Home 3d printing uk

Building for Humanity to construct UK's first 3D printed homes in Accrington

0Shares

Nominations for the 2022 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Let us know by casting your vote now.

Non-profit housing restoration and construction firm Building for Humanity has announced plans to build the UK’s first 3D printed homes.

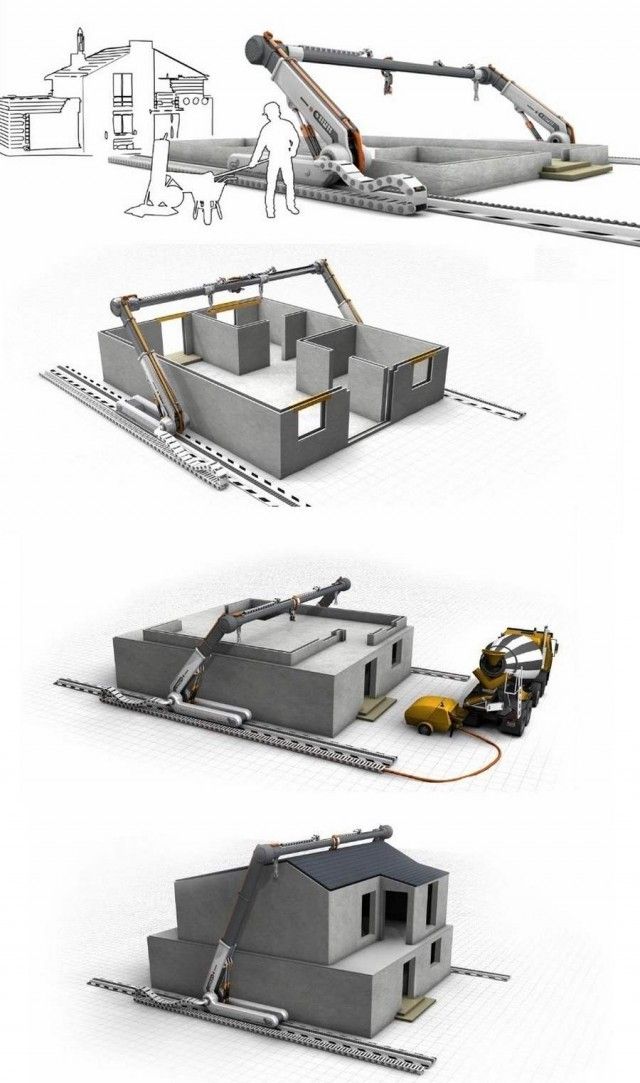

As part of the £6 million Charter Street regeneration project in Accrington, the company plans to COBOD 3D print 46 new energy-efficient homes. Once built, the housing is expected to be marketed as more accessible lodgings for veterans and low-income families in the town, who can’t currently afford to rent or buy there.

“Our aim is to ensure quality housing is accessible to everyone through our unique affordable housing model,” said Building for Humanity Founder Scott Moon. “The model is simple, to create a charitable housing institute that is driven by human fulfilment and wellbeing rather than profit. All surplus profits go to our chosen charity partner, Homes for Humanity, meaning it goes into the community to provide housing, support and training.”

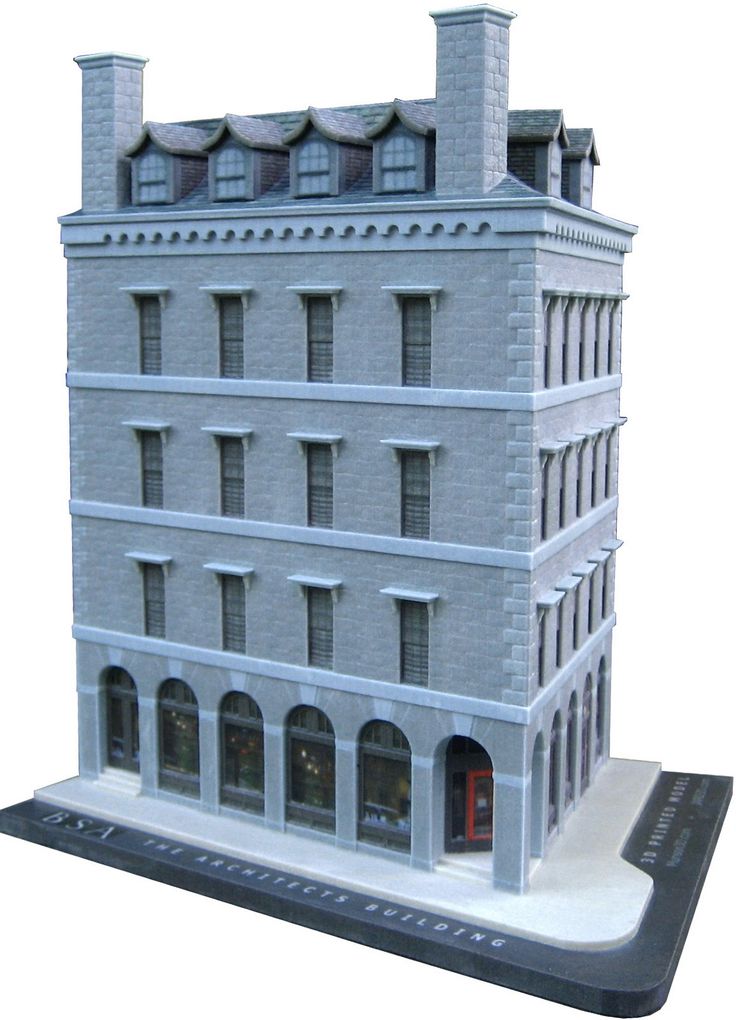

Building for Humanity’s proposed Charter Street homes. Image via Building for Humanity.“Ultimately this development is about so much more than housing, it is about people and giving them the opportunity to thrive.”

Building for Humanity

Working from its offices in Accrington, Cornwall and Newark, Building for Humanity is a Community Interest Company (CIC) that’s dedicated to tackling homelessness and assisting those facing fuel poverty. As well as seeking to help families and individuals on low-income, the firm has made it its mission to assist ex-military personnel, by housing them and involving them in its home-building activities.

However, not just satisfied with building homes for the disadvantaged, Building for Humanity prioritizes doing so sustainably. In practice, this has led the company to focus on retrofitting homes with insulation, new boilers and green energy-generating solar panels, to help residents teetering on the brink of fuel poverty.

To assist those already without a home, Building for Humanity has also turned to 3D printing, by pledging to use the technology in the construction of new high-quality, low-cost homes in Accrington. In future, the firm says 3D printing can “reinvent home ownership” by enabling the creation of low-energy, high-performance housing, which is affordable enough to be “in the reach of every person in the UK.”

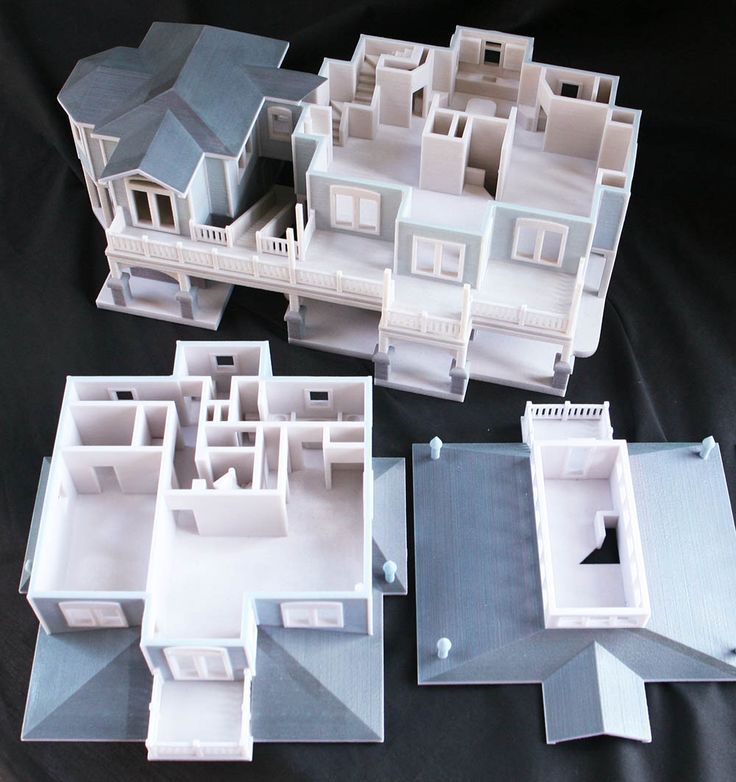

Building for Humanity’s Whalley Road redevelopment site. Photo via Building for Humanity.A UK-first 3D printing initiative

The Charter Street project will see Building for Humanity work with partner Harcourt Technologies (HTL) to transform a disused piece of land into a ‘Community Hub.’ HTL is a COBOD partner that uses its technologies to offer construction services, such as those related to equipment leasing, servicing, training, R&D and site development.

Working with Building for Humanity as part of its latest project, the firm says it now aims to construct the “largest printed building of its kind in the whole of Europe. ” When ready, the build will be divided up into a mixture of one and two-bedroom apartments and three and four-bedroom houses, interspersed with a communal garden and training hub.

” When ready, the build will be divided up into a mixture of one and two-bedroom apartments and three and four-bedroom houses, interspersed with a communal garden and training hub.

In preparation for the initiative, HTL has worked with partners Lindsay Baxter Design and Harcourt Architects at an R&D facility based inside Accrington & Rossendale College. There, the firms say they’ve managed to develop a means of deploying the technology in compliance with UK building regulations, which could facilitate its wider adoption post-project.

When it comes to the Accrington builds, it’s thought COBOD 3D printing them will reduce their construction cost by 30%, while halving their lead times. Through the efficient placement of materials, HTL also aims to cut the amount of waste produced during construction by 60%, without having to compromise on quality.

COBOD’s BOD2 3D printer. Photo via COBOD.3D printing affordable housing

Cost-efficiency is often cited as a core benefit of construction 3D printing, and the technology has already been used to build multiple affordable homes. In November last year, Alquist3D, the PERI Group and Printed Farms Florida, unveiled plans to 3D print more accessible US homes for rural communities, using COBOD’s technology.

In November last year, Alquist3D, the PERI Group and Printed Farms Florida, unveiled plans to 3D print more accessible US homes for rural communities, using COBOD’s technology.

Azure Printed Homes has also been contracted by Californian real estate firm ReInhabit to 3D print ten new eco-friendly houses. By 3D printing the buildings from recycled plastic, ReInhabit expects to realize significant cost and lead time gains, in a way that drives up its return on investment (ROI) when they’re rented out to residents next year.

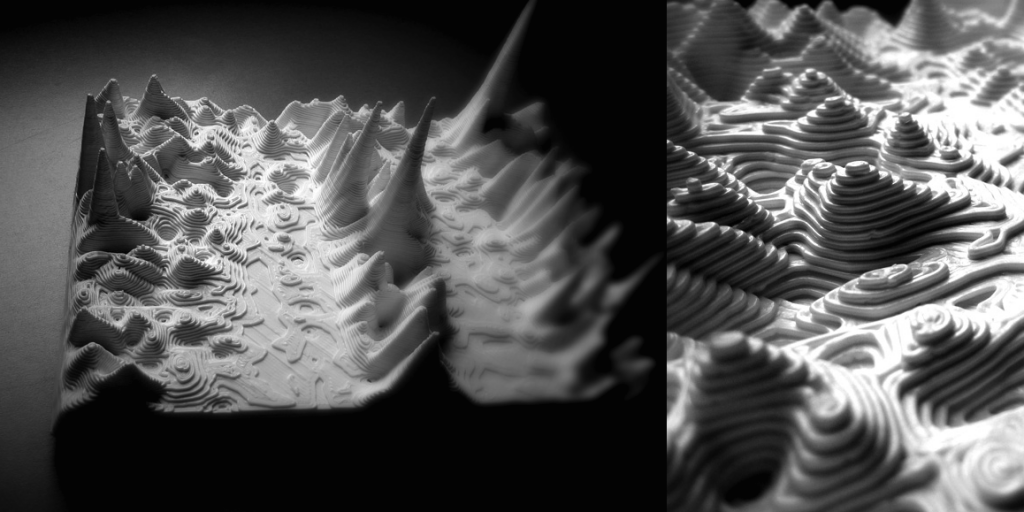

Elsewhere, at the University of Tehran, researchers have proven that 3D printing homes improves energy efficiency. Having developed a novel concrete, the team say it can be 3D printed into housing that generates 400-times less CO2 emissions.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook..jpg)

While you’re here, why not subscribe to our Youtube channel? featuring discussion, debriefs, video shorts and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Building for Humanity’s proposed Charter Street homes. Image via Building for Humanity.

Tags Accrington & Rossendale College Alquist3D Azure Printed Homes Building for Humanity COBOD GE Renewable Energy Harcourt Architects Harcourt Technologies Homes for Humanity Lindsay Baxter Design PERI Group Printed Farms Florida ReInhabit Scott Moon University of Tehran

Paul Hanaphy

Paul is a history and journalism graduate with a passion for finding the latest scoop in technology news.

UK’s first 3D-printed homes scheme being delivered by Irish firm

From left: HTL.tech CEO Justin Kinsella, Accrington and Rossendale College assistant principal Andy Parkin and Building for Humanity founder Scott Moon. Image: Building for Humanity

Image: Building for Humanity

Harcourt Technologies is working with a UK not-for-profit to bring 3D-printed homes to low-income families.

A £6m project in the UK aims to provide homeless veterans and low-income families with houses that can printed within weeks.

The Charter Street project will have 46 “eco homes”, with a mix of apartments and houses on a site in Lancashire. The plans also include a community centre, training hub and both private and communal gardens to help create a local community.

The site is being developed by Building for Humanity, a UK-based not-for-profit housing provider. The organisation said this is the UK’s first residential project using 3D construction printing (3DCP) technology and will be the largest of its kind in Europe.

The 3D-printed homes are being delivered by Ireland’s Harcourt Technologies (HTL.tech), which has been developing and testing the technology over the past 18 months to prepare for a commercial roll-out in Ireland and the UK.

HTL.tech is the strategic partner and exclusive distributor of Cobod 3DCP technology in the UK and Ireland.

The Irish firm said this 3D printing can reduce building costs, while cutting construction time. The technology also uses recycled materials in the printable concrete mix.

“HTL’s core objective is to develop the use of 3DCP to create less wasteful and more sustainable building solutions which harness the benefits of advanced manufacturing technology to provide affordable, higher quality structures, faster and more reliably and in an environmentally beneficial manner,” HTL.tech CEO Justin Kinsella said.

HTL.tech has been working at an R&D facility at Accrington and Rossendale College to ensure the 3D-printed homes are compliant with UK building regulations. This college plans to support the technology by facilitating a 3DCP introduction course on 21 October.

This college plans to support the technology by facilitating a 3DCP introduction course on 21 October.

Building for Humanity said the technology also allows other building components, such as doors, windows and floors, to be prefabricated and brought to site during the print sequence. The not-for-profit said its goal is to create a housing system that provides stable, environmentally efficient and secure housing.

“The model is simple, to create a charitable housing institute that is driven by human fulfilment and wellbeing rather than profit,” said Building for Humanity founder Scott Moon.

“Ultimately this development is about so much more than housing, it is about people and giving them the opportunity to thrive.”

10 things you need to know direct to your inbox every weekday. Sign up for the Daily Brief, Silicon Republic’s digest of essential sci-tech news.

Leigh Mc Gowran is a journalist with Silicon Republic

editorial@siliconrepublic. com

com

Helpful Tips for 3D Printing at Home

You, like many people around the world, may have had to quickly change from working in a workshop or office with many tools at hand to working at home where resources are more limited . During this difficult period, the ability to adapt to new circumstances and challenges helps to reduce production disruptions and avoid disruptions in the organization of the development cycle.

Formlabs desktop stereolithography (SLA) 3D printers are compact in size and can be used from home or outside the office environment. In addition, the ability to use over 30 different materials that mimic everything from silicone and polypropylene to ABS and more increases flexibility, expands the scope and makes it easy to adapt to new tasks as they arise. nine0003

Introducing 3D printing technology in-house will help you cut costs and keep your feet on the ground during times of uncertainty, especially if you have previously used or currently use third-party 3D printed models. Our customers are using home 3D printing to reduce costs, improve manufacturing process efficiency, continue developing critical products, and help overcome the COVID-19 crisis..

Our customers are using home 3D printing to reduce costs, improve manufacturing process efficiency, continue developing critical products, and help overcome the COVID-19 crisis..

Dan Kirchgessner, Communications Specialist, and Jake Kapusta, Senior Maintenance Specialist share practical tips for printing at home.

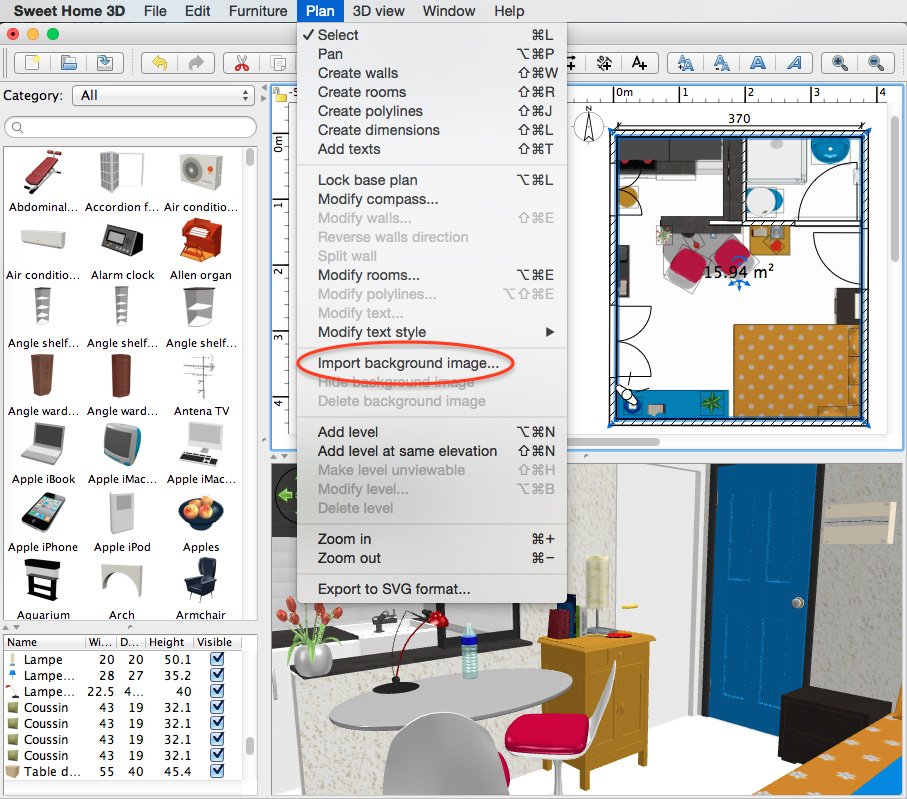

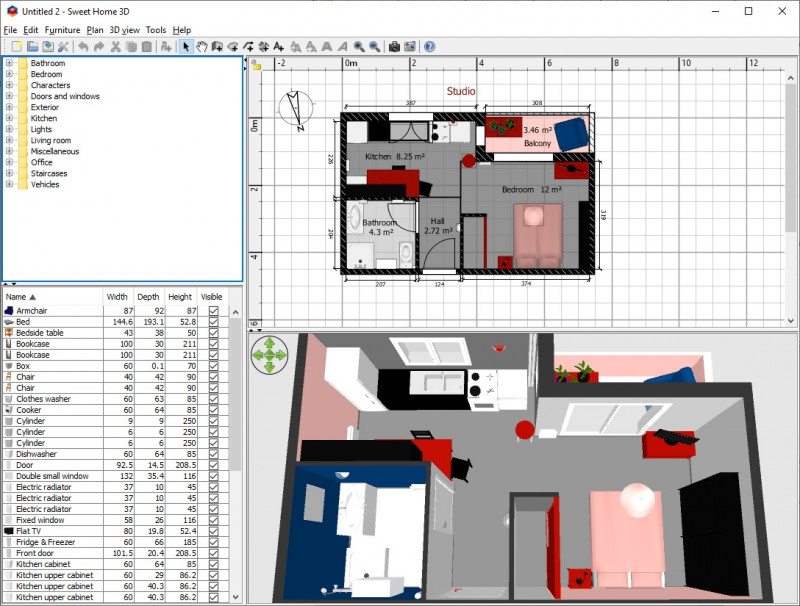

Before the 3D printer is delivered to your home, you need to organize your space and workspace so that you can print, post-process, and finish everything you need. You will need space to house the printer(s), post-processing stations such as Form Wash and Form Cure, workspace to separate and finish parts, and short-term storage space for items such as spare wash solvent, resin reservoirs, cartridges for resins, gloves, post-processing tools, etc.

Alexis Hope, designer and researcher at MIT's Media Lab and MIT's Center for Social Interaction Tools, says that in setting up her home workshop, “getting the printer home was a great incentive to reorganize the workplace. Space is required for flushing and curing systems, as well as space for storing models, so proper organization of space is necessary for productive work. ”

Space is required for flushing and curing systems, as well as space for storing models, so proper organization of space is necessary for productive work. ”

Alexis Hope's home workshop. nine0010

Some of the most frequently asked questions about 3D printing at home have to do with environmental factors such as sounds and smells. To account for sensitivity to odors, we advise placing the post-processing station in a well-ventilated area or near an open window. Although the Form 3 is relatively quiet - it produces a noise comparable to that of a microwave oven - you may prefer to place it away from those areas of your home where you don't want to disturb the silence. nine0003

Woody Hedberg, Formlabs Print Process Engineer, recently hosted a Form 3L in his apartment for material testing purposes. “As a protective measure, I installed thick cardboard on the floor and walls of the room,” says Hedberg. In addition, for the workplace, he chose a space near an open window and behind a closed door to reduce the penetration of potential smells and sounds.

After preparing the workspace, lay out the items needed for 3D printing, such as wash containers, baskets and bottles, tweezers, spatula, detach tool, wire cutters, disposable nitrile gloves, and any additional tools that you may need during the work 3D printing process. nine0003

If you already have a 3D printer, the first thing you should consider is transporting it from your office or workplace to your home. When preparing your Formlabs 3D printer for shipping, first remove the resin cartridge, then remove and clean the platform, and finally remove the resin reservoir and close the lid before placing it in its storage case. Ensure that all accessories containing polymers are securely closed before transport.

Before shipping the Form 3 printer, secure the Light Processing Unit (LPU) with wing screws and latch. Failure to lock the LPU may damage the printer. Contact us if you can't find the screws. nine0003

Carefully wrap the printer in protective material and, if possible, place it in the original packaging. Be sure to pack all the accessories you may need for 3D printing and post-processing: Form Wash and Form Cure or post-processing kit and an alternative curing solution and consumables such as resin reservoirs and cartridges, gloves, tools for post-processing, isopropyl alcohol, etc.

Be sure to pack all the accessories you may need for 3D printing and post-processing: Form Wash and Form Cure or post-processing kit and an alternative curing solution and consumables such as resin reservoirs and cartridges, gloves, tools for post-processing, isopropyl alcohol, etc.

After unpacking 3D printing supplies at home and before printing, be sure to check that the printer is level and stable in the new location. nine0003

Now that your printer is ready to use at home, there are several ways to improve and streamline your workflow.

Schedule the start and end times for printing to fit your work schedule. This way you can load the printer to the maximum. You can schedule the start of your next print using PreForm's Estimated Print Duration feature. Print time-consuming models while you're away from your workspace so you can print while you're away so you can start the next one when you get back. nine0003

Kevin Gauthier, Business Development Specialist at Formlabs, found that when working remotely, his team sent models to each other more often: "Never forget to print an instance of an object for yourself so you can refer to it later. "

"

Kevin Gauthier's home workspace.

Continuing the same line, Hedberg suggests documenting and photographing every 3D printed model in detail, especially if your storage space is limited. “Now that we are working remotely, we need a proper documentation system. This does not mean that every 3D printed model should be saved, but carefully documenting the printed models and keeping records for my colleagues, yes,” he says. nine0003

Use the Dashboard to monitor the printing process in real time, as well as tank usage and resin usage. You'll also be able to track quality prints and scrap rates so you know which designs are the best and use them for future iterations.

“Do all the design work you can and prioritize critical physical prototyping tasks for different teams,” says Zach Frew, Formlabs Technical Specialist. Frew says you need to prioritize these tasks, especially when work resources are limited, and share them with your team members. nine0003

Follow safety guidelines when using Formlabs products. Handle IPS with nitrile gloves in a well-ventilated area. Keep the IPS away from heat, sparks and open flames. Isopropyl alcohol evaporates quickly, so keep containers covered if possible. For detailed safety information, contact the manufacturer or supplier of this chemical.

Handle IPS with nitrile gloves in a well-ventilated area. Keep the IPS away from heat, sparks and open flames. Isopropyl alcohol evaporates quickly, so keep containers covered if possible. For detailed safety information, contact the manufacturer or supplier of this chemical.

As Formlabs Materials Expert Zak Zguris says, “You have to practice good chemical hygiene. Keep everything clean. Wipe up any drops or spilled liquids immediately. To avoid sticky residue, use acetone or isopropyl alcohol. When washing in the IRS, ventilation of the working space with fresh air should be provided. The cabinet is not at all suitable for the active use of a 3D printer or a washing station in an IRS.” nine0003

Always wear gloves to protect your skin when handling resin cartridges and containers. Store ink cartridges upright, out of direct sunlight, in a well-ventilated area. Close the cartridge outlet cap to prevent resin leakage.

Liquid or partially cured polymers must not be poured down the drain or disposed of with household waste. Do not pour isopropyl alcohol (IPA) with the polymer dissolved in it down the drain or dispose of it with household waste. All solvents and polymers should, as always, be disposed of in accordance with local regulations and the supplier's MSP. More information about security measures can be found on our technical support website. nine0003

Do not pour isopropyl alcohol (IPA) with the polymer dissolved in it down the drain or dispose of it with household waste. All solvents and polymers should, as always, be disposed of in accordance with local regulations and the supplier's MSP. More information about security measures can be found on our technical support website. nine0003

Do you have any helpful tips or advice that you could share based on your experience of transitioning to working from home? We'd love to hear about them. We invite you to share them on social media with the tag @formlabs or #EngineeringFromHome or by commenting on our forums.

Innovative home weather station predicts the weather within a radius of 30 kilometers

11/29/2012, 12:16 11202

"A smart gadget will make a forecast for the next 12-24 hours. All the useful functions of the predictor can not be counted: clock, calendar, alarm clock, projection of time and temperature on the wall or ceiling, various warning signals (frost, storm, increased rainfall). "

"

Tell a friend

Almaty. November 28. Kazakhstan Today - Oregon Scientific's innovative home weather station is able to predict the weather for the next 12-24 hours within a radius of 30 kilometers from its immediate location with an accuracy of at least 75%, Kazakhstan Today reports. nine0003

We have long been accustomed to the unpredictable vagaries of nature. The issue of weather is one of the key issues for us. It is on it that our well-being, mood and performance largely depend. Oregon Scientific's home weather station can predict the weather like a long-legged TV girl. Moreover, the smart gadget will make a forecast for the next 12-24 hours," the agency was told at the manufacturing company of the high-tech device Oregon Scientific , which in December starts selling its unique gadgets in Kazakhstan through the Sulpak, Technodom, "Planet of Electronics" and "Dream"

According to the company's specialists, many devices are connected and synchronized with a computer, which allows not only obtaining information about the environment, but also analyzing various parameters. Plus, the station will show the temperature and humidity level indoors and outdoors, as well as display atmospheric pressure. If necessary, up to ten wireless sensors can be connected to the device in order to know the “situation” in a wide variety of rooms, for example, in a nursery, bedroom or living room, and if you want, in a pool or wine cellar. The station can predict the weather within a radius of 30 kilometers from its location. nine0003

Plus, the station will show the temperature and humidity level indoors and outdoors, as well as display atmospheric pressure. If necessary, up to ten wireless sensors can be connected to the device in order to know the “situation” in a wide variety of rooms, for example, in a nursery, bedroom or living room, and if you want, in a pool or wine cellar. The station can predict the weather within a radius of 30 kilometers from its location. nine0003

All the useful functions of the predictor can not be counted: clock, calendar, alarm clock, projection of time and temperature on the wall or ceiling, various warning signals (frost, storm, increased rainfall, etc.). It all depends on the specific desire and needs: you can choose from the simplest device to a multi-functional weather station with a sophisticated design," Oregon Scientific said.

After listening to the news and weather forecast in the morning, we go to work or start make plans for the weekend.But, as they say, "forecasters make mistakes once, but every day!", therefore, once on the street, we periodically languish from the heat, carrying an umbrella with us, or, conversely, we are forced to get wet and cold. do not watch TV or surf the Internet, but trust your own intuition or have clothes with you all year round for all occasions ... But there is a more interesting way out: get a personal assistant - a home weather station Oregon Scientific . This electronic predictor friend is easy to use, always at hand and surprisingly truthful," the company informed. Oregon Scientific Oregon Scientific , founded in 1989 in the United States, is a global manufacturer of innovative digital electronics designed for the whole family.Oregon Scientific produces high-quality, multifunctional devices for communication, recreation and sports.The company's products have received numerous awards and accolades in the field of technology and Collaboration with renowned design labs makes Oregon Scientific devices especially elegant and different.

Learn more