3D printers features

3D Printer Features | Airwolf 3D

SPEED

Airwolf 3D AXIOM models operate at printing speeds of up to 250 millimeters per second, and travel speeds as high as 400 millimeters per second. At Airwolf 3D we understand that time is critical, and this is why we have developed one of the fastest desktop 3D printers on the market.

SIZE

Size limitation is currently a major drawback with most 3D printers on the market. Not at Airwolf 3D. With a huge build platform, the AXIOM series can print large models without having to print in multiple pieces.

ACCURACY

With a 40 micron minimum layer height, and an X, Y resolution of 20 microns, the AXIOM series printers are extremely accurate. Airwolf 3D has worked hard on balancing resolution and speed, and has come up with a system that provides the best of both worlds.

DURABILITY

At Airwolf 3D, we don’t only make and sell 3D printers, but we also use them as a tool on a daily basis for our own production line. This requires a durable machine that requires little maintenance. We hold these same standards for our customers, and have constructed our printers with the highest quality parts possible.

MATERIALS

The list continues to grow……At 40 materials and counting, the possibilities are endless. With a large temperature range, and the ability to reach up to 320C on the hotend, the AXIOM series is able to print with numerous materials, ranging from PLA and ABS to TPU, Nylon and Polycarbonate.

| MATERIAL | DESCRIPTION | TEMPERATURE | BED TEMP. | USER CLASS | HOT-END COMPATIBLE | ||

| Material temperatures given are just starting points. These temperatures may vary depending on printer, hot end, outside temperature, filament quality, filament age, and many other factors. Use these temperatures as a starting point, but please keep in mind they may need to be adjusted slightly. | |||||||

| ABS (Acrylonitrile Butadiene Styrene) | Acrylonitrile Butadiene Styrene is the most commonly used 3D printing material. This is the same material that most Lego building blocks are made of. Airwolf 3D utilizes ABS in the manufacture of many of its components because of its ease-of-use and resistance to high temperatures. | 250 °C | 120 °C | Standard 3D Printing Materials | JR2X, JRX, JR | ||

| ALLOY 910 | With a combined tensile strength higher than the strongest co-polyesters, the durability of Nylons, a shrinkage factor that rivals our t-glase, a vast range of chemical resistance and a 95C working range, you now have one solution easily printable at 245C. | 245 °C | 80 °C | Engineering 3D Printing Materials | JR2X, JRX, JR | ||

| Bamboofill | This is a PLA/PHA based compound mixed with natural bamboo fibers. | 195-220 °C | 50-60 °C | Infused Hybrid Materials | JR2X, JRX, JR | ||

| Bendlay | This is an extremely translucent material that will allow you to print nearly clear items, while at the same time being remarkably resilient and elastic. | 210°C-240 °C | 20-55 ° C | Standard 3D Printing Materials | JR2X, JRX, JR | ||

| Brassfill | This product is based on a proprietary PLA formulation and allows the user to achieve a polished golden appearance when finished. | 190-210 ° C | 20-55 ° C | Infused Hybrid Materials | JR2X, JRX, JR | ||

| Bronzefill | This is composed of an 80/20 bronze to PLA mixture which results in a metallic finish. Sanding and polishing Bronzefill will result in a shiny metalic finish. Sanding and polishing Bronzefill will result in a shiny metalic finish. | 190-210 ° C | 20-55 ° C | Infused Hybrid Materials | JR2X, JRX, JR | ||

| bioFila Linen | bioFila Linen is composed of organic material known as lignins that are suspended in a PLA matrix. Lignins are responsible for providing strength and rigidity to the cell walls of plants and are one of the main ingredients found in paper. The resulting filament is non toxic and biodegradable and produces prints with a linen-like texture. | 165 – 200 ° C | 90 ° C | Standard 3D Printing | JR2X, JRX, JR | ||

| Carbon Fiber ABS | CFR-ABS consists of carbon fibers suspended in an ABS matrix. The filament is ideal for applications that require high strength and rigidity. The resulting print will have a matte black appearance. | 160 – 190 ° C | 220 – 240 ° C | Infused Hybrid Materials | JR2X, JRX, JR | ||

| Carbon Fiber PLA | CFPLA is a durable filament with carbon fibers suspended in a PLA matrix. The resulting 3D prints are rigid with a matte black finish and exhibit extremely low warping characteristics. | 195 – 220 ° C | 50 ° C | Infused Hybrid Materials | JR2X, JRX, JR | ||

| ColorfabbXT | This product is similar to PLA but with improved temperature resistance, and bonding strength. Printed projects have a smooth glossy sheen. | 240 – 260 ° C | 60 – 70 ° C | Standard 3D Printing Materials | JR2X, JRX, JR | ||

| Copperfill | When sanded and polished this material will produce a metallic shine. Copperfill is approximately 3 times heavier than traditional PLA/PHA polymers, so it will create objects with a bit of heft to them. | 190-210 ° C | 20-55 ° C | Infused Hybrid Materials | JR2X, JRX, JR | ||

| ESD ABS | This belongs to a family of specialty filaments that utilize carbon wall nanotubes to produce a product that is capable of conducting electricity. This product is commonly used in applications that require electrostatic discharge (ESD) protection. | 240 – 245 ° C | 110 ° C | Standard 3D Printing Materials | JR2X, JRX, JR | ||

| GEL-LAY | This is a jelly-like material that is ideal for creating rubbery, squishy, objects. Gel-Lay is part rubber-elastomeric polymer and part PVS. When rinsed in water only the rubber polymer remains as a micro-porous and flexible object. | 225 – 235 ° C | 20 – 55 ° C | Standard 3D Printing Materials | JR2X, JRX, JR | ||

| HIPS | HIPS is short for High Impact Polystyrene. It has very similar properties to ABS and works well as a support material using Limonene to dissolve it. | 240 ° C | 120 ° C | Standard 3D Printing Materials | JR2X, JRX, JR | ||

| Igus Iglidur | Igus iglidur is a relatively new material that is up to 50 times more abrasion resistant than conventional 3D print materials. | 240 ° C | 120 ° C | Engineering 3D Printing Materials | JR2X, JRX, JR | ||

| LAY FOMM 40 | This product is composed of rubber-elastomeric polymer and PVA giving it a foamy, porous consistency. When rinsed in water only the rubber polymer remains as a micro-porous, flexible, object. | 220 – 230 °C | 40 – 60 °C | Standard 3D Printing Materials | JR2X, JRX, JR | ||

| LAY-FELT | This product prints porous, flexible, objects with a felt consistency. When rinsed in water the PVA component dissolves leaving behind a felt-like rubbery material. | 225 – 235 °C | 20 – 55 °C | Standard 3D Printing Materials | JR2X, JRX, JR | ||

| LAY-FOMM 60 | This product is composed of rubber-elastomeric polymer and PVA giving it a foamy, porous consistency. When rinsed in water only the rubber polymer remains as a micro-porous, flexible, object that is slightly more firm than Lay-Fomm 40. | 220- 230 °C | 40 – 60 °C | Standard 3D Printing Materials | JR2X, JRX, JR | ||

| LayWOO-D3 | LayWOO-D3 is a mixture of recycled wood fibers and polymer binders. The printed wood can be made to appear rough (similar to MDF) or to have a smooth surface. | 175 – 250 °C | 30 °C | Infused Hybrid Materials | JR2X, JRX, JR | ||

| Nylon “Platinum Series” | Platinum Series Nylon is a strong, durable material that is ideal for applications that require abrasion and impact resistance. Unlike most nylon filaments, Platinum Series Nylon can print at lower temperatures which makes it better suited for use with print jobs that require two different types of materials. Platinum Series Nylon is naturally white and can be dyed with standard clothing dye to achieve custom colors. | 245 °C | 80 °C | Engineering 3D Printing Materials | JR2X, JRx | ||

| Nylon 618 | Taulman’s “618” is a high strength nylon co-polymer. It is very strong but tends to warp strongly, similar to ABS. Unlike ABS, however, it’s hard to get it to stick to the print surface. The best prints are produced when 1/4″ Garolite LE is placed over the heated bed on an Airwolf 3D printer. | 235 – 270 °C | 55 °C | Engineering 3D Printing Materials | JR2X, JRx | ||

| Nylon 645 | Taulman’s “645” offers very high strength, high durability, and good chemical resistance. | 245 – 255 °C | 45 °C | Engineering 3D Printing Materials | JR2X, JRx | ||

| NYLON 680 | The polymer is a pure polymer that is FDA approved. There are no additives used in the chemical manufacturing or extrusion processes. Nylon 680 uses processes to accommodate it’s use in FFM style/type 3D Printers. Nylon 680 uses processes to accommodate it’s use in FFM style/type 3D Printers. | 240 °C | 70 °C | Engineering 3D Printing Materials | JR2X, JRX, JR | ||

| Nylon Bridge | This filament is named “bridge” for its ability to bridge the gap between ABS and Nylon filamment for FFF style 3D printing. Nylon Bridge has strength characteristics similar to Nylon 645 but with better printing characteristics including enhanced bed adhesion. Nylon Bridge has strength characteristics similar to Nylon 645 but with better printing characteristics including enhanced bed adhesion. | 285 °C | 80 °C | Engineering 3D Printing Materials | JR2X, JRx | ||

| PCTPE | PCTPE has several unique features that allow users to print highly flexible parts with the durability of nylon polymers. PCTPE provides the smooth lustrous texture of nylon with the added flexibility offered in rubbery products like TPE. PCTPE provides the smooth lustrous texture of nylon with the added flexibility offered in rubbery products like TPE. | 240 °C | 70 °C | Standard 3D Printing Materials | JR2X, JRx | ||

| PET | PET or PolyEthylene Terephthalate is a lightweight, colorless, material commonly used to print translucent objects that are strong and impact-resistant. | 210 – 255 °C | 55 °C | Standard 3D Printing Materials | JR2X, JRx | ||

| PETG | PETG is also known as glycol modified PET, or less commonly as GPET. This material has a high degree of durability and impact resilience yet it is also very flexible and is capable of being recycled. PETG can be found in many colors including transparent. PETG can be found in many colors including transparent. | 240 °C | 80 °C | Standard 3D Printing Materials | JR2X, JRX, JR | ||

| PLA (Polylactic Acid) | This is one of the most commonly used materials in 3D printing today. It is biodegradable, easy to use, and provides great surface finish and print quality. PLA can be dissolved in lye-based drain cleaner (such as Drano) while leaving other materials such as ABS unaffected, which makes it an excellent support material. | 220 °C | 70 °C | Standard 3D Printing Materials | JR2X, JRX, JR | ||

| Polycarbonate/ABS | This is an incredibly tough material designed for strong, resilient parts. PC-ABS alloy provides vast improvements over standard ABS in terms of heat deflection, impact resistance, rigidity, and surface finish. | 285 °C | 130 °C | Engineering 3D Printing Materials | JR2X, JRX, JR | ||

| Polycarbonate | This is a strong, durable material that can be put to the test with functioning prototypes. Polycarbonate filament is a high temperature material that offers good heat resistance and layer bonding, and is produces an excellent finish when printed. | 315 °C | 135 °C | Engineering 3D Printing Materials. | JR2X, JRx | ||

| Soft PLA | This is a flexible 3D printing material that feels and acts like rubber. It prints easily and can be removed easily when used as a support material. This material is best used with small layer heights due to the increased stresses that result during flexion. | 220 – 235 °C | 20 – 55 °C | Standard 3D Printing Materials | JR2X, JRX, JR | ||

| Stainless Steel PLA | This material utilizes metallic powder suspended in PLA to produce objects that appear to be made of steel. The material may be sanded and polished to produce a metalic sheen or left with a rough texture to produce the effect seen in the picture to the left. | 195 – 220 °C | 50 °C | Infused Hybrid Materials | JR2X, JRX, JR | ||

| T-Glase | T-glase (pronounced Tee Glass) is a special formulation of PETG produced by Taulman 3D. It is made of FDA approved polymers for direct food contact in applications such as containers. Printed parts have a clear, crystal-like quality. T-glase also prints easily on acrylic, glass, and PET film. | 250 °C | 90 °C | Standard 3D Printing Materials | JR2X, JRX, JR | ||

| TPU (Wolfbend) | TPU stands for thermoplastic polyurethane. TPU has good elasticity and transparency, and it is resistant to oil, grease, and abrasion. Wolfbend TPU is much stronger than typical TPU. Layer-to-layer bonding is incredible and layer separation is virtually non-existent. | 195 – 230 °C | 70 °C | Standard 3D Printing Materials | JR2X, JRX, JR | ||

| Laybrick | This product utilizes fine milled chalk suspended in polymers to produce objects with a stone-like consistency. | 180 – 200 °C | 20 – 55 °C | Infused Hybrid Materials | JR2X, JRX, JR | ||

| Ninjaflex TPE | This is a “Thermoplastic elastomer” also known as “Thermoplastic rubber.” TPE feels rubber-like and springs back into shape when decompressed. | 240 °C | 50 °C | Standard 3D Printing Materials | JR2X, JRX, JR | ||

| PLA 4043D | This is a popular environmentally friendly form of PLA. It tends to extrude at lower temperatures than traditional PLA and appears more like ABS when printed. | 180 – 220 °C | 60 – 65 °C | Standard 3D Printing Materials | JR2X, JRX, JR | ||

| PVA | Polyvinyl alcohol is a water-soluble synthetic polymer. It prints very easily and can be used as a wash away support structure. | 170 – 190 °C | 45 °C | Standard 3D Printing Materials | JR2X, JRX, JR |

What to Look for When Buying a 3D Printer

3D printing, and accordingly 3D printers, have exploded in popularity. While once these awesome gadgets were relegated to the most hardcore makers, increasingly affordable 3D printers and a slew of resources, from downloadable 3D printable files to 3D printing software, now the masses can enjoy 3D printing at home. However, as with virtually any purchase, and especially in the technology arena, you’ll want to focus on the right features. Learn what to look for in this 3D printer buying guide!

However, as with virtually any purchase, and especially in the technology arena, you’ll want to focus on the right features. Learn what to look for in this 3D printer buying guide!

What to Look for When Buying a 3D Printer - Why Purchase a 3D Printer?

Though the price tag for even a budget 3D printer can be pretty steep, buying a 3D printer is worth it. Owning a 3D printer provides nearly limitless opportunity to create your household objects, from Raspberry Pi cases to napkin holders. You can create replacement parts for furniture, and extend the life of objects around your home.

Whereas normally you’ll need to either visit a maker space or order a print off of a website such as Thingiverse, now you can simply make your creations at home. You might even be able to make a bit of income by processing print jobs. Moreover, it’s simply fun. I have a blast with my Elegoo Neptune and Elegoo Mars printers, whipping up anything from chess pieces to a T-800 endoskeleton bust to sit under my computer monitor. Finally, it’s a fantastic learning opportunity. You’ll get hands-on with hardware and software, a better understanding of how.

I have a blast with my Elegoo Neptune and Elegoo Mars printers, whipping up anything from chess pieces to a T-800 endoskeleton bust to sit under my computer monitor. Finally, it’s a fantastic learning opportunity. You’ll get hands-on with hardware and software, a better understanding of how.

Reasons to buy a 3D printer:

3D Printer Buying Guide - What to Look for When Buying a 3D Printer

If you’re buying a 3D printer, there are tons of considerations. From resin vs. filament printers to self-levelling beds, these are the features you should look for when purchasing a 3D printer!

Resin vs. Filament 3D Printers

The first debate you’ll have is whether to opt for a resin or filament 3D printer. Both are excellent and should satisfy basic users. Generally, filament 3D printers are more common. FDM or fused deposition modelling printing melts down a string of plastic, known as filament. This filament gets melted and deposited through a HotEnd onto a bed. Then, the filament is added layer by layer until the final print is produced. When using an FDM printer, the material is deposited beginning with the bottom layer and builds up from there.

Then, the filament is added layer by layer until the final print is produced. When using an FDM printer, the material is deposited beginning with the bottom layer and builds up from there.

Resin printing, on the other hand, uses a liquid resin. The build plate lowers into a vat of resin and uses a light source to cure its liquid resin into layers. Resin printers boast better quality than their FDM printer counterparts, excelling with fine detail. However, this often comes at a price. Namely, monetary cost as well as messiness. Resin is pretty nasty stuff, making set up and clean up a chore. Moreover, resin printers are typically more expensive. Still, certain affordable resin printers are available.

3D Printer Noise

3D printer noise is a huge factor. No 3D printers are completely silent, but some remain quieter than others. Likewise, physical set up can contribute to the noise level. If you’re printing in your bedroom, 3D printer noise level plays a key role, especially since even a moderately-sized print can take the upwards of a few hours. Even if you’ve got a dedicated 3D printing area, 3D printing sounds can be heard around your home or by neighbours. Tricks such as placing your printer on a solid surface, on top of a yoga mat or carpet, and dampening surfaces help for 3D printer noise reduction.

Even if you’ve got a dedicated 3D printing area, 3D printing sounds can be heard around your home or by neighbours. Tricks such as placing your printer on a solid surface, on top of a yoga mat or carpet, and dampening surfaces help for 3D printer noise reduction.

Printing Speed

Speed of 3D printers varies. Typically, resin printers feature slower printing speeds than their FDM counterparts. If you’re merely printing for fun, speed might not matter quite as much. However, for business purposes, 3D printing speed may be more of an issue. For smaller print jobs, faster speeds don’t usually impact quality. But for larger prints, faster might come at the expense of fine details, and may even create problems such as vertical banding, or ringing. At the same time, too slow of a print could lead to stringing. Regardless, you’ll want a printer able to meet your desired printing speed requirements.

Self-levelling Bed

Among the most sought-after 3D printer features is a self-levelling bed. Manual bed levelling can be a right pain, a lengthy, frustrating process. An unlevel bed botches prints. Thankfully, many prints come with auto bed levelling features where a sensor tests various points on the print bed to best calculate the distance between the nozzle and print bed. Then, software adjustments ensure that the nozzle maintains the correct distance from the bed while printing. Although some users may prefer manual bed levelling, an auto-levelling 3D printer bed offers a fairly plug-and-print experience which massively streamlines the printing process. An auto-levelling bed is a great pick for 3D printing beginners.

Manual bed levelling can be a right pain, a lengthy, frustrating process. An unlevel bed botches prints. Thankfully, many prints come with auto bed levelling features where a sensor tests various points on the print bed to best calculate the distance between the nozzle and print bed. Then, software adjustments ensure that the nozzle maintains the correct distance from the bed while printing. Although some users may prefer manual bed levelling, an auto-levelling 3D printer bed offers a fairly plug-and-print experience which massively streamlines the printing process. An auto-levelling bed is a great pick for 3D printing beginners.

3D Printer Connectivity Options

Before you print anything, you’ll need to send a 3D printable file to your printer. This can be accomplished through several methods. Most 3D printers feature a means of connecting via USB cable. Additionally, 3D printers commonly feature an SD card slot or USB port for plugging in a flash drive or SD card. My Elegoo Neptune comes with a USB bus as well as SD card slot whereas my Elegoo Mars resin 3D printer touts a USB port for printing straight from a flash drive.

My Elegoo Neptune comes with a USB bus as well as SD card slot whereas my Elegoo Mars resin 3D printer touts a USB port for printing straight from a flash drive.

Device Footprint and Build Size

While resin, filament, bed levelling, and print speed are all essential, you’ll want to think about how much physical space you’ve got. 3D printers come in all shapes and sizes, from mini 3D printers to industrial-sized behemoths. Tied pretty directly with device footprint, there’s build size. The 3D printing volume is the total maximum size of a print. Most resin printers carry a smaller build size than comparable filament-based 3D printers. For the average user, a moderate to smaller build platform should suffice. But for later prints, you’ll need to snag a 3D printer with a larger print volume, and even then you might have to print multiple pieces, then put everything together into a larger whole.

Print Quality, Accuracy, Precision, and More

Quality and accuracy of 3D prints are hugely variable. However, accuracy doesn’t necessarily translate to precision. You might find some printers are precise but inaccurate. While accuracy is a measure of hitting a target metric, precision focuses on determining repeated actions. So a printer may be accurate insofar as it hits close to the desired spot on a print bed, but imprecise insofar as it fails to consistently deposit in the same spot repeatedly.

However, accuracy doesn’t necessarily translate to precision. You might find some printers are precise but inaccurate. While accuracy is a measure of hitting a target metric, precision focuses on determining repeated actions. So a printer may be accurate insofar as it hits close to the desired spot on a print bed, but imprecise insofar as it fails to consistently deposit in the same spot repeatedly.

Price

Finally, there’s the price. 3D printers, even budget devices, usually retail for hundreds of dollars. Nevertheless, there are loads of 3D printers under $500 which don’t compromise on quality. If you’re starting a 3D printer-centric business, such as selling 3D printed miniature figurines, consider upping your budget. But if you’re just getting a 3D printer for kicks, you might instead pick an affordable 3D printer.

3D Printer Buying Guide - Final Thoughts

Purchasing a 3D printer requires thinking about your specific use cases, preferences, and needs. Resin printers are often pricier than competing filament 3D printers but boasts better fine detail quality. However, they’re much slower than filament printers. Print volume, noise level, printing speed, and bed levelling mechanism rank among the most essential considerations. I prefer resin printers despite the messiness, smell, and slower speed. Quality of budget resin printers often surpasses that of mid-range to high-end filament printers. I’d recommend for filament printers snagging a unit with a self-levelling bed if possible, though many budget 3D printers come with a manual levelling print bed.

Resin printers are often pricier than competing filament 3D printers but boasts better fine detail quality. However, they’re much slower than filament printers. Print volume, noise level, printing speed, and bed levelling mechanism rank among the most essential considerations. I prefer resin printers despite the messiness, smell, and slower speed. Quality of budget resin printers often surpasses that of mid-range to high-end filament printers. I’d recommend for filament printers snagging a unit with a self-levelling bed if possible, though many budget 3D printers come with a manual levelling print bed.

What features do you suggest looking for when selecting a 3D printer?

Features of the operation of 3D printers and their use in practice

Many of the phenomena described in the science fiction works of Asimov, Clark or Verne have found their embodiment in reality. Nowadays, few people can be surprised by a cell phone, electric car or Skype, no matter the distance. However, there is a place for non-standard products today. We are talking about 3D printers.

However, there is a place for non-standard products today. We are talking about 3D printers.

History of 3D printers

Chuck Hull is considered the founder of 3D printing. It was he who invented the first printer at 1984 year. The new technology was called "stereolithography" and was patented in 1986. The first device based on it was created in 1988 by 3D-Systems, founded by Chuck Hull. Already in 1993, Solidscape began mass production of inkjet-based 3D printers that could produce small parts with perfect surface quality. A major breakthrough was the creation of a device that can print three-dimensional objects in color. This happened in 2005 thanks to the efforts of Z Corp. Already in 2006, a printer appeared that could reproduce half of its own components.

What is a 3D printer and how does it work? He builds the final object by layering the material. The main elements of a 3D printer are the print head and the working platform. The printhead is needed to apply the layers of material and form the object.

It can only move in a horizontal plane. The working platform moves in the vertical direction. It is necessary to place the object.

It can only move in a horizontal plane. The working platform moves in the vertical direction. It is necessary to place the object. Scheme of operation of the 3D printer

At the first stage of the device operation, its platform is in the upper position. Then the print head forms the bottom layer of the future product. After its application, the platform descends exactly to the thickness of the layer and the head applies the next one. This cycle is repeated until the required object is "grown". This is how a 3D printer works. The consumables can be metal clay, ceramic powder, plastic filament or photopolymer resin.

3D Printing Technologies

There are various 3D printing technologies that allow you to understand what can be printed on a 3D printer. One of the earliest and most common is stereolithography or SLA. It is based on the ability of a liquid photopolymer resin to harden under the influence of a laser beam. To build each subsequent layer, the working platform is immersed in a container with liquid resin by a layer size of 0. 05-0.15 mm. After leveling the surface, its formation begins. The main advantage of stereolithography is its high precision. Due to this property, it is used to make prototypes of dental prostheses or jewelry.

05-0.15 mm. After leveling the surface, its formation begins. The main advantage of stereolithography is its high precision. Due to this property, it is used to make prototypes of dental prostheses or jewelry.

SLA technology

Digital LED projection or DLP is also based on liquid photopolymer resins. Only in this case, the printer projects the image of the entire layer of the object at the same time until the resin hardens. The technology is highly accurate, allowing it to be used in the manufacture of souvenirs or jewelry, as well as in dentistry.

Another known method is selective laser sintering or SLS. In this case, the formation of the final object occurs as a result of layer-by-layer sintering of particles of powdered material under the influence of a laser beam. This printing technology has become widespread due to the ability to produce parts of complex geometric shapes. These include art and even sports shoes. Sand or composite mixtures, metals and alloys, various polymers can be used as consumables.

SLS technology

Electron beam melting (or EBM) technology is based on the use of electron emitters for layer-by-layer melting of metal powder in an airless chamber. This method allows you to create parts of high strength and density. The final products are indistinguishable in mechanical properties from cast ones. With the help of EBM, medical implants, parts of rocket and jet engines, bearing elements of aircraft are made.

Another technology to note is 3D inkjet printing or 3DP. In this case, three-dimensional objects are created by layer-by-layer application of any powders, including sand mixtures, plastics, and even metals. Color printing is provided by the addition of dyes to the binder. The 3DP method makes it possible to manufacture products of complex geometric shapes that will not be subjected to mechanical stress in the future. With its help, souvenirs, jewelry or models are made.

Using 3D technologies in everyday life

Given the wide variety of consumables and technologies used, refilling 3D printers is a rather specific operation, but applicable to any device model. Currently, they are used in medical, construction, architectural, educational, jewelry and other fields. A device has been created that can build a full-fledged two-story house in just 20 hours. It is likely that in the near future the process of building construction will be simplified and accelerated as much as possible. 3D printers are also indispensable in medicine. They allow not only to produce strong and durable implants, but even human skin. These devices have become a real step into the future.

Currently, they are used in medical, construction, architectural, educational, jewelry and other fields. A device has been created that can build a full-fledged two-story house in just 20 hours. It is likely that in the near future the process of building construction will be simplified and accelerated as much as possible. 3D printers are also indispensable in medicine. They allow not only to produce strong and durable implants, but even human skin. These devices have become a real step into the future.

All about 3D printing. additive manufacturing. Basic concepts.

- 1 Technology

- 2 Terminology

- 3 Fundamentals

- 4 Printing Technologies

- 5 3D printers

- 6 Application

- 7 Domestic and hobby use

- 8 Clothing

- 9 3D bioprinting

- 10 3D printing of implants and medical devices

- 11 3D printing services

- 12 Research into new applications

- 13 Intellectual Property

- 14 Influence of 3D printing

- 15 Space research

- 16 Social change

- 17 Firearms

Technology

Charles Hull, the father of modern 3D printing

3D printing, or “additive manufacturing”, is the process of creating a solid digital model of almost any 3D shape. 3D printing is based on the concept of building an object in successive layers that display the contours of the model. In fact, 3D printing is the complete opposite of traditional mechanical production and processing methods such as milling or cutting, where the appearance of the product is formed by removing excess material (so-called "subtractive manufacturing").

3D printing is based on the concept of building an object in successive layers that display the contours of the model. In fact, 3D printing is the complete opposite of traditional mechanical production and processing methods such as milling or cutting, where the appearance of the product is formed by removing excess material (so-called "subtractive manufacturing").

3D printers are computer-controlled machines that build parts in an additive way. Although 3D printing technology appeared in the 80s of the last century, 3D printers were widely used commercially only in the early 2010s. The first viable 3D printer was created by Charles Hull, one of the founders of 3D Systems Corporation. At the beginning of the 21st century, there was a significant increase in sales, which led to a sharp drop in the cost of devices. According to the consulting firm Wohlers Associates, the global market for 3D printers and related services reached $2.2 billion in 2012, growing by 29%.% compared to 2011.

3D printing technologies are used for prototyping and distributed manufacturing in architecture, construction, industrial design, automotive, aerospace, military-industrial, engineering and medical industries, bioengineering (to create artificial fabrics), fashion and footwear, jewelry, in education, geographic information systems, food industry and many other areas. According to research, open source home 3D printers will allow you to win back the capital costs of your own purchase through the economy of household production of items.

Terminology

Additive manufacturing involves the construction of objects by adding the necessary material, and not by removing excess, as is the case with subtractive methods

The term "additive manufacturing" refers to the technology of creating objects by applying successive layers material. Models made using the additive method can be used at any stage of production - both for the production of prototypes (so-called rapid prototyping) and as finished products themselves (so-called rapid production).

In manufacturing, especially machining, the term "subtractive" implies more traditional methods and is a retronym coined in recent years to distinguish between traditional methods and new additive methods. Although traditional manufacturing has used essentially "additive" methods for centuries (such as riveting, welding, and screwing), they lack a 3D information technology component. Machining, on the other hand, (the production of parts of an exact shape), as a rule, is based on subtractive methods - filing, milling, drilling and grinding.

The term "stereolithography" was defined by Charles Hull in a 1984 patent as "a system for generating three-dimensional objects by layering".

Fundamentals

3D printed models

3D models are created by hand-held computer graphic design or 3D scanning. Hand modeling, or the preparation of geometric data for the creation of 3D computer graphics, is somewhat like sculpture. 3D scanning is the automatic collection and analysis of data from a real object, namely shape, color and other characteristics, with subsequent conversion into a digital three-dimensional model.

3D scanning is the automatic collection and analysis of data from a real object, namely shape, color and other characteristics, with subsequent conversion into a digital three-dimensional model.

Both manual and automatic creation of 3D printed models can be difficult for the average user. In this regard, 3D printed marketplaces have become widespread in recent years. Some of the more popular examples include Shapeways, Thingiverse, and Threeding.

3D printing

The following digital models are used as drawings for 3D printed objects , powder, paper or sheet material, building a 3D model from a series of cross sections. These layers, corresponding to virtual cross-sections in the CAD model, are connected or fused together to create an object of a given shape. The main advantage of this method is the ability to create geometric shapes of almost unlimited complexity.

"Resolution" of the printer means the thickness of the applied layers (Z-axis) and the accuracy of positioning the print head in the horizontal plane (along the X and Y axes). Resolution is measured in DPI (dots per inch) or micrometers (the obsolete term is "micron"). Typical layer thicknesses are 100µm (250 DPI), although some devices like the Objet Connex and 3D Systems ProJet are capable of printing layers as thin as 16µm (1600 DPI). The resolution on the X and Y axes is similar to that of conventional 2D laser printers. A typical particle size is about 50-100µm (510 to 250 DPI) in diameter.

Resolution is measured in DPI (dots per inch) or micrometers (the obsolete term is "micron"). Typical layer thicknesses are 100µm (250 DPI), although some devices like the Objet Connex and 3D Systems ProJet are capable of printing layers as thin as 16µm (1600 DPI). The resolution on the X and Y axes is similar to that of conventional 2D laser printers. A typical particle size is about 50-100µm (510 to 250 DPI) in diameter.

One of the methods for obtaining a digital model is 3D scanning. Pictured here is a MakerBot Digitizer

3D Scanner Building a model using modern technology can take hours to days, depending on the method used and the size and complexity of the model. Industrial additive systems can typically reduce the time to a few hours, but it all depends on the type of plant, as well as the size and number of models produced at the same time.

Traditional manufacturing methods such as injection molding can be less expensive when producing large batches of polymer products, but additive manufacturing has advantages in small batch production, allowing for higher production rates and design flexibility, along with increased cost per unit produced. In addition, desktop 3D printers allow designers and developers to create concept models and prototypes without leaving the office.

In addition, desktop 3D printers allow designers and developers to create concept models and prototypes without leaving the office.

Machining

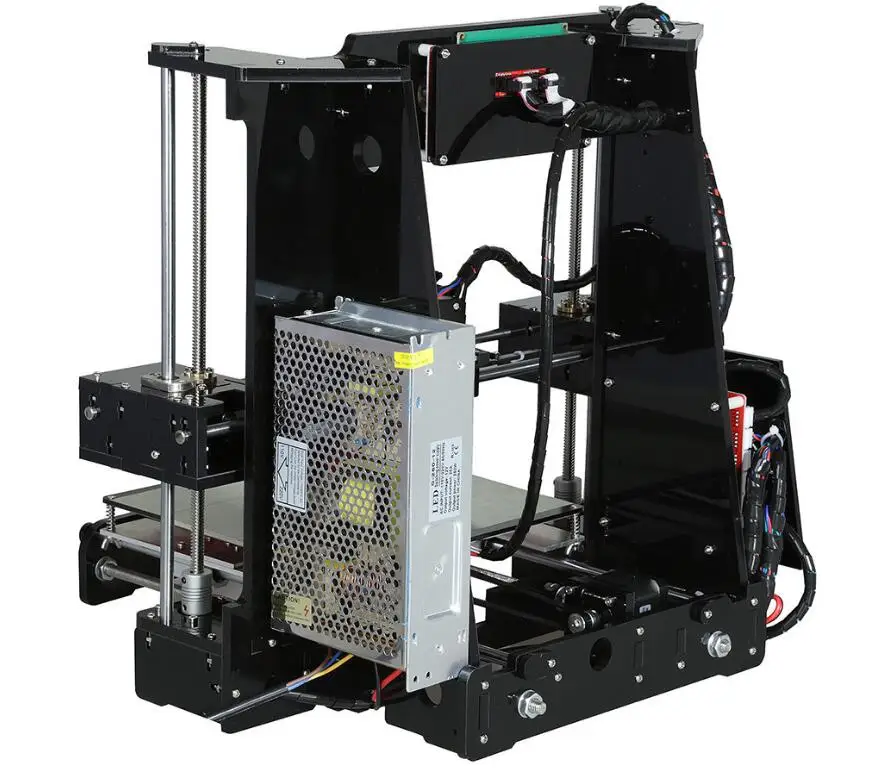

FDM Type 3D Printer Schematic

Although the resolution of the printers is adequate for most projects, printing slightly oversized objects and then subtractive machining with high precision tools allows you to create models of increased accuracy.

The LUMEX Avance-25 is an example of devices with a similar combined manufacturing and processing method. Some additive manufacturing methods allow for the use of multiple materials, as well as different colors, within a single production run. Many of the 3D printers use "supports" or "supports" during printing. Supports are needed to build model fragments that are not in contact with the underlying layers or the working platform. The supports themselves are not part of the given model, and upon completion of printing, they either break off (in the case of using the same material as for printing the model itself), or dissolve (usually in water or acetone - depending on the material used to create the supports). ).

).

Printing technologies

Since the late 1970s, several 3D printing methods have come into being. The first printers were large, expensive and very limited.

Completed skull with supports not yet removed

A wide variety of additive manufacturing methods are now available. The main differences are in the layering method and consumables used. Some methods rely on melting or softening materials to create layers: these include selective laser sintering (SLS), selective laser melting (SLM), direct metal laser sintering (DMLS), fusing deposition printing (FDM or FFF). Another trend has been the production of solid models by polymerization of liquid materials, known as stereolithography (SLA).

In the case of lamination of sheet materials (LOM), thin layers of material are cut to the required contour, and then joined into a single whole. Paper, polymers and metals can be used as LOM materials. Each of these methods has its own advantages and disadvantages, which is why some companies offer a choice of consumables for building a model - polymer or powder. LOM printers often use regular office paper to build durable prototypes. The key points when choosing the right device are the speed of printing, the price of a 3D printer, the cost of printed prototypes, as well as the cost and range of compatible consumables.

Each of these methods has its own advantages and disadvantages, which is why some companies offer a choice of consumables for building a model - polymer or powder. LOM printers often use regular office paper to build durable prototypes. The key points when choosing the right device are the speed of printing, the price of a 3D printer, the cost of printed prototypes, as well as the cost and range of compatible consumables.

Printers that produce full-fledged metal models are quite expensive, but it is possible to use less expensive devices for the production of molds and subsequent casting of metal parts.

The main methods of additive manufacturing are presented in the table:

| | ||

| Method | Technology | Materials used |

| Extrusion | Fused deposition modeling (FDM or FFF) | Thermoplastics (such as polylactide (PLA), acrylonitrile butadiene styrene (ABS), etc. ) ) |

| Wire | Manufacture of arbitrary shapes by electron beam fusing (EBFȝ) | Virtually all metal alloys |

| Powder | Direct Metal Laser Sintering (DMLS) | Virtually all metal alloys |

| Electron Beam Melting (EBM) | Titanium alloys | |

| Selective laser melting (SLM) | Titanium alloys, cobalt-chromium alloys, stainless steel, aluminum | |

| Selective heat sintering (SHS) | Powder thermoplastics | |

| Selective laser sintering (SLS) | Thermoplastics, metal powders, ceramic powders | |

| Inkjet | 3D Inkjet(3DP) | Gypsum, plastics, metal powders, sand mixtures |

| Lamination | Laminating Objects (LOM) | Paper, metal foil, plastic film |

| Polymerization | Stereolithography (SLA) | Photopolymers |

| Digital LED projection (DLP) | Photopolymers |

Extrusion Printing

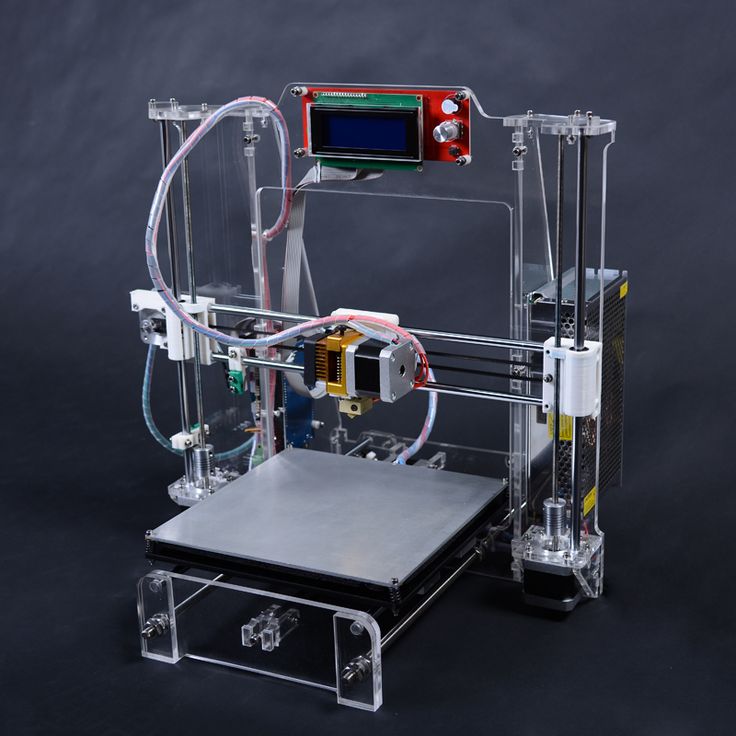

Fused Deposition Modeling (FDM/FFF) was developed by S. Scott Trump in the late 1980s and commercialized in the 1990s by Stratasys, a company of which Trump is one of the founders. Due to the expiration of the patent, there is a large community of open source 3D printer developers as well as commercial organizations using the technology. As a consequence, the cost of devices has decreased by two orders of magnitude since the invention of the technology.

Scott Trump in the late 1980s and commercialized in the 1990s by Stratasys, a company of which Trump is one of the founders. Due to the expiration of the patent, there is a large community of open source 3D printer developers as well as commercial organizations using the technology. As a consequence, the cost of devices has decreased by two orders of magnitude since the invention of the technology.

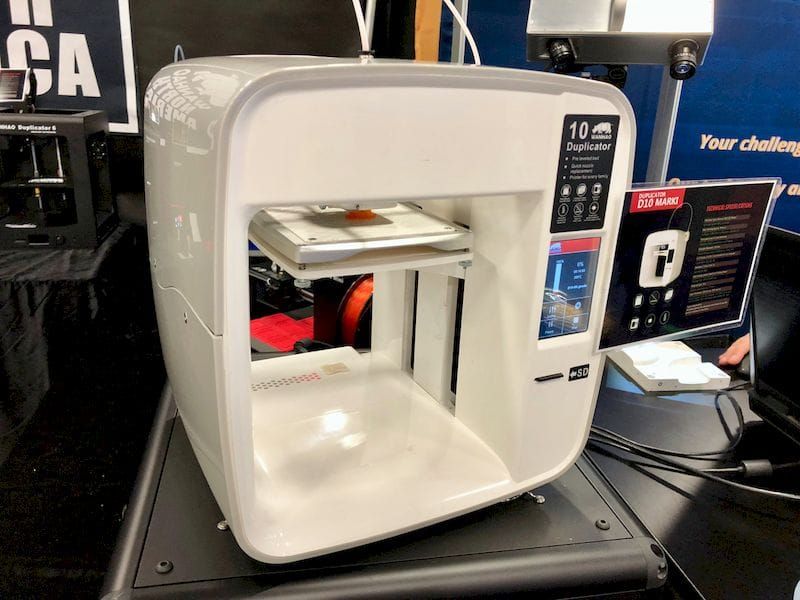

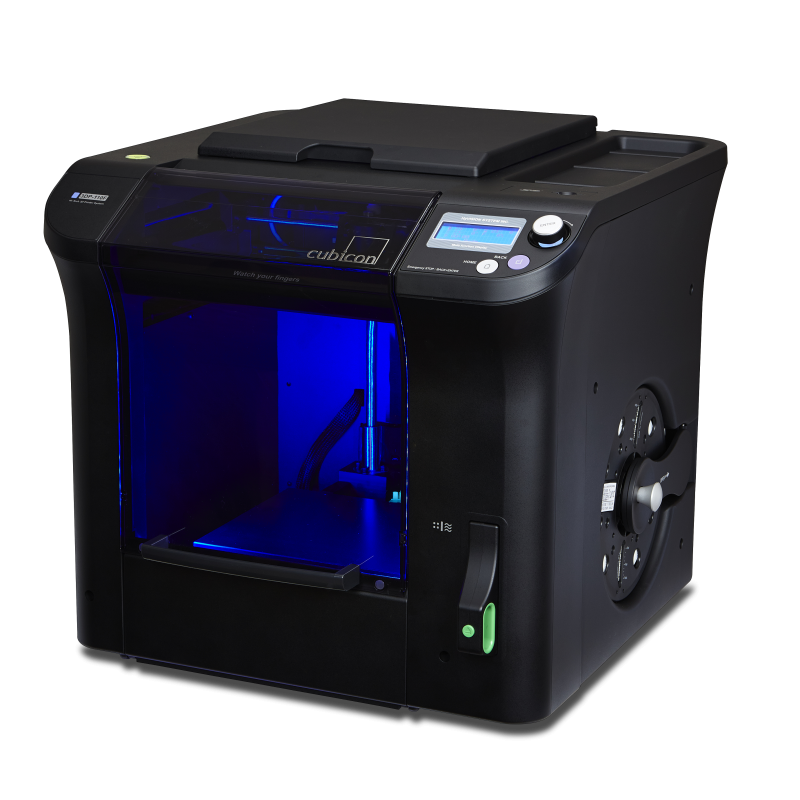

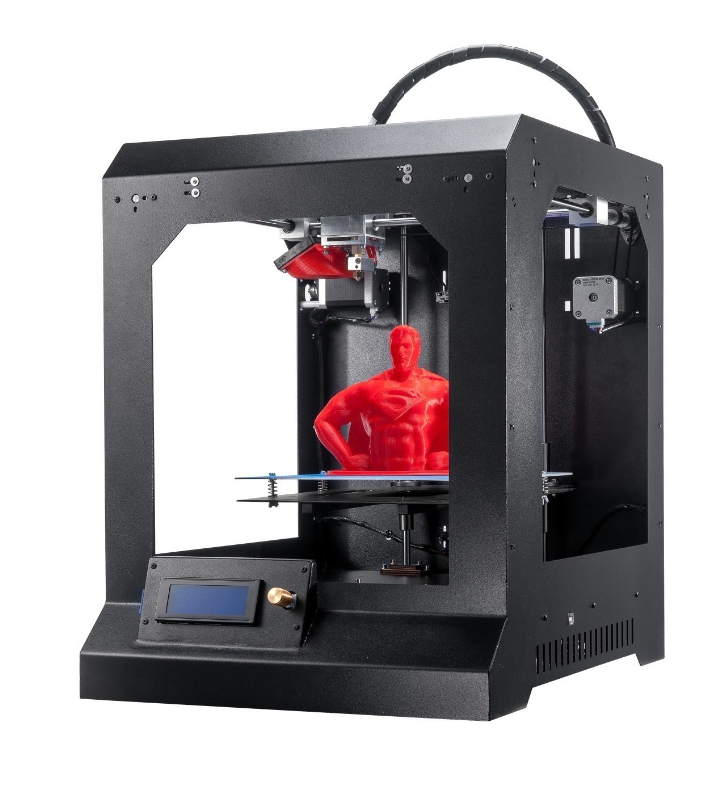

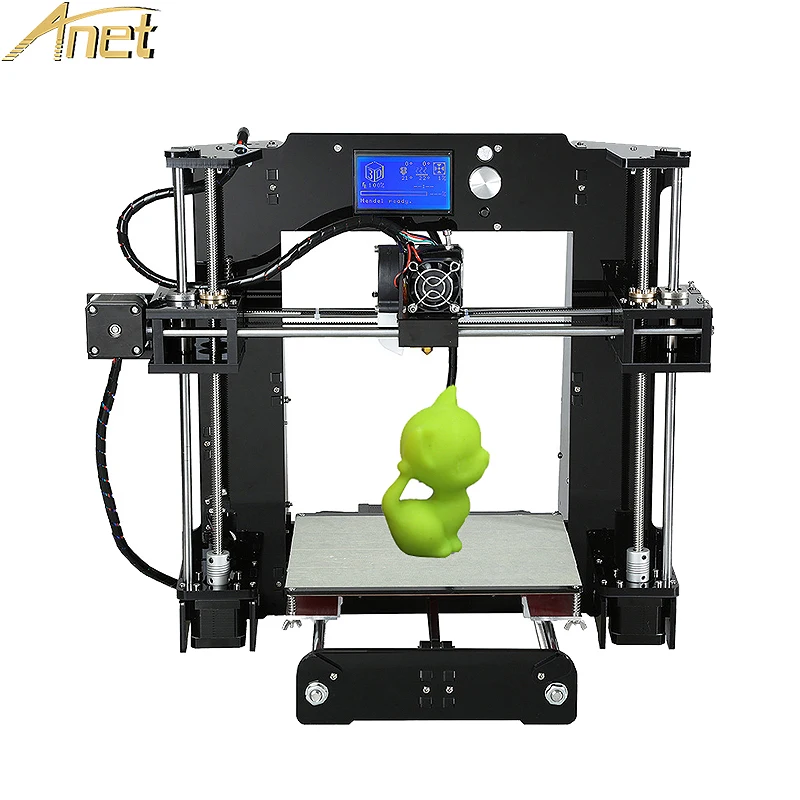

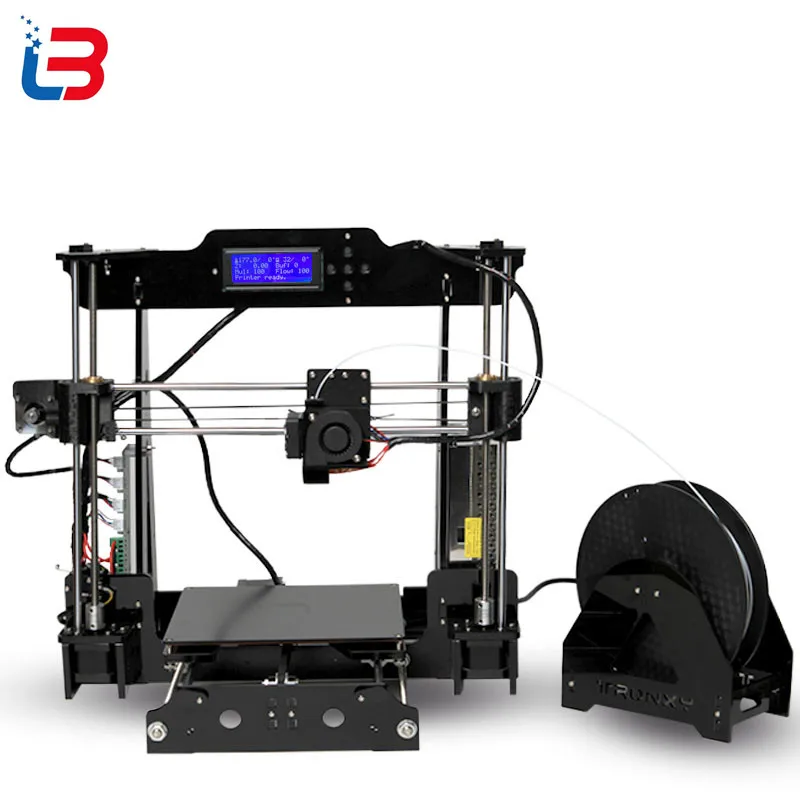

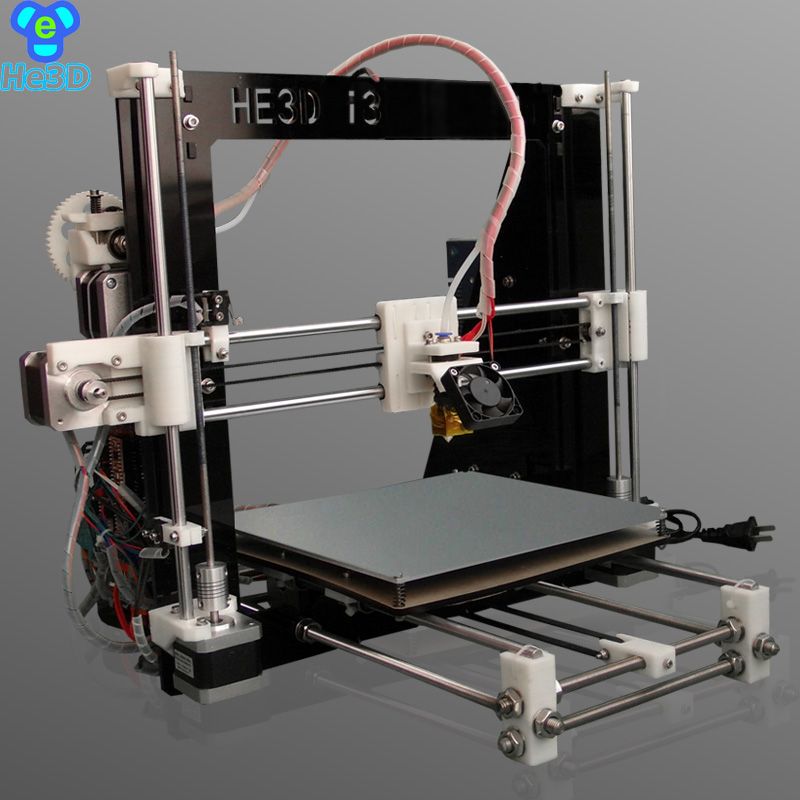

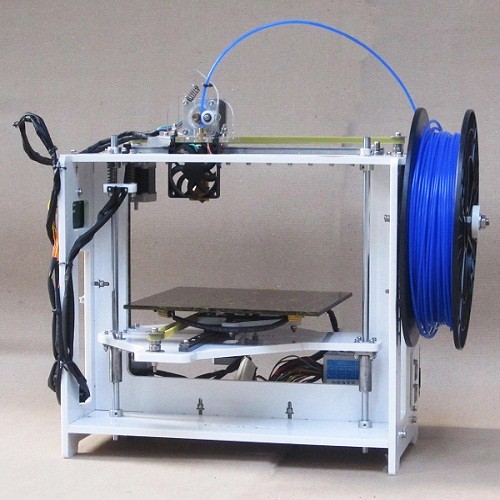

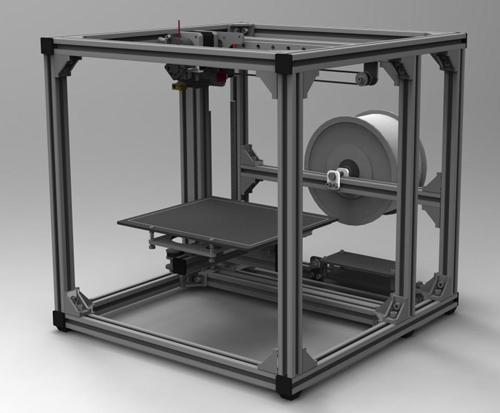

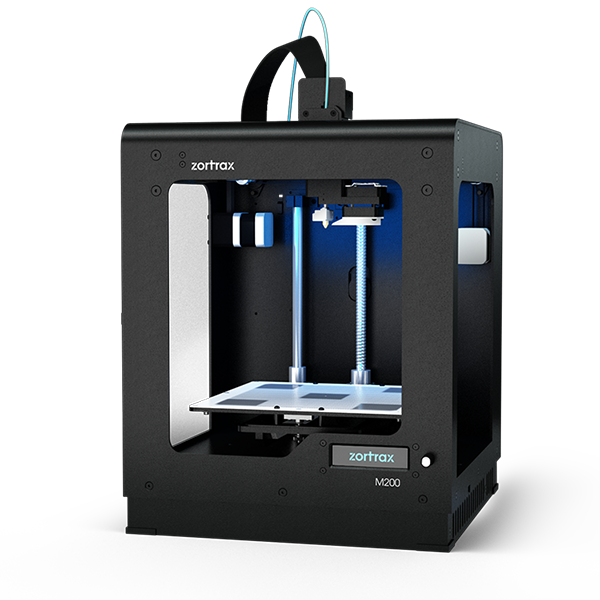

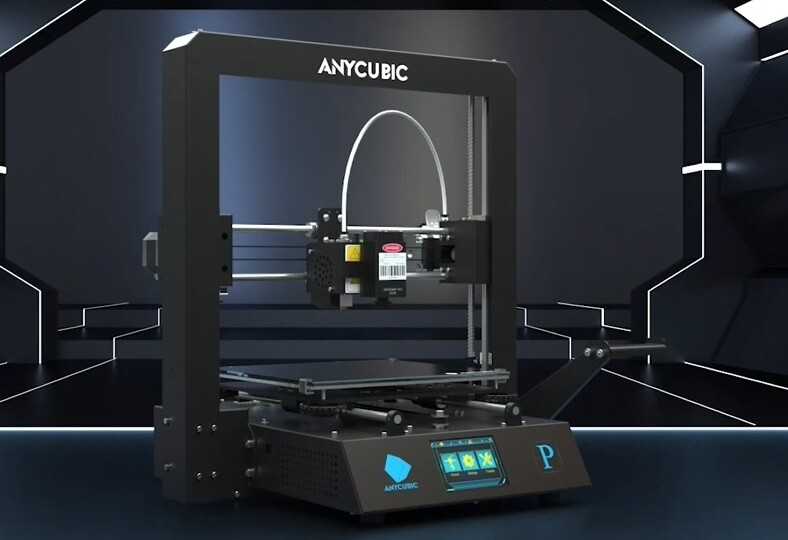

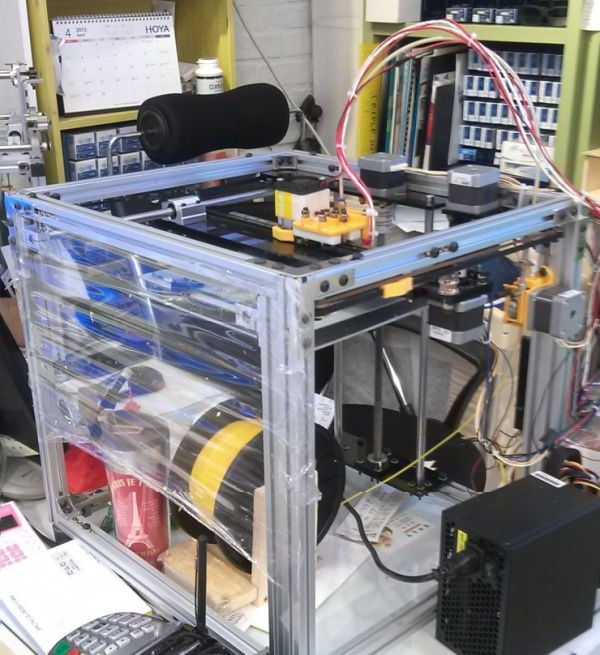

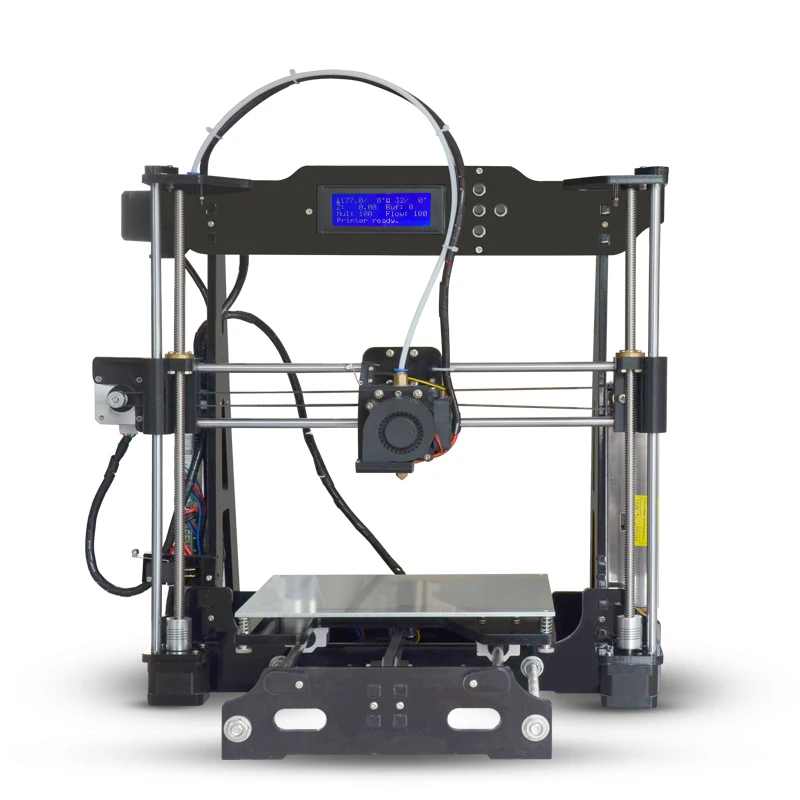

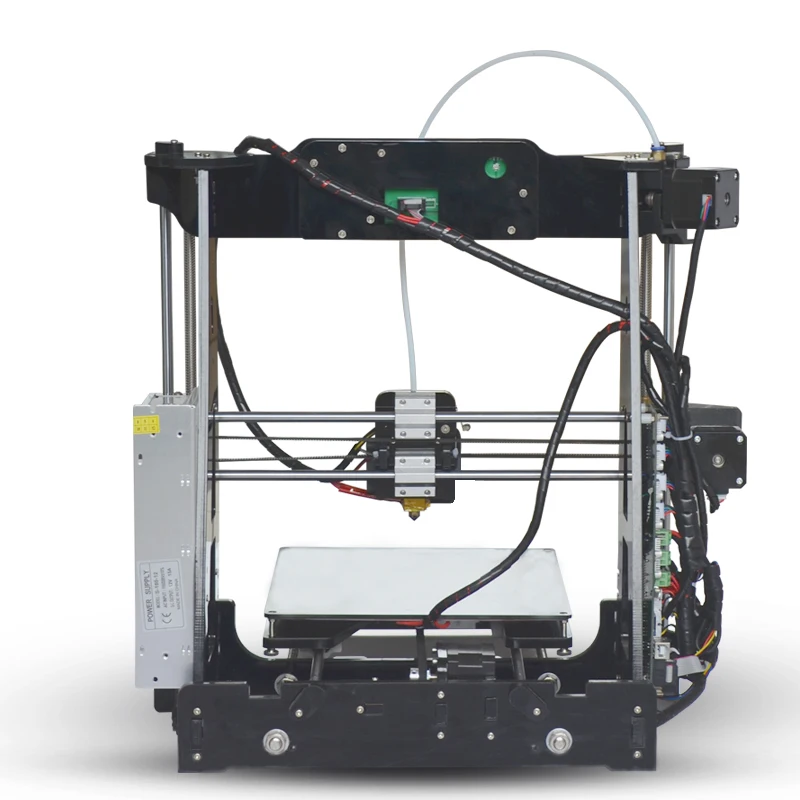

3D printers range from simple do-it-yourself printers to plastic...

Fusion printing process involves the creation of layers by extrusion of a fast-curing material in the form of microdrops or thin jets. Typically, consumable material (such as thermoplastic) comes in the form of spools from which the material is fed into a printhead called an "extruder". The extruder heats the material to its melting temperature, followed by extrusion of the molten mass through a nozzle. The extruder itself is driven by stepper motors or servomotors to position the printhead in three planes. The movement of the extruder is controlled by a manufacturing software (CAM) linked to a microcontroller.

The movement of the extruder is controlled by a manufacturing software (CAM) linked to a microcontroller.

A variety of polymers are used as consumables, including acrylonitrile butadiene styrene (ABS), polycarbonate (PC), polylactide (PLA), high pressure polyethylene (HDPE), polycarbonate-ABS blends, polyphenylene sulfone (PPSU), etc. Typically, polymer supplied in the form of a filler made of pure plastic. There are several projects in the 3D printing enthusiast community that aim to recycle used plastic into materials for 3D printing. The projects are based on the production of consumables using shredders and melters.

FDM/FFF technology has certain limitations on the complexity of the generated geometric shapes. For example, the creation of suspended structures (such as stalactites) is impossible by itself, due to the lack of necessary support. This limitation is compensated by the creation of temporary support structures that are removed after printing is completed.

Powder print

One of the additive manufacturing methods is selective sintering of powder materials. Model layers are drawn (sintered) in a thin layer of powdered material, after which the work platform is lowered and a new layer of powder is applied. The process is repeated until a complete model is obtained. The unused material remains in the working chamber and serves to support the overhanging layers without requiring the creation of special supports.

The most common methods are based on laser sintering: selective laser sintering (SLS) for working with metals and polymers (e.g. polyamide (PA), glass fiber reinforced polyamide (PA-GF), glass fiber (GF), polyetheretherketone) (PEEK), polystyrene (PS), alumide, carbon fiber reinforced polyamide (Carbonmide), elastomers) and direct metal laser sintering (DMLS).

... to expensive industrial plants that work with metals

Selective Laser Sintering (SLS) was developed and patented by Carl Deckard and Joseph Beeman of the University of Texas at Austin in the mid-1080s under the auspices of the Defense Advanced Research Projects Agency (DARPA). A similar method was patented by R. F. Householder in 1979, but has not been commercialized.

A similar method was patented by R. F. Householder in 1979, but has not been commercialized.

Selective laser melting (SLM) is characterized by the fact that it does not sinter, but actually melts the powder at the points of contact with a powerful laser beam, allowing you to create high-density materials that are similar in terms of mechanical characteristics to products made by traditional methods.

Electron beam melting (EBM) is a similar method for the additive manufacturing of metal parts (eg titanium alloys) but using electron beams instead of lasers. EBM is based on melting metal powders layer by layer in a vacuum chamber. In contrast to sintering at temperatures below melting thresholds, models made by electron beam melting are characterized by solidity with a corresponding high strength.

Finally, there is the 3D inkjet printing method. In this case, a binder is applied to thin layers of powder (gypsum or plastic) in accordance with the contours of successive layers of the digital model. The process is repeated until the finished model is obtained. The technology provides a wide range of applications, including the creation of color models, suspended structures, the use of elastomers. The design of models can be strengthened by subsequent impregnation with wax or polymers.

The process is repeated until the finished model is obtained. The technology provides a wide range of applications, including the creation of color models, suspended structures, the use of elastomers. The design of models can be strengthened by subsequent impregnation with wax or polymers.

Lamination

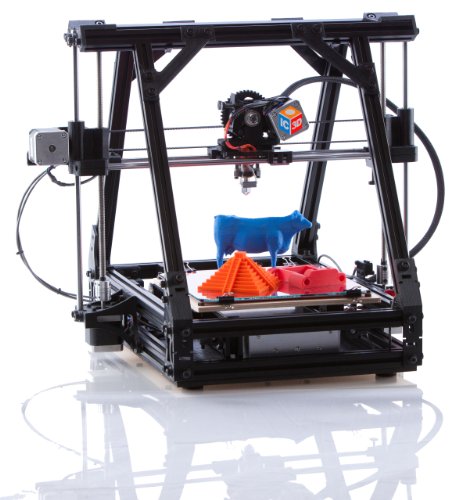

FDM 3D printers are the most popular among hobbyists and enthusiasts

Some printers use paper as a material for building models, thereby reducing the cost of printing. Such devices experienced the peak of popularity in the 1990s. The technology consists in cutting out the layers of the model from paper using a carbon dioxide laser with simultaneous lamination of the contours to form the finished product.

In 2005, Mcor Technologies Ltd developed a variant of the technology that uses plain office paper, a tungsten carbide blade instead of a laser, and selective adhesive application.

There are also device variants that laminate thin metal and plastic sheets.

Photopolymerization

3D printing allows you to create functional monolithic parts of complex geometric shapes, like this jet engine nozzle

Stereolithography was patented by Charles Hull in 1986. Photopolymerization is primarily used in stereolithography (SLA) to create solid objects from liquid materials. This method differs significantly from previous attempts, from the sculptural portraits of François Willem (1830-1905) to photopolymerization by the Matsubara method (1974).

The Digital Projection Method (DLP) uses liquid photopolymer resins that are cured by exposure to ultraviolet light emitted from digital projectors in a coated working chamber. After the material has hardened, the working platform is immersed to a depth equal to the thickness of one layer, and the liquid polymer is irradiated again. The procedure is repeated until the completion of the model building. An example of a rapid prototyping system using digital LED projectors is the EnvisionTEC Perfactory.

Inkjet printers (eg Objet PolyJet) spray thin layers (16-30µm) of photopolymer onto the build platform until a complete model is obtained. Each layer is irradiated with an ultraviolet beam until hardened. The result is a model ready for immediate use. The gel-like support material used to support the components of geometrically complex models is removed after the model has been handcrafted and washed. The technology allows the use of elastomers.

Ultra-precise detailing of models can be achieved using multiphoton polymerization. This method is reduced to drawing the contours of a three-dimensional object with a focused laser beam. Due to non-linear photoexcitation, the material solidifies only at the focusing points of the laser beam. This method makes it easy to achieve resolutions above 100 µm, as well as build complex structures with moving and interacting parts.

Another popular method is curing with LED projectors or "projection stereolithography".

Projection stereolithography

This method involves dividing a 3D digital model into horizontal layers, converting each layer into a 2D projection similar to photomasks. The 2D images are projected onto successive layers of photopolymer resin that harden according to the projected contours.

In some systems, the projectors are located at the bottom, helping to level the surface of the photopolymer material when the model moves vertically (in this case, the build platform with the applied layers moves up, rather than sinking into the material) and reduces the production cycle to minutes instead of hours.

The technology allows you to create models with layers of several materials with different curing rates.

Some commercial models, such as the Objet Connex, apply resin using small nozzles.

3D printers

Industrial plants

Industrial adoption of additive manufacturing is proceeding at a rapid pace. For example, US-Israeli joint venture Stratasys supplies $2,000 to $500,000 additive manufacturing machines, while General Electric uses high-end machines to produce gas turbine parts.

For example, US-Israeli joint venture Stratasys supplies $2,000 to $500,000 additive manufacturing machines, while General Electric uses high-end machines to produce gas turbine parts.

Home appliances

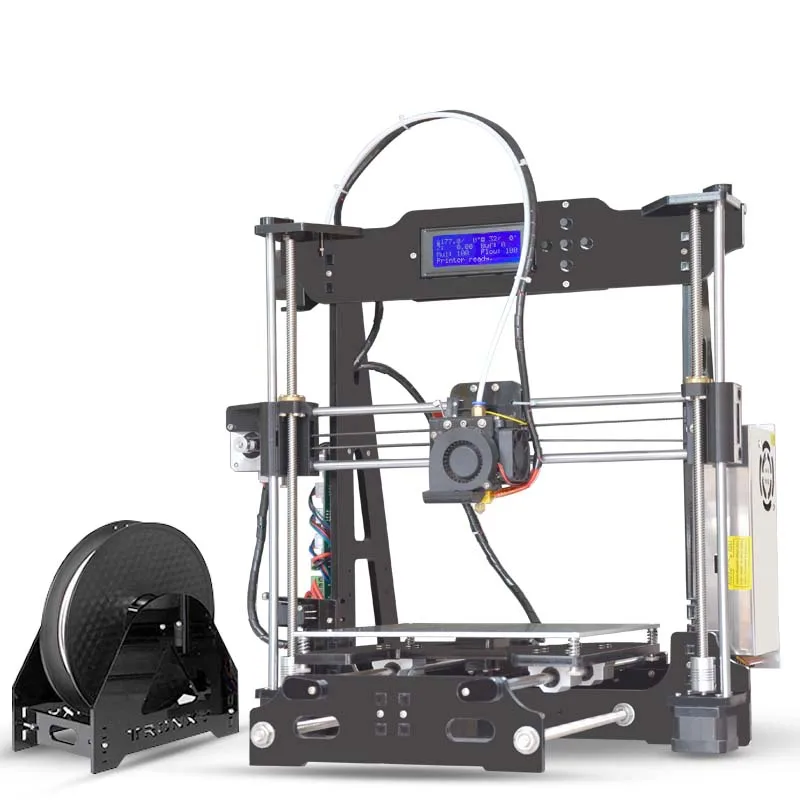

LOM takes papier-mâché to the next level The development of 3D printers for home use is being pursued by a growing number of companies and enthusiasts. Most of the work is done by amateurs for their own and public needs, with help from the academic community and hackers.

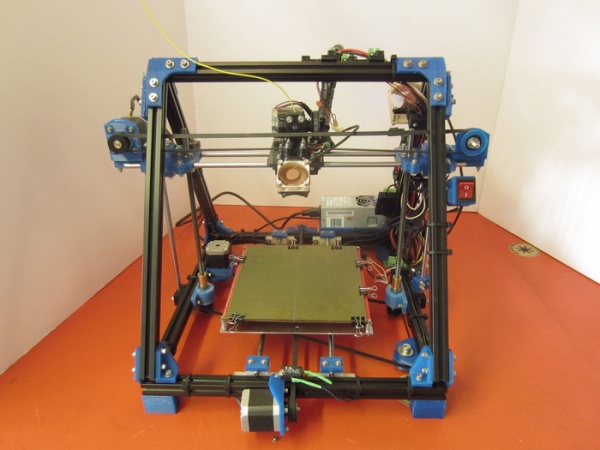

The oldest and longest running project in the desktop 3D printer category is RepRap. The RepRap project aims to create free and open source (FOSH) 3D printers provided under the GNU General Public License. RepRap devices are capable of printing custom-designed plastic components that can be used to build clones of the original device. Individual RepRap devices have been successfully applied to the production of printed circuit boards and metal parts.

Due to open access to drawings of RepRap printers, many of the projects adopt the technical solutions of analogues, thus creating a semblance of an ecosystem consisting mostly of freely modifiable devices. The wide availability of open source designs only encourages variations. On the other hand, there is a significant variation in the level of quality and complexity of both the designs themselves and the devices manufactured on their basis. The rapid development of open source 3D printers is leading to a rise in popularity and the emergence of public and commercial portals (such as Thingiverse or Cubify) offering a variety of printable 3D designs. In addition, the development of technology contributes to the sustainable development of local economies through the possibility of using locally available materials for the production of printers.

The wide availability of open source designs only encourages variations. On the other hand, there is a significant variation in the level of quality and complexity of both the designs themselves and the devices manufactured on their basis. The rapid development of open source 3D printers is leading to a rise in popularity and the emergence of public and commercial portals (such as Thingiverse or Cubify) offering a variety of printable 3D designs. In addition, the development of technology contributes to the sustainable development of local economies through the possibility of using locally available materials for the production of printers.

Stereolithographic 3D printers are often used in dental prosthetics

The cost of 3D printers has been declining at a significant rate since about 2010: devices that cost $20,000 at the time are now $1,000 or less. Many companies and individual developers are already offering budget RepRap kits under $500. The Fab@Home open source project has led to the development of general purpose printers capable of printing anything that can be squeezed through a nozzle, from chocolate to silicone putty and chemicals.

Printers based on this design have been available as kits since 2012 for around $2,000. Some 3D printers, including the mUVe 3D and Lumifold, are designed to be as affordable as possible from the start, with the Peachy Printer being priced around $100. .

Professional Kickstarter-funded printers often perform well: Rapide 3D printers are quiet and fumes-free at $1499. 3D Doodler's '3D Printing Pen' Raised $2.3M in Kickstarter donations, with a selling price of $99 for the device itself. True, it is difficult to call the 3D Doodler a full-fledged 3D printer.

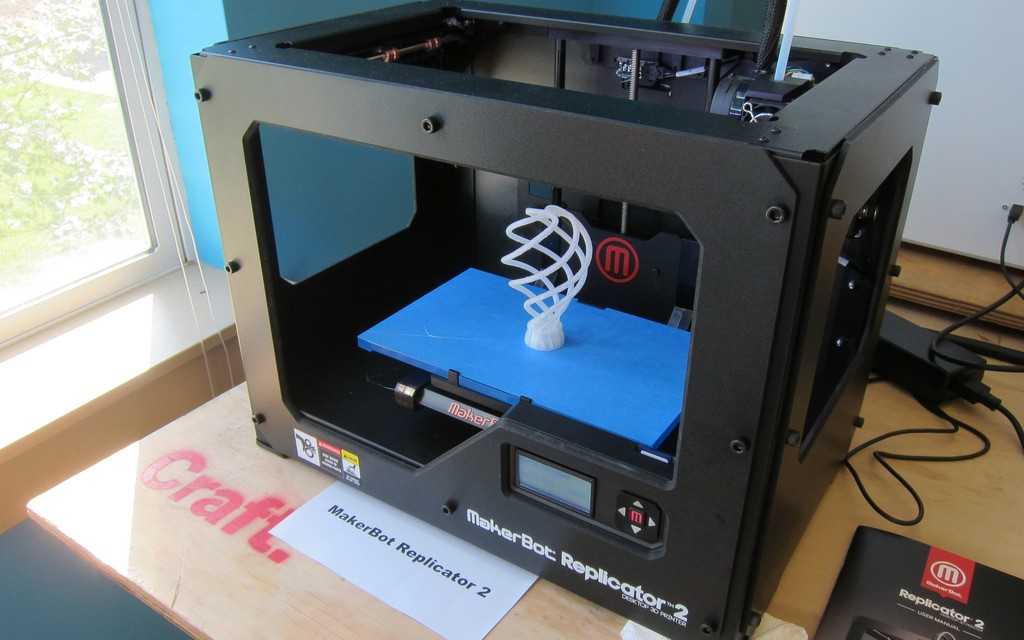

3D Systems Cube is a popular consumer 3D printer

As prices fall, 3D printers are becoming more attractive for consumer production. In addition, home use of 3D printing technologies can reduce the environmental footprint of industry by reducing the volume of consumables and the energy and fuel costs of transporting materials and goods.

Parallel to the creation of home 3D-printing devices, the development of devices for processing household waste into printed materials, the so-called. Recyclebot. For example, the commercial model Filastrucer was designed to recycle plastic waste (shampoo bottles, milk containers) into inexpensive consumables for RepRap printers. Such methods of household disposal are not only practical, but also have a positive impact on the ecological situation.

Recyclebot. For example, the commercial model Filastrucer was designed to recycle plastic waste (shampoo bottles, milk containers) into inexpensive consumables for RepRap printers. Such methods of household disposal are not only practical, but also have a positive impact on the ecological situation.

The development and customization of RepRap 3D printers has created a new category of semi-professional printers for small businesses. Manufacturers such as Solidoodle, RoBo and RepRapPro offer kits for under $1,000. The accuracy of these devices is between industrial and consumer printers. Recently, high-performance printers using a delta-shaped coordinate system, or the so-called "delta robots", are gaining popularity. Some companies offer software to support printers made by other companies.

Application

The use of LED projectors helps reduce the cost of stereolithography printers. In the illustration DLP printer Nova

3D printing allows you to equalize the cost of producing one part and mass production, which poses a threat to large-scale economies. The impact of 3D printing may be similar to the introduction of manufacture. In the 1450s, no one could predict the consequences of the printing press, in the 1750s, no one took the steam engine seriously, and transistors 19The 50s seemed like a curious innovation. But the technology continues to evolve and is likely to have an impact on every scientific and industrial branch with which it comes into contact.

The impact of 3D printing may be similar to the introduction of manufacture. In the 1450s, no one could predict the consequences of the printing press, in the 1750s, no one took the steam engine seriously, and transistors 19The 50s seemed like a curious innovation. But the technology continues to evolve and is likely to have an impact on every scientific and industrial branch with which it comes into contact.

The earliest application of additive manufacturing can be considered rapid prototyping, aimed at reducing the development time of new parts and devices compared to earlier subtractive methods (too slow and expensive). The improvement of additive manufacturing technologies leads to their spread in various fields of science and industry. The production of parts previously only available through machining is now possible through additive methods, and at a better price.

Applications include breadboarding, prototyping, molding, architecture, education, mapping, healthcare, retail, etc.

Industrial applications:

Rapid prototyping: Industrial 3D printers have been used for rapid prototyping and research since the early 1980s . As a rule, these are quite large installations using powder metals, sand mixtures, plastics and paper. Such devices are often used by universities and commercial companies.

Advances in rapid prototyping have led to the creation of materials suitable for the production of final products, which in turn has contributed to the development of 3D production of finished products as an alternative to traditional methods. One of the advantages of fast production is the relatively low cost of manufacturing small batches.

Rapid production: Rapid production remains a fairly new technique whose possibilities have not yet been fully explored. Nevertheless, many experts tend to consider rapid production a new level of technology. Some of the most promising areas for rapid prototyping to adapt to rapid manufacturing are selective laser sintering (SLS) and direct metal sintering (DMLS).

Bulk customization: Some companies offer services for customizing objects using simplified software and then creating unique custom 3D models. One of the most popular areas was the manufacture of cell phone cases. In particular, Nokia has made publicly available the designs of its phone cases for user customization and 3D printing.

Mass production: The current low print speed of 3D printers limits their use in mass production. To combat this shortcoming, some FDM devices are equipped with multiple extruders, allowing you to print different colors, different polymers, and even create several models at the same time. In general, this approach increases productivity without requiring the use of multiple printers - a single microcontroller is enough to operate multiple printheads.

Devices with multiple extruders allow the creation of several identical objects from only one digital model, but at the same time allow the use of different materials and colors. The print speed increases in proportion to the number of print heads. In addition, certain energy savings are achieved through the use of a common working chamber, which often requires heating. Together, these two points reduce the cost of the process.

The print speed increases in proportion to the number of print heads. In addition, certain energy savings are achieved through the use of a common working chamber, which often requires heating. Together, these two points reduce the cost of the process.

Many printers are equipped with dual printheads, however this configuration is only used for printing single models in different colors and materials.

Consumer and hobby use

Today, consumer 3D printing mainly attracts the attention of enthusiasts and hobbyists, while practical use is rather limited. However, 3D printers have already been used to print working mechanical clocks, woodworking gears, jewelry, and more. Home 3D printing websites often offer designs for hooks, doorknobs, massage tools, and more.

3D printing is also being used in hobby veterinary medicine and zoology – in 2013, a 3D printed prosthesis allowed a duckling to stand up, and hermit crabs love stylish 3D printed shells. 3D printers are widely used for the domestic production of jewelry - necklaces, rings, handbags, etc.

3D printers are widely used for the domestic production of jewelry - necklaces, rings, handbags, etc.

The Fab@Home open project aims to develop general purpose home printers. The devices have been tested in research environments using the latest 3D printing technologies for the production of chemical compounds. The printer can print any material suitable for extrusion from a syringe in the form of a liquid or paste. The development is aimed at the possibility of home production of medicines and household chemicals in remote areas of residence.

Student project OpenReflex resulted in a design for an analog SLR camera suitable for 3D printing.

Clothing

3D printing is gaining ground in the fashion world as couturiers use printers to experiment with swimwear, shoes and dresses. Commercial applications include rapid prototyping and 3D printing of professional athletic shoes - the Vapor Laser Talon for soccer players and New Balance for track and field athletes.

3D bioprinting

EBM titanium medical implants

3D printing is currently being researched by biotech companies and academic institutions. The research is aimed at exploring the possibility of using inkjet/drip 3D printing in tissue engineering to create artificial organs. The technology is based on the application of layers of living cells on a gel substrate or sugar matrix, with a gradual layer-by-layer build-up to create three-dimensional structures, including vascular systems. The first 3D tissue printing production system based on NovoGen bioprinting technology was introduced in 2009year. A number of terms are used to describe this research area: organ printing, bioprinting, computer tissue engineering, etc.

One of the pioneers of 3D printing, research company Organovo, conducts laboratory research and develops the production of functional 3D human tissue samples for use in medical and therapeutic research. For bioprinting, the company uses a NovoGen MMX 3D printer. Organovo believes that bioprinting will speed up the testing of new medicines before clinical trials, saving time and money invested in drug development. In the long term, Organovo hopes to adapt bioprinting technology for graft and surgical applications.

For bioprinting, the company uses a NovoGen MMX 3D printer. Organovo believes that bioprinting will speed up the testing of new medicines before clinical trials, saving time and money invested in drug development. In the long term, Organovo hopes to adapt bioprinting technology for graft and surgical applications.

3D printing of implants and medical devices

3D printing is used to create implants and devices used in medicine. Successful surgeries include examples such as titanium pelvic and jaw implants and plastic tracheal splints. The most widespread use of 3D printing is expected in the production of hearing aids and dentistry. In March 2014, Swansea surgeons used 3D printing to reconstruct the face of a motorcyclist who was seriously injured in a road accident.

3D printing services

Some companies offer online 3D printing services available to individuals and industrial companies. The customer is required to upload a 3D design to the site, after which the model is printed using industrial installations. The finished product is either delivered to the customer or subject to pickup.

The customer is required to upload a 3D design to the site, after which the model is printed using industrial installations. The finished product is either delivered to the customer or subject to pickup.

Exploring new applications

3D printing makes it possible to create fully functional metal products, including weapons.

Future applications of 3D printing may include the creation of open source scientific equipment for use in open laboratories and other scientific applications - fossil reconstruction in paleontology, the creation of duplicates of priceless archaeological artifacts, the reconstruction of bones and body parts for forensic analysis, the reconstruction of heavily damaged evidence collected from crime scenes. The technology is also being considered for application in construction.

In 2005, academic journals began to publish materials on the possibility of using 3D printing technologies in art. In 2007, the Wall Street Journal and Time magazine included 3D design in their list of the 100 most significant achievements of the year. The Victoria and Albert Museum at the London Design Festival in 2011 presented an exhibition by Murray Moss entitled "Industrial Revolution 2.0: how the material world materializes again", dedicated to 3D printing technologies.

The Victoria and Albert Museum at the London Design Festival in 2011 presented an exhibition by Murray Moss entitled "Industrial Revolution 2.0: how the material world materializes again", dedicated to 3D printing technologies.

In 2012, a University of Glasgow pilot project showed that 3D printing could be used to produce chemical compounds, including hitherto unknown ones. The project printed chemical storage vessels into which “chemical ink” was injected using additive machines and then reacted. The viability of the technology was proven by the production of new compounds, but a specific practical application was not pursued during the experiment. Cornell Creative Machines has confirmed the feasibility of creating food products using hydrocolloid 3D printing. Professor Leroy Cronin of the University of Glasgow has suggested using "chemical ink" to print medicines.

The use of 3D scanning technologies makes it possible to create replicas of real objects without the use of casting methods, which are expensive, difficult to perform and can have a destructive effect in cases of precious and fragile objects of cultural heritage.

An additional example of 3D printing technologies being developed is the use of additive manufacturing in construction. This could make it possible to accelerate the pace of construction while reducing costs. In particular, the possibility of using technology to build space colonies is being considered. For example, the Sinterhab project aims to explore the possibility of additive manufacturing of lunar bases using lunar regolith as the main building material. Instead of using binding materials, the possibility of microwave sintering of regolith into solid building blocks is being considered.

Additive manufacturing allows you to create waveguides, sleeves and bends in terahertz devices. The high geometric complexity of such products could not be achieved by traditional production methods. A commercially available professional EDEN 260V setup was used to create structures with a resolution of 100 microns. The printed structures were galvanized with gold to create a terahertz plasmonic apparatus.

China has allocated nearly $500 million. for the development of 10 national institutes for the development of 3D printing technologies. In 2013, Chinese scientists began printing living cartilage, liver and kidney tissue using specialized 3D bioprinters. Researchers at Hangzhou Dianqi University have even developed their own 3D bioprinter for this challenging task, dubbed Regenovo. One of Regenovo's developers, Xu Mingeng, said it takes less than an hour for the printer to produce a small sample of liver tissue or a four to five inch sample of ear cartilage. Xu predicts the emergence of the first full-fledged printed artificial organs within the next 10-20 years. That same year, researchers at the Belgian Hasselt University successfully printed a new jaw for an 83-year-old woman. After the implant is implanted, the patient can chew, talk and breathe normally.

In Bahrain, sandstone-like 3D printing has created unique structures to support coral growth and restore damaged reefs. These structures have a more natural shape than previously used structures and do not have the acidity of concrete.

These structures have a more natural shape than previously used structures and do not have the acidity of concrete.

Intellectual property

Section of liver tissue printed by Organovo, which is working to improve 3D printing technology for the production of artificial organs

3D printing has been around for decades, and many aspects of the technology are subject to patents, copyrights, and trademark protection. However, from a legal point of view, it is not entirely clear how intellectual property protection laws will be applied in practice if 3D printers become widely used.

distribution and will be used in household production of goods for personal use, non-commercial use or for sale.

Any of the protective measures may negatively affect the distribution of designs used in 3D printing or the sale of printed products. The use of protected technologies may require the permission of the owner, which in turn will require the payment of royalties.

Patents cover certain processes, devices, and materials. The duration of patents varies from country to country.

Often, copyright extends to the expression of ideas in the form of material objects and lasts for the life of the author, plus 70 years. Thus, if someone creates a statue and obtains copyright, it will be illegal to distribute designs for printing of an identical or similar statue.

Influence of 3D printing

Additive manufacturing requires manufacturing companies to be flexible and constantly improve available technologies to stay competitive. Advocates of additive manufacturing predict that the opposition between 3D printing and globalization will escalate as home production displaces trade in goods between consumers and large manufacturers. In reality, the integration of additive technologies into commercial production serves as a complement to traditional subtractive methods, rather than a complete replacement for the latter.

Space exploration

In 2010, work began on the application of 3D printing in zero gravity and low gravity. The main goal is to create hand tools and more complex devices "as needed" instead of using valuable cargo volume and fuel to deliver finished products to orbit.

Even NASA is interested in 3D printing

At the same time, NASA is conducting joint tests with Made in Space to assess the potential of 3D printing to reduce the cost and increase the efficiency of space exploration. Nasa's additive-manufactured rocket parts were successfully tested in July 2013, with two fuel injectors performing on par with conventionally produced parts during operational tests subjecting the parts to temperatures of around 3,300°C and high pressure levels. It is noteworthy that NASA is preparing to launch a 3D printer into space: the agency is going to demonstrate the possibility of creating spare parts directly in orbit, instead of expensive transportation from the ground.

Social change

The topic of social and cultural change as a result of the introduction of commercially available additive technologies has been discussed by writers and sociologists since the 1950s. One of the most interesting assumptions was the possible blurring of boundaries between everyday life and workplaces as a result of the massive introduction of 3D printers into the home. It also points to the ease of transferring digital designs, which, in combination with local production, will help reduce the need for global transportation. Finally, copyright protection may change to reflect the ease of additive manufacturing of many products.

Firearms

In 2012, US company Defense Distributed released plans to create a "design of a functional plastic weapon that could be downloaded and reproduced by anyone with access to a 3D printer." Defense Distributed has developed a 3D printed version of the receiver for the AR-15 rifle, capable of withstanding more than 650 shots, and a 30-round magazine for the M-16 rifle.