3D printer binder

What is Binder Jetting 3D printing?

In this introduction to Binder Jetting 3D printing, we cover the basic principles of the technology. After reading this article you will understand the fundamental mechanics of the Binder Jetting process and how these relate to its benefits and limitations.

How does Binder Jetting work?

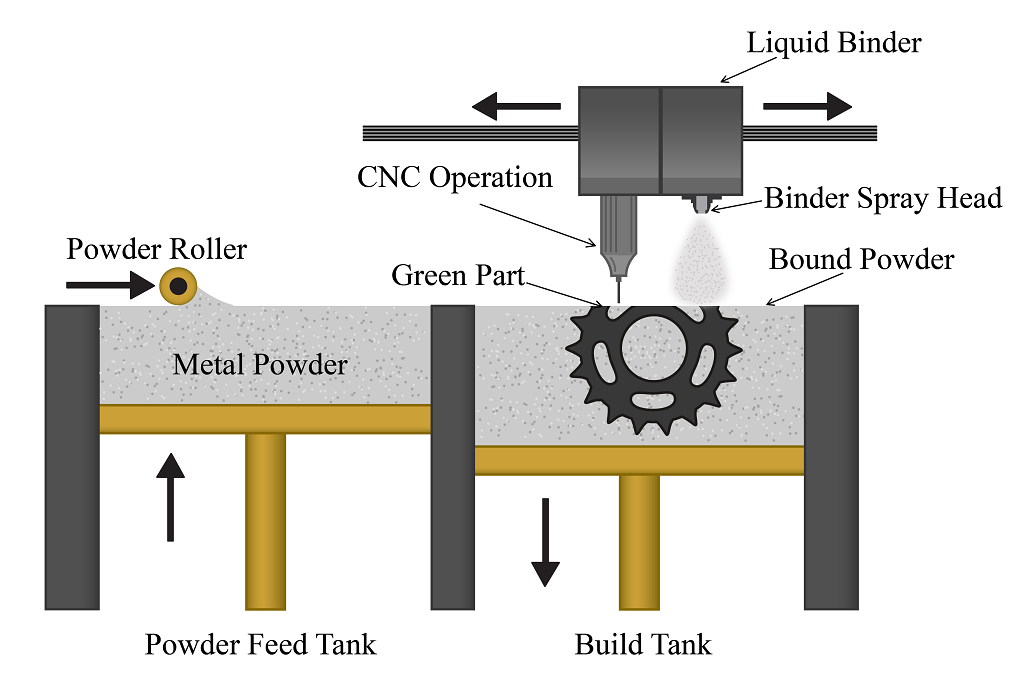

Here is how the Binder Jetting process works:

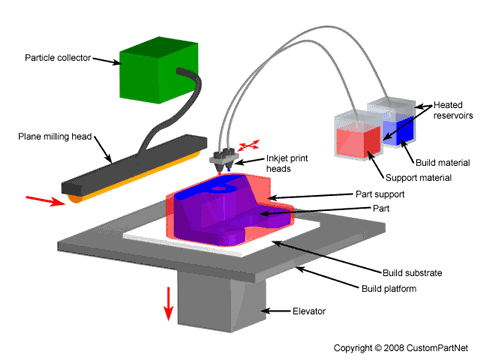

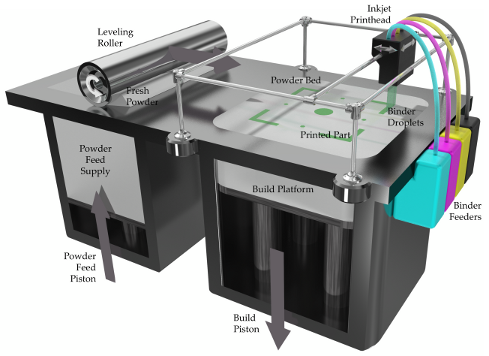

I. First, a recoating blade spreads a thin layer of powder over the build platform.

II. Then, a carriage with inkjet nozzles (which are similar to the nozzles used in desktop 2D printers) passes over the bed, selectively depositing droplets of a binding agent (glue) that bond the powder particles together. In full-color Binder Jetting, the colored ink is also deposited during this step. The size of each drop is approximately 80 μm in diameter, so good resolution can be achieved.

III. When the layer is complete, the build platform moves downwards and the blade re-coats the surface. The process then repeats until the whole part is complete.

IV. After printing, the part is encapsulated in the powder and is left to cure and gain strength. Then the part is removed from the powder bin and the unbound, excess powder is cleaned via pressurized air.

Depending on the material, a post-processing step is usually required. For example, metal Binder Jetting parts need to be sintered (or otherwise heat treated) or infiltrated with a low-melting-temperature metal (typically bronze). Full-color prototypes are also infiltrated with acrylic and coated to improve the vibrancy of colors. Sand casting cores and molds are typically ready to use after 3D printing.

This is because the parts are in a "green" state when they leave the printer. Binder Jetting parts in the green state have poor mechanical properties (they are very brittle) and high porosity.

Schematic of a Binder Jetting 3D printerWhat are the characteristics of Binder Jetting 3D printing?

Printer Parameters

In Binder Jetting, almost all process parameters are preset by the machine manufacturer.

The typical layer height depends on the material: for full color models the typical layer height is 100 microns, for metal parts 50 microns and for sand casting mold materials 200-400 microns.

A key advantage of Binder Jetting over other 3D printing processes is that bonding occurs at room temperature. This means that dimensional distortions connected to thermal effects (such as warping in FDM, SLS, DMSL/SLM or curling in SLA/DLP) are not a problem in Binder Jetting.

As a result, the build volume of Binder Jetting machines are amongst the largest compared to all 3D printing technologies (up to 2200 x 1200 x 600 mm). These large machines are generally used to produce sand casting molds. Metal Binder Jetting systems typically have larger build volumes than DMSL/SLM systems (up to 800 x 500 x 400 mm), which allows the parallel manufacturing of multiple parts at a time. The maximum part size though is restricted to a recommended length of up to 50 mm, due to the post-processing step involved.

Moreover, Binder Jetting requires no support structures: the surrounding powder provides to the part all the necessary support (similar to SLS). This is a key difference between metal Binder Jetting and other metal 3D printing processes, which usually require extensive use of support structures, and allows for the creation of freeform metal structures with very few geometric restrictions. Geometric inaccuracies in metal Binder Jetting come mainly from the post-processing steps, as discussed in a later section.

Since the parts in Binder Jetting do not need to be attached to the build platform, the whole build volume can be utilized. Thus, Binder Jetting is suitable for low-to-medium batch production. To take advantage of the full capabilities of Binder Jetting, it is very important to consider how to fill effectively the whole build volume of the machine (bin packing).

Small metal Binder Jetting with fine holes of great dimensional accuracy.

Image courtesy ofDigital Metal

Full Color Binder Jetting

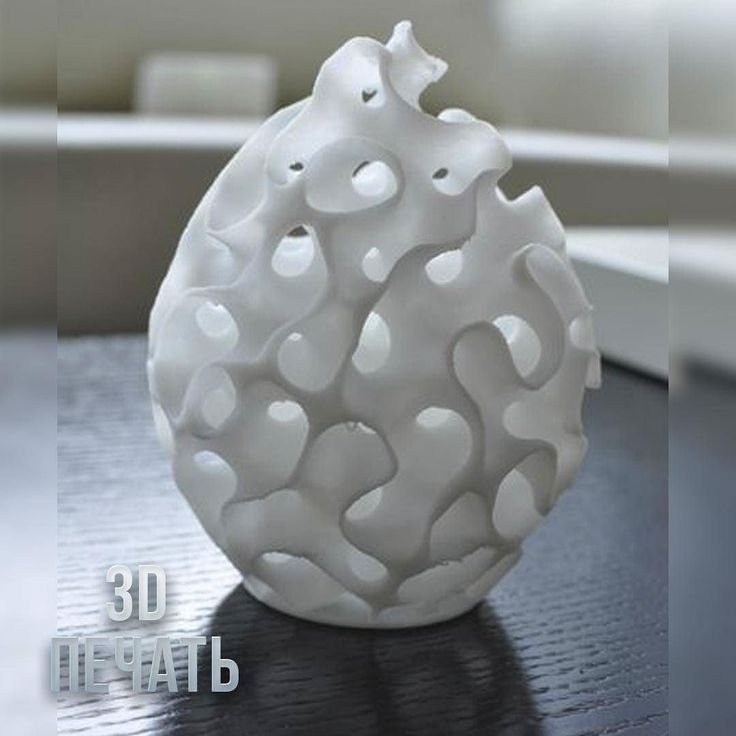

Binder Jetting can produce full color 3D printed parts in a similar way to Material Jetting. It is often used to 3D print figurines and topographical maps, because of its low cost.

Full-color models are printed using sandstone powder or PMMA powder. The main printhead first jets the binding agent, while a secondary print head jets a colored ink. Inks with different colors can be combined to produce a very large array of colors, in a similar way to a 2D inkjet printer.

After printing, the parts are then coated with cyanoacrylate (super glue) or a different infiltrant to improve part strength and enhance the vibrancy of the colors. A secondary epoxy layer can then also be added to further improve strength and color appearance. Even with these extra steps, full-color Binder Jetting parts are very brittle and they are not recommended for functional applications.

To produce full-color prints, a CAD model that contains the color information must be provided. Color can be applied to CAD models via two methods: on a per face approach or as a texture map. Applying color on a per face basis is quick and easy to implement, but using a texture map allows for more controls and greater detail. Refer to your native CAD software for specific instructions.

Color can be applied to CAD models via two methods: on a per face approach or as a texture map. Applying color on a per face basis is quick and easy to implement, but using a texture map allows for more controls and greater detail. Refer to your native CAD software for specific instructions.

Sand Casting Cores and Molds

The production of large sand casting patterns is one of the most common uses for Binder Jetting. The low cost and speed of the process make it an excellent solution for elaborate pattern designs that would be very difficult or impossible to produce using traditional techniques.

The cores and molds are generally printed with sand or silica. After printing, the molds are generally immediately ready for casting. The casted metal component is usually removed from them after casting by breaking the mold. Even though these molds are used only once, the time and cost savings compared to traditional manufacturing are substantial.

Image courtesy of ExOne

Metal Binder Jetting

Metal Binder Jetting is up to 10x more economical than other metal 3D printing processes (DMSL/SLM). Moreover, the build size of Binder Jetting is considerably large and the produced parts require no support structures during printing, enabling the creation of complex geometries. This makes metal Binder Jetting a very appealing technology for low-to-medium metal production.

The main drawback of metal Binder Jetting parts are their mechanical properties, which are not suitable for high-end applications. Nevertheless, the material properties of the produced parts are equivalent to metal parts produced with Metal Injection Molding, which is one of the most widely used manufacturing methods for the mass production of metal parts.

Infiltration & Sintering

Metal Binder Jetting parts require a secondary process after printing, like infiltration or sintering, to achieve their good mechanical properties, as the as-printed parts basically consist of metal particles bound together with a polymer adhesive.

Infiltration: After printing, the part is placed in a furnace, where the binder is burnt out leaving voids. At this point, the part is approximately 60% porous. Bronze is then used to infiltrate the voids via capillary action, resulting in parts with low porosity and good strength.

Sintering: After printing is complete, the parts are placed in a high temperature furnace, where the binder is burnt out and the remaining metal particles are sintered (bonded) together, resulting in parts with very low porosity.

An oil and gas stator printed from stainless steel and infiltrated with bronze. Notice the surface finish, which is typical for Binder Jetted parts.Image courtesy of ExOne

Characteristics of metal Binder Jetting

Accuracy and tolerance can vary greatly depending on the model and are hard to predict as they are greatly dependant on the geometry. For example, parts with length up to 25 - 75 mm shrink between 0. 8 to 2% after infiltration, while larger parts have an estimated average shrinkage of 3%. For sintering, the part shrinkage is approximately 20%. The dimensions of the parts are compensated for shrinkage by the machine's software, but non-uniform shrinkage can be an issue and must be accounted for during the design stage in collaboration with the Binder Jetting machine operator.

8 to 2% after infiltration, while larger parts have an estimated average shrinkage of 3%. For sintering, the part shrinkage is approximately 20%. The dimensions of the parts are compensated for shrinkage by the machine's software, but non-uniform shrinkage can be an issue and must be accounted for during the design stage in collaboration with the Binder Jetting machine operator.

The post-processing step can also be the source of inaccuracies. For example, during sintering, the part is heated to a high temperature and becomes softer. In this softer state, unsupported areas might deform under their own weight. Moreover, as the part shrinks during sintering, there here is friction between the plate of the furnace and the lower surface of the part, which may lead to warping. Again, communication with the Binder Jetting machine operator is key here to ensure optimal results.

Sintered or infiltrated Binder Jetting metal parts will have an internal porosity (sintering produces 97% dense parts, while infiltration approximately 90%). This affects the mechanical properties of metal Binder Jetting parts, as the voids can lead to crack initiation. Fatigue and fracture strength and elongation at break are the material properties that are most affected by internal porosity. Advanced metallurgical processes (like Hot isostatic pressing or HIP) can be applied to produce parts with almost no internal porosity. For applications where mechanical performance is critical though, DMLS or SLM are the recommended solutions.

This affects the mechanical properties of metal Binder Jetting parts, as the voids can lead to crack initiation. Fatigue and fracture strength and elongation at break are the material properties that are most affected by internal porosity. Advanced metallurgical processes (like Hot isostatic pressing or HIP) can be applied to produce parts with almost no internal porosity. For applications where mechanical performance is critical though, DMLS or SLM are the recommended solutions.

An advantage of metal Binder Jetting compared to DMLS/SLM, is the surface roughness of the produced parts. Typically, metal Binder Jetted parts have a surface roughness of Ra 6 μm after post-processing, which can be reduced to Ra 3 μm if a bead-blasting step is employed. In comparison, the as-printed surface roughness of DMLS/SLM parts is approximately Ra 12-16 μm. This is particularly beneficial for parts with internal geometries, for example internal channels, where post-processing is difficult.

The table below summarizes the differences in the main mechanical properties of Stainless Steel parts, printed with Binder Jetting and DMLS/SLM:

| Binder Jetting Stainless Steel 316 (sintered) | Binder Jetting Stainless Steel 316 (bronze infiltrated) | DMLS/SLM Stainless Steel 316L | |

|---|---|---|---|

| Yield Strength | 214 MPa | 283 MPa | 470 MPa |

| Elongation at Break | 34% | 14.5% | 40% |

| Modulus of Elasticity | 165 GPa | 135 GPa | 180 GPa |

What are the benefits & limitations of Binder Jetting 3D printing?

The key advantages and disadvantages of the technology are summarised below:

Binder Jetting produces metal parts and full-color prototypes at a fraction of the cost compared to DMLS/SLM and Material Jetting respectively.

Binder Jetting can manufacture very large parts and conplex metal geometries, as it is not limited by any thermal effects (e.g. warping).

The manufacturing capabilities of Binder Jetting are excellent for low to medium batch production.

Metal Binder Jetting parts have lower mechanical properties than DMSL/SLM parts, due to their higher porosity.

Only rough details can be printed with Binder Jetting, as the parts are very brittle in their green state and may fracture during post processing.

Compared to other 3D printing process, Binder Jetting offers a limited material selection.

The main characteristics of Binder Jetting are summarized in the table below:

| Binder Jetting | |

|---|---|

| Materials | Metals, Ceramics (sand) |

| Dimensional accuracy | Metal: ± 2% or 0. 2 mm (down to ± 0.5% or ± 0.05) Full-color: ± 0.3 mm Sand: ± 0.3 mm 2 mm (down to ± 0.5% or ± 0.05) Full-color: ± 0.3 mm Sand: ± 0.3 mm |

| Typical build size | Metal: 400 x 250 x 250 mm (up to 800 x 500 x 400 mm) Full-color: 200 x 250 x 200 mm (up to 500 x 380 x 230 mm) Sand: 800 x 500 x 400 (up to 2200 x 1200 x 600 mm) |

| Common layer thickness | Metal: 35 - 50 μm Full-color: 100 μm Sand: 200 - 400 μm |

| Support | Not required |

Ready to transform your CAD file into a custom part? Upload your designs for a free, instant quote.

Get an instant quoteWhy Binder Jetting? | Desktop Metal

As the first additive manufacturing systems to unlock benefits like mass production of end-use parts, mass customization, tooling-free manufacturing and more, the Shop System and Production System are poised to kick-start a revolution in manufacturing, what Desktop Metal calls Additive Manufacturing 2. 0.

0.

And at the heart of both systems is binder jetting, a technology that enables additive manufacturing to compete with traditional mass production methods by delivering a host of benefits - chief among them speed.

Because they’re built around inkjet print heads - the same type of print heads found in millions of at-home printers - binder jetting printers can produce parts as much as 100 times faster than laser powder bed fusion systems.

While that speed allows binder jetting systems to deliver per-part costs that can compete with traditional processes like casting and forging, speed is just one of many advantages.

Binder jetting also offers many of the traditional 3D printing benefits - everything from the ability to create complex geometry, including internal features and channels, to unlocking generative design to assembly consolidation and more.

It’s the combination of those benefits with the speed of binder jetting that truly unlocks the potential of Additive Manufacturing 2. 0.

0.

Besides being fast and capable of manufacturing complex shapes, binder jetting systems are also incredibly accurate.

With a native resolution of 1200 dpi, the Shop System is the highest resolution single-pass binder jetting system available, and is capable of producing as many as 670 million drops of binder each second. That precision makes it easy to create parts - like this clipper blade - that feature incredibly fine details that would normally require expensive tooling.

The Production System, meanwhile, combines 1200 dpi resolution and layer heights as small as 50 µm with a unique Single Pass Jetting system that uses every movement of the print head to build parts.

The result is a system that is not only accurate enough to print a watch bezel with precise detailing around its edge, but also fast enough to produce as many as 1,200 of them in a single build, at a cost of just $1.06.

Like other 3D printing approaches, binder jetting’s tooling-free nature makes it easy to customize designs.

Unlike other approaches, though, binder jetting also enables batch production, meaning manufacturers can produce multiple versions of a single part in a single print, ultimately helping to reduce part costs.

One of the other key areas where binder jetting systems excel has to do with what happens after parts are printed. For many laser-based systems, the first step following printing is often hours of post-processing to machine away support structures and free parts that must be welded to the printer’s build plate.

Binder jet parts, by comparison, are supported by loose powder in the build chamber, eliminating need for time-consuming post processing. The lack of support structure also allows parts to be densely nested, maximizing the number of parts produced per build and helping to ultimately lower per-part costs.

Further reducing part costs is the fact that some binder jetting systems - particularly the Production System - use low-cost MIM powders, meaning customers can rely on established suppliers to deliver the volume and variety of metal powder needed to support volume production.

Laser-based systems, by comparison, have a limited materials menu. Because they only work with low-oxygen metal powders, their material costs can reach as high as $60 per kilogram, resulting in finished part costs that run into the hundreds of dollars per kilogram - far too costly for mass production.

Binder jet systems can recover and reuse loose powder - the Production System can be recycled as much as 99 percent of unused powder - resulting in less waste and more cost efficiencies.

With Desktop Metal-engineered powders and processing parameters, the Shop System is designed to be a turnkey binder jetting solution, allowing users to easily go from design to finished part.

Among the most important characteristics of those parts is the fact that binder jet parts are isotropic, or equally strong in all directions.

That hasn’t always been true for 3D printed parts. Because they’re built up layer-by-layer, some parts - depending on printing method - may be stronger in one direction than another. To compensate for the difference, designers were forced to reorient parts for printing to ensure mechanical stresses fell along their strongest axis.

To compensate for the difference, designers were forced to reorient parts for printing to ensure mechanical stresses fell along their strongest axis.

Binder jet parts, by comparison, emerge from the furnace fully dense, meaning they’re equally strong in all directions, giving designers and engineers greater freedom to both design and print parts in the way that best suits their needs.

Binder jetting also changes the cost equation wWhen compared to traditional manufacturing, which have largely been dominated by labor and material costs.

Binder jetting, by comparison, uses less expensive materials, but has higher equipment costs, placing more emphasis on equipment and labor costs associated with depowdering.

Because they’re faster and more productive, binder jet systems can help drive down those equipment costs by allowing manufacturers to more quickly amortize the cost of equipment over larger production volumes. On the labor side, costs will be driven down as automation continues to develop.

By investing in binder jet systems, manufacturers can ultimately expect to see a variety of savings - the initial savings from lower material cost and production efficiency and speed, and later savings from reduction in labor cost.

Binder jetting’s impact, however, seems likely to reach beyond the manufacturing floor.

A key technology driving the emergence of Additive Manufacturing 2.0, today is poised at the edge of a revolution, one that will reshape how we manufacture many of the things we use everyday.

China Inorganic Binder Sandblast 3D Printer Metal Casting Manufacturers, Suppliers - Made in China

Company Profile:

Among all Chinese 3D printer manufacturers, FHZL stands out with its intelligent 3D printing machine. As the first enterprise to commercialize sand core 3D printing technology, FHZL has accumulated more than twenty years of experience, supplying both high quality industrial sand core 3D printing systems and fast service for all kinds of complex metal parts based on our own 3D printing technology. for various industries such as automotive, military, mining, pumps and valves, new energy, etc.

for various industries such as automotive, military, mining, pumps and valves, new energy, etc.

Products:

1. We offer sand 3D printers with various prints to satisfy various customer requests:

|

| 9000 9000 9000 9000 |

0 PC2200 | 2200X1000X800 mm, 1760 L |

| PCM18000006 | |

| PCM1500 | 1500X1000X700мм, 1050л |

| PCM1200 | 1200X1000X600 мм, 720 л |

| PCM800 | 800X750X500 мм, 300 л |

| PCM300 | 300X250X250mm 18. |

0030

PCM800

49 l / h

PCM300

6 l / h

3. For prototyping in 3D-printed FHZLs FHZL for sands for the sands. binders and various types of sand, which provides high flexibility in the use of consumables for customers:

| Acceptable binder types: 91 |

Benefits of FHZL sand 3D Printer:

● Low operating costs: Machines are priced much lower than competitors, and consumable optimization helps customers reduce costs.

● Low maintenance cost: only 2-4 printheads are required for printing, and the printhead life is up to 5000 hours. Most wear parts are from top foreign brands with superior quality. So customers don't have to spend a lot on maintenance.

Most wear parts are from top foreign brands with superior quality. So customers don't have to spend a lot on maintenance.

● Prompt and professional service: Customers will be provided with a comprehensive pre-sales service, including twice training and necessary technical data, so that their representatives can handle basic operations and solve common problems themselves. In addition, 7X24h service is available.

hot label : inorganic binder, inkjet sand 3D printer, metal casting, China, manufacturers, suppliers, made in China

OMarket

Our news

10.10.2022 OMarket.kz updates (10.10.2022)

05.10.2022 Legal Information for Customers

09/22/2022 OMarket.kz updates (09/22/2022)

Subscribe to store news

Subscribe to the newsletter and receive the latest news and promotions from our store.

Store News

Transport

Industrial chemicals

Auto goods

Audio, Video, TV

Household appliances

Water supply and sewerage

Geodetic instruments and equipment

Children's goods

Leisure, books

Test equipment

Stationery

Computers

Beauty and health

Furniture

Medical supplies

Laundry and dry cleaning equipment

Footwear

Clothing

Security and safety

Food processing equipment

Printing equipment and materials

Party paraphernalia

Foodstuffs

Industrial equipment

Professional equipment

Symbols

Sports, tourism

Construction, repair

Phones and gadgets

Goods for home and garden

Office supplies

Articles for animals

Fuel

Commercial equipment

Jewelry and accessories

Street improvement

Educational equipment

Household goods

Agriculture

Paper for office equipment SvetoCopy Classic, А4, 500 sheets, white 2 410 tenge

Sorghum broom LLP "Kazkomproekt" 650 tenge

Floor cloth OfficeClean, 80*100cm, cotton 144 tenge

General notebook Vector A4, 96 sheets, cell, blue cover 411 tenge

Paper for office equipment SvetoCopy Classic, А3, 500 sheets, white 5 244 tenge

Ballpoint pen Cello 'Maxriter XS' blue, 0.

75L

75L