Iit 3d printing

Active Learning at Illinois Tech

It’s time to get

doing.Action-oriented, immersive experiences define the Illinois Tech education. We’re one-of-a-kind, and our hands-on programs prove it. From Illinois Tech’s signature Elevate Your Future program to our distinctive project-based courses in the Interprofessional Projects (IPRO) Program to high-tech maker spaces and cutting-edge research, we prepare you to think big and lead big like no other university can. And it all begins in your first year of study.

Active Learning Programs

Elevate

Our one-of-a-kind Elevate program guarantees you hands-on experiences like internship, research, and study away opportunities, plus mentorship and a personalized career plan, to help you achieve your professional goals.

IPRO Program

An Illinois Tech bragging right for 26 years, the IPRO Program mimics real-world project teams, challenging you to work with your fellow students to address issues that matter.

Kaplan Institute

Our on-campus innovation hub gives you access to advanced tools and training programs that will prepare you to create new products and think like a tech leader.

Idea Shop

Our state-of-the-art maker space is equipped with the tools you need to turn your ideas into reality.

Leadership Academy

Illinois Tech’s distinctive leadership training program teaches you how to be an effective leader and team member, offering courses, retreats, and a certificate option.

Student Research

When it comes to research at Illinois Tech, it’s all about access. Students can work on research projects in as early as year one. Opportunities abound through our Elevate program, individual colleges and schools, our Office of Research, academic student groups, and more.

“By taking part in the Museum of Science and Industry volunteer and intern program (available exclusively to Illinois Tech students), I discovered my passion and aptitude for education.

I would have never realized how much I value helping others learn without this experience.”

—Henry White (Aerospace Engineering 4th Year), Mosca, Colorado

“The Armour R&D Summer Immersion Program was an awesome experience where I worked with a professor in BME on a team of upperclassman to create a software toolbox to better help surgeons analyze images in FGS.”

—Monica Bhagavan (Biomedical Engineering 4th Year), Westmont, Illinois

“Illinois Tech has the resources of the city, its supporters, its staff, its alumni, and students that are unparalleled to other universities in the area. The hands-on learning that Illinois Tech offers leads you to discover yourself to solve problems in creative fashions that not only apply to the problem at hand, but to everything you do from here on out.”

—Andrew Jiang (Architecture ’20), Madison, Wisconsin

“The experience that I learned in the student group Stuart Investments helped me land my current internship.

During my interview, the corporation was extremely interested in the work we do in Stuart Investments. Illinois Tech provided this unique opportunity that allowed me to stand out compared to other applicants.”

—Mohamed Shamel (Business/M.S. Finance 5th Year), Cairo, Egypt

Illinois Tech Today | 3D Printing

-

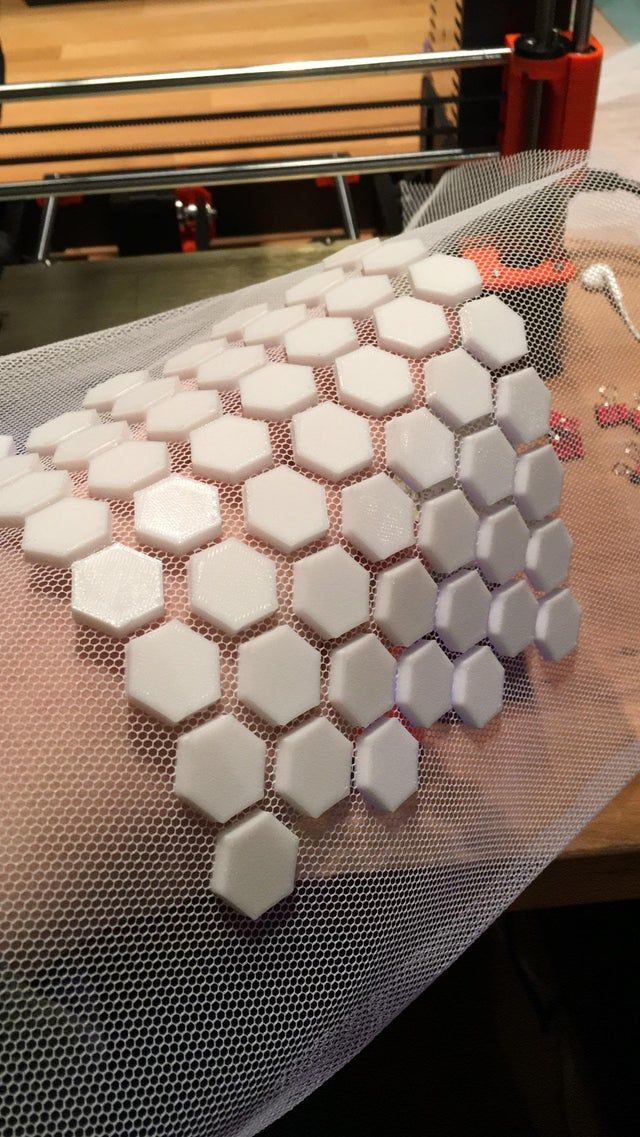

Workshop: Make Your Own Laser Cut or 3D Printed Holiday Ornament November 28-29

November 22, 2022

Looking for a thoughtful gift idea? Kaplan Institute's Idea Shop is holding a two-day interactive workshop November 28-29 where students will get to use a laser cutter and/or 3D printer to create a unique pair of holiday tree ornaments!

Full Story

-

MMAE Seminar: 3D Printing, Microstructure, Synchrotron Experiments and Machine Learning by Dr.

Anthony Rollett

Anthony Rollett September 8, 2020

Armour College of Engineering’s Mechanical, Materials, and Aerospace Engineering Department will welcome Dr. Anthony D. Rollett, professor of materials science and engineering at Carnegie Mellon University, on Wednesday, September 9, 2020 to present lecture on 3D Printing, Microstructure, Synchrotron Experiments and Machine Learning.

Full Story

-

MMAE Seminar, Extrusion 3D-Printing: From Inks to Metal Microlattices

February 4, 2020

The MMAE department welcomes David Dunand, Ph.D., professor of materials science and engineering at Northwestern University, on February 5 to discuss "Extrusion 3D-Printing: From Inks to Metal Microlattices."

Full Story

-

College of Architecture Pro.

Robert Krawczyk in Winter Exhibits

Robert Krawczyk in Winter Exhibits November 7, 2019

College of Architecture Pro. Robert Krawczyk’s two pieces from the 3D printed, metallic plastic, Containing Air, Exploring Structure series are included in the “Handmade By Robots” exhibition at the Northeastern Illinois University’s Salme Harju Fine Arts Center Gallery, Chicago, IL.

Full Story

-

3D Printing Tutorial Using Tinkercad

September 12, 2019

Learn how to design your own 3D object for the 3D printer using Tinkercad, a free online CAD app that is easy to use.

Full Story

-

Assistant Professor of Civil, Architectural and Environmental Engineering, Brent Stephens, is interviewed about his latest research into the potentially harmful emissions of 3D printers in several media outlets including the Chicago Tribune.

February 3, 2016

Read the article in the Chicago Tribune here. Read the article in Fox News Technology here. Read the article in Yahoo! News here.…

Full Story

-

Illinois Institute of Technology’s research project with the Built Environment Research Group (BERG) on eco-friendly 3D printing is mentioned in several national publications.

May 20, 2015

Read the article in Smart Grid here. Read the article in Consumer Electronics Net here. Read the article in Virtual-Strategy Magazine here.…

Full Story

What is 3D printing and how it can be used! Interesting!

What is 3D printing

3D printing technology was patented in the 80s of the last century, but gained popularity relatively recently. New, promising techniques have been developed and the possibilities of 3D technologies have reached a completely new level. However, to this day, the technique is not known in all circles, and not everyone is aware of what 3D printing is. In today's article, we will try to explain in detail and in an accessible way what 3D printing is and where it is used. nine0005

New, promising techniques have been developed and the possibilities of 3D technologies have reached a completely new level. However, to this day, the technique is not known in all circles, and not everyone is aware of what 3D printing is. In today's article, we will try to explain in detail and in an accessible way what 3D printing is and where it is used. nine0005

In short, 3D printing is a technique for manufacturing three-dimensional products based on digital models. Regardless of the specific technology, the essence of the process is the gradual layer-by-layer reproduction of objects.

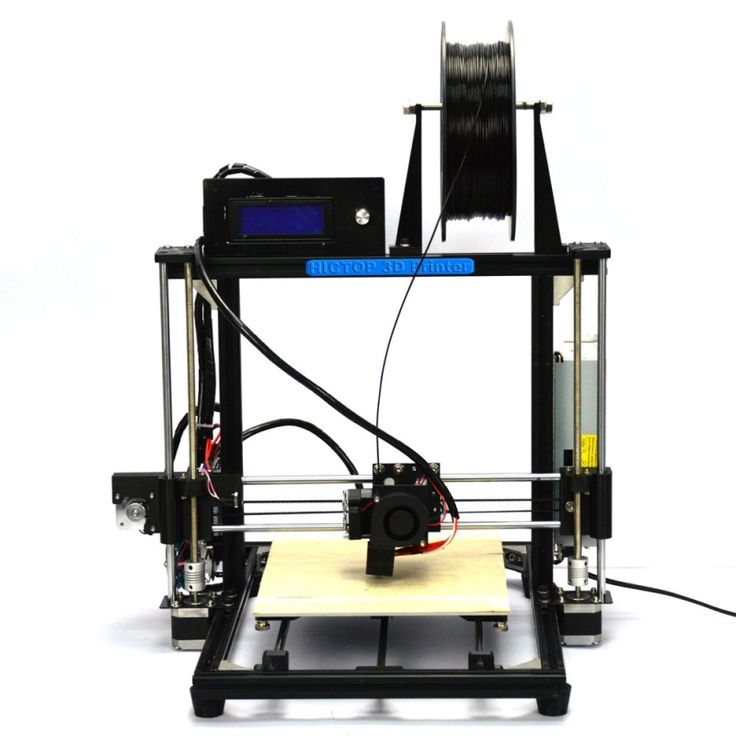

This process uses a special device - a 3D printer, which prints certain types of materials. More details about it are written here. Other names for the technology are rapid prototyping or additive manufacturing. Often the phrase "additive technologies" is used in the meaning of "3D technologies". nine0005

3D printing steps

To make it clearer what 3D printing is, let's take a look at the playback process step by step. Below are the specific stages of 3D printing. How it works:

Below are the specific stages of 3D printing. How it works:

- 3D modeling of the required object is performed according to certain rules;

- The file with the digital model is loaded into the slicer program, which generates the control code for the 3D printer;

- Sets required 3D printing options;

- The code is written to a removable memory that connects to the 3D printer; nine0015

- 3D model reproduced.

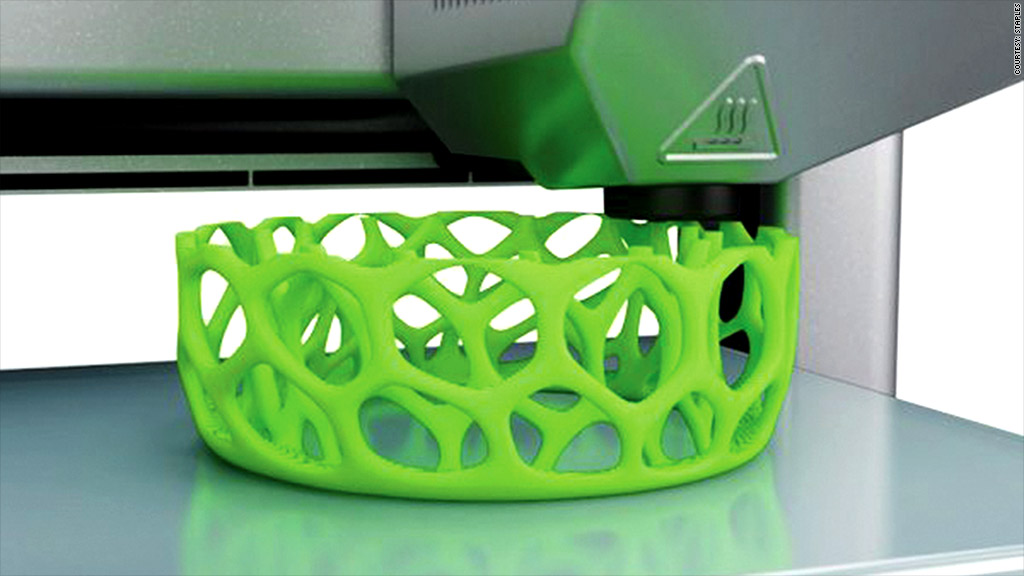

Objects are reproduced gradually. According to the required shape, the selected material is applied layer by layer, forming the finished product. It is worth noting that the possibilities of 3D printing are almost limitless, that is, anything can be made. In some technologies, very thin overhanging elements are provided with supports, thanks to which they can be avoided from sagging.

Naturally, this is a very simplified description of the stages of 3D printing, but they give a very clear idea of the essence of the technique. nine0005

nine0005

Other questions and answers about 3D printers and 3D printing:

- Basics What is 3D scanning?

- Basics What is a 3D model?

3D Printing Technologies

Different 3D printing technologies are used to reproduce different objects. They differ both in the consumables used, and in the speed and accuracy of printing. Here are the main 3D printing technologies:

- Fused deposition modeling (FDM) . One of the most common 3D printing technologies, used in most desktop 3D printers, and represents an ideal price / quality ratio. Printing occurs by layer-by-layer supply of a thread of molten plastic;

- Laser stereolithography (SLA) . The formation of the object occurs due to the layer-by-layer illumination of a liquid photopolymer resin by a laser, which hardens under the influence of radiation. One of the variations of this technology is DLP 3D printing. It uses a special projector instead of a laser.

Both 3D printing methods are used to create objects with a high degree of detail. In the case of DLP printing, speed is also an added advantage; nine0015

Both 3D printing methods are used to create objects with a high degree of detail. In the case of DLP printing, speed is also an added advantage; nine0015 - Selective laser sintering (SLS) . Reproduction is performed by layer-by-layer melting of a special powder under the action of laser radiation. This 3D printing method is widely used in the industry for the manufacture of durable metal elements

3D Printing Applications

As you may have guessed by now, 3D printing is extremely versatile. The second name of the technology - rapid prototyping - speaks for itself. In the manufacture of prototypes and models of models, 3D printing can be simply indispensable. It is also a very cost-effective solution for small-scale production. In the aerospace and automotive industries, 3D technologies are already being used with might and main due to the high profitability and speed of manufacturing components. Culinary professionals are working on the development of 3D food printers, and in medicine, 3D printing has become something of a technology of the future. With the help of 3D bioprinting, it is planned to produce bones, organs and living tissues, but for now, implants and full-fledged medicines are printed on 3D printers. Desktop 3D printers can be used for domestic purposes: for repairs, making various household items, and so on. And designers, fashion designers, sculptors and artists appreciate the possibilities of 3D printing and 3D modeling as an unusual way to realize their talent. nine0005

With the help of 3D bioprinting, it is planned to produce bones, organs and living tissues, but for now, implants and full-fledged medicines are printed on 3D printers. Desktop 3D printers can be used for domestic purposes: for repairs, making various household items, and so on. And designers, fashion designers, sculptors and artists appreciate the possibilities of 3D printing and 3D modeling as an unusual way to realize their talent. nine0005

Well, that was a brief description of what 3D printing is. We hope we were able to provide the necessary information in an accessible way. If you have additional questions that we have not covered, write to us by e-mail and we, if necessary, will add your questions! Best regards, 3DDevice team.

We also want to remind you about the possibility to order 3D printing, 3D scanning, 3D modeling services or purchase of related equipment and consumables with delivery throughout Ukraine in 3DDevice. If you have any questions, please contact us at one of the phone numbers listed here. We look forward to collaborating! nine0005

We look forward to collaborating! nine0005

Back to Home

What is 3D Printing

Accelerate product development, reduce costs with a digital manufacturing platform.

Get an instant quote

Upload to production in 5 min.

3D printing - fast reproduction of objects based on a digital model with low costs and unique materials. The complete opposite of traditional production.

Definition and general principles

3D printing, also known as additive manufacturing (from the English. Add - add), is the exact opposite of subtractive technologies (from the English. Subtract - subtract) such as CNC machining, or molding methods for manufacturing products - injection molding.

Instead of machining or subtracting material to form an object, the printing process adds layer by layer gradually.

1. The process always starts with a digital 3D model, a design of a physical object as a CAD file in STL format. nine0005

nine0005

2. The model is loaded into the 3D printer and placed on the platform by the operator.

3. The printer software slices the model into thin 2D layers and turns it into a set of machine language (G-code) printer instructions.

4. Further operation of a 3D printer depends on the printing technology that underlies it. For example, desktop FDM printers melt plastic filaments and lay them on a print platform through a nozzle. Large industrial SLS machines use a laser to melt (or sinter) thin layers of metal or plastic powders. nine0005

3D printing does not require any special tools or fixtures. The part is made directly on the platform in the printer chamber. The materials used are directly dependent on the printing process. Thermoplastics are the most commonly used, but photopolymers, epoxies and metals are also used.

Manufactured parts can also have specific properties, forming from optically clear to rubbery objects.

Depending on the size of the part and the type of printer, printing usually takes between 4 and 30 hours. However, 3D printed parts are rarely ready for use immediately after printing. They often require post-treatment to achieve the desired level of surface finish. nine0005

However, 3D printed parts are rarely ready for use immediately after printing. They often require post-treatment to achieve the desired level of surface finish. nine0005

A Brief History of 3D Printing

Science fiction author Arthur Clarke was the first to describe the basic functions of a 3D printer in 1964. The first 3D printer was released in 1987 by 3D Systems, Chuck Hull, and used the "stereolithography" (SLA) process. In the 90s and 00s, other 3D printing technologies were developed, including FDM from Stratasys.

In 1989, DTM Corporation patented the SLS printing method developed by a group of students led by Dr. Carl Descartes at the University of Austin, Texas. DTM Corporation was later bought by 3D Systems in 2001. nine0005

In 2009, the ASTM F42 committee published a document containing standards for additive manufacturing terminology. This allowed 3D printing to stand on a par with traditional industrial production technologies. That same year, the FDM patents expired, and the RepRap project resulted in the first low-cost desktop 3D printers. This greatly influenced the development of the market. Affordable printers appeared for less than $2,000.

That same year, the FDM patents expired, and the RepRap project resulted in the first low-cost desktop 3D printers. This greatly influenced the development of the market. Affordable printers appeared for less than $2,000.

In 2016, HP launched its first 3D printing system and by 2017 had become one of the most popular industrial printers. More than 1 million desktop 3D printers were sold globally between 2015 and 2017, and sales of industrial metal printers in 2017 nearly doubled from the previous year. nine0005

The excitement of the past years was based on the idea of widespread consumer adoption of new technology. This has been, and still is, a misleading view of where 3D printing really adds value to a product. Despite this, the technology today has occupied its niche in the world of production and is widely used by both professionals and amateurs.

3D printing is an evolving technology. Every year, new 3D printers are released that can have a significant impact on the industry. nine0005

nine0005

Benefits

3D printing is an actively developing technology and has a number of fundamental differences and advantages in comparison with traditional production methods.

+ Complex geometries at no additional cost

3D printing makes it easy to produce complex shapes, many of which cannot be produced with traditional methods. The additive principle of technology makes it possible to complicate the geometry of the product without changing the cost of production. Complex structured parts optimized for 3D printing cost the same as simpler parts designed for traditional production (and sometimes even cheaper because less material is used). nine0005

+ Low cost per piece

When casting a part, it is necessary to make a unique expensive injection mold. In order to recoup these costs, it is necessary to produce a large number of products.

3D printing does not require the manufacture of special tools or tooling, so start-up costs are significantly lower. The cost of a printed part depends only on the amount of material used, the time it took the machine to print it, and the post-processing if required. nine0005

The cost of a printed part depends only on the amount of material used, the time it took the machine to print it, and the post-processing if required. nine0005

+ Allows easy changes to the product

Since the startup costs are low enough to create a unique product, you just need to change the 3D model. Each element can be changed to suit the needs of the buyer without increasing production costs.

+ Prototyping

Prototyping is one of the main applications of 3D printing today. Prototyping becomes an inexpensive and fast stage in product development and mass production thanks to new technology. Parts printed on a simple 3D printer, as a rule, will be ready within a few hours, on professional industrial equipment - in 5-7 working days. nine0007 The speed of prototyping greatly speeds up the design cycle. Products that would have taken months of development can now be ready in just a few weeks.

+ Large selection of materials

The most common 3D printing materials used today are plastics, but metal 3D printing is also finding an increasing number of industrial applications.