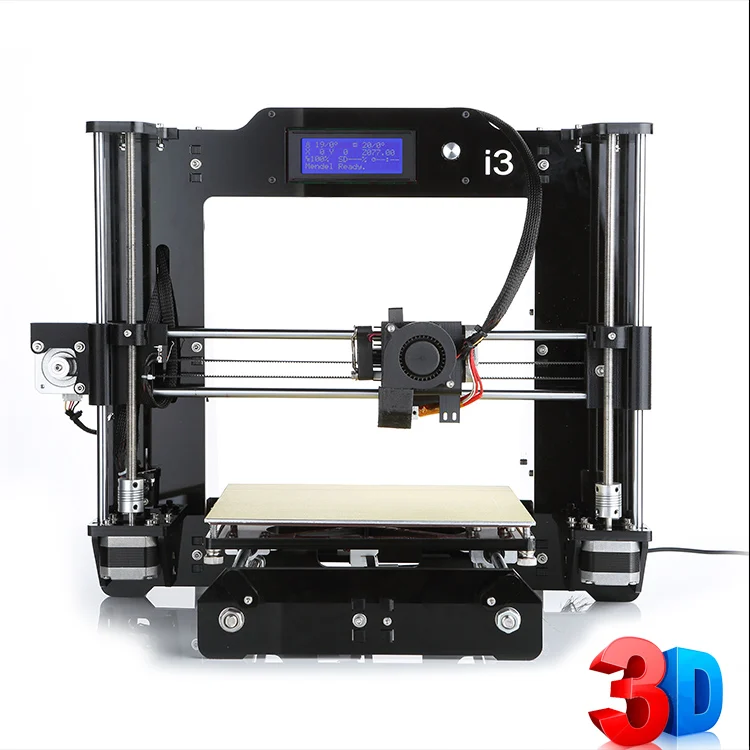

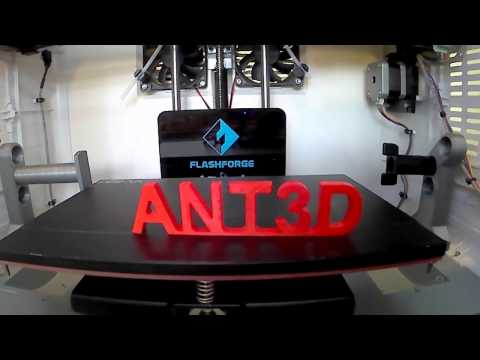

Dreamer 3d printer

Flashforge Dreamer 3D Printer

Flashforge Dreamer

Dual extruder | Smart temp. regulator | High quality print

BUY NOW

Dual Extruder

Better print effects

Temperature auto-regulation

230*150*140(mm)Build Volume

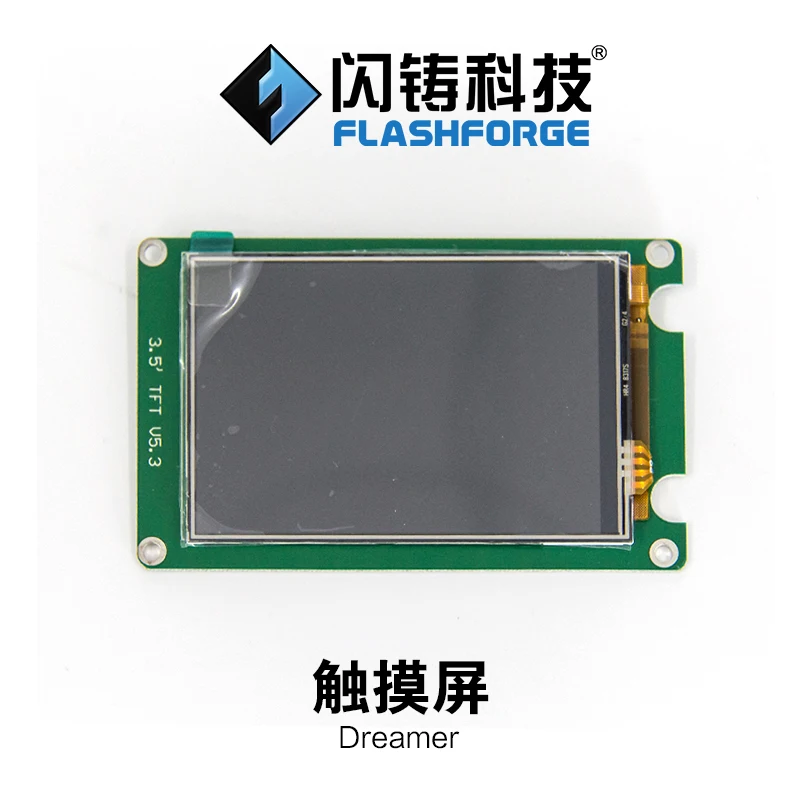

Touch Screen

120℃ Heating Build Plate

3 big advantages of Flashforge Dreamer

1. The smart temperature controller within the chamber of Flashforge Dreamer 3D printer enables it to automatically regulate the print temperature, thus achieving better printing effects.

2. Patent dual extruding system of Flash forge Dreamer makes it compatible with more filaments!

3. Matching with multiple slicers, e.g., FlashPrint, Simplify3D, Slic3r, Skeinforge, Cura.

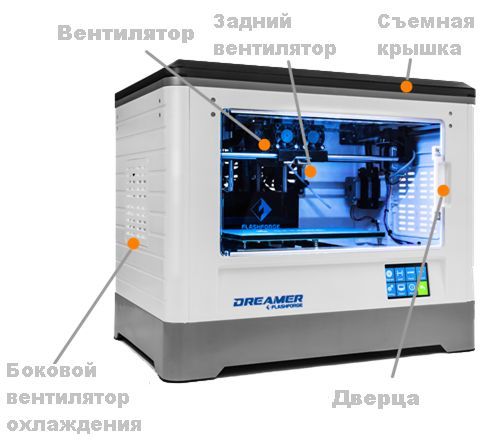

Full-enclosed chamber

ensures stable printing of ABS

Temperature is crucial to ABS filament printing. Flashforge Dreamer 3D printer features a door that can be closed and a removable top lid to keep out dust and foreign particles, meanwhile eliminates exterior temperature interference. The build-in heat-controlling sensor activates fans automatically to stabilize the printing temperature for high-quality ABS prints.

Unique build plate of Flashforge Dreamer reduces model warping.

1. Build plate of Flash forge dreamer is make of 6.5mm-thick Aerospace-grade aluminum, stable and sturdy and fine evenness in level.

2. The build plate is heatable that is very helpful for the printed model to nicely stick onto the plate, hence reducing model corner warping.

BUY NOW

Patented extruder for dual color/filament printing

Flashforge Dreamer dual extruder 3D printer greatly improved the final print quality and it applied its patent. Flashforge dreamer 3D printer dual extruder loads filaments smoothly and steadily, compatible with most printing filaments in the market.

Dual color print

FlashPrint – official slicing App for Flashforge Dreamer 3D printer

Monthly iteration | Simple use | Professional slicing

FlashPrint is a slicing software developed by Flashforge Corporation independently. Flashforge official slicer FlashPrint perfectly matches Flashforge 3D printers. It has its own copyright and software certificate, guaranteed the sales rights and interests of global distributors efficiently.

Flashforge official slicer FlashPrint perfectly matches Flashforge 3D printers. It has its own copyright and software certificate, guaranteed the sales rights and interests of global distributors efficiently.

User Case

Specification

Printing

- Extruder Quantity 2

- Nozzle Diameter 0.4mm

- Maximum Extruder Temperature 240℃ (464℉)

- Print Speed 30-100mm/s

- Maximum platform Temperature 120℃ (248℉)

- Filament Compatibility PLA, TPU95A, ABS, PETG

- Filament Diameter 1.75mm (0.069IN)

- Print Volume 230*150*140mm (9.1*5.9*5.5IN)

- Layer Thickness 0.1mm-0.4mm

- Print Precision ±0.2mm

Mechanical & Dimension

- Printer Dimension 485*344*382mm (19.1*13.5*15.03IN)

- Screen 3.5-inch touch screen

- Net Weight 10.7kg (23.6 LBS)

- Gross Weight 16.5kg (36.4 LBS)

- Internal Storage 8G

- Spool External

- Running Noise 50dB

- Working Environment 15-30℃ (59-86℉)

Electrical

- Power Input AC100-240V, 47-63Hz

- Power 320W

- Power Output 24V, 13.

3A

3A - Connectivity USB cable, SD card, Wi-Fi

Software

- Software FlashPrint

- File Input Format 3MF / STL / OBJ / FPP / BMP / PNG / JPG / JPEG files

- File Output Format GX/G

BUY NOW

Flashforge Dreamer Review 2022 - Why This 3D Printer Is So GOOD!

4.5

See Price

| Printing Area | 230mm x 150mm x 140mm |

| Layer Resolution | 100 to 500 Microns |

| Supported Filament | PLA, ABS, limonene-dissolvable support material, nylon, HIPS, Flex, T-glass, woodFill, copperFill, brassFill |

| Filament Diameter | 1.75mm |

| Extruders | 2 |

| Extruder Diameter | 0.4 mm |

Flashforge has hustled to establish itself as one of the leading consumer brands in today’s saturated 3D printing market. With no less than ten models for sale concurrently, the Chinese giant continues to make waves with a nifty balance of quality and competitive pricing.

With no less than ten models for sale concurrently, the Chinese giant continues to make waves with a nifty balance of quality and competitive pricing.

Today, we take our magnifying glass to the Flashforge Dreamer, an easy to use printer producing quality prints fit for the home, office, or educational context if we are to go by the marketing pitch. Does it live up to these claims? Let’s find out.

Table of ContentsShow

Design and Features

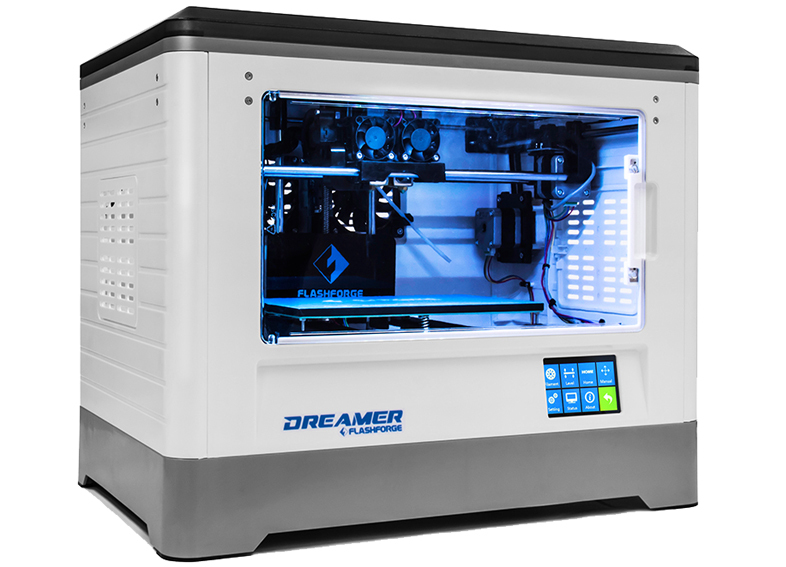

With a look more akin to an MRI machine than one set to energize a workshop with stirring creative juices, the Flashforge Dreamer continues the unfortunate trend of drab, dare we say, ugly 3D printers.

The main culprit is the uninspired three-tone color scheme (white, gray, and black) that although clean and clinical, places this model at odds with rival manufacturers who’ve put in a little more time to conjure up alternatives that illicit attraction, and by extension a desire for usage on the part of the owner. Luckily, the look is somewhat bolstered by LED strips that light up the print chamber for a bit more design flair.

The enclosed outer casing is made of high-quality plastic-alloy, which invariably makes things look cheap (not to mention the constant fear that it will melt with the heat of the printing process), while the rest of the components are made of high-quality aluminum and acrylic. Combined, the Dreamer weighs in at a respectable 33.1 lbs, placing it on the lower end of the spectrum and as such easily transportable.

Both side panels have removable ventilated hatches for maintenance and replacing filament, while the top cover can be lifted off for materials that need cooler temperatures. The acrylic front door also swivels open to access the print bed and is secured by magnetized latches. The enclosed chamber is ideal for stabilizing the inner temperature but also works to limit foreign bodies from tarnishing the layers during the printing process.

As we all know – and this no more true than in the sphere of 3D printing – looks aren’t everything, and the Dreamer conceals quite the assemblage of excellent features hidden under a banal exterior.

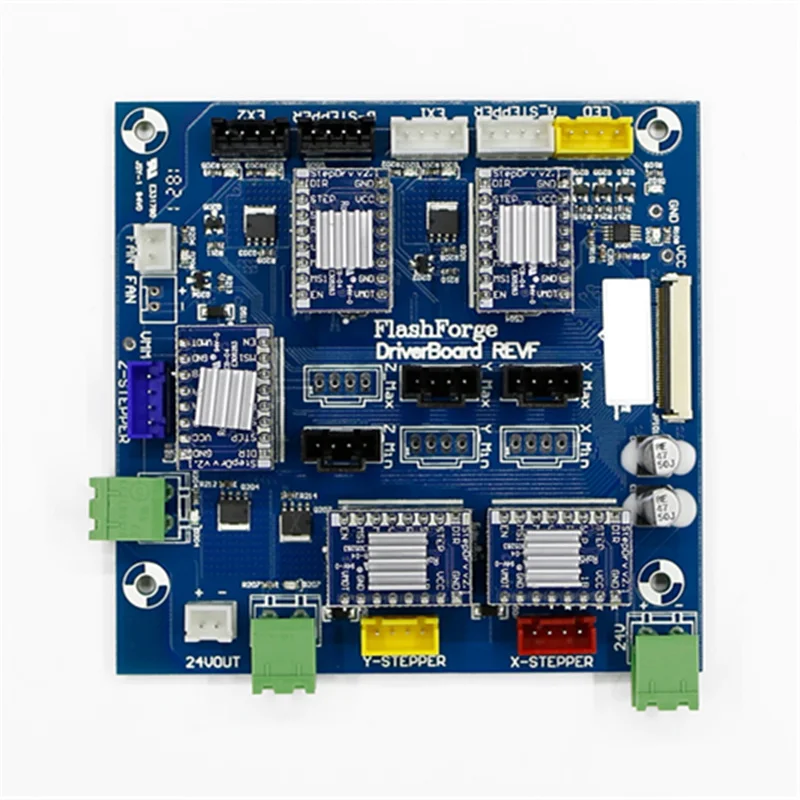

Using FFF (Fused Filament Fabrication) technology, the Dreamer is an XYZ Cartesian style printer that uses a standard dual rod and Moons-manufactured stepper motor setup for both the X and Y axes, with the Z axes running along a threaded rod as well as two classic flush rods.

The print area measures in at a comparatively small 230mm x 150mm x 140mm, but sufficient for the majority of hobbyist projects and ample room to print multiple parts in the same session.

The Dreamer sports a dual direct drive extruder setup with a nozzle diameter of 0.4 mm capable of layer resolutions ranging from 100 to 500 microns. The heated build plate is a chunky 6.3 mm slab of aerospace-grade aluminum for uniform heat distribution that can reach temperatures up to 120 degrees centigrade.

The Flashforge Dreamer is versatile when it comes to materials with support for PLA, ABS, limonene-dissolvable support material, nylon, HIPS, Flex, T-glass, woodFill, copperFill, and brassFill. Filament diameter sticks to the standard 1. 75 mm with support for third-party filament spools.

75 mm with support for third-party filament spools.

Filament sits inside purpose-designed spool berths (or holders) inside the chamber, which Flashforge argues keeps the filament at a higher temperature thus prolonging the lifespan of the material by removing moisture but is primarily a space saving characteristic.

However, the size of the berths means cartridges are limited to the 0.6 kg variety. Fortunately, the side hatches mean you can also use 1 kg or larger spools by seating them to the sides of the printer.

It’s worth noting that the Dreamer is equally geared towards PLA as it is ABS, unlike countless other models that tend to focus on one with only a handful of cursory arrangements made for the other to be listed as compatible with both materials.

A dual fan setup is fitted to the back panel that works in unison with the triple extruder fans to cool PLA by extracting the warm air. Equally, the Dreamer is equipped with a meter that monitors the ambient temperature to make sure the enclosed chamber is consistently warm enough to avoid ABS warping and cool enough to avoid PLA stringing.

A 3.5-inch full-color HD IPS touchscreen is integrated into the front panel of the Dreamer. We found it particularly responsive and easy to navigate. It features the ability to trigger prints, monitor and preheat extruder and platform temperatures, load/unload filament, activate the bed-leveling wizard, axes homing, update the firmware, and an array of other settings. The touchscreen has support for English, German, Dutch, Polish, French, Korean, and Japanese languages.

The Dreamer has both an SD card reader slot and a USB-to-PC port, in addition to Wi-Fi connectivity for untethered use. The USB feature is uncommon in that the Dreamer itself has 4GB of onboard memory to store prints of the device itself. If the PC crashes or shuts down unexpectedly, the printer still has access to model details to continue a job uninterrupted.

Flashforge recommends using the Dreamer with its proprietary FlashPrint slicing software, but the printer remains open-sourced so you can use all manner of third-party slicers such as Cura, Simplify3D, and the like.

Flashprint supports Mac, Linux, and PC. Overall, it is incredibly easy to use and walks the user through loading in a model file (STL, OBJ), converting it to Gcode, tweaking a few temperature/slicing/build quality options or using one of the many presets, then triggering the print. When printing, FlashPrint provides a visible progress model, material usage, and finish time estimates.

Advanced opinions allow for support integration, print speed adjustments, first layer thickness tinkering, scheduled pause options, splitting models into several parts, and a feature to convert 2D pictures into 3D models.

Assembly

The packaging is the usual mix of styrofoam cut outs, zip ties, and plastic bubble wrap, which is more than adequate and the printer arrived in perfect condition. The only real issue is that the extruders are housed in a cardboard box that sits inside the printer yet are attached to the printer, so some care needs to be taken when removing the box not to yank out the extruders while doing so.

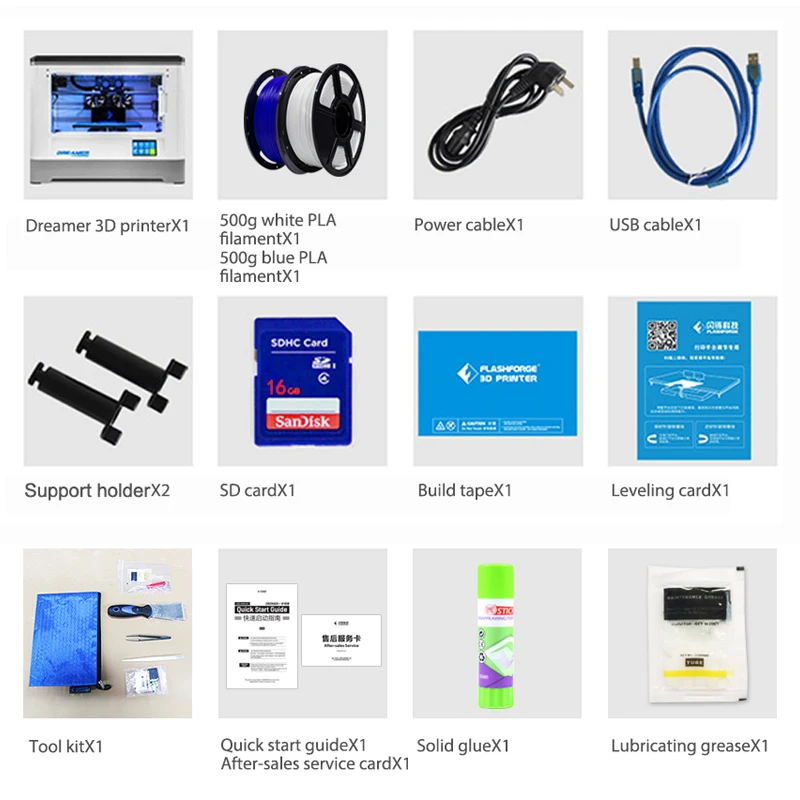

The package includes official documentation, quick start guide, the printer itself, power cord, USB cable, a tool kit (2GB SD card, tweezers, graver, scraper, two wrenches, grease, Allen key, Phillips screwdriver, unclogging pin tool, PTFE tube, screws, and leveling knob), two spools of filament (PLA and ABS), spool holders, leveling card, extruders, top cover, either a roll of blue painter’s tape or a handful of print bed sheets, a set of screws, and side hatches.

The Flashforge Dreamer arrives pre-assembled and full setup was a matter of minutes. The extruder casing needs installing via a set of three screws. The process is detailed concisely in the quick start guide and involves placing the extruder in the extruder seat, aligning the extruder to the bolt holes, securing the bolts, and finally attaching the turbofan baffle in the same manner.

Although the Dreamer has no auto-calibration feature, the assisted build plate leveling process is easy enough thanks to instructions from the touchscreen. The manual movement of the build plate is assured by a rotating knob that moves the plate up and down. The process is the usual process of establishing the right gap between the plate and the nozzle using the leveling card.

The manual movement of the build plate is assured by a rotating knob that moves the plate up and down. The process is the usual process of establishing the right gap between the plate and the nozzle using the leveling card.

Next, we installed the filament cartridges by feeding the spool holder through the center and snapping them into place. Finally, feeding the filament into the tubing was simple enough before we had to trigger the gearing to grip the material via the touchscreen. Once the extruder was heated, we fed the filament into the extruder by pressing down on the gear button simultaneously. From here onwards, we encountered no issues feeding filament, and it worked beautifully every time.

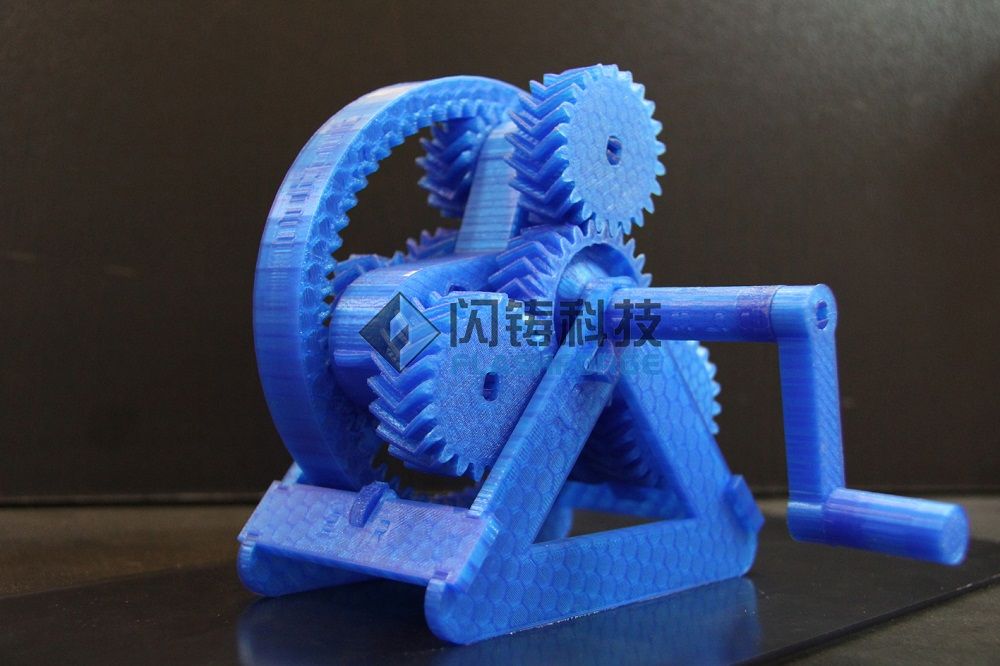

Printing

What can we say? Its questionable exterior belies a versatile beast capable of systematic quality prints. Contours were smooth, layers were almost unnoticeable, and imperfections so rare they aren’t even worth mentioning.

For the price of the Dreamer, there isn’t an equivalent that offers both out of the box functionality and such a high quality of prints regardless of whether you go for rapid, low-resolution prototyping or high-resolution detail-oriented ornaments.

The dual extruders work well, especially when it comes to supports that quelled any fears we had of botched jobs due to insufficient support. Additionally, the Dreamer is a pretty nifty little printer as well, finishing up jobs in entirely respectable times even at higher resolutions.

The cherry on top is that the Dreamer is a relatively silent printer even with the top cover and hatches off.

Support

Flashforge offers a standard 180-Day manufacturer’s warranty for the Dreamer, although extensions of up to 12 months are available by buying the ProCare Extended Warranty.

The Flashforge website is packed with instructional videos, walkthroughs, troubleshooting articles and more. The customer support from the company is of the highest quality with a team intent of finding solutions to the rare problems you may face.

Verdict

Although we weren’t enamored with the aesthetic design of the Flashforge Dreamer, we were incredibly impressed by what it hides under the hood as well as the high quality of the prints. It’s a reliable printer that will suit first-timers and daily users alike. You can trust it to complete prints, and it isn’t a model you need to babysit or tinker with merely to get it working. If you haven’t already guessed, we love the Dreamer.

It’s a reliable printer that will suit first-timers and daily users alike. You can trust it to complete prints, and it isn’t a model you need to babysit or tinker with merely to get it working. If you haven’t already guessed, we love the Dreamer.

"Dreamer" - 3D printer of my dreams - 3 - UMNIKA's blog

Start here.

General design description.

The printer is assembled inside a plastic housing which is a carrier. The table moves up and down along two guides on one side and the screw looks like a trapezoid, it seems that it is multi-threaded, with a bronze nut.

The head moves along round guides through possibly linear bearings (or maybe it seems to me?), belt drive. There are two belts along the Y axis, which are driven from one shaft.

Loved the table. Too bad it's small.....

Aluminium, approx. 5 mm thick, very flat. There are no height sensors, they are not needed here. Once you adjust the position with three screws and everything is fine.

Some tricky rug is glued on top of the table, and two more pieces were given in reserve. Until the spares came in handy. The rug is interesting, on top it seems to be greasy to the touch, approximately like something teflon. 3M adhesive on the bottom. The mat is relatively thick, 0.67 mm with a protective film, slightly less rigid than, for example, a bank card.

The stickiness of the piece to the mat is by far the best I've tried so far (blue tape, kapton). Although the truth is that this stickiness is somehow not 100% stable .... Sometimes you still want to sprinkle with special glue. Especially when you print ABS. Although sometimes parts without glue stick tightly. The small spatula that was given in the kit came in very handy. The detail is torn off only by him and with difficulty. At the same time, the rug is quite durable, when you pry off a part from a table covered with a thin Kapton film, the film is very often damaged. You tear off the part from this rug with a sharp steel spatula, the rug is like new. The rug does not tear, does not scratch.

The rug does not tear, does not scratch.

But if you print with flexible plastic, on the contrary, all traces of glue must be washed off, otherwise the flexible plastic will not stick to the table. But when the table is washed from the glue, the item made of Flex material will stick tightly. The first (flexible) part was almost torn to pieces when I tore it off the table.

I really liked that the surface of the rug is rough, so the side that heals on the table turns out to be rough, not so different from the rest in appearance. When you print on kapton, the bottom is glossy, which spoils the look of the part.

This photo clearly shows that the bottom surface of the part is not glossy: I don’t know if it’s possible to buy something similar to this rug for any size, just in case I bought myself spare ones in my size, though in another (not official) store, but they look exactly the same. I have not tried to stick it yet, the very first one is intact, like new.

The printer has two fans on the back of the printer. Since there are hot extruders and a hot table inside, by ventilating the case, you can regulate the temperature inside. And it's not hot when printing PLA and hot when printing ABS. I did not understand the logic of controlling these fans, when printing, you cannot set the temperature inside the case or turn these fans on and off.

As far as I understand it, if the fan blowing the part is on (the printer also has one, there are two more on the hot ends of the extruders), then the fans are on all the time when printing. If the part blowing is not turned on, the fans turn on sometimes, so that the temperature inside the casing would be about 50 degrees. There is a temperature sensor inside the case (you can see it). I did not find a way to find out the temperature inside or set it anywhere.

Actually, somehow it turns out that when you print PLA, the fans run all the time and everything prints well. When ABS - then turn on sometimes and everything also prints well.

I haven't printed much of ABS parts lately, because they liked to come off the table at an angle on my old printer and slanted. It almost never happens here, so ABS is back in my favor.

For print settings in the FlashPrint program there are several presets - PLA, ABS, Flex, each of them with several (up to 4) print quality gradations. Anyone can be remembered under a different name and customize something for yourself. In fact, the presets are quite suitable, most often I make changes to them in terms of filling density and rough support. Minus - today I did not find how to change the fill angle of the top layer.

The support is first built in principle (where it should be in principle) in one place in the program, then parameters are selected in the print settings - thickness, distance from the wall, etc.

Now about the print quality. There is such a useful product - a cap to close an open tin can. My wife needs several of them, some I printed a long time ago, some she asked to print on a new printer. Here we compare them. Rec Flex material.

Here we compare them. Rec Flex material.

Top layer. New printer on the left, old on the right. The new surface is much more uniform, more beautiful:

Bottom layer. The new one (on the left) has a rough, even surface. At the old glossy, traces are visible, where the part was peeled off from the table during printing:

and several more details printed on a dreamer:

9000 9000 9000 9000 9000

002

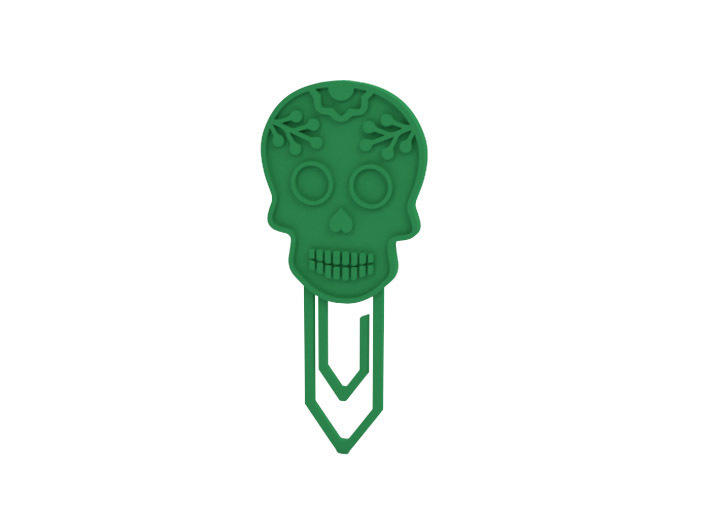

STL file Day dreamer・Model for download and 3D printing・Cults

Tikarantula

7.41 €

Mask and free additional stand

11.40 €

KIT - E

6.27 €

Pirate

€15.79 -fifty% 7. 90 €

90 €

Contemplator

14.25 €

Antique lady with panels

2.85 €

Violinist

5,70 €

Clown

3.36 €

Fan art bust of Vecna

3.42 €

2 Giger Alien Models

3.42 €

Snake

2.85 €

Tikarantula

7.41 €

Best Files for 3D Printers in the Art Category

Running Rhino

€7.87

Monster King Snake

5 €

Articulated fluffy caterpillar

3. 12 €

12 €

Bust of Paris

Free

Secret design

Bust of Thanos

Free

Sadness

Free

Charizard

Free

Art category bestsellers

Flexi PRINT-IN-PLACE Hand

1,96 €

Cute squirrel with flexi print

2.53 €

Astronaut on flexi printer

2,97 €

Crystal Dragon, Articulating Animal Flexi Wiggle Pet, Print on the Spot, Fantasy

4.03 €

Articulated toy "Python Snake", imprint body, snap head, cute flexi

3,98 €

Hannya wall masks

3,80 €

Skeleton hand with flexi print

2 €

FLEXI XXLPRINT-IN-PLACE SKELETON

10. 07 €

07 €

Cute frog with flexi print

1,96 €

Triceratops on flexi printer

2,97 €

Baby Crystalwing Whelp, Cinderwing3D, Articulating Flexi Wiggle Pet, Print On Site, Fantasy

4.03 €

Cute sloth with flexi print

2,97 €

GHOST ZU - GHOST WITH FEET

3.05 €

Cute T-Rex dinosaur with flexi print

2,97 €

Leopard Gecko Articulated Toy, Printed Body, Snap Head, Cute Flex

3.43 €

Cute circus baby elephant with flexi print

2,97 €

Do you want to support Cults?

Do you like Cults and want to help us continue our journey on our own ? Please note that we are a small team of 3 people, so support us in maintaining the activities of and creating future developments is very simple.