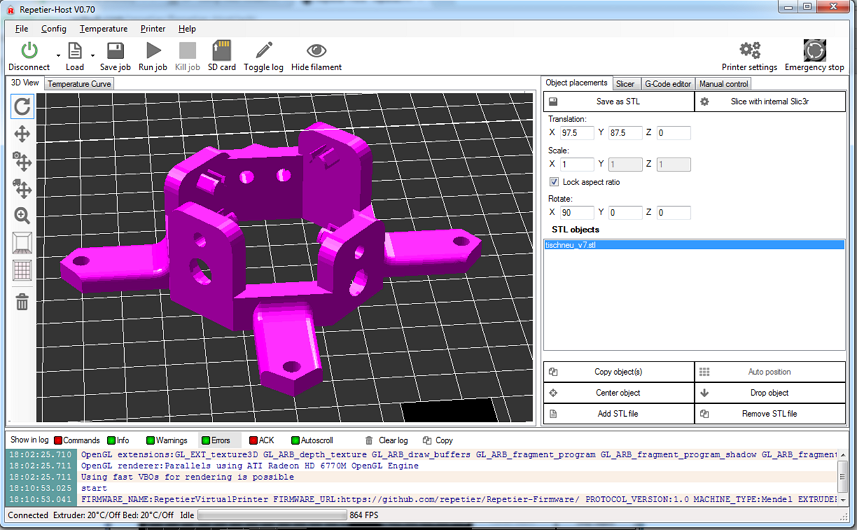

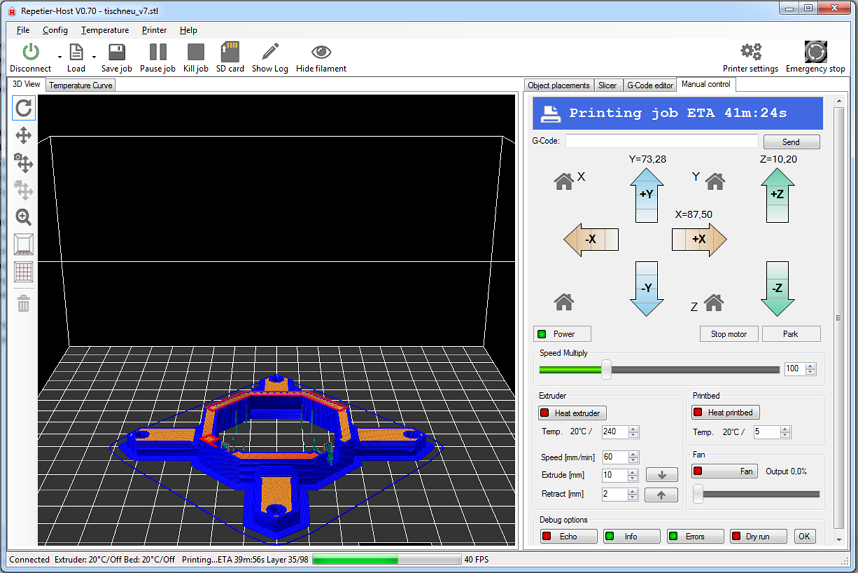

No. 10: Repetier

For advanced to prepare STL files for 3D printing

9002 the next level of 3D printer slicer software, but if you want to stay open source, you should look into Repetier. It is the great grandfather of 3D printing software and a favorite of the RepRap community.Today the program is moving by leaps and bounds from the level for beginners to advanced users. Packaged in an all-in-one configuration, it supports up to 16 extruders, multi-slicing via plug-ins, and virtually every fusing 3D printer on the market. Get ready to tinker!

What's more, Repetier Host works remotely via Repetier Server, so that the 3D printer can be controlled via a browser, tablet or smartphone.

Download: Repetier

Price: Free

Systems: PC, Mac, Linux

#11: FreeCAD

The program is a great option for developing your design skills. More technically, this parametric 3D modeling program allows you to easily change the project by rolling back through the history of the model and editing the parameters.

More technically, this parametric 3D modeling program allows you to easily change the project by rolling back through the history of the model and editing the parameters.

3

Download: freecadweb.org

Price: Free

Systems: PC, Mac, Linux

#12: SketchUp

For beginners who want to create 3D printable models

SketchUp is the perfect combination of simplicity and the perfect combination functionality, with a user-friendly interface and a relatively flat learning curve (i.e., as experience grows with the time spent), the ideal program for developing three-dimensional models.

The Make SketchUp version is free and will have everything you need for 3D modeling if you also download and install the free STL exporter. There is also a professional edition for architects, interior designers and engineers.

Download: sketchup.com

Price: Free (SketchUp Make), $695 (SketchUp Pro)

Systems: PC, Mac, Linux

#13: 3D-Tool Free Viewer

view and check STL files

3D-Tool Free Viewer is a sophisticated tool that, among other things, allows you to check the structural integrity and printability of your file. With the Cross-Section function, for example, you can look at the model from the inside and check the wall thickness. Very useful if you want to check your STL file for killer errors before printing.

With the Cross-Section function, for example, you can look at the model from the inside and check the wall thickness. Very useful if you want to check your STL file for killer errors before printing.

Download: 3D-Tool

Price: Free

Systems: PC

#14: Meshfix

your model for errors.

Price: Free

Systems: Browser

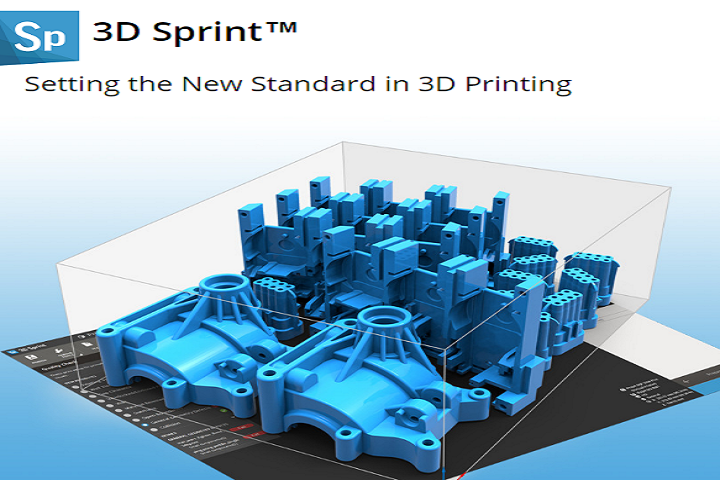

#15: Simplify3D

For professionals to prepare STL files for 3D printing print. A flexible algorithm checks the model for problems, fixes them, shows a preview of the printing process (ideal for identifying potential problems), and then slices it.

This slicer offers the best infill pattern options in the competition. For models that require supports, Simplify3D will create the appropriate structures on its own and give you full control over their placement. For printers with a dual extruder, when printing with different materials, the Dual Extrusion wizard will help, as a result of which, for example, it will be easier to remove the dissolving filament.

Simplify3D supports 90% of today's commercially available desktop 3D printers and is compatible with Marlin, Sprinter, Repetier, XYZprinting, FlashForge, Sailfish and MakerBot firmware. Simplify3D can also be used to directly control the printer, but then the printer and computer must be connected to each other.

Download: simplify3d.com

Price: $149

Systems: PC, Mac, Linux

#16: Slic3r

source code, which has a reputation as a carrier of super new functionality, which you will not find anywhere else. The current version of the program is able to show the model from multiple angles, so that the user gets a better preview experience.

There's also an incredible 3D honeycomb infill, the first of its kind that can extend over multiple layers rather than repeating itself like a stamp. This significantly increases the strength of the internal filling of the model and the final printout.

Another option is direct integration with Octoprint. Once the files on the user's desktop are sliced, they can be directly uploaded to Octoprint with one click.

Once the files on the user's desktop are sliced, they can be directly uploaded to Octoprint with one click.

Download: Slic3r

Price: Free

Systems: PC, Mac, Linux

#17: Blender

For professionals who want to create 3D printable models

Blender is a popular computer-aided design (CAD) system with a steep learning curve. Not at all the best choice for beginners, but what you need if you are quite experienced and need something more complex for modeling and printing.

In short, Blender is one of the most powerful tools in existence. Its community is always ready to help, there are a lot of educational materials. It's also open source, so enthusiasts often write extensions to make it even better and more powerful.

Download: blender.org

Price: Free

Systems: PC, Mac, Linux

#18: MeshLab

For professionals to prepare STL files for 3D printing

MeshLab - advanced editor. It allows you to remove parts of a 3D model, merge two models into one, patch holes. If you need a program to modify models for 3D printing or some kind of "repair" work, MeshLab is the right choice.

It allows you to remove parts of a 3D model, merge two models into one, patch holes. If you need a program to modify models for 3D printing or some kind of "repair" work, MeshLab is the right choice.

Price: Free

Systems: PC, Mac, Linux

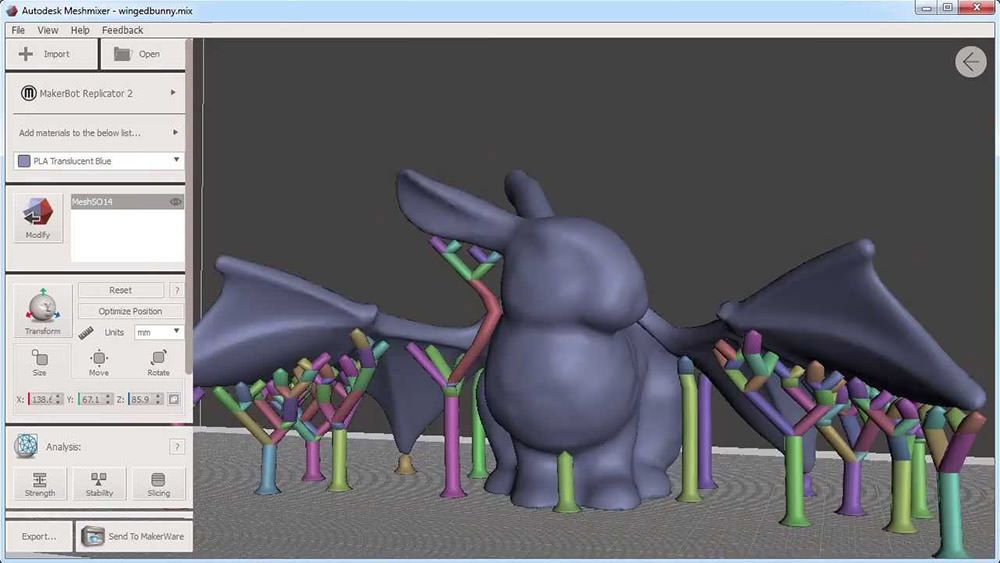

#19: Meshmixer

For professionals to prepare STL files for 3D printing files. It's especially good for identifying potential problems and fixing them automatically. For example, it will show paper-thin walls that can lead to problems with 3D printing. Meshmixer is part of the Autodesk family of 3D printer software, so it should work well with tools like TinkerCAD.

Price: Free

Systems: PC, Mac

#20: OctoPrint

start, pause or interrupt 3D print jobs. Combined with Wi-Fi capable devices, it makes for a great monitor for remotely monitoring the 3D printing process.

Octoprint understands the G-codes of almost all 3D printers and slicers and includes a gCodeVisualizer to visualize this code before or during printing.