3D printer distribution

3D Printers - 3D Distributed

Home

3D Printers

3D Printers Designed By 3D Distributed- SolidCore CoreXY_WorkHorse Large Format 3D PrinterDIY 3D Printer Build Plans

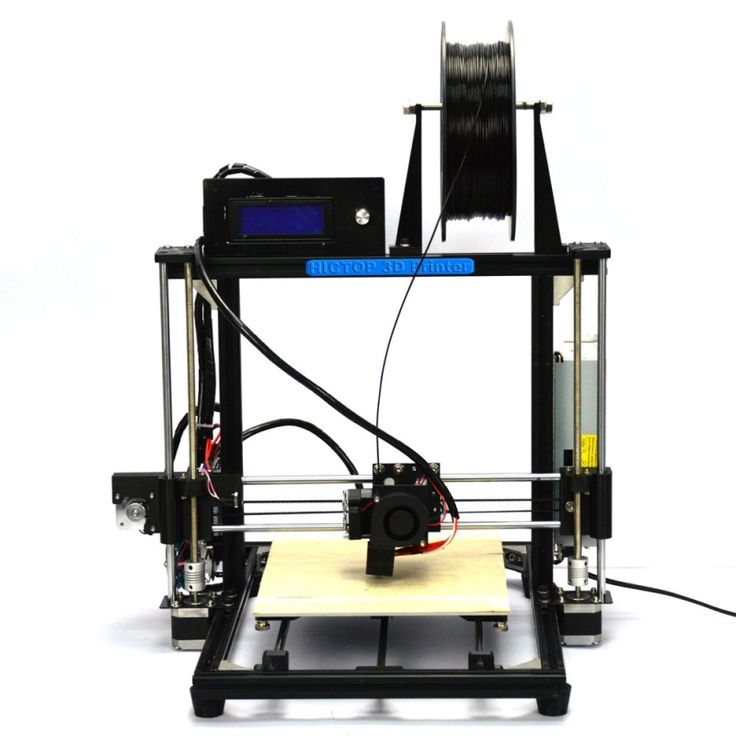

The WorkHorse is a large scale machine platform for 3d printing.

Modular Scalable Linear Rails Balanced Carriage Pull Enclosure BOM utilizes most available parts All Metal Parts or 3D Printed Z-Axis: Independent Driven or Shared Belt Routing

DIY 3D Printer

Kits- See WorkHorse Printer

- See SolidCore CoreXY

Table Of Contents

- DIY 3D Printer Build Plans

- DIY 3D Printer Kits

- WorkHorse – Large Scale 3D Printers

- Workhorse and Workhorse XL 3D Printer

- WorkHorse 3D Printer

- Lead Screw Driven Motion

- WorkHorse Build Volume

- WorkHorse XL Build Volume

- Fixed Bed

- Configurable / Customizable

- WorkHorse 3D Printer

- Electronics

- Documentation

- SolidCore CoreXY

- Design Constraints In Large Scale 3D Printers

- Lead Screw & Ball Screw vs Belt Driven

- High Quality Lead Screw vs Cheap Lead Screw

- Lead Screw & Ball Screw Print Speed

- Lead Screw Pitch And Required Torque

- Building A Large 3D Printer

- Frame

- 3D Printing Large Objects

- Workhorse Printer Parts

- SolidCore Parts

WorkHorse – Large Scale 3D Printers

Workhorse 3D PrinterWorkhorse and Workhorse XL 3D Printer

- OPEN SOURCE

- LARGE BUILD VOLUME

- XYZ-axis Lead Screw Motion System

- Fixed Bed Moving Gantry

WorkHorse 3D Printer

The Workhorse Printer is a open-source designed by 3D Distributed. In this mechanical arrangement lead screw driven motion is used on the X,Y, and Z axis .

Lead Screw Driven Motion

Most 3d printers use belt driven motion in the x and y axis to increase print speed but a belt driven motion system may lose quality when more weight is applied to the gantry or carriage. The Workhorse utilizes Igus lead screw on the X and Y-Axis. The high helix pitch includes a twelve start thread to allow increased print speeds while maintaining the quality of a ball printer. The robust and rigid motion system is particularly useful in applications that add more weight to the gantry or carriage. Materials such as clay, chocolate, plastic pellet extrusion or other foods can increase weight that is moved around which results decreased quality or print speeds. We originally designed the fdm 3d printers to be driven by ball screws but quickly switched to multi-start lead screw to increase travel speed. If your looking for a belt driven configuration check out our new corexy kit.

WorkHorse Build Volume

- Build Volume – 650 x 350 x 350 mm

WorkHorse XL Build Volume

- Build Volume – 650 x 650 x 650 mm

Fixed Bed

While most large format printers use a moving bed that moves along the Z-Axis, the Workhorse’s fixed bed and moving gantry design is more ideal for the large scale 3d printing process.

Configurable / Customizable

The Workhorse 3d printer is available with custom mods and upgrades. We’ve several custom designed machines for many of our customers. If there is a specific size or requirement you just give us a shout. Additive manufacturing has many applications and we designed this modular platform to be adaptable and scalable for your industrial printing needs.

Additive manufacturing has many applications and we designed this modular platform to be adaptable and scalable for your industrial printing needs.

WorkHorse 3D Printer

- See WorkHorse Printer

- See WorkHorse XL

- See All Metal Part Store

Electronics

Workhorse Printer Electronics Control BoardWe recommend the Duet 3 by Duet3D.

See RepRap Firmware

Documentation

Google Drive Folder

See WorkHorse Documentation

See WorkHorse BOM

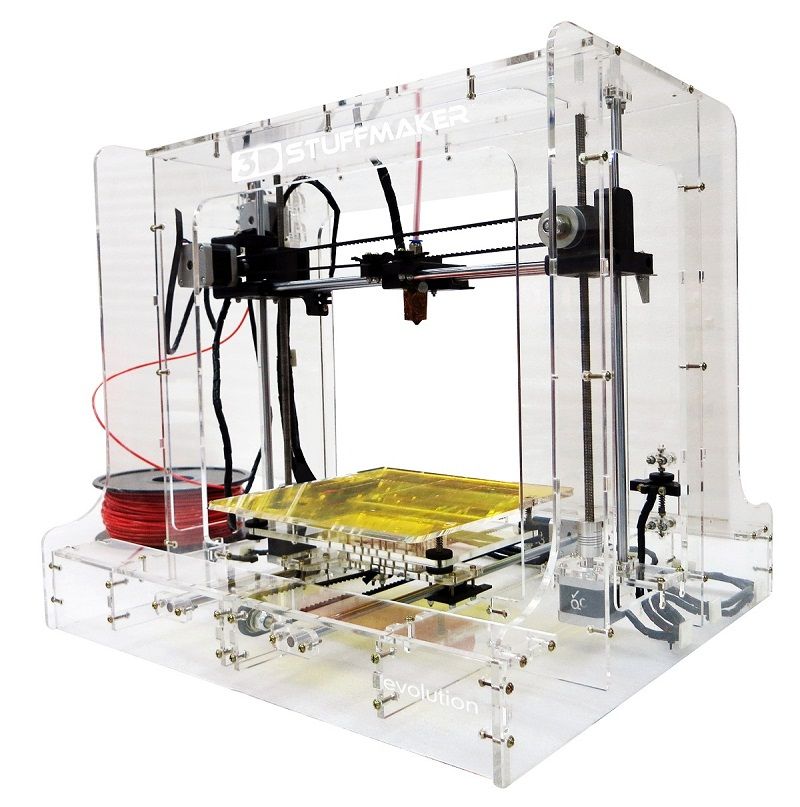

SolidCore CoreXY

SolidCore CoreXY 3D PrinterSee SolidCore CoreXY

See All Metal Part Store

see SolidCore BOM

SolidCore CoreXY 3D PrinterSolidCore CoreXY 3D Printer KitDesign Constraints In Large Scale 3D Printers

Larger Printers can be much more challenging to get the same performance as smaller printers due to rigidity, deflection and smoothness of gantry or bed motion. This relates to the typical speeds and forces applied to mechanical components while in motion. The idea is to reinforce areas that experience more force or deflection without increasing gantry weight or over designing in a way that may introduce mechanical binds or resonance.

This relates to the typical speeds and forces applied to mechanical components while in motion. The idea is to reinforce areas that experience more force or deflection without increasing gantry weight or over designing in a way that may introduce mechanical binds or resonance.

Lead Screw & Ball Screw vs Belt Driven

There are many decisions to make when building a large format 3d printer. The wrong mechanical arrangement can compromise speed and quality. Lead screw is known for backlash but backlash can be eliminated using anti backlash nuts. Lead screw pitch is another critical decision to make. Most lead screws don’t have the lead to compete with speed but the precision can be well suited. Once dialed in, the repeatability is useful for long prints.

Ball screw or lead screw may not always be the right choice because of wobble and resonance. Large 3d printers that use belts require frequent maintenance as the belts need tightening or tensioning to prevent missed steps. Lead screws for the X and Y axis can be precise and reliable if properly implemented.

Lead screws for the X and Y axis can be precise and reliable if properly implemented.

High Quality Lead Screw vs Cheap Lead Screw

Quality lead screws and ball screws cost much more but cheap lead screws can have tolerance issues. Longer ball screws may wobble at a distance and need support and rigidity. Although backlash is mostly a problem in XY-axis movements while the z-axis is the preloaded weight of the bed and gravity.

Lead Screw & Ball Screw Print Speed

A large stepper motor such as a Nema 23 must be used for the X and Y axis depending on the lead screw length. Issues with speed, resonance, artifacts can be a challenge in any 3d printer build but can be reduced by travel speed and acceleration but is compromised with slower travel speed the longer it takes to print an object.

Lead Screw Pitch And Required Torque

Lead screws are similar to a gear, when the pitch changes the lead and torque required to drive the system changes as well. Most 3D printers use 1/16 or 1/32 microstepping but the resolution of 3d printed plastic can only be so precise. Larger stepper motors have more inductance and need more voltage to reach the same RPM. Increasing the step rate for the reduced travel rate of the drive, a higher voltage stepper driver and supply may be needed to reach ideal motor performance.

Most 3D printers use 1/16 or 1/32 microstepping but the resolution of 3d printed plastic can only be so precise. Larger stepper motors have more inductance and need more voltage to reach the same RPM. Increasing the step rate for the reduced travel rate of the drive, a higher voltage stepper driver and supply may be needed to reach ideal motor performance.

Building A Large 3D Printer

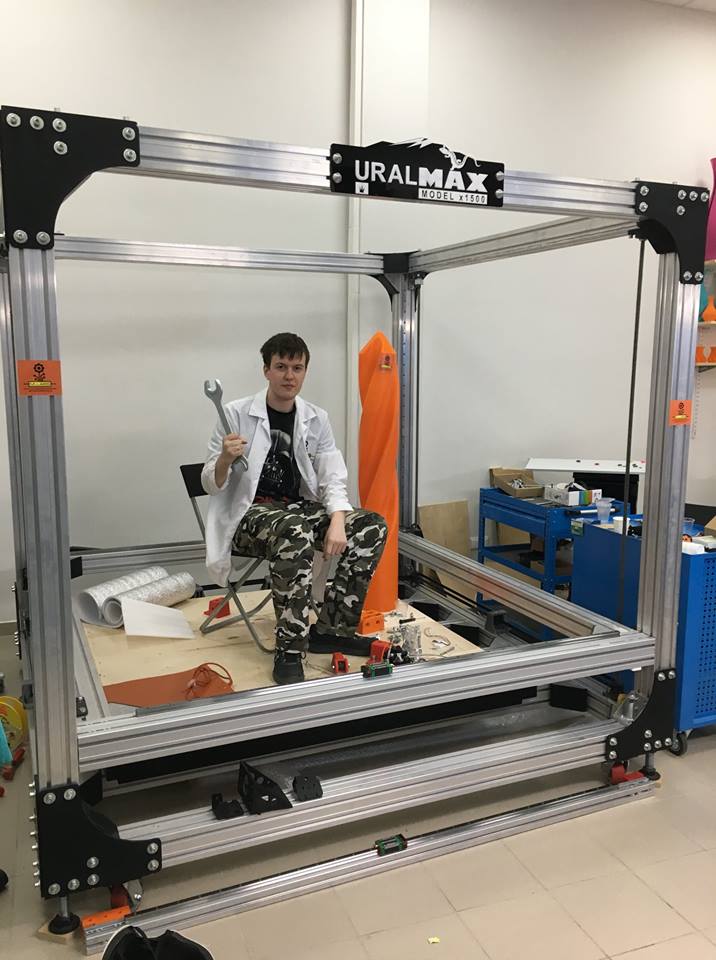

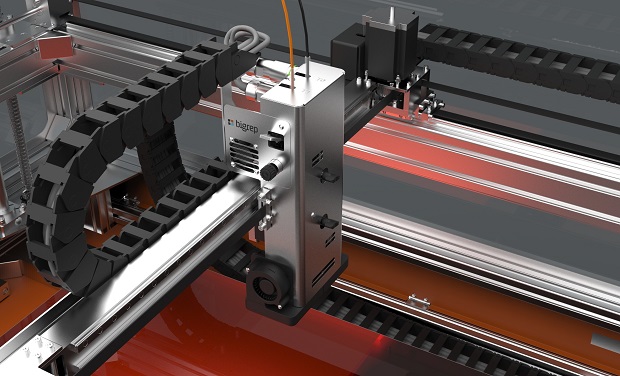

Workhorse Extruder CarriageThe best thing to do is keep the mindset that the printer you’re designing is going to be built to print “X.” Do you want a printer that prints long but short parts or do you want a printer that prints tall parts. You can increase all three directions but that’s where things get more challenging for repeatability and acquiring the needed speeds and quality. It’s totally possible and the many problems that may be introduced can be designed around.

3D Printer Carriage AssemblyFrame

Regarding the 3d printer frame rigidity, I would just suggest larger width extrusions depending on the length and adding gussets where needed. The only reason I go in such detail is because I get a lot of requests from people wanting me to design a printer with a “1000mm x 1000mm x 1000mm build area. The trick is to avoid the sacrifice of performance, speed and repeatability which becomes more and more challenging. The last thing you want is a really big 3d printer that’s really slow or has repeatability problems. You may or may not have the necessary design solution to avoid this scenario. From my experience the challenge is balancing rigidity, repeatability and reliability without exponentially increasing the price. Whether you’re aiming for a moving bed or moving gantry you need to add rigidity without over constraining the motion. You’ll experience this in z-axis repeatability between prints and bed leveling. For example, you probe your bed with an auto level routine followed by a mesh leveling routine. Everything is perfect depending on the flatness of your bed compared to rigidity of the overall system. Then the bed probe routine is followed by a G28 homing of the z-axis.

The only reason I go in such detail is because I get a lot of requests from people wanting me to design a printer with a “1000mm x 1000mm x 1000mm build area. The trick is to avoid the sacrifice of performance, speed and repeatability which becomes more and more challenging. The last thing you want is a really big 3d printer that’s really slow or has repeatability problems. You may or may not have the necessary design solution to avoid this scenario. From my experience the challenge is balancing rigidity, repeatability and reliability without exponentially increasing the price. Whether you’re aiming for a moving bed or moving gantry you need to add rigidity without over constraining the motion. You’ll experience this in z-axis repeatability between prints and bed leveling. For example, you probe your bed with an auto level routine followed by a mesh leveling routine. Everything is perfect depending on the flatness of your bed compared to rigidity of the overall system. Then the bed probe routine is followed by a G28 homing of the z-axis. An over constrained bed or gantry may experience some repeatability issues after traveling home and returning to the print surface which will result in a bad first layer. But let’s assume everything is good. So proceed to print your object. After the object is finished the next step is to remove the object.

An over constrained bed or gantry may experience some repeatability issues after traveling home and returning to the print surface which will result in a bad first layer. But let’s assume everything is good. So proceed to print your object. After the object is finished the next step is to remove the object.

3D Printing Large Objects

Workhorse-printing3d printing larger objects is going to be more difficult to remove and the process of removal will result in forces applied to the bed or gantry which will cause the bed or gantry to experience some sort of misalignment. So the following print will experience some sort of bed leveling issue resulting in a bad first layer. But your first layer is the most critical and will affect the rest of the print such as warping from bed adhesion or the object becoming loose from the bed. The longer the print takes the more critical layer adhesion becomes. But you can minimize this chain reaction by re-probing the bed before each print. But this takes a long time due to the increased number of points the probe maps out. You could reduce the number of points but a larger print bed will include more dips and peaks from stresses or bows. So you have to maximize the number of points used in probing so that the machine can compensate for each to get that first layer. Another issue to prepare for is the environment’s effect from the introduced heat of the printed object relative to the dimensional stability of the mechanical components and bed.

But this takes a long time due to the increased number of points the probe maps out. You could reduce the number of points but a larger print bed will include more dips and peaks from stresses or bows. So you have to maximize the number of points used in probing so that the machine can compensate for each to get that first layer. Another issue to prepare for is the environment’s effect from the introduced heat of the printed object relative to the dimensional stability of the mechanical components and bed.

Workhorse Printer Parts

SolidCore Parts

Like this:

Like Loading...

Workhorse Printer - 3D Distributed

Home

3D Printers

Workhorse Printer

Workhorse 3D PrinterWorkhorse- Large DIY Industrial 3D Printer Platform

Build Volume – 650 x 350 x 350 mm

DIY 3D Printer Build – Large 3D Printer Kit

Motion System – XYZ Lead Screw / Ball Screw

Machine Kinematics – Fixed Bed / Moving Gantry

Enclosure – Polycarbonate Enclosed

Extruder – Bowden / Direct Drive Extruder

Materials – Filament – FDM / FFF

Controller – Duet3D

Operating System – RepRap Firmware

Design – Open Source

Software– Simplify3D / SuperSlicer

Skill Level – Advanced

Lead Screw vs Belts

The WorkHorse is a large customizable 3d printer platform for designers, builders, and makers. The XYZ Lead Screw motion system is an open-source design that can be adapted to specific materials and applications. In most cases, belt driven 3d printers are better suited compared to lead screw. But this isn’t most cases and the lead screw we selected to drive the WorkHorse isn’t your standard lead screw. We’ve tried a range of different styles of lead screw and had mixed results. We settled with a Igus high helix thread pitch with a 50mm lead.

The XYZ Lead Screw motion system is an open-source design that can be adapted to specific materials and applications. In most cases, belt driven 3d printers are better suited compared to lead screw. But this isn’t most cases and the lead screw we selected to drive the WorkHorse isn’t your standard lead screw. We’ve tried a range of different styles of lead screw and had mixed results. We settled with a Igus high helix thread pitch with a 50mm lead.

If you’re looking for an advanced project like building a large 3d printer, the WorkHorse is an open-source design that you can customize for a specific application or project.

Large DIY 3D Printer BuildLead Screw / Ball Screw Motion System

WorkHorse PrinterWorkHorse Build Resources

- WorkHorse BOM

- WorkHorse Documentation

The fixed bed / moving gantry is intended to make the 3d printer more scalable as the bed and z-axis mechanism becomes heavier.

- Fixed Bed / Moving Gantry

- X and Y-Axis Lead Screw

While most 3d printers use belt driven motion in the x and y axis to increase print speed but loses quality when more weight is applied to the gantry or carriage. The lead screw used on the Workhorse has a high helix pitch with multiple threads to allow increased print speeds while maintaining the quality provided from lead screw and ball screw motion. The system is particularly useful in applications that add more weight to the gantry or carriage. Materials such as clay, chocolate, plastic pellet extrusion or other foods can increase weight that is moved around which results decreased quality or print speeds. Workhorse Printer’s are available to purchase in Machined Component Kit, Hardware Kit or Complete Kit.

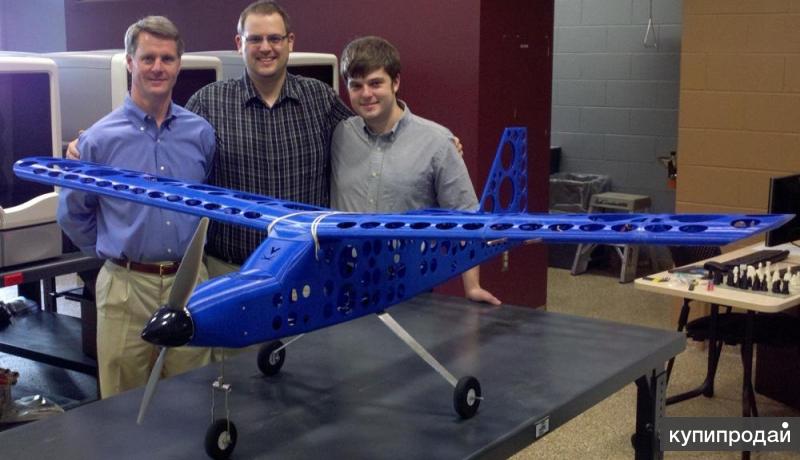

Workhorse 3D Printer MRRF 2019- OPEN SOURCE

- LARGE BUILD VOLUME

- ADVANCED LEAD SCREW MOTION

- MODULAR MACHINE DESIGN

- CUSTOM MODS

- CUSTOM BUILDS

- ENCLOSURE

- HEATED BED

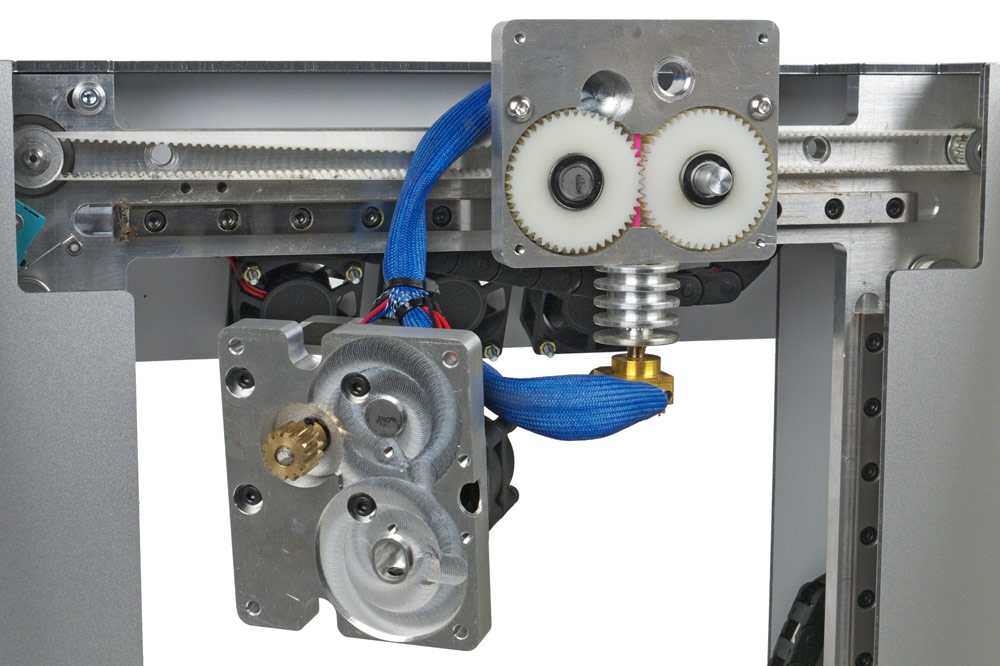

Carriage

Workhorse DIY 3D Printer Carriage DesignLarge 3D Printer KitFrameWorkhorse Printer Frame and Gantry OnlyWe’re experimenting with changing the frame size and switching to a 3030 extrusion profile. We also made the side panels two inches wider to have more room in the electronics / Filament compartment.

Z-Axis Updates

WorkHorse 3D Printer V2 Gantry Plate Z axis lead screwWe finally made a better z-axis lead screw mount.

Z-Axis Lead Screw To Gantry Plate MountDownload 3D Model

workhorse large 3d printer build 3d printed lead screw nut mountsThe old version of the lead screw nut mounts were 3d printed. They would crack over time so the version is now made from aluminum.

The Workhorse X-Carriage design is a heavy duty solution for lead screw driven motion that uses MGN12H linear rails and 20×40 or 20×20 aluminum extrusions.

Y-Axis Motor Mount

Y-Axis Motor Mount to X-Carriage WorkHorse CarriageThe Workhorse 3d printer is available with custom mods and upgrades. We’ve several custom designed machines for many of our customers. If there is a specific size or requirement you just give us a shout.

New Heated BedWorkHorse Printer UpdatesDownload Files

WorkHorse Printer CADBOM| Lead Screw | Description | Part Number |

| X-Axis 2pcs. x 762mm Long | Igus High Helix 10mm w/50mm Lead | DST-LS-10×50-R |

| Y-Axis 1pc. x 485mm Long | Igus High Helix 10mm w/50mm Lead | DST-LS-10×50-R |

| XY-Axis 3pcs x Lead Screw Nuts | Igus Lead Screw Nuts | DST-JFRM009 |

| Z-Axis 2pcs x T12x2 Trapezoidal ACME Lead Screw w/ Brass Nut | 500mm Long | WK-Z-T12500 |

| Linear Rails | Discription | Discription |

1pc. x 450mm Long x 450mm Long | MGN12H 20mm x 20mm Hole Pattern | WK-Y-LRMGN12h500 |

| 2pcs. x 700mm Long | MGN12H 20mm x 20mm Hole Pattern | WK-Y-LRMGN12h500 |

| 4pcs. x 500mm Long w/ Two Carriage Blocks | MGN12H 20mm x 20mm Hole Pattern | WK-Y-LRMGN12h500 |

Buy WorkHorse 3D Printer Parts

WorkHorse 3D Printer PartsWorkHorse 3D Printer Gantry Plates| Machined Hardware | Price $ | Source |

| Gantry Plates | 3DDistributed | |

| X- Axis C- Carriages 2pcs | 3DDistributed | |

| Y-Axis C- Carriage 1pc | 3DDistributed | |

| Y-Axis Motor Mount 1pc | 3DDistributed | |

| Y-Axis Idler Mount 1pc | 3DDistributed | |

| Hotend Mount | 3DDistributed | |

| Z-Axis Motor Mounts 2pcs | 3DDistributed | |

| Aluminum Build Plate | $135. 00 00 | 3DDistributed |

Electronics

Buy Stepper Motors

See Stepper Motors

Z-Axis Motor Mounts

Z-Axis Motor MountsWorkHorse Printer V2

Workhorse Z-Axis Motor AssemblyDuet3D Firmware Files

Download

We now recommend the Duet 3 Mainboard 6HC electronics by Duet3D.

Build Instructions

Here

Sourcing Parts For Your Workhorse 3D Printer

Sourcing Lead Screw

Sourcing Frame Components

Buying Frame PartsFrame Assembly

Workhorse Frame ExtrusionsThe frame is made out of 2020 (20mm x 20mm) aluminum extrusions.

- 20mm x 20mm

- 4pcs 930mm Long

- 6pcs 510mm Long

- 10pcs 570mm Long

- 3pcs 808mm Long

.

20mm x 40mm HFS5 Aluminum Extrusions (Misumi Brand)

4pcs 510mm Long

Frame:

BOMFrame BOM Part List

| Frame Extrusions | Length | Units | Discription | Misumi Part # |

| 2020 (20mm x 20mm) | 930mm Long | 4pcs | Horizontals | HFS5-2020-930 |

| 2020 (20mm x 20mm) | 510mm Long | 6pcs | Verticals | HFS5-2020-510 |

| 2020 (20mm x 20mm) | 570mm Long | 10pcs | Frame Width | HFS5-2020-570 |

| 2020 (20mm x 20mm) | 808mm Long | 3pcs | Bed Support | HFS5-2020-808 |

| Gantry Extrusions | Length | Units | Description | Part# |

| 2040 (20mm x 40mm) | 770. 5mm Long 5mm Long | 2pcs | Gantry Horizontals | HFS5-2040-770 |

| 2040 (20mm x 40mm) | 456mm Long | |||

| 2040 (20mm x 40mm) | 510mm Long | 4pcs. | Z axis Linear Rail Verticals | HFS5-2040-510 |

| Frame Components | Type | Units | Description | Part# |

| Frame Brackets | 20mm Wide | 90pcs | Reversal Tabbed Brackets | HBLFSNF5 |

| T-Nuts (Misumi) | M4 | 75pcs | M4 | HNKK5-4 |

| T-Nuts (Misumi) | M5 | 180pcs | M5 | HNKK5-5 |

| T-Nuts (Misumi) | M3 | 75pcs | M3 | HNKK5-3 |

| Frame Price | Price $ | |||

| Profile Extrusions | $ 122. 29 29 | extrusions and brackets w/tax and shipping | ||

| M5 x 10 Cap Screws (200pcs) | $ 9.99 | 225$ | ||

| brackets | $ 40.32 | |||

| T-nuts | $ 19.32 | |||

| Total | $ 191.92 |

Frame Assembly

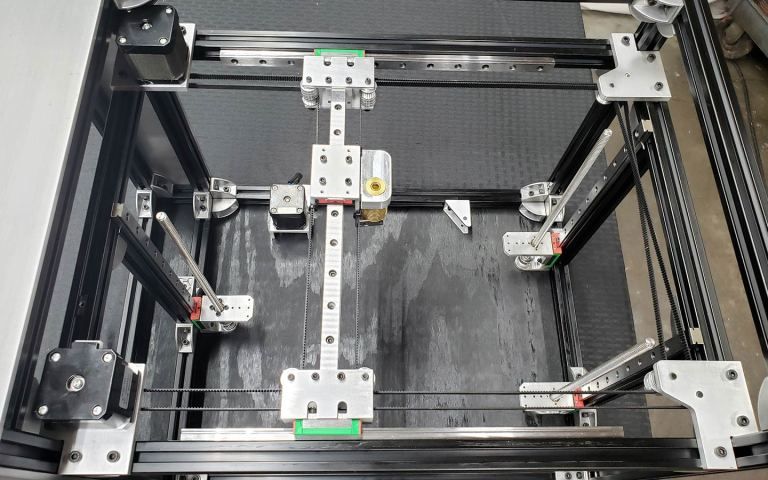

Workhorse Frame Step 1Workhorse Frame Assembly DiagramFrame Diagram Front ViewFrame Diagram Front ViewGantry

Gantry Motor PlatesAssembling The Gantry PlatesPart List:

- 1pc. x Gantry Motor Plate

- 1pc. x Gantry Idler Plate

- 16pcs. x M5 x 14mm Long Screws

Gantry Plates Before Gantry Frame And Motor

Gantry Plates Assembled To FrameView this post on Instagram

A post shared by 3D Distributed (@3d_distributed)

X-Carriage

X-CarriageX and Y-Carriages use 4 M3x6mm Screws

- X-Carriage (X-Axis) 2pcs

- Y-Carriage (Y-Axis) 1pc

- M3x6mm Screws 12pcs (4 for each Carriage)

The x-axis carriage screws down to the 2040 Y-axis extrusion and rail. *Note* The y-axis 2040 extrusion must have hand tapped M5 threaded holes.

Y-Axis AssemblyLinear Rails

The Workhorse Printer uses MGN12H linear rails with a 20mm x 20mm Hole Pattern.

BOM:

- 500mm Long Z Axis (4pc)

- 700mm Long X Axis (2pc)

- 450mm Long w Y axis (1pc)

Linear Rail Screw:

- M3x9mm Long Screws 26 per X-Axis

- M3x9mm Long Screws 14 for Y-Axis

- M3x9mm Long Screws 18 per Z–Axis

Total M3x9mm screws 138pcs.

Motor Mount to Carriage

- M3x8mm Long Screws 4pcs

Igus dryspin lead screw nuts do not require lubrication. This is normal for Igus materials. If you have any sounds, vibrations or wear, then the problem is most likely in the alignment and assembly of the mechanical components.

X-Carriage Lead Screw Nut Insert 2pcs

- Each Insert uses:

- M3x35mm screws 4pcs

- M5x55mm Long

Electronics

Stepper Motors

Heated Bed

View this post on Instagram

A post shared by 3D Distributed (@3d_distributed)

Like this:

Like Loading...

13 BEST CONSTRUCTION 3D PRINTERS OF 2019

A 3D construction printer is a machine that can build houses by applying material (concrete) layer by layer. The paste type material used, in this case concrete or earth, is forced through the nozzle in layers to print buildings.

Concrete 3D printing in the construction industry saves time, effort and material when compared to traditional methods. However, it is important to note that 3D printers are not yet capable of creating a fully functional home, only the frame and walls can be created, other elements such as windows, electricity or plumbing must be installed separately. Concrete 3D printers can also be used to print bridges, benches, or simply outdoor decorations. nine0003 To provide a complete overview of the construction 3D printer market, we have listed the top 12 construction 3D printing solutions. Some of them are 3D printers already available for sale, while others are still in the prototype stage or provide 3D printing services for external structures.

Concrete 3D printers can also be used to print bridges, benches, or simply outdoor decorations. nine0003 To provide a complete overview of the construction 3D printer market, we have listed the top 12 construction 3D printing solutions. Some of them are 3D printers already available for sale, while others are still in the prototype stage or provide 3D printing services for external structures.

HOW TO BUILD A 3D PRINTED HOUSE?

Construction 3D printers use extrusion technology. Some construction 3D printers are similar to FFF/FDM desktop 3D printers, only larger (gantry style), while others consist of a rotating mechanical arm. nine0003 In both cases, paste-type components such as concrete are used as the filament. The material is ejected from a special nozzle to form layers. In simpler (very) extrusion of pasta is like using a bag to dispense frosting on a cake.

The printer builds foundations and walls layer by layer. The base is literally the printer's build plate. However, some concrete 3D printers are used to 3D print brick molds. Once molded, the bricks are stacked on top of each other manually (or with a robotic arm). nine0003 Benefits of building 3D printing

However, some concrete 3D printers are used to 3D print brick molds. Once molded, the bricks are stacked on top of each other manually (or with a robotic arm). nine0003 Benefits of building 3D printing

• Eco-friendly : 3D printed houses can be built with sustainable materials. What's more, some construction 3D printers use solar energy and emit little CO2.

• Affordable: 3D construction printers can build affordable housing, providing great relief to people in poor areas or after natural disasters.

• Scalability: 3D construction printing reduces certain construction costs. For example, the cost of 1 square meter of wall using traditional construction methods is approximately $75, while for an Apis Cor house 3D printer it is only $27. nine0003 • Efficient: Because materials are 3D printed on demand, machines produce less waste. In addition, 3D construction printers can complete the foundation of a house in less than a few days, while traditional construction methods take weeks or even months.

• Design flexibility: Curved walls and unique facades can be easily created with a 3D printer

Disadvantages of 3D construction

• Expensive initial investment: These 3D printers can sometimes cost up to a million dollars. nine0003 • Partially Built Houses : Only house frames are built. The 3D printing process is usually paused to manually install plumbing, wiring, and fittings.

• Rough Appearance : The exterior of most 3D printed houses is not as smooth as traditional houses.

• Lack of Certification: Construction sites are regulated by law and there are important safety standards that must be met, which can be difficult with 3D printing methods (different repeatability, dimensional stability, etc.). nine0003

CONSTRUCTION 3D PRINTERS: OVERVIEW

We divide construction 3D printers into three categories: house building 3D printers that you can buy, prototype concrete printers, and concrete 3D printing services.

Home 3D printers available

AMT printers

Pictured: AMT S-6044 Long and AMT S-300

), 11 x 31 x 80 (maximum)

• Material: Concrete / Clay / Gypsum

• Country: Russia

Equipment manufactured by AMT-SPETSAVIA - workshop and field portal construction 3D printers (COP-printers, Construction Objects Printing): and from small-format (for printing small architectural forms ) to large (for printing buildings up to 30 floors high). Productivity from 0.5 to 2.5 cubic meters per hour, management by 2 people. AMT printers are capable of printing with any kind of concrete, clay and gypsum.

Productivity from 0.5 to 2.5 cubic meters per hour, management by 2 people. AMT printers are capable of printing with any kind of concrete, clay and gypsum.

BetAbram P1

• Assembly size : 1.6 x 8.2 x 2.5 m

• Material : Concrete

• Country : Slovenia

BetAbram is a small Slovenian team that has been working on building 3D printing equipment since 2012. Their flagship home 3D printer, the BetAbram P1, is currently in its second iteration and is available with additional printheads: basic, "Orto" for smoother layers, and rotatable for more design options.

COBOD BOD2

• Build size : 11.98 x 45.07 x 1.53 m

• Material : Concrete

• Country : Denmark

This construction 3D printer is fast, with a speed of up to 18 meters per minute. BOD2 is modular and can be adapted to various sizes. COBOD is a 3D Printhuset company.

Constructions-3D 3D Constructor

• Assembly size : 13 x 13 x 3. 8 m

8 m

• Material : Concrete

• Country : France Their 3D Constructor machine is mobile thanks to its rubber tracks and fits in a 20ft shipping container for easy transportation from one construction site to another. nine0007

CyBe Construction CyBe RC 3Dp

• Assembly size: 2.75 x 2.75 x 2.75 m

• Material: Concrete

• Country: Netherlands This easy-to-use 3D printer is capable of reaching heights of up to 2.75 meters and only requires two people to operate.

ICON Vulcan II

• Build Size : 2.6 x 8.5 x ∞ m

• Material : Concrete

• Country : United States

ICON wants to revolutionize the construction industry with its Vulcan II printer. The whole process is designed to be user friendly with a tablet-based interface, and the ICON Lavacrete concrete mix is optimized for easy printing.

MudBots Concrete 3D Printer

• Build Size : 1.83 x 1.83 x 1.22 m (minimum)

• Material : Concrete

• Country : United States of Mudts003 Concrete 3D Printers USA. Their smallest model (approximately 1830 x 1830 x 1220 mm) is available for $35,000. Large build sizes are also available, reaching up to 30 meters in length. nine0003 According to MudBots, their 3D printers can print a small house in just 12 hours and cut costs by 70% compared to traditional building methods.

Their smallest model (approximately 1830 x 1830 x 1220 mm) is available for $35,000. Large build sizes are also available, reaching up to 30 meters in length. nine0003 According to MudBots, their 3D printers can print a small house in just 12 hours and cut costs by 70% compared to traditional building methods.

Stroybot2

Build Size : 10m x 15m x 6m

Material : Concrete

Country : United States

StroyBot, also known as the Rudenko 3D Printer, is a versatile mobile design printing system supplied as a build kit user. On average, he can print a 100 square meter house in 48 hours (walls only). nine0007

WASP Crane WASP “Infinity 3D Printer”

• Build Size : Ø 6.3 x 3 m

• Material : Concrete / Earth materials

• Country : Italy

WASP Crane is an evolution of the previous WASP construction printer 12MT. This open source builder is modular and multiple Crane printers can work together on the same project, giving theoretically endless 3D printing possibilities.

Concrete printers work projects

Apis Cor 3D printer

• Assembly size : 8.5 x 1.6 x 1.5 m

• Material : Concrete

• Country : United States

Apis Cor, a 3D based construction company Francisco and claims to be able to 3D print a house in less than 24 hours. Their Apis Cor printer is similar to a robotic arm and won first place in NASA's 3-stage 3D printing competition.

Batiprint3D 3D Printer

• Build Size : -

• Material : Concrete / Other

• Country : France

Batiprint 3D made headlines internationally when it completed the Yhnova 3D print shop in Nantes, France. Their 3D printer not only prints cement but also insulating foam, making it one of the most complete 3D building solutions.

S-Squared ARCS VVS NEPTUNE

• Build Size : 9.1 x 4.4 x ∞

• Material : Concrete

• Country : United States

S-Squared, also known as Square3D "4D printing", which aims to provide fast, reliable, environmentally friendly and affordable housing for poor areas. ARCS VVS NEPTUNE is one of the company's working models, but it will not be available for commercial sale. nine0007

ARCS VVS NEPTUNE is one of the company's working models, but it will not be available for commercial sale. nine0007

Construction printing services

Contour Crafting 3D Printing System

• Material • Material: Concrete

• Country: United States

This automatic construction system is capable of 3D -printing large buildings and high -high infrastings. Contour Crafting (also known as CC Corp) aims to improve the effectiveness of disaster relief through concrete admixture technology. nine0007

XtreeE 3D Printer

• Build Size : -

• Material : Concrete

• Country : France

XtreeE develops custom 3D printing solutions for construction, engineering and architectural design. This startup is located in France and has already completed a number of 3D construction projects.

Will 3D printing change the world? / Habr

"Technologies, potential and consequences of additive manufacturing", - an article under this heading was published by the specialists of the Strategic Foresight Initiative. This organization was created to analyze the potential consequences of long-term global trends, revolutionary changes and upheavals that can occur in the world. For the past six years, the Strategic Foresights Initiative, in conjunction with the US National Intelligence Council, has published reports forecasting long-term trends through 2025-2030. This time they are turning their attention to 3D printing and other methods of so-called additive manufacturing (AP, additive manufacturing). nine0007

This organization was created to analyze the potential consequences of long-term global trends, revolutionary changes and upheavals that can occur in the world. For the past six years, the Strategic Foresights Initiative, in conjunction with the US National Intelligence Council, has published reports forecasting long-term trends through 2025-2030. This time they are turning their attention to 3D printing and other methods of so-called additive manufacturing (AP, additive manufacturing). nine0007

According to researchers, AP is capable of radically changing society and the global economy. In terms of impact, this can be compared with the invention of the steam engine, the electric light bulb, atomic energy, or the microchip. And right now, in their opinion, the technology is “ready to take off”, and in the next decade, a sharp increase in the use of 3D printing in industry will begin.

The report briefly reviews existing additive manufacturing technologies and their current areas of application. The authors note that AP was originally used for rapid prototyping, that is, the rapid production of conceptual models and prototypes. But as materials and processes improved, AM technologies moved first to creating parts for functional testing, then to creating parts for presses and other industrial production tools, and finally directly to industrial production. In 2009In 2008, studies showed that 16% of AM devices were used directly for part manufacturing, 21% for functional modeling, and 23% for tool making.

The authors note that AP was originally used for rapid prototyping, that is, the rapid production of conceptual models and prototypes. But as materials and processes improved, AM technologies moved first to creating parts for functional testing, then to creating parts for presses and other industrial production tools, and finally directly to industrial production. In 2009In 2008, studies showed that 16% of AM devices were used directly for part manufacturing, 21% for functional modeling, and 23% for tool making.

Estimate and forecast revenue (in millions of US dollars) from AP products and services

There are now several “success stories”, that is, areas where AP has been successfully used to make parts:

- automotive parts , for example, some parts of Formula 1 car engines are made by direct laser firing on metal; nine0199

- aircraft parts eg tube for F-18 fighter/attack aircraft environmental control system;

- Custom Orthodontics : Align Technology uses AP to create accurate custom braces for hundreds of thousands of patients around the world using stereolithography from 3D oral scans, using an FDA-approved resin as the braces material;

- individual hearing aids : Manufactured by Siemens and Phonak based on a 3D scan of the ear canal so that the device fits the user perfectly and is almost invisible.

Among the existing limitations of AP are the poor choice of materials used and the low speed of 3D printing (several tens of cubic centimeters per hour). According to the authors of the study, these limitations are temporary and can be considered either insignificant or surmountable in the future.

But the potential of technology is truly difficult to overestimate. Mass production can be transformed beyond recognition: for many products, standard conveyors can be greatly reduced or completely replaced by 3D printers, because the final product - for example, a car - will not be assembled from hundreds and thousands of individual parts, but within a single process. This will affect many manufacturers and suppliers - many factories around the world that make parts for this conveyor. nine0007

Globalization will change its face. The movement of goods will take place not in the physical world (on barges, containers and cargo trucks), but on the Internet - in the form of digital files and 3D models. Just as an email can be sent to the other side of the world and printed in 2D there, a 3D STL model file can be sent and printed on a 3D printer, receiving the original device. STL files will be created either by 3D scanning of originals or designed by designers in 3D modeling packages. nine0007

Just as an email can be sent to the other side of the world and printed in 2D there, a 3D STL model file can be sent and printed on a 3D printer, receiving the original device. STL files will be created either by 3D scanning of originals or designed by designers in 3D modeling packages. nine0007

In some cases, it will be easier and cheaper for villagers to print a couple of hundred of the latest iPhones for villagers on a local printer than to manufacture millions of devices in China, transport them across the ocean, and then ensure delivery to this locality, remote from major distribution centers . Due to the localization of production, current exporting countries, whose exports exceed imports, such as Germany, Japan and China, may suffer in the future. The winners will be the importing countries (USA), as well as countries with a large domestic market (USA) and countries with a large potential for exporting intellectual products (USA again). In general, the researchers believe that due to the spread of three-dimensional printing, the United States can regain its former influence in the global economy, industry, the market for intellectual property, design, innovation, and the export of intellectual products. nine0007

nine0007

Despite the improvement in the foreign trade balance due to the localization of production in some of the countries listed above that benefit from the introduction of AP, such a transformation of the economy can lead to political destabilization due to rising unemployment. But in the United States, experts believe, this trend can be offset by the aging of the population and the natural reduction in the number of able-bodied population. In addition, the AP itself will create a new industry with a turnover of hundreds of billions of dollars, which will require specialists in new professions (more 3D designers, programmers, engineers, printer developers, printer factories and supplies packaging). nine0007

AP devices in the future will be able to handle a wide variety of materials without complicated reconfiguration. But the key technologies that will provide a breakthrough in AM in the coming years will be two:

- Direct AM of metal components . Significant progress has been made in this area over the past five years.

Learn more