3D printer alexandria

3D Printing Service for Alexandria, Virginia

CapabilitiesCustom Online 3D Printing ServiceVirginiaAlexandria

High Quality Alexandria, Virginia 3D Printing | 60+ Materials Available

Endless Options

Choose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

Easy to Use

Get your parts delivered right to your door without the hassle of sourcing, project management, logistics, or shipping.

Quality Assurance

Our number one job at Xometry is making your custom parts to your specifications.

Your Alexandria, Virginia 3D Printing Service: 3D Prototypes and Production Parts

A Global Leader in Industrial-Grade 3D Printing

Xometry is an industry-leading 3D printing service. Whether you need prototypes or production parts, we can make them for you in as fast as a day. We are your one-stop-shop for accurate, precise custom 3D printed parts at a low cost. Upload your 3D CAD file to get a quote and lead time within seconds. We use the latest additive manufacturing processes to build affordable functional prototypes & end-use parts in over 60 metals and plastics.

We offer eight high-quality 3D printing processes including selective laser sintering, fused deposition modeling, stereolithography, direct metal laser sintering, polyjet, Carbon DLS, binder jet metal, and HP Multi Jet Fusion. We use commercial and industrial-grade printers such as Stratasys Fortus 900mc and Fortus 450 FDM, EOS Polymer Laser Sintering (SLS) and DMLS, Concept Laser, SLM Solutions, 3D Systems, ExOne, and more.

Xometry's High Quality 3D Printing Services

Selective Laser Sintering (SLS)

Selective Laser Sintering (SLS) is a powerful 3D printing technology that produces highly accurate and durable parts that are capable of being used directly in end-use, low-volume production, or for rapid prototyping.

An additive manufacturing layer technology, SLS involves the use of a high power laser (for example, a carbon dioxide laser) to fuse small particles of plastic powders into a mass that has a desired three-dimensional shape. The laser selectively fuses powdered material by scanning cross-sections generated from a 3-D digital description of the part (for example from a CAD file or scan data) on the surface of a powder bed. After each cross-section is scanned, the powder bed is lowered by one layer thickness, a new layer of material is applied on top, and the process is repeated until the part is completed.

The laser selectively fuses powdered material by scanning cross-sections generated from a 3-D digital description of the part (for example from a CAD file or scan data) on the surface of a powder bed. After each cross-section is scanned, the powder bed is lowered by one layer thickness, a new layer of material is applied on top, and the process is repeated until the part is completed.

Download the SLS Design Guide.

Stereolithography (SLA)

Stereolithography (SLA) is a robust 3D printing technology that produces extremely accurate and high-resolution parts that are capable of being used directly in end-use, low-volume production, or for rapid prototyping.

SLA is an additive manufacturing process that focuses an ultraviolet (UV) light on a vat of photopolymer resin. It offers higher resolution printing than many other 3D printing technologies, allowing customers to print parts with fine details and surface finishes. SLA 3D printing is a highly-versatile platform for making custom parts in prototype and production settings; often acting as a stand-in for injection-molded plastic parts.

Xometry offers both standard and high-resolution options for fine detail parts, and can also print larger sized parts and products, with some materials offering up to a 58" inch build area. In addition, Xometry's manufacturing partner network allows us to offer a larger variety of materials than other 3D printing companies - we offer a wide range of both Accura and Somos brand materials.

Download the SLA Design Guide.

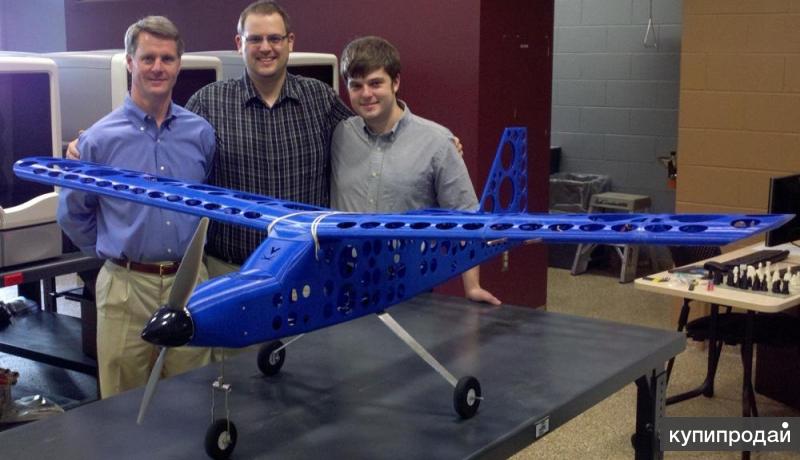

Fused Deposition Modeling (FDM)

Fused Deposition Modeling (FDM) is a 3D printing technology widely known for its speed, accuracy, and competitive cost. A machine precisely extrudes melted plastic filament to create a part. Parts are very rigid, especially compared to Selective Laser Sintering (SLS), which makes them a great fit for projects with a rigidity requirement. Xometry's FDM solution offers large build volumes up to 24″ x 36″ x 36″, a variety of colors, and a diverse selection of production-grade thermoplastics — from ABS to Polycarbonate to Ultem.

Download the FDM Design Guide.

HP Multi Jet Fusion (HP MJF)

HP Multi Jet Fusion is a new 3D printing technology that produces highly accurate and durable parts that are capable of being used directly in end-use, low-volume production, or for rapid prototyping. Since the process uses well-established 2D printing ink-jetting, it has remarkably fast layer times compared to other powder bed fusion technologies.

Download the HP Multi Jet Fusion Design Guide.

PolyJet 3D (PJ3D)

PolyJet 3D is a 3D printing technology known for its customizable material properties and excellent surface finish. It works by jetting UV curable resin onto a build tray in a process that is somewhat similar to inkjet printing. PolyJet 3D printing offers one of the most advanced industrial 3D printing solutions available, producing parts with incredible precision and speed. It also supports a wide variety of build materials including rigid and rubber-like plastics. Xometry's PolyJet solution has a maximum build envelope of 19. 3 × 15.4 × 7.9 in. (490 × 390 × 200 mm) in a variety of colors and materials.

3 × 15.4 × 7.9 in. (490 × 390 × 200 mm) in a variety of colors and materials.

Download the PolyJet 3D Design Guide.

Direct Metal Laser Sintering (DMLS)

Direct Metal Laser Sintering (DMLS) is an 3D metal printing technology that builds prototype and production metal parts from a CAD file using a laser to selectively fuse a fine metal powder in either stainless steel or aluminum materials. A DMLS machine is capable of producing highly complex features and all-in-one assemblies using metal materials that would be difficult to achieve with subtractive manufacturing techniques.

Our DMLS metal 3D printing service typically offers build volumes up to 250 x 250 x 325 mm, but we may be able to accommodate larger part volumes upon request in the quote. (See our Manufacturing Standards for more details) A good first step is to find out the cost of the parts you need using DMLS and compare them to other 3D printing processes and CNC machining.

Download the DMLS Design Guide.

Carbon DLS™

Carbon DLS™ uses digital light projection, oxygen-permeable optics, and programmable liquid resins to produce products with end-use durability, resolution and surface finish. This 3D printing technology is called Digital Light Synthesis™, or DLS for short. Another legacy term for the process is Continuous Liquid Interface Production (CLIP). Along with Carbon’s custom liquid resins, DLS unlocks new business opportunities and product designs previously impossible, including mass customization and on-demand inventory of end-use products.

Carbon bridges, and sometimes substitutes, for processes like Urethane Casting and Injection Molding service production, because the materials are urethane-based or epoxy-based, giving excellent mechanical properties. There are even elastomer and silicone resins that outperform most additive manufactured rubber-like materials.

The typical build area is 7.4” x 4.6” x 12.8”. Parts with dimensions exceeding 4” x 4” x 6” will require manual review.

Download the Carbon DLS Design Guide.

Metal Binder Jetting

With binder jetting, an inkjet print head quickly deposits a bonding agent onto a thin layer of powdered particles -- either metal, sand, ceramics or composites. This process is repeated, layer-by-layer, using a map from a digital design file, until the object is complete. Binder jetting is offered through our Digital RFQ Marketplace through Xometry's partnership with ExOne.

Download the Binder Jetting Design Guide.

Locations near Alexandria, Virginia

Arlington

VirginiaBethesda

MarylandSilver Spring

MarylandCollege Park

MarylandAnnapolis

MarylandBaltimore

MarylandHagerstown

MarylandRichmond

VirginiaLancaster

PennsylvaniaCharlottesville

VirginiaHarrisburg

PennsylvaniaWilmington

DelawareNewport News

VirginiaPhiladelphia

PennsylvaniaAltoona

PennsylvaniaNorfolk

VirginiaChesapeake

VirginiaState College

PennsylvaniaJohnstown

PennsylvaniaVirginia Beach

Virginia

Ready to start making custom 3D printed parts?

Alexandria 3D Printing | COLETEK

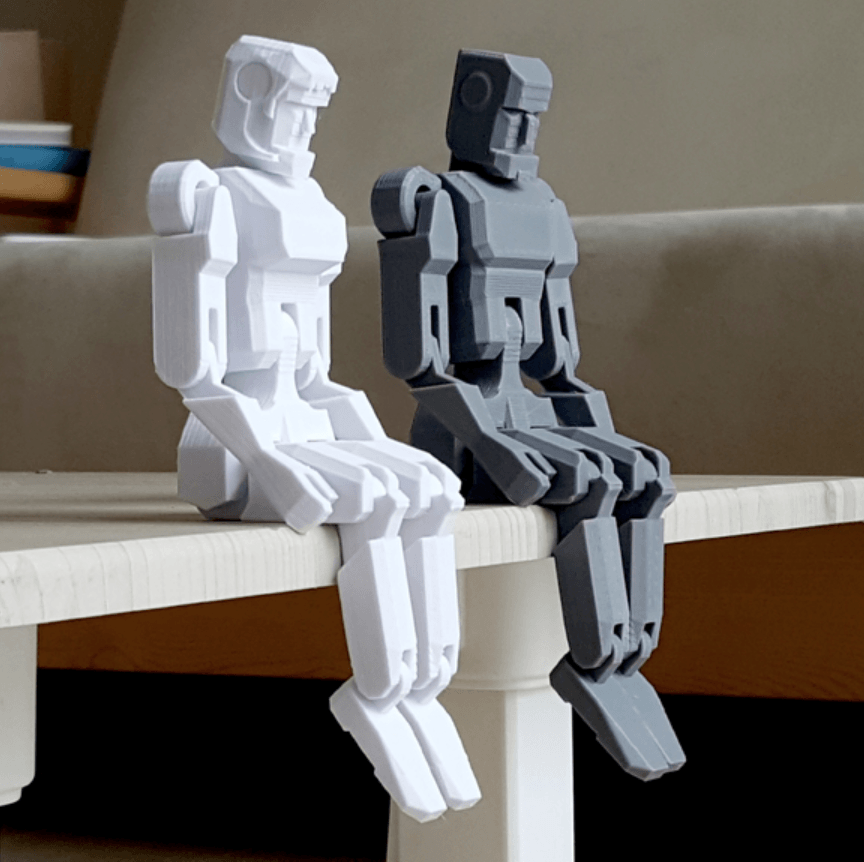

ONLY AVAILABLE TO OUR CLIENTS THAT WE DO 3D CAD DESIGN WORK FORWith 3D Printing we can provide rapid prototyping or final solutions for you ideas, or products. 3D Printing is the future of product development for all plastic shapes, which can be assembled together to more complex (possible moving) prototype or product. To learn more about 3D Printing please see Wikipedia.

3D Printing is the future of product development for all plastic shapes, which can be assembled together to more complex (possible moving) prototype or product. To learn more about 3D Printing please see Wikipedia.

To get more information and pricing, please email us your 3D computer model. We accept most file types, however we would prefer a STL (.stl), OBJ (.obj), STEP (.stp) or IGES (.igs).

3D Printing via Stereolithography (SLA)

We can provide you with 3D prints via Stereolithography (SLA). From our experience SLA 3D Printing is the best 3D Printing technology. Selective Laser Sintering (SLS) 3D prints are high precision, but are weak and generally not suitable for function testing. In the past we have used FDM 3D Printing for function testing, due to its high strength. However SLA is just as strong as FDM, if not stronger with some resins. The only issue with SLA is it is more costly.

In summary SLA 3D Printing is high resolution, high strength & precision, and outstanding surface finish!

SLA Printing Areas

- Form-2 - 145 L x 145 W x 175 H mm

NOTE: We can create bigger parts, via splitting and gluing.

SLA Resolution

0.05mm or 0.025mm (however we generally do flexible at 0.1mm).

NOTE: We can do higher resolutions, if you would like to save on time and machine-hour costs.

Tech Specs / Resin Datasheets

https://formlabs.com/3d-printers/tech-specs/

SLA Material / Resin

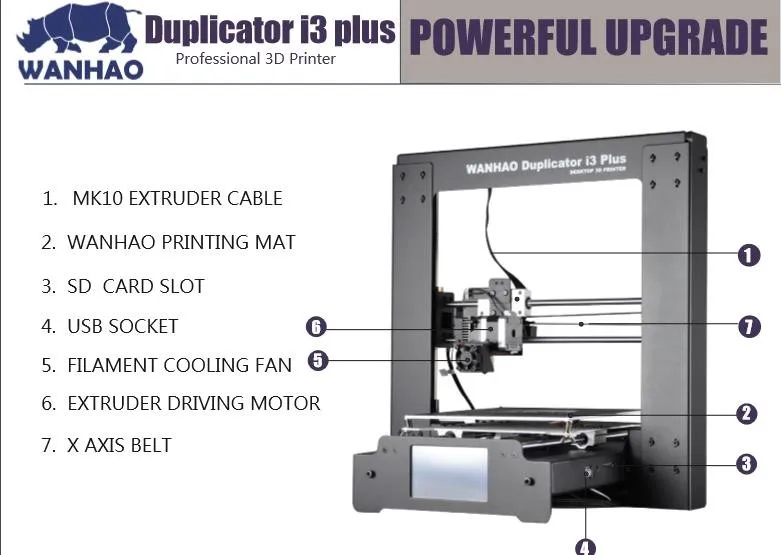

3D Printing via Fused Deposition Modeling (FDM)

We can also provide you with 3D prints via Fused Deposition Modeling (FDM) 3D printers, which is great for quick validation of your physical design. The primary issue with these prints is shrinkage and warpage can occur on models and is purely geometry dependent.

FDM Printing Areas

- UP BOX+ - 255 L x 255 W x 205 H mm

(ideal for high quality/precision) - Replicator Z18 - 305 L x 305 W x 457 H mm

(ideal for large prints) - Replicator 2X - 246 L x 152 W x 155 H mm

(ideal for filament experimentation)

NOTE: We can create bigger parts, via splitting and plastic welding or gluing.

FDM Resolution

0.1mm (however we generally do flexible at 0.25mm).

NOTE: We can do higher resolutions, if you would like to save on time and machine-hour costs.

FDM Material / Filament

Other materials/colours are possible, but adds lead time.

How Do We 3D Print Your Object?

To 3D print an object, a 3D computer model is required. You have three options:

- Email us your 3D computer model - we accept most file types, however we would prefer a STL (.

stl), OBJ (.obj), STEP (.stp) or IGES (.igs).

stl), OBJ (.obj), STEP (.stp) or IGES (.igs). - Ask us to create your 3D computer model.

- 3D scanning and post-processing.

Our capacity: 1x SLA 3D printer and 3x FDM 3D printers.

How Do We Charge?

Our printing prices are based on three factors:

- Man-hours: Includes print setup, part removal, support material removal, hand finishing where required, assembly if required, and in some large part cases gluing or plastic welding. This is done at our typical mechanical engineers hourly rate.

- Machine-hours: Rate based on type of machine (e.g. SLA or FDM). This is a low hourly rate.

- Materials: The cost of the filament or resin used for the print. The material includes the actual part and the support material. Generally a negligible cost.

Our minimum order is $180 + GST, mostly due to the labour involved for support material removal and hand finishing if/where required.

One-off Part?

Are you looking for a one-off part to replace something that is broken, or no longer on the market? Unfortunately, we are confident that in most cases 3D Printing services is not financially feasible.

Generally 3D Printing is used for new product development prototyping. And therefore is a cheaper alternative to production methods such as plastic injection moulding, blow moulding, etc.

Mexico has the world's first 3D printed residential area

Not far from a city in southern Mexico, a ten meter printer has recently printed walls for the world's first 3D printed residential area.

At the beginning of December, the printed houses received a roof, windows and interior decoration. New Story, a charity behind the project, believes 3D printing can bring affordable housing to people in the poorest parts of the world. “We believe we were able to prove the reality of this idea by taking this device to rural Mexico where there is seismic activity and being able to print the first houses with it,” says Brett Hagler, CEO and co-founder of New Story. nine0003

nine0003

Founded five years ago, his company provides housing for people living in extreme poverty. The organization has already built more than 2,700 houses in the traditional way in Bolivia, Mexico, El Salvador and Haiti.

Photo: New Story

After the 2010 earthquake in Haiti, it was difficult to rebuild houses after the destruction, but New Story improved the construction process so that housing could be built faster. The organization realized that with the help of new technology, it was possible to work faster and at less cost. Two years ago, she partnered with Icon to develop a 3D printer capable of printing even under the most difficult conditions. nine0003

The printer is called Vulcan II. This is not the first device that can print an entire house. However, a new residential area in Mexico of 50 printed houses will be the first place where this technology has been used on such a scale. Other companies have experimented with building printed houses, but all trials have been conducted in controlled environments or locations with a low risk of natural disasters.

Initially, the New Story team planned to print houses in another part of Mexico, but ran into difficulties - for a long time the organization could not obtain a building permit from the government. Therefore, it was decided to print houses further south, in Tabasco, a state bordering Guatemala. The new location had a higher risk of earthquakes, so the design of the houses had to be finalized. nine0003

Photo: New Story

After successful testing, the printer was trucked to the state, but it got stuck in customs for three months. “The device is brand new, obviously it doesn’t exist [in the database],” Hagler explains. When the 3D printer arrived at its destination, the rainy season began. At some point, the entrance to the construction site was flooded, and no one could get there for a week.

However, the most important test—whether the printer can print on site at home—succeeded. The printer lays out the concrete mixture in layers, and the floors and walls are obtained. The program monitors the weather conditions and adjusts the mixture accordingly. “The weather can be dry in the morning and wet in the evening, so you have to change the viscosity of the mixture to keep the print quality the same all day,” explains New Story co-founder Alexandria Lafzi. nine0003

The program monitors the weather conditions and adjusts the mixture accordingly. “The weather can be dry in the morning and wet in the evening, so you have to change the viscosity of the mixture to keep the print quality the same all day,” explains New Story co-founder Alexandria Lafzi. nine0003

The printing process is autonomous, the team can only make minor adjustments to the scheme. In this case, you can print several houses at the same time. The first two houses printed at the same time, the total printing time was 24 hours, but it lasted several days because the team only wanted to work during the day. In the future, the authors of the project hope to be able to run the printer for longer periods to speed up the construction process.

The resulting houses have two bedrooms, a living room, a kitchen, and a bathroom, much better than the simple huts the locals live in. Families who will live in printed houses earn an average of $76.50 a month. “For many families, this will be the first home with a toilet outside the yard and a full sewer,” says Lafzi. And, unlike huts, such houses are able to withstand an earthquake. The charity is partnering with the local government to provide land and infrastructure to build roads and provide electricity to 50 families who need housing the most. When New Story finishes printing all the houses, new tenants will immediately move into them. nine0003

And, unlike huts, such houses are able to withstand an earthquake. The charity is partnering with the local government to provide land and infrastructure to build roads and provide electricity to 50 families who need housing the most. When New Story finishes printing all the houses, new tenants will immediately move into them. nine0003

Photo: New Story

Some families have already inspected the resulting houses and noted that they do not leak during heavy rain. “When it rains, the roof of our house starts to leak, and the worst thing is when it happens at night,” says Candelaria Hernandez, who lives in a one-room hut with seven members of her family. “We have to wake up and arrange the pans so that things don’t get wet.”

“The construction industry needs a paradigm shift,” says Alex Le Roux, co-founder and CTO of Icon. “We don’t have to choose between affordability and reliability.” The company plans to print more new houses and develop its technology. Many representatives of local governments in Latin America have already shown interest in the project and even visited the current construction site.